transparent

-

A KAIST research team develops a washable, transparent, and flexible OLED with MXene nanotechnology

Transparent and flexible displays, which have received a lot of attention in various fields including automobile displays, bio-healthcare, military, and fashion, are in fact known to break easily when experiencing small deformations. To solve this problem, active research is being conducted on many transparent and flexible conductive materials such as carbon nanotubes, graphene, silver nanowires, and conductive polymers.

On June 13, a joint research team led by Professor Kyung Cheol Choi from the KAIST School of Electrical Engineering and Dr. Yonghee Lee from the National Nano Fab Center (NNFC) announced the successful development of a water-resistant, transparent, and flexible OLED using MXene nanotechnology. The material can emit and transmit light even when exposed to water.

MXene is a 2D material with high electrical conductivity and optical transmittance, and it can be produced on a large scale through solution processes. However, despite these attractive properties, MXene’s applications were limited as a long-term electrical device due to its electrical properties being degraded easily by atmospheric moisture and water. The material was therefore unable to be systemized into the form of a matrix that can display information.

Professor Choi’s research team used an encapsulation tactic that can protect materials from oxidation caused by moisture and oxygen to develop a MXene-based OLED with a long lifespan and high stability against external environmental factors. The research team first focused on analyzing the degradation mechanism of MXene’s electrical conductivity, and then concentrated on designing an encapsulation membrane. The team blocked moisture and provided flexibility through residual stress offset, ultimately producing a double-layered encapsulation membrane. In addition, a thin plastic film with a thickness of a few micrometers was attached to the top layer to allow washing in water without degradation.

< Figure 1. (a) Transparent passive-matrix display made of MXene-based OLED, (b) Cross-sectional image of MXene-based OLED observed by transmission electron microscope (TEM), (c) Electro-optical characteristic graph of red, green, and blue MXene-based OLED >

Through this study, the research team developed a MXene-based red(R)/green(G)/blue(B) OLED that emits a brightness of over 1,000 cd/m2 that is detectable by the naked eye even under sunlight, thereby meeting the conditions for outdoor displays. As for the red MXene-based OLED, the researchers confirmed a standby storage life of 2,000 hours (under 70% luminescence), a standby operation life of 1,500 hours (under 60% luminescence), and a flexibility withstanding 1,000 cycles under a low curvature of under 1.5mm. In addition, they showed that its performance was maintained even after six hours of immersion under water (under 80% luminescence). Furthermore, a patterning technique was used to produce the MXene-based OLED in the form of a passive matrix, and the team demonstrated its use as a transparent display by displaying letters and shapes.

Ph.D. candidate So Yeong Jeong, who led this study, said, “To improve the reliability of MXene OLED, we focused on producing an adequate encapsulation structure and a suitable process design.” She added, “By producing a matrix-type MXene OLED and displaying simple letters and shapes, we have laid the foundations for MXene’s application in the field of transparent displays.”

< Image 1. Cover of ACS Nano Front Cover (Conceptual diagram of MXene-based OLED display) >

Professor Choi said, “This research will become the guideline for applying MXene in electrical devices, but we expect for it to also be applied in other fields that require flexible and transparent displays like automobiles, fashion, and functional clothing. And to widen the gap with China’s OLED technology, these new OLED convergence technologies must continue to be developed.”

This research was supported by the National Research Foundation of Korea and funded by the Ministry of Science and ICT, Korea. It was published as a front cover story of ACS Nano under the title, “Highly Air-Stable, Flexible, and Water-Resistive 2D Titanium Carbide MXene-Based RGB Organic Light-Emitting Diode Displays for Transparent Free-Form Electronics” on June 13.

2023.07.10 View 3968

A KAIST research team develops a washable, transparent, and flexible OLED with MXene nanotechnology

Transparent and flexible displays, which have received a lot of attention in various fields including automobile displays, bio-healthcare, military, and fashion, are in fact known to break easily when experiencing small deformations. To solve this problem, active research is being conducted on many transparent and flexible conductive materials such as carbon nanotubes, graphene, silver nanowires, and conductive polymers.

On June 13, a joint research team led by Professor Kyung Cheol Choi from the KAIST School of Electrical Engineering and Dr. Yonghee Lee from the National Nano Fab Center (NNFC) announced the successful development of a water-resistant, transparent, and flexible OLED using MXene nanotechnology. The material can emit and transmit light even when exposed to water.

MXene is a 2D material with high electrical conductivity and optical transmittance, and it can be produced on a large scale through solution processes. However, despite these attractive properties, MXene’s applications were limited as a long-term electrical device due to its electrical properties being degraded easily by atmospheric moisture and water. The material was therefore unable to be systemized into the form of a matrix that can display information.

Professor Choi’s research team used an encapsulation tactic that can protect materials from oxidation caused by moisture and oxygen to develop a MXene-based OLED with a long lifespan and high stability against external environmental factors. The research team first focused on analyzing the degradation mechanism of MXene’s electrical conductivity, and then concentrated on designing an encapsulation membrane. The team blocked moisture and provided flexibility through residual stress offset, ultimately producing a double-layered encapsulation membrane. In addition, a thin plastic film with a thickness of a few micrometers was attached to the top layer to allow washing in water without degradation.

< Figure 1. (a) Transparent passive-matrix display made of MXene-based OLED, (b) Cross-sectional image of MXene-based OLED observed by transmission electron microscope (TEM), (c) Electro-optical characteristic graph of red, green, and blue MXene-based OLED >

Through this study, the research team developed a MXene-based red(R)/green(G)/blue(B) OLED that emits a brightness of over 1,000 cd/m2 that is detectable by the naked eye even under sunlight, thereby meeting the conditions for outdoor displays. As for the red MXene-based OLED, the researchers confirmed a standby storage life of 2,000 hours (under 70% luminescence), a standby operation life of 1,500 hours (under 60% luminescence), and a flexibility withstanding 1,000 cycles under a low curvature of under 1.5mm. In addition, they showed that its performance was maintained even after six hours of immersion under water (under 80% luminescence). Furthermore, a patterning technique was used to produce the MXene-based OLED in the form of a passive matrix, and the team demonstrated its use as a transparent display by displaying letters and shapes.

Ph.D. candidate So Yeong Jeong, who led this study, said, “To improve the reliability of MXene OLED, we focused on producing an adequate encapsulation structure and a suitable process design.” She added, “By producing a matrix-type MXene OLED and displaying simple letters and shapes, we have laid the foundations for MXene’s application in the field of transparent displays.”

< Image 1. Cover of ACS Nano Front Cover (Conceptual diagram of MXene-based OLED display) >

Professor Choi said, “This research will become the guideline for applying MXene in electrical devices, but we expect for it to also be applied in other fields that require flexible and transparent displays like automobiles, fashion, and functional clothing. And to widen the gap with China’s OLED technology, these new OLED convergence technologies must continue to be developed.”

This research was supported by the National Research Foundation of Korea and funded by the Ministry of Science and ICT, Korea. It was published as a front cover story of ACS Nano under the title, “Highly Air-Stable, Flexible, and Water-Resistive 2D Titanium Carbide MXene-Based RGB Organic Light-Emitting Diode Displays for Transparent Free-Form Electronics” on June 13.

2023.07.10 View 3968 -

KAIST Team Develops Semi-Transparent Solar Cells with Thermal Mirror Capability

A research team led by KAIST and Sungkyunkwan University professors has created semi-transparent perovskite solar cells that demonstrate high-power conversion efficiency and transmit visible light while blocking infrared light, making them great candidates for solar windows.

Modern architects prefer to build exteriors designed with glass mainly from artistic or cost perspectives. Scientists, however, go one step further and see opportunities from its potential ability to harness solar energy. Researchers have thus explored ways to make solar cells transparent or semi-transparent as a substitute material for glass, but this has proven to be a challenging task because solar cells need to absorb sunlight to generate electricity, and when they are transparent, it reduces their energy efficiency.

Typical solar cells today are made of crystalline silicon, but it is difficult to make them translucent. Semi-transparent solar cells under development use, for example, organic or dye-sensitized materials, but compared to crystalline silicon-based cells, their power-conversion efficiencies are relatively low. Perovskites are hybrid organic-inorganic halide-based photovoltaic materials, which are cheap to produce and easy to manufacture. They have recently received much attention as the efficiency of perovskite solar cells has rapidly increased to the level of silicon technologies in the past few years.

Using perovskites, a Korean research team led by Professor Seunghyup Yoo of the Electrical Engineering School at KAIST and Professor Nam-Gyu Park of the Chemical Engineering School at Sungkyunkwan University developed a semi-transparent solar cell that is highly efficient and, additionally, functions very effectively as a thermal-mirror.

The team has developed a top transparent electrode (TTE) that works well with perovskite solar cells. In most cases, a key to success in realizing semi-transparent solar cells is to find a TTE that is compatible with a given photoactive material system, which is also the case for perovskite solar cells. The proposed TTE is based on a multilayer stack consisting of a metal film sandwiched between a high refractive-index (high-index) layer and an interfacial buffer layer. This TTE, placed as a top-most layer, can be prepared without damaging ingredients used in perovskite solar cells. Unlike conventional transparent electrodes focusing only on transmitting visible light, the proposed TTE plays the dual role of passing through visible light while reflecting infrared rays. The semi-transparent solar cells made with the proposed TTEs exhibited average power conversion efficiency as high as 13.3% with 85.5% infrared rejection.

The team believes that if the semi-transparent perovskite solar cells are scaled up for practical applications, they can be used in solar windows for buildings and automobiles, which not only generate electrical energy but also enable the smart heat management for indoor environments, thereby utilizing solar energy more efficiently and effectively.

This result was published as a cover article in the July 20, 2016 issue of Advanced Energy Materials. The research paper is entitled “Empowering Semi-transparent Solar Cells with Thermal-mirror Functionality.” (DOI: 10.1002/aenm.201502466)

The team designed the transparent electrode (TE) stack in three layers: A thin-film of silver (Ag) is placed in between the bottom interfacial layer of molybdenum trioxide (MoO3) and the top high-index dielectric layer of zinc sulfide (ZnS). Such a tri-layer approach has been known as a means to increase the overall visible-light transmittance of metallic thin films via index matching technique, which is essentially the same technique used for anti-reflection coating of glasses except that the present case involves a metallic layer.

Traditionally, when a TE is based on a metal film, such as Ag, the film should be extremely thin, e.g., 7-12 nanometers (nm), to obtain transparency and, accordingly, to transmit visible light. However, the team took a different approach in this research. They made the Ag TE two or three times thicker (12-24 nm) than conventional metal films and, as a result, it reflected more infrared light. The high refractive index of the ZnS layer plays an essential role in keeping the visible light transmittance of the proposed TTE high even with the relatively thick Ag film when its thickness is carefully optimized for maximal destructive interference, leading to low reflectance (and thus high transmittance) within its visible light range.

The team confirmed the semi-transparent perovskite solar cell’s thermal-mirror function through an experiment in which a halogen lamp illuminated an object for five minutes through three mediums: a window of bare glass, automotive tinting film, and the proposed semi-transparent perovskite solar cell. An infrared (IR) camera took thermal images of the object as well as that of each window’s surface. The object’s temperature, when exposed through the glass window, rose to 36.8 Celsius degrees whereas both the tinting film and the cell allowed the object to remain below 27 Celsius degrees. The tinting film absorbs light to block solar energy, so the film’s surface became hot as it was continuously exposed to the lamp light, but the proposed semi-transparent solar cell stayed cool since it rejects solar heat energy by reflection, rather than by absorption. The total solar energy rejection (TSER) of the proposed cell was as high as 89.6%.

Professor Yoo of KAIST said, “The major contributions of this work are to find transparent electrode technology suitable for translucent perovskite cells and to provide a design approach to fully harness the potential it can further deliver as a heat mirror in addition to its main role as an electrode. The present work can be further fine-tuned to include colored solar cells and to incorporate flexible or rollable form factors, as they will allow for greater design freedom and thus offer more opportunities for them to be integrated into real-world objects and structures such as cars, buildings, and houses.”

The lead authors are Hoyeon Kim and Jaewon Ha, both Ph.D. candidates in the School of Electrical Engineering at KAIST, and Hui-Seon Kim, a student in the School of Chemical Engineering at Sungkyunkwan University. This research was supported mainly by the Climate Change Research Hub Program of KAIST.

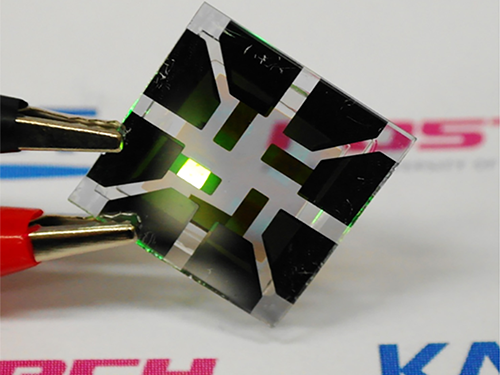

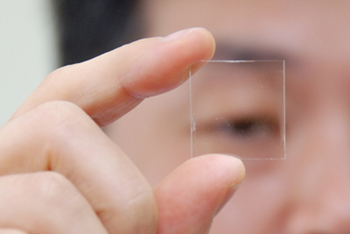

Picture 1: Semi-transparent Perovskite Solar Cell

This picture shows a prototype of a semi-transparent perovskite solar cell with thermal-mirror functionality.

Picture 2: A Heat Rejection Performance Comparison Experiment

This picture presents thermal images taken by an infrared camera for comparing the heat rejection performance of bare glass, automotive tinting film, and a semi-transparent perovskite solar cell after being illuminated by a halogen lamp for five minutes.

2016.08.02 View 11443

KAIST Team Develops Semi-Transparent Solar Cells with Thermal Mirror Capability

A research team led by KAIST and Sungkyunkwan University professors has created semi-transparent perovskite solar cells that demonstrate high-power conversion efficiency and transmit visible light while blocking infrared light, making them great candidates for solar windows.

Modern architects prefer to build exteriors designed with glass mainly from artistic or cost perspectives. Scientists, however, go one step further and see opportunities from its potential ability to harness solar energy. Researchers have thus explored ways to make solar cells transparent or semi-transparent as a substitute material for glass, but this has proven to be a challenging task because solar cells need to absorb sunlight to generate electricity, and when they are transparent, it reduces their energy efficiency.

Typical solar cells today are made of crystalline silicon, but it is difficult to make them translucent. Semi-transparent solar cells under development use, for example, organic or dye-sensitized materials, but compared to crystalline silicon-based cells, their power-conversion efficiencies are relatively low. Perovskites are hybrid organic-inorganic halide-based photovoltaic materials, which are cheap to produce and easy to manufacture. They have recently received much attention as the efficiency of perovskite solar cells has rapidly increased to the level of silicon technologies in the past few years.

Using perovskites, a Korean research team led by Professor Seunghyup Yoo of the Electrical Engineering School at KAIST and Professor Nam-Gyu Park of the Chemical Engineering School at Sungkyunkwan University developed a semi-transparent solar cell that is highly efficient and, additionally, functions very effectively as a thermal-mirror.

The team has developed a top transparent electrode (TTE) that works well with perovskite solar cells. In most cases, a key to success in realizing semi-transparent solar cells is to find a TTE that is compatible with a given photoactive material system, which is also the case for perovskite solar cells. The proposed TTE is based on a multilayer stack consisting of a metal film sandwiched between a high refractive-index (high-index) layer and an interfacial buffer layer. This TTE, placed as a top-most layer, can be prepared without damaging ingredients used in perovskite solar cells. Unlike conventional transparent electrodes focusing only on transmitting visible light, the proposed TTE plays the dual role of passing through visible light while reflecting infrared rays. The semi-transparent solar cells made with the proposed TTEs exhibited average power conversion efficiency as high as 13.3% with 85.5% infrared rejection.

The team believes that if the semi-transparent perovskite solar cells are scaled up for practical applications, they can be used in solar windows for buildings and automobiles, which not only generate electrical energy but also enable the smart heat management for indoor environments, thereby utilizing solar energy more efficiently and effectively.

This result was published as a cover article in the July 20, 2016 issue of Advanced Energy Materials. The research paper is entitled “Empowering Semi-transparent Solar Cells with Thermal-mirror Functionality.” (DOI: 10.1002/aenm.201502466)

The team designed the transparent electrode (TE) stack in three layers: A thin-film of silver (Ag) is placed in between the bottom interfacial layer of molybdenum trioxide (MoO3) and the top high-index dielectric layer of zinc sulfide (ZnS). Such a tri-layer approach has been known as a means to increase the overall visible-light transmittance of metallic thin films via index matching technique, which is essentially the same technique used for anti-reflection coating of glasses except that the present case involves a metallic layer.

Traditionally, when a TE is based on a metal film, such as Ag, the film should be extremely thin, e.g., 7-12 nanometers (nm), to obtain transparency and, accordingly, to transmit visible light. However, the team took a different approach in this research. They made the Ag TE two or three times thicker (12-24 nm) than conventional metal films and, as a result, it reflected more infrared light. The high refractive index of the ZnS layer plays an essential role in keeping the visible light transmittance of the proposed TTE high even with the relatively thick Ag film when its thickness is carefully optimized for maximal destructive interference, leading to low reflectance (and thus high transmittance) within its visible light range.

The team confirmed the semi-transparent perovskite solar cell’s thermal-mirror function through an experiment in which a halogen lamp illuminated an object for five minutes through three mediums: a window of bare glass, automotive tinting film, and the proposed semi-transparent perovskite solar cell. An infrared (IR) camera took thermal images of the object as well as that of each window’s surface. The object’s temperature, when exposed through the glass window, rose to 36.8 Celsius degrees whereas both the tinting film and the cell allowed the object to remain below 27 Celsius degrees. The tinting film absorbs light to block solar energy, so the film’s surface became hot as it was continuously exposed to the lamp light, but the proposed semi-transparent solar cell stayed cool since it rejects solar heat energy by reflection, rather than by absorption. The total solar energy rejection (TSER) of the proposed cell was as high as 89.6%.

Professor Yoo of KAIST said, “The major contributions of this work are to find transparent electrode technology suitable for translucent perovskite cells and to provide a design approach to fully harness the potential it can further deliver as a heat mirror in addition to its main role as an electrode. The present work can be further fine-tuned to include colored solar cells and to incorporate flexible or rollable form factors, as they will allow for greater design freedom and thus offer more opportunities for them to be integrated into real-world objects and structures such as cars, buildings, and houses.”

The lead authors are Hoyeon Kim and Jaewon Ha, both Ph.D. candidates in the School of Electrical Engineering at KAIST, and Hui-Seon Kim, a student in the School of Chemical Engineering at Sungkyunkwan University. This research was supported mainly by the Climate Change Research Hub Program of KAIST.

Picture 1: Semi-transparent Perovskite Solar Cell

This picture shows a prototype of a semi-transparent perovskite solar cell with thermal-mirror functionality.

Picture 2: A Heat Rejection Performance Comparison Experiment

This picture presents thermal images taken by an infrared camera for comparing the heat rejection performance of bare glass, automotive tinting film, and a semi-transparent perovskite solar cell after being illuminated by a halogen lamp for five minutes.

2016.08.02 View 11443 -

Graphene-Based Transparent Electrodes for Highly Efficient Flexible OLEDs

A Korean research team developed an ideal electrode structure composed of graphene and layers of titanium dioxide and conducting polymers, resulting in highly flexible and efficient OLEDs.

The arrival of a thin and lightweight computer that even rolls up like a piece of paper will not be in the far distant future. Flexible organic light-emitting diodes (OLEDs), built upon a plastic substrate, have received greater attention lately for their use in next-generation displays that can be bent or rolled while still operating.

A Korean research team led by Professor Seunghyup Yoo from the School of Electrical Engineering, KAIST and Professor Tae-Woo Lee from the Department of Materials Science and Engineering, Pohang University of Science and Technology (POSTECH) has developed highly flexible OLEDs with excellent efficiency by using graphene as a transparent electrode (TE) which is placed in between titanium dioxide (TiO2) and conducting polymer layers. The research results were published online on June 2, 2016 in Nature Communications.

OLEDs are stacked in several ultra-thin layers on glass, foil, or plastic substrates, in which multi-layers of organic compounds are sandwiched between two electrodes (cathode and anode). When voltage is applied across the electrodes, electrons from the cathode and holes (positive charges) from the anode draw toward each other and meet in the emissive layer. OLEDs emit light as an electron recombines with a positive hole, releasing energy in the form of a photon. One of the electrodes in OLEDs is usually transparent, and depending on which electrode is transparent, OLEDs can either emit from the top or bottom.

In conventional bottom-emission OLEDs, an anode is transparent in order for the emitted photons to exit the device through its substrate. Indium-tin-oxide (ITO) is commonly used as a transparent anode because of its high transparency, low sheet resistance, and well-established manufacturing process. However, ITO can potentially be expensive, and moreover, is brittle, being susceptible to bending-induced formation of cracks.

Graphene, a two-dimensional thin layer of carbon atoms tightly bonded together in a hexagonal honeycomb lattice, has recently emerged as an alternative to ITO. With outstanding electrical, physical, and chemical properties, its atomic thinness leading to a high degree of flexibility and transparency makes it an ideal candidate for TEs. Nonetheless, the efficiency of graphene-based OLEDs reported to date has been, at best, about the same level of ITO-based OLEDs.

As a solution, the Korean research team, which further includes Professors Sung-Yool Choi (Electrical Engineering) and Taek-Soo Kim (Mechanical Engineering) of KAIST and their students, proposed a new device architecture that can maximize the efficiency of graphene-based OLEDs. They fabricated a transparent anode in a composite structure in which a TiO2 layer with a high refractive index (high-n) and a hole-injection layer (HIL) of conducting polymers with a low refractive index (low-n) sandwich graphene electrodes. This is an optical design that induces a synergistic collaboration between the high-n and low-n layers to increase the effective reflectance of TEs. As a result, the enhancement of the optical cavity resonance is maximized. The optical cavity resonance is related to the improvement of efficiency and color gamut in OLEDs. At the same time, the loss from surface plasmon polariton (SPP), a major cause for weak photon emissions in OLEDs, is also reduced due to the presence of the low-n conducting polymers.

Under this approach, graphene-based OLEDs exhibit 40.8% of ultrahigh external quantum efficiency (EQE) and 160.3 lm/W of power efficiency, which is unprecedented in those using graphene as a TE. Furthermore, these devices remain intact and operate well even after 1,000 bending cycles at a radius of curvature as small as 2.3 mm. This is a remarkable result for OLEDs containing oxide layers such as TiO2 because oxides are typically brittle and prone to bending-induced fractures even at a relatively low strain. The research team discovered that TiO2 has a crack-deflection toughening mechanism that tends to prevent bending-induced cracks from being formed easily.

Professor Yoo said, “What’s unique and advanced about this technology, compared with previous graphene-based OLEDs, is the synergistic collaboration of high- and low-index layers that enables optical management of both resonance effect and SPP loss, leading to significant enhancement in efficiency, all with little compromise in flexibility.” He added, “Our work was the achievement of collaborative research, transcending the boundaries of different fields, through which we have often found meaningful breakthroughs.”

Professor Lee said, “We expect that our technology will pave the way to develop an OLED light source for highly flexible and wearable displays, or flexible sensors that can be attached to the human body for health monitoring, for instance.”

The research paper is entitled “Synergistic Electrode Architecture for Efficient Graphene-based Flexible Organic Light-emitting Diodes” (DOI. 10.1038/NCOMMS11791). The lead authors are Jae-Ho Lee, a Ph.D. candidate at KAIST; Tae-Hee Han, a Ph.D. researcher at POSTECH; and Min-Ho Park, a Ph.D. candidate at POSTECH.

This study was supported by the Basic Science Research Program of the National Research Foundation of Korea (NRF) through the Center for Advanced Flexible Display (CAFDC) funded by the Ministry of Science, ICT and Future Planning (MSIP); by the Center for Advanced Soft-Electronics funded by the MSIP as a Global Frontier Project; by the Graphene Research Center Program of KAIST; and by grants from the IT R&D Program of the Ministry of Trade, Industry and Energy of Korea (MOTIE).

Figure 1: Application of Graphene-based OLEDs

This picture shows an OLED with the composite structure of TiO2/graphene/conducting polymer electrode in operation. The OLED exhibits 40.8% of ultrahigh external quantum efficiency (EQE) and 160.3 lm/W of power efficiency. The device prepared on a plastic substrate shown in the right remains intact and operates well even after 1,000 bending cycles at a radius of curvature as small as 2.3 mm.

Figure 2: Schematic Device Structure of Graphene-based OLEDs

This picture shows the new architecture to develop highly flexible OLEDs with excellent efficiency by using graphene as a transparent electrode (TE).

2016.06.07 View 12496

Graphene-Based Transparent Electrodes for Highly Efficient Flexible OLEDs

A Korean research team developed an ideal electrode structure composed of graphene and layers of titanium dioxide and conducting polymers, resulting in highly flexible and efficient OLEDs.

The arrival of a thin and lightweight computer that even rolls up like a piece of paper will not be in the far distant future. Flexible organic light-emitting diodes (OLEDs), built upon a plastic substrate, have received greater attention lately for their use in next-generation displays that can be bent or rolled while still operating.

A Korean research team led by Professor Seunghyup Yoo from the School of Electrical Engineering, KAIST and Professor Tae-Woo Lee from the Department of Materials Science and Engineering, Pohang University of Science and Technology (POSTECH) has developed highly flexible OLEDs with excellent efficiency by using graphene as a transparent electrode (TE) which is placed in between titanium dioxide (TiO2) and conducting polymer layers. The research results were published online on June 2, 2016 in Nature Communications.

OLEDs are stacked in several ultra-thin layers on glass, foil, or plastic substrates, in which multi-layers of organic compounds are sandwiched between two electrodes (cathode and anode). When voltage is applied across the electrodes, electrons from the cathode and holes (positive charges) from the anode draw toward each other and meet in the emissive layer. OLEDs emit light as an electron recombines with a positive hole, releasing energy in the form of a photon. One of the electrodes in OLEDs is usually transparent, and depending on which electrode is transparent, OLEDs can either emit from the top or bottom.

In conventional bottom-emission OLEDs, an anode is transparent in order for the emitted photons to exit the device through its substrate. Indium-tin-oxide (ITO) is commonly used as a transparent anode because of its high transparency, low sheet resistance, and well-established manufacturing process. However, ITO can potentially be expensive, and moreover, is brittle, being susceptible to bending-induced formation of cracks.

Graphene, a two-dimensional thin layer of carbon atoms tightly bonded together in a hexagonal honeycomb lattice, has recently emerged as an alternative to ITO. With outstanding electrical, physical, and chemical properties, its atomic thinness leading to a high degree of flexibility and transparency makes it an ideal candidate for TEs. Nonetheless, the efficiency of graphene-based OLEDs reported to date has been, at best, about the same level of ITO-based OLEDs.

As a solution, the Korean research team, which further includes Professors Sung-Yool Choi (Electrical Engineering) and Taek-Soo Kim (Mechanical Engineering) of KAIST and their students, proposed a new device architecture that can maximize the efficiency of graphene-based OLEDs. They fabricated a transparent anode in a composite structure in which a TiO2 layer with a high refractive index (high-n) and a hole-injection layer (HIL) of conducting polymers with a low refractive index (low-n) sandwich graphene electrodes. This is an optical design that induces a synergistic collaboration between the high-n and low-n layers to increase the effective reflectance of TEs. As a result, the enhancement of the optical cavity resonance is maximized. The optical cavity resonance is related to the improvement of efficiency and color gamut in OLEDs. At the same time, the loss from surface plasmon polariton (SPP), a major cause for weak photon emissions in OLEDs, is also reduced due to the presence of the low-n conducting polymers.

Under this approach, graphene-based OLEDs exhibit 40.8% of ultrahigh external quantum efficiency (EQE) and 160.3 lm/W of power efficiency, which is unprecedented in those using graphene as a TE. Furthermore, these devices remain intact and operate well even after 1,000 bending cycles at a radius of curvature as small as 2.3 mm. This is a remarkable result for OLEDs containing oxide layers such as TiO2 because oxides are typically brittle and prone to bending-induced fractures even at a relatively low strain. The research team discovered that TiO2 has a crack-deflection toughening mechanism that tends to prevent bending-induced cracks from being formed easily.

Professor Yoo said, “What’s unique and advanced about this technology, compared with previous graphene-based OLEDs, is the synergistic collaboration of high- and low-index layers that enables optical management of both resonance effect and SPP loss, leading to significant enhancement in efficiency, all with little compromise in flexibility.” He added, “Our work was the achievement of collaborative research, transcending the boundaries of different fields, through which we have often found meaningful breakthroughs.”

Professor Lee said, “We expect that our technology will pave the way to develop an OLED light source for highly flexible and wearable displays, or flexible sensors that can be attached to the human body for health monitoring, for instance.”

The research paper is entitled “Synergistic Electrode Architecture for Efficient Graphene-based Flexible Organic Light-emitting Diodes” (DOI. 10.1038/NCOMMS11791). The lead authors are Jae-Ho Lee, a Ph.D. candidate at KAIST; Tae-Hee Han, a Ph.D. researcher at POSTECH; and Min-Ho Park, a Ph.D. candidate at POSTECH.

This study was supported by the Basic Science Research Program of the National Research Foundation of Korea (NRF) through the Center for Advanced Flexible Display (CAFDC) funded by the Ministry of Science, ICT and Future Planning (MSIP); by the Center for Advanced Soft-Electronics funded by the MSIP as a Global Frontier Project; by the Graphene Research Center Program of KAIST; and by grants from the IT R&D Program of the Ministry of Trade, Industry and Energy of Korea (MOTIE).

Figure 1: Application of Graphene-based OLEDs

This picture shows an OLED with the composite structure of TiO2/graphene/conducting polymer electrode in operation. The OLED exhibits 40.8% of ultrahigh external quantum efficiency (EQE) and 160.3 lm/W of power efficiency. The device prepared on a plastic substrate shown in the right remains intact and operates well even after 1,000 bending cycles at a radius of curvature as small as 2.3 mm.

Figure 2: Schematic Device Structure of Graphene-based OLEDs

This picture shows the new architecture to develop highly flexible OLEDs with excellent efficiency by using graphene as a transparent electrode (TE).

2016.06.07 View 12496 -

Transparent Glass Wall as a Touch Game Media

Professor Woo-hoon Lee

- Selected as the “Highlight” at SIGGRAPH emerging technology conference

- “An excellent example of the transparent display panel in everyday life”

A joint research team led by KAIST Industrial Design Department’s Prof. Woo-hoon Lee and Computer Sciences Prof. Ki-hyuk Lee has developed a brand new concept game media “TransWall”, which utilizes both sides of the glass wall as the touch medium.

TransWall has been chosen as the “highlight” of 2013 SIGGRAPH emerging technology conference. SIGGRAPH is a world-renowned conference in the area of computer graphics and interaction technique, last held 21st-25th July at Anaheim, in the United States.

It all started with the thought, wouldn’t it be possible to turn the glass walls surrounding us into a medium for entertainment and communication?

TransWall utilizes holographic screen film inserted between two glass sheets with a multi-touch function, onto which the image can be projected using the beam projector from both sides. Furthermore, an additional Surface Transducer attached to the glass can deliver the sound and vibration.

What seemed as an ordinary glass wall has been transformed into a multi-sensory media that can transmit and receive visual, auditory and tactile information.

TransWall can be implemented at public places such as theme parks, large shopping malls and subway stations, providing the citizens with a new form of entertainment. This touch-interaction method can also be applied to developing a variety of cultural contents in the future.

Professor Lee said, “TransWall shows an example of near-future where touch-interaction method can be utilized with the soon-to-be commercialized transparent display panel in everyday lives.”

TransWall Introduction video (https://vimeo.com/70391422)

TransWall at SIGGRAPH 2013 Display (https://vimeo.com/71718874)

Picture 1. Both sides of the glass wall can be used as a touch platform for various medias, including games.

Picture 2. TransWall attracts the interests of the audience at SIGGRAPH emerging technology.

Picture 3. Structure of TransWall

Picture 4. Photo of TransWall from side

2013.09.19 View 8891

Transparent Glass Wall as a Touch Game Media

Professor Woo-hoon Lee

- Selected as the “Highlight” at SIGGRAPH emerging technology conference

- “An excellent example of the transparent display panel in everyday life”

A joint research team led by KAIST Industrial Design Department’s Prof. Woo-hoon Lee and Computer Sciences Prof. Ki-hyuk Lee has developed a brand new concept game media “TransWall”, which utilizes both sides of the glass wall as the touch medium.

TransWall has been chosen as the “highlight” of 2013 SIGGRAPH emerging technology conference. SIGGRAPH is a world-renowned conference in the area of computer graphics and interaction technique, last held 21st-25th July at Anaheim, in the United States.

It all started with the thought, wouldn’t it be possible to turn the glass walls surrounding us into a medium for entertainment and communication?

TransWall utilizes holographic screen film inserted between two glass sheets with a multi-touch function, onto which the image can be projected using the beam projector from both sides. Furthermore, an additional Surface Transducer attached to the glass can deliver the sound and vibration.

What seemed as an ordinary glass wall has been transformed into a multi-sensory media that can transmit and receive visual, auditory and tactile information.

TransWall can be implemented at public places such as theme parks, large shopping malls and subway stations, providing the citizens with a new form of entertainment. This touch-interaction method can also be applied to developing a variety of cultural contents in the future.

Professor Lee said, “TransWall shows an example of near-future where touch-interaction method can be utilized with the soon-to-be commercialized transparent display panel in everyday lives.”

TransWall Introduction video (https://vimeo.com/70391422)

TransWall at SIGGRAPH 2013 Display (https://vimeo.com/71718874)

Picture 1. Both sides of the glass wall can be used as a touch platform for various medias, including games.

Picture 2. TransWall attracts the interests of the audience at SIGGRAPH emerging technology.

Picture 3. Structure of TransWall

Picture 4. Photo of TransWall from side

2013.09.19 View 8891 -

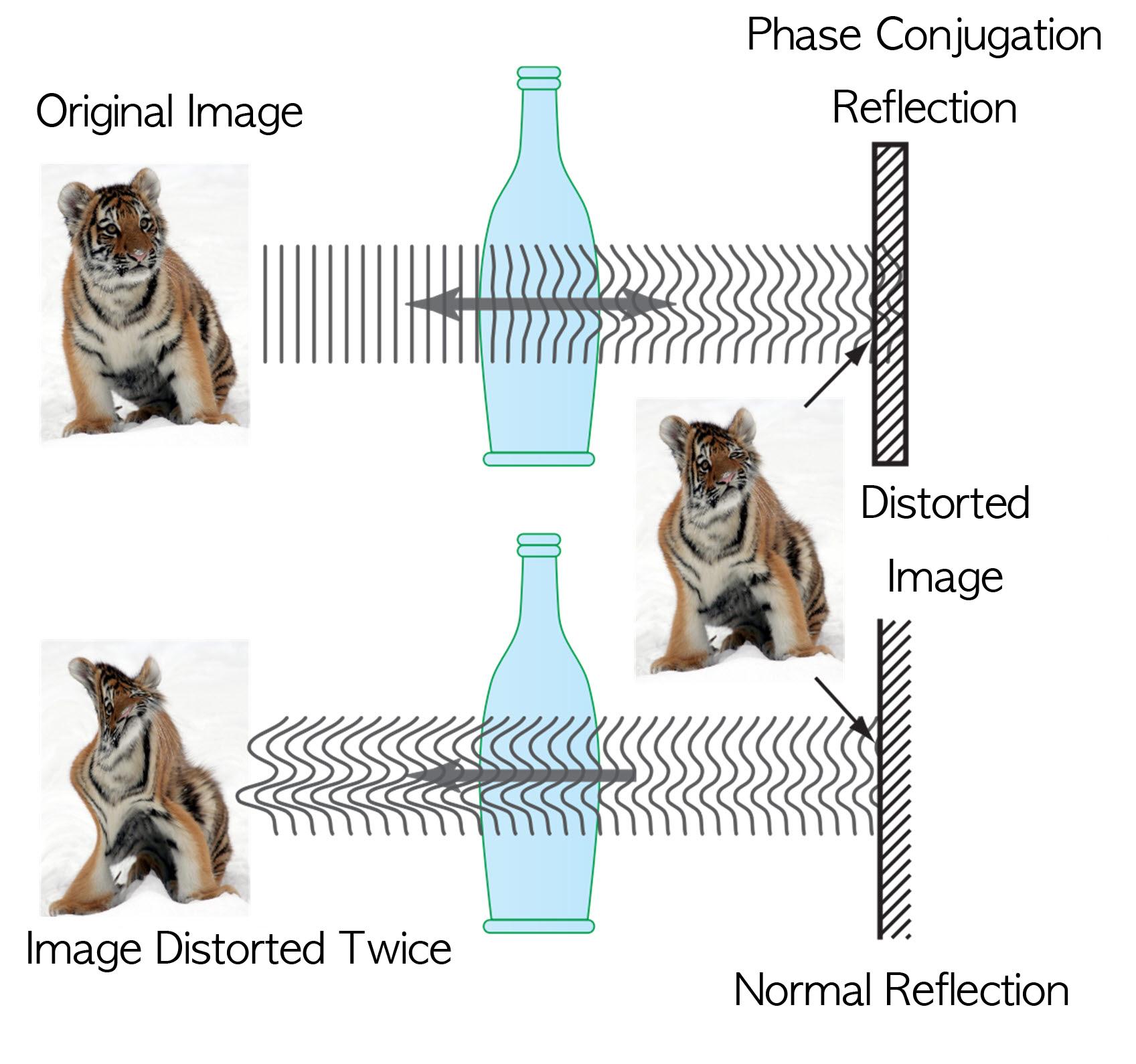

Technology Developed to Control Light Scattering Using Holography

Published on May 29th Nature Scientific Reports online

Recently, a popular article demonstrated that an opaque glass becomes transparent as transparent tape is applied to the glass. The scientific principle is that light is less scattered as the rough surface of the opaque glass is filled by transparent tape, thereby making things behind the opaque glass look clearer.

Professor Yong-Keun Park from KAIST’s Department of Physics, in a joint research with MIT Spectroscopy Lab, has developed a technology to easily control light scattering using holography. Their results are published on Nature’s Scientific Reports May 29th online edition.

This technology allows us to see things behind visual obstructions such as cloud and smoke, or even human skin that is highly scattering, optically thick materials. The research team applied the holography technology that records both the direction and intensity of light, and controlled light scattering of obstacles lied between an observer and a target image. The team was able to retrieve the original image by recording the information of scattered light and reflecting the light precisely to the other side.This phenomenon is known as “phase conjugation” in physics. Professor Park’s team applied phase conjugation and digital holography to observe two-dimensional image behind a highly scattering wall. “This technology will be utilized in many fields of physics, optics, nanotechnology, medical science, and even military science,” said Professor Park. “This is different from what is commonly known as penetrating camera or invisible clothes.” He nevertheless drew the line at over-interpreting the technology, “Currently, the significance is on the development of the technology itself that allows us to accurately control the scattering of light."

Figure I. Observed Images

Figure II. Light Scattering Control

2013.07.19 View 7814

Technology Developed to Control Light Scattering Using Holography

Published on May 29th Nature Scientific Reports online

Recently, a popular article demonstrated that an opaque glass becomes transparent as transparent tape is applied to the glass. The scientific principle is that light is less scattered as the rough surface of the opaque glass is filled by transparent tape, thereby making things behind the opaque glass look clearer.

Professor Yong-Keun Park from KAIST’s Department of Physics, in a joint research with MIT Spectroscopy Lab, has developed a technology to easily control light scattering using holography. Their results are published on Nature’s Scientific Reports May 29th online edition.

This technology allows us to see things behind visual obstructions such as cloud and smoke, or even human skin that is highly scattering, optically thick materials. The research team applied the holography technology that records both the direction and intensity of light, and controlled light scattering of obstacles lied between an observer and a target image. The team was able to retrieve the original image by recording the information of scattered light and reflecting the light precisely to the other side.This phenomenon is known as “phase conjugation” in physics. Professor Park’s team applied phase conjugation and digital holography to observe two-dimensional image behind a highly scattering wall. “This technology will be utilized in many fields of physics, optics, nanotechnology, medical science, and even military science,” said Professor Park. “This is different from what is commonly known as penetrating camera or invisible clothes.” He nevertheless drew the line at over-interpreting the technology, “Currently, the significance is on the development of the technology itself that allows us to accurately control the scattering of light."

Figure I. Observed Images

Figure II. Light Scattering Control

2013.07.19 View 7814 -

KAIST paves the way to commercialize flexible display screens

Source: IDTechEX, Feb. 28, 2011

KAIST paves the way to commercialize flexible display screens

28 Feb 2011

Transparent plastic and glass cloths, which have a limited thermal expansion needed for the production of flexible display screens and solar power cells, were developed by researchers at KAIST (Korea Advance Institute of Science & Technology).

The research, led by KAIST"s Professor Byoung-Soo Bae, was funded by the Engineering Research Center under the initiative of the Ministry of Education, Science and Technology and the National Research Foundation. The research result was printed as the cover paper of "Advanced Materials".

Professor Bae"s team developed a hybrid material with the same properties as fiber glass. With the material, they created a transparent, plastic film sheet resistant to heat. Transparent plastic film sheets were used by researchers all over the world to develop devices such as flexible displays or solar power cells that can be fit into various living spaces. However, plastic films are heat sensitive and tend to expand as temperature increases, thereby making it difficult to produce displays or solar power cells.

The new transparent, plastic film screen shows that heat expansion index (13ppm/oC) similar to that of glass fiber (9ppm/oC) due to the presence of glass fibers; its heat resistance allows to be used for displays and solar power cells over 250oC.

Professor Bae"s team succeeded in producing a flexible thin plastic film available for use in LCD or AMOLED screens and thin solar power cells.

Professor Bae commented, "Not only the newly developed plastic film has superior qualities, compared to the old models, but also it is cheap to produce, potentially bringing forward the day when flexible displays and solar panels become commonplace. With the cooperation of various industries, research institutes and universities, we will strive to improve the existing design and develop it further."

http://www.printedelectronicsworld.com/articles/kaist_paves_the_way_to_commercialize_flexible_display_screens_00003144.asp?sessionid=1

2011.03.01 View 12359

KAIST paves the way to commercialize flexible display screens

Source: IDTechEX, Feb. 28, 2011

KAIST paves the way to commercialize flexible display screens

28 Feb 2011

Transparent plastic and glass cloths, which have a limited thermal expansion needed for the production of flexible display screens and solar power cells, were developed by researchers at KAIST (Korea Advance Institute of Science & Technology).

The research, led by KAIST"s Professor Byoung-Soo Bae, was funded by the Engineering Research Center under the initiative of the Ministry of Education, Science and Technology and the National Research Foundation. The research result was printed as the cover paper of "Advanced Materials".

Professor Bae"s team developed a hybrid material with the same properties as fiber glass. With the material, they created a transparent, plastic film sheet resistant to heat. Transparent plastic film sheets were used by researchers all over the world to develop devices such as flexible displays or solar power cells that can be fit into various living spaces. However, plastic films are heat sensitive and tend to expand as temperature increases, thereby making it difficult to produce displays or solar power cells.

The new transparent, plastic film screen shows that heat expansion index (13ppm/oC) similar to that of glass fiber (9ppm/oC) due to the presence of glass fibers; its heat resistance allows to be used for displays and solar power cells over 250oC.

Professor Bae"s team succeeded in producing a flexible thin plastic film available for use in LCD or AMOLED screens and thin solar power cells.

Professor Bae commented, "Not only the newly developed plastic film has superior qualities, compared to the old models, but also it is cheap to produce, potentially bringing forward the day when flexible displays and solar panels become commonplace. With the cooperation of various industries, research institutes and universities, we will strive to improve the existing design and develop it further."

http://www.printedelectronicsworld.com/articles/kaist_paves_the_way_to_commercialize_flexible_display_screens_00003144.asp?sessionid=1

2011.03.01 View 12359 -

Transparent Antenna for Automobile Developed

A research team led by Prof. Jae-Woo Park of the School of Electrical Engineering & Computer Science, KAIST, developed a transparent antenna for the next-generation automobiles, university authorities said on Monday (Aug. 17).

The development was made possible through joint researches with the Hyundai-Kia Automotive Group; Winncom, a car antenna manufacturer; and a group of researchers led by Han-Ki Kim of the Department of Display Materials Engineering at Kyung Hee University in Seoul.

The transparent antennas were developed in two kinds -- one for the HSDPA (High-Speed Downlink Packet Access), a new protocol for mobile telephone data transmission, and the other for transmitting and receiving radio wave for emergency call.

Using the transparent electrically conductive film formation technology, the transparent antennas are to be mounted on the windshield of a vehicle.

"The development of transparent antenna represents a step forward for the advancement of the next-generation automotive electronic technology," said Seong-woo Kim, a senior researcher at the Hyundai-Kia Group.

2009.08.18 View 12354

Transparent Antenna for Automobile Developed

A research team led by Prof. Jae-Woo Park of the School of Electrical Engineering & Computer Science, KAIST, developed a transparent antenna for the next-generation automobiles, university authorities said on Monday (Aug. 17).

The development was made possible through joint researches with the Hyundai-Kia Automotive Group; Winncom, a car antenna manufacturer; and a group of researchers led by Han-Ki Kim of the Department of Display Materials Engineering at Kyung Hee University in Seoul.

The transparent antennas were developed in two kinds -- one for the HSDPA (High-Speed Downlink Packet Access), a new protocol for mobile telephone data transmission, and the other for transmitting and receiving radio wave for emergency call.

Using the transparent electrically conductive film formation technology, the transparent antennas are to be mounted on the windshield of a vehicle.

"The development of transparent antenna represents a step forward for the advancement of the next-generation automotive electronic technology," said Seong-woo Kim, a senior researcher at the Hyundai-Kia Group.

2009.08.18 View 12354 -

KAIST to hold International Workshop on Flexible Displays

The 2009 KAIST International Workshop on Flexible Displays will take place at the Electrical Engineering Building on June 25, university sources said on Tuesday (June 23).

The workshop organized by the Center for Advanced Flexible Display Convergence (CAFDC) will explore the status and future vision of flexible and transparent plasma displays, which are among the key technologies for the development of the next-generation displays. There will be also discussions about technologies to realize the large-scale flexible and transparent display which is regarded as the display of the future.

Among the speakers are some of the most prominent figures in the field. Gary Eden from University of Illinois, Prof. Kunihide Tachibana from Kyoto University, and Carol Wedding, the president of Imaging Systems Tech., USA and several other well-known professors and engineers will participate in the workshop.

Professor Kyung-Cheol Choi, CAFDC chair, said: "The workshop will provide an excellent opportunity to examine the flexible and transparent plasma display technologies. It will also be a good chance to explore large-scale flexible and transparent displays from various technical viewpoints."

2009.06.24 View 16489

KAIST to hold International Workshop on Flexible Displays

The 2009 KAIST International Workshop on Flexible Displays will take place at the Electrical Engineering Building on June 25, university sources said on Tuesday (June 23).

The workshop organized by the Center for Advanced Flexible Display Convergence (CAFDC) will explore the status and future vision of flexible and transparent plasma displays, which are among the key technologies for the development of the next-generation displays. There will be also discussions about technologies to realize the large-scale flexible and transparent display which is regarded as the display of the future.

Among the speakers are some of the most prominent figures in the field. Gary Eden from University of Illinois, Prof. Kunihide Tachibana from Kyoto University, and Carol Wedding, the president of Imaging Systems Tech., USA and several other well-known professors and engineers will participate in the workshop.

Professor Kyung-Cheol Choi, CAFDC chair, said: "The workshop will provide an excellent opportunity to examine the flexible and transparent plasma display technologies. It will also be a good chance to explore large-scale flexible and transparent displays from various technical viewpoints."

2009.06.24 View 16489 -

KAIST Scientists Creates Transparent Memory Chip

--See-Through Semis Could Revolutionize Displays

A group of KAIST scientists led by Prof. Jae-Woo Park and Koeng-Su Lim has created a working computer chip that is almost completely clear -- the first of its kind.

The new chip, called "transparent resistive random access memory (TRRAM), is similar in type to an existing technology known as complementary metal-oxide semiconductor (CMOS) memory -- common commercial chips that provide the data storage for USB flash drives and other devices. Like CMOS devices, the new chip provides "non-volatile" memory, meaning that it stores digital information without losing data when it is powered off. Unlike CMOS devices, however, the new TRRAM chip is almost completely clear.

The paper on the new technology, entitled "Transparent resistive random access memory and its characteristics for non-volatile resistive switching," was published in the December issue of the Applied Physics Letters (APL), and the American Institute of Physics, the publisher of APL, issued a press release about this breakthrough.

"It is a new milestone of transparent electronic systems," says researcher Jung-Won Seo, who is the first author of the paper. "By integrating TRRAM devices with other transparent electronic components, we can create a totally see-through embedded electronic system."

Technically, TRRAM devices rely upon an existing technology known as resistive random access memory (RRAM), which is already in commercial development for future electronic data storage devices. RRAM is built using metal oxide materials between equally transparent electrodes and substrates.

According to the research team, TRRAM devices are easy to fabricate and may be commercially available in just 3-4 years.

"We are sure that TRRAM will become one of alternative devices to current CMOS-based flash memory in the near future after its reliability is proven and once any manufacturing issues are solved," says Prof. Jae-Woo Park, who is the co-author on the paper. He adds that the new devices have the potential to be manufactured cheaply because any transparent materials can be utilized as substrate and electrode. They also may not require incorporating rare elements such as Indium.

2008.12.17 View 15864

KAIST Scientists Creates Transparent Memory Chip

--See-Through Semis Could Revolutionize Displays

A group of KAIST scientists led by Prof. Jae-Woo Park and Koeng-Su Lim has created a working computer chip that is almost completely clear -- the first of its kind.

The new chip, called "transparent resistive random access memory (TRRAM), is similar in type to an existing technology known as complementary metal-oxide semiconductor (CMOS) memory -- common commercial chips that provide the data storage for USB flash drives and other devices. Like CMOS devices, the new chip provides "non-volatile" memory, meaning that it stores digital information without losing data when it is powered off. Unlike CMOS devices, however, the new TRRAM chip is almost completely clear.

The paper on the new technology, entitled "Transparent resistive random access memory and its characteristics for non-volatile resistive switching," was published in the December issue of the Applied Physics Letters (APL), and the American Institute of Physics, the publisher of APL, issued a press release about this breakthrough.

"It is a new milestone of transparent electronic systems," says researcher Jung-Won Seo, who is the first author of the paper. "By integrating TRRAM devices with other transparent electronic components, we can create a totally see-through embedded electronic system."

Technically, TRRAM devices rely upon an existing technology known as resistive random access memory (RRAM), which is already in commercial development for future electronic data storage devices. RRAM is built using metal oxide materials between equally transparent electrodes and substrates.

According to the research team, TRRAM devices are easy to fabricate and may be commercially available in just 3-4 years.

"We are sure that TRRAM will become one of alternative devices to current CMOS-based flash memory in the near future after its reliability is proven and once any manufacturing issues are solved," says Prof. Jae-Woo Park, who is the co-author on the paper. He adds that the new devices have the potential to be manufactured cheaply because any transparent materials can be utilized as substrate and electrode. They also may not require incorporating rare elements such as Indium.

2008.12.17 View 15864 -

Home-Grown Transparent Thin Film Transistor Developed

KAIST, Aug. 6, 2008 -- A KAIST research team led by Profs. Jae-Woo Park and Seung-Hyup Yoo of the Electrical Engineering Division has developed a home-grown technology to create transparent thin film transistor using titanium dioxide., university authorities said.The KAIST team made the technological advance in collaboration with the LCD Division of Samsung Electronics and the Techno Semichem Co., a local LCD equipment maker. Transparent thin film transistor continues to enjoy a wealth of popularity and intensive research interest since it is used in producing operating circuits including transparent display, active-matrix OLED (AMOLED) display and flexible display.

The new technology is significant in that it is based on a titanium dioxide, the first such attempt in the world, while the technologies patented by the United States and Japan are based on ZnO.

Researchers will continue to work on securing technological reliability and developing a technology to mass-produce in a large-scale chemical vapor deposition equipment for the next couple of years.

"The development of technology to produce transparent thin film transistor will help Korean LCD makers reduce its dependence on foreign technologies, as well as maintain Korea"s status as a leader of the world"s display industry," said Prof. Park.

KAIST has applied for local patent registration of the technology and the process is expected to complete by this October or November. International patents have been also applied for in the U.S., Japan and Europe.

The new technology was introduced in the latest edition of the Electron Device Letters, a journal published by the Institute of Electrical and Electronics Engineers or IEEE, a New York-based international non-profit, professional organization for the advancement of technology related to electricity. It will be presented at the International Display Workshop 2008 on Dec. 5 in Niigata, Japan.

2008.08.07 View 14235

Home-Grown Transparent Thin Film Transistor Developed

KAIST, Aug. 6, 2008 -- A KAIST research team led by Profs. Jae-Woo Park and Seung-Hyup Yoo of the Electrical Engineering Division has developed a home-grown technology to create transparent thin film transistor using titanium dioxide., university authorities said.The KAIST team made the technological advance in collaboration with the LCD Division of Samsung Electronics and the Techno Semichem Co., a local LCD equipment maker. Transparent thin film transistor continues to enjoy a wealth of popularity and intensive research interest since it is used in producing operating circuits including transparent display, active-matrix OLED (AMOLED) display and flexible display.

The new technology is significant in that it is based on a titanium dioxide, the first such attempt in the world, while the technologies patented by the United States and Japan are based on ZnO.

Researchers will continue to work on securing technological reliability and developing a technology to mass-produce in a large-scale chemical vapor deposition equipment for the next couple of years.

"The development of technology to produce transparent thin film transistor will help Korean LCD makers reduce its dependence on foreign technologies, as well as maintain Korea"s status as a leader of the world"s display industry," said Prof. Park.

KAIST has applied for local patent registration of the technology and the process is expected to complete by this October or November. International patents have been also applied for in the U.S., Japan and Europe.

The new technology was introduced in the latest edition of the Electron Device Letters, a journal published by the Institute of Electrical and Electronics Engineers or IEEE, a New York-based international non-profit, professional organization for the advancement of technology related to electricity. It will be presented at the International Display Workshop 2008 on Dec. 5 in Niigata, Japan.

2008.08.07 View 14235