research

< Professor Steve Park (left) and the First Author Mr. Jinwon Oh (right) >

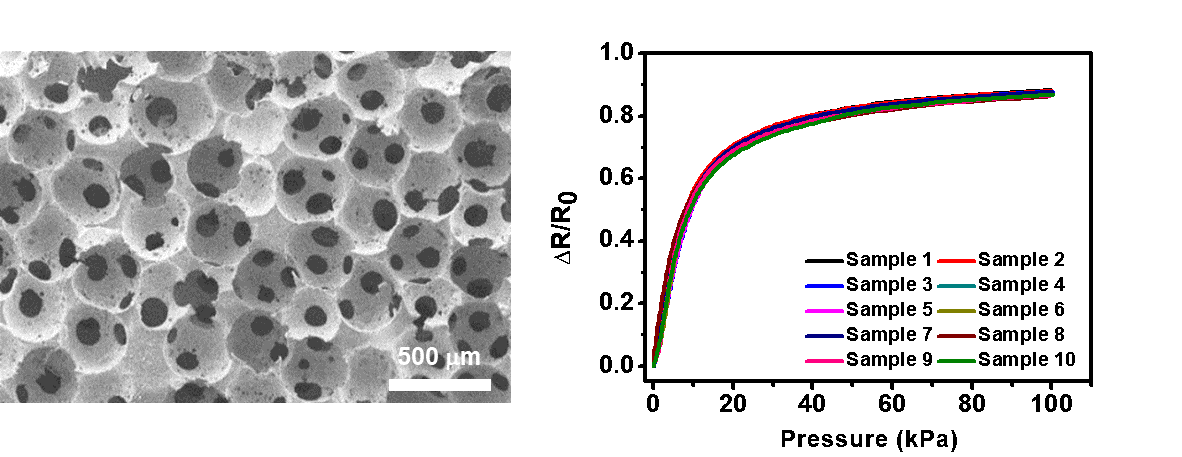

Researchers have designed a flexible pressure sensor that is expected to have a much wider applicability. A KAIST research team fabricated a piezoresistive pressure sensor of high uniformity with low hysteresis by chemically grafting a conductive polymer onto a porous elastomer template.

The team discovered that the uniformity of pore size and shape is directly related to the uniformity of the sensor. The team noted that by increasing pore size and shape variability, the variability of the sensor characteristics also increases.

Researchers led by Professor Steve Park from the Department of Materials Science and Engineering confirmed that compared to other sensors composed of randomly sized and shaped pores, which had a coefficient of variation in relative resistance change of 69.65%, their newly developed sensor exhibited much higher uniformity with a coefficient of variation of 2.43%. This study was reported in Small as the cover article on August 16.

Flexible pressure sensors have been actively researched and widely applied in electronic equipment such as touch screens, robots, wearable healthcare devices, electronic skin, and human-machine interfaces. In particular, piezoresistive pressure sensors based on elastomer‐conductive material composites hold significant potential due to their many advantages including a simple and low-cost fabrication process.

Various research results have been reported for ways to improve the performance of piezoresistive pressure sensors, most of which have been focused on increasing the sensitivity. Despite its significance, maximizing the sensitivity of composite-based piezoresistive pressure sensors is not necessary for many applications. On the other hand, sensor-to-sensor uniformity and hysteresis are two properties that are of critical importance to realize any application.

The importance of sensor-to-sensor uniformity is obvious. If the sensors manufactured under the same conditions have different properties, measurement reliability is compromised, and therefore the sensor cannot be used in a practical setting.

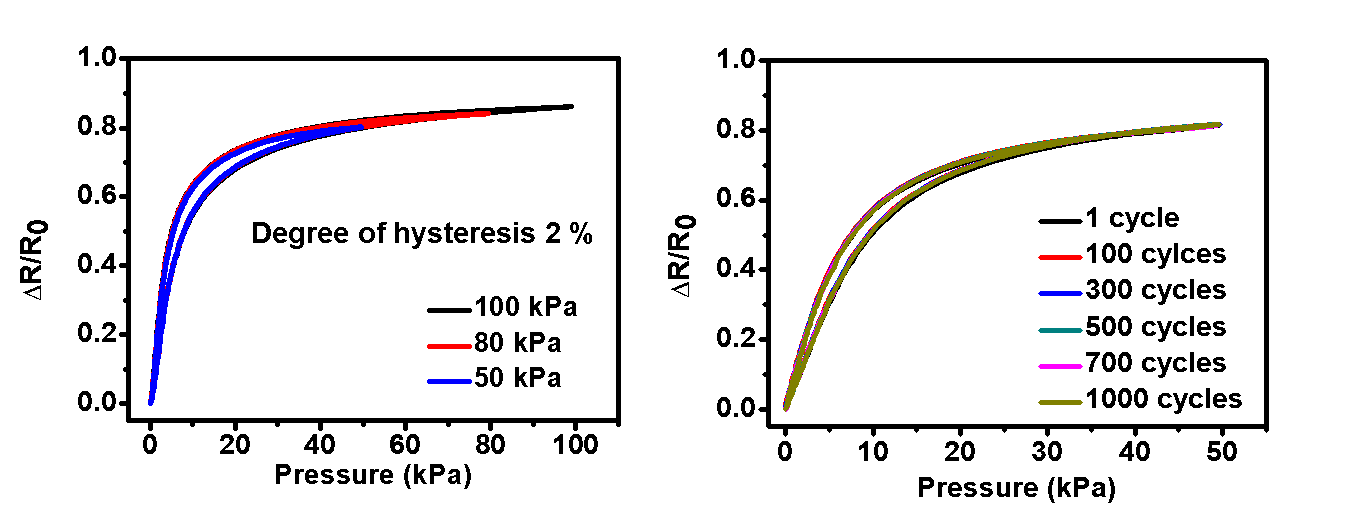

In addition, low hysteresis is also essential for improved measurement reliability. Hysteresis is a phenomenon in which the electrical readings differ depending on how fast or slow the sensor is being pressed, whether pressure is being released or applied, and how long and to what degree the sensor has been pressed. When a sensor has high hysteresis, the electrical readings will differ even under the same pressure, making the measurements unreliable.

Researchers said they observed a negligible hysteresis degree which was only 2%. This was attributed to the strong chemical bonding between the conductive polymer and the elastomer template, which prevents their relative sliding and displacement, and the porosity of the elastomer that enhances elastic behavior.

“This technology brings forth insight into how to address the two critical issues in pressure sensors: uniformity and hysteresis. We expect our technology to play an important role in increasing practical applications and the commercialization of pressure sensors in the near future,” said Professor Park.

This work was conducted as part of the KAIST‐funded Global Singularity Research Program for 2019, and also supported by the KUSTAR‐KAIST Institute.

< 20190819144743_14389_711855822.png >

Figure 1. Image of a porous elastomer template with uniform pore size and shape (left), Graph showing high uniformity in the sensors’ performance (right).

< 20190819144806_73806_1803568279.png >

Figure 2. Hysteresis loops of the sensor at different pressure levels (left), and after a different number of cycles (right).

< 20190819144830_68195_563196854.png >

Figure 3. The cover page of Small Journal, Volume 15, Issue 33.

Publication:

Jinwon Oh, Jin‐Oh Kim, Yunjoo Kim, Han Byul Choi, Jun Chang Yang, Serin Lee, Mikhail Pyatykh, Jung Kim, Joo Yong Sim, and Steve Park. 2019. Highly Uniform and Low Hysteresis Piezoresistive Pressure Sensors Based on Chemical Grafting of Polypyrrole on Elastomer Template with Uniform Pore Size. Small. Wiley-VCH Verlag GmbH & Co. KgaA, Weinheim, Germany, Volume No. 15, Issue No. 33, Full Paper No. 201901744, 8 pages. https://doi.org/10.1002/smll.201901744

Profile: Prof. Steve Park, MS, PhD

stevepark@kaist.ac.kr

http://steveparklab.kaist.ac.kr/

Assistant Professor

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Mr. Jinwon Oh, MS

jwoh1701@gmail.com

http://steveparklab.kaist.ac.kr/

Researcher

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Prof. Jung Kim, MS, PhD

jungkim@kaist.ac.kr

http://medev.kaist.ac.kr/

Professor

Biorobotics Laboratory

Department of Mechanical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Joo Yong Sim, PhD

jsim@etri.re.kr

Researcher

Bio-Medical IT Convergence Research Department

Electronics and Telecommunications Research Institute (ETRI)

https://www.etri.re.kr

Daejeon 34129, Korea

(END)

-

research A High-Performance and Cost Effective Hydrogen Sensor

(Research team of Professor Park, Professor Jung, and research fellow Gao Min) A KAIST research team reported a high-performance and cost effective hydrogen sensor using novel fabrication process based on the combination of polystyrene nanosphere lithography and semiconductor microfabrication processes. The research team, led by Professor Inkyu Park in the Department of Mechanical Engineering and Professor Yeon Sik Jung in the Department of Materials Science and Engineering, fabricat

2018-05-21 -

people Samsung Electronics' Chairman Kwon Becomes the First Alumnus Honorary Doctorate

(Samsung Electronics' Chairman & CEO Kwon,left, and President Shin) The semiconductor has bred innovation in Korea, as one of the staples of economic growth. Without the success of the semiconductor industry of Korea, it is hard to imagine the high tech dominance in the global market enjoyed by Korean companies. It is said that one in every four Ph.D.s working in the semiconductor industry of Korea graduated from KAIST. Among them, Chairman and CEO Oh-Hyun Kwon of Samsung Electronics

2018-02-26 -

people Professor Lee's Research Selected as Top 100 National R&D Projects

A research project, led by Research Professor Ju Yong Lee from the KAIST Institute for IT Convergence, was selected as one of the Top 100 National Research and Development Projects 2017. This research project, titled LTE-A-based Single RF Small Base Station supporting Multiple Streams, developed 300Mbps low power, low complexity and broadband small base station technology that supports 4x4 MIMO (Multiple Input and Multiple Output) by proposing a new antenna structure and a new RF (Radio Frequ

2017-11-08 -

research KAIST Develops a Method to Transfer Graphene by Stamping

Professor Sung-Yool Choi’s research team from KAIST's Department of Electrical Engineering has developed a technique that can produce a single-layer graphene from a metal etching. Through this, transferring a graphene layer onto a circuit board can be done as easily as stamping a seal on paper. The research findings were published in the January 14th issue of Small as the lead article. This technology will allow different types of wafer transfer methods such as transfer onto a surf

2015-01-23 -

research Metabolically engineered E. coli producing phenol

Many chemicals we use in everyday life are derived from fossil resources. Due to the increasing concerns on the use of fossil resources, there has been much interest in producing chemicals from renewable resources through biotechnology. Phenol is an important commodity chemical, and is a starting material for the production of numerous industrial chemicals and polymers, including bisphenol A and phenolic resins, and others. At present, the production of phenol entirely depends on the chemical

2013-11-05