research

Research Outputs over Carbon Nanotube by Prof. Choi Selected as Research Highlight by ACS

Research Outputs over Carbon Nanotube by Prof. Choi Selected as Research Highlight by ACS

A research team headed by Seong-Min Choi, a professor of Nuclear and Quantum Engineering, KAIST, has developed technologies to stably disperse carbon nanotube particles in aqueous solutions and organic solvents, essential for industrial applications of carbon nanotube, and discovered the dispersion characteristics of carbon nanotube. The research outputs have been published by ‘Advanced materials’ (19, 929, 2007), the most distinguished journal in Material Science field, and introduced as Research Highlight at the May 7th edition of ‘Heart Cut’ by the American Chemical Society (ACS).

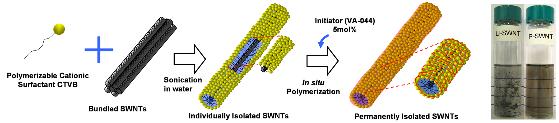

A number of processes for industrial applications of carbon nanotube require the dispersion of carbon nanotube in aqueous solutions or organic solvents, and thus far, surfactant particles or DNAs have been used to disperse carbon nanotube particles. However, they have shortcomings of easy destruction of dispersion. In order to overcome such shortcomings, Prof. Choi’s team produced carbon nanotube particle-dispersed aqueous solutions by using surfactant particles and then polymerized surfactant particles absorbed to the surfaces of carbon nanotube in situ to develop carbon nanotube with hydrophile and safe surfaces. The functional carbon nanotube so obtained shows features of easy dispersion in aqueous solutions and organic solvents even after being processed, such as freeze drying, therefore, is expected to significantly contribute to the development of application technologies of carbon nanotubes. Tae-Hwan Kim and Chang-Woo Doh, both doctoral students, played key roles in the researches carried out under the auspices of the Ministry of Science and Technology (MOST) as a nuclear power R&D project, and the relevant technologies were filed for patent applications.

Figures: Carbon nanotube before polymerization (left), carbon nanotube polymerized with surfactant particles (right)

-

research KAIST Extends Lithium Metal Battery Lifespan by 750% Using Water

Lithium metal, a next-generation anode material, has been highlighted for overcoming the performance limitations of commercial batteries. However, issues inherent to lithium metal have caused shortened battery lifespans and increased fire risks. KAIST researchers have achieved a world-class breakthrough by extending the lifespan of lithium metal anodes by approximately 750% only using water. KAIST (represented by President Kwang Hyung Lee) announced on the 2nd of December that Professor Il-Doo

2024-12-12 -

research KAIST Team Develops an Insect-Mimicking Semiconductor to Detect Motion

The recent development of an “intelligent sensor” semiconductor that mimics the optic nerve of insects while operating at ultra-high speeds and low power offers extensive expandability into various innovative technologies. This technology is expected to be applied to various fields including transportation, safety, and security systems, contributing to both industry and society. On February 19, a KAIST research team led by Professor Kyung Min Kim from the Department of Materials S

2024-02-29 -

research Flexible Sensor-Integrated RFA Needle Leads to Smarter Medical Treatment

Clinical trial of flexible sensor-integrated radiofrequency ablation (RFA) needle tip monitors physical changes and steam pop Researchers have designed a thin polymeric sensor platform on a radiofrequency ablation needle to monitor temperature and pressure in real time. The sensors integrated onto 1.5 mm diameter needle tip have proven their efficacy during clinical tests and expect to provide a new opportunity for safer and more effective medical practices. The research was reported in Advance

2021-10-20 -

research Lead-free, Efficient Perovskite for Photovoltaic Cells

(Clockwise from left: Post-doc Researcher Lamjed Debbichi, Master’s Candidate Songju Lee, Professor Min Seok Jang and Professor Hyungjun Kim) A KAIST research team has proposed a perovskite material, Cs2Au2I6 that serves as a potential active material for highly efficient lead-free thin-film photovoltaic devices. This material is expected to lay the foundation to overcome previously known limitations of perovskite including its stability and toxicity issues. As strong can

2018-06-08 -

research Tactile Sensor for Robot Skin Advanced by KAIST Team

The joint research team of Professors Jung Kim and Inkyu Park from the Department of Mechanical Engineering developed a tactile sensor that can act as skin for robots using silicon and carbon materials. This technology produced a sensor that can absorb shock and distinguish various forms of touch, and it is hoped to be used as robot skin in the future. Skin serves an important role as the largest organ of the human body. As well as protecting major organs from external shock, skin also measures

2017-04-17