ES

-

Unravelling Inherent Electrocatalysis to Improve the Performance of Hydrogen Fuel Cells

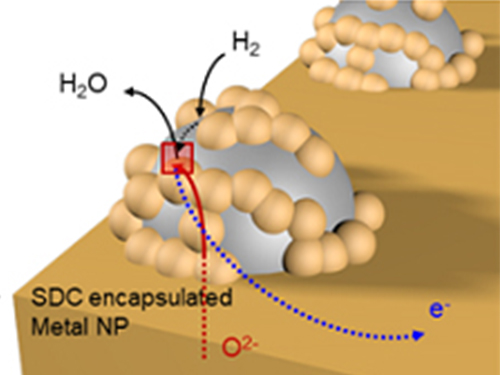

(Figure 1. Electrode structure for the precise evaluation of the metal nanoparticles’ electrochemical catalytic characteristics at a high temperature.)

A KAIST team presented an ideal electrode design to enhance the performance of high-temperature fuel cells. The new analytical platform with advanced nanoscale patterning method quantitatively revealed the electrochemical value of metal nanoparticles dispersed on the oxide electrode, thus leading to electrode design directions that can be used in a variety of eco-friendly energy technologies.

The team, working under Professor WooChul Jung and Professor Sang Ouk Kim at the Department of Materials Science and Engineering, described an accurate analysis of the reactivity of oxide electrodes boosted by metal nanoparticles, where all particles participate in the reaction. They identified how the metal catalysts activate hydrogen electro-oxidation on the ceria-based electrode surface and quantify how rapidly the reaction rate increases with the proper choice of metals.

Metal nanoparticles with diameters of 10 nanometers or less have become a key component in high-performance heterogeneous catalysts, primarily serving as a catalytic activator. Recent experimental and theoretical findings suggest that the optimization of the chemical nature at the metal and support interfaces is essential for performance improvement.

However, the high cost associated with cell fabrication and operation as well as poorer stability of metal nanoparticles at high temperatures have been a long-standing challenge. To solve this problem, the team utilized a globally recognized metal nano patterning technology that uses block copolymer self-assembled nano templates and succeeded in uniformly synthesizing metal particles 10 nanometers in size on the surface of oxide fuel cell electrodes. They also developed a technology to accurately analyze the catalyst characteristics of single particles at high temperatures and maximize the performance of a fuel cell with minimal catalyst use.

The research team confirmed that platinum, which is a commonly used metal catalyst, could boost fuel cell performance by as much as 21 times even at an amount of 300 nanograms, which only costs about 0.015 KRW.

The team quantitatively identified and compared the characteristics of widely used metal catalysts other than platinum, such as palladium, gold, and cobalt, and also elucidated the precise principle of catalyst performance through theoretical analysis.

(Figure 2. Comparison of the electrochemical catalytic characteristics for various 10nm metal nanoparticles (platinum, palladium, cobalt, gold) at a high temperature.)

Professor Jung said, "We have broken the conventional methods of increasing the amount of catalyst which have deemed inefficient and expensive. Our results suggest a clear idea for high performance fuel cells using very small amounts of nanoparticles. This technology can be applied to many different industrial fields, advancing the commercialization of eco-friendly energy technologies such as fuel cells that generate electricity and electrolytic cells that produce hydrogen from water.”

The research has been published as the cover article of Nature Nanotechnology in the March issue. This research was carried out with support from the Nano-Material Technology Development Program through the National Research Foundation of Korea.

2019.03.28 View 29339

Unravelling Inherent Electrocatalysis to Improve the Performance of Hydrogen Fuel Cells

(Figure 1. Electrode structure for the precise evaluation of the metal nanoparticles’ electrochemical catalytic characteristics at a high temperature.)

A KAIST team presented an ideal electrode design to enhance the performance of high-temperature fuel cells. The new analytical platform with advanced nanoscale patterning method quantitatively revealed the electrochemical value of metal nanoparticles dispersed on the oxide electrode, thus leading to electrode design directions that can be used in a variety of eco-friendly energy technologies.

The team, working under Professor WooChul Jung and Professor Sang Ouk Kim at the Department of Materials Science and Engineering, described an accurate analysis of the reactivity of oxide electrodes boosted by metal nanoparticles, where all particles participate in the reaction. They identified how the metal catalysts activate hydrogen electro-oxidation on the ceria-based electrode surface and quantify how rapidly the reaction rate increases with the proper choice of metals.

Metal nanoparticles with diameters of 10 nanometers or less have become a key component in high-performance heterogeneous catalysts, primarily serving as a catalytic activator. Recent experimental and theoretical findings suggest that the optimization of the chemical nature at the metal and support interfaces is essential for performance improvement.

However, the high cost associated with cell fabrication and operation as well as poorer stability of metal nanoparticles at high temperatures have been a long-standing challenge. To solve this problem, the team utilized a globally recognized metal nano patterning technology that uses block copolymer self-assembled nano templates and succeeded in uniformly synthesizing metal particles 10 nanometers in size on the surface of oxide fuel cell electrodes. They also developed a technology to accurately analyze the catalyst characteristics of single particles at high temperatures and maximize the performance of a fuel cell with minimal catalyst use.

The research team confirmed that platinum, which is a commonly used metal catalyst, could boost fuel cell performance by as much as 21 times even at an amount of 300 nanograms, which only costs about 0.015 KRW.

The team quantitatively identified and compared the characteristics of widely used metal catalysts other than platinum, such as palladium, gold, and cobalt, and also elucidated the precise principle of catalyst performance through theoretical analysis.

(Figure 2. Comparison of the electrochemical catalytic characteristics for various 10nm metal nanoparticles (platinum, palladium, cobalt, gold) at a high temperature.)

Professor Jung said, "We have broken the conventional methods of increasing the amount of catalyst which have deemed inefficient and expensive. Our results suggest a clear idea for high performance fuel cells using very small amounts of nanoparticles. This technology can be applied to many different industrial fields, advancing the commercialization of eco-friendly energy technologies such as fuel cells that generate electricity and electrolytic cells that produce hydrogen from water.”

The research has been published as the cover article of Nature Nanotechnology in the March issue. This research was carried out with support from the Nano-Material Technology Development Program through the National Research Foundation of Korea.

2019.03.28 View 29339 -

Distinguished Professor Sang Yup Lee Honored with the 23rd NAEK Award

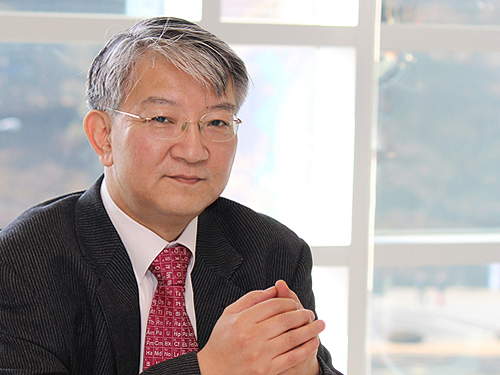

(Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering)

Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering was honored to be the laureate of the 23rd NAEK Award.

The NAEK (National Academy of Engineering of Korea) Award was instituted in 1997 to honor and recognize engineers who have made significant contributions to the development of the engineering and technology field at universities, industries, and institutions. Every year, it is conferred to only one person who has achieved original and world-leading research that has led to national development.

Distinguished Professor Lee is a pioneering scholar of the field of systems metabolic engineering and he was recognized for his significant achievements in the biochemical industry by developing novel microbial bioprocesses. In particular, he is globally renowned for biological plastic synthesis, making or decomposing polymers with microorganisms instead of using fossil resources.

He has produced numerous high-quality research breakthroughs in metabolic and systems engineering. In 2016, he produced an easily degradable plastic with Escherichia coli (E. coli). In 2018, he successfully produced aromatic polyesters, the main material for PET (poly ethylene terephthalate) from E. coli strains. He also identified microorganism structures for PET degradation and improved its degradability with a novel variant.

His research was ranked number one in the research and development division of Top Ten Science and Technology News 2018 announced by Korean Federation of Science & Technology Societies. He is one of highly cited researchers (HCR) ranked in the top 1% by citations for their field by the Clarivate Analytics.

2019.03.21 View 6900

Distinguished Professor Sang Yup Lee Honored with the 23rd NAEK Award

(Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering)

Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering was honored to be the laureate of the 23rd NAEK Award.

The NAEK (National Academy of Engineering of Korea) Award was instituted in 1997 to honor and recognize engineers who have made significant contributions to the development of the engineering and technology field at universities, industries, and institutions. Every year, it is conferred to only one person who has achieved original and world-leading research that has led to national development.

Distinguished Professor Lee is a pioneering scholar of the field of systems metabolic engineering and he was recognized for his significant achievements in the biochemical industry by developing novel microbial bioprocesses. In particular, he is globally renowned for biological plastic synthesis, making or decomposing polymers with microorganisms instead of using fossil resources.

He has produced numerous high-quality research breakthroughs in metabolic and systems engineering. In 2016, he produced an easily degradable plastic with Escherichia coli (E. coli). In 2018, he successfully produced aromatic polyesters, the main material for PET (poly ethylene terephthalate) from E. coli strains. He also identified microorganism structures for PET degradation and improved its degradability with a novel variant.

His research was ranked number one in the research and development division of Top Ten Science and Technology News 2018 announced by Korean Federation of Science & Technology Societies. He is one of highly cited researchers (HCR) ranked in the top 1% by citations for their field by the Clarivate Analytics.

2019.03.21 View 6900 -

Blue-enriched White Light to Wake You Up in the Morning

(from left: Professor Hyun Jung Chung, Professor Hyeon-Jeong Suk, Taesu Kim and Professor Kyungah Choi)

Here is a good news for those of who have difficulty with morning alertness. A KAIST research team proposed that a blue-enriched LED light can effectively help people overcome morning drowsiness. This study will provide the basis for major changes in future lighting strategies and thereby help create better indoor environments.

Considerable research has been devoted to unmasking circadian rhythms. The 2017 Nobel Prize in Physiology or Medicine went to Jeffrey C. Hall, Michael Rosbash, and Michael W. Young for unveiling the molecular mechanisms that control circadian rhythms. In particular, the relationship between light and its physiological effects has been investigated since the discovery of a novel, third type of photoreceptor in the human retina in the early 2000s. Rods and cones regulate visual effects, while the third type, photosensitive retinal ganglion cells, regulate a large variety of biological and behavioral processes including melatonin and cortisol secretion, alertness, and functional magnetic resonance imaging (fMRI).

Initial studies on light sources have shown that blue monochromatic, fully saturated lights are effective for stimulating physiological responses, but the relative effectiveness of commercially available white light sources is less well understood. Moreover, the research was more focused on the negative effects of blue light; for instance, when people are exposed to blue light at night, they have trouble achieving deep sleep because the light restrains melatonin secretion.

However, Professor Hyeon-Jeong Suk and Professor Kyungah Choi from the Department of Industrial Design and their team argue that the effects of blue-enriched morning light on physiological responses are time dependent, and that it has positive effects on melatonin levels and the subjective perception of alertness, mood, and visual comfort compared with warm white light.

The team conducted an experiment with 15 university students. They investigated whether an hour of morning light exposure with different chromaticity would affect their physiological and subjective responses differently. The decline of melatonin levels was significantly greater after the exposure to blue-enriched white light in comparison with warm white light.

Professor Suk said, “Light takes a huge part of our lives since we spend most of our time indoors. Light is one of the most powerful tools to affect changes in how we perceive and experience the environment around us.”

Professor Choi added, “When we investigate all of the psychological and physiological effects of light, we see there is much more to light than just efficient quantities. I believe that human-centric lighting strategies could be applied to a variety of environments, including residential areas, learning environments, and working spaces to improve our everyday lives.”

This research was collaborated with Professor Hyun Jung Chung from the Graduate School of Nanoscience and Technology and was published in Scientific Reports (10.1038/s41598-018-36791-5) on January 23, 2019.

Figure 1. Changes in melatonin secretion during day and night time

2019.03.06 View 10515

Blue-enriched White Light to Wake You Up in the Morning

(from left: Professor Hyun Jung Chung, Professor Hyeon-Jeong Suk, Taesu Kim and Professor Kyungah Choi)

Here is a good news for those of who have difficulty with morning alertness. A KAIST research team proposed that a blue-enriched LED light can effectively help people overcome morning drowsiness. This study will provide the basis for major changes in future lighting strategies and thereby help create better indoor environments.

Considerable research has been devoted to unmasking circadian rhythms. The 2017 Nobel Prize in Physiology or Medicine went to Jeffrey C. Hall, Michael Rosbash, and Michael W. Young for unveiling the molecular mechanisms that control circadian rhythms. In particular, the relationship between light and its physiological effects has been investigated since the discovery of a novel, third type of photoreceptor in the human retina in the early 2000s. Rods and cones regulate visual effects, while the third type, photosensitive retinal ganglion cells, regulate a large variety of biological and behavioral processes including melatonin and cortisol secretion, alertness, and functional magnetic resonance imaging (fMRI).

Initial studies on light sources have shown that blue monochromatic, fully saturated lights are effective for stimulating physiological responses, but the relative effectiveness of commercially available white light sources is less well understood. Moreover, the research was more focused on the negative effects of blue light; for instance, when people are exposed to blue light at night, they have trouble achieving deep sleep because the light restrains melatonin secretion.

However, Professor Hyeon-Jeong Suk and Professor Kyungah Choi from the Department of Industrial Design and their team argue that the effects of blue-enriched morning light on physiological responses are time dependent, and that it has positive effects on melatonin levels and the subjective perception of alertness, mood, and visual comfort compared with warm white light.

The team conducted an experiment with 15 university students. They investigated whether an hour of morning light exposure with different chromaticity would affect their physiological and subjective responses differently. The decline of melatonin levels was significantly greater after the exposure to blue-enriched white light in comparison with warm white light.

Professor Suk said, “Light takes a huge part of our lives since we spend most of our time indoors. Light is one of the most powerful tools to affect changes in how we perceive and experience the environment around us.”

Professor Choi added, “When we investigate all of the psychological and physiological effects of light, we see there is much more to light than just efficient quantities. I believe that human-centric lighting strategies could be applied to a variety of environments, including residential areas, learning environments, and working spaces to improve our everyday lives.”

This research was collaborated with Professor Hyun Jung Chung from the Graduate School of Nanoscience and Technology and was published in Scientific Reports (10.1038/s41598-018-36791-5) on January 23, 2019.

Figure 1. Changes in melatonin secretion during day and night time

2019.03.06 View 10515 -

KAIST Develops Analog Memristive Synapses for Neuromorphic Chips

(Professor Sung-Yool Choi from the School of Electrical Engineering)

A KAIST research team developed a technology that makes a transition of the operation mode of flexible memristors to synaptic analog switching by reducing the size of the formed filament. Through this technology, memristors can extend their role to memristive synapses for neuromorphic chips, which will lead to developing soft neuromorphic intelligent systems.

Brain-inspired neuromorphic chips have been gaining a great deal of attention for reducing the power consumption and integrating data processing, compared to conventional semiconductor chips. Similarly, memristors are known to be the most suitable candidate for making a crossbar array which is the most efficient architecture for realizing hardware-based artificial neural network (ANN) inside a neuromorphic chip.

A hardware-based ANN consists of a neuron circuit and synapse elements, the connecting pieces. In the neuromorphic system, the synaptic weight, which represents the connection strength between neurons, should be stored and updated as the type of analog data at each synapse.

However, most memristors have digital characteristics suitable for nonvolatile memory. These characteristics put a limitation on the analog operation of the memristors, which makes it difficult to apply them to synaptic devices.

Professor Sung-Yool Choi from the School of Electrical Engineering and his team fabricated a flexible polymer memristor on a plastic substrate, and found that changing the size of the conductive metal filaments formed inside the device on the scale of metal atoms can make a transition of the memristor behavior from digital to analog.

Using this phenomenon, the team developed flexible memristor-based electronic synapses, which can continuously and linearly update synaptic weight, and operate under mechanical deformations such as bending.

The team confirmed that the ANN based on these memristor synapses can effectively classify person’s facial images even when they were damaged. This research demonstrated the possibility of a neuromorphic chip that can efficiently recognize faces, numbers, and objects.

Professor Choi said, “We found the principles underlying the transition from digital to analog operation of the memristors. I believe that this research paves the way for applying various memristors to either digital memory or electronic synapses, and will accelerate the development of a high-performing neuromorphic chip.”

In a joint research project with Professor Sung Gap Im (KAIST) and Professor V. P. Dravid (Northwestern University), this study was led by Dr. Byung Chul Jang (Samsung Electronics), Dr. Sungkyu Kim (Northwestern University) and Dr. Sang Yoon Yang (KAIST), and was published online in Nano Letters (10.1021/acs.nanolett.8b04023) on January 4, 2019.

Figure 1. a) Schematic illustration of a flexible pV3D3 memristor-based electronic synapse array. b) Cross-sectional TEM image of the flexible pV3D3 memristor

2019.02.28 View 7831

KAIST Develops Analog Memristive Synapses for Neuromorphic Chips

(Professor Sung-Yool Choi from the School of Electrical Engineering)

A KAIST research team developed a technology that makes a transition of the operation mode of flexible memristors to synaptic analog switching by reducing the size of the formed filament. Through this technology, memristors can extend their role to memristive synapses for neuromorphic chips, which will lead to developing soft neuromorphic intelligent systems.

Brain-inspired neuromorphic chips have been gaining a great deal of attention for reducing the power consumption and integrating data processing, compared to conventional semiconductor chips. Similarly, memristors are known to be the most suitable candidate for making a crossbar array which is the most efficient architecture for realizing hardware-based artificial neural network (ANN) inside a neuromorphic chip.

A hardware-based ANN consists of a neuron circuit and synapse elements, the connecting pieces. In the neuromorphic system, the synaptic weight, which represents the connection strength between neurons, should be stored and updated as the type of analog data at each synapse.

However, most memristors have digital characteristics suitable for nonvolatile memory. These characteristics put a limitation on the analog operation of the memristors, which makes it difficult to apply them to synaptic devices.

Professor Sung-Yool Choi from the School of Electrical Engineering and his team fabricated a flexible polymer memristor on a plastic substrate, and found that changing the size of the conductive metal filaments formed inside the device on the scale of metal atoms can make a transition of the memristor behavior from digital to analog.

Using this phenomenon, the team developed flexible memristor-based electronic synapses, which can continuously and linearly update synaptic weight, and operate under mechanical deformations such as bending.

The team confirmed that the ANN based on these memristor synapses can effectively classify person’s facial images even when they were damaged. This research demonstrated the possibility of a neuromorphic chip that can efficiently recognize faces, numbers, and objects.

Professor Choi said, “We found the principles underlying the transition from digital to analog operation of the memristors. I believe that this research paves the way for applying various memristors to either digital memory or electronic synapses, and will accelerate the development of a high-performing neuromorphic chip.”

In a joint research project with Professor Sung Gap Im (KAIST) and Professor V. P. Dravid (Northwestern University), this study was led by Dr. Byung Chul Jang (Samsung Electronics), Dr. Sungkyu Kim (Northwestern University) and Dr. Sang Yoon Yang (KAIST), and was published online in Nano Letters (10.1021/acs.nanolett.8b04023) on January 4, 2019.

Figure 1. a) Schematic illustration of a flexible pV3D3 memristor-based electronic synapse array. b) Cross-sectional TEM image of the flexible pV3D3 memristor

2019.02.28 View 7831 -

KAIST 2019 Commencement at a Glance

(KAIST 2019 Commencement Ceremony)

This year, KAIST awarded a total of 2,705 degrees: 654 PhD degrees, 1,255 master’s degrees, and 796 bachelor’s degrees. Including this year’s numbers, KAIST has conferred a total of 63,830 degrees since its foundation in 1971.

Parents, family, and friends came to campus to congratulate the graduates with big smiles and hugs. Faculty and staff members also attended the ceremony to celebrate their graduation. This year, distinguished guests including National Assembly Member Kyung-Jin Kim and Vice Minister for Science, Technology and Innovation Dae-sik came to celebrate the day with the KAIST community.

During the commencement, KAIST also announced the recipients of its undergraduate academic awards. The Minister of Science and ICT Award was won by Do-Yoon Kim from the Department of Aerospace Engineering, the KAIST Board of Trustee Chairperson Award went to Se-rin Lee from the Department of Materials Science and Engineering, the KAIST Presidential Award was won by Hee-Ju Kim from the Department of Physics, the KAIST Alumni Association President Award went to Hyeon-Seong Park from the School of Electrical Engineering, and finally the KAIST Development Foundation Chairperson Award was won by Gyeong-Hoon Lee from the Department of Mathematical Sciences.

This year’s valedictorian Eun-Seok Jeong from the School of Computing said, “I believe that we are able to stand here today because we challenged ourselves to confront our shortcomings and our uncertainty. If we continue to develop, we will become a better person than we were yesterday.”

(KAIST President Sung-Chul Shin and Woo-Seok Jeong, '19 PhD in Aerospace Engineering)

As a KAIST alumnus and fellow scientist, President Sung-Chul Shin offered his congratulations and emphasized that graduates should continue to pursue the C³ spirit. “In this age of great transformation, embrace challenges and exercise creativity as you have learnt through your education and research at KAIST. And keep in mind the importance of caring for others. Please remember that challenge and creativity will have more meaning if rendered with a caring spirit,” he said.

2019.02.15 View 8567

KAIST 2019 Commencement at a Glance

(KAIST 2019 Commencement Ceremony)

This year, KAIST awarded a total of 2,705 degrees: 654 PhD degrees, 1,255 master’s degrees, and 796 bachelor’s degrees. Including this year’s numbers, KAIST has conferred a total of 63,830 degrees since its foundation in 1971.

Parents, family, and friends came to campus to congratulate the graduates with big smiles and hugs. Faculty and staff members also attended the ceremony to celebrate their graduation. This year, distinguished guests including National Assembly Member Kyung-Jin Kim and Vice Minister for Science, Technology and Innovation Dae-sik came to celebrate the day with the KAIST community.

During the commencement, KAIST also announced the recipients of its undergraduate academic awards. The Minister of Science and ICT Award was won by Do-Yoon Kim from the Department of Aerospace Engineering, the KAIST Board of Trustee Chairperson Award went to Se-rin Lee from the Department of Materials Science and Engineering, the KAIST Presidential Award was won by Hee-Ju Kim from the Department of Physics, the KAIST Alumni Association President Award went to Hyeon-Seong Park from the School of Electrical Engineering, and finally the KAIST Development Foundation Chairperson Award was won by Gyeong-Hoon Lee from the Department of Mathematical Sciences.

This year’s valedictorian Eun-Seok Jeong from the School of Computing said, “I believe that we are able to stand here today because we challenged ourselves to confront our shortcomings and our uncertainty. If we continue to develop, we will become a better person than we were yesterday.”

(KAIST President Sung-Chul Shin and Woo-Seok Jeong, '19 PhD in Aerospace Engineering)

As a KAIST alumnus and fellow scientist, President Sung-Chul Shin offered his congratulations and emphasized that graduates should continue to pursue the C³ spirit. “In this age of great transformation, embrace challenges and exercise creativity as you have learnt through your education and research at KAIST. And keep in mind the importance of caring for others. Please remember that challenge and creativity will have more meaning if rendered with a caring spirit,” he said.

2019.02.15 View 8567 -

President Shin Speaks on Closing the Skills Gap at the WEF

(President Shin poses (far right) with the National University of Singapore President Tan Eng Chye (center) along with Distinguished Professor Sang Yup Lee in Davos last week.)

President Sung-Chul Shin shared his ideas on how reskilling is a critical element of growth, dynamism, and competitiveness for countries during a session titled “Closing the Skills Gap: Creating a Reskilling Revolution” at the World Economic Forum on January 24 in Davos.

While discussing a reskilling imperative alongside French Labor Minister Muriel Penicaud, he presented how the Korean government and KAIST are responding to the socio-economic transformation of workforces in the Fourth Industrial Revolution. After their presentation, Minister of Economy and Enterprise of Spain Nadia Calvirno Santamaria, Minister of Commerce and Industry of Oman Ali bin Masoud bin Ali Al Sunaidy, and Minister of Petroleum and Natural Gas, Skill Development, and Entrepreneurship of India Dharmendra Pradhan shared their views on the course of decision making regarding the proactive practices and policies they have applied for closing the gaps from their countries’ perspectives.

President Shin presented how to upskill and reskill SMEs and startups, the real players who will jumpstart the economy in the Fourth Industrial Revolution. He explained that the government is striving to change the existing structure of the economy, which is dominated by a few giant conglomerates. He added that the Korean government is trying to support SMEs and startups in terms of both funding and technology reskilling in order to rejuvenate the economy.

To better align itself with the government’s efforts, KAIST has introduced SME 4.0. SME 4.0 proposes to innovate the production process through the creation of a partnered platform between KAIST and SMEs across the country. With this platform, KAIST assists local SMEs for standardizing and systemizing all their processes of production, delivery, and management with enterprise resources planning (ERP) and manufacturing execution systems (MES). In addition, SME 4.0 offers retraining and re-tooling programs by linking the data generated through this platform in real time to better facilitate SMEs’ smart business.

(President Shin shakes hands with H.E.Mohammed Al-Tuwairi, Minister of Economy and Planning of Saudi Arabia before holding a bilaterla meeting in Davos.)

President Shin also explained about upskilling the leading corporations’ technological competitiveness, partnering with major leading corporations for upskilling their advanced technologies.

He also held a series of bilateral meetings with dignitaries attending the WEF annual meeting to discuss partnerships and collaborations. He also attended the Global University Leaders Forum (GULF), a community composed of 28 presidents from the world’s top universities on January 23. President Shin, who is on the advisory board of the Center for Fourth Industrial Revolution (C4IR), also participated in the board meeting and discussed the upcoming launching of the Korea C4IR, which will open at KAIST in March.

2019.01.28 View 6143

President Shin Speaks on Closing the Skills Gap at the WEF

(President Shin poses (far right) with the National University of Singapore President Tan Eng Chye (center) along with Distinguished Professor Sang Yup Lee in Davos last week.)

President Sung-Chul Shin shared his ideas on how reskilling is a critical element of growth, dynamism, and competitiveness for countries during a session titled “Closing the Skills Gap: Creating a Reskilling Revolution” at the World Economic Forum on January 24 in Davos.

While discussing a reskilling imperative alongside French Labor Minister Muriel Penicaud, he presented how the Korean government and KAIST are responding to the socio-economic transformation of workforces in the Fourth Industrial Revolution. After their presentation, Minister of Economy and Enterprise of Spain Nadia Calvirno Santamaria, Minister of Commerce and Industry of Oman Ali bin Masoud bin Ali Al Sunaidy, and Minister of Petroleum and Natural Gas, Skill Development, and Entrepreneurship of India Dharmendra Pradhan shared their views on the course of decision making regarding the proactive practices and policies they have applied for closing the gaps from their countries’ perspectives.

President Shin presented how to upskill and reskill SMEs and startups, the real players who will jumpstart the economy in the Fourth Industrial Revolution. He explained that the government is striving to change the existing structure of the economy, which is dominated by a few giant conglomerates. He added that the Korean government is trying to support SMEs and startups in terms of both funding and technology reskilling in order to rejuvenate the economy.

To better align itself with the government’s efforts, KAIST has introduced SME 4.0. SME 4.0 proposes to innovate the production process through the creation of a partnered platform between KAIST and SMEs across the country. With this platform, KAIST assists local SMEs for standardizing and systemizing all their processes of production, delivery, and management with enterprise resources planning (ERP) and manufacturing execution systems (MES). In addition, SME 4.0 offers retraining and re-tooling programs by linking the data generated through this platform in real time to better facilitate SMEs’ smart business.

(President Shin shakes hands with H.E.Mohammed Al-Tuwairi, Minister of Economy and Planning of Saudi Arabia before holding a bilaterla meeting in Davos.)

President Shin also explained about upskilling the leading corporations’ technological competitiveness, partnering with major leading corporations for upskilling their advanced technologies.

He also held a series of bilateral meetings with dignitaries attending the WEF annual meeting to discuss partnerships and collaborations. He also attended the Global University Leaders Forum (GULF), a community composed of 28 presidents from the world’s top universities on January 23. President Shin, who is on the advisory board of the Center for Fourth Industrial Revolution (C4IR), also participated in the board meeting and discussed the upcoming launching of the Korea C4IR, which will open at KAIST in March.

2019.01.28 View 6143 -

Hierarchical Porous Titanium Nitride Synthesized by Multiscale Phase Separation for LSBs

(from left: Professor Jinwoo Lee and PhD candidate Won-Gwang Lim)

A KAIST research team developed ultra-stable, high-rate lithium-sulfur batteries (LSBs) by using hierarchical porous titanium nitride as a sulfur host, and achieved superior cycle stability and high rate performance for LSBs.

The control of large amounts of energy is required for use in an electric vehicle or smart grid system. In this sense, the development of next-generation secondary batteries is in high demand. Theoretically, LSBs have an energy density seven times higher than commercial lithium ion batteries (LIBs). Also, their production cost can be reduced dramatically since sulfur can be obtained at a low price.

Despite these positive aspects, there have been several issues impeding the commercialization of LSBs, such as the low electric conductivity of sulfur, the dissolution of active materials during operation, and sluggish conversion reactions. These issues decrease the cycle stability and rate capability of batteries.

To tackle those issues, Professor Jinwoo Lee from the Department of Chemical and Biomolecular Engineering and his team synthesized a well-developed hierarchical macro/mesoporous titanium nitride as a host material for sulfur. The titanium nitride has a high chemical affinity for sulfur and high electrical conductivity. As a result, it prevents the dissolution of active materials and facilitates the charge transfer. Moreover, the synergistic effect of macropore and mesopore structures allows the stable accommodation of large amounts of sulfur and facilitates the electrolyte penetration.

Previously reported polar inorganic materials have a high affinity for sulfur, but it was challenging to control the porous architecture suitable to the sulfur host. This work breaks such limitations by developing a synthetic route to easily control the porous architecture of inorganic materials, which led to obtaining superior cycle stability and high rate capabilities.

Professor Lee said, “Some problems still remain in commercializing LSBs as next-generation batteries. Hence, there should be a continued research on this matter to solve the issues. Through this research, we secured a key technology for ultrastable, high-rate LSBs.”

This research was led by PhD candidate Won-Gwang Lim and collaborated on by Jeong Woo Han from POSTECH. It was chosen as the cover article of Advanced Materials on January 15, 2019.

Figure 1. Schematic illustration for the synthetic route of co-continuous h-TiN

Figure 2. The hierarchical multiscale porous structure is still retained without any collapse after the conversion to h-TiN. The good retention of the porous structure is attributed to the thick pore wall of the h-TiO₂derived from the block copolymer self-assembly

Figure 3. The cover page of Advanced Materials

2019.01.28 View 6262

Hierarchical Porous Titanium Nitride Synthesized by Multiscale Phase Separation for LSBs

(from left: Professor Jinwoo Lee and PhD candidate Won-Gwang Lim)

A KAIST research team developed ultra-stable, high-rate lithium-sulfur batteries (LSBs) by using hierarchical porous titanium nitride as a sulfur host, and achieved superior cycle stability and high rate performance for LSBs.

The control of large amounts of energy is required for use in an electric vehicle or smart grid system. In this sense, the development of next-generation secondary batteries is in high demand. Theoretically, LSBs have an energy density seven times higher than commercial lithium ion batteries (LIBs). Also, their production cost can be reduced dramatically since sulfur can be obtained at a low price.

Despite these positive aspects, there have been several issues impeding the commercialization of LSBs, such as the low electric conductivity of sulfur, the dissolution of active materials during operation, and sluggish conversion reactions. These issues decrease the cycle stability and rate capability of batteries.

To tackle those issues, Professor Jinwoo Lee from the Department of Chemical and Biomolecular Engineering and his team synthesized a well-developed hierarchical macro/mesoporous titanium nitride as a host material for sulfur. The titanium nitride has a high chemical affinity for sulfur and high electrical conductivity. As a result, it prevents the dissolution of active materials and facilitates the charge transfer. Moreover, the synergistic effect of macropore and mesopore structures allows the stable accommodation of large amounts of sulfur and facilitates the electrolyte penetration.

Previously reported polar inorganic materials have a high affinity for sulfur, but it was challenging to control the porous architecture suitable to the sulfur host. This work breaks such limitations by developing a synthetic route to easily control the porous architecture of inorganic materials, which led to obtaining superior cycle stability and high rate capabilities.

Professor Lee said, “Some problems still remain in commercializing LSBs as next-generation batteries. Hence, there should be a continued research on this matter to solve the issues. Through this research, we secured a key technology for ultrastable, high-rate LSBs.”

This research was led by PhD candidate Won-Gwang Lim and collaborated on by Jeong Woo Han from POSTECH. It was chosen as the cover article of Advanced Materials on January 15, 2019.

Figure 1. Schematic illustration for the synthetic route of co-continuous h-TiN

Figure 2. The hierarchical multiscale porous structure is still retained without any collapse after the conversion to h-TiN. The good retention of the porous structure is attributed to the thick pore wall of the h-TiO₂derived from the block copolymer self-assembly

Figure 3. The cover page of Advanced Materials

2019.01.28 View 6262 -

Ultrathin Digital Camera Inspired by Xenos Peckii Eyes

(Professor Ki-Hun Jeong from the Department of Bio and Brain Engineering)

The visual system of Xenos peckii, an endoparasite of paper wasps, demonstrates distinct benefits for high sensitivity and high resolution, differing from the compound eyes of most insects. Taking their unique features, a KAIST team developed an ultrathin digital camera that emulates the unique eyes of Xenos peckii.

The ultrathin digital camera offers a wide field of view and high resolution in a slimmer body compared to existing imaging systems. It is expected to support various applications, such as monitoring equipment, medical imaging devices, and mobile imaging systems.

Professor Ki-Hun Jeong from the Department of Bio and Brain Engineering and his team are known for mimicking biological visual organs. The team’s past research includes an LED lens based on the abdominal segments of fireflies and biologically inspired anti-reflective structures.

Recently, the demand for ultrathin digital cameras has increased, due to the miniaturization of electronic and optical devices. However, most camera modules use multiple lenses along the optical axis to compensate for optical aberrations, resulting in a larger volume as well as a thicker total track length of digital cameras. Resolution and sensitivity would be compromised if these modules were to be simply reduced in size and thickness.

To address this issue, the team have developed micro-optical components, inspired from the visual system of Xenos peckii, and combined them with a CMOS (complementary metal oxide semiconductor) image sensor to achieve an ultrathin digital camera.

This new camera, measuring less than 2mm in thickness, emulates the eyes of Xenos peckii by using dozens of microprism arrays and microlens arrays. A microprism and microlens pair form a channel and the light-absorbing medium between the channels reduces optical crosstalk. Each channel captures the partial image at slightly different orientation, and the retrieved partial images are combined into a single image, thereby ensuring a wide field of view and high resolution.

Professor Jeong said, “We have proposed a novel method of fabricating an ultrathin camera. As the first insect-inspired, ultrathin camera that integrates a microcamera on a conventional CMOS image sensor array, our study will have a significant impact in optics and related fields.”

This research, led by PhD candidates Dongmin Keum and Kyung-Won Jang, was published in Light: Science & Applications on October 24, 2018.

Figure 1. Natural Xenos peckii eye and the biological inspiration for the ultrathin digital camera (Light: Science & Applications 2018)

Figure 2. Optical images captured by the bioinspired ultrathin digital camera (Light: Science & Applications 2018)

2018.12.31 View 7679

Ultrathin Digital Camera Inspired by Xenos Peckii Eyes

(Professor Ki-Hun Jeong from the Department of Bio and Brain Engineering)

The visual system of Xenos peckii, an endoparasite of paper wasps, demonstrates distinct benefits for high sensitivity and high resolution, differing from the compound eyes of most insects. Taking their unique features, a KAIST team developed an ultrathin digital camera that emulates the unique eyes of Xenos peckii.

The ultrathin digital camera offers a wide field of view and high resolution in a slimmer body compared to existing imaging systems. It is expected to support various applications, such as monitoring equipment, medical imaging devices, and mobile imaging systems.

Professor Ki-Hun Jeong from the Department of Bio and Brain Engineering and his team are known for mimicking biological visual organs. The team’s past research includes an LED lens based on the abdominal segments of fireflies and biologically inspired anti-reflective structures.

Recently, the demand for ultrathin digital cameras has increased, due to the miniaturization of electronic and optical devices. However, most camera modules use multiple lenses along the optical axis to compensate for optical aberrations, resulting in a larger volume as well as a thicker total track length of digital cameras. Resolution and sensitivity would be compromised if these modules were to be simply reduced in size and thickness.

To address this issue, the team have developed micro-optical components, inspired from the visual system of Xenos peckii, and combined them with a CMOS (complementary metal oxide semiconductor) image sensor to achieve an ultrathin digital camera.

This new camera, measuring less than 2mm in thickness, emulates the eyes of Xenos peckii by using dozens of microprism arrays and microlens arrays. A microprism and microlens pair form a channel and the light-absorbing medium between the channels reduces optical crosstalk. Each channel captures the partial image at slightly different orientation, and the retrieved partial images are combined into a single image, thereby ensuring a wide field of view and high resolution.

Professor Jeong said, “We have proposed a novel method of fabricating an ultrathin camera. As the first insect-inspired, ultrathin camera that integrates a microcamera on a conventional CMOS image sensor array, our study will have a significant impact in optics and related fields.”

This research, led by PhD candidates Dongmin Keum and Kyung-Won Jang, was published in Light: Science & Applications on October 24, 2018.

Figure 1. Natural Xenos peckii eye and the biological inspiration for the ultrathin digital camera (Light: Science & Applications 2018)

Figure 2. Optical images captured by the bioinspired ultrathin digital camera (Light: Science & Applications 2018)

2018.12.31 View 7679 -

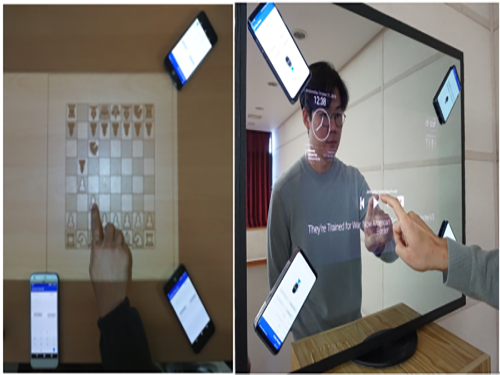

Sound-based Touch Input Technology for Smart Tables and Mirrors

(from left: MS candidate Anish Byanjankar, Research Assistant Professor Hyosu Kim and Professor Insik Shin)

Time passes so quickly, especially in the morning. Your hands are so busy brushing your teeth and checking the weather on your smartphone. You might wish that your mirror could turn into a touch screen and free up your hands. That wish can be achieved very soon. A KAIST team has developed a smartphone-based touch sound localization technology to facilitate ubiquitous interactions, turning objects like furniture and mirrors into touch input tools.

This technology analyzes touch sounds generated from a user’s touch on a surface and identifies the location of the touch input. For instance, users can turn surrounding tables or walls into virtual keyboards and write lengthy e-mails much more conveniently by using only the built-in microphone on their smartphones or tablets. Moreover, family members can enjoy a virtual chessboard or enjoy board games on their dining tables.

Additionally, traditional smart devices such as smart TVs or mirrors, which only provide simple screen display functions, can play a smarter role by adding touch input function support (see the image below).

Figure 1.Examples of using touch input technology: By using only smartphone, you can use surrounding objects as a touch screen anytime and anywhere.

The most important aspect of enabling the sound-based touch input method is to identify the location of touch inputs in a precise manner (within about 1cm error). However, it is challenging to meet these requirements, mainly because this technology can be used in diverse and dynamically changing environments. Users may use objects like desks, walls, or mirrors as touch input tools and the surrounding environments (e.g. location of nearby objects or ambient noise level) can be varied. These environmental changes can affect the characteristics of touch sounds.

To address this challenge, Professor Insik Shin from the School of Computing and his team focused on analyzing the fundamental properties of touch sounds, especially how they are transmitted through solid surfaces.

On solid surfaces, sound experiences a dispersion phenomenon that makes different frequency components travel at different speeds. Based on this phenomenon, the team observed that the arrival time difference (TDoA) between frequency components increases in proportion to the sound transmission distance, and this linear relationship is not affected by the variations of surround environments.

Based on these observations, Research Assistant Professor Hyosu Kim proposed a novel sound-based touch input technology that records touch sounds transmitted through solid surfaces, then conducts a simple calibration process to identify the relationship between TDoA and the sound transmission distance, finally achieving accurate touch input localization.

The accuracy of the proposed system was then measured. The average localization error was lower than about 0.4 cm on a 17-inch touch screen. Particularly, it provided a measurement error of less than 1cm, even with a variety of objects such as wooden desks, glass mirrors, and acrylic boards and when the position of nearby objects and noise levels changed dynamically. Experiments with practical users have also shown positive responses to all measurement factors, including user experience and accuracy.

Professor Shin said, “This is novel touch interface technology that allows a touch input system just by installing three to four microphones, so it can easily turn nearby objects into touch screens.”

The proposed system was presented at ACM SenSys, a top-tier conference in the field of mobile computing and sensing, and was selected as a best paper runner-up in November 2018.

(The demonstration video of the sound-based touch input technology)

2018.12.26 View 7599

Sound-based Touch Input Technology for Smart Tables and Mirrors

(from left: MS candidate Anish Byanjankar, Research Assistant Professor Hyosu Kim and Professor Insik Shin)

Time passes so quickly, especially in the morning. Your hands are so busy brushing your teeth and checking the weather on your smartphone. You might wish that your mirror could turn into a touch screen and free up your hands. That wish can be achieved very soon. A KAIST team has developed a smartphone-based touch sound localization technology to facilitate ubiquitous interactions, turning objects like furniture and mirrors into touch input tools.

This technology analyzes touch sounds generated from a user’s touch on a surface and identifies the location of the touch input. For instance, users can turn surrounding tables or walls into virtual keyboards and write lengthy e-mails much more conveniently by using only the built-in microphone on their smartphones or tablets. Moreover, family members can enjoy a virtual chessboard or enjoy board games on their dining tables.

Additionally, traditional smart devices such as smart TVs or mirrors, which only provide simple screen display functions, can play a smarter role by adding touch input function support (see the image below).

Figure 1.Examples of using touch input technology: By using only smartphone, you can use surrounding objects as a touch screen anytime and anywhere.

The most important aspect of enabling the sound-based touch input method is to identify the location of touch inputs in a precise manner (within about 1cm error). However, it is challenging to meet these requirements, mainly because this technology can be used in diverse and dynamically changing environments. Users may use objects like desks, walls, or mirrors as touch input tools and the surrounding environments (e.g. location of nearby objects or ambient noise level) can be varied. These environmental changes can affect the characteristics of touch sounds.

To address this challenge, Professor Insik Shin from the School of Computing and his team focused on analyzing the fundamental properties of touch sounds, especially how they are transmitted through solid surfaces.

On solid surfaces, sound experiences a dispersion phenomenon that makes different frequency components travel at different speeds. Based on this phenomenon, the team observed that the arrival time difference (TDoA) between frequency components increases in proportion to the sound transmission distance, and this linear relationship is not affected by the variations of surround environments.

Based on these observations, Research Assistant Professor Hyosu Kim proposed a novel sound-based touch input technology that records touch sounds transmitted through solid surfaces, then conducts a simple calibration process to identify the relationship between TDoA and the sound transmission distance, finally achieving accurate touch input localization.

The accuracy of the proposed system was then measured. The average localization error was lower than about 0.4 cm on a 17-inch touch screen. Particularly, it provided a measurement error of less than 1cm, even with a variety of objects such as wooden desks, glass mirrors, and acrylic boards and when the position of nearby objects and noise levels changed dynamically. Experiments with practical users have also shown positive responses to all measurement factors, including user experience and accuracy.

Professor Shin said, “This is novel touch interface technology that allows a touch input system just by installing three to four microphones, so it can easily turn nearby objects into touch screens.”

The proposed system was presented at ACM SenSys, a top-tier conference in the field of mobile computing and sensing, and was selected as a best paper runner-up in November 2018.

(The demonstration video of the sound-based touch input technology)

2018.12.26 View 7599 -

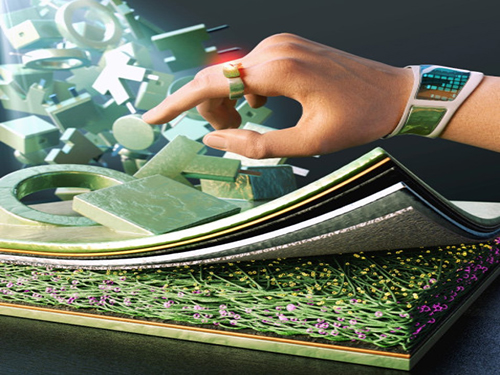

Fabrication of Shape-conformable Batteries with 3D-Printing

(from left: Dr. Bok Yeop Ahn, Dr. Chanhoon Kim, Professor Il-Doo Kim and Professor Jennifer A. Lewis)

Flexible, wireless electronic devices are rapidly emerging and have reached the level of commercialization; nevertheless, most of battery shapes are limited to either spherical and/or rectangular structures, which results in inefficient space use. Professor Il-Doo Kim’s team from the Department of Materials Science at KAIST has successfully developed technology to significantly enhance the variability of battery design through collaboration research with Professor Jennifer A. Lewis and her team from the School of Engineering and Applied Sciences at Harvard University.

Most of the battery shapes today are optimized for coin cell and/or pouch cells. Since the battery as an energy storage device occupies most of the space in microelectronic devices with different designs, new technology to freely change the shape of the battery is required.

The KAIST-Harvard research collaboration team has successfully manufactured various kinds of battery shapes, such as ring-type, H, and U shape, using 3D printing technology. And through the research collaboration with Dr. Youngmin Choi at the Korea Research Institute of Chemical Technology (KRICT), 3D-printed batteries were applied to small-scale wearable electronic devices (wearable light sensor rings).

The research group has adopted environmentally friendly aqueous Zn-ion batteries to make customized battery packs. This system, which uses Zn2+ instead of Li+ as charge carriers, is much safer compared with the conventional lithium rechargeable batteries that use highly inflammable organic electrolytes. Moreover, the processing conditions of lithium-ion batteries are very complicated because organic solvents can ignite upon exposure to moisture and oxygen.

As the aqueous Zn-ion batteries adopted by the research team are stable upon contact with atmospheric moisture and oxygen, they can be fabricated in the ambient air condition, and have advantages in packaging since packaged plastic does not dissolve in water even when plastic packaging is applied using a 3D printer.

To fabricate a stable cathode that can be modulated in various forms and allows high charge-discharge, the research team fabricated a carbon fiber current collector using electrospinning process and uniformly coated electrochemically active polyaniline conductive polymer on the surface of carbon fiber for a current collector-active layer integrated cathode. The cathode, based on conductive polyaniline consisting of a 3D structure, exhibits very fast charging speeds (50% of the charge in two minutes) and can be fabricated without the detachment of active cathode materials, so various battery forms with high mechanical stability can be manufactured.

Prof. Kim said, “Zn-ion batteries employing aqueous electrolytes have the advantage of fabrication under ambient conditions, so it is easy to fabricate the customized battery packs using 3D printing.”

“3D-printed batteries can be easily applied for niche applications such as wearable, personalized, miniaturized micro-robots, and implantable medical devices or microelectronic storage devices with unique designs,” added Professor Lewis.

With Dr. Chanhoon Kim in the Department of Materials Science and Engineering at KAIST and Dr. Bok Yeop Ahn School of Engineering and Applied Sciences at Harvard University participating as equally contributing first authors, this work was published in the December issue of ACS Nano.

This work was financially supported by the Global Research Laboratory (NRF-2015K1A1A2029679) and Wearable Platform Materials Technology Center (2016R1A5A1009926).

Figure 1.Fabrication of shape-conformable batteries based on 3D-printing technology and the application of polyaniline carbon nanofiber cathodes and wearable electronic devices

Figure 2.Fabricated shape-conformable batteries based on a 3D-printing method

Meanwhile, Professor Il-Doo Kim was recently appointed as an Associate Editor of ACS Nano, a highly renowned journal in the field of nanoscience.

Professor Kim said, “It is my great honor to be an Associate Editor of the highly renowned journal ACS Nano, which has an impact factor reaching 13.709 with 134,596 citations as of 2017. Through the editorial activities in the fields of energy, I will dedicate myself to improving the prominence of KAIST and expanding the scope of Korea’s science and technology. I will also contribute to carrying out more international collaborations with world-leading research groups.”

(Associate Editor of ACS Nano Professor Il-Doo Kim)

2018.12.20 View 9344

Fabrication of Shape-conformable Batteries with 3D-Printing

(from left: Dr. Bok Yeop Ahn, Dr. Chanhoon Kim, Professor Il-Doo Kim and Professor Jennifer A. Lewis)

Flexible, wireless electronic devices are rapidly emerging and have reached the level of commercialization; nevertheless, most of battery shapes are limited to either spherical and/or rectangular structures, which results in inefficient space use. Professor Il-Doo Kim’s team from the Department of Materials Science at KAIST has successfully developed technology to significantly enhance the variability of battery design through collaboration research with Professor Jennifer A. Lewis and her team from the School of Engineering and Applied Sciences at Harvard University.

Most of the battery shapes today are optimized for coin cell and/or pouch cells. Since the battery as an energy storage device occupies most of the space in microelectronic devices with different designs, new technology to freely change the shape of the battery is required.

The KAIST-Harvard research collaboration team has successfully manufactured various kinds of battery shapes, such as ring-type, H, and U shape, using 3D printing technology. And through the research collaboration with Dr. Youngmin Choi at the Korea Research Institute of Chemical Technology (KRICT), 3D-printed batteries were applied to small-scale wearable electronic devices (wearable light sensor rings).

The research group has adopted environmentally friendly aqueous Zn-ion batteries to make customized battery packs. This system, which uses Zn2+ instead of Li+ as charge carriers, is much safer compared with the conventional lithium rechargeable batteries that use highly inflammable organic electrolytes. Moreover, the processing conditions of lithium-ion batteries are very complicated because organic solvents can ignite upon exposure to moisture and oxygen.

As the aqueous Zn-ion batteries adopted by the research team are stable upon contact with atmospheric moisture and oxygen, they can be fabricated in the ambient air condition, and have advantages in packaging since packaged plastic does not dissolve in water even when plastic packaging is applied using a 3D printer.

To fabricate a stable cathode that can be modulated in various forms and allows high charge-discharge, the research team fabricated a carbon fiber current collector using electrospinning process and uniformly coated electrochemically active polyaniline conductive polymer on the surface of carbon fiber for a current collector-active layer integrated cathode. The cathode, based on conductive polyaniline consisting of a 3D structure, exhibits very fast charging speeds (50% of the charge in two minutes) and can be fabricated without the detachment of active cathode materials, so various battery forms with high mechanical stability can be manufactured.

Prof. Kim said, “Zn-ion batteries employing aqueous electrolytes have the advantage of fabrication under ambient conditions, so it is easy to fabricate the customized battery packs using 3D printing.”

“3D-printed batteries can be easily applied for niche applications such as wearable, personalized, miniaturized micro-robots, and implantable medical devices or microelectronic storage devices with unique designs,” added Professor Lewis.

With Dr. Chanhoon Kim in the Department of Materials Science and Engineering at KAIST and Dr. Bok Yeop Ahn School of Engineering and Applied Sciences at Harvard University participating as equally contributing first authors, this work was published in the December issue of ACS Nano.

This work was financially supported by the Global Research Laboratory (NRF-2015K1A1A2029679) and Wearable Platform Materials Technology Center (2016R1A5A1009926).

Figure 1.Fabrication of shape-conformable batteries based on 3D-printing technology and the application of polyaniline carbon nanofiber cathodes and wearable electronic devices

Figure 2.Fabricated shape-conformable batteries based on a 3D-printing method

Meanwhile, Professor Il-Doo Kim was recently appointed as an Associate Editor of ACS Nano, a highly renowned journal in the field of nanoscience.

Professor Kim said, “It is my great honor to be an Associate Editor of the highly renowned journal ACS Nano, which has an impact factor reaching 13.709 with 134,596 citations as of 2017. Through the editorial activities in the fields of energy, I will dedicate myself to improving the prominence of KAIST and expanding the scope of Korea’s science and technology. I will also contribute to carrying out more international collaborations with world-leading research groups.”

(Associate Editor of ACS Nano Professor Il-Doo Kim)

2018.12.20 View 9344 -

Reducing the Drag Force of a Moving Body Underwater

(from left: Professor Yeunwoo Cho and PhD Jaeho Chung)

Professor Yeunwoo Cho and his team from the Department of Mechanical Engineering developed new technology that reduces the drag force of a moving body in a still fluid by using the supercavitation phenomenon.

When a body moves in air, the frictional drag is lower than that of the same body moving in water. Therefore, the body that moves in water can reduce the drag significantly when it is completely enveloped in a gaseous cavity.

The team used compressed air to create so-called supercavitation, which is a phenomenon created by completely enveloping a body in a single large gaseous cavity. The drag force exerted on the body is then measured.

As a result, the team confirmed that the drag force for a moving body enveloped in air is about 25% of the drag force for a moving body without envelopment.

These results can be applied for developing high-speed underwater vehicles and the development of air-lubricated, high-speed vessels.

The team expects that the results can be applied for developing high-speed underwater vehicles and the development of air lubrication for a ship’s hull.

This research, led by PhD Jaeho Chung, was published in the Journal of Fluid Mechanics as a cover article on November 10, 2018.

Figure 1. The cover article of the Journal of Fluid Mechanics Vol. 854

2018.12.04 View 3734

Reducing the Drag Force of a Moving Body Underwater

(from left: Professor Yeunwoo Cho and PhD Jaeho Chung)

Professor Yeunwoo Cho and his team from the Department of Mechanical Engineering developed new technology that reduces the drag force of a moving body in a still fluid by using the supercavitation phenomenon.

When a body moves in air, the frictional drag is lower than that of the same body moving in water. Therefore, the body that moves in water can reduce the drag significantly when it is completely enveloped in a gaseous cavity.

The team used compressed air to create so-called supercavitation, which is a phenomenon created by completely enveloping a body in a single large gaseous cavity. The drag force exerted on the body is then measured.

As a result, the team confirmed that the drag force for a moving body enveloped in air is about 25% of the drag force for a moving body without envelopment.

These results can be applied for developing high-speed underwater vehicles and the development of air-lubricated, high-speed vessels.

The team expects that the results can be applied for developing high-speed underwater vehicles and the development of air lubrication for a ship’s hull.

This research, led by PhD Jaeho Chung, was published in the Journal of Fluid Mechanics as a cover article on November 10, 2018.

Figure 1. The cover article of the Journal of Fluid Mechanics Vol. 854

2018.12.04 View 3734 -

KAIST Seals the Deal for Kenya KAIST Project

KAIST will participate in Kenya’s strategic economic development plan under the provision of a turnkey-based science and technology education consultancy for the establishment of the Kenya Advanced Institute of Science and Technology (Kenya KAIST).KAIST signed the contract on November 30 with the Konza Technopolis Development Authority to establish Kenya KAIST. Korea Eximbank will offer a 95 million USD loan to the Kenyan government for this project. The project will include the educational and architectural design and construction of Kenya KAIST. The campus will be constructed in the Konza Techno City nearby Nairobi by 2021, with the first batch of 200 graduate students starting classes in 2022. KAIST, in consortium with Samwoo and Sunjin architecture and engineering companies, will take the lead of the three-year project, with the kick-off ceremony planned at the end of next January in Nairobi. The Kenyan government plans to transform Kenya into a middle-income country under Vision 2030 through promoting science, technology, and innovation for national economic growth. Nicknamed Africa’s Silicon Savannah, Konza Techno City is a strategic science and technology hub to realize this vision. To this end, the medium-term plan set a goal to provide specialized research and training in various leading-edge engineering and advanced science fields.In the two-phase evaluation of the consultancy bidding, KAIST won preferred bidder status in the technical proposal evaluation, outbidding three other Korean consortia. Invited to the financial proposal bidding, the KAIST consortium successfully completed month-long contract negotiations with Kenya last week.KAIST will develop academic curricula for six initial departments (Mechanical Engineering, Electrical/Electronic Engineering, ICT Engineering, Chemical Engineering, Civil Engineering, and Agricultural Biotechnology), which will lay the ground work for engineering research and education in Kenya to meet emerging socioeconomic demands. In addition, KAIST will provide the education of basic sciences of math, physics, chemistry, and biology for students.It is also notable that the Kenyan government asked to develop an industry-academy cooperation program in Konza Techno City. It reflects the growing industrial needs of Kenya KAIST, which will be located in the center of the Konza Technopolis. It is anticipated that the technopolis will create 16,675 jobs in the medium term and over 200,000 after completion, positioning Kenya as an ICT hub within the region.KAIST also shares a similar history of establishment with Kenya KAIST, as it will be built with a foreign loan. KAIST, created by the Korean government in 1971 to drive the economic engine through advancement of science and technology with a six-million USD loan from USAID, has now become a donor institution that hands down science and technology education systems including the construction of campuses to underdeveloped countries.The successful case of KAIST has been benchmarked by many countries for years. For instance, KAIST set up the curriculum of the nuclear engineering program at the Khalifa University of Science and Technology in UAE in 2010. In China, Chongqing University of Technology is running its electrical engineering and computer science programs based on the educational systems and curricula offered by KAIST from 2015. In October, KAIST also signed an MOU with the Prince Mohammad Bin Salman College of Cyber Security, AI, and Advanced Technologies in Saudi Arabia to provide the undergraduate program for robotics.Among all these programs benchmarking KAIST, Kenya KAIST clearly stands out, for it is carrying out a turnkey-based project that encompasses every aspect of institution building ranging from educational curriculum development to campus construction and supervision.President Sung-Chul Shin is extremely excited about finalizing the deal, remarking, “It is of great significance that KAIST’s successful development model has carved out a unique path to becoming a global leading university that will benefit other countries. In only a half century, we have transitioned from a receiver to a donor institution, as the country itself has done.”“KAIST will spare no effort for Kenya KAIST to become a successful science and technology university that will play a crucial role in Kenya’s national development. I believe Kenya KAIST will be an exemplary case of an ODA (Official Development Assistance) project based on the development of science and technology to benefit underdeveloped countries,” he added.

2018.12.03 View 8469

KAIST Seals the Deal for Kenya KAIST Project

KAIST will participate in Kenya’s strategic economic development plan under the provision of a turnkey-based science and technology education consultancy for the establishment of the Kenya Advanced Institute of Science and Technology (Kenya KAIST).KAIST signed the contract on November 30 with the Konza Technopolis Development Authority to establish Kenya KAIST. Korea Eximbank will offer a 95 million USD loan to the Kenyan government for this project. The project will include the educational and architectural design and construction of Kenya KAIST. The campus will be constructed in the Konza Techno City nearby Nairobi by 2021, with the first batch of 200 graduate students starting classes in 2022. KAIST, in consortium with Samwoo and Sunjin architecture and engineering companies, will take the lead of the three-year project, with the kick-off ceremony planned at the end of next January in Nairobi. The Kenyan government plans to transform Kenya into a middle-income country under Vision 2030 through promoting science, technology, and innovation for national economic growth. Nicknamed Africa’s Silicon Savannah, Konza Techno City is a strategic science and technology hub to realize this vision. To this end, the medium-term plan set a goal to provide specialized research and training in various leading-edge engineering and advanced science fields.In the two-phase evaluation of the consultancy bidding, KAIST won preferred bidder status in the technical proposal evaluation, outbidding three other Korean consortia. Invited to the financial proposal bidding, the KAIST consortium successfully completed month-long contract negotiations with Kenya last week.KAIST will develop academic curricula for six initial departments (Mechanical Engineering, Electrical/Electronic Engineering, ICT Engineering, Chemical Engineering, Civil Engineering, and Agricultural Biotechnology), which will lay the ground work for engineering research and education in Kenya to meet emerging socioeconomic demands. In addition, KAIST will provide the education of basic sciences of math, physics, chemistry, and biology for students.It is also notable that the Kenyan government asked to develop an industry-academy cooperation program in Konza Techno City. It reflects the growing industrial needs of Kenya KAIST, which will be located in the center of the Konza Technopolis. It is anticipated that the technopolis will create 16,675 jobs in the medium term and over 200,000 after completion, positioning Kenya as an ICT hub within the region.KAIST also shares a similar history of establishment with Kenya KAIST, as it will be built with a foreign loan. KAIST, created by the Korean government in 1971 to drive the economic engine through advancement of science and technology with a six-million USD loan from USAID, has now become a donor institution that hands down science and technology education systems including the construction of campuses to underdeveloped countries.The successful case of KAIST has been benchmarked by many countries for years. For instance, KAIST set up the curriculum of the nuclear engineering program at the Khalifa University of Science and Technology in UAE in 2010. In China, Chongqing University of Technology is running its electrical engineering and computer science programs based on the educational systems and curricula offered by KAIST from 2015. In October, KAIST also signed an MOU with the Prince Mohammad Bin Salman College of Cyber Security, AI, and Advanced Technologies in Saudi Arabia to provide the undergraduate program for robotics.Among all these programs benchmarking KAIST, Kenya KAIST clearly stands out, for it is carrying out a turnkey-based project that encompasses every aspect of institution building ranging from educational curriculum development to campus construction and supervision.President Sung-Chul Shin is extremely excited about finalizing the deal, remarking, “It is of great significance that KAIST’s successful development model has carved out a unique path to becoming a global leading university that will benefit other countries. In only a half century, we have transitioned from a receiver to a donor institution, as the country itself has done.”“KAIST will spare no effort for Kenya KAIST to become a successful science and technology university that will play a crucial role in Kenya’s national development. I believe Kenya KAIST will be an exemplary case of an ODA (Official Development Assistance) project based on the development of science and technology to benefit underdeveloped countries,” he added.

2018.12.03 View 8469