SOT

-

KAIST research team develops a forgery prevention technique using salmon DNA

The authenticity scandal that plagued the artwork “Beautiful Woman” by Kyung-ja Chun for 30 years shows how concerns about replicas can become a burden to artists, as most of them are not experts in the field of anti-counterfeiting. To solve this problem, artist-friendly physical unclonable functions (PUFs) based on optical techniques instead of electronic ones, which can be applied immediately onto artwork through brushstrokes are needed.

On May 23, a KAIST research team led by Professor Dong Ki Yoon in the Department of Chemistry revealed the development of a proprietary technology for security and certification using random patterns that occur during the self-assembly of soft materials.

With the development of the Internet of Things in recent years, various electronic devices and services can now be connected to the internet and carry out new innovative functions. However, counterfeiting technologies that infringe on individuals’ privacy have also entered the marketplace.

The technique developed by the research team involves random and spontaneous patterns that naturally occur during the self-assembly of two different types of soft materials, which can be used in the same way as human fingerprints for non-replicable security. This is very significant in that even non-experts in the field of security can construct anti-counterfeiting systems through simple actions like drawing a picture.

The team developed two unique methods. The first method uses liquid crystals. When liquid crystals become trapped in patterned substrates, they induce the symmetrical destruction of the structure and create a maze-like topology (Figure 1). The research team defined the pathways open to the right as 0 (blue), and those open to the left as 1 (red), and confirmed that the structure could be converted into a digital code composed of 0’s and 1’s that can serve as a type of fingerprint through object recognition using machine learning. This groundbreaking technique can be utilized by non-experts, as it does not require complex semiconductor patterns that are required by existing technology, and can be observed through the level of resolution of a smartphone camera. In particular, this technique can reconstruct information more easily than conventional methods that use semiconductor chips.

< Figure 1. Security technology using the maze made up of magnetically-assembled structures formed on a substrate patterned with liquid crystal materials. >

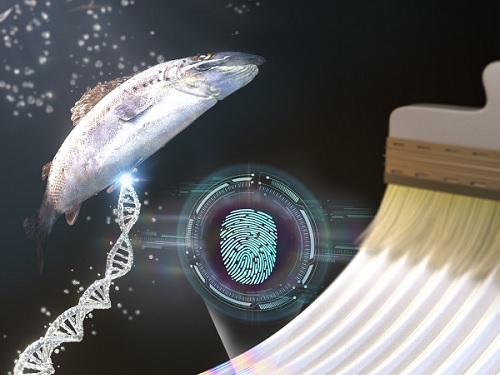

The second method uses DNA extracted from salmon. The DNA can be dissolved in water and applied with a brush to induce bulking instability, which forms random patterns similar to a zebra’s stripes. Here, the patterns create ridge endings and bifurcation, which are characteristics in fingerprints, and these can also be digitalized into 0’s and 1’s through machine learning. The research team applied conventional fingerprint recognition technology to this patterning technique and demonstrated its use as an artificial fingerprint. This method can be easily carried out using a brush, and the solution can be mixed into various colors and used as a new security ink.

< Figure 2. Technology to produce security ink using DNA polymers extracted from salmon >

This new security technology developed by the research team uses only simple organic materials and requires basic manufacturing processes, making it possible to enhance security at a low cost. In addition, users can produce patterns in the shapes and sizes they want, and even if the patterns are made in the same way, their randomness makes each individual pattern different. This provides high levels of security and gives the technique enhanced marketability.

Professor Dong Ki Yoon said, “These studies have taken the randomness that naturally occurs during self-assembly to create non-replicable patterns that can act like human fingerprints.” He added, “These ideas will be the cornerstone of technology that applies the many randomities that exist in nature to security systems.”

The two studies were published in the journal Advanced Materials under the titles “1Planar Spin Glass with Topologically-Protected Mazes in the Liquid Crystal Targeting for Reconfigurable Micro Security Media” and “2Paintable Physical Unclonable Function Using DNA” on May 6 and 5, respectively.

Author Information: 1Geonhyeong Park, Yun-Seok Choi, S. Joon Kwon*, and Dong Ki Yoon*/ 2Soon Mo Park†, Geonhyeong Park†, Dong Ki Yoon*: †co-first authors, *corresponding author

This research was funded by the Center for Multiscale Chiral Architectures and supported by the Ministry of Science and ICT-Korea Research Foundation, BRIDGE Convergent Research and Development Program, the Running Together Project, and the Samsung Future Technology Development Program.

< Figure 1-1. A scene from the schematic animation of the process of Blues (0) and Reds (1) forming the PUF by exploring the maze. From "Planar Spin Glass with Topologically-Protected Mazes in the Liquid Crystal Targeting for Reconfigurable Micro Security Media" by Geonhyeong Park, Yun-Seok Choi, S. Joon Kwon, Dong Ki Yoon. https://doi.org/10.1002/adma.202303077 >

< Figure 2-1. A schematic diagram of the formation of digital fingerprints formed using the DNA ink. From "Paintable Physical Unclonable Function Using DNA" by Soon Mo Park, Geonhyeong Park, Dong Ki Yoon. https://doi.org/10.1002/adma.202302135 >

2023.06.08 View 8795

KAIST research team develops a forgery prevention technique using salmon DNA

The authenticity scandal that plagued the artwork “Beautiful Woman” by Kyung-ja Chun for 30 years shows how concerns about replicas can become a burden to artists, as most of them are not experts in the field of anti-counterfeiting. To solve this problem, artist-friendly physical unclonable functions (PUFs) based on optical techniques instead of electronic ones, which can be applied immediately onto artwork through brushstrokes are needed.

On May 23, a KAIST research team led by Professor Dong Ki Yoon in the Department of Chemistry revealed the development of a proprietary technology for security and certification using random patterns that occur during the self-assembly of soft materials.

With the development of the Internet of Things in recent years, various electronic devices and services can now be connected to the internet and carry out new innovative functions. However, counterfeiting technologies that infringe on individuals’ privacy have also entered the marketplace.

The technique developed by the research team involves random and spontaneous patterns that naturally occur during the self-assembly of two different types of soft materials, which can be used in the same way as human fingerprints for non-replicable security. This is very significant in that even non-experts in the field of security can construct anti-counterfeiting systems through simple actions like drawing a picture.

The team developed two unique methods. The first method uses liquid crystals. When liquid crystals become trapped in patterned substrates, they induce the symmetrical destruction of the structure and create a maze-like topology (Figure 1). The research team defined the pathways open to the right as 0 (blue), and those open to the left as 1 (red), and confirmed that the structure could be converted into a digital code composed of 0’s and 1’s that can serve as a type of fingerprint through object recognition using machine learning. This groundbreaking technique can be utilized by non-experts, as it does not require complex semiconductor patterns that are required by existing technology, and can be observed through the level of resolution of a smartphone camera. In particular, this technique can reconstruct information more easily than conventional methods that use semiconductor chips.

< Figure 1. Security technology using the maze made up of magnetically-assembled structures formed on a substrate patterned with liquid crystal materials. >

The second method uses DNA extracted from salmon. The DNA can be dissolved in water and applied with a brush to induce bulking instability, which forms random patterns similar to a zebra’s stripes. Here, the patterns create ridge endings and bifurcation, which are characteristics in fingerprints, and these can also be digitalized into 0’s and 1’s through machine learning. The research team applied conventional fingerprint recognition technology to this patterning technique and demonstrated its use as an artificial fingerprint. This method can be easily carried out using a brush, and the solution can be mixed into various colors and used as a new security ink.

< Figure 2. Technology to produce security ink using DNA polymers extracted from salmon >

This new security technology developed by the research team uses only simple organic materials and requires basic manufacturing processes, making it possible to enhance security at a low cost. In addition, users can produce patterns in the shapes and sizes they want, and even if the patterns are made in the same way, their randomness makes each individual pattern different. This provides high levels of security and gives the technique enhanced marketability.

Professor Dong Ki Yoon said, “These studies have taken the randomness that naturally occurs during self-assembly to create non-replicable patterns that can act like human fingerprints.” He added, “These ideas will be the cornerstone of technology that applies the many randomities that exist in nature to security systems.”

The two studies were published in the journal Advanced Materials under the titles “1Planar Spin Glass with Topologically-Protected Mazes in the Liquid Crystal Targeting for Reconfigurable Micro Security Media” and “2Paintable Physical Unclonable Function Using DNA” on May 6 and 5, respectively.

Author Information: 1Geonhyeong Park, Yun-Seok Choi, S. Joon Kwon*, and Dong Ki Yoon*/ 2Soon Mo Park†, Geonhyeong Park†, Dong Ki Yoon*: †co-first authors, *corresponding author

This research was funded by the Center for Multiscale Chiral Architectures and supported by the Ministry of Science and ICT-Korea Research Foundation, BRIDGE Convergent Research and Development Program, the Running Together Project, and the Samsung Future Technology Development Program.

< Figure 1-1. A scene from the schematic animation of the process of Blues (0) and Reds (1) forming the PUF by exploring the maze. From "Planar Spin Glass with Topologically-Protected Mazes in the Liquid Crystal Targeting for Reconfigurable Micro Security Media" by Geonhyeong Park, Yun-Seok Choi, S. Joon Kwon, Dong Ki Yoon. https://doi.org/10.1002/adma.202303077 >

< Figure 2-1. A schematic diagram of the formation of digital fingerprints formed using the DNA ink. From "Paintable Physical Unclonable Function Using DNA" by Soon Mo Park, Geonhyeong Park, Dong Ki Yoon. https://doi.org/10.1002/adma.202302135 >

2023.06.08 View 8795 -

Professor Byong-Guk Park Named Scientist of October

< Professor Byong-Guk Park >

Professor Byong-Guk Park from the Department of Materials Science and Engineering was selected as the ‘Scientist of the Month’ for October 2019 by the Ministry of Science and ICT and the National Research Foundation of Korea. Professor Park was recognized for his contributions to the advancement of spin-orbit torque (SOT)-based magnetic random access memory (MRAM) technology. He received 10 million KRW in prize money.

A next-generation, non-volatile memory device MRAM consists of thin magnetic films. It can be applied in “logic-in-memory” devices, in which logic and memory functionalities coexist, thus drastically improving the performance of complementary metal-oxide semiconductor (CMOS) processors. Conventional MRAM technology is limited in its ability to increase the operation speed of a memory device while maintaining a high density.

Professor Park tackled this challenge by introducing a new material, antiferromagnet (IrMn), that generates a sizable amount of SOT as well as an exchange-bias field, which makes successful data writing possible without an external magnetic field. This research outcome paved the way for the development of MRAM, which has a simple device structure but features high speeds and density.

Professor Park said, “I feel rewarded to have forwarded the feasibility and applicability of MRAM. I will continue devoting myself to studying further on the development of new materials that can help enhance the performance of memory devices."

(END)

2019.10.10 View 11793

Professor Byong-Guk Park Named Scientist of October

< Professor Byong-Guk Park >

Professor Byong-Guk Park from the Department of Materials Science and Engineering was selected as the ‘Scientist of the Month’ for October 2019 by the Ministry of Science and ICT and the National Research Foundation of Korea. Professor Park was recognized for his contributions to the advancement of spin-orbit torque (SOT)-based magnetic random access memory (MRAM) technology. He received 10 million KRW in prize money.

A next-generation, non-volatile memory device MRAM consists of thin magnetic films. It can be applied in “logic-in-memory” devices, in which logic and memory functionalities coexist, thus drastically improving the performance of complementary metal-oxide semiconductor (CMOS) processors. Conventional MRAM technology is limited in its ability to increase the operation speed of a memory device while maintaining a high density.

Professor Park tackled this challenge by introducing a new material, antiferromagnet (IrMn), that generates a sizable amount of SOT as well as an exchange-bias field, which makes successful data writing possible without an external magnetic field. This research outcome paved the way for the development of MRAM, which has a simple device structure but features high speeds and density.

Professor Park said, “I feel rewarded to have forwarded the feasibility and applicability of MRAM. I will continue devoting myself to studying further on the development of new materials that can help enhance the performance of memory devices."

(END)

2019.10.10 View 11793 -

A Technology Holding Company Establishes Two Companies Based on Technologies Developed at KAIST

Mirae Holdings is a technology holding company created by four science and technology universities, KAIST, DIGIST (Daegu Gyeongbuk Institute of Science and Technology), GIST (Gwangju Institute of Science and Technology), and UNIST (Ulsan National Institute of Science and Technology) in 2014 to commercialize the universities’ research achievements. The company identifies promising technologies for commercialization, makes business plans, establishes venture capitals, and invests in startup companies.

Over the past year, Mirae Holdings has established two venture companies based on the technologies developed at KAIST. In September 2014, it founded Cresem Inc., a company used the anisotropic conductive film (ACF) bonding technology, which was developed by Professor Kyung-Wook Paik of the Material Science and Engineering Department at KAIST. Cresem provides a technology to bond electronic parts ultrasonically. The company is expected to have 860,000 USD worth of sales within the first year of its launching.

Last June, Mirae Holdings created another company, Doctor Kitchen, with the technology developed by Professor Gwan-Su Yi of the Bio and Brain Engineering Department at KAIST. Doctor Kitchen supplies precooked food, which helps diabetic patients regulate their diet. The company offers a personalized diet plan to customers so that they can effectively manage their disease and monitor their blood sugar level efficiently.

The Chief Executive Officer of Mirae Holdings, Young-Ho Kim, said, “We can assist KAIST researchers who aspire to create a company based on their research outcomes through various stages of startup services such as making business plans, securing venture capitals, and networking with existing businesses.”

Young-Ho Kim (left in the picture), the Chief Executive Officer of Mirae Holdings, holds a certificate of company registration with Sang-Min Oh (right in the picture), the Chief Executive Officer of Cresem.

Young-Ho Kim (left in the picture), the Chief Executive Officer of Mirae Holdings, holds a certificate of company registration with Jae-Yeun Park (right in the picture), the Chief Executive Officer of Dr. Kitchen.

2015.07.29 View 14725

A Technology Holding Company Establishes Two Companies Based on Technologies Developed at KAIST

Mirae Holdings is a technology holding company created by four science and technology universities, KAIST, DIGIST (Daegu Gyeongbuk Institute of Science and Technology), GIST (Gwangju Institute of Science and Technology), and UNIST (Ulsan National Institute of Science and Technology) in 2014 to commercialize the universities’ research achievements. The company identifies promising technologies for commercialization, makes business plans, establishes venture capitals, and invests in startup companies.

Over the past year, Mirae Holdings has established two venture companies based on the technologies developed at KAIST. In September 2014, it founded Cresem Inc., a company used the anisotropic conductive film (ACF) bonding technology, which was developed by Professor Kyung-Wook Paik of the Material Science and Engineering Department at KAIST. Cresem provides a technology to bond electronic parts ultrasonically. The company is expected to have 860,000 USD worth of sales within the first year of its launching.

Last June, Mirae Holdings created another company, Doctor Kitchen, with the technology developed by Professor Gwan-Su Yi of the Bio and Brain Engineering Department at KAIST. Doctor Kitchen supplies precooked food, which helps diabetic patients regulate their diet. The company offers a personalized diet plan to customers so that they can effectively manage their disease and monitor their blood sugar level efficiently.

The Chief Executive Officer of Mirae Holdings, Young-Ho Kim, said, “We can assist KAIST researchers who aspire to create a company based on their research outcomes through various stages of startup services such as making business plans, securing venture capitals, and networking with existing businesses.”

Young-Ho Kim (left in the picture), the Chief Executive Officer of Mirae Holdings, holds a certificate of company registration with Sang-Min Oh (right in the picture), the Chief Executive Officer of Cresem.

Young-Ho Kim (left in the picture), the Chief Executive Officer of Mirae Holdings, holds a certificate of company registration with Jae-Yeun Park (right in the picture), the Chief Executive Officer of Dr. Kitchen.

2015.07.29 View 14725 -

KAIST Research Team Unveils Method to Fabricate Photonic Janus Balls

A research team led by Prof. Seung-Man Yang of the Department of Chemical and Biomolecular Engineering has found a method to fabricate photonic Janus balls with isotropic structural colors.

The finding draws attention since the newly-fabricated photonic balls may prove useful pigments for the realization of e-paper or flexible electronic displays.

The breakthrough was published in the Nov. 3 edition of the science journal "Advanced Materials." The Nov. 6 issue of "Nature" also featured it as one of the research highlights under the title of "Future Pixels."

Prof. Yang"s research team found that tiny marbles, black on one side and colored on the other, can be made by "curing" suspensions of silica particles with an ultraviolet lamp. When an electric field is applied, the marbles line up so that the black sides all face upwards, which suggests they may prove useful pigments for flexible electronic displays.

The researchers suspended a flow of carbon-black particles mixed with silica and a transparent or colored silica flow in a resin that polymerizes under ultraviolet light. They then passed the mixture through a tiny see-through tube. The light solidified the silica and resin as balls with differently colored regions, each about 200 micrometers in diameter.

Over the last decades, the development of industrial platforms to artificially fabricate structural color pigments has been a pressing issue in the research areas of materials science and optics. Prof. Yang, who is also the director of the National Creative Research Initiative Center for Integrated Optofluidic Systems, has led the researches focused on fabrication of functional nano-materials through the process of assembling nano-building blocks into designed patterns.

The "complementary hybridization of optical and fluidic devices for integrated optofluidic systems" research was supported by a grant from the Creative Research Initiative Program of the Ministry of Education, Science & Technology.

2008.11.12 View 16840

KAIST Research Team Unveils Method to Fabricate Photonic Janus Balls

A research team led by Prof. Seung-Man Yang of the Department of Chemical and Biomolecular Engineering has found a method to fabricate photonic Janus balls with isotropic structural colors.

The finding draws attention since the newly-fabricated photonic balls may prove useful pigments for the realization of e-paper or flexible electronic displays.

The breakthrough was published in the Nov. 3 edition of the science journal "Advanced Materials." The Nov. 6 issue of "Nature" also featured it as one of the research highlights under the title of "Future Pixels."

Prof. Yang"s research team found that tiny marbles, black on one side and colored on the other, can be made by "curing" suspensions of silica particles with an ultraviolet lamp. When an electric field is applied, the marbles line up so that the black sides all face upwards, which suggests they may prove useful pigments for flexible electronic displays.

The researchers suspended a flow of carbon-black particles mixed with silica and a transparent or colored silica flow in a resin that polymerizes under ultraviolet light. They then passed the mixture through a tiny see-through tube. The light solidified the silica and resin as balls with differently colored regions, each about 200 micrometers in diameter.

Over the last decades, the development of industrial platforms to artificially fabricate structural color pigments has been a pressing issue in the research areas of materials science and optics. Prof. Yang, who is also the director of the National Creative Research Initiative Center for Integrated Optofluidic Systems, has led the researches focused on fabrication of functional nano-materials through the process of assembling nano-building blocks into designed patterns.

The "complementary hybridization of optical and fluidic devices for integrated optofluidic systems" research was supported by a grant from the Creative Research Initiative Program of the Ministry of Education, Science & Technology.

2008.11.12 View 16840 -

Ki-Won Lee Receives Best Student Paper Award

Ki-Won Lee Receives Best Student Paper Award

Ki-Won Lee, a doctoral student of Materials Science & Engineering, has received the Best Student Paper Award ‘Motorola Fellowship Award’ at 2007 Electronic Components and Technology Conference (ECTC).

Lee’s paper is about a new bonding process of anisotropic conductive film using ultrasonic wave, which applies ultrasonic wave, instead of thermal compression, at the room temperature to reduce the process time from ten to three seconds.

The recipients of Motorola Fellowship Award are selected by IEEE Components, Packaging and Manufacturing Technology Society, and Motorola awards special scholarship to recipients. The ECTC is the world’s largest yearly conference concerning electronic packaging technologies with more than 1,000 attendees and more than 300 presented papers.

2007.07.02 View 20029

Ki-Won Lee Receives Best Student Paper Award

Ki-Won Lee Receives Best Student Paper Award

Ki-Won Lee, a doctoral student of Materials Science & Engineering, has received the Best Student Paper Award ‘Motorola Fellowship Award’ at 2007 Electronic Components and Technology Conference (ECTC).

Lee’s paper is about a new bonding process of anisotropic conductive film using ultrasonic wave, which applies ultrasonic wave, instead of thermal compression, at the room temperature to reduce the process time from ten to three seconds.

The recipients of Motorola Fellowship Award are selected by IEEE Components, Packaging and Manufacturing Technology Society, and Motorola awards special scholarship to recipients. The ECTC is the world’s largest yearly conference concerning electronic packaging technologies with more than 1,000 attendees and more than 300 presented papers.

2007.07.02 View 20029 -

Professor Yang Receives Academic Award

By Ki-beom Lee / Reporter

The KAIST Herald December 3, 2003

The Professor Dong-yol Yang of the Department of Mechanical Engineering received the Sang-woo Academic Award last month. Unlike other awards of similar nature, this award is given to one of many leading scientists who has written six to seven papers in the previous year. This award is special in that Professor Yang retired as chairman of the Korean Society for Technology of Plasticity in December 2002. Professor Yang received a prize on the research of the anisotropic pressing out process. He has also written papers based on the twenty-five years of research at Korea Advanced Institute of Science and Technology and has researched high-speed modeling for the first time in Korea.

2004.03.15 View 20575

Professor Yang Receives Academic Award

By Ki-beom Lee / Reporter

The KAIST Herald December 3, 2003

The Professor Dong-yol Yang of the Department of Mechanical Engineering received the Sang-woo Academic Award last month. Unlike other awards of similar nature, this award is given to one of many leading scientists who has written six to seven papers in the previous year. This award is special in that Professor Yang retired as chairman of the Korean Society for Technology of Plasticity in December 2002. Professor Yang received a prize on the research of the anisotropic pressing out process. He has also written papers based on the twenty-five years of research at Korea Advanced Institute of Science and Technology and has researched high-speed modeling for the first time in Korea.

2004.03.15 View 20575