Modu

-

A KAIST Team Develops Face-Conforming LED Mask Showing 340% Improved Efficacy in Deep Skin Elasticity

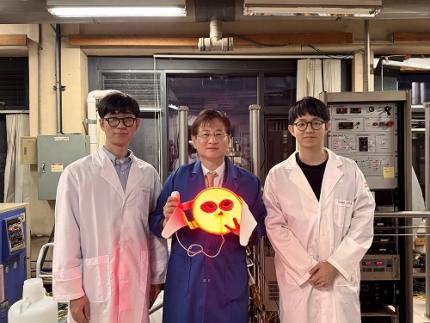

- A KAIST research team led by Professor Keon Jae Lee has developed a deep skin-stimulating LED mask which has been verified in clinical trials to improve dermis elasticity by 340%.

< Figure 1. Overall concept of face-fit surface-lighting micro-LEDs (FSLED) mask. a. Optical image of the FSLED mask showing uniform surface-lighting. schematic illustration of the FSLED mask. The 2D to 3D transformation procedure b. Difference in cosmetic effect on deep skin elasticity, wrinkles, and sagging between FSLED mask and CLED mask. (improvement percentage in eight weeks) >

Conventional LED masks, with their rigid design, fail to conform closely to the skin's contours. This limitation causes substantial light reflection, with up to 90% reflected over a distance of 2 cm, reducing light penetration and limiting stimulation of the deep skin layers essential for effective skin rejuvenation.

To address these challenges, Professor Lee's team developed a face-conforming surface lighting micro-LED (FSLED) mask, which can provide uniform photostimulation to the dermis. The key technology lies in the mask's ability to deliver uniform light to deep skin tissues while maintaining a conformal skin attachment. This is achieved through a 3D origami structure, integrated with 3,770 micro-LEDs and flexible surface light-diffusion layer, minimizing the gaps between the light source and the skin.

In clinical trials involving 33 participants, the FSLED mask demonstrated a 340% improvement in deep skin elasticity compared to conventional LED masks, proving its efficacy in significantly reducing skin wrinkles, sagging and aging.

Professor Keon Jae Lee said, “The FSLED mask provides cosmetic benefits to the entire facial dermis without the side effects of low-temperature burns, making home-care anti-aging treatment that enhances the quality of human life possible. The product is being manufactured by Fronics, KAIST startup company, and will be distributed globally through Amorepacific's network, with sales starting in November.”

This result titled “Clinical Validation of Face-fit Surface-lighting Micro Light-emitting Diode Mask for Skin Anti-aging Treatment”, in which Min Seo Kim, a student of the Master-Doctorate integrated program, and Jaehun An, a Ph.D. candidate, in the Department of Materials Science and Engineering of KAIST, took part as co-first authors, was published in Advanced Materials on October 22nd, 2024 (DOI: 10.1002/adma.202411651).

Introductory Video: Face-conforming surface LED mask for skin anti-aging ( https://www.youtube.com/watch?v=kSccLwx8N_w )

2024.10.29 View 7554

A KAIST Team Develops Face-Conforming LED Mask Showing 340% Improved Efficacy in Deep Skin Elasticity

- A KAIST research team led by Professor Keon Jae Lee has developed a deep skin-stimulating LED mask which has been verified in clinical trials to improve dermis elasticity by 340%.

< Figure 1. Overall concept of face-fit surface-lighting micro-LEDs (FSLED) mask. a. Optical image of the FSLED mask showing uniform surface-lighting. schematic illustration of the FSLED mask. The 2D to 3D transformation procedure b. Difference in cosmetic effect on deep skin elasticity, wrinkles, and sagging between FSLED mask and CLED mask. (improvement percentage in eight weeks) >

Conventional LED masks, with their rigid design, fail to conform closely to the skin's contours. This limitation causes substantial light reflection, with up to 90% reflected over a distance of 2 cm, reducing light penetration and limiting stimulation of the deep skin layers essential for effective skin rejuvenation.

To address these challenges, Professor Lee's team developed a face-conforming surface lighting micro-LED (FSLED) mask, which can provide uniform photostimulation to the dermis. The key technology lies in the mask's ability to deliver uniform light to deep skin tissues while maintaining a conformal skin attachment. This is achieved through a 3D origami structure, integrated with 3,770 micro-LEDs and flexible surface light-diffusion layer, minimizing the gaps between the light source and the skin.

In clinical trials involving 33 participants, the FSLED mask demonstrated a 340% improvement in deep skin elasticity compared to conventional LED masks, proving its efficacy in significantly reducing skin wrinkles, sagging and aging.

Professor Keon Jae Lee said, “The FSLED mask provides cosmetic benefits to the entire facial dermis without the side effects of low-temperature burns, making home-care anti-aging treatment that enhances the quality of human life possible. The product is being manufactured by Fronics, KAIST startup company, and will be distributed globally through Amorepacific's network, with sales starting in November.”

This result titled “Clinical Validation of Face-fit Surface-lighting Micro Light-emitting Diode Mask for Skin Anti-aging Treatment”, in which Min Seo Kim, a student of the Master-Doctorate integrated program, and Jaehun An, a Ph.D. candidate, in the Department of Materials Science and Engineering of KAIST, took part as co-first authors, was published in Advanced Materials on October 22nd, 2024 (DOI: 10.1002/adma.202411651).

Introductory Video: Face-conforming surface LED mask for skin anti-aging ( https://www.youtube.com/watch?v=kSccLwx8N_w )

2024.10.29 View 7554 -

A KAIST research team develops a high-performance modular SSD system semiconductor

In recent years, there has been a rise in demand for large amounts of data to train AI models and, thus, data size has become increasingly important over time. Accordingly, solid state drives (SSDs, storage devices that use a semiconductor memory unit), which are core storage devices for data centers and cloud services, have also seen an increase in demand. However, the internal components of higher performing SSDs have become more tightly coupled, and this tightly-coupled structure limits SSD from maximized performance.

On June 15, a KAIST research team led by Professor Dongjun Kim (John Kim) from the School of Electrical Engineering (EE) announced the development of the first SSD system semiconductor structure that can increase the reading/writing performance of next generation SSDs and extend their lifespan through high-performance modular SSD systems.

Professor Kim’s team identified the limitations of the tightly-coupled structures in existing SSD designs and proposed a de-coupled structure that can maximize SSD performance by configuring an internal on-chip network specialized for flash memory. This technique utilizes on-chip network technology, which can freely send packet-based data within the chip and is often used to design non-memory system semiconductors like CPUs and GPUs. Through this, the team developed a ‘modular SSD’, which shows reduced interdependence between front-end and back-end designs, and allows their independent design and assembly.

*on-chip network: a packet-based connection structure for the internal components of system semiconductors like CPUs/GPUs. On-chip networks are one of the most critical design components for high-performing system semiconductors, and their importance grows with the size of the semiconductor chip.

Professor Kim’s team refers to the components nearer to the CPU as the front-end and the parts closer to the flash memory as back-end. They newly constructed an on-chip network specific to flash memory in order to allow data transmission between the back-end’s flash controller, proposing a de-coupled structure that can minimize performance drop.

The SSD can accelerate some functions of the flash translation layer, a critical element to drive the SSD, in order to allow flash memory to actively overcome its limitations. Another advantage of the de-coupled, modular structure is that the flash translation layer is not limited to the characteristics of specific flash memories. Instead, their front-end and back-end designs can be carried out independently. Through this, the team could produce 21-times faster response times compared to existing systems and extend SSD lifespan by 23% by also applying the DDS defect detection technique.

< Figure 1. Schematic diagram of the structure of a high-performance modular SSD system developed by Professor Dong-Jun Kim's team >

This research, conducted by first author and Ph.D. candidate Jiho Kim from the KAIST School of EE and co-author Professor Myoungsoo Jung, was presented on the 19th of June at the 50th IEEE/ACM International Symposium on Computer Architecture, the most prestigious academic conference in the field of computer architecture, held in Orlando, Florida. (Paper Title: Decoupled SSD: Rethinking SSD Architecture through Network-based Flash Controllers)

< Figure 2. Conceptual diagram of hardware acceleration through high-performance modular SSD system >

Professor Dongjun Kim, who led the research, said, “This research is significant in that it identified the structural limitations of existing SSDs, and showed that on-chip network technology based on system memory semiconductors like CPUs can drive the hardware to actively carry out the necessary actions. We expect this to contribute greatly to the next-generation high-performance SSD market.” He added, “The de-coupled architecture is a structure that can actively operate to extend devices’ lifespan. In other words, its significance is not limited to the level of performance and can, therefore, be used for various applications.”

KAIST commented that this research is also meaningful in that the results were reaped through a collaborative study between two world-renowned researchers: Professor Myeongsoo Jung, recognized in the field of computer system storage devices, and Professor Dongjun Kim, a leading researcher in computer architecture and interconnection networks.

This research was funded by the National Research Foundation of Korea, Samsung Electronics, the IC Design Education Center, and Next Generation Semiconductor Technology and Development granted by the Institute of Information & Communications Technology, Planning & Evaluation.

2023.06.23 View 8239

A KAIST research team develops a high-performance modular SSD system semiconductor

In recent years, there has been a rise in demand for large amounts of data to train AI models and, thus, data size has become increasingly important over time. Accordingly, solid state drives (SSDs, storage devices that use a semiconductor memory unit), which are core storage devices for data centers and cloud services, have also seen an increase in demand. However, the internal components of higher performing SSDs have become more tightly coupled, and this tightly-coupled structure limits SSD from maximized performance.

On June 15, a KAIST research team led by Professor Dongjun Kim (John Kim) from the School of Electrical Engineering (EE) announced the development of the first SSD system semiconductor structure that can increase the reading/writing performance of next generation SSDs and extend their lifespan through high-performance modular SSD systems.

Professor Kim’s team identified the limitations of the tightly-coupled structures in existing SSD designs and proposed a de-coupled structure that can maximize SSD performance by configuring an internal on-chip network specialized for flash memory. This technique utilizes on-chip network technology, which can freely send packet-based data within the chip and is often used to design non-memory system semiconductors like CPUs and GPUs. Through this, the team developed a ‘modular SSD’, which shows reduced interdependence between front-end and back-end designs, and allows their independent design and assembly.

*on-chip network: a packet-based connection structure for the internal components of system semiconductors like CPUs/GPUs. On-chip networks are one of the most critical design components for high-performing system semiconductors, and their importance grows with the size of the semiconductor chip.

Professor Kim’s team refers to the components nearer to the CPU as the front-end and the parts closer to the flash memory as back-end. They newly constructed an on-chip network specific to flash memory in order to allow data transmission between the back-end’s flash controller, proposing a de-coupled structure that can minimize performance drop.

The SSD can accelerate some functions of the flash translation layer, a critical element to drive the SSD, in order to allow flash memory to actively overcome its limitations. Another advantage of the de-coupled, modular structure is that the flash translation layer is not limited to the characteristics of specific flash memories. Instead, their front-end and back-end designs can be carried out independently. Through this, the team could produce 21-times faster response times compared to existing systems and extend SSD lifespan by 23% by also applying the DDS defect detection technique.

< Figure 1. Schematic diagram of the structure of a high-performance modular SSD system developed by Professor Dong-Jun Kim's team >

This research, conducted by first author and Ph.D. candidate Jiho Kim from the KAIST School of EE and co-author Professor Myoungsoo Jung, was presented on the 19th of June at the 50th IEEE/ACM International Symposium on Computer Architecture, the most prestigious academic conference in the field of computer architecture, held in Orlando, Florida. (Paper Title: Decoupled SSD: Rethinking SSD Architecture through Network-based Flash Controllers)

< Figure 2. Conceptual diagram of hardware acceleration through high-performance modular SSD system >

Professor Dongjun Kim, who led the research, said, “This research is significant in that it identified the structural limitations of existing SSDs, and showed that on-chip network technology based on system memory semiconductors like CPUs can drive the hardware to actively carry out the necessary actions. We expect this to contribute greatly to the next-generation high-performance SSD market.” He added, “The de-coupled architecture is a structure that can actively operate to extend devices’ lifespan. In other words, its significance is not limited to the level of performance and can, therefore, be used for various applications.”

KAIST commented that this research is also meaningful in that the results were reaped through a collaborative study between two world-renowned researchers: Professor Myeongsoo Jung, recognized in the field of computer system storage devices, and Professor Dongjun Kim, a leading researcher in computer architecture and interconnection networks.

This research was funded by the National Research Foundation of Korea, Samsung Electronics, the IC Design Education Center, and Next Generation Semiconductor Technology and Development granted by the Institute of Information & Communications Technology, Planning & Evaluation.

2023.06.23 View 8239 -

Energy-Efficient AI Hardware Technology Via a Brain-Inspired Stashing System

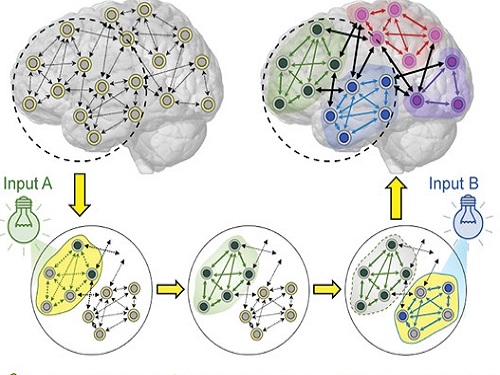

Researchers demonstrate neuromodulation-inspired stashing system for the energy-efficient learning of a spiking neural network using a self-rectifying memristor array

Researchers have proposed a novel system inspired by the neuromodulation of the brain, referred to as a ‘stashing system,’ that requires less energy consumption. The research group led by Professor Kyung Min Kim from the Department of Materials Science and Engineering has developed a technology that can efficiently handle mathematical operations for artificial intelligence by imitating the continuous changes in the topology of the neural network according to the situation. The human brain changes its neural topology in real time, learning to store or recall memories as needed. The research group presented a new artificial intelligence learning method that directly implements these neural coordination circuit configurations.

Research on artificial intelligence is becoming very active, and the development of artificial intelligence-based electronic devices and product releases are accelerating, especially in the Fourth Industrial Revolution age. To implement artificial intelligence in electronic devices, customized hardware development should also be supported. However most electronic devices for artificial intelligence require high power consumption and highly integrated memory arrays for large-scale tasks. It has been challenging to solve these power consumption and integration limitations, and efforts have been made to find out how the human brain solves problems.

To prove the efficiency of the developed technology, the research group created artificial neural network hardware equipped with a self-rectifying synaptic array and algorithm called a ‘stashing system’ that was developed to conduct artificial intelligence learning. As a result, it was able to reduce energy by 37% within the stashing system without any accuracy degradation. This result proves that emulating the neuromodulation in humans is possible.

Professor Kim said, "In this study, we implemented the learning method of the human brain with only a simple circuit composition and through this we were able to reduce the energy needed by nearly 40 percent.”

This neuromodulation-inspired stashing system that mimics the brain’s neural activity is compatible with existing electronic devices and commercialized semiconductor hardware. It is expected to be used in the design of next-generation semiconductor chips for artificial intelligence.

This study was published in Advanced Functional Materials in March 2022 and supported by KAIST, the National Research Foundation of Korea, the National NanoFab Center, and SK Hynix.

-Publication:

Woon Hyung Cheong, Jae Bum Jeon†, Jae Hyun In, Geunyoung Kim, Hanchan Song, Janho An, Juseong Park, Young Seok Kim, Cheol Seong Hwang, and Kyung Min Kim (2022)

“Demonstration of Neuromodulation-inspired Stashing System for Energy-efficient Learning of Spiking Neural Network using a Self-Rectifying Memristor Array,” Advanced FunctionalMaterials March 31, 2022 (DOI: 10.1002/adfm.202200337)

-Profile:

Professor Kyung Min Kimhttp://semi.kaist.ac.kr https://scholar.google.com/citations?user=BGw8yDYAAAAJ&hl=ko

Department of Materials Science and EngineeringKAIST

2022.05.18 View 12392

Energy-Efficient AI Hardware Technology Via a Brain-Inspired Stashing System

Researchers demonstrate neuromodulation-inspired stashing system for the energy-efficient learning of a spiking neural network using a self-rectifying memristor array

Researchers have proposed a novel system inspired by the neuromodulation of the brain, referred to as a ‘stashing system,’ that requires less energy consumption. The research group led by Professor Kyung Min Kim from the Department of Materials Science and Engineering has developed a technology that can efficiently handle mathematical operations for artificial intelligence by imitating the continuous changes in the topology of the neural network according to the situation. The human brain changes its neural topology in real time, learning to store or recall memories as needed. The research group presented a new artificial intelligence learning method that directly implements these neural coordination circuit configurations.

Research on artificial intelligence is becoming very active, and the development of artificial intelligence-based electronic devices and product releases are accelerating, especially in the Fourth Industrial Revolution age. To implement artificial intelligence in electronic devices, customized hardware development should also be supported. However most electronic devices for artificial intelligence require high power consumption and highly integrated memory arrays for large-scale tasks. It has been challenging to solve these power consumption and integration limitations, and efforts have been made to find out how the human brain solves problems.

To prove the efficiency of the developed technology, the research group created artificial neural network hardware equipped with a self-rectifying synaptic array and algorithm called a ‘stashing system’ that was developed to conduct artificial intelligence learning. As a result, it was able to reduce energy by 37% within the stashing system without any accuracy degradation. This result proves that emulating the neuromodulation in humans is possible.

Professor Kim said, "In this study, we implemented the learning method of the human brain with only a simple circuit composition and through this we were able to reduce the energy needed by nearly 40 percent.”

This neuromodulation-inspired stashing system that mimics the brain’s neural activity is compatible with existing electronic devices and commercialized semiconductor hardware. It is expected to be used in the design of next-generation semiconductor chips for artificial intelligence.

This study was published in Advanced Functional Materials in March 2022 and supported by KAIST, the National Research Foundation of Korea, the National NanoFab Center, and SK Hynix.

-Publication:

Woon Hyung Cheong, Jae Bum Jeon†, Jae Hyun In, Geunyoung Kim, Hanchan Song, Janho An, Juseong Park, Young Seok Kim, Cheol Seong Hwang, and Kyung Min Kim (2022)

“Demonstration of Neuromodulation-inspired Stashing System for Energy-efficient Learning of Spiking Neural Network using a Self-Rectifying Memristor Array,” Advanced FunctionalMaterials March 31, 2022 (DOI: 10.1002/adfm.202200337)

-Profile:

Professor Kyung Min Kimhttp://semi.kaist.ac.kr https://scholar.google.com/citations?user=BGw8yDYAAAAJ&hl=ko

Department of Materials Science and EngineeringKAIST

2022.05.18 View 12392 -

Professor Sang Su Lee’s Team Wins Seven iF Design Awards 2022

Professor Sang Su Lee from the Department of Industrial Design and his team’s five apps made in collaboration with NH Investment and Securities won iF Design Awards in the fields of UI, UX, service design, product design, and communication. These apps are now offered as NH Investment and Securities mobile applications.

The iF Design Awards recognize top quality creativity in product design, communication, packaging, service design and concepts, and architecture and interior design, as well as user experience (UX) and interface for digital media (UI).

In the field of UI, ‘Gretell’ is a mobile stock investment app service designed by Lee and his team to support investors struggling to learn about investing by archiving personalized information. Gretell provides investment information including news and reports. Users learn, evaluate, and leave comments. This shows both quantitative and qualitative indications, leading to rational decision-making. Other user’s comments are shared to reduce confirmation bias. Through this process, Gretell helps users who are impulsive or easily swayed by others’ opinions to grow as independent investors.

‘Bright’ is another app created by Lee’s team. It helps people exercise their rights as shareholders. As the need to exercise shareholders’ rights increases, many people are frustrated that investors with a small number of shares don’t have a lot of power. Bright provides a space for shareholders to share their opinions and brings people together so that individuals can be more proactive as shareholders. The Integrated Power of Attorney System (IPAS) expands the chances for shareholders to exercise their rights and allows users to submit proposals that can be communicated during the general meeting. Bright fosters influential shareholders, responsible companies, and a healthy society.

For communications, ‘Rewind’ is a stock information services app that visualizes past stock charts through sentiment analysis. Existing services focus on numbers, while Rewind takes a qualitative approach. Rewind analyzes public sentiment toward each event by collecting opinions on social media and then visualizes them chronologically along with the stock chart. Rewind allows users to review stock market movements and record their thoughts. Users can gain their own insights into current events in the stock market and make wiser investment decisions. The intuitive color gradient design provides a pleasant and simplified information experience.

In the area of interfaces for digital media and service design, ‘Groo’ is a green bond investing service app that helps users participate in green investment though investing in green bonds that support green projects for environmental improvement. Not restricted to trading bonds, Groo joins users in the holistic experience of green investing, from taking an interest in environmental issues to confirming the impact of the investment.

Next, ‘Modu’ is a story-based empathy expression training game for children with intellectual disabilities. Modu was developed to support emotion recognition and empathy behavior training in children with mild intellectual disabilities (MID) and borderline intellectual functioning (BIF).

Finally, the diving VR device for neutral buoyancy training, ‘Blow-yancy’, also made winner’s list. The device mimics scuba diving training without having to go into the water, therefore beginner divers are able getting feeling of diving while remaining perfectly safe and not harming any corals. It is expected that the device will be able to help protect at-risk underwater ecosystems.

2022.05.10 View 9877

Professor Sang Su Lee’s Team Wins Seven iF Design Awards 2022

Professor Sang Su Lee from the Department of Industrial Design and his team’s five apps made in collaboration with NH Investment and Securities won iF Design Awards in the fields of UI, UX, service design, product design, and communication. These apps are now offered as NH Investment and Securities mobile applications.

The iF Design Awards recognize top quality creativity in product design, communication, packaging, service design and concepts, and architecture and interior design, as well as user experience (UX) and interface for digital media (UI).

In the field of UI, ‘Gretell’ is a mobile stock investment app service designed by Lee and his team to support investors struggling to learn about investing by archiving personalized information. Gretell provides investment information including news and reports. Users learn, evaluate, and leave comments. This shows both quantitative and qualitative indications, leading to rational decision-making. Other user’s comments are shared to reduce confirmation bias. Through this process, Gretell helps users who are impulsive or easily swayed by others’ opinions to grow as independent investors.

‘Bright’ is another app created by Lee’s team. It helps people exercise their rights as shareholders. As the need to exercise shareholders’ rights increases, many people are frustrated that investors with a small number of shares don’t have a lot of power. Bright provides a space for shareholders to share their opinions and brings people together so that individuals can be more proactive as shareholders. The Integrated Power of Attorney System (IPAS) expands the chances for shareholders to exercise their rights and allows users to submit proposals that can be communicated during the general meeting. Bright fosters influential shareholders, responsible companies, and a healthy society.

For communications, ‘Rewind’ is a stock information services app that visualizes past stock charts through sentiment analysis. Existing services focus on numbers, while Rewind takes a qualitative approach. Rewind analyzes public sentiment toward each event by collecting opinions on social media and then visualizes them chronologically along with the stock chart. Rewind allows users to review stock market movements and record their thoughts. Users can gain their own insights into current events in the stock market and make wiser investment decisions. The intuitive color gradient design provides a pleasant and simplified information experience.

In the area of interfaces for digital media and service design, ‘Groo’ is a green bond investing service app that helps users participate in green investment though investing in green bonds that support green projects for environmental improvement. Not restricted to trading bonds, Groo joins users in the holistic experience of green investing, from taking an interest in environmental issues to confirming the impact of the investment.

Next, ‘Modu’ is a story-based empathy expression training game for children with intellectual disabilities. Modu was developed to support emotion recognition and empathy behavior training in children with mild intellectual disabilities (MID) and borderline intellectual functioning (BIF).

Finally, the diving VR device for neutral buoyancy training, ‘Blow-yancy’, also made winner’s list. The device mimics scuba diving training without having to go into the water, therefore beginner divers are able getting feeling of diving while remaining perfectly safe and not harming any corals. It is expected that the device will be able to help protect at-risk underwater ecosystems.

2022.05.10 View 9877 -

A Team of Three PhD Candidates Wins the Korea Semiconductor Design Contest

“We felt a sense of responsibility to help the nation advance its semiconductor design technology”

A CMOS (complementary metal-oxide semiconductor)-based “ultra-low noise signal chip” for 6G communications designed by three PhD candidates at the KAIST School of Electrical Engineering won the Presidential Award at the 22nd Korea Semiconductor Design Contest.

The winners are PhD candidates Sun-Eui Park, Yoon-Seo Cho, and Ju-Eun Bang from the Integrated Circuits and System Lab run by Professor Jaehyouk Choi. The contest, which is hosted by the Ministry of Trade, Industry and Energy and the Korea Semiconductors Industry Association, is one of the top national semiconductor design contests for college students.

Park said the team felt a sense of responsibility to help advance semiconductor design technology in Korea when deciding to participate the contest. The team expressed deep gratitude to Professor Choi for guiding their research on 6G communications.

“Our colleagues from other labs and seniors who already graduated helped us a great deal, so we owe them a lot,” explained Park. Cho added that their hard work finally got recognized and that acknowledgement pushes her to move forward with her research. Meanwhile, Bang said she is delighted to see that many people seem to be interested in her research topic.

Research for 6G is attempting to reach 1 tera bps (Tbps), 50 times faster than 5G communications with transmission speeds of up to 20 gigabytes. In general, the wider the communication frequency band, the higher the data transmission speed. Thus, the use of frequency bands above 100 gigahertz is essential for delivering high data transmission speeds for 6G communications.

However, it remains a big challenge to make a precise benchmark signal that can be used as a carrier wave in a high frequency band. Despite the advantages of CMOS’s ultra-small and low-power design, it still has limitations at high frequency bands and its operating frequency. Thus, it was difficult to achieve a frequency band above 100 gigahertz.

To overcome these challenges, the three students introduced ultra-low noise signal generation technology that can support high-order modulation technologies. This technology is expected to contribute to increasing the price competitiveness and density of 6G communication chips that will be used in the future.

5G just got started in 2020 and still has long way to go for full commercialization. Nevertheless, many researchers have started preparing for 6G technology, targeting 2030 since a new cellular communication appears in every other decade.

Professor Choi said, “Generating ultra-high frequency signals in bands above 100 GHz with highly accurate timing is one of the key technologies for implementing 6G communication hardware. Our research is significant for the development of the world’s first semiconductor chip that will use the CMOS process to achieve noise performance of less than 80fs in a frequency band above 100 GHz.”

The team members plan to work as circuit designers in Korean semiconductor companies after graduation. “We will continue to research the development of signal generators on the topic of award-winning 6G. We would like to continue our research on high-speed circuit designs such as ultra-fast analog-to-digital converters,” Park added.

2021.11.30 View 10476

A Team of Three PhD Candidates Wins the Korea Semiconductor Design Contest

“We felt a sense of responsibility to help the nation advance its semiconductor design technology”

A CMOS (complementary metal-oxide semiconductor)-based “ultra-low noise signal chip” for 6G communications designed by three PhD candidates at the KAIST School of Electrical Engineering won the Presidential Award at the 22nd Korea Semiconductor Design Contest.

The winners are PhD candidates Sun-Eui Park, Yoon-Seo Cho, and Ju-Eun Bang from the Integrated Circuits and System Lab run by Professor Jaehyouk Choi. The contest, which is hosted by the Ministry of Trade, Industry and Energy and the Korea Semiconductors Industry Association, is one of the top national semiconductor design contests for college students.

Park said the team felt a sense of responsibility to help advance semiconductor design technology in Korea when deciding to participate the contest. The team expressed deep gratitude to Professor Choi for guiding their research on 6G communications.

“Our colleagues from other labs and seniors who already graduated helped us a great deal, so we owe them a lot,” explained Park. Cho added that their hard work finally got recognized and that acknowledgement pushes her to move forward with her research. Meanwhile, Bang said she is delighted to see that many people seem to be interested in her research topic.

Research for 6G is attempting to reach 1 tera bps (Tbps), 50 times faster than 5G communications with transmission speeds of up to 20 gigabytes. In general, the wider the communication frequency band, the higher the data transmission speed. Thus, the use of frequency bands above 100 gigahertz is essential for delivering high data transmission speeds for 6G communications.

However, it remains a big challenge to make a precise benchmark signal that can be used as a carrier wave in a high frequency band. Despite the advantages of CMOS’s ultra-small and low-power design, it still has limitations at high frequency bands and its operating frequency. Thus, it was difficult to achieve a frequency band above 100 gigahertz.

To overcome these challenges, the three students introduced ultra-low noise signal generation technology that can support high-order modulation technologies. This technology is expected to contribute to increasing the price competitiveness and density of 6G communication chips that will be used in the future.

5G just got started in 2020 and still has long way to go for full commercialization. Nevertheless, many researchers have started preparing for 6G technology, targeting 2030 since a new cellular communication appears in every other decade.

Professor Choi said, “Generating ultra-high frequency signals in bands above 100 GHz with highly accurate timing is one of the key technologies for implementing 6G communication hardware. Our research is significant for the development of the world’s first semiconductor chip that will use the CMOS process to achieve noise performance of less than 80fs in a frequency band above 100 GHz.”

The team members plan to work as circuit designers in Korean semiconductor companies after graduation. “We will continue to research the development of signal generators on the topic of award-winning 6G. We would like to continue our research on high-speed circuit designs such as ultra-fast analog-to-digital converters,” Park added.

2021.11.30 View 10476 -

MCM Utilized at Residential Treatment Center in Gyeonggi

The Mobile Clinic Module (MCM) developed by the KAIST Action for Respiratory Epidemics was installed at special residential treatment center in Gyeonggi Province on September 13.

The MCM is an isolate negative pressure unit fitted with high-quality medical equipment, developed by Professor Taek-Jin Nam of the Department of Industrial Design under the KAIST New Deal R&D Initiative. This is also a part of the Korean Disease Control Package Development Project from last July.

In January, a ward with four beds for critical care was installed at the Korea Institute for Radiological & Medical Sciences in Seoul for a trial operation, and two mild cases were treated there. It was also implemented as an isolated negative pressure unit in the Daejeon Konyang University Hospital emergency room in June, and has treated 138 cases since.

The special residential treatment center installed in the Gyeonggi Provincial Academy gymnasium, which consists of 28 beds in 14 rooms (double occupancy) and a multipurpose room (for X-rays and treatment), is to remain open through October 10. Unlike existing treatment centers that have quarantined COVID-19 patients for two weeks, the Gyeonggi MCM will act as a self-treatment-associated short-term treatment center. While in self-treatment, patients showing symptoms requiring special attention will be moved to the MCM, followed by short-term hospitalization of 1-3 days for observation before further measures are taken.

Patients can be treated using the MCM’s own treatment capacities, including in-person and oxygen treatment, X-rays, and IVs. There are individual bathrooms in each room, and the pressure, ventilation, and the automatic opening and closing of the entrance can be centrally monitored and controlled. Patients showing symptoms during treatment will be moved to a specially designated hospital for critical care, and will return to the self-treatment center if no further abnormalities are reported.

The Gyeonggi Provincial Medical Center’s Ansung Hospital will take charge of operating the special treatment center. Each day, one or two doctors, three nurses, two nursing assistants, one administrative staff member, two or three disinfection specialists, and a medical imaging engineer will work in three shifts. There will also be about 20 additional specially designated staff members including KAIST researchers, firefighters, and police officers.

The MCM was internationally recognized as an excellent medical facility not only for its functionality, economic feasibility, and utility, but also for its unique design and aesthetics. It received two Best of Best awards at the Red Dot Award in product design and Communication Design in user interface.

By running this special treatment center, KAIST will conduct research on how to build an optimized model for efficient negative pressure medical units. This research is expected to lead to advances in waste water treatment systems, mobile bathrooms optimized for infectious cases, and MCM user interfaces for electronic devices, etc.

Professor Taek-Jin Nam, the general director of the project and design, said “if there is a gymnasium available, we can convert it into a special treatment center fitted with a waste water treatment system, and pressure equipment in two weeks even without additional infrastructure.”

The head of the KAIST New Deal R&D Initiative Choongsik Bae said, “our MCM research started in July of last year, and in just over a year, it has become a successful and innovative case that has undergone trials and become commercialized in a short period of time.” He added, “In response to COVID-19, KAIST is conducting research and empirical studies, not just in relation to the MCM, but in other areas of disease control as well.”

Based on the excellent disease control technologies developed by KAIST research teams, the KAIST Action for Respiratory Epidemics is conducting technology transfers and industrialization, and is developing a Korean disease control package model

2021.09.15 View 13038

MCM Utilized at Residential Treatment Center in Gyeonggi

The Mobile Clinic Module (MCM) developed by the KAIST Action for Respiratory Epidemics was installed at special residential treatment center in Gyeonggi Province on September 13.

The MCM is an isolate negative pressure unit fitted with high-quality medical equipment, developed by Professor Taek-Jin Nam of the Department of Industrial Design under the KAIST New Deal R&D Initiative. This is also a part of the Korean Disease Control Package Development Project from last July.

In January, a ward with four beds for critical care was installed at the Korea Institute for Radiological & Medical Sciences in Seoul for a trial operation, and two mild cases were treated there. It was also implemented as an isolated negative pressure unit in the Daejeon Konyang University Hospital emergency room in June, and has treated 138 cases since.

The special residential treatment center installed in the Gyeonggi Provincial Academy gymnasium, which consists of 28 beds in 14 rooms (double occupancy) and a multipurpose room (for X-rays and treatment), is to remain open through October 10. Unlike existing treatment centers that have quarantined COVID-19 patients for two weeks, the Gyeonggi MCM will act as a self-treatment-associated short-term treatment center. While in self-treatment, patients showing symptoms requiring special attention will be moved to the MCM, followed by short-term hospitalization of 1-3 days for observation before further measures are taken.

Patients can be treated using the MCM’s own treatment capacities, including in-person and oxygen treatment, X-rays, and IVs. There are individual bathrooms in each room, and the pressure, ventilation, and the automatic opening and closing of the entrance can be centrally monitored and controlled. Patients showing symptoms during treatment will be moved to a specially designated hospital for critical care, and will return to the self-treatment center if no further abnormalities are reported.

The Gyeonggi Provincial Medical Center’s Ansung Hospital will take charge of operating the special treatment center. Each day, one or two doctors, three nurses, two nursing assistants, one administrative staff member, two or three disinfection specialists, and a medical imaging engineer will work in three shifts. There will also be about 20 additional specially designated staff members including KAIST researchers, firefighters, and police officers.

The MCM was internationally recognized as an excellent medical facility not only for its functionality, economic feasibility, and utility, but also for its unique design and aesthetics. It received two Best of Best awards at the Red Dot Award in product design and Communication Design in user interface.

By running this special treatment center, KAIST will conduct research on how to build an optimized model for efficient negative pressure medical units. This research is expected to lead to advances in waste water treatment systems, mobile bathrooms optimized for infectious cases, and MCM user interfaces for electronic devices, etc.

Professor Taek-Jin Nam, the general director of the project and design, said “if there is a gymnasium available, we can convert it into a special treatment center fitted with a waste water treatment system, and pressure equipment in two weeks even without additional infrastructure.”

The head of the KAIST New Deal R&D Initiative Choongsik Bae said, “our MCM research started in July of last year, and in just over a year, it has become a successful and innovative case that has undergone trials and become commercialized in a short period of time.” He added, “In response to COVID-19, KAIST is conducting research and empirical studies, not just in relation to the MCM, but in other areas of disease control as well.”

Based on the excellent disease control technologies developed by KAIST research teams, the KAIST Action for Respiratory Epidemics is conducting technology transfers and industrialization, and is developing a Korean disease control package model

2021.09.15 View 13038 -

Repurposed Drugs Present New Strategy for Treating COVID-19

Virtual screening of 6,218 drugs and cell-based assays identifies best therapeutic medication candidates

A joint research group from KAIST and Institut Pasteur Korea has identified repurposed drugs for COVID-19 treatment through virtual screening and cell-based assays. The research team suggested the strategy for virtual screening with greatly reduced false positives by incorporating pre-docking filtering based on shape similarity and post-docking filtering based on interaction similarity. This strategy will help develop therapeutic medications for COVID-19 and other antiviral diseases more rapidly. This study was reported at the Proceedings of the National Academy of Sciences of the United States of America (PNAS).

Researchers screened 6,218 drugs from a collection of FDA-approved drugs or those under clinical trial and identified 38 potential repurposed drugs for COVID-19 with this strategy. Among them, seven compounds inhibited SARS-CoV-2 replication in Vero cells. Three of these drugs, emodin, omipalisib, and tipifarnib, showed anti-SARS-CoV-2 activity in human lung cells, Calu-3.

Drug repurposing is a practical strategy for developing antiviral drugs in a short period of time, especially during a global pandemic. In many instances, drug repurposing starts with the virtual screening of approved drugs. However, the actual hit rate of virtual screening is low and most of the predicted drug candidates are false positives.

The research group developed effective filtering algorithms before and after the docking simulations to improve the hit rates. In the pre-docking filtering process, compounds with similar shapes to the known active compounds for each target protein were selected and used for docking simulations. In the post-docking filtering process, the chemicals identified through their docking simulations were evaluated considering the docking energy and the similarity of the protein-ligand interactions with the known active compounds.

The experimental results showed that the virtual screening strategy reached a high hit rate of 18.4%, leading to the identification of seven potential drugs out of the 38 drugs initially selected.

“We plan to conduct further preclinical trials for optimizing drug concentrations as one of the three candidates didn’t resolve the toxicity issues in preclinical trials,” said Woo Dae Jang, one of the researchers from KAIST.

“The most important part of this research is that we developed a platform technology that can rapidly identify novel compounds for COVID-19 treatment. If we use this technology, we will be able to quickly respond to new infectious diseases as well as variants of the coronavirus,” said Distinguished Professor Sang Yup Lee.

This work was supported by the KAIST Mobile Clinic Module Project funded by the Ministry of Science and ICT (MSIT) and the National Research Foundation of Korea (NRF). The National Culture Collection for Pathogens in Korea provided the SARS-CoV-2 (NCCP43326).

-PublicationWoo Dae Jang, Sangeun Jeon, Seungtaek Kim, and Sang Yup Lee. Drugs repurposed for COVID-19 by virtual screening of 6,218 drugs and cell-based assay. Proc. Natl. Acad. Sci. U.S.A. (https://doi/org/10.1073/pnas.2024302118)

-ProfileDistinguished Professor Sang Yup LeeMetabolic &Biomolecular Engineering National Research Laboratoryhttp://mbel.kaist.ac.kr

Department of Chemical and Biomolecular EngineeringKAIST

2021.07.08 View 15845

Repurposed Drugs Present New Strategy for Treating COVID-19

Virtual screening of 6,218 drugs and cell-based assays identifies best therapeutic medication candidates

A joint research group from KAIST and Institut Pasteur Korea has identified repurposed drugs for COVID-19 treatment through virtual screening and cell-based assays. The research team suggested the strategy for virtual screening with greatly reduced false positives by incorporating pre-docking filtering based on shape similarity and post-docking filtering based on interaction similarity. This strategy will help develop therapeutic medications for COVID-19 and other antiviral diseases more rapidly. This study was reported at the Proceedings of the National Academy of Sciences of the United States of America (PNAS).

Researchers screened 6,218 drugs from a collection of FDA-approved drugs or those under clinical trial and identified 38 potential repurposed drugs for COVID-19 with this strategy. Among them, seven compounds inhibited SARS-CoV-2 replication in Vero cells. Three of these drugs, emodin, omipalisib, and tipifarnib, showed anti-SARS-CoV-2 activity in human lung cells, Calu-3.

Drug repurposing is a practical strategy for developing antiviral drugs in a short period of time, especially during a global pandemic. In many instances, drug repurposing starts with the virtual screening of approved drugs. However, the actual hit rate of virtual screening is low and most of the predicted drug candidates are false positives.

The research group developed effective filtering algorithms before and after the docking simulations to improve the hit rates. In the pre-docking filtering process, compounds with similar shapes to the known active compounds for each target protein were selected and used for docking simulations. In the post-docking filtering process, the chemicals identified through their docking simulations were evaluated considering the docking energy and the similarity of the protein-ligand interactions with the known active compounds.

The experimental results showed that the virtual screening strategy reached a high hit rate of 18.4%, leading to the identification of seven potential drugs out of the 38 drugs initially selected.

“We plan to conduct further preclinical trials for optimizing drug concentrations as one of the three candidates didn’t resolve the toxicity issues in preclinical trials,” said Woo Dae Jang, one of the researchers from KAIST.

“The most important part of this research is that we developed a platform technology that can rapidly identify novel compounds for COVID-19 treatment. If we use this technology, we will be able to quickly respond to new infectious diseases as well as variants of the coronavirus,” said Distinguished Professor Sang Yup Lee.

This work was supported by the KAIST Mobile Clinic Module Project funded by the Ministry of Science and ICT (MSIT) and the National Research Foundation of Korea (NRF). The National Culture Collection for Pathogens in Korea provided the SARS-CoV-2 (NCCP43326).

-PublicationWoo Dae Jang, Sangeun Jeon, Seungtaek Kim, and Sang Yup Lee. Drugs repurposed for COVID-19 by virtual screening of 6,218 drugs and cell-based assay. Proc. Natl. Acad. Sci. U.S.A. (https://doi/org/10.1073/pnas.2024302118)

-ProfileDistinguished Professor Sang Yup LeeMetabolic &Biomolecular Engineering National Research Laboratoryhttp://mbel.kaist.ac.kr

Department of Chemical and Biomolecular EngineeringKAIST

2021.07.08 View 15845 -

Wearable Device to Monitor Sweat in Real Time

An on-skin platform for the wireless monitoring of flow rate, cumulative loss, and temperature of sweat in real time

An electronic patch can monitor your sweating and check your health status. Even more, the soft microfluidic device that adheres to the surface of the skin, captures, stores, and performs biomarker analysis of sweat as it is released through the eccrine glands.

This wearable and wireless electronic device developed by Professor Kyeongha Kwon and her collaborators is a digital and wireless platform that could help track the so-called ‘filling process’ of sweat without having to visually examine the device. The platform was integrated with microfluidic systems to analyze the sweat’s components.

To monitor the sweat release rate in real time, the researchers created a ‘thermal flow sensing module.’ They designed a sophisticated microfluidic channel to allow the collected sweat to flow through a narrow passage and a heat source was placed on the outer surface of the channel to induce a heat exchange between the sweat and the heated channel.

As a result, the researchers could develop a wireless electronic patch that can measure the temperature difference in a specific location upstream and downstream of the heat source with an electronic circuit and convert it into a digital signal to measure the sweat release rate in real time. The patch accurately measured the perspiration rate in the range of 0-5 microliters/minute (μl/min), which was considered physiologically significant. The sensor can measure the flow of sweat directly and then use the information it collected to quantify total sweat loss. Moreover, the device features advanced microfluidic systems and colorimetric chemical reagents to gather pH measurements and determine the concentration of chloride, creatinine, and glucose in a user's sweat.

Professor Kwon said that these indicators could be used to diagnose various diseases related with sweating such as cystic fibrosis, diabetes, kidney dysfunction, and metabolic alkalosis. “As the sweat flowing in the microfluidic channel is completely separated from the electronic circuit, the new patch overcame the shortcomings of existing flow rate measuring devices, which were vulnerable to corrosion and aging,” she explained.

The patch can be easily attached to the skin with flexible circuit board printing technology and silicone sealing technology. It has an additional sensor that detects changes in skin temperature. Using a smartphone app, a user can check the data measured by the wearable patch in real time.

Professor Kwon added, “This patch can be widely used for personal hydration strategies, the detection of dehydration symptoms, and other health management purposes. It can also be used in a systematic drug delivery system, such as for measuring the blood flow rate in blood vessels near the skin’s surface or measuring a drug’s release rate in real time to calculate the exact dosage.”

-PublicationKyeongha Kwon, Jong Uk Kim, John A. Rogers, et al. “An on-skin platform for wireless monitoring of flow rate, cumulative loss and temperature of sweat in real time.” Nature Electronics (doi.org/10.1038/s41928-021-00556-2)

-ProfileProfessor Kyeongha KwonSchool of Electrical EngineeringKAIST

2021.06.25 View 12090

Wearable Device to Monitor Sweat in Real Time

An on-skin platform for the wireless monitoring of flow rate, cumulative loss, and temperature of sweat in real time

An electronic patch can monitor your sweating and check your health status. Even more, the soft microfluidic device that adheres to the surface of the skin, captures, stores, and performs biomarker analysis of sweat as it is released through the eccrine glands.

This wearable and wireless electronic device developed by Professor Kyeongha Kwon and her collaborators is a digital and wireless platform that could help track the so-called ‘filling process’ of sweat without having to visually examine the device. The platform was integrated with microfluidic systems to analyze the sweat’s components.

To monitor the sweat release rate in real time, the researchers created a ‘thermal flow sensing module.’ They designed a sophisticated microfluidic channel to allow the collected sweat to flow through a narrow passage and a heat source was placed on the outer surface of the channel to induce a heat exchange between the sweat and the heated channel.

As a result, the researchers could develop a wireless electronic patch that can measure the temperature difference in a specific location upstream and downstream of the heat source with an electronic circuit and convert it into a digital signal to measure the sweat release rate in real time. The patch accurately measured the perspiration rate in the range of 0-5 microliters/minute (μl/min), which was considered physiologically significant. The sensor can measure the flow of sweat directly and then use the information it collected to quantify total sweat loss. Moreover, the device features advanced microfluidic systems and colorimetric chemical reagents to gather pH measurements and determine the concentration of chloride, creatinine, and glucose in a user's sweat.

Professor Kwon said that these indicators could be used to diagnose various diseases related with sweating such as cystic fibrosis, diabetes, kidney dysfunction, and metabolic alkalosis. “As the sweat flowing in the microfluidic channel is completely separated from the electronic circuit, the new patch overcame the shortcomings of existing flow rate measuring devices, which were vulnerable to corrosion and aging,” she explained.

The patch can be easily attached to the skin with flexible circuit board printing technology and silicone sealing technology. It has an additional sensor that detects changes in skin temperature. Using a smartphone app, a user can check the data measured by the wearable patch in real time.

Professor Kwon added, “This patch can be widely used for personal hydration strategies, the detection of dehydration symptoms, and other health management purposes. It can also be used in a systematic drug delivery system, such as for measuring the blood flow rate in blood vessels near the skin’s surface or measuring a drug’s release rate in real time to calculate the exact dosage.”

-PublicationKyeongha Kwon, Jong Uk Kim, John A. Rogers, et al. “An on-skin platform for wireless monitoring of flow rate, cumulative loss and temperature of sweat in real time.” Nature Electronics (doi.org/10.1038/s41928-021-00556-2)

-ProfileProfessor Kyeongha KwonSchool of Electrical EngineeringKAIST

2021.06.25 View 12090 -

Research Day Highlights the Most Impactful Technologies of the Year

Technology Converting Full HD Image to 4-Times Higher UHD Via Deep Learning Cited as the Research of the Year

The technology converting a full HD image into a four-times higher UHD image in real time via AI deep learning was recognized as the Research of the Year. Professor Munchurl Kim from the School of Electrical Engineering who developed the technology won the Research of the Year Grand Prize during the 2021 KAIST Research Day ceremony on May 25. Professor Kim was lauded for conducting creative research on machine learning and deep learning-based image processing.

KAIST’s Research Day recognizes the most notable research outcomes of the year, while creating opportunities for researchers to immerse themselves into interdisciplinary research projects with their peers. The ceremony was broadcast online due to Covid-19 and announced the Ten R&D Achievement of the Year that are expected to make a significant impact.

To celebrate the award, Professor Kim gave a lecture on “Computational Imaging through Deep Learning for the Acquisition of High-Quality Images.” Focusing on the fact that advancements in artificial intelligence technology can show superior performance when used to convert low-quality videos to higher quality, he introduced some of the AI technologies that are currently being applied in the field of image restoration and quality improvement.

Professors Eui-Cheol Shin from the Graduate School of Medical Science and Engineering and In-Cheol Park from the School of Electrical Engineering each received Research Awards, and Professor Junyong Noh from the Graduate School of Culture Technology was selected for the Innovation Award. Professors Dong Ki Yoon from the Department of Chemistry and Hyungki Kim from the Department of Mechanical Engineering were awarded the Interdisciplinary Award as a team for their joint research.

Meanwhile, out of KAIST’s ten most notable R&D achievements, those from the field of natural and biological sciences included research on rare earth element-platinum nanoparticle catalysts by Professor Ryong Ryoo from the Department of Chemistry, real-time observations of the locational changes in all of the atoms in a molecule by Professor Hyotcherl Ihee from the Department of Chemistry, and an investigation on memory retention mechanisms after synapse removal from an astrocyte by Professor Won-Suk Chung from the Department of Biological Sciences.

Awardees from the engineering field were a wearable robot for paraplegics with the world’s best functionality and walking speed by Professor Kyoungchul Kong from the Department of Mechanical Engineering, fair machine learning by Professor Changho Suh from the School of Electrical Engineering, and a generative adversarial networks processing unit (GANPU), an AI semiconductor that can learn from even mobiles by processing multiple and deep networks by Professor Hoi-Jun Yoo from the School of Electrical Engineering.

Others selected as part of the ten research studies were the development of epigenetic reprogramming technology in tumour by Professor Pilnam Kim from the Department of Bio and Brain Engineering, the development of an original technology for reverse cell aging by Professor Kwang-Hyun Cho from the Department of Bio and Brain Engineering, a heterogeneous metal element catalyst for atmospheric purification by Professor Hyunjoo Lee from the Department of Chemical and Biomolecular Engineering, and the Mobile Clinic Module (MCM): a negative pressure ward for epidemic hospitals by Professor Taek-jin Nam (reported at the Wall Street Journal) from the Department of Industrial Design.

2021.05.31 View 16904

Research Day Highlights the Most Impactful Technologies of the Year

Technology Converting Full HD Image to 4-Times Higher UHD Via Deep Learning Cited as the Research of the Year

The technology converting a full HD image into a four-times higher UHD image in real time via AI deep learning was recognized as the Research of the Year. Professor Munchurl Kim from the School of Electrical Engineering who developed the technology won the Research of the Year Grand Prize during the 2021 KAIST Research Day ceremony on May 25. Professor Kim was lauded for conducting creative research on machine learning and deep learning-based image processing.

KAIST’s Research Day recognizes the most notable research outcomes of the year, while creating opportunities for researchers to immerse themselves into interdisciplinary research projects with their peers. The ceremony was broadcast online due to Covid-19 and announced the Ten R&D Achievement of the Year that are expected to make a significant impact.

To celebrate the award, Professor Kim gave a lecture on “Computational Imaging through Deep Learning for the Acquisition of High-Quality Images.” Focusing on the fact that advancements in artificial intelligence technology can show superior performance when used to convert low-quality videos to higher quality, he introduced some of the AI technologies that are currently being applied in the field of image restoration and quality improvement.

Professors Eui-Cheol Shin from the Graduate School of Medical Science and Engineering and In-Cheol Park from the School of Electrical Engineering each received Research Awards, and Professor Junyong Noh from the Graduate School of Culture Technology was selected for the Innovation Award. Professors Dong Ki Yoon from the Department of Chemistry and Hyungki Kim from the Department of Mechanical Engineering were awarded the Interdisciplinary Award as a team for their joint research.

Meanwhile, out of KAIST’s ten most notable R&D achievements, those from the field of natural and biological sciences included research on rare earth element-platinum nanoparticle catalysts by Professor Ryong Ryoo from the Department of Chemistry, real-time observations of the locational changes in all of the atoms in a molecule by Professor Hyotcherl Ihee from the Department of Chemistry, and an investigation on memory retention mechanisms after synapse removal from an astrocyte by Professor Won-Suk Chung from the Department of Biological Sciences.

Awardees from the engineering field were a wearable robot for paraplegics with the world’s best functionality and walking speed by Professor Kyoungchul Kong from the Department of Mechanical Engineering, fair machine learning by Professor Changho Suh from the School of Electrical Engineering, and a generative adversarial networks processing unit (GANPU), an AI semiconductor that can learn from even mobiles by processing multiple and deep networks by Professor Hoi-Jun Yoo from the School of Electrical Engineering.

Others selected as part of the ten research studies were the development of epigenetic reprogramming technology in tumour by Professor Pilnam Kim from the Department of Bio and Brain Engineering, the development of an original technology for reverse cell aging by Professor Kwang-Hyun Cho from the Department of Bio and Brain Engineering, a heterogeneous metal element catalyst for atmospheric purification by Professor Hyunjoo Lee from the Department of Chemical and Biomolecular Engineering, and the Mobile Clinic Module (MCM): a negative pressure ward for epidemic hospitals by Professor Taek-jin Nam (reported at the Wall Street Journal) from the Department of Industrial Design.

2021.05.31 View 16904 -

Mobile Clinic Module Wins Red Dot and iF Design Awards

The Mobile Clinic Module (MCM), an inflatable negative pressure ward building system developed by the Korea Aid for Respiratory Epidemic (KARE) initiative at KAIST, gained international acclaim by winning the prestigious Red Dot Design Award and iF Design Award.

The MCM was recognized as one of the Red Dot Product Designs of the Year. It also won four iF Design Awards in communication design, interior architecture, user interface, and user experience. Winning the two most influential design awards demonstrates how product design can make a valuable contribution to help contain pandemics and reflects new consumer trends for dealing with pandemics.

Designed to be patient friendly, even in the extreme medical situations such as pandemics or triage, the MCM is the result of collaborations among researchers in a variety of fields including mechanical engineering, computing, industrial and systems engineering, medical hospitals, and engineering companies. The research team was led by Professor Tek-Jin Nam from the Department of Industrial Design.

The MCM is expandable, moveable, and easy to store through a combination of negative pressure frames, air tents, and multi-functional panels. Positive air pressure devices supply fresh air from outside the tent. An air pump and controller maintain air beam pressure, while filtering exhausted air from inside. An internal air information monitoring system efficiently controls inside air pressure and purifies the air. It requires only one-fourth of the volume of existing wards and takes up approximately 40% of their weight. The unit can be transported in a 40-foot container truck.

MCMs are now located at the Korea Institute of Radiological & Medical Sciences and Jeju Vaccine Center and expect to be used at many other facilities. KARE is developing antiviral solutions and devices such as protective gear, sterilizers, and test kits to promptly respond to the pandemic. More than 100 researchers at KAIST are collaborating with industry and clinical hospitals to develop antiviral technologies that will improve preventive measures, diagnoses, and treatments.

Professor Nam said, “Our designers will continue to identify the most challenging issues, and try to resolve them by realizing user-friendly functions. We believe this will significantly contribute to relieving the drastic need for negative pressure beds and provide a place for monitoring patients with moderate symptoms. We look forward to the MCM upgrading epidemic management resources around the globe.”

(END)

2021.04.21 View 11119

Mobile Clinic Module Wins Red Dot and iF Design Awards

The Mobile Clinic Module (MCM), an inflatable negative pressure ward building system developed by the Korea Aid for Respiratory Epidemic (KARE) initiative at KAIST, gained international acclaim by winning the prestigious Red Dot Design Award and iF Design Award.

The MCM was recognized as one of the Red Dot Product Designs of the Year. It also won four iF Design Awards in communication design, interior architecture, user interface, and user experience. Winning the two most influential design awards demonstrates how product design can make a valuable contribution to help contain pandemics and reflects new consumer trends for dealing with pandemics.

Designed to be patient friendly, even in the extreme medical situations such as pandemics or triage, the MCM is the result of collaborations among researchers in a variety of fields including mechanical engineering, computing, industrial and systems engineering, medical hospitals, and engineering companies. The research team was led by Professor Tek-Jin Nam from the Department of Industrial Design.

The MCM is expandable, moveable, and easy to store through a combination of negative pressure frames, air tents, and multi-functional panels. Positive air pressure devices supply fresh air from outside the tent. An air pump and controller maintain air beam pressure, while filtering exhausted air from inside. An internal air information monitoring system efficiently controls inside air pressure and purifies the air. It requires only one-fourth of the volume of existing wards and takes up approximately 40% of their weight. The unit can be transported in a 40-foot container truck.

MCMs are now located at the Korea Institute of Radiological & Medical Sciences and Jeju Vaccine Center and expect to be used at many other facilities. KARE is developing antiviral solutions and devices such as protective gear, sterilizers, and test kits to promptly respond to the pandemic. More than 100 researchers at KAIST are collaborating with industry and clinical hospitals to develop antiviral technologies that will improve preventive measures, diagnoses, and treatments.

Professor Nam said, “Our designers will continue to identify the most challenging issues, and try to resolve them by realizing user-friendly functions. We believe this will significantly contribute to relieving the drastic need for negative pressure beds and provide a place for monitoring patients with moderate symptoms. We look forward to the MCM upgrading epidemic management resources around the globe.”

(END)

2021.04.21 View 11119 -

Ushering in a New Era at the 50th Innoversary Ceremony

President Moon Jae-In declares KAIST the future of Korea

KAIST reaffirmed its goal of becoming an institute that can serve the world for the next century, marking its 50th anniversary on February 16. The KAIST community and distinguished guests gathered online during the official ceremony to commemorate KAIST’s anniversary and envisioned ways to serve the world, a major shift from its founding mission focusing on national growth.

The ceremony celebrated the legacy of KAIST, which has become a trailblazer by fostering the most competent scientists and engineers and making breakthroughs which led to the nation becoming a global high-tech leader.

President Moon Jae-In applauded KAIST as “the future of Korea” in his online congratulatory message, saying that “KAIST has made us feel proud when the nation stays ahead in science and technology. The dream of KAIST has been the dream of Korea. The passion of KAIST has been the passion of Korea. KAIST is the future of Korea.”

“KAIST has overcome challenges and created innovations for advancing the nation, from the first internet network to launching our first satellite in the early 80s to the Mobile Clinic Module (MCM), a negative pressure ward module in response to COVID-19. Whenever the nation faced a challenge, KAIST was there.”

President Moon also asked KAIST researchers to find sustainable ways to balance nature and humanity in this time of climate change and the Fourth Industrial Revolution.

Executive Chairman of the World Economic Forum Dr.Klaus Schwab also congratulated, saying "KAIST is a leader in ensuring social inclusion. Founded with the support of USAID, today it is paying it forward and sharing the same support through the Kenya-KAIST project."

The ceremony first brought Dr. KunMo Chung to the stage, the man who proposed the idea of founding the first advanced science and technology institute in Korea. His proposal to the then administrator of USAID John Hannah resulted in the Korean government meriting a 6 million USD loan for to start KAIST. He was the only Korean member of the USAID feasibility study team led by Dr. Frederick Terman, the former vice president of Stanford University. Dr. Chung wrote the Terman Report, which gave a green light to the establishment of KAIST in Korea in 1970.

Dr. Chung said the nation’s strong desire to escape from poverty through the advancement of science and technology was thoroughly realized by KAIST. “The Terman Report’s vision was perfectly realized. Now it’s time to envision the next dream of KAIST for another century.”

President Sung-Chul Shin said in his anniversary speech that KAIST has now transformed into a university that will serve the all of humanity by advancing science and technology while fostering new talents best fit for the new global environment. President Shin said that to fulfill KAIST’s second dream, the university will drive innovation in the five major areas of education, research, technology commercialization, globalization, and future strategy, under the C3 spirit of a Challenging spirit, Creativity, and Caring minds.

“In the next 50 years, KAIST hopes to fulfill the 10-10-10 Dream, that is, to have 10 Singularity Professors who have produced world-class achievements, 10 Decacorn startups valued at 10 trillion won, and global campuses in 10 countries.”

Then, four young KAIST professors who are conducting research in the flagship fields of mobility, new materials, post-AI, and bio-medicine presented their research vision and gave speeches. Professor Hae-Won Park from the Department of Mechanical Engineering and Professor Jihyeon Yeom from the Department of Materials Science and Engineering said the advent of new mobility combined with robotics and new nano-materials scaled down into spintronics, ‘KAISTronic materials’, will provide new momentum for the industry and the wellbeing of humanity. Professor Kijung Shin from the Graduate School of AI spoke on the new future transformed by quantum computers. Professor Young Seok Ju from the Graduate School of Medical Science and Engineering predicted a future in which cancer will no longer be a terminal disease and digital cells and the digitization of bio-medicine will significantly improve our quality of life. He said the combination of anti-aging and reverse aging studies will make a difference in our lives.

After the official ceremony, KAIST’s administrative leadership including President Shin and Dr. Kun-Mo Chung attended a ceremony to dedicate the sky lounge at the Academic Cultural Complex as the John Hannah Hall. Terman Hall, located in the Creative Learning Building, was dedicated in 2004 in honor of Dr. Frederick Terman.

2021.02.17 View 13953

Ushering in a New Era at the 50th Innoversary Ceremony

President Moon Jae-In declares KAIST the future of Korea

KAIST reaffirmed its goal of becoming an institute that can serve the world for the next century, marking its 50th anniversary on February 16. The KAIST community and distinguished guests gathered online during the official ceremony to commemorate KAIST’s anniversary and envisioned ways to serve the world, a major shift from its founding mission focusing on national growth.

The ceremony celebrated the legacy of KAIST, which has become a trailblazer by fostering the most competent scientists and engineers and making breakthroughs which led to the nation becoming a global high-tech leader.

President Moon Jae-In applauded KAIST as “the future of Korea” in his online congratulatory message, saying that “KAIST has made us feel proud when the nation stays ahead in science and technology. The dream of KAIST has been the dream of Korea. The passion of KAIST has been the passion of Korea. KAIST is the future of Korea.”

“KAIST has overcome challenges and created innovations for advancing the nation, from the first internet network to launching our first satellite in the early 80s to the Mobile Clinic Module (MCM), a negative pressure ward module in response to COVID-19. Whenever the nation faced a challenge, KAIST was there.”

President Moon also asked KAIST researchers to find sustainable ways to balance nature and humanity in this time of climate change and the Fourth Industrial Revolution.

Executive Chairman of the World Economic Forum Dr.Klaus Schwab also congratulated, saying "KAIST is a leader in ensuring social inclusion. Founded with the support of USAID, today it is paying it forward and sharing the same support through the Kenya-KAIST project."

The ceremony first brought Dr. KunMo Chung to the stage, the man who proposed the idea of founding the first advanced science and technology institute in Korea. His proposal to the then administrator of USAID John Hannah resulted in the Korean government meriting a 6 million USD loan for to start KAIST. He was the only Korean member of the USAID feasibility study team led by Dr. Frederick Terman, the former vice president of Stanford University. Dr. Chung wrote the Terman Report, which gave a green light to the establishment of KAIST in Korea in 1970.

Dr. Chung said the nation’s strong desire to escape from poverty through the advancement of science and technology was thoroughly realized by KAIST. “The Terman Report’s vision was perfectly realized. Now it’s time to envision the next dream of KAIST for another century.”

President Sung-Chul Shin said in his anniversary speech that KAIST has now transformed into a university that will serve the all of humanity by advancing science and technology while fostering new talents best fit for the new global environment. President Shin said that to fulfill KAIST’s second dream, the university will drive innovation in the five major areas of education, research, technology commercialization, globalization, and future strategy, under the C3 spirit of a Challenging spirit, Creativity, and Caring minds.