research

Scientists at KAIST have developed a new way of making fuel cell membranes using nanoscale fasteners, paving the way for lower-cost, higher-efficiency and more easily manufactured fuel cells.

The internal workings of fuel cells vary, but basically all types mix hydrogen and oxygen to produce a chemical reaction that delivers usable electricity and exhausts ordinary water as a by-product. One of the most efficient types is the proton exchange membrane (PEM) fuel cell, which operates at low enough temperatures to be used in homes and vehicles.

To generate electricity, PEM fuel cells rely on two chemical compartments separated by a permeable catalyst membrane. This membrane acts as an electrolyte; a negative electrode is bonded to one side of the membrane and a positive electrode is bonded to the other. The electrolyte membrane is often based on a polymer of perfluorosulfonic acid. Due to its high cost, however, a less expensive hydrocarbon-based electrolyte membrane has attracted interest in this technology sector.

Until now, the challenge in adopting such a hydrocarbon membrane has been that the interface between the electrode and hydrocarbon membrane is weak. This causes the membrane to delaminate relatively easily, falling apart and losing efficiency with use.

Professor Hee-Tak Kim of the Department of Chemical and Biomolecular Engineering at the Korea Advanced Institute of Science and Technology (KAIST) and his research team have developed a new fastening system that bonds the two materials mechanically rather than chemically. This opens the way to the development of fuel cell membranes that are less expensive, easier to manufacture, stronger and more efficient.

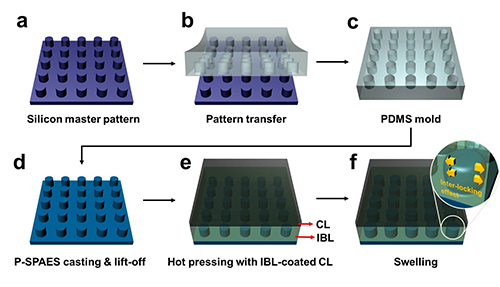

The researchers achieved this by moulding a pattern of tiny cylindrical pillars on the face of the hydrocarbon membrane. The pillars protrude into a softened skin of the electrode with heat. The mechanical bond sets and strengthens as the material cools and absorbs water. The pillar-patterned hydrocarbon membrane is cast using silicone moulds.

Professor Kim said, “This physically fastened bond is almost five times stronger and harder to separate than current bonds between the same layers.”

The new interlocking method also appears to offer a way to bond many types of hydrocarbon membranes that, until now, have been rejected because they couldn’t be fastened robustly. This would make hydrocarbon membranes practical for a number of applications beyond fuel cells such as rechargeable “redox flow” batteries.

The research team is now developing a stronger and more scalable interlocking interface for their nanoscale fasteners.

Picture: Schematic Diagram of the Fabrication of the Pillar P-SPAES Membrane and Its Working Principle of Interlocking Effects

-

research KAIST researcher Se Jin Park develops 'SpeechSSM,' opening up possibilities for a 24-hour AI voice assistant.

<(From Left)Prof. Yong Man Ro and Ph.D. candidate Sejin Park> Se Jin Park, a researcher from Professor Yong Man Ro’s team at KAIST, has announced 'SpeechSSM', a spoken language model capable of generating long-duration speech that sounds natural and remains consistent. An efficient processing technique based on linear sequence modeling overcomes the limitations of existing spoken language models, enabling high-quality speech generation without time constraints. It is expe

2025-07-04 -

event King Saud University and KAIST discussed Strategic AI Partnership

<From left> President Abdulla Al-Salman(King Saud University), President Kwang Hyung Lee(KAIST) KAIST (President Kwang Hyung Lee) and King Saud University (President Abdulla Al-Salman) held a meeting on July 3 at the KAIST Campus in Seoul and agreed to pursue strategic cooperation in AI and digital platform development. The global AI landscape is increasingly polarized between closed models developed by the U.S. and China’s nationally focused technology ecosystems. In this context

2025-07-04 -

research KAIST Uses AI to Discover Optimal New Material for Removing Radioactive Iodine Contamination

<(From the Right) Professor Ho Jin Ryu, Department of Nuclear and Quantum Engineering, Dr. Sujeong Lee, a graduate of the KAIST Department of Materials Science and Engineering, and Dr. Juhwan Noh of KRICT’s Digital Chemistry Research Center> Managing radioactive waste is one of the core challenges in the use of nuclear energy. In particular, radioactive iodine poses serious environmental and health risks due to its long half-life (15.7 million years in the case of I-129), hi

2025-07-03 -

research KAIST Enhances Immunotherapy for Difficult-to-Treat Brain Tumors with Gut Microbiota

< Photo 1.(From left) Prof. Heung Kyu Lee, Department of Biological Sciences, and Dr. Hyeon Cheol Kim> Advanced treatments, known as immunotherapies that activate T cells—our body's immune cells—to eliminate cancer cells, have shown limited efficacy as standalone therapies for glioblastoma, the most lethal form of brain tumor. This is due to their minimal response to glioblastoma and high resistance to treatment. Now, a KAIST research team has now demonstrated a new th

2025-07-02 -

event 2025 KAIST Global Entrepreneurship Summer School Concludes Successfully in Silicon Valley

< A group photo taken at the 2025 GESS Special Lecture.Vice President So Young Kim from the International Office, VC Jay Eum from GFT Ventures, Professor Byungchae Jin from the Impact MBA Program at the Business School, and Research Assistant Professor Sooa Lee from the Office of Global Initiative> The “2025 KAIST Global Entrepreneurship Summer School (2025 KAIST GESS),” organized by the Office of Global Initiative of the KAIST International Office (Vice President

2025-07-01