-

There Won't Be a Singularity: Professor Jerry Kaplan

(Professor Jerry Kaplan gave a lecture titled, Artificial Intelligence: Think Again at KAIST)

“People are so concerned about super intelligence, but the singularity will not happen,” said Professor Jerry Kaplan at Stanford University, an AI guru and Silicon Valley entrepreneur during a lecture at KAIST. He visited KAIST to give a lecture on Artificial Intelligence: Think Again on September 6.

Professor Kaplan said that some people argue that Korea’s AI research is behind the US and China but he doesn’t agree with that. “Korea is the most digitally connected one and has the world’s best engineers in the field. Korean companies are building products the consumers really like at reasonable prices. Those are attracting global consumers,” he added.

Instead of investing loads of money on AI research, he suggested three tasks for Korea taking a better position in the field of AI: Collecting and saving lots of data; training engineers, not the research talents in AI; and investing in AI infrastructure and relieving regulations by the government.

Referring to AI hype, Professor Kaplan argued that machines are intelligent, but they do not think in the way humans can, and assured the audience that the singularity some futurists predict will not be coming. He said, “Machine learning is a tool extracting useful information, but it does not mean they are so smart that they are taking over the world.”

(Professor Jerry Kaplan gave a lecture titled, Artificial Intelligence: Think Again at KAIST)

But what has made us believing AI myths? He first began pointing out how AI has been mythicized by three major drivers. Those are the entertainment industry, the popular media, and the AI community all wanting to attract more public attention and prestige. The abovementioned drivers are falsely making robots more human and are adding human characteristics.

Instead of being captivated by those AI myths and thinking about how to save the world from robots, he strongly argued, “We need to develop standards for the unintended side effects from AI.” To provide machines socially and ethically mingling with the human world, he believed principles should be set as follows: Define the Safe Operating Envelope (SOE), “safe modes” when out of bounds, study human behavior programmatically, certification and licensing standards, limitations on machine “agency,” and basic computational ethics such as when it is okay to break the law.

Professor Kaplan gave a positive view of AI for humans. “The future will be bright, thanks to AI. They do difficult work and help us and that will drive wealth and quality of life. The rich might get richer, but the benefits will spread throughout the people. It is time to think of innovative ways for using AI for building better world,” he concluded.

2018.09.10 View 5465

There Won't Be a Singularity: Professor Jerry Kaplan

(Professor Jerry Kaplan gave a lecture titled, Artificial Intelligence: Think Again at KAIST)

“People are so concerned about super intelligence, but the singularity will not happen,” said Professor Jerry Kaplan at Stanford University, an AI guru and Silicon Valley entrepreneur during a lecture at KAIST. He visited KAIST to give a lecture on Artificial Intelligence: Think Again on September 6.

Professor Kaplan said that some people argue that Korea’s AI research is behind the US and China but he doesn’t agree with that. “Korea is the most digitally connected one and has the world’s best engineers in the field. Korean companies are building products the consumers really like at reasonable prices. Those are attracting global consumers,” he added.

Instead of investing loads of money on AI research, he suggested three tasks for Korea taking a better position in the field of AI: Collecting and saving lots of data; training engineers, not the research talents in AI; and investing in AI infrastructure and relieving regulations by the government.

Referring to AI hype, Professor Kaplan argued that machines are intelligent, but they do not think in the way humans can, and assured the audience that the singularity some futurists predict will not be coming. He said, “Machine learning is a tool extracting useful information, but it does not mean they are so smart that they are taking over the world.”

(Professor Jerry Kaplan gave a lecture titled, Artificial Intelligence: Think Again at KAIST)

But what has made us believing AI myths? He first began pointing out how AI has been mythicized by three major drivers. Those are the entertainment industry, the popular media, and the AI community all wanting to attract more public attention and prestige. The abovementioned drivers are falsely making robots more human and are adding human characteristics.

Instead of being captivated by those AI myths and thinking about how to save the world from robots, he strongly argued, “We need to develop standards for the unintended side effects from AI.” To provide machines socially and ethically mingling with the human world, he believed principles should be set as follows: Define the Safe Operating Envelope (SOE), “safe modes” when out of bounds, study human behavior programmatically, certification and licensing standards, limitations on machine “agency,” and basic computational ethics such as when it is okay to break the law.

Professor Kaplan gave a positive view of AI for humans. “The future will be bright, thanks to AI. They do difficult work and help us and that will drive wealth and quality of life. The rich might get richer, but the benefits will spread throughout the people. It is time to think of innovative ways for using AI for building better world,” he concluded.

2018.09.10 View 5465 -

NEREC Summer Program Keeps Fellows Thinking, Engaged in Nuclear Nonproliferation

Nuclear technology is more than just technology. It is the fruit of the most advanced science and technology. It also requires high standards of policymaking and global cooperation for benefiting the technology.

As part of the fifth annual Nuclear Nonproliferation Education and Research Center (NEREC) Summer Fellows Program at KAIST, 24 students from 15 countries participated in six-week intensive education and training program. NEREC is the only university-based center dedicated to nuclear nonproliferation education and research established in 2014.

The program, which provides multidisciplinary lectures and seminars on nuclear technology and policy as well as international relations, was designed to nurture global nuclear technology experts well equipped in three areas: in-depth knowledge of technology, applicability gained from sound policy building, and negotiating for international cooperation. It now has grown into the most popular summer program at KAIST.

During the program from July 6 to August 18, participants were able to engage in enriching and stimulating learning experiences in tandem with policies and technology for the utilization and provision of peaceful and safe nuclear technology.

Participating fellows also had to conduct a group research project on a given topic. This year, they explored nuclear nonproliferation issues in relation to nuclear exports and brainstormed some recommendations for current policy. They presented their outcomes at the 2018 NEREC Conference on Nuclear Nonproliferation. After intensive lecture sessions and group research work, the fellows went off to key policy think-tanks, nuclear research institutes, and research power facilities in Korea, Japan, and China.

“NEREC emphasizes nuclear nonproliferation issues related to civilian nuclear power and the associated nuclear fuel cycle development from the point of technology users. I am very glad that the number of participants are increasing year by year,” said the Director of NEREC Man-Sung Yim, a professor in the Department of Nuclear and Quantum Engineering.

Participants’ majors vary from nuclear engineering to international relations to economics. The fellows divided into two groups of graduate and undergraduate courses. They expressed their deep satisfactory in the multidisciplinary lectures by scholars from KAIST, Seoul National University, and Korea National Defense University.

Many participants reported that they learned a lot, not only about policy and international relations but on the research they are conducting and what the key issues will be in dealing for producing meaningful research work.

Moad Aldbissi from the KTH Royal Institute of Technology is one of the students who shared the same view. He said, “Coming from a technical background in nuclear engineering, I managed to learn a lot about nuclear policy and international relations. The importance of integrating the technical and political fields became even clearer.”

Most students concurred that they recognized how important it was to make international collaboration in this powerful field for each country through this program.

“As an engineering student, I just approached this program like an empty glass in policy areas. While working with colleagues during the program, I came to understand how important it is to make cooperation in these fields for the better result of national development and international relations,” said Thanataon Pornphatdetaudom from the Tokyo Institute of Technology.

To Director Yim, this program is becoming well positioned to educate nuclear policy experts in a number of countries of strategic importance. He believes the continuous supply of these experts will contribute to promoting global nuclear nonproliferation and the peaceful use of nuclear energy while the use of nuclear technology continues.

2018.09.04 View 10709

NEREC Summer Program Keeps Fellows Thinking, Engaged in Nuclear Nonproliferation

Nuclear technology is more than just technology. It is the fruit of the most advanced science and technology. It also requires high standards of policymaking and global cooperation for benefiting the technology.

As part of the fifth annual Nuclear Nonproliferation Education and Research Center (NEREC) Summer Fellows Program at KAIST, 24 students from 15 countries participated in six-week intensive education and training program. NEREC is the only university-based center dedicated to nuclear nonproliferation education and research established in 2014.

The program, which provides multidisciplinary lectures and seminars on nuclear technology and policy as well as international relations, was designed to nurture global nuclear technology experts well equipped in three areas: in-depth knowledge of technology, applicability gained from sound policy building, and negotiating for international cooperation. It now has grown into the most popular summer program at KAIST.

During the program from July 6 to August 18, participants were able to engage in enriching and stimulating learning experiences in tandem with policies and technology for the utilization and provision of peaceful and safe nuclear technology.

Participating fellows also had to conduct a group research project on a given topic. This year, they explored nuclear nonproliferation issues in relation to nuclear exports and brainstormed some recommendations for current policy. They presented their outcomes at the 2018 NEREC Conference on Nuclear Nonproliferation. After intensive lecture sessions and group research work, the fellows went off to key policy think-tanks, nuclear research institutes, and research power facilities in Korea, Japan, and China.

“NEREC emphasizes nuclear nonproliferation issues related to civilian nuclear power and the associated nuclear fuel cycle development from the point of technology users. I am very glad that the number of participants are increasing year by year,” said the Director of NEREC Man-Sung Yim, a professor in the Department of Nuclear and Quantum Engineering.

Participants’ majors vary from nuclear engineering to international relations to economics. The fellows divided into two groups of graduate and undergraduate courses. They expressed their deep satisfactory in the multidisciplinary lectures by scholars from KAIST, Seoul National University, and Korea National Defense University.

Many participants reported that they learned a lot, not only about policy and international relations but on the research they are conducting and what the key issues will be in dealing for producing meaningful research work.

Moad Aldbissi from the KTH Royal Institute of Technology is one of the students who shared the same view. He said, “Coming from a technical background in nuclear engineering, I managed to learn a lot about nuclear policy and international relations. The importance of integrating the technical and political fields became even clearer.”

Most students concurred that they recognized how important it was to make international collaboration in this powerful field for each country through this program.

“As an engineering student, I just approached this program like an empty glass in policy areas. While working with colleagues during the program, I came to understand how important it is to make cooperation in these fields for the better result of national development and international relations,” said Thanataon Pornphatdetaudom from the Tokyo Institute of Technology.

To Director Yim, this program is becoming well positioned to educate nuclear policy experts in a number of countries of strategic importance. He believes the continuous supply of these experts will contribute to promoting global nuclear nonproliferation and the peaceful use of nuclear energy while the use of nuclear technology continues.

2018.09.04 View 10709 -

Adding Smart to Science Museum

KAIST and the National Science Museum (NSM) created an Exhibition Research Center for Smart Science to launch exhibitions that integrate emerging technologies in the Fourth Industrial Revolution, including augmented reality (AR), virtual reality (VR), Internet of Things (IoTs), and artificial intelligence (AI).

There has been a great demand for a novel technology for better, user-oriented exhibition services. The NSM continuously faces the problem of not having enough professional guides. Additionally, there have been constant complaints about its current mobile application for exhibitions not being very effective.

To tackle these problems, the new center was founded, involving 11 institutes and universities. Sponsored by the National Research Foundation, it will oversee 15 projects in three areas: exhibition-based technology, exhibition operational technology, and exhibition content.

The group first aims to provide a location-based exhibition guide system service, which allows it to incorporate various technological services, such as AR/VR to visitors. An indoor locating system named KAILOS, which was developed by KAIST, will be applied to this service. They will also launch a mobile application service that provides audio-based exhibition guides.

To further cater to visitors’ needs, the group plans to apply a user-centered ecosystem, a living lab concept to create pleasant environment for visitors.

“Every year, hundred thousands of young people visit the National Science Museum. I believe that the exhibition guide system has to be innovative, using cutting-edge IT technology in order to help them cherish their dreams and inspirations through science,” Jeong Heoi Bae, President of Exhibition and Research Bureau of NSM, emphasized.

Professor Dong Soo Han from the School of Computing, who took the position of research head of the group, said, “We will systematically develop exhibition technology and contents for the science museum to create a platform for smart science museums. It will be the first time to provide an exhibition guide system that integrates AR/VR with an indoor location system.”

The center will first apply the new system to the NSM and then expand it to 167 science museums and other regional museums.

2018.09.04 View 9001

Adding Smart to Science Museum

KAIST and the National Science Museum (NSM) created an Exhibition Research Center for Smart Science to launch exhibitions that integrate emerging technologies in the Fourth Industrial Revolution, including augmented reality (AR), virtual reality (VR), Internet of Things (IoTs), and artificial intelligence (AI).

There has been a great demand for a novel technology for better, user-oriented exhibition services. The NSM continuously faces the problem of not having enough professional guides. Additionally, there have been constant complaints about its current mobile application for exhibitions not being very effective.

To tackle these problems, the new center was founded, involving 11 institutes and universities. Sponsored by the National Research Foundation, it will oversee 15 projects in three areas: exhibition-based technology, exhibition operational technology, and exhibition content.

The group first aims to provide a location-based exhibition guide system service, which allows it to incorporate various technological services, such as AR/VR to visitors. An indoor locating system named KAILOS, which was developed by KAIST, will be applied to this service. They will also launch a mobile application service that provides audio-based exhibition guides.

To further cater to visitors’ needs, the group plans to apply a user-centered ecosystem, a living lab concept to create pleasant environment for visitors.

“Every year, hundred thousands of young people visit the National Science Museum. I believe that the exhibition guide system has to be innovative, using cutting-edge IT technology in order to help them cherish their dreams and inspirations through science,” Jeong Heoi Bae, President of Exhibition and Research Bureau of NSM, emphasized.

Professor Dong Soo Han from the School of Computing, who took the position of research head of the group, said, “We will systematically develop exhibition technology and contents for the science museum to create a platform for smart science museums. It will be the first time to provide an exhibition guide system that integrates AR/VR with an indoor location system.”

The center will first apply the new system to the NSM and then expand it to 167 science museums and other regional museums.

2018.09.04 View 9001 -

Potential Drug to Cure Ciliopathies

(from left: Professor Joon Kim and PhD candidate Yong Joon Kim)

Ciliopathies are rare disorders involving functional and structural abnormalities of cilia. Although they are rare, they may reach 1 in 1,000 births. Unfortunately, there are no small-molecule drugs for treating ciliary defects. A KAIST research team conducted successful research that introduces a potential treatment that will be a foundation for developing drugs to treat the disease as well as a platform for developing small-molecule drugs for similar genetic disorders.

It was found that mutations in genes required for the formation or function of primary cilia cause ciliopathies and they result in cerebellar disorders, kidney dysfunction, and retinal degeneration.

Primary cilia are cell organelles playing a crucial role in the human body. They participate in intercellular signal transduction during embryonic development and allow retinal photoreceptor cells to function.

Currently, there are no approved drugs available for treating most ciliopathies. In fact, this is the case for most of the rare genetic disorders involving functional abnormalities through genetic mutation, and gene therapy is usually the only treatment available.

To tackle this issue, a team led by Professor Joon Kim from the Graduate School of Medical Science and Engineering and Ho Jeong Kwon from Yonsei University constructed a cell that mimics a gene-mutated CEP290, one of the main causes of ciliopathies, through genome editing. They then used cell-based compound library screening to obtain a natural small-molecule compound capable of relieving defects in ciliogenesis, the production of cilia.

The CEP290 protein forms a complex with a ciliopathy protein called NPHP5 to support the function of the ciliary transition zone. In cases where the CEP290 protein is not formed due to a genetic mutation, NPHP5 will not function normally. Here, the compound was confirmed to partially restore the function of the complex by normalizing the function of NPHP5.

The team also identified that the compound is capable of retarding retinal degeneration by injecting the compound into animal models.

As a result, they discovered a lead compound for developing medication to treat ciliopathy patients involving retinal degeneration. Hence, the findings imply that chemical compounds that target other proteins interacting with the disease protein can mitigate shortages of a disease protein in recessive genetic disorders.

PhD candidate Yong Joon Kim stated, “This study shows how genetic disorders caused by genetic mutation can be treated with small-molecule drugs.”

Professor Kim said, “Since the efficacy of the candidate drug has been verified through animal testing, a follow-up study will also be conducted to demonstrate the effect on humans.”

This research was published in the Journal of Clinical Investigation on July 23.

Figure 1. Identification of compounds that rescue ciliogenesis defects caused by CEP290 knockout

Figure 2. Eupatilin injection ameliorates M-opsin trafficking and electrophysiological response of cone photoreceptors in rd16 mice

2018.08.30 View 8282

Potential Drug to Cure Ciliopathies

(from left: Professor Joon Kim and PhD candidate Yong Joon Kim)

Ciliopathies are rare disorders involving functional and structural abnormalities of cilia. Although they are rare, they may reach 1 in 1,000 births. Unfortunately, there are no small-molecule drugs for treating ciliary defects. A KAIST research team conducted successful research that introduces a potential treatment that will be a foundation for developing drugs to treat the disease as well as a platform for developing small-molecule drugs for similar genetic disorders.

It was found that mutations in genes required for the formation or function of primary cilia cause ciliopathies and they result in cerebellar disorders, kidney dysfunction, and retinal degeneration.

Primary cilia are cell organelles playing a crucial role in the human body. They participate in intercellular signal transduction during embryonic development and allow retinal photoreceptor cells to function.

Currently, there are no approved drugs available for treating most ciliopathies. In fact, this is the case for most of the rare genetic disorders involving functional abnormalities through genetic mutation, and gene therapy is usually the only treatment available.

To tackle this issue, a team led by Professor Joon Kim from the Graduate School of Medical Science and Engineering and Ho Jeong Kwon from Yonsei University constructed a cell that mimics a gene-mutated CEP290, one of the main causes of ciliopathies, through genome editing. They then used cell-based compound library screening to obtain a natural small-molecule compound capable of relieving defects in ciliogenesis, the production of cilia.

The CEP290 protein forms a complex with a ciliopathy protein called NPHP5 to support the function of the ciliary transition zone. In cases where the CEP290 protein is not formed due to a genetic mutation, NPHP5 will not function normally. Here, the compound was confirmed to partially restore the function of the complex by normalizing the function of NPHP5.

The team also identified that the compound is capable of retarding retinal degeneration by injecting the compound into animal models.

As a result, they discovered a lead compound for developing medication to treat ciliopathy patients involving retinal degeneration. Hence, the findings imply that chemical compounds that target other proteins interacting with the disease protein can mitigate shortages of a disease protein in recessive genetic disorders.

PhD candidate Yong Joon Kim stated, “This study shows how genetic disorders caused by genetic mutation can be treated with small-molecule drugs.”

Professor Kim said, “Since the efficacy of the candidate drug has been verified through animal testing, a follow-up study will also be conducted to demonstrate the effect on humans.”

This research was published in the Journal of Clinical Investigation on July 23.

Figure 1. Identification of compounds that rescue ciliogenesis defects caused by CEP290 knockout

Figure 2. Eupatilin injection ameliorates M-opsin trafficking and electrophysiological response of cone photoreceptors in rd16 mice

2018.08.30 View 8282 -

Rh Ensemble Catalyst for Effective Automobile Exhaust Treatment

(from left: Professor Hyunjoo Lee and PhD candidate Hojin Jeong)

A KAIST research team has developed a fully dispersed Rh ensemble catalyst (ENS) that shows better performance than commercial diesel oxidation catalyst (DOC). This newly developed ENSs could improve low-temperature automobile exhaust treatment.

Precious metals have been used for various heterogeneous reactions, but it is crucial to maximize efficiency of catalysts due to their high cost. Single-atom catalysts (SACs) have received much attention because it is possible for all of the metal atoms to be used for reactions, yet they do not show catalytic activity for reactions that require ensemble sites.

Meanwhile, hydrocarbons, such as propylene (C3H6) and propane (C3H8) are typical automobile exhaust gas pollutants and must be converted to carbon dioxide (CO2) and water (H2O) before they are released as exhaust. Since the hydrocarbon oxidation reaction proceeds only during carbon-carbon (C-C) or carbon-hydrogen (C-H) bond cleavage, it is essential to secure the metal ensemble site for the catalytic reaction. Therefore, precious metal catalysts with high dispersion and ensemble sites are greatly needed.

To solve this issue, Professor Hyunjoo Lee from the Department of Chemical and Biomolecular Engineering and Professor Jeong Woo Han from POSTECH developed an Rh ensemble catalyst with 100% dispersion, and applied it to automobile after-treatment. Having a 100% dispersion means that every metal atom is used for the reaction since it is exposed on the surface.

SACs also have 100% dispersion, but the difference is that ENSs have the unique advantage of having an ensemble site with two or more atoms.

As a result of the experiment, the ENSs showed excellent catalytic performance in CO, NO, propylene, and propane oxidation at low temperatures. This complements the disadvantage of nanoparticle catalyst (NPs) that perform catalysis poorly at low temperatures due to low metal dispersion, or SACs without hydrocarbon oxidation.

In particular, the ENSs have superior low-temperature activity even better than commercial DOC, hence they are expected to be applied to automobile exhaust treatment.

Professor Lee said, “I believe that the ENSs have given academic contribution for proposing a new concept of metal catalysts, differentiating from conventional SACs and NPs. At the same time, they are of great value in the industry of exhaust treatment catalysts.”

This research, led by PhD candidate Hojin Jeong, was published in the Journal of the American Chemical Society on July 5.

Figure 1. Concept of Rh ensemble catalyst for automobile exhaust treatment

Figure 2. Structure and performance comparison of single-atom catalyst and ensemble catalyst

Figure 3. Energy-dispersive X-ray spectroscopy (EDS) mapping images for SAC, ENS, and NP, respectively (green, Eh; red, Ce)

2018.08.29 View 7250

Rh Ensemble Catalyst for Effective Automobile Exhaust Treatment

(from left: Professor Hyunjoo Lee and PhD candidate Hojin Jeong)

A KAIST research team has developed a fully dispersed Rh ensemble catalyst (ENS) that shows better performance than commercial diesel oxidation catalyst (DOC). This newly developed ENSs could improve low-temperature automobile exhaust treatment.

Precious metals have been used for various heterogeneous reactions, but it is crucial to maximize efficiency of catalysts due to their high cost. Single-atom catalysts (SACs) have received much attention because it is possible for all of the metal atoms to be used for reactions, yet they do not show catalytic activity for reactions that require ensemble sites.

Meanwhile, hydrocarbons, such as propylene (C3H6) and propane (C3H8) are typical automobile exhaust gas pollutants and must be converted to carbon dioxide (CO2) and water (H2O) before they are released as exhaust. Since the hydrocarbon oxidation reaction proceeds only during carbon-carbon (C-C) or carbon-hydrogen (C-H) bond cleavage, it is essential to secure the metal ensemble site for the catalytic reaction. Therefore, precious metal catalysts with high dispersion and ensemble sites are greatly needed.

To solve this issue, Professor Hyunjoo Lee from the Department of Chemical and Biomolecular Engineering and Professor Jeong Woo Han from POSTECH developed an Rh ensemble catalyst with 100% dispersion, and applied it to automobile after-treatment. Having a 100% dispersion means that every metal atom is used for the reaction since it is exposed on the surface.

SACs also have 100% dispersion, but the difference is that ENSs have the unique advantage of having an ensemble site with two or more atoms.

As a result of the experiment, the ENSs showed excellent catalytic performance in CO, NO, propylene, and propane oxidation at low temperatures. This complements the disadvantage of nanoparticle catalyst (NPs) that perform catalysis poorly at low temperatures due to low metal dispersion, or SACs without hydrocarbon oxidation.

In particular, the ENSs have superior low-temperature activity even better than commercial DOC, hence they are expected to be applied to automobile exhaust treatment.

Professor Lee said, “I believe that the ENSs have given academic contribution for proposing a new concept of metal catalysts, differentiating from conventional SACs and NPs. At the same time, they are of great value in the industry of exhaust treatment catalysts.”

This research, led by PhD candidate Hojin Jeong, was published in the Journal of the American Chemical Society on July 5.

Figure 1. Concept of Rh ensemble catalyst for automobile exhaust treatment

Figure 2. Structure and performance comparison of single-atom catalyst and ensemble catalyst

Figure 3. Energy-dispersive X-ray spectroscopy (EDS) mapping images for SAC, ENS, and NP, respectively (green, Eh; red, Ce)

2018.08.29 View 7250 -

Levitating 2D Semiconductor for Better Performance

(from top: Professor Yeon Sik Jung and PhD candidate Soomin Yim)

Atomically thin 2D semiconductors have been drawing attention for their superior physical properties over silicon semiconductors; nevertheless, they are not the most appealing materials due to their structural instability and costly manufacturing process. To shed some light on these limitations, a KAIST research team suspended a 2D semiconductor on a dome-shaped nanostructure to produce a highly efficient semiconductor at a low cost.

2D semiconducting materials have emerged as alternatives for silicon-based semiconductors because of their inherent flexibility, high transparency, and excellent carrier transport properties, which are the important characteristics for flexible electronics.

Despite their outstanding physical and chemical properties, they are oversensitive to their environment due to their extremely thin nature. Hence, any irregularities in the supporting surface can affect the properties of 2D semiconductors and make it more difficult to produce reliable and well performing devices. In particular, it can result in serious degradation of charge-carrier mobility or light-emission yield.

To solve this problem, there have been continued efforts to fundamentally block the substrate effects. One way is to suspend a 2D semiconductor; however, this method will degrade mechanical durability due to the absence of a supporter underneath the 2D semiconducting materials.

Professor Yeon Sik Jung from the Department of Materials Science and Engineering and his team came up with a new strategy based on the insertion of high-density topographic patterns as a nanogap-containing supporter between 2D materials and the substrate in order to mitigate their contact and to block the substrate-induced unwanted effects.

More than 90% of the dome-shaped supporter is simply an empty space because of its nanometer scale size. Placing a 2D semiconductor on this structure creates a similar effect to levitating the layer. Hence, this method secures the mechanical durability of the device while minimizing the undesired effects from the substrate. By applying this method to the 2D semiconductor, the charge-carrier mobility was more than doubled, showing a significant improvement of the performance of the 2D semiconductor.

Additionally, the team reduced the price of manufacturing the semiconductor. In general, constructing an ultra-fine dome structure on a surface generally involves costly equipment to create individual patterns on the surface. However, the team employed a method of self-assembling nanopatterns in which molecules assemble themselves to form a nanostructure. This method led to reducing production costs and showed good compatibility with conventional semiconductor manufacturing processes.

Professor Jung said, “This research can be applied to improve devices using various 2D semiconducting materials as well as devices using graphene, a metallic 2D material. It will be useful in a broad range of applications, such as the material for the high speed transistor channels for next-generation flexible displays or for the active layer in light detectors.”

This research, led by PhD candidate Soomin Yim, was published in Nano Letters in April.

Figure 1. Image of a 2D semiconductor using dome structures

2018.08.28 View 6661

Levitating 2D Semiconductor for Better Performance

(from top: Professor Yeon Sik Jung and PhD candidate Soomin Yim)

Atomically thin 2D semiconductors have been drawing attention for their superior physical properties over silicon semiconductors; nevertheless, they are not the most appealing materials due to their structural instability and costly manufacturing process. To shed some light on these limitations, a KAIST research team suspended a 2D semiconductor on a dome-shaped nanostructure to produce a highly efficient semiconductor at a low cost.

2D semiconducting materials have emerged as alternatives for silicon-based semiconductors because of their inherent flexibility, high transparency, and excellent carrier transport properties, which are the important characteristics for flexible electronics.

Despite their outstanding physical and chemical properties, they are oversensitive to their environment due to their extremely thin nature. Hence, any irregularities in the supporting surface can affect the properties of 2D semiconductors and make it more difficult to produce reliable and well performing devices. In particular, it can result in serious degradation of charge-carrier mobility or light-emission yield.

To solve this problem, there have been continued efforts to fundamentally block the substrate effects. One way is to suspend a 2D semiconductor; however, this method will degrade mechanical durability due to the absence of a supporter underneath the 2D semiconducting materials.

Professor Yeon Sik Jung from the Department of Materials Science and Engineering and his team came up with a new strategy based on the insertion of high-density topographic patterns as a nanogap-containing supporter between 2D materials and the substrate in order to mitigate their contact and to block the substrate-induced unwanted effects.

More than 90% of the dome-shaped supporter is simply an empty space because of its nanometer scale size. Placing a 2D semiconductor on this structure creates a similar effect to levitating the layer. Hence, this method secures the mechanical durability of the device while minimizing the undesired effects from the substrate. By applying this method to the 2D semiconductor, the charge-carrier mobility was more than doubled, showing a significant improvement of the performance of the 2D semiconductor.

Additionally, the team reduced the price of manufacturing the semiconductor. In general, constructing an ultra-fine dome structure on a surface generally involves costly equipment to create individual patterns on the surface. However, the team employed a method of self-assembling nanopatterns in which molecules assemble themselves to form a nanostructure. This method led to reducing production costs and showed good compatibility with conventional semiconductor manufacturing processes.

Professor Jung said, “This research can be applied to improve devices using various 2D semiconducting materials as well as devices using graphene, a metallic 2D material. It will be useful in a broad range of applications, such as the material for the high speed transistor channels for next-generation flexible displays or for the active layer in light detectors.”

This research, led by PhD candidate Soomin Yim, was published in Nano Letters in April.

Figure 1. Image of a 2D semiconductor using dome structures

2018.08.28 View 6661 -

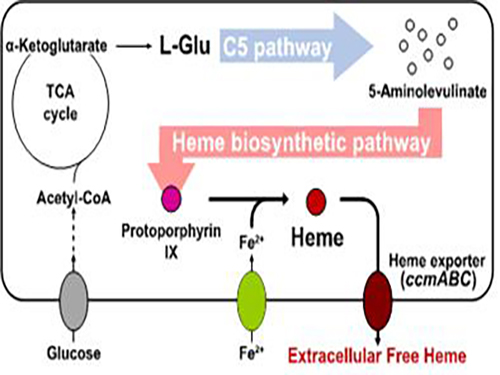

Metabolic Engineering of E. coli for the Secretory Production of Free Haem

Researchers of KAIST have defined a novel strategy for the secretory production of free haem using engineered Escherichia coli (E. coli) strains. They utilized the C5 pathway, the optimized downstream pathways, and the haem exporter to construct a recombinant micro-organism producing extracellular haem using fed-batch fermentation. This is the first report to extracellularly produce haem using engineered E. coli.

This strategy will expedite the efficient production of free haem to serve as a bioavailable iron-supplying agent and an important prosthetic group of multiple hemoproteins for medical uses. This study, led by Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering, was published in Nature Catalysis on Aug. 28.

Haem, an organometallic compound complexed with a ferrous ion, is an essential molecule delivering oxygen in the blood of many animals. It is also a key component of electron transport chains responsible for the respiration of aerobic organisms including diverse bacteria. It is now being widely applied as a bioavailable iron-supplying agent in the healthcare and dietary supplement industries. The demand for haem and the need for the efficient production of this compound continue to grow.

Many previous researchers have attempted to produce free haem using engineered E. coli. However, none of the studies was successful in producing free haem extracellularly, requiring an additional step to extract the accumulated haem from cells for subsequent uses. The secretion of haem in the form of haem peptides or proteins also requires an extraction step to isolate the free haem from the secreted products. Thus, the secretory production of free haem is an important task for the economical production of haem that is suitable for human consumption.

Although some researchers could produce intracellular haem using recombinant E. coli strains, its final titer was extremely low, resulting from the use of sub-optimal metabolic pathways. Furthermore, the addition of the precursors L-glycine and succinate was deemed undesirable for massive industrial production. Thus, it is necessary to construct an optimized haem biosynthetic pathway to enable the efficient production of haem and examine the consequent secretion of free haem.

To address this issue, the KAIST team used multiple strategies to produce extracellular free haem by enhancing its biosynthesis in E. coli. First, the capacities of the C4 and C5 pathways to produce aminolevulinate (ALA) without feeding precursors were examined. After confirming the superior performance of the C5 pathway over the C4 pathway, the metabolic genes of the C5 pathway and downstream pathways for haem biosynthesis were overexpressed. Then, the metabolic pathways were optimized by adjusting the expression levels of the relevant genes and disrupting the putative haem degradation enzyme encoded by the yfeX gene.

Consequently, the resulting engineered strain secreted a significant amount of haem to the medium. Subsequent optimization of the cultivation conditions and the supplementation of nitrogen sources further increased both the titer of the total free haem and the amount of free haem secreted to the medium. Finally, the overexpression of the ccmABC genes encoding the haem exporter further enhanced the production and secretion of haem, producing the highest titer of haem both intracellularly and extracellularly from glucose.

Professor Lee said, “The eco-friendly and sustainable chemical industry is a key global agenda every nation faces. We are conducting research to bio-synthesize high concentrations, high yields, and high productivity in natural products. This novel technology will serve as an opportunity to advance the biochemical industry moving forward.”

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries (NRF-2012M1A2A2026556 and NRF-2012M1A2A2026557) from the Ministry of Science and ICT through the National Research Foundation (NRF) of Korea. Further Contact: Dr. Sang Yup Lee, Distinguished Professor, KAIST, Daejeon, Korea ( leesy@kaist.ac.kr+82-42-350-3930).

2018.08.28 View 5928

Metabolic Engineering of E. coli for the Secretory Production of Free Haem

Researchers of KAIST have defined a novel strategy for the secretory production of free haem using engineered Escherichia coli (E. coli) strains. They utilized the C5 pathway, the optimized downstream pathways, and the haem exporter to construct a recombinant micro-organism producing extracellular haem using fed-batch fermentation. This is the first report to extracellularly produce haem using engineered E. coli.

This strategy will expedite the efficient production of free haem to serve as a bioavailable iron-supplying agent and an important prosthetic group of multiple hemoproteins for medical uses. This study, led by Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering, was published in Nature Catalysis on Aug. 28.

Haem, an organometallic compound complexed with a ferrous ion, is an essential molecule delivering oxygen in the blood of many animals. It is also a key component of electron transport chains responsible for the respiration of aerobic organisms including diverse bacteria. It is now being widely applied as a bioavailable iron-supplying agent in the healthcare and dietary supplement industries. The demand for haem and the need for the efficient production of this compound continue to grow.

Many previous researchers have attempted to produce free haem using engineered E. coli. However, none of the studies was successful in producing free haem extracellularly, requiring an additional step to extract the accumulated haem from cells for subsequent uses. The secretion of haem in the form of haem peptides or proteins also requires an extraction step to isolate the free haem from the secreted products. Thus, the secretory production of free haem is an important task for the economical production of haem that is suitable for human consumption.

Although some researchers could produce intracellular haem using recombinant E. coli strains, its final titer was extremely low, resulting from the use of sub-optimal metabolic pathways. Furthermore, the addition of the precursors L-glycine and succinate was deemed undesirable for massive industrial production. Thus, it is necessary to construct an optimized haem biosynthetic pathway to enable the efficient production of haem and examine the consequent secretion of free haem.

To address this issue, the KAIST team used multiple strategies to produce extracellular free haem by enhancing its biosynthesis in E. coli. First, the capacities of the C4 and C5 pathways to produce aminolevulinate (ALA) without feeding precursors were examined. After confirming the superior performance of the C5 pathway over the C4 pathway, the metabolic genes of the C5 pathway and downstream pathways for haem biosynthesis were overexpressed. Then, the metabolic pathways were optimized by adjusting the expression levels of the relevant genes and disrupting the putative haem degradation enzyme encoded by the yfeX gene.

Consequently, the resulting engineered strain secreted a significant amount of haem to the medium. Subsequent optimization of the cultivation conditions and the supplementation of nitrogen sources further increased both the titer of the total free haem and the amount of free haem secreted to the medium. Finally, the overexpression of the ccmABC genes encoding the haem exporter further enhanced the production and secretion of haem, producing the highest titer of haem both intracellularly and extracellularly from glucose.

Professor Lee said, “The eco-friendly and sustainable chemical industry is a key global agenda every nation faces. We are conducting research to bio-synthesize high concentrations, high yields, and high productivity in natural products. This novel technology will serve as an opportunity to advance the biochemical industry moving forward.”

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries (NRF-2012M1A2A2026556 and NRF-2012M1A2A2026557) from the Ministry of Science and ICT through the National Research Foundation (NRF) of Korea. Further Contact: Dr. Sang Yup Lee, Distinguished Professor, KAIST, Daejeon, Korea ( leesy@kaist.ac.kr+82-42-350-3930).

2018.08.28 View 5928 -

Improved Efficiency of CQD Solar Cells Using an Organic Thin Film

(from left: Professor Jung-Yong Lee and Dr. Se-Woong Baek)

Recently, the power conversion efficiency (PCE) of colloidal quantum dot (CQD)-based solar cells has been enhanced, paving the way for their commercialization in various fields; nevertheless, they are still a long way from being commercialized due to their efficiency not matching their stability. In this research, a KAIST team achieved highly stable and efficient CQD-based solar cells by using an amorphous organic layer to block oxygen and water permeation.

CQD-based solar cells are light-weight, flexible, and they boost light harvesting by absorbing near-infrared lights. Especially, they draw special attention for their optical properties controlled efficiently by changing the quantum dot sizes. However, they are still incompatible with existing solar cells in terms of efficiency, stability, and cost. Therefore, there is great demand for a novel technology that can simultaneously improve both PCE and stability while using an inexpensive electrode material.

Responding to this demand, Professor Jung-Yong Lee from the Graduate School of Energy, Environment, Water and Sustainability and his team introduced a technology to improve the efficiency and stability of CQD-based solar cells.

The team found that an amorphous organic thin film has a strong resistance to oxygen and water. Using these properties, they employed this doped organic layer as a top-hole selective layer (HSL) for the PbS CQD solar cells, and confirmed that the hydro/oxo-phobic properties of the layer efficiently protected the PbS layer. According to the molecular dynamics simulations, the layer significantly postponed the oxygen and water permeation into the PbS layer. Moreover, the efficient injection of the holes in the layer reduced interfacial resistance and improved performance.

With this technology, the team finally developed CQD-based solar cells with excellent stability. The PCE of their device stood at 11.7% and maintained over 90% of its initial performance when stored for one year under ambient conditions.

Professor Lee said, “This technology can be also applied to QD LEDs and Perovskite devices. I hope this technology can hasten the commercialization of CQD-based solar cells.”

This research, led by Dr. Se-Woong Baek and a Ph.D. student, Sang-Hoon Lee, was published in Energy & Environmental Science on May 10.

Figure 1. The schematic of the equilibrated structure of the amorphous organic film

Figure 2. Schematic illustration of CQD-based solar cells and graphs showing their performance

2018.08.27 View 8176

Improved Efficiency of CQD Solar Cells Using an Organic Thin Film

(from left: Professor Jung-Yong Lee and Dr. Se-Woong Baek)

Recently, the power conversion efficiency (PCE) of colloidal quantum dot (CQD)-based solar cells has been enhanced, paving the way for their commercialization in various fields; nevertheless, they are still a long way from being commercialized due to their efficiency not matching their stability. In this research, a KAIST team achieved highly stable and efficient CQD-based solar cells by using an amorphous organic layer to block oxygen and water permeation.

CQD-based solar cells are light-weight, flexible, and they boost light harvesting by absorbing near-infrared lights. Especially, they draw special attention for their optical properties controlled efficiently by changing the quantum dot sizes. However, they are still incompatible with existing solar cells in terms of efficiency, stability, and cost. Therefore, there is great demand for a novel technology that can simultaneously improve both PCE and stability while using an inexpensive electrode material.

Responding to this demand, Professor Jung-Yong Lee from the Graduate School of Energy, Environment, Water and Sustainability and his team introduced a technology to improve the efficiency and stability of CQD-based solar cells.

The team found that an amorphous organic thin film has a strong resistance to oxygen and water. Using these properties, they employed this doped organic layer as a top-hole selective layer (HSL) for the PbS CQD solar cells, and confirmed that the hydro/oxo-phobic properties of the layer efficiently protected the PbS layer. According to the molecular dynamics simulations, the layer significantly postponed the oxygen and water permeation into the PbS layer. Moreover, the efficient injection of the holes in the layer reduced interfacial resistance and improved performance.

With this technology, the team finally developed CQD-based solar cells with excellent stability. The PCE of their device stood at 11.7% and maintained over 90% of its initial performance when stored for one year under ambient conditions.

Professor Lee said, “This technology can be also applied to QD LEDs and Perovskite devices. I hope this technology can hasten the commercialization of CQD-based solar cells.”

This research, led by Dr. Se-Woong Baek and a Ph.D. student, Sang-Hoon Lee, was published in Energy & Environmental Science on May 10.

Figure 1. The schematic of the equilibrated structure of the amorphous organic film

Figure 2. Schematic illustration of CQD-based solar cells and graphs showing their performance

2018.08.27 View 8176 -

Robotic Herding of a Flock of Birds Using Drones

A joint team from KAIST, Caltech, and Imperial College London, presents a drone with a new algorithm to shepherd birds safely away from airports

Researchers made a new algorithm for enabling a single robotic unmanned aerial vehicle to herd a flock of birds away from a designated airspace. This novel approach allows a single autonomous quadrotor drone to herd an entire flock of birds away without breaking their formation.

Professor David Hyunchul Shim at KAIST in collaboration with Professor Soon-Jo Chung of Caltech and Professor Aditya Paranjape of Imperial College London investigated the problem of diverting a flock of birds away from a prescribed area, such as an airport, using a robotic UVA. A novel boundary control strategy called the m-waypoint algorithm was introduced for enabling a single pursuer UAV to safely herd the flock without fragmenting it.

The team developed the herding algorithm on the basis of macroscopic properties of the flocking model and the response of the flock. They tested their robotic autonomous drone by successfully shepherding an entire flock of birds out of a designated airspace near KAIST’s campus in Daejeon, South Korea. This study is published in IEEE Transactions on Robotics.

“It is quite interesting, and even awe-inspiring, to monitor how birds react to threats and collectively behave against threatening objects through the flock. We made careful observations of flock dynamics and interactions between flocks and the pursuer. This allowed us to create a new herding algorithm for ideal flight paths for incoming drones to move the flock away from a protected airspace,” said Professor Shim, who leads the Unmanned Systems Research Group at KAIST.

Bird strikes can threaten the safety of airplanes and their passengers. Korean civil aircraft suffered more than 1,000 bird strikes between 2011 and 2016. In the US, 142,000 bird strikes destroyed 62 civilian airplanes, injured 279 people, and killed 25 between 1990 and 2013. In the UK in 2016, there were 1,835 confirmed bird strikes, about eight for every 10,000 flights. Bird and other wildlife collisions with aircraft cause well over 1.2 billion USD in damages to the aviation industry worldwide annually. In the worst case, Canadian geese knocked out both engines of a US Airway jet in January 2009. The flight had to make an emergency landing on the Hudson River.

Airports and researchers have continued to reduce the risk of bird strikes through a variety of methods. They scare birds away using predators such as falcons or loud noises from small cannons or guns. Some airports try to prevent birds from coming by ridding the surrounding areas of crops that birds eat and hide in.

However, birds are smart. “I was amazed with the birds’ capability to interact with flying objects. We thought that only birds of prey have a strong sense of maneuvering with the prey. But our observation of hundreds of migratory birds such as egrets and loons led us to reach the hypothesis that they all have similar levels of maneuvering with the flying objects. It will be very interesting to collaborate with ornithologists to study further with birds’ behaviors with aerial objects,” said Professor Shim. “Airports are trying to transform into smart airports. This algorithm will help improve safety for the aviation industry. In addition, this will also help control avian influenza that plagues farms nationwide every year,” he stressed.

For this study, two drones were deployed. One drone performed various types of maneuvers around the flocks as a pursuer of herding drone, while a surveillance drone hovered at a high altitude with a camera pointing down for recording the trajectories of the pursuer drone and the birds.

During the experiments on egrets, the birds made frequent visits to a hunting area nearby and a large number of egrets were found to return to their nests at sunset. During the time, the team attempted to fly the herding drone in various directions with respect to the flock.

The drone approached the flock from the side. When the birds noticed the drone, they diverted from their original paths and flew at a 45˚ angle to their right. When the birds noticed the drone while it was still far away, they adjusted their paths horizontally and made smaller changes in the vertical direction. In the second round of the experiment on loons, the drone flew almost parallel to the flight path of a flock of birds, starting from an initial position located just off the nominal flight path. The birds had a nominal flight speed that was considerably higher than that of the drone so the interaction took place over a relatively short period of time.

Professor Shim said, “I think we just completed the first step of the research. For the next step, more systems will be developed and integrated for bird detection, ranging, and automatic deployment of drones.” “Professor Chung at Caltech is a KAIST graduate. And his first student was Professor Paranjape who now teaches at Imperial. It is pretty interesting that this research was made by a KAIST faculty member, an alumnus, and his student on three different continents,” he said.

(Figure A. Case 1: drone approaches the herd with sufficient distance to induce horizontal deviation)

(Figure B. Case 2: drone approaches the herd abruptly to cause vertical deviation)

2018.08.23 View 9771

Robotic Herding of a Flock of Birds Using Drones

A joint team from KAIST, Caltech, and Imperial College London, presents a drone with a new algorithm to shepherd birds safely away from airports

Researchers made a new algorithm for enabling a single robotic unmanned aerial vehicle to herd a flock of birds away from a designated airspace. This novel approach allows a single autonomous quadrotor drone to herd an entire flock of birds away without breaking their formation.

Professor David Hyunchul Shim at KAIST in collaboration with Professor Soon-Jo Chung of Caltech and Professor Aditya Paranjape of Imperial College London investigated the problem of diverting a flock of birds away from a prescribed area, such as an airport, using a robotic UVA. A novel boundary control strategy called the m-waypoint algorithm was introduced for enabling a single pursuer UAV to safely herd the flock without fragmenting it.

The team developed the herding algorithm on the basis of macroscopic properties of the flocking model and the response of the flock. They tested their robotic autonomous drone by successfully shepherding an entire flock of birds out of a designated airspace near KAIST’s campus in Daejeon, South Korea. This study is published in IEEE Transactions on Robotics.

“It is quite interesting, and even awe-inspiring, to monitor how birds react to threats and collectively behave against threatening objects through the flock. We made careful observations of flock dynamics and interactions between flocks and the pursuer. This allowed us to create a new herding algorithm for ideal flight paths for incoming drones to move the flock away from a protected airspace,” said Professor Shim, who leads the Unmanned Systems Research Group at KAIST.

Bird strikes can threaten the safety of airplanes and their passengers. Korean civil aircraft suffered more than 1,000 bird strikes between 2011 and 2016. In the US, 142,000 bird strikes destroyed 62 civilian airplanes, injured 279 people, and killed 25 between 1990 and 2013. In the UK in 2016, there were 1,835 confirmed bird strikes, about eight for every 10,000 flights. Bird and other wildlife collisions with aircraft cause well over 1.2 billion USD in damages to the aviation industry worldwide annually. In the worst case, Canadian geese knocked out both engines of a US Airway jet in January 2009. The flight had to make an emergency landing on the Hudson River.

Airports and researchers have continued to reduce the risk of bird strikes through a variety of methods. They scare birds away using predators such as falcons or loud noises from small cannons or guns. Some airports try to prevent birds from coming by ridding the surrounding areas of crops that birds eat and hide in.

However, birds are smart. “I was amazed with the birds’ capability to interact with flying objects. We thought that only birds of prey have a strong sense of maneuvering with the prey. But our observation of hundreds of migratory birds such as egrets and loons led us to reach the hypothesis that they all have similar levels of maneuvering with the flying objects. It will be very interesting to collaborate with ornithologists to study further with birds’ behaviors with aerial objects,” said Professor Shim. “Airports are trying to transform into smart airports. This algorithm will help improve safety for the aviation industry. In addition, this will also help control avian influenza that plagues farms nationwide every year,” he stressed.

For this study, two drones were deployed. One drone performed various types of maneuvers around the flocks as a pursuer of herding drone, while a surveillance drone hovered at a high altitude with a camera pointing down for recording the trajectories of the pursuer drone and the birds.

During the experiments on egrets, the birds made frequent visits to a hunting area nearby and a large number of egrets were found to return to their nests at sunset. During the time, the team attempted to fly the herding drone in various directions with respect to the flock.

The drone approached the flock from the side. When the birds noticed the drone, they diverted from their original paths and flew at a 45˚ angle to their right. When the birds noticed the drone while it was still far away, they adjusted their paths horizontally and made smaller changes in the vertical direction. In the second round of the experiment on loons, the drone flew almost parallel to the flight path of a flock of birds, starting from an initial position located just off the nominal flight path. The birds had a nominal flight speed that was considerably higher than that of the drone so the interaction took place over a relatively short period of time.

Professor Shim said, “I think we just completed the first step of the research. For the next step, more systems will be developed and integrated for bird detection, ranging, and automatic deployment of drones.” “Professor Chung at Caltech is a KAIST graduate. And his first student was Professor Paranjape who now teaches at Imperial. It is pretty interesting that this research was made by a KAIST faculty member, an alumnus, and his student on three different continents,” he said.

(Figure A. Case 1: drone approaches the herd with sufficient distance to induce horizontal deviation)

(Figure B. Case 2: drone approaches the herd abruptly to cause vertical deviation)

2018.08.23 View 9771 -

'K-FLEX' Makes a Splash as a Flexible Endoscopic Surgical Robot

( Robot arms perform an incision during an ex-vivo test on a porcine gallbladder.)

K-FLEX, a flexible endoscopic surgical robot developed by the KAIST Future Medical Robotics Research Center, opens a new chapter for minimally invasive robot-assisted surgery with its precision control of 3.7 mm diameter robotic arms. The two arms, placing at the end of flexible endoscopes, highlight impeccable precision control and robust mini-joint design technologies. While cruising through the complicated inner body pliably, it carries out procedures on the spot with its robotic arms.

The research team under Professor Dong-Soo Kwon recently tested the device in-vivo, conducting a complicated endoscopic procedure dissecting a porcine gallbladder in collaboration with Professor Dae-Kyung Son of the National Cancer Center. The arms successfully manipulated the tissue safely.

During the test, K-FLEX, inserted through an incision in the navel, snaked through the narrow passages of the complicated inner organs. When reaching the desired spot, one of the robot arms pushed aside and held up the nearby tissue to secure proper vision and space for the procedure. Meanwhile, a cautery needle mounted at the tip of the other hand removed the lesion tissue on the gallbladder. The tiny camera installed at the front of the robot arms relayed the internal conditions. The full procedure was able to be monitored from the master console.

The two arms are placed onto 4.2 mm internal channels of an endoscope which is 17 mm in diameter. The arms can be deployable forward and backward and are extendable up to 7 cm for performing procedures.

K-FLEX is made of domestically produced components, except for the endoscopic module. It will expand new medical robotics research while offering novel therapeutic capabilities for endoscopes.

Flexible endoscopes are very promising for surgical applications because they can treat areas thought to be difficult to reach, such as the posterior side of an organ. Current rigid-type laparoscopic tools could not reach a lesion if it occurs in such serpentine and complicated areas. However, this flexible endoscopic surgery robot will bypass obstacles to reach the troubled area.

The ability to seamlessly integrate effective actuation into millimeter-scale deployable mechanisms fits well with minimally invasive surgical procedures. This flexible endoscopic surgery robot, only half the size of current laparoscopic surgical robots, is deployable into natural orifices such as the mouth, anus, and vagina without requiring external incisions. Laparoscopic devices and robots require at least three to four external incisions to insert the devices; however, the applicability of internal incisions reduces the possibility of complications arousing from excessive bleeding and bacterial infections.

Despite these advantages, it has remained challenging to manipulate the robotic arms of flexible endoscopes with integrated grabbing force, flexibility, and multiple degrees of freedom for clinical environments.

The team focused on smaller but smarter devices. Dr. Min-Ho Hwang, a principal researcher of K-FLEX, said that developing tiny robots that are able to generate the necessary forces without compromising safety was the challenge. They created a robust but smaller-joint technology that can exert a relatively greater force even into millimeter scale.

Professor Kwon said, “K-FLEX is the first flexible endoscopic surgery robot in Korea. We already confirmed the clinical adaptation through ex vivo tests and will see complete commercialization in two to three years.” The team believes K-FLEX will be very effective for surgery on incipient cancer cells in the stomach, colon, and thyroid.

Professor Kwon and his eight researchers recently established a tech start-up called EasyEndo Surgical Inc. with these core technologies. In June, K-FLEX won the ‘Best Application Award’ and the ‘Overall Winner’ at the Surgical Robot Challenge 2018 held at Imperial College London. The Korea Research Foundation funded the research on K-FLEX.

(The team conducts a procedure using K-FLEX, flexible endoscopic surgical robot.)

2018.08.17 View 8799

'K-FLEX' Makes a Splash as a Flexible Endoscopic Surgical Robot

( Robot arms perform an incision during an ex-vivo test on a porcine gallbladder.)

K-FLEX, a flexible endoscopic surgical robot developed by the KAIST Future Medical Robotics Research Center, opens a new chapter for minimally invasive robot-assisted surgery with its precision control of 3.7 mm diameter robotic arms. The two arms, placing at the end of flexible endoscopes, highlight impeccable precision control and robust mini-joint design technologies. While cruising through the complicated inner body pliably, it carries out procedures on the spot with its robotic arms.

The research team under Professor Dong-Soo Kwon recently tested the device in-vivo, conducting a complicated endoscopic procedure dissecting a porcine gallbladder in collaboration with Professor Dae-Kyung Son of the National Cancer Center. The arms successfully manipulated the tissue safely.

During the test, K-FLEX, inserted through an incision in the navel, snaked through the narrow passages of the complicated inner organs. When reaching the desired spot, one of the robot arms pushed aside and held up the nearby tissue to secure proper vision and space for the procedure. Meanwhile, a cautery needle mounted at the tip of the other hand removed the lesion tissue on the gallbladder. The tiny camera installed at the front of the robot arms relayed the internal conditions. The full procedure was able to be monitored from the master console.

The two arms are placed onto 4.2 mm internal channels of an endoscope which is 17 mm in diameter. The arms can be deployable forward and backward and are extendable up to 7 cm for performing procedures.

K-FLEX is made of domestically produced components, except for the endoscopic module. It will expand new medical robotics research while offering novel therapeutic capabilities for endoscopes.

Flexible endoscopes are very promising for surgical applications because they can treat areas thought to be difficult to reach, such as the posterior side of an organ. Current rigid-type laparoscopic tools could not reach a lesion if it occurs in such serpentine and complicated areas. However, this flexible endoscopic surgery robot will bypass obstacles to reach the troubled area.

The ability to seamlessly integrate effective actuation into millimeter-scale deployable mechanisms fits well with minimally invasive surgical procedures. This flexible endoscopic surgery robot, only half the size of current laparoscopic surgical robots, is deployable into natural orifices such as the mouth, anus, and vagina without requiring external incisions. Laparoscopic devices and robots require at least three to four external incisions to insert the devices; however, the applicability of internal incisions reduces the possibility of complications arousing from excessive bleeding and bacterial infections.

Despite these advantages, it has remained challenging to manipulate the robotic arms of flexible endoscopes with integrated grabbing force, flexibility, and multiple degrees of freedom for clinical environments.

The team focused on smaller but smarter devices. Dr. Min-Ho Hwang, a principal researcher of K-FLEX, said that developing tiny robots that are able to generate the necessary forces without compromising safety was the challenge. They created a robust but smaller-joint technology that can exert a relatively greater force even into millimeter scale.

Professor Kwon said, “K-FLEX is the first flexible endoscopic surgery robot in Korea. We already confirmed the clinical adaptation through ex vivo tests and will see complete commercialization in two to three years.” The team believes K-FLEX will be very effective for surgery on incipient cancer cells in the stomach, colon, and thyroid.

Professor Kwon and his eight researchers recently established a tech start-up called EasyEndo Surgical Inc. with these core technologies. In June, K-FLEX won the ‘Best Application Award’ and the ‘Overall Winner’ at the Surgical Robot Challenge 2018 held at Imperial College London. The Korea Research Foundation funded the research on K-FLEX.

(The team conducts a procedure using K-FLEX, flexible endoscopic surgical robot.)

2018.08.17 View 8799 -

Flexible Drug Delivery Microdevice to Advance Precision Medicine

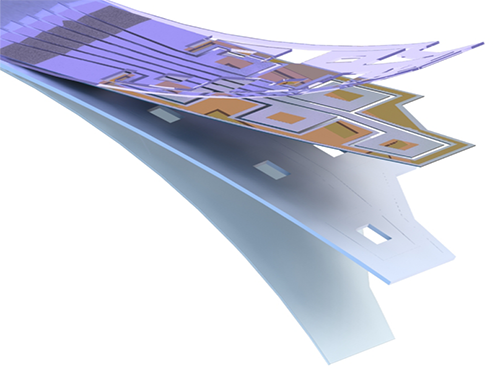

(Schematic view of flexible microdevice: The flexible drug delivery device for controlled release fabricated via inorganic laser lift off.)

A KAIST research team has developed a flexible drug delivery device with controlled release for personalized medicine, blazing the path toward theragnosis.

Theragnosis, an emerging medical technology, is gaining attention as key factor to advance precision medicine for its featuring simultaneous diagnosis and therapeutics. Theragnosis devices including smart contact lenses and microneedle patches integrate physiological data sensors and drug delivery devices. The controlled drug delivery boasts fewer side-effects, uniform therapeutic results, and minimal dosages compared to oral ingestion. Recently, some research groups conducted in-human applications of controlled-release bulky microchips for osteoporosis treatment. However they failed to demonstrate successful human-friendly flexible drug delivery systems for controlled release.

For this microdevice, the team under Professor Daesoo Kim from the Department of Biological Science and Professor Keon Jae Lee from the Department of Materials Science and Engineering, fabricated a device on a rigid substrate and transferred a 50 µm-thick active drug delivery layer to the flexible substrate via inorganic laser lift off. The fabricated device shows mechanical flexibility while maintaining the capability of precise administration of exact dosages at desired times. The core technology is to produce a freestanding gold capping layer directly on top of the microreservoir with the drugs inside, which had been regarded as impossible in conventional microfabrication.

The developed flexible drug delivery system can be applied to smart contact lenses or the brain disease treatments by implanting them into cramped and corrugated organs. In addition, when powered wirelessly, it will represent a novel platform for personalized medicine. The team already proved through animal experimentation that treatment for brain epilepsy made progress by releasing anti-epileptic medication through the device.

Professor Lee believes the flexible microdevice will further expand the applications of smart contact lenses, therapeutic treatments for brain disease, and subcutaneous implantations for daily healthcare system. This study “Flexible Wireless Powered Drug Delivery System for Targeted Administration on Cerebral Cortex” was described in the June online issue of Nano Energy.

(Photo: The flexible drug delivery device for contolled relase attached on a glass rod.)

2018.08.13 View 9104

Flexible Drug Delivery Microdevice to Advance Precision Medicine

(Schematic view of flexible microdevice: The flexible drug delivery device for controlled release fabricated via inorganic laser lift off.)

A KAIST research team has developed a flexible drug delivery device with controlled release for personalized medicine, blazing the path toward theragnosis.

Theragnosis, an emerging medical technology, is gaining attention as key factor to advance precision medicine for its featuring simultaneous diagnosis and therapeutics. Theragnosis devices including smart contact lenses and microneedle patches integrate physiological data sensors and drug delivery devices. The controlled drug delivery boasts fewer side-effects, uniform therapeutic results, and minimal dosages compared to oral ingestion. Recently, some research groups conducted in-human applications of controlled-release bulky microchips for osteoporosis treatment. However they failed to demonstrate successful human-friendly flexible drug delivery systems for controlled release.

For this microdevice, the team under Professor Daesoo Kim from the Department of Biological Science and Professor Keon Jae Lee from the Department of Materials Science and Engineering, fabricated a device on a rigid substrate and transferred a 50 µm-thick active drug delivery layer to the flexible substrate via inorganic laser lift off. The fabricated device shows mechanical flexibility while maintaining the capability of precise administration of exact dosages at desired times. The core technology is to produce a freestanding gold capping layer directly on top of the microreservoir with the drugs inside, which had been regarded as impossible in conventional microfabrication.

The developed flexible drug delivery system can be applied to smart contact lenses or the brain disease treatments by implanting them into cramped and corrugated organs. In addition, when powered wirelessly, it will represent a novel platform for personalized medicine. The team already proved through animal experimentation that treatment for brain epilepsy made progress by releasing anti-epileptic medication through the device.

Professor Lee believes the flexible microdevice will further expand the applications of smart contact lenses, therapeutic treatments for brain disease, and subcutaneous implantations for daily healthcare system. This study “Flexible Wireless Powered Drug Delivery System for Targeted Administration on Cerebral Cortex” was described in the June online issue of Nano Energy.

(Photo: The flexible drug delivery device for contolled relase attached on a glass rod.)

2018.08.13 View 9104 -

The MSE/CBE Int'l Workshop Explores Big Ideas in Emerging Materials

(KAIST President Sung-Chul Shin with scholars participated in the workshop)

The MSE/CBE International Workshop brought together editors from key academic journals in multidisciplinary materials science and scholars from leading universities at KAIST on Aug. 7.

The workshop hosted ten distinguished speakers in the fields of nanostructures for next-generation emerging applications, chemical and bio-engineering, and materials innovation for functional applications. They explored opportunities and challenges for reinventing novel materials that will solve complex problems.

(From left: Professor Buriak, Professor Swager and Professor Il-Doo Kim)

Speakers included: Chief Editor of Nature Materials Vincent Dusastre; Editor-in- Chief of ACS NANO and professor at UCLA Paul S. Weiss; Jillian M. Buriak, Editor-in-Chief of Chemistry of Materials; Associate Editor of Macromolecules and professor at MIT Timothy M. Swager; Coordinating Editor of Acta Materialia and Head of the Department of Materials Science and Engineering at MIT Christopher A. Schuh; Editor-in-Chief of Biotechnology Journal and Metabolic Engineering and Distinguished Professor at KAIST Sang-Yup Lee; Associate Editor of Energy Storage Materials and professor at KAIST Sang Ouk Kim; Professor Jeffrey C. Grossman at MIT; Professor Zhenan Bao at Stanford University; and Professor Hyuck Mo Lee, head of the Department of Materials Science and Engineering at KAIST.

Interdisciplinary materials research holds the key to building technological competitiveness in many industrial sectors extending from energy, environment, and health care to medicine and beyond. It has also been the bedrock of KAIST’s scholarship and research innovation. More than 200 faculty members in the field of materials science produce about 800 SCI papers every year. The two departments of materials science and chemical biomolecular engineering are leading KAIST’s global reputation, as they were both ranked 13th and 14th in the QS World University Ranking by Subject this year.

(Professor Il-Doo Kim fromt he Department of Materials Science Engineering)

Professor Il-Doo Kim from the Department of Materials Science Engineering has been the chair of this workshop from 2016. In hosting the second one this year, he said that he hopes this year’s workshop will inspire many materials scientists to have big ideas and work to make those big ideas get noticed in order to have a real impact.

(KAIST President Sung-Chul Shin)