-

Six Professors Recognized for the National R&D Excellence 100

Six KAIST professors were listed among the 2018 National R&D Excellence 100 announced by the Ministry of Science and ICT and Korea Institute of S&T Evaluation and Planning.

Professor Il-Doo Kim from the Department of Materials Science and Engineering was recognized for his research on developing source technology for manufacturing a highly sensitive gas sensor with low power consumption. His work was recognized as most excellent in the field of mechanics and materials.

Additionally, Professor Ho Min Kim from the Graduate School of Medical Science & Engineering was listed as most excellent in the field of life and marine science for providing structural insights into the mechanism of proteins that regulates synapse development.

Meanwhile, Professor Byong-Guk Park from the Department of Materials Science and Engineering was listed as excellent in the field of mechanics and materials for his work on thermal spin current.

In the field of energy and environment, Professor Jae Woo Lee from the Department of Chemical and Biomolecular Engineering was listed as excellent for his work on CO₂ conversion to carbon materials.

Last but not least, Professor Min H. Kim from the School of Computing and Professor Kyung Cheol Choi from the School of Electrical Engineering were recognized as being excellent in the field of information and electronics. Professor Kim was recognized for image processing technology that reconstructs interlaced high-dynamic range video while Professor Choi was lauded for realizing flexible displays on fabrics.

A certificate from the Minister of Ministry of Science and ICT will be conferred to the scientists and their names will be listed on a special 2018 National R&D Excellence 100 plaque to celebrate their achievement.

These six professors will be nominated for merits including the Order of Merit, the President’s commendation, and the Prime Minister’s commendation and given privileges during the process of new R&D project selection.

2018.10.18 View 4935

Six Professors Recognized for the National R&D Excellence 100

Six KAIST professors were listed among the 2018 National R&D Excellence 100 announced by the Ministry of Science and ICT and Korea Institute of S&T Evaluation and Planning.

Professor Il-Doo Kim from the Department of Materials Science and Engineering was recognized for his research on developing source technology for manufacturing a highly sensitive gas sensor with low power consumption. His work was recognized as most excellent in the field of mechanics and materials.

Additionally, Professor Ho Min Kim from the Graduate School of Medical Science & Engineering was listed as most excellent in the field of life and marine science for providing structural insights into the mechanism of proteins that regulates synapse development.

Meanwhile, Professor Byong-Guk Park from the Department of Materials Science and Engineering was listed as excellent in the field of mechanics and materials for his work on thermal spin current.

In the field of energy and environment, Professor Jae Woo Lee from the Department of Chemical and Biomolecular Engineering was listed as excellent for his work on CO₂ conversion to carbon materials.

Last but not least, Professor Min H. Kim from the School of Computing and Professor Kyung Cheol Choi from the School of Electrical Engineering were recognized as being excellent in the field of information and electronics. Professor Kim was recognized for image processing technology that reconstructs interlaced high-dynamic range video while Professor Choi was lauded for realizing flexible displays on fabrics.

A certificate from the Minister of Ministry of Science and ICT will be conferred to the scientists and their names will be listed on a special 2018 National R&D Excellence 100 plaque to celebrate their achievement.

These six professors will be nominated for merits including the Order of Merit, the President’s commendation, and the Prime Minister’s commendation and given privileges during the process of new R&D project selection.

2018.10.18 View 4935 -

Dr. Sejeong Kim Recognized as Excellent Young Scientist

(Dr. Sejeong Kim)

Dr. Sejeong Kim, a postdoctoral research associate in the School of Mathematical and Physical Sciences at the University of Technology Sydney was honored to receive the Excellence Award for a Young Scientist by the Korea Federation of Women’s Science & Technology Association (KOFWST). The award ceremony will be held on October 31 in Seoul.

KOFWST recognizes ten promising young female scientists and engineers every year who show significant potential, passion, and remarkable achievement in their work. The awardees are selected among those who finished their degree within the previous five years. Dr. Kim earned her Ph.D. in physics at KAIST in 2014 and was selected as the winner in the field of physics in recognition of her outstanding research activities in photonics.

Dr. Kim conducted various research activities in the field of photonics and was published in high impact journals including Nano Letters and Advanced materials. In July, she developed the first photonic cavity from van der Waals materials and published the study in Nature Communications titled “Photonic Crystal Cavities from Hexagonal Boron Nitride.” At UTS, she carries out research activities supervised by Professor Igor Aharonovich and has engaged in many science outreach activities.

2018.10.18 View 5731

Dr. Sejeong Kim Recognized as Excellent Young Scientist

(Dr. Sejeong Kim)

Dr. Sejeong Kim, a postdoctoral research associate in the School of Mathematical and Physical Sciences at the University of Technology Sydney was honored to receive the Excellence Award for a Young Scientist by the Korea Federation of Women’s Science & Technology Association (KOFWST). The award ceremony will be held on October 31 in Seoul.

KOFWST recognizes ten promising young female scientists and engineers every year who show significant potential, passion, and remarkable achievement in their work. The awardees are selected among those who finished their degree within the previous five years. Dr. Kim earned her Ph.D. in physics at KAIST in 2014 and was selected as the winner in the field of physics in recognition of her outstanding research activities in photonics.

Dr. Kim conducted various research activities in the field of photonics and was published in high impact journals including Nano Letters and Advanced materials. In July, she developed the first photonic cavity from van der Waals materials and published the study in Nature Communications titled “Photonic Crystal Cavities from Hexagonal Boron Nitride.” At UTS, she carries out research activities supervised by Professor Igor Aharonovich and has engaged in many science outreach activities.

2018.10.18 View 5731 -

Skin Hardness to Estimate Better Human Thermal Status

(Professor Young-Ho Cho and Researcher Sunghyun Yoon)

Under the same temperature and humidity, human thermal status may vary due to individual body constitution and climatic environment. A KAIST research team previously developed a wearable sweat rate sensor for human thermal comfort monitoring. Furthering the development, this time they proposed skin hardness as an additional, independent physiological sign to estimate human thermal status more accurately. This novel approach can be applied to developing systems incorporating human-machine interaction, which requires accurate information about human thermal status.

Professor Young-Ho Cho and his team from the Department of Bio and Brain Engineering had previously studied skin temperature and sweat rate to determine human thermal comfort, and developed a watch-type sweat rate sensor that accurately and steadily detects thermal comfort last February (title: Wearable Sweat Rate Sensors for Human Thermal Comfort Monitoring ).

However, skin temperature and sweat rate are still not enough to estimate exact human thermal comfort. Hence, an additional indicator is required for enhancing the accuracy and reliability of the estimation and the team selected skin hardness. When people feel hot or cold, arrector pili muscles connected to hair follicles contract and expand, and skin hardness comes from this contraction and relaxation of the muscles. Based on the phenomenon of changing skin hardness, the team proposed skin hardness as a new indicator for measuring human thermal sensation.

With this new estimation model using three physiological signs for estimating human thermal status, the team conducted human experiments and verified that skin hardness is effective and independent from the two conventional physiological signs. Adding skin hardness to the conventional model can reduce errors by 23.5%, which makes its estimation more reliable.

The team will develop a sensor that detects skin hardness and applies it to cognitive air-conditioning and heating systems that better interact with humans than existing systems.

Professor Cho said, “Introducing this new indicator, skin hardness, elevates the reliability of measuring human thermal comfort regardless of individual body constitution and climatic environment. Based on this method, we can develop a personalized air conditioning and heating system that will allow affective interaction between humans and machines by sharing both physical and mental health conditions and emotions.”

This research, led by researchers Sunghyun Yoon and Jai Kyoung Sim, was published in Scientific Reports, Vol.8, Article No.12027 on August 13, 2018. (pp.1-6)

Figure 1. Measuring human thermal status through skin hardness

Figure 2. The instrument used for measuring human thermal status through skin hardness

2018.10.17 View 6402

Skin Hardness to Estimate Better Human Thermal Status

(Professor Young-Ho Cho and Researcher Sunghyun Yoon)

Under the same temperature and humidity, human thermal status may vary due to individual body constitution and climatic environment. A KAIST research team previously developed a wearable sweat rate sensor for human thermal comfort monitoring. Furthering the development, this time they proposed skin hardness as an additional, independent physiological sign to estimate human thermal status more accurately. This novel approach can be applied to developing systems incorporating human-machine interaction, which requires accurate information about human thermal status.

Professor Young-Ho Cho and his team from the Department of Bio and Brain Engineering had previously studied skin temperature and sweat rate to determine human thermal comfort, and developed a watch-type sweat rate sensor that accurately and steadily detects thermal comfort last February (title: Wearable Sweat Rate Sensors for Human Thermal Comfort Monitoring ).

However, skin temperature and sweat rate are still not enough to estimate exact human thermal comfort. Hence, an additional indicator is required for enhancing the accuracy and reliability of the estimation and the team selected skin hardness. When people feel hot or cold, arrector pili muscles connected to hair follicles contract and expand, and skin hardness comes from this contraction and relaxation of the muscles. Based on the phenomenon of changing skin hardness, the team proposed skin hardness as a new indicator for measuring human thermal sensation.

With this new estimation model using three physiological signs for estimating human thermal status, the team conducted human experiments and verified that skin hardness is effective and independent from the two conventional physiological signs. Adding skin hardness to the conventional model can reduce errors by 23.5%, which makes its estimation more reliable.

The team will develop a sensor that detects skin hardness and applies it to cognitive air-conditioning and heating systems that better interact with humans than existing systems.

Professor Cho said, “Introducing this new indicator, skin hardness, elevates the reliability of measuring human thermal comfort regardless of individual body constitution and climatic environment. Based on this method, we can develop a personalized air conditioning and heating system that will allow affective interaction between humans and machines by sharing both physical and mental health conditions and emotions.”

This research, led by researchers Sunghyun Yoon and Jai Kyoung Sim, was published in Scientific Reports, Vol.8, Article No.12027 on August 13, 2018. (pp.1-6)

Figure 1. Measuring human thermal status through skin hardness

Figure 2. The instrument used for measuring human thermal status through skin hardness

2018.10.17 View 6402 -

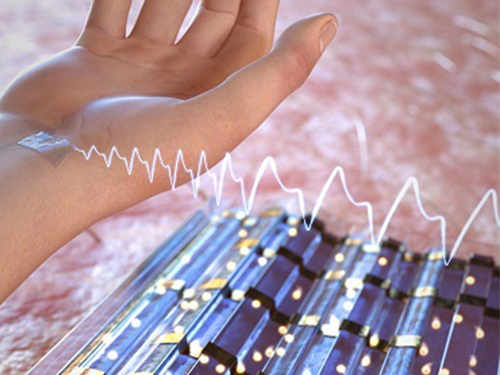

High-Performance Flexible Transparent Force Touch Sensor for Wearable Devices

Researchers reported a high-performance and transparent nanoforce touch sensor by developing a thin, flexible, and transparent hierarchical nanocomposite (HNC) film. The research team says their sensor simultaneously features all the necessary characters for industrial-grade application: high sensitivity, transparency, bending insensitivity, and manufacturability.

Force touch sensors that recognize the location and pressure of external stimuli have received considerable attention for various applications, such as wearable devices, flexible displays, and humanoid robots. For decades, huge amounts of research and development have been devoted to improving pressure sensitivity to realize industrial-grade sensing devices. However, it remains a challenge to apply force touch sensors in flexible applications because sensing performance is subject to change and degraded by induced mechanical stress and deformation when the device is bent.

To overcome these issues, the research team focused on the development of non-air gap sensors to break away from the conventional technology where force touch sensors need to have air-gaps between electrodes for high sensitivity and flexibility.

The proposed non air-gap force touch sensor is based on a transparent nanocomposite insulator containing metal nanoparticles which can maximize the capacitance change in dielectrics according to the pressure, and a nanograting substrate which can increase transparency as well as sensitivity by concentrating pressure. As a result, the team succeeded in fabricating a highly sensitive, transparent, flexible force touch sensor that is mechanically stable against repetitive pressure.

Furthermore, by placing the sensing electrodes on the same plane as the neutral plane, the force touch sensor can operate, even when bending to the radius of the ballpoint pen, without changes in performance levels.

The proposed force touch has also satisfied commercial considerations in mass production such as large-area uniformity, production reproducibility, and reliability according to temperature and long-term use.

Finally, the research team applied the developed sensor to a pulse-monitoring capable healthcare wearable device and detected a real-time human pulse. In addition, the research team confirmed with HiDeep, Inc. that a seven-inch large-area sensor can be integrated into a commercial smartphone.

The team of Professor Jun-Bo Yoon, PhD student Jae-Young Yoo, and Dr. Min-Ho Seo from the School of Electrical Engineering carried out this study that was featured as a back cover in Advanced Functional Materials Journal.

PhD student Jae-Young Yoo who led this research said, "We successfully developed an industrial-grade force touch sensor by using a simple structure and fabrication process. We expect it to be widely used in user touch interfaces and wearable devices."

This research was supported by the Basic Research Program through the National Research Foundation of Korea funded by the Ministry of Science and ICT, and also supported by the Open Innovation Lab Cooperation Project funded by the National Nano Fab Center.

Figure 1. Schematic illustration of a transparent, flexible force touch sensor (upper image) and sensitivity enhancement by using stress concentration (lower image).

2018.10.15 View 6729

High-Performance Flexible Transparent Force Touch Sensor for Wearable Devices

Researchers reported a high-performance and transparent nanoforce touch sensor by developing a thin, flexible, and transparent hierarchical nanocomposite (HNC) film. The research team says their sensor simultaneously features all the necessary characters for industrial-grade application: high sensitivity, transparency, bending insensitivity, and manufacturability.

Force touch sensors that recognize the location and pressure of external stimuli have received considerable attention for various applications, such as wearable devices, flexible displays, and humanoid robots. For decades, huge amounts of research and development have been devoted to improving pressure sensitivity to realize industrial-grade sensing devices. However, it remains a challenge to apply force touch sensors in flexible applications because sensing performance is subject to change and degraded by induced mechanical stress and deformation when the device is bent.

To overcome these issues, the research team focused on the development of non-air gap sensors to break away from the conventional technology where force touch sensors need to have air-gaps between electrodes for high sensitivity and flexibility.

The proposed non air-gap force touch sensor is based on a transparent nanocomposite insulator containing metal nanoparticles which can maximize the capacitance change in dielectrics according to the pressure, and a nanograting substrate which can increase transparency as well as sensitivity by concentrating pressure. As a result, the team succeeded in fabricating a highly sensitive, transparent, flexible force touch sensor that is mechanically stable against repetitive pressure.

Furthermore, by placing the sensing electrodes on the same plane as the neutral plane, the force touch sensor can operate, even when bending to the radius of the ballpoint pen, without changes in performance levels.

The proposed force touch has also satisfied commercial considerations in mass production such as large-area uniformity, production reproducibility, and reliability according to temperature and long-term use.

Finally, the research team applied the developed sensor to a pulse-monitoring capable healthcare wearable device and detected a real-time human pulse. In addition, the research team confirmed with HiDeep, Inc. that a seven-inch large-area sensor can be integrated into a commercial smartphone.

The team of Professor Jun-Bo Yoon, PhD student Jae-Young Yoo, and Dr. Min-Ho Seo from the School of Electrical Engineering carried out this study that was featured as a back cover in Advanced Functional Materials Journal.

PhD student Jae-Young Yoo who led this research said, "We successfully developed an industrial-grade force touch sensor by using a simple structure and fabrication process. We expect it to be widely used in user touch interfaces and wearable devices."

This research was supported by the Basic Research Program through the National Research Foundation of Korea funded by the Ministry of Science and ICT, and also supported by the Open Innovation Lab Cooperation Project funded by the National Nano Fab Center.

Figure 1. Schematic illustration of a transparent, flexible force touch sensor (upper image) and sensitivity enhancement by using stress concentration (lower image).

2018.10.15 View 6729 -

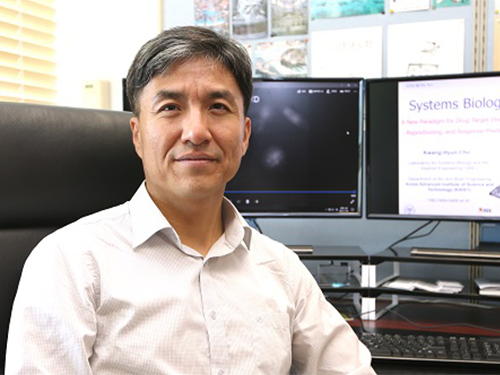

Trigger of the Hyperactivation of Fibrosis Identified

(Professor Kwang-Hyun Cho from the Department of Bio and Brain Engineering)

Scientists have been investigating the negative effects that the hyperactivation of fibrosis has on fibrotic diseases and cancer. A KAIST research team unveiled a positive feedback loop that bi-stably activates fibroblasts in collaboration with Samsung Medical Center. This finding will contribute to developing therapeutic targets for both fibrosis and cancer.

Human fibroblasts are dormant in normal tissue, but show radical activation during wound healing. However, the principle that induces their explosive activation has not yet been identified.

Here, Professor Kwang-Hyun Cho from the Department of Bio and Brain Engineering, in collaboration with Professor Seok-Hyung Kim from Samsung Medical Center, discovered the principle of a circuit that continuously activates fibroblasts.

They constructed a positive feedback loops (PFLs) where Twist1, Prrx1, and Tenascin-C (TNC) molecules consecutively activate fibroblasts. They confirmed that these are the main inducers of fibroblast activation by conducting various experiments, including molecular biological tests, mathematical modeling, animal testing, and computer simulations to conclude that they are the main inducers of fibroblast activation.

According to their research, Twist 1 is a key regulator of cancer-associated fibroblasts, which directly upregulates Prrx1 and then triggers TNC, which also increases Twist1 expression. This circuit consequently forms a Twist-Prrx1-TNC positive feedback loop.

Activated fibroblasts need to be deactivated after wounds are healed. However, if the PFLs continue, the fibroblasts become the major cause of worsening fibrotic diseases and cancers.

Therefore, the team expects that Twist1-Prrx1-TNC positive PFLs will be applied for novel and effective therapeutic targeting of fibrotic diseases and cancers.

This research was published in Nature Communications on August 1, 2018.

Figure 1. Twist1 increases tenascin-c expression in cancer-associated fibroblasts. Twist1 is a potent but indirect inducer of tenascin-c (TNC), which is essential for maintaining Twist1 expression in cancer-associated fibroblasts (CAFs).

Figure 2. Summary of the study. The Twist1-Prrx1-TNC positive feedback regulation provides clues for understanding the activation of fibroblasts during wound healing under normal conditions, as well as abnormally activated fibroblasts in pathological conditions such as cancerous and fibrotic diseases. Under normal conditions, the PFL acts as a reversible bistable switch by which the activation of fibroblasts is “ON" above a sufficient level of stimulation and “OFF" for the withdrawal of the stimulus. However, this switch can be permanently turned on under pathologic conditions by continued activation of the PFL, resulting in sustained proliferation of fibroblasts.

2018.10.11 View 6435

Trigger of the Hyperactivation of Fibrosis Identified

(Professor Kwang-Hyun Cho from the Department of Bio and Brain Engineering)

Scientists have been investigating the negative effects that the hyperactivation of fibrosis has on fibrotic diseases and cancer. A KAIST research team unveiled a positive feedback loop that bi-stably activates fibroblasts in collaboration with Samsung Medical Center. This finding will contribute to developing therapeutic targets for both fibrosis and cancer.

Human fibroblasts are dormant in normal tissue, but show radical activation during wound healing. However, the principle that induces their explosive activation has not yet been identified.

Here, Professor Kwang-Hyun Cho from the Department of Bio and Brain Engineering, in collaboration with Professor Seok-Hyung Kim from Samsung Medical Center, discovered the principle of a circuit that continuously activates fibroblasts.

They constructed a positive feedback loops (PFLs) where Twist1, Prrx1, and Tenascin-C (TNC) molecules consecutively activate fibroblasts. They confirmed that these are the main inducers of fibroblast activation by conducting various experiments, including molecular biological tests, mathematical modeling, animal testing, and computer simulations to conclude that they are the main inducers of fibroblast activation.

According to their research, Twist 1 is a key regulator of cancer-associated fibroblasts, which directly upregulates Prrx1 and then triggers TNC, which also increases Twist1 expression. This circuit consequently forms a Twist-Prrx1-TNC positive feedback loop.

Activated fibroblasts need to be deactivated after wounds are healed. However, if the PFLs continue, the fibroblasts become the major cause of worsening fibrotic diseases and cancers.

Therefore, the team expects that Twist1-Prrx1-TNC positive PFLs will be applied for novel and effective therapeutic targeting of fibrotic diseases and cancers.

This research was published in Nature Communications on August 1, 2018.

Figure 1. Twist1 increases tenascin-c expression in cancer-associated fibroblasts. Twist1 is a potent but indirect inducer of tenascin-c (TNC), which is essential for maintaining Twist1 expression in cancer-associated fibroblasts (CAFs).

Figure 2. Summary of the study. The Twist1-Prrx1-TNC positive feedback regulation provides clues for understanding the activation of fibroblasts during wound healing under normal conditions, as well as abnormally activated fibroblasts in pathological conditions such as cancerous and fibrotic diseases. Under normal conditions, the PFL acts as a reversible bistable switch by which the activation of fibroblasts is “ON" above a sufficient level of stimulation and “OFF" for the withdrawal of the stimulus. However, this switch can be permanently turned on under pathologic conditions by continued activation of the PFL, resulting in sustained proliferation of fibroblasts.

2018.10.11 View 6435 -

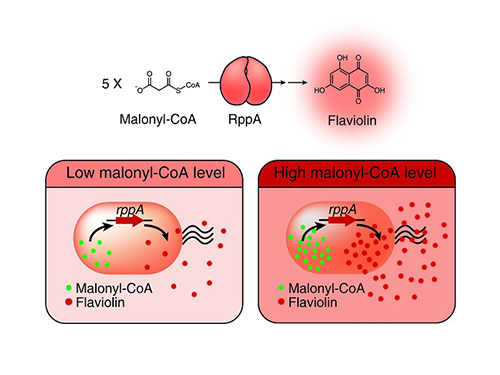

A Novel Biosensor to Advance Diverse High-Level Production of Microbial Cell Factories

A research group at KAIST presented a novel biosensor which can produce diverse, high-level microbial cell factories. The biosensor monitors the concentration of products and even intermediates when new strains are being developed. This strategy provides a new platform for manufacturing diverse natural products from renewable resources. The team succeeded in creating four natural products of high-level pharmaceutical importance with this strategy.

Malonyl-CoA is a major building block for many value-added chemicals including diverse natural products with pharmaceutical importance. However, due to the low availability of malonyl-CoA in bacteria, many malonyl-CoA-derived natural products have been produced by chemical synthesis or extraction from natural resources that are harmful to the environment and are unsustainable. For the sustainable biological production of malonyl-CoA-derived natural products, increasing the intracellular malonyl-CoA pool is necessary. To this end, the development of a robust and efficient malonyl-CoA biosensor was required to monitor the concentration of intracellular malonyl-CoA abundance as new strains are developed.

Metabolic engineering researchers at KAIST addressed this issue. This research reports the development of a simple and robust malonyl-CoA biosensor by repurposing a type III polyketide synthase (also known as RppA), which produces flaviolin, a colorimetric indicator of malonyl-CoA. Subsequently, the RppA biosensor was used for the rapid and efficient colorimetric screening of gene manipulation targets enabling enhanced malonyl-CoA abundance. The screened beneficial gene targets were employed for the high-level production of four representative natural products derived from malonyl-CoA. Compared with the previous strategies, which were expensive and time-consuming, the new biosensor could be easily applied to industrially relevant bacteria including Escherichia coli, Pseudomonas putida, and Corynebacterium glutamicum to enable a one-step process.

The study employs synthetic small regulatory RNA (sRNA) technology to rapidly and efficiently reduce endogenous target gene expression for improved malonyl-CoA production. The researchers constructed an E. coli genome-scale synthetic sRNA library targeting 1,858 genes covering all major metabolic genes in E. coli. This library was employed with the RppA biosensor to screen for gene targets which are believed to be beneficial for enhancing malonyl-CoA accumulation upon their expression knockdown.

From this colorimetric screening, 14 gene targets were selected, all of which were successful at significantly increasing the production of four natural products (6-methylsalicylic acid, aloesone, resveratrol, and naringenin). Although specific examples are demonstrated in E. coli as a host, the researchers showed that the biosensor is also functional in P. putida and C. glutamicum, industrially important representative gram-negative and gram-positive bacteria, respectively. The malonyl-CoA biosensor developed in this research will serve as an efficient platform for the rapid development of strains capable of producing natural products crucial for the pharmaceutical, chemical, cosmetics, and food industries.

An important aspect of this work is that the high-performance strains constructed in this research were developed rapidly and easily by utilizing the simple approach of colorimetric screening, without involving extensive metabolic engineering approaches. 6-Methylsalicylic acid (an antibiotic) could be produced to the highest titer reported for E. coli, and the microbial production of aloesone (a precursor of aloesin, an anti-inflammatory agent/whitening agent) was achieved for the first time.

“A sustainable process for producing diverse natural products using renewable resources is of great interest. This study represents the development of a robust and efficient malonyl-CoA biosensor generally applicable to a wide range of industrially important bacteria. The capability of this biosensor for screening a large library was demonstrated to show that the rapid and efficient construction of high-performance strains is feasible. This research will be useful for further accelerating the development process of strains capable of producing valuable chemicals to industrially relevant levels,” said Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering, who led the research.

This study entitled “Repurposing type III polyketide synthase as a malonyl-CoA biosensor for metabolic engineering in bacteria,” was published in the Proceedings of the National Academy of Sciences of the United States of America (PNAS) on October 02.

PhD students Dongsoo Yang and Won Jun Kim, MS student Shin Hee Ha, research staff Mun Hee Lee, Research Professor Seung Min Yoo, and Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering and Dr. Jong Hyun Choi of the Applied Microbiology Research Center at the Korea Research Institute of Bioscience and Biotechnology (KRIBB) participated in this research.

Figure: Type III polyketide synthase (RppA) as a malonyl-CoA biosensor. RppA converts five molecules of malonyl-CoA into one molecule of red-colored flaviolin. This schematic diagram shows the overall conceptualization of the malonyl-CoA biosensor by indicating that higher malonyl-CoA abundance leads to higher production and secretion of flaviolin, resulting in a deeper red color of the culture. This system was employed for the enhanced production of four representative natural products (6-methylsalicylic acid, aloesone, resveratrol, and naringenin) from engineered E. coli strains.

2018.10.11 View 9760

A Novel Biosensor to Advance Diverse High-Level Production of Microbial Cell Factories

A research group at KAIST presented a novel biosensor which can produce diverse, high-level microbial cell factories. The biosensor monitors the concentration of products and even intermediates when new strains are being developed. This strategy provides a new platform for manufacturing diverse natural products from renewable resources. The team succeeded in creating four natural products of high-level pharmaceutical importance with this strategy.

Malonyl-CoA is a major building block for many value-added chemicals including diverse natural products with pharmaceutical importance. However, due to the low availability of malonyl-CoA in bacteria, many malonyl-CoA-derived natural products have been produced by chemical synthesis or extraction from natural resources that are harmful to the environment and are unsustainable. For the sustainable biological production of malonyl-CoA-derived natural products, increasing the intracellular malonyl-CoA pool is necessary. To this end, the development of a robust and efficient malonyl-CoA biosensor was required to monitor the concentration of intracellular malonyl-CoA abundance as new strains are developed.

Metabolic engineering researchers at KAIST addressed this issue. This research reports the development of a simple and robust malonyl-CoA biosensor by repurposing a type III polyketide synthase (also known as RppA), which produces flaviolin, a colorimetric indicator of malonyl-CoA. Subsequently, the RppA biosensor was used for the rapid and efficient colorimetric screening of gene manipulation targets enabling enhanced malonyl-CoA abundance. The screened beneficial gene targets were employed for the high-level production of four representative natural products derived from malonyl-CoA. Compared with the previous strategies, which were expensive and time-consuming, the new biosensor could be easily applied to industrially relevant bacteria including Escherichia coli, Pseudomonas putida, and Corynebacterium glutamicum to enable a one-step process.

The study employs synthetic small regulatory RNA (sRNA) technology to rapidly and efficiently reduce endogenous target gene expression for improved malonyl-CoA production. The researchers constructed an E. coli genome-scale synthetic sRNA library targeting 1,858 genes covering all major metabolic genes in E. coli. This library was employed with the RppA biosensor to screen for gene targets which are believed to be beneficial for enhancing malonyl-CoA accumulation upon their expression knockdown.

From this colorimetric screening, 14 gene targets were selected, all of which were successful at significantly increasing the production of four natural products (6-methylsalicylic acid, aloesone, resveratrol, and naringenin). Although specific examples are demonstrated in E. coli as a host, the researchers showed that the biosensor is also functional in P. putida and C. glutamicum, industrially important representative gram-negative and gram-positive bacteria, respectively. The malonyl-CoA biosensor developed in this research will serve as an efficient platform for the rapid development of strains capable of producing natural products crucial for the pharmaceutical, chemical, cosmetics, and food industries.

An important aspect of this work is that the high-performance strains constructed in this research were developed rapidly and easily by utilizing the simple approach of colorimetric screening, without involving extensive metabolic engineering approaches. 6-Methylsalicylic acid (an antibiotic) could be produced to the highest titer reported for E. coli, and the microbial production of aloesone (a precursor of aloesin, an anti-inflammatory agent/whitening agent) was achieved for the first time.

“A sustainable process for producing diverse natural products using renewable resources is of great interest. This study represents the development of a robust and efficient malonyl-CoA biosensor generally applicable to a wide range of industrially important bacteria. The capability of this biosensor for screening a large library was demonstrated to show that the rapid and efficient construction of high-performance strains is feasible. This research will be useful for further accelerating the development process of strains capable of producing valuable chemicals to industrially relevant levels,” said Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering, who led the research.

This study entitled “Repurposing type III polyketide synthase as a malonyl-CoA biosensor for metabolic engineering in bacteria,” was published in the Proceedings of the National Academy of Sciences of the United States of America (PNAS) on October 02.

PhD students Dongsoo Yang and Won Jun Kim, MS student Shin Hee Ha, research staff Mun Hee Lee, Research Professor Seung Min Yoo, and Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering and Dr. Jong Hyun Choi of the Applied Microbiology Research Center at the Korea Research Institute of Bioscience and Biotechnology (KRIBB) participated in this research.

Figure: Type III polyketide synthase (RppA) as a malonyl-CoA biosensor. RppA converts five molecules of malonyl-CoA into one molecule of red-colored flaviolin. This schematic diagram shows the overall conceptualization of the malonyl-CoA biosensor by indicating that higher malonyl-CoA abundance leads to higher production and secretion of flaviolin, resulting in a deeper red color of the culture. This system was employed for the enhanced production of four representative natural products (6-methylsalicylic acid, aloesone, resveratrol, and naringenin) from engineered E. coli strains.

2018.10.11 View 9760 -

Permanent, Wireless Self-charging System Using NIR Band

(Professor Jung-Yong Lee from the Graduate School of Energy, Environment, Water and Sustainability)

As wearable devices are emerging, there are numerous studies on wireless charging systems. Here, a KAIST research team has developed a permanent, wireless self-charging platform for low-power wearable electronics by converting near-infrared (NIR) band irradiation to electrical energy. This novel technology can be applied to flexible, wearable charging systems without needing any attachments.

Colloidal-quantum-dots (CQDs) are promising materials for manufacturing semiconductors; in particular, PbS-based CQDs have facile optical tunability from the visible to infrared wavelength region. Hence, they can be applied to various devices, such as lighting, photovoltaics (PVs), and photodetectors.

Continuous research on CQD-based optoelectronic devices has increased their power conversion efficiency (PCE) to 12%; however, applicable fields have not yet been found for them. Meanwhile, wearable electronic devices commonly face the problem of inconvenient charging systems because users have to constantly charge batteries attached to an energy source.

A joint team led by Professor Jung-Yong Lee from the Graduate School of Energy, Environment, Water and Sustainability and Jang Wok Choi from Seoul National University decided to apply CQD PVs, which have high quantum efficiency in NIR band to self-charging systems on wearable devices.

They employed a stable and efficient NIR energy conversion strategy. The system was comprised of a PbS CQD-based PV module, a flexible interdigitated lithium-ion battery, and various types of NIR-transparent films.

The team removed the existing battery from the already commercialized wearable healthcare bracelet and replaced it with the proposed self-charging system. They confirmed that the system can be applied to a low power wearable device via the NIR band.

There have been numerous platforms using solar irradiation, but the newly developed platform has more advantages because it allows conventional devices to be much more comfortable to wear and charged easily in everyday life using various irradiation sources for constant charging.

With this aspect, the proposed platform facilitates more flexible designs, which are the important component for actual commercialization. It also secures higher photostability and efficient than existing structures.

Professor Lee said, “By using the NIR band, we proposed a new approach to solve charging system issues of wearable devices. I believe that this platform will be a novel platform for energy conversion and that its application can be further extended to various fields, including mobiles, IoTs, and drones.”

This research, led by PhD Se-Woong Baek and M.S. candidate Jungmin Cho, was published in Advanced Materials on May 11.

Figure 1. a) Conceptual NIR-driven self-charging system including a flexible CQD PVs module and an interdigitatedly structured LIB. b) Photographic images of a conventional wearable healthcare bracelet and a self-charging system-integrated wearable device.

Figure 2. Illustration of the CQD PVs structure and performance of the wireless self-charging platform.

2018.10.08 View 8359

Permanent, Wireless Self-charging System Using NIR Band

(Professor Jung-Yong Lee from the Graduate School of Energy, Environment, Water and Sustainability)

As wearable devices are emerging, there are numerous studies on wireless charging systems. Here, a KAIST research team has developed a permanent, wireless self-charging platform for low-power wearable electronics by converting near-infrared (NIR) band irradiation to electrical energy. This novel technology can be applied to flexible, wearable charging systems without needing any attachments.

Colloidal-quantum-dots (CQDs) are promising materials for manufacturing semiconductors; in particular, PbS-based CQDs have facile optical tunability from the visible to infrared wavelength region. Hence, they can be applied to various devices, such as lighting, photovoltaics (PVs), and photodetectors.

Continuous research on CQD-based optoelectronic devices has increased their power conversion efficiency (PCE) to 12%; however, applicable fields have not yet been found for them. Meanwhile, wearable electronic devices commonly face the problem of inconvenient charging systems because users have to constantly charge batteries attached to an energy source.

A joint team led by Professor Jung-Yong Lee from the Graduate School of Energy, Environment, Water and Sustainability and Jang Wok Choi from Seoul National University decided to apply CQD PVs, which have high quantum efficiency in NIR band to self-charging systems on wearable devices.

They employed a stable and efficient NIR energy conversion strategy. The system was comprised of a PbS CQD-based PV module, a flexible interdigitated lithium-ion battery, and various types of NIR-transparent films.

The team removed the existing battery from the already commercialized wearable healthcare bracelet and replaced it with the proposed self-charging system. They confirmed that the system can be applied to a low power wearable device via the NIR band.

There have been numerous platforms using solar irradiation, but the newly developed platform has more advantages because it allows conventional devices to be much more comfortable to wear and charged easily in everyday life using various irradiation sources for constant charging.

With this aspect, the proposed platform facilitates more flexible designs, which are the important component for actual commercialization. It also secures higher photostability and efficient than existing structures.

Professor Lee said, “By using the NIR band, we proposed a new approach to solve charging system issues of wearable devices. I believe that this platform will be a novel platform for energy conversion and that its application can be further extended to various fields, including mobiles, IoTs, and drones.”

This research, led by PhD Se-Woong Baek and M.S. candidate Jungmin Cho, was published in Advanced Materials on May 11.

Figure 1. a) Conceptual NIR-driven self-charging system including a flexible CQD PVs module and an interdigitatedly structured LIB. b) Photographic images of a conventional wearable healthcare bracelet and a self-charging system-integrated wearable device.

Figure 2. Illustration of the CQD PVs structure and performance of the wireless self-charging platform.

2018.10.08 View 8359 -

AI |QC ITRC Opens at KAIST

(from left: Dean of College of Engineering Jong-Hwan Kim, Director of AI│QC ITRC June-Koo Rhee, Vice President for R&DB Heekyung Park and Director General for Industrial Policy Hong Taek Yong)

Artificial Intelligence|The Quantum Computing Information Technology Research Center (AI|QC ITRC) opened at KAIST on October 2.

AI|QC ITRC, established with government funding, is the first institute specializing in quantum computing. Three universities (Seoul National University, Korea University, and Kyung Hee University), and four corporations, KT, Homomicus, Actusnetworks, and Mirae Tech are jointly participating in the center. Over four years, the institute will receive 3.2 billion KRW of research funds.

Last April, KAIST selected quantum technology as one of its flagship research areas. AI|QC ITRC will dedicate itself to developing quantum computing technology that provides the computability required for human-level artificial intelligence. It will also foster leaders in related industries by introducing industry-academic educational programs in graduate schools.

QC is receiving a great deal of attention for transcending current digital computers in terms of computability. World-class IT companies like IBM, Google, and Intel and ventures including D-Wave, Rigetti, and IonQ are currently leading the industry and investing heavily in securing source technologies.

Starting from the establishment of the ITRC, KAIST will continue to plan strategies to foster the field of QC. KAIST will carry out two-track strategies; one is to secure source technology of first-generation QC technology, and the other is to focus on basic research that can preoccupy next-generation QC technology.

Professor June-Koo Rhee, the director of AI│QC ITRC said, “I believe that QC will be the imperative technology that enables the realization of the Fourth Industrial Revolution. AIQC ITRC will foster experts required for domestic academia and industries and build a foundation to disseminate the technology to industries.”

Vice President for R&DB Heekyung Park, Director General for Industrial Policy Hong Taek Yong from the Ministry of Science and ICT, Seung Pyo Hong from the Institute for Information & communications Technology Promotion, Head of Technology Strategy Jinhyon Youn from KT, and participating companies attended and celebrated the opening of the AI│QC ITRC.

2018.10.05 View 6853

AI |QC ITRC Opens at KAIST

(from left: Dean of College of Engineering Jong-Hwan Kim, Director of AI│QC ITRC June-Koo Rhee, Vice President for R&DB Heekyung Park and Director General for Industrial Policy Hong Taek Yong)

Artificial Intelligence|The Quantum Computing Information Technology Research Center (AI|QC ITRC) opened at KAIST on October 2.

AI|QC ITRC, established with government funding, is the first institute specializing in quantum computing. Three universities (Seoul National University, Korea University, and Kyung Hee University), and four corporations, KT, Homomicus, Actusnetworks, and Mirae Tech are jointly participating in the center. Over four years, the institute will receive 3.2 billion KRW of research funds.

Last April, KAIST selected quantum technology as one of its flagship research areas. AI|QC ITRC will dedicate itself to developing quantum computing technology that provides the computability required for human-level artificial intelligence. It will also foster leaders in related industries by introducing industry-academic educational programs in graduate schools.

QC is receiving a great deal of attention for transcending current digital computers in terms of computability. World-class IT companies like IBM, Google, and Intel and ventures including D-Wave, Rigetti, and IonQ are currently leading the industry and investing heavily in securing source technologies.

Starting from the establishment of the ITRC, KAIST will continue to plan strategies to foster the field of QC. KAIST will carry out two-track strategies; one is to secure source technology of first-generation QC technology, and the other is to focus on basic research that can preoccupy next-generation QC technology.

Professor June-Koo Rhee, the director of AI│QC ITRC said, “I believe that QC will be the imperative technology that enables the realization of the Fourth Industrial Revolution. AIQC ITRC will foster experts required for domestic academia and industries and build a foundation to disseminate the technology to industries.”

Vice President for R&DB Heekyung Park, Director General for Industrial Policy Hong Taek Yong from the Ministry of Science and ICT, Seung Pyo Hong from the Institute for Information & communications Technology Promotion, Head of Technology Strategy Jinhyon Youn from KT, and participating companies attended and celebrated the opening of the AI│QC ITRC.

2018.10.05 View 6853 -

Scientist of October, Professor Haeshin Lee

(Professor Haeshin Lee from the Department of Chemistry)

Professor Haeshin Lee from the Department of Chemistry received the ‘Science and Technology Award of October’ from the Ministry of Science and ICT and the National Research Foundation of Korea for his contribution to developing an antibleeding injection needle. This novel outcome will fundamentally prevent the problem of secondary infections of AIDS, Ebola and Hepatitis viruses transmitting from patients to medical teams.

This needle’s surface is coated with hemostatic materials. Its concept is simple and the key to this technology is to make materials that are firmly coated on the needle so that they can endure frictional force when being injected into skin and blood vessels. Moreover, the materials should be adhesive to skin and the interior of blood vessels, but harmless to humans.

Professor Lee found a solution from natural polymer ingredients. Catecholamine can be found in mussels. Professor Lee conjugated catechol groups on the chitosan backbone. He applied this mussel-inspired adhesive polymer Chitosan-catechol, which immediately forms an adhesive layer with blood, as a bioadhesion for the antibleeding injection needle.

Professor Lee said, “Chitosan-catechol, which copies the adhesive mechanism of mussels, shows high solubility in physiological saline as well as great mucoadhesion. Hence, it is perfectly suitable for coating the injection needle. Combining it with proteins allows for efficient drug delivery to the heart, which is a challenging injection location, so it will be also useful for treating incurable heart disease.”

2018.10.05 View 10221

Scientist of October, Professor Haeshin Lee

(Professor Haeshin Lee from the Department of Chemistry)

Professor Haeshin Lee from the Department of Chemistry received the ‘Science and Technology Award of October’ from the Ministry of Science and ICT and the National Research Foundation of Korea for his contribution to developing an antibleeding injection needle. This novel outcome will fundamentally prevent the problem of secondary infections of AIDS, Ebola and Hepatitis viruses transmitting from patients to medical teams.

This needle’s surface is coated with hemostatic materials. Its concept is simple and the key to this technology is to make materials that are firmly coated on the needle so that they can endure frictional force when being injected into skin and blood vessels. Moreover, the materials should be adhesive to skin and the interior of blood vessels, but harmless to humans.

Professor Lee found a solution from natural polymer ingredients. Catecholamine can be found in mussels. Professor Lee conjugated catechol groups on the chitosan backbone. He applied this mussel-inspired adhesive polymer Chitosan-catechol, which immediately forms an adhesive layer with blood, as a bioadhesion for the antibleeding injection needle.

Professor Lee said, “Chitosan-catechol, which copies the adhesive mechanism of mussels, shows high solubility in physiological saline as well as great mucoadhesion. Hence, it is perfectly suitable for coating the injection needle. Combining it with proteins allows for efficient drug delivery to the heart, which is a challenging injection location, so it will be also useful for treating incurable heart disease.”

2018.10.05 View 10221 -

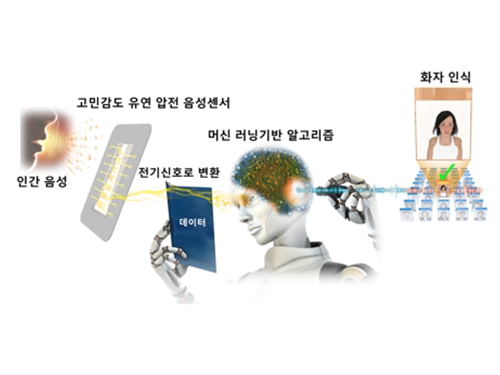

Flexible Piezoelectric Acoustic Sensors for Speaker Recognition

A KAIST research team led by Professor Keon Jae Lee from the Department of Material Science and Engineering has developed a machine learning-based acoustic sensor for speaker recognition.

Acoustic sensors were spotlighted as one of the most intuitive bilateral communication devices between humans and machines. However, conventional acoustic sensors use a condenser-type device for measuring capacitance between two conducting layers, resulting in low sensitivity, short recognition distance, and low speaker recognition rates.

The team fabricated a flexible piezoelectric membrane by mimicking the basilar membrane in the human cochlear. Resonant frequencies vibrate corresponding regions of the trapezoidal piezoelectric membrane, which converts voice to electrical signal with a highly sensitive self-powered acoustic sensor.

This multi-channel piezoelectric acoustic sensor exhibits sensitivity more than two times higher and allows for more abundant voice information compared to conventional acoustic sensors, which can detect minute sounds from farther distances. In addition, the acoustic sensor can achieve a 97.5% speaker recognition rate using a machine learning algorithm, reducing by 75% error rate than the reference microphone.

AI speaker recognition is the next big thing for future individual customized services. However, conventional technology attempts to improve recognition rates by using software upgrades, resulting in limited speaker recognition rates. The team enhanced the speaker recognition system by replacing the existing hardware with an innovative flexible piezoelectric acoustic sensor. Further software improvement of the piezoelectric acoustic sensor will significantly increase the speaker and voice recognition rate in diverse environments.

Professor Lee said, “Highly sensitive self-powered acoustic sensors for speaker recognition can be used for personalized voice services such as smart home appliances, AI secretaries, always-on IoT, biometric authentication, and FinTech.”

These research “Basilar Membrane-Inspired Self-Powered Acoustic Sensor” and “Machine Learning-based Acoustic Sensor for Speaker Recognition” were published in the September 2018 issue of Nano Energy.

Firgure 1: A flexible piezoelectric acoustic sensor mimicking the human cochlear.

Figure 2: Speaker recognition with a machine learning algorithm.

2018.10.04 View 7519

Flexible Piezoelectric Acoustic Sensors for Speaker Recognition

A KAIST research team led by Professor Keon Jae Lee from the Department of Material Science and Engineering has developed a machine learning-based acoustic sensor for speaker recognition.

Acoustic sensors were spotlighted as one of the most intuitive bilateral communication devices between humans and machines. However, conventional acoustic sensors use a condenser-type device for measuring capacitance between two conducting layers, resulting in low sensitivity, short recognition distance, and low speaker recognition rates.

The team fabricated a flexible piezoelectric membrane by mimicking the basilar membrane in the human cochlear. Resonant frequencies vibrate corresponding regions of the trapezoidal piezoelectric membrane, which converts voice to electrical signal with a highly sensitive self-powered acoustic sensor.

This multi-channel piezoelectric acoustic sensor exhibits sensitivity more than two times higher and allows for more abundant voice information compared to conventional acoustic sensors, which can detect minute sounds from farther distances. In addition, the acoustic sensor can achieve a 97.5% speaker recognition rate using a machine learning algorithm, reducing by 75% error rate than the reference microphone.

AI speaker recognition is the next big thing for future individual customized services. However, conventional technology attempts to improve recognition rates by using software upgrades, resulting in limited speaker recognition rates. The team enhanced the speaker recognition system by replacing the existing hardware with an innovative flexible piezoelectric acoustic sensor. Further software improvement of the piezoelectric acoustic sensor will significantly increase the speaker and voice recognition rate in diverse environments.

Professor Lee said, “Highly sensitive self-powered acoustic sensors for speaker recognition can be used for personalized voice services such as smart home appliances, AI secretaries, always-on IoT, biometric authentication, and FinTech.”

These research “Basilar Membrane-Inspired Self-Powered Acoustic Sensor” and “Machine Learning-based Acoustic Sensor for Speaker Recognition” were published in the September 2018 issue of Nano Energy.

Firgure 1: A flexible piezoelectric acoustic sensor mimicking the human cochlear.

Figure 2: Speaker recognition with a machine learning algorithm.

2018.10.04 View 7519 -

The 1st Korea Toray Science and Technology Awardee, Prof. Sukbok Chang

(Distinguished Professor Sukbok Chang from the Department of Chemistry)

The Korea Toray Science Foundation (KTSF) awarded the first Korea Toray Science Technology Award in basic science to Distinguished Professor Sukbok Chang from the Department of Chemistry on September 19.

KTSF was established in January 2018, and its award goes to researchers who have significantly contributed to the development of chemistry and materials research with funds to support research projects.

Distinguished Professor Chang has devoted himself in organocatalysis research; in particular, his work on catalysts for effective lactam formation, which was an intricate problem, received great attention.

The award ceremony will take place in The Federation of Korean Industries Hall on October 31. KTFS board members, judges, and the CEO of Toray Industries Akihiro Nikkaku will attend the ceremony. Also, Dr. Ryoji Noyori, the Nobel Laureate in Chemistry, will give a talk on the role of chemistry and creative challenges as a researcher.

2018.10.04 View 8558

The 1st Korea Toray Science and Technology Awardee, Prof. Sukbok Chang

(Distinguished Professor Sukbok Chang from the Department of Chemistry)

The Korea Toray Science Foundation (KTSF) awarded the first Korea Toray Science Technology Award in basic science to Distinguished Professor Sukbok Chang from the Department of Chemistry on September 19.

KTSF was established in January 2018, and its award goes to researchers who have significantly contributed to the development of chemistry and materials research with funds to support research projects.

Distinguished Professor Chang has devoted himself in organocatalysis research; in particular, his work on catalysts for effective lactam formation, which was an intricate problem, received great attention.

The award ceremony will take place in The Federation of Korean Industries Hall on October 31. KTFS board members, judges, and the CEO of Toray Industries Akihiro Nikkaku will attend the ceremony. Also, Dr. Ryoji Noyori, the Nobel Laureate in Chemistry, will give a talk on the role of chemistry and creative challenges as a researcher.

2018.10.04 View 8558 -

Spray Coated Tactile Sensor on a 3-D Surface for Robotic Skin

Robots will be able to conduct a wide variety of tasks as well as humans if they can be given tactile sensing capabilities.

A KAIST research team has reported a stretchable pressure insensitive strain sensor by using an all solution-based process. The solution-based process is easily scalable to accommodate for large areas and can be coated as a thin-film on 3-dimensional irregularly shaped objects via spray coating. These conditions make their processing technique unique and highly suitable for robotic electronic skin or wearable electronic applications.

The making of electronic skin to mimic the tactile sensing properties of human skin is an active area of research for various applications such as wearable electronics, robotics, and prosthetics. One of the major challenges in electronic skin research is differentiating various external stimuli, particularly between strain and pressure. Another issue is uniformly depositing electrical skin on 3-dimensional irregularly shaped objects.

To overcome these issues, the research team led by Professor Steve Park from the Department of Materials Science and Engineering and Professor Jung Kim from the Department of Mechanical Engineering developed electronic skin that can be uniformly coated on 3-dimensional surfaces and distinguish mechanical stimuli. The new electronic skin can also distinguish mechanical stimuli analogous to human skin. The structure of the electronic skin was designed to respond differently under applied pressure and strain. Under applied strain, conducting pathways undergo significant conformational changes, considerably changing the resistance. On the other hand, under applied pressure, negligible conformational change in the conducting pathway occurs; e-skin is therefore non-responsive to pressure. The research team is currently working on strain insensitive pressure sensors to use with the developed strain sensors.

The research team also spatially mapped the local strain without the use of patterned electrode arrays utilizing electrical impedance tomography (EIT). By using EIT, it is possible to minimize the number of electrodes, increase durability, and enable facile fabrication onto 3-dimensional surfaces.

Professor Park said, “Our electronic skin can be mass produced at a low cost and can easily be coated onto complex 3-dimensional surfaces. It is a key technology that can bring us closer to the commercialization of electronic skin for various applications in the near future.”

The result of this work entitled “Pressure Insensitive Strain Sensor with Facile Solution-based Process for Tactile Sensing Applications” was published in the August issue of ACS Nano as a cover article.

(Figure: Detecting mechanical stimuli using electrical impedance tomography.)

2018.09.21 View 8457

Spray Coated Tactile Sensor on a 3-D Surface for Robotic Skin

Robots will be able to conduct a wide variety of tasks as well as humans if they can be given tactile sensing capabilities.

A KAIST research team has reported a stretchable pressure insensitive strain sensor by using an all solution-based process. The solution-based process is easily scalable to accommodate for large areas and can be coated as a thin-film on 3-dimensional irregularly shaped objects via spray coating. These conditions make their processing technique unique and highly suitable for robotic electronic skin or wearable electronic applications.

The making of electronic skin to mimic the tactile sensing properties of human skin is an active area of research for various applications such as wearable electronics, robotics, and prosthetics. One of the major challenges in electronic skin research is differentiating various external stimuli, particularly between strain and pressure. Another issue is uniformly depositing electrical skin on 3-dimensional irregularly shaped objects.

To overcome these issues, the research team led by Professor Steve Park from the Department of Materials Science and Engineering and Professor Jung Kim from the Department of Mechanical Engineering developed electronic skin that can be uniformly coated on 3-dimensional surfaces and distinguish mechanical stimuli. The new electronic skin can also distinguish mechanical stimuli analogous to human skin. The structure of the electronic skin was designed to respond differently under applied pressure and strain. Under applied strain, conducting pathways undergo significant conformational changes, considerably changing the resistance. On the other hand, under applied pressure, negligible conformational change in the conducting pathway occurs; e-skin is therefore non-responsive to pressure. The research team is currently working on strain insensitive pressure sensors to use with the developed strain sensors.

The research team also spatially mapped the local strain without the use of patterned electrode arrays utilizing electrical impedance tomography (EIT). By using EIT, it is possible to minimize the number of electrodes, increase durability, and enable facile fabrication onto 3-dimensional surfaces.

Professor Park said, “Our electronic skin can be mass produced at a low cost and can easily be coated onto complex 3-dimensional surfaces. It is a key technology that can bring us closer to the commercialization of electronic skin for various applications in the near future.”

The result of this work entitled “Pressure Insensitive Strain Sensor with Facile Solution-based Process for Tactile Sensing Applications” was published in the August issue of ACS Nano as a cover article.

(Figure: Detecting mechanical stimuli using electrical impedance tomography.)

2018.09.21 View 8457