SMA

-

Book Announcement: Sound Visualization and Manipulation

The movie

Gravity

won seven Oscar awards this year, one of which was for its outstanding 3D sound mixing, immersing viewers in the full experience of the troubled space expedition.

3D audio effects are generated by manipulating the sound produced by speakers, speaker-arrays, or headphones to place a virtual sound source at a desired location in 3D space such as behind, above, or below the listener's head.

Two professors from the Department of Mechanical Engineering at KAIST have recently published a book that explains two important technologies related to 3D sound effects: sound visualization and manipulation.

Professor Yang-Hann Kim, an eminent scholar in sound engineering, and Professor Jung-Woo Choi collaborated to write Sound Visualization and Manipulation (Wily 2013), which uniquely addresses the two most important problems in the field in a unified way.

The book introduces general concepts and theories and describes a number of techniques in sound visualization and manipulation, offering an interrelated approach to two very different topics: sound field visualization techniques based on microphone arrays and controlled sound field generation techniques using loudspeaker arrays.

The authors also display a solid understanding of the associated physical and mathematical concepts applied to solve the visualization and manipulation problems and provide extensive examples demonstrating the benefits and drawbacks of various applications, including beamforming and acoustic holography technology.

The book will be an excellent reference for graduate students, researchers, and professionals in acoustic engineering, as well as in audio and noise control system development.

For detailed descriptions of the book:

http://as.wiley.com/WileyCDA/WileyTitle/productCd-1118368479.html

2014.03.10 View 15622

Book Announcement: Sound Visualization and Manipulation

The movie

Gravity

won seven Oscar awards this year, one of which was for its outstanding 3D sound mixing, immersing viewers in the full experience of the troubled space expedition.

3D audio effects are generated by manipulating the sound produced by speakers, speaker-arrays, or headphones to place a virtual sound source at a desired location in 3D space such as behind, above, or below the listener's head.

Two professors from the Department of Mechanical Engineering at KAIST have recently published a book that explains two important technologies related to 3D sound effects: sound visualization and manipulation.

Professor Yang-Hann Kim, an eminent scholar in sound engineering, and Professor Jung-Woo Choi collaborated to write Sound Visualization and Manipulation (Wily 2013), which uniquely addresses the two most important problems in the field in a unified way.

The book introduces general concepts and theories and describes a number of techniques in sound visualization and manipulation, offering an interrelated approach to two very different topics: sound field visualization techniques based on microphone arrays and controlled sound field generation techniques using loudspeaker arrays.

The authors also display a solid understanding of the associated physical and mathematical concepts applied to solve the visualization and manipulation problems and provide extensive examples demonstrating the benefits and drawbacks of various applications, including beamforming and acoustic holography technology.

The book will be an excellent reference for graduate students, researchers, and professionals in acoustic engineering, as well as in audio and noise control system development.

For detailed descriptions of the book:

http://as.wiley.com/WileyCDA/WileyTitle/productCd-1118368479.html

2014.03.10 View 15622 -

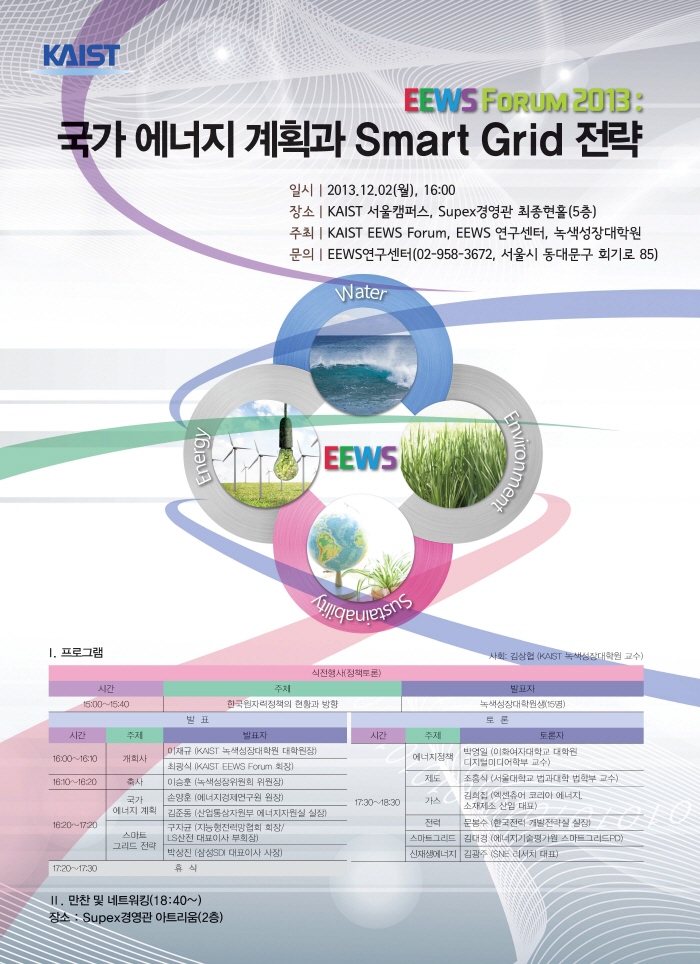

2013 EEWS Forum on National Energy Plan and Smart Grid Strategy

The Graduate School of Energy, Environment, Water, and Sustainability (EEWS) at KAIST hosted a forum on national energy planning and smart grid strategies on December 2 in the Jong-Hyun Choi Hall on KAIST’s Seoul campus. EEWS is a research and education program operated by KAIST to deal with the issues of energy, global warming, water, and sustainable growth.About 20 specialists including Jae-Kyu Lee, President of the Graduate School of Green Growth at KAIST; Kwang-Sik Choi, President of the EEWS Forum; Seong-Hoon Lee, Chairman of the Presidential Committee on Green Growth; Yang-Hoon Sohn, President of the Energy Economics Institute; and Jun-Dong Kim, Deputy Minister in the Ministry of Trade, Industry, and Energy, participated in the forum. Presentations and discussions were made in the fields of national energy plans, smart grid strategies, energy policy, as well as gas, electricity and sustainable energy.

2013.12.11 View 8902

2013 EEWS Forum on National Energy Plan and Smart Grid Strategy

The Graduate School of Energy, Environment, Water, and Sustainability (EEWS) at KAIST hosted a forum on national energy planning and smart grid strategies on December 2 in the Jong-Hyun Choi Hall on KAIST’s Seoul campus. EEWS is a research and education program operated by KAIST to deal with the issues of energy, global warming, water, and sustainable growth.About 20 specialists including Jae-Kyu Lee, President of the Graduate School of Green Growth at KAIST; Kwang-Sik Choi, President of the EEWS Forum; Seong-Hoon Lee, Chairman of the Presidential Committee on Green Growth; Yang-Hoon Sohn, President of the Energy Economics Institute; and Jun-Dong Kim, Deputy Minister in the Ministry of Trade, Industry, and Energy, participated in the forum. Presentations and discussions were made in the fields of national energy plans, smart grid strategies, energy policy, as well as gas, electricity and sustainable energy.

2013.12.11 View 8902 -

KAIST Takes Steps towards a Self-Sustainable Campus

KAIST has been selected for a $45-million national smart grid initiative organized under the Ministry of Trade, Industry and Energy. Ninteen institutions will participate in the 2-year-long initiative. The consortium’s work is expected to take place from 2015 to 2017 after a review by the Ministry of Strategy and Finance.

The Smart Grid Explansion Initiative which has been considered the future of electric power industry implements information and communications technology to conventional grid system to maximize energy efficiency. The ROK government has selected the Smart Grid Expansion Initiative as one of South Korea’s primary national projects and plans to implement it nationwide based on multiple demonstration projects in major cities including Jeju.

KAIST plans to invest $45 million in developing systems for renewable energy power plants, efficient energy management, smart grid data, and electric vehicles to build the energy self-sustainable campus. It also hopes to contribute to fostering specialized talents and companies in energy management.

Byoung-Yoon Kim, the vice-president for research at KAIST, expects that by 2017, KAIST will be able to dramatically improve its energy capacity especially during peak periods and gain energy efficiency around the campus. He hopes that the micro grid project at KAIST will set a new standard for the self-sustainable campus.

2013.12.11 View 10089

KAIST Takes Steps towards a Self-Sustainable Campus

KAIST has been selected for a $45-million national smart grid initiative organized under the Ministry of Trade, Industry and Energy. Ninteen institutions will participate in the 2-year-long initiative. The consortium’s work is expected to take place from 2015 to 2017 after a review by the Ministry of Strategy and Finance.

The Smart Grid Explansion Initiative which has been considered the future of electric power industry implements information and communications technology to conventional grid system to maximize energy efficiency. The ROK government has selected the Smart Grid Expansion Initiative as one of South Korea’s primary national projects and plans to implement it nationwide based on multiple demonstration projects in major cities including Jeju.

KAIST plans to invest $45 million in developing systems for renewable energy power plants, efficient energy management, smart grid data, and electric vehicles to build the energy self-sustainable campus. It also hopes to contribute to fostering specialized talents and companies in energy management.

Byoung-Yoon Kim, the vice-president for research at KAIST, expects that by 2017, KAIST will be able to dramatically improve its energy capacity especially during peak periods and gain energy efficiency around the campus. He hopes that the micro grid project at KAIST will set a new standard for the self-sustainable campus.

2013.12.11 View 10089 -

Wearable computer follows suit of smart phones

KAIST hosts “Wearable Computer Competition” in KI Building, Daejeon Campus, on the 7th-8th of November

“Computer that controls smart phones with the movement of facial muscles” and 12 other wearable computers to be presented

As technology transitions to “Wearable Computers,” KAIST is hosting its 9th “Wearable Computer Competition.” The competition will take place over two days, 7th-8th of November, in KI building, on the main Daejeon Campus.

The “wearable computer” is designed to enable users to use the computer whilst moving by limiting its weight and size so that it can be worn as a part of the body and clothing. Wearable computers have been considered the future of information technology (IT) ever since smart phones and other miniaturized IT devices made an appearance.

The “Wearable Computer Competition” has been held since 2005 under the leadership of Professor Hoi-Jun Yoo from the KAIST Department of Electrical Engineering. It is the only competition in the nation where undergraduate students use their unique ideas and newest technology to produce computers that seem to be existed only in sci-fi movies and comic books.

A total of 15 teams out of 70 made the competition and went through a rigorous selection process based on written applications and interviews to enter the final. The teams at the final received USD 1,400 and IT devices including smart phones to produce a wearable computer.

KAIST increased the number of finalists from the last year"s 10 to 15 this year as the wearable computer industry is extending, and there is growing interest in the computer around the world after the launch of Google Glass and Samsung Galaxy Gear.

This year’s entries included a product for quadriplegic patients to control smart phones with the movement of facial muscles, which attracted public interest. The product in the form of a headband can be worn by quadriplegic patients or someone with limited hand movement. The user can activate the product by clenching their molars and move the mouse on the smart phones with the movement of muscles in their face.

Furthermore, a wearable band shaped device that can control smart phones with simple hand movements is also attracting interest. Broad hand movements of the user allows him/her to receive calls and take photos, and handshakes between users control sharing of files. Body communication can be used to protect private information without a password or locking the device.

In addition, gloves and shoes that can sense the user’s movement to play an instrument without the instrument being present; a cane for the blind that converts visual information to tactile; a belt that protects children from sexual crimes; and a game where the user can be Super Mario to play and other practical products are presented.

The chairman of the competition, Professor Yoo said, “As you can see from the launch of Samsung Galaxy Gear, wearable computers will follow smart phones as the leader of IT devices in the next generation.” He continued, “This competition and workshop is an opportunity to increase public interest in wearable computers and serves as a communication platform for experts to view the present and the future of wearable computers.”

The “Wearable Computer Workshop” will be held this year as well. The workshop under the theme of “the present and the future of wearable computers” invited Professor Kyu-Ho Park, Vice President of KAIST, as a keynote speaker to talk on “ubiquitous, fashionable computers.” Moreover, Samsung’s Dong-Jun Geum and the Electronics and Telecommunications Research Institute’s Hyeon-Tae Jeong will lecture on the “trend and direction of progress of wearable devices” and the “technological trend and prospect of industry of wearable computers,” respectively.

To participate in the competition or the workshop, please visit the website (http://www.ufcom.org)

for further information.

2013.11.28 View 11391

Wearable computer follows suit of smart phones

KAIST hosts “Wearable Computer Competition” in KI Building, Daejeon Campus, on the 7th-8th of November

“Computer that controls smart phones with the movement of facial muscles” and 12 other wearable computers to be presented

As technology transitions to “Wearable Computers,” KAIST is hosting its 9th “Wearable Computer Competition.” The competition will take place over two days, 7th-8th of November, in KI building, on the main Daejeon Campus.

The “wearable computer” is designed to enable users to use the computer whilst moving by limiting its weight and size so that it can be worn as a part of the body and clothing. Wearable computers have been considered the future of information technology (IT) ever since smart phones and other miniaturized IT devices made an appearance.

The “Wearable Computer Competition” has been held since 2005 under the leadership of Professor Hoi-Jun Yoo from the KAIST Department of Electrical Engineering. It is the only competition in the nation where undergraduate students use their unique ideas and newest technology to produce computers that seem to be existed only in sci-fi movies and comic books.

A total of 15 teams out of 70 made the competition and went through a rigorous selection process based on written applications and interviews to enter the final. The teams at the final received USD 1,400 and IT devices including smart phones to produce a wearable computer.

KAIST increased the number of finalists from the last year"s 10 to 15 this year as the wearable computer industry is extending, and there is growing interest in the computer around the world after the launch of Google Glass and Samsung Galaxy Gear.

This year’s entries included a product for quadriplegic patients to control smart phones with the movement of facial muscles, which attracted public interest. The product in the form of a headband can be worn by quadriplegic patients or someone with limited hand movement. The user can activate the product by clenching their molars and move the mouse on the smart phones with the movement of muscles in their face.

Furthermore, a wearable band shaped device that can control smart phones with simple hand movements is also attracting interest. Broad hand movements of the user allows him/her to receive calls and take photos, and handshakes between users control sharing of files. Body communication can be used to protect private information without a password or locking the device.

In addition, gloves and shoes that can sense the user’s movement to play an instrument without the instrument being present; a cane for the blind that converts visual information to tactile; a belt that protects children from sexual crimes; and a game where the user can be Super Mario to play and other practical products are presented.

The chairman of the competition, Professor Yoo said, “As you can see from the launch of Samsung Galaxy Gear, wearable computers will follow smart phones as the leader of IT devices in the next generation.” He continued, “This competition and workshop is an opportunity to increase public interest in wearable computers and serves as a communication platform for experts to view the present and the future of wearable computers.”

The “Wearable Computer Workshop” will be held this year as well. The workshop under the theme of “the present and the future of wearable computers” invited Professor Kyu-Ho Park, Vice President of KAIST, as a keynote speaker to talk on “ubiquitous, fashionable computers.” Moreover, Samsung’s Dong-Jun Geum and the Electronics and Telecommunications Research Institute’s Hyeon-Tae Jeong will lecture on the “trend and direction of progress of wearable devices” and the “technological trend and prospect of industry of wearable computers,” respectively.

To participate in the competition or the workshop, please visit the website (http://www.ufcom.org)

for further information.

2013.11.28 View 11391 -

The World Economic Forum Invites KAIST to 2014 Davos Forum

President Steve Kang and Distinguished Professor Sang Yup Lee have been invited by the World Economic Forum (WEF) to attend its annual meeting slated for January 22-25, 2014 in Davos-Klosters, Switzerland.

The president will also join the Global University Leaders Forum (GULF) to be held during the annual meeting. The GULF consists of leading research universities throughout the world, at which President Kang will address agenda related to higher education and research.

From September 11th to 13th, KAIST was invited to the WEF’s 2013 Summer Davos Forum held in Dalian, China. The Summer Davos Forum is recognized as a barometer of the world economy, and KAIST hosted three sessions there.

In a session titled “Smart Regulations,” Professor Sang Yup Lee hosted presentations and discussions under the topic of “How regulation models can strengthen technical innovation and expansion.” President Steve Kang, Peter Sands, CEO of Standard Chartered Bank Group, Mark Weinberger, CEO of Ernest & Young, and Peter Terium, CEO of RWE, participated in the discussions.

The KAIST delegates also presented and participated in a session titled “From Trade Center to Innovative Hub” to discuss how to lead innovations in Asia, as well as “Marine Resources: Finding New Frontier” to address issues of how to develop and manage oceanic resources for potential growth.

President Kang said, “The World Economic Forum allows us to introduce the results of our innovative and creative research to global leaders and to demonstrate that our global position continues to grow.”

The WEF has been hosting Summer Davos Forum in China since 2007. About 1,500 participants from over 90 countries joined in this year’s summer forum under the theme of “Innovation: Inevitable Mainstream.” New strategies for innovations and solutions for global threats were suggested through presentations and discussions in 125 sessions.

The World Economic Forum (WEF) is an independent, international, and non-profit organization based in Geneva, Switzerland. It is committed to improving the state of the world by engaging business, political, academic, and government leaders to shape global, regional and industry agenda.

Among the meetings and forums organized by the WEF, its annual meeting held each January in Davos, a.k.a. the Davos Forum, has been the best known gathering. The Davos Forum brings together some 2,500 top business leaders, international political leaders, selected intellectuals and journalists to discuss the most pressing issues facing the world including health and environment.

2013.11.07 View 12519

The World Economic Forum Invites KAIST to 2014 Davos Forum

President Steve Kang and Distinguished Professor Sang Yup Lee have been invited by the World Economic Forum (WEF) to attend its annual meeting slated for January 22-25, 2014 in Davos-Klosters, Switzerland.

The president will also join the Global University Leaders Forum (GULF) to be held during the annual meeting. The GULF consists of leading research universities throughout the world, at which President Kang will address agenda related to higher education and research.

From September 11th to 13th, KAIST was invited to the WEF’s 2013 Summer Davos Forum held in Dalian, China. The Summer Davos Forum is recognized as a barometer of the world economy, and KAIST hosted three sessions there.

In a session titled “Smart Regulations,” Professor Sang Yup Lee hosted presentations and discussions under the topic of “How regulation models can strengthen technical innovation and expansion.” President Steve Kang, Peter Sands, CEO of Standard Chartered Bank Group, Mark Weinberger, CEO of Ernest & Young, and Peter Terium, CEO of RWE, participated in the discussions.

The KAIST delegates also presented and participated in a session titled “From Trade Center to Innovative Hub” to discuss how to lead innovations in Asia, as well as “Marine Resources: Finding New Frontier” to address issues of how to develop and manage oceanic resources for potential growth.

President Kang said, “The World Economic Forum allows us to introduce the results of our innovative and creative research to global leaders and to demonstrate that our global position continues to grow.”

The WEF has been hosting Summer Davos Forum in China since 2007. About 1,500 participants from over 90 countries joined in this year’s summer forum under the theme of “Innovation: Inevitable Mainstream.” New strategies for innovations and solutions for global threats were suggested through presentations and discussions in 125 sessions.

The World Economic Forum (WEF) is an independent, international, and non-profit organization based in Geneva, Switzerland. It is committed to improving the state of the world by engaging business, political, academic, and government leaders to shape global, regional and industry agenda.

Among the meetings and forums organized by the WEF, its annual meeting held each January in Davos, a.k.a. the Davos Forum, has been the best known gathering. The Davos Forum brings together some 2,500 top business leaders, international political leaders, selected intellectuals and journalists to discuss the most pressing issues facing the world including health and environment.

2013.11.07 View 12519 -

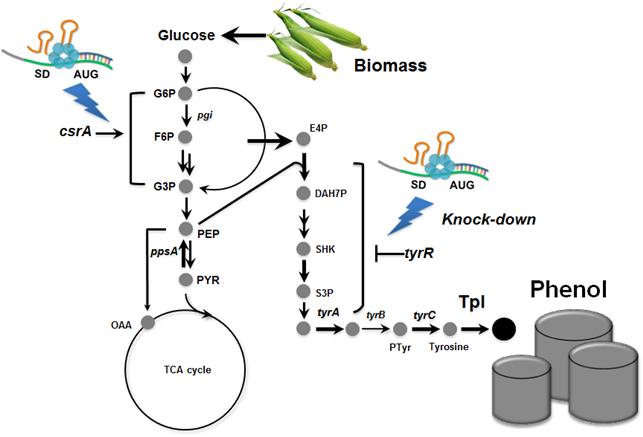

Metabolically engineered E. coli producing phenol

Many chemicals we use in everyday life are derived from fossil resources. Due to the increasing concerns on the use of fossil resources, there has been much interest in producing chemicals from renewable resources through biotechnology.

Phenol is an important commodity chemical, and is a starting material for the production of numerous industrial chemicals and polymers, including bisphenol A and phenolic resins, and others. At present, the production of phenol entirely depends on the chemical synthesis from benzene, and its annual production exceeds 8 million tons worldwide. Microbial production of phenol seems to be a non-viable process considering the high toxicity of phenol to the cell.

In the paper published online in Biotechnology Journal, a Korean research team led by Distinguished Professor Sang Yup Lee at the Department of Chemical and Biomolecular Engineering from the Korea Advanced Institute of Science and Technology (KAIST) reported the successful development of an engineered Escherichia coli (E. coli) strain which can produce phenol from glucose. E. coli has been a workhorse for biological production of various value-added compounds such as succinic acid and 1,4-butanediol in industrial scale. However, due to its low tolerance to phenol, E. coli was not considered a viable host strain for the biological production of phenol.

Professor Lee"s team, a leading research group in metabolic engineering, noted the genetic and physiological differences of various E. coli strains and investigated 18 different E. coli strains with respect to phenol tolerance and engineered all of the 18 strains simultaneously. If the traditional genetic engineering methods were used, this work would have taken years to do. To overcome this challenge, the research team used synthetic small RNA (sRNA) technology they recently developed (Nature Biotechnology, vol 31, pp 170-174, 2013). The sRNA technology allowed the team to screen 18 E. coli strains with respect to the phenol tolerance, and the activities of the metabolic pathway and enzyme involved in the production of phenol. The research team also metabolically engineered the E. coli strains to increase carbon flux toward phenol and finally generated an engineered E. coli strain which can produce phenol from glucose.

Furthermore, the team developed a biphasic extractive fermentation process to minimize the toxicity of phenol to E. coli cells. Glycerol tributyrate was found to have low toxicity to E. coli and allowed efficient extraction of phenol from the culture broth. Through the biphasic fed-batch fermentation using glycerol tributyrate as an in situ extractant, the final engineered E. coli strain produced phenol to the highest titer and productivity reported (3.8 g/L and 0.18 g/L/h, respectively). The strategy used for the strain development and the fermentation process will serve as a framework for metabolic engineering of microorganisms for the production of toxic chemicals from renewable resources.

This work was supported by the Intelligent Synthetic Biology Center through the Global Frontier Project (2011-0031963) of the Ministry of Science, ICT & Future Planning through the National Research Foundation of Korea.

Process of Phenol Production

2013.11.05 View 11537

Metabolically engineered E. coli producing phenol

Many chemicals we use in everyday life are derived from fossil resources. Due to the increasing concerns on the use of fossil resources, there has been much interest in producing chemicals from renewable resources through biotechnology.

Phenol is an important commodity chemical, and is a starting material for the production of numerous industrial chemicals and polymers, including bisphenol A and phenolic resins, and others. At present, the production of phenol entirely depends on the chemical synthesis from benzene, and its annual production exceeds 8 million tons worldwide. Microbial production of phenol seems to be a non-viable process considering the high toxicity of phenol to the cell.

In the paper published online in Biotechnology Journal, a Korean research team led by Distinguished Professor Sang Yup Lee at the Department of Chemical and Biomolecular Engineering from the Korea Advanced Institute of Science and Technology (KAIST) reported the successful development of an engineered Escherichia coli (E. coli) strain which can produce phenol from glucose. E. coli has been a workhorse for biological production of various value-added compounds such as succinic acid and 1,4-butanediol in industrial scale. However, due to its low tolerance to phenol, E. coli was not considered a viable host strain for the biological production of phenol.

Professor Lee"s team, a leading research group in metabolic engineering, noted the genetic and physiological differences of various E. coli strains and investigated 18 different E. coli strains with respect to phenol tolerance and engineered all of the 18 strains simultaneously. If the traditional genetic engineering methods were used, this work would have taken years to do. To overcome this challenge, the research team used synthetic small RNA (sRNA) technology they recently developed (Nature Biotechnology, vol 31, pp 170-174, 2013). The sRNA technology allowed the team to screen 18 E. coli strains with respect to the phenol tolerance, and the activities of the metabolic pathway and enzyme involved in the production of phenol. The research team also metabolically engineered the E. coli strains to increase carbon flux toward phenol and finally generated an engineered E. coli strain which can produce phenol from glucose.

Furthermore, the team developed a biphasic extractive fermentation process to minimize the toxicity of phenol to E. coli cells. Glycerol tributyrate was found to have low toxicity to E. coli and allowed efficient extraction of phenol from the culture broth. Through the biphasic fed-batch fermentation using glycerol tributyrate as an in situ extractant, the final engineered E. coli strain produced phenol to the highest titer and productivity reported (3.8 g/L and 0.18 g/L/h, respectively). The strategy used for the strain development and the fermentation process will serve as a framework for metabolic engineering of microorganisms for the production of toxic chemicals from renewable resources.

This work was supported by the Intelligent Synthetic Biology Center through the Global Frontier Project (2011-0031963) of the Ministry of Science, ICT & Future Planning through the National Research Foundation of Korea.

Process of Phenol Production

2013.11.05 View 11537 -

KAIST hosts 2013 Wearable Computer Contest

2013 Wearable Computer Contest (WCC) will be held in early November. This year’s contest is hosted by KAIST and sponsored by Samsung Electronics.

Wearable computers are drawing attention in the IT world as a potentially convenient information and communication device for future generations, which are attached to clothing or on the body. As smartphones have grown increasingly more popular, various supporting devices are being developed. The IT industry is targeting wearable computers for future development. The main leaders of the field, Samsung, Apple (i-Watch) and Google (Google Glasses) are joining the race for its development.

European and US firms halted their research in wearable computers in the 2000s, but there has been a great burst of interest recently. Korea has been consistently taking on wearable computer research since 2003 and held the Wearable Computer Contest for the last nine years. Since 2005, the contest aims to promote leading edge technological research and Intellectual Property (IP) as well as cultivate a professional workforce in Korea. The contest has promoted world class research in the field of wearable computer technology.

Moreover, KAIST has increased support for its competing teams through Samsung sponsorship and is considering applying the technology from the contest into Samsung products. Winning teams receive 1,500,000 Korean won and Samsung smart IT devices to produce an actual wearable computer. KAIST has increased the number of members who can participate in the competing teams in the finals from 10 to 15 to provide more opportunities to develop wearable computers.

With the theme “Smart IT: Any-information for Anybody,” the 2013 Wearable Computer Contest requires competing teams to suggest an innovative idea which combines IT and fashion for wearable computers. Teams that pass the paper and presentation evaluation go on to the finals, where 15 teams will have four months of production period for the final evaluation in November.

The final teams also receive systematic education on ubiquitous computing, wearable computer platforms, and Human-Computer Interaction (HCI).

The Wearable Computer Contest is holding an ideas contest pitched in a poster format. This contest evaluates proposals for wearable computers, and there is no requirement to enter the rest of the contest. Anyone can compete without having to physically make the product.

More information on the registration and the contest can be found at http://www.ufcom.org/.

2013.04.30 View 8517

KAIST hosts 2013 Wearable Computer Contest

2013 Wearable Computer Contest (WCC) will be held in early November. This year’s contest is hosted by KAIST and sponsored by Samsung Electronics.

Wearable computers are drawing attention in the IT world as a potentially convenient information and communication device for future generations, which are attached to clothing or on the body. As smartphones have grown increasingly more popular, various supporting devices are being developed. The IT industry is targeting wearable computers for future development. The main leaders of the field, Samsung, Apple (i-Watch) and Google (Google Glasses) are joining the race for its development.

European and US firms halted their research in wearable computers in the 2000s, but there has been a great burst of interest recently. Korea has been consistently taking on wearable computer research since 2003 and held the Wearable Computer Contest for the last nine years. Since 2005, the contest aims to promote leading edge technological research and Intellectual Property (IP) as well as cultivate a professional workforce in Korea. The contest has promoted world class research in the field of wearable computer technology.

Moreover, KAIST has increased support for its competing teams through Samsung sponsorship and is considering applying the technology from the contest into Samsung products. Winning teams receive 1,500,000 Korean won and Samsung smart IT devices to produce an actual wearable computer. KAIST has increased the number of members who can participate in the competing teams in the finals from 10 to 15 to provide more opportunities to develop wearable computers.

With the theme “Smart IT: Any-information for Anybody,” the 2013 Wearable Computer Contest requires competing teams to suggest an innovative idea which combines IT and fashion for wearable computers. Teams that pass the paper and presentation evaluation go on to the finals, where 15 teams will have four months of production period for the final evaluation in November.

The final teams also receive systematic education on ubiquitous computing, wearable computer platforms, and Human-Computer Interaction (HCI).

The Wearable Computer Contest is holding an ideas contest pitched in a poster format. This contest evaluates proposals for wearable computers, and there is no requirement to enter the rest of the contest. Anyone can compete without having to physically make the product.

More information on the registration and the contest can be found at http://www.ufcom.org/.

2013.04.30 View 8517 -

An efficient strategy for developing microbial cell factories by employing synthetic small regulatory RNAs

A new metabolic engineering tool that allows fine control of gene expression level by employing synthetic small regulatory RNAs was developed to efficiently construct microbial cell factories producing desired chemicals and materials

Biotechnologists have been working hard to address the climate change and limited fossil resource issues through the development of sustainable processes for the production of chemicals, fuels and materials from renewable non-food biomass. One promising sustainable technology is the use of microbial cell factories for the efficient production of desired chemicals and materials. When microorganisms are isolated from nature, the performance in producing our desired product is rather poor. That is why metabolic engineering is performed to improve the metabolic and cellular characteristics to achieve enhanced production of desired product at high yield and productivity. Since the performance of microbial cell factory is very important in lowering the overall production cost of the bioprocess, many different strategies and tools have been developed for the metabolic engineering of microorganisms.

One of the big challenges in metabolic engineering is to find the best platform organism and to find those genes to be engineered so as to maximize the production efficiency of the desired chemical. Even Escherichia coli, the most widely utilized simple microorganism, has thousands of genes, the expression of which is highly regulated and interconnected to finely control cellular and metabolic activities. Thus, the complexity of cellular genetic interactions is beyond our intuition and thus it is very difficult to find effective target genes to engineer. Together with gene amplification strategy, gene knockout strategy has been an essential tool in metabolic engineering to redirect the pathway fluxes toward our desired product formation. However, experiment to engineer many genes can be rather difficult due to the time and effort required; for example, gene deletion experiment can take a few weeks depending on the microorganisms. Furthermore, as certain genes are essential or play important roles for the survival of a microorganism, gene knockout experiments cannot be performed. Even worse, there are many different microbial strains one can employ. There are more than 50 different E. coli strains that metabolic engineer can consider to use. Since gene knockout experiment is hard-coded (that is, one should repeat the gene knockout experiments for each strain), the result cannot be easily transferred from one strain to another.

A paper published in Nature Biotechnology online today addresses this issue and suggests a new strategy for identifying gene targets to be knocked out or knocked down through the use of synthetic small RNA. A Korean research team led by Distinguished Professor Sang Yup Lee at the Department of Chemical and Biomolecular Engineering, Korea Advanced Institute of Science and Technology (KAIST), a prestigeous science and engineering university in Korea reported that synthetic small RNA can be employed for finely controlling the expression levels of multiple genes at the translation level. Already well-known for their systems metabolic engineering strategies, Professor Lee’s team added one more strategy to efficiently develop microbial cell factories for the production of chemicals and materials.

Gene expression works like this: the hard-coded blueprint (DNA) is transcribed into messenger RNA (mRNA), and the coding information in mRNA is read to produce protein by ribosomes. Conventional genetic engineering approaches have often targeted modification of the blueprint itself (DNA) to alter organism’s physiological characteristics. Again, engineering the blueprint itself takes much time and effort, and in addition, the results obtained cannot be transferred to another organism without repeating the whole set of experiments. This is why Professor Lee and his colleagues aimed at controlling the gene expression level at the translation stage through the use of synthetic small RNA. They created novel RNAs that can regulate the translation of multiple messenger RNAs (mRNA), and consequently varying the expression levels of multiple genes at the same time. Briefly, synthetic regulatory RNAs interrupt gene expression process from DNA to protein by destroying the messenger RNAs to different yet controllable extents. The advantages of taking this strategy of employing synthetic small regulatory RNAs include simple, easy and high-throughput identification of gene knockout or knockdown targets, fine control of gene expression levels, transferability to many different host strains, and possibility of identifying those gene targets that are essential.

As proof-of-concept demonstration of the usefulness of this strategy, Professor Lee and his colleagues applied it to develop engineered E. coli strains capable of producing an aromatic amino acid tyrosine, which is used for stress symptom relief, food supplements, and precursor for many drugs. They examined a large number of genes in multiple E. coli strains, and developed a highly efficient tyrosine producer. Also, they were able to show that this strategy can be employed to an already metabolically engineered E. coli strain for further improvement by demonstrating the development of highly efficient producer of cadaverine, an important platform chemical for nylon in the chemical industry.

This new strategy, being simple yet very powerful for systems metabolic engineering, is thus expected to facilitate the efficient development of microbial cell factories capable of producing chemicals, fuels and materials from renewable biomass.

Source: Dokyun Na, Seung Min Yoo, Hannah Chung, Hyegwon Park, Jin Hwan Park, and Sang Yup Lee, “Metabolic engineering of Escherichia coli using synthetic small regulatory RNAs”, Nature Biotechnology, doi:10.1038/nbt.2461 (2013)

2013.03.19 View 11437

An efficient strategy for developing microbial cell factories by employing synthetic small regulatory RNAs

A new metabolic engineering tool that allows fine control of gene expression level by employing synthetic small regulatory RNAs was developed to efficiently construct microbial cell factories producing desired chemicals and materials

Biotechnologists have been working hard to address the climate change and limited fossil resource issues through the development of sustainable processes for the production of chemicals, fuels and materials from renewable non-food biomass. One promising sustainable technology is the use of microbial cell factories for the efficient production of desired chemicals and materials. When microorganisms are isolated from nature, the performance in producing our desired product is rather poor. That is why metabolic engineering is performed to improve the metabolic and cellular characteristics to achieve enhanced production of desired product at high yield and productivity. Since the performance of microbial cell factory is very important in lowering the overall production cost of the bioprocess, many different strategies and tools have been developed for the metabolic engineering of microorganisms.

One of the big challenges in metabolic engineering is to find the best platform organism and to find those genes to be engineered so as to maximize the production efficiency of the desired chemical. Even Escherichia coli, the most widely utilized simple microorganism, has thousands of genes, the expression of which is highly regulated and interconnected to finely control cellular and metabolic activities. Thus, the complexity of cellular genetic interactions is beyond our intuition and thus it is very difficult to find effective target genes to engineer. Together with gene amplification strategy, gene knockout strategy has been an essential tool in metabolic engineering to redirect the pathway fluxes toward our desired product formation. However, experiment to engineer many genes can be rather difficult due to the time and effort required; for example, gene deletion experiment can take a few weeks depending on the microorganisms. Furthermore, as certain genes are essential or play important roles for the survival of a microorganism, gene knockout experiments cannot be performed. Even worse, there are many different microbial strains one can employ. There are more than 50 different E. coli strains that metabolic engineer can consider to use. Since gene knockout experiment is hard-coded (that is, one should repeat the gene knockout experiments for each strain), the result cannot be easily transferred from one strain to another.

A paper published in Nature Biotechnology online today addresses this issue and suggests a new strategy for identifying gene targets to be knocked out or knocked down through the use of synthetic small RNA. A Korean research team led by Distinguished Professor Sang Yup Lee at the Department of Chemical and Biomolecular Engineering, Korea Advanced Institute of Science and Technology (KAIST), a prestigeous science and engineering university in Korea reported that synthetic small RNA can be employed for finely controlling the expression levels of multiple genes at the translation level. Already well-known for their systems metabolic engineering strategies, Professor Lee’s team added one more strategy to efficiently develop microbial cell factories for the production of chemicals and materials.

Gene expression works like this: the hard-coded blueprint (DNA) is transcribed into messenger RNA (mRNA), and the coding information in mRNA is read to produce protein by ribosomes. Conventional genetic engineering approaches have often targeted modification of the blueprint itself (DNA) to alter organism’s physiological characteristics. Again, engineering the blueprint itself takes much time and effort, and in addition, the results obtained cannot be transferred to another organism without repeating the whole set of experiments. This is why Professor Lee and his colleagues aimed at controlling the gene expression level at the translation stage through the use of synthetic small RNA. They created novel RNAs that can regulate the translation of multiple messenger RNAs (mRNA), and consequently varying the expression levels of multiple genes at the same time. Briefly, synthetic regulatory RNAs interrupt gene expression process from DNA to protein by destroying the messenger RNAs to different yet controllable extents. The advantages of taking this strategy of employing synthetic small regulatory RNAs include simple, easy and high-throughput identification of gene knockout or knockdown targets, fine control of gene expression levels, transferability to many different host strains, and possibility of identifying those gene targets that are essential.

As proof-of-concept demonstration of the usefulness of this strategy, Professor Lee and his colleagues applied it to develop engineered E. coli strains capable of producing an aromatic amino acid tyrosine, which is used for stress symptom relief, food supplements, and precursor for many drugs. They examined a large number of genes in multiple E. coli strains, and developed a highly efficient tyrosine producer. Also, they were able to show that this strategy can be employed to an already metabolically engineered E. coli strain for further improvement by demonstrating the development of highly efficient producer of cadaverine, an important platform chemical for nylon in the chemical industry.

This new strategy, being simple yet very powerful for systems metabolic engineering, is thus expected to facilitate the efficient development of microbial cell factories capable of producing chemicals, fuels and materials from renewable biomass.

Source: Dokyun Na, Seung Min Yoo, Hannah Chung, Hyegwon Park, Jin Hwan Park, and Sang Yup Lee, “Metabolic engineering of Escherichia coli using synthetic small regulatory RNAs”, Nature Biotechnology, doi:10.1038/nbt.2461 (2013)

2013.03.19 View 11437 -

New BioFactory Technique Developed using sRNAs

Professor Sang Yup Lee

- published on the online edition of Nature Biotechnology. “Expected as a new strategy for the bio industry that may replace the chemical industry.”-

KAIST Chemical & Biomolecular engineering department’s Professor Sang Yup Lee and his team has developed a new technology that utilizes the synthetic small regulatory RNAs (sRNAs) to implement the BioFactory in a larger scale with more effectiveness.

* BioFactory: Microbial-based production system which creates the desired compound in mass by manipulating the genes of the cell.

In order to solve the problems of modern society, such as environmental pollution caused by the exhaustion of fossil fuels and usage of petrochemical products, an eco-friendly and sustainable bio industry is on the rise. BioFactory development technology has especially attracted the attention world-wide, with its ability to produce bio-energy, pharmaceuticals, eco-friendly materials and more.

For the development of an excellent BioFactory, selection for the gene that produces the desired compounds must be accompanied by finding the microorganism with high production efficiency; however, the previous research method had a complicated and time-consuming problem of having to manipulate the genes of the microorganism one by one.

Professor Sang Yup Lee’s research team, including Dr. Dokyun Na and Dr. Seung Min Yoo, has produced the synthetic sRNAs and utilized it to overcome the technical limitations mentioned above.

In particular, unlike the existing method, this technology using synthetic sRNAs exhibits no strain specificity which can dramatically shorten the experiment that used to take months to just a few days.

The research team applied the synthetic small regulatory RNA technology to the production of the tyrosine*, which is used as the precursor of the medicinal compound, and cadaverine**, widely utilized in a variety of petrochemical products, and has succeeded developing BioFactory with the world’s highest yield rate (21.9g /L, 12.6g / L each).

*tyrosine: amino acid known to control stress and improve concentration

**cadaverine: base material used in many petrochemical products, such as polyurethane

Professor Sang Yup Lee highlighted the significance of this research: “it is expected the synthetic small regulatory RNA technology will stimulate the BioFactory development and also serve as a catalyst which can make the chemical industry, currently represented by its petroleum energy, transform into bio industry.”

The study was carried out with the support of Global Frontier Project (Intelligent Bio-Systems Design and Synthesis Research Unit (Chief Seon Chang Kim)) and the findings have been published on January 20th in the online edition of the worldwide journal Nature Biotechnology.

2013.02.21 View 13207

New BioFactory Technique Developed using sRNAs

Professor Sang Yup Lee

- published on the online edition of Nature Biotechnology. “Expected as a new strategy for the bio industry that may replace the chemical industry.”-

KAIST Chemical & Biomolecular engineering department’s Professor Sang Yup Lee and his team has developed a new technology that utilizes the synthetic small regulatory RNAs (sRNAs) to implement the BioFactory in a larger scale with more effectiveness.

* BioFactory: Microbial-based production system which creates the desired compound in mass by manipulating the genes of the cell.

In order to solve the problems of modern society, such as environmental pollution caused by the exhaustion of fossil fuels and usage of petrochemical products, an eco-friendly and sustainable bio industry is on the rise. BioFactory development technology has especially attracted the attention world-wide, with its ability to produce bio-energy, pharmaceuticals, eco-friendly materials and more.

For the development of an excellent BioFactory, selection for the gene that produces the desired compounds must be accompanied by finding the microorganism with high production efficiency; however, the previous research method had a complicated and time-consuming problem of having to manipulate the genes of the microorganism one by one.

Professor Sang Yup Lee’s research team, including Dr. Dokyun Na and Dr. Seung Min Yoo, has produced the synthetic sRNAs and utilized it to overcome the technical limitations mentioned above.

In particular, unlike the existing method, this technology using synthetic sRNAs exhibits no strain specificity which can dramatically shorten the experiment that used to take months to just a few days.

The research team applied the synthetic small regulatory RNA technology to the production of the tyrosine*, which is used as the precursor of the medicinal compound, and cadaverine**, widely utilized in a variety of petrochemical products, and has succeeded developing BioFactory with the world’s highest yield rate (21.9g /L, 12.6g / L each).

*tyrosine: amino acid known to control stress and improve concentration

**cadaverine: base material used in many petrochemical products, such as polyurethane

Professor Sang Yup Lee highlighted the significance of this research: “it is expected the synthetic small regulatory RNA technology will stimulate the BioFactory development and also serve as a catalyst which can make the chemical industry, currently represented by its petroleum energy, transform into bio industry.”

The study was carried out with the support of Global Frontier Project (Intelligent Bio-Systems Design and Synthesis Research Unit (Chief Seon Chang Kim)) and the findings have been published on January 20th in the online edition of the worldwide journal Nature Biotechnology.

2013.02.21 View 13207 -

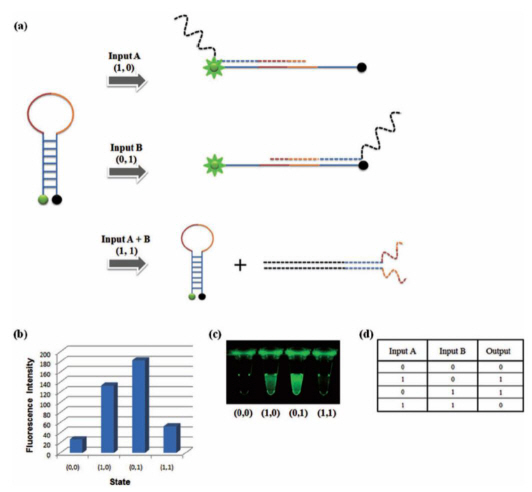

DNA based semiconductor technology developed

Professor Park Hyun Gyu’s research team from the Department of Chemical and Biomolecular Engineering at KAIST has successfully implemented all logic gates using DNA, a feat that led the research to be published as the cover paper for the international nanotechnology paper "Small".

Even with the latest technology, it was impossible to create a silicon based semiconductor smaller than 10nm, but because DNA has a thickness of only 2nm, this could lead to the creation of semiconductors with groundbreaking degrees of integration.

A 2 nm semiconductor will be able to store 10,000 HD movies within a size of a postage stamp, at least 100 times more than the current 20nm semiconductors.

DNAs are comprised of 4 bases which are continually connected: Adenine (A) with Thymine (T), and Guanine (G) with Cytosine (C).

For this research, the team used the specific binding properties of DNA, which forms its helix-shape, and a circular molecular beacon that has fluorescent signaling properties under structural changes.

The research team used input signals to open and close the circular DNA, the same principle that is applied to logic gates in digital circuits.

The output signal was measured using the increase and decrease of the fluorescent signal from the molecular beacon due to the opening and closing of the circular DNA respectively.

The team overcame the limited system problems of the existing logic gates and managed to implement all 8 logic gates (AND, OR, XOR, INHIBIT, NAND, NOR, XNOR, IMPlCATION). A multilevel circuit that connects different logic gates was also tested to show its regenerative properties.

Professor Park said that “cheap bio-electric devices with high degrees of integration will be made possible by this research” and that “there will be a large difference in the field of molecular level electronic research”

Mr. Park Gi Su, a doctoral candidate and the 1st author of this research, said that “a DNA sequence of 10 bases is only 3.4nm long and 2nm thick, which can be used to effectively increase the degree of integration of electronic devices” and that “a bio computer could materialize in the near future through DNA semiconductors with accurate logic gates”.

XOR Gate: The output signal 1 comes through the open circular DNA when either input DNA A or input DNA B is present. When both inputs are not present, the flourescent signal does not come through

2012.09.27 View 11109

DNA based semiconductor technology developed

Professor Park Hyun Gyu’s research team from the Department of Chemical and Biomolecular Engineering at KAIST has successfully implemented all logic gates using DNA, a feat that led the research to be published as the cover paper for the international nanotechnology paper "Small".

Even with the latest technology, it was impossible to create a silicon based semiconductor smaller than 10nm, but because DNA has a thickness of only 2nm, this could lead to the creation of semiconductors with groundbreaking degrees of integration.

A 2 nm semiconductor will be able to store 10,000 HD movies within a size of a postage stamp, at least 100 times more than the current 20nm semiconductors.

DNAs are comprised of 4 bases which are continually connected: Adenine (A) with Thymine (T), and Guanine (G) with Cytosine (C).

For this research, the team used the specific binding properties of DNA, which forms its helix-shape, and a circular molecular beacon that has fluorescent signaling properties under structural changes.

The research team used input signals to open and close the circular DNA, the same principle that is applied to logic gates in digital circuits.

The output signal was measured using the increase and decrease of the fluorescent signal from the molecular beacon due to the opening and closing of the circular DNA respectively.

The team overcame the limited system problems of the existing logic gates and managed to implement all 8 logic gates (AND, OR, XOR, INHIBIT, NAND, NOR, XNOR, IMPlCATION). A multilevel circuit that connects different logic gates was also tested to show its regenerative properties.

Professor Park said that “cheap bio-electric devices with high degrees of integration will be made possible by this research” and that “there will be a large difference in the field of molecular level electronic research”

Mr. Park Gi Su, a doctoral candidate and the 1st author of this research, said that “a DNA sequence of 10 bases is only 3.4nm long and 2nm thick, which can be used to effectively increase the degree of integration of electronic devices” and that “a bio computer could materialize in the near future through DNA semiconductors with accurate logic gates”.

XOR Gate: The output signal 1 comes through the open circular DNA when either input DNA A or input DNA B is present. When both inputs are not present, the flourescent signal does not come through

2012.09.27 View 11109 -

KAIST to Support R&D Plans of Mid-Small Sized Enterprises

KAIST signed a MOU for the ‘Support for R&D Plans for Mid-Small Sized Firms’ with the Small and Medium Business Conference and Korea South-East Power Co. Ltd.

KAIST and Korea South-East Power Co. Ltd. will now be improving their cooperation on supporting R&D plans to help the technology development and commercialization for Small and Medium Businesses.

Korea South-East Power Co. Ltd. will now select 20 best qualified firms out of its 300 cooperating firms and suggest them as candidates to KAIST Business membership System.

The suggested firms will be given: ▲Strategy R&D Planning ▲Consult Difficult Technology ▲Provide Information on Research Labs and Researchers among other various programs.

The firms participating in the KAIST Business membership System will be able to minimize risk and increase its possibility for success on Development Technology.

KAIST Business membership System is a program provided to firms for a membership fee, in order to create technological innovation and strengthen cooperation between university and industry.

2012.01.31 View 10058

KAIST to Support R&D Plans of Mid-Small Sized Enterprises

KAIST signed a MOU for the ‘Support for R&D Plans for Mid-Small Sized Firms’ with the Small and Medium Business Conference and Korea South-East Power Co. Ltd.

KAIST and Korea South-East Power Co. Ltd. will now be improving their cooperation on supporting R&D plans to help the technology development and commercialization for Small and Medium Businesses.

Korea South-East Power Co. Ltd. will now select 20 best qualified firms out of its 300 cooperating firms and suggest them as candidates to KAIST Business membership System.

The suggested firms will be given: ▲Strategy R&D Planning ▲Consult Difficult Technology ▲Provide Information on Research Labs and Researchers among other various programs.

The firms participating in the KAIST Business membership System will be able to minimize risk and increase its possibility for success on Development Technology.

KAIST Business membership System is a program provided to firms for a membership fee, in order to create technological innovation and strengthen cooperation between university and industry.

2012.01.31 View 10058 -

Ten Breakthroughs of the Year 2011 by Science

Porous Zeolite Crytals

Science, an internationally renowned scientific journal based in the US, has recently released a special issue of “Breakthrough of the Year, 2011,” dated December 23, 2011. In the issue, the journal introduces ten most important research breakthroughs made this year, and Professor Ryong Ryoo, Department of Chemistry at KAIST, was one of the scientists behind such notable advancements in 2011. Professor Ryoo has been highly regarded internationally for his research on the development of synthetic version of zeolites, a family of porous minerals that is widely used for products such as laundry detergents, cat litters, etc. Below is the article from Science, stating the zeolite research:

For Science’s “Breakthrough of the Year, 2011”, please go to:

http://www.sciencemag.org/site/special/btoy2011/

[Excerpt from the December 23, 2011 Issue of Science]

Industrial Molecules, Tailor-Made

If you ever doubt that chemistry is still a creative endeavor, just look at zeolites. This family of porous minerals was first discovered in 1756. They"re formed from different arrangements of aluminum, silicon, and oxygen atoms that crystallize into holey structures pocked with a perfect arrangement of pores. Over the past 250 years, 40 natural zeolites have been discovered, and chemists have chipped in roughly 150 more synthetic versions.

View larger version:

In this page

In a new window

Assembly required.

Porous zeolite crystals are widely used as filters and catalysts. This year, researchers found new ways to tailor the size of their pores and create thinner, cheaper membranes.

CREDIT: K. VAROON ET AL., SCIENCE334, 6052 (7 OCTOBER 2001)

This abundance isn"t just for show. Three million tons of zeolites are produced every year for use in laundry detergents, cat litter, and many other products. But zeolites really strut their stuff in two uses: as catalysts and molecular sieves. Oil refineries use zeolite catalysts to break down long hydrocarbon chains in oil into the shorter, volatile hydrocarbons in gasoline. And the minerals" small, regularly arranged pores make them ideal filters for purifying everything from the air on spaceships to the contaminated water around the nuclear reactors destroyed earlier this year in Fukushima, Japan.

Zeolites have their limitations, though. Their pores are almost universally tiny, making it tough to use them as catalysts for large molecules. And they"re difficult to form into ultrathin membranes, which researchers would like to do to enable cheaper separations. But progress by numerous teams on zeolite synthesis this year gave this “mature” area of chemistry new life.

Researchers in South Korea crafted a family of zeolites in which the usual network of small pores is surrounded by walls holed with larger voids. That combination of large and small pores should lead to catalysts for numerous large organic molecules.

Labs in Spain and China produced related large- and small-pore zeolites by using a combination of inorganic and organic materials to guide the structures as they formed.

Meanwhile, researchers in France and Germany discovered that, by carefully controlling growth conditions, they could form a large-pore zeolite without the need for the expensive organic compounds typically used to guide their architecture as they grow. The advance opens the way for cheaper catalysts. In yet another lab, researchers in Minnesota came up with a new route for making ultrathin zeolite membranes, which are likely to be useful as a wide variety of chemically selective filters.

This surge of molecular wizardry provides a vivid reminder that the creativity of chemists keeps their field ever young.

Related References and Web Sites

2011.12.23 View 13671

Ten Breakthroughs of the Year 2011 by Science

Porous Zeolite Crytals

Science, an internationally renowned scientific journal based in the US, has recently released a special issue of “Breakthrough of the Year, 2011,” dated December 23, 2011. In the issue, the journal introduces ten most important research breakthroughs made this year, and Professor Ryong Ryoo, Department of Chemistry at KAIST, was one of the scientists behind such notable advancements in 2011. Professor Ryoo has been highly regarded internationally for his research on the development of synthetic version of zeolites, a family of porous minerals that is widely used for products such as laundry detergents, cat litters, etc. Below is the article from Science, stating the zeolite research:

For Science’s “Breakthrough of the Year, 2011”, please go to:

http://www.sciencemag.org/site/special/btoy2011/

[Excerpt from the December 23, 2011 Issue of Science]

Industrial Molecules, Tailor-Made

If you ever doubt that chemistry is still a creative endeavor, just look at zeolites. This family of porous minerals was first discovered in 1756. They"re formed from different arrangements of aluminum, silicon, and oxygen atoms that crystallize into holey structures pocked with a perfect arrangement of pores. Over the past 250 years, 40 natural zeolites have been discovered, and chemists have chipped in roughly 150 more synthetic versions.

View larger version:

In this page

In a new window

Assembly required.

Porous zeolite crystals are widely used as filters and catalysts. This year, researchers found new ways to tailor the size of their pores and create thinner, cheaper membranes.

CREDIT: K. VAROON ET AL., SCIENCE334, 6052 (7 OCTOBER 2001)

This abundance isn"t just for show. Three million tons of zeolites are produced every year for use in laundry detergents, cat litter, and many other products. But zeolites really strut their stuff in two uses: as catalysts and molecular sieves. Oil refineries use zeolite catalysts to break down long hydrocarbon chains in oil into the shorter, volatile hydrocarbons in gasoline. And the minerals" small, regularly arranged pores make them ideal filters for purifying everything from the air on spaceships to the contaminated water around the nuclear reactors destroyed earlier this year in Fukushima, Japan.

Zeolites have their limitations, though. Their pores are almost universally tiny, making it tough to use them as catalysts for large molecules. And they"re difficult to form into ultrathin membranes, which researchers would like to do to enable cheaper separations. But progress by numerous teams on zeolite synthesis this year gave this “mature” area of chemistry new life.

Researchers in South Korea crafted a family of zeolites in which the usual network of small pores is surrounded by walls holed with larger voids. That combination of large and small pores should lead to catalysts for numerous large organic molecules.

Labs in Spain and China produced related large- and small-pore zeolites by using a combination of inorganic and organic materials to guide the structures as they formed.

Meanwhile, researchers in France and Germany discovered that, by carefully controlling growth conditions, they could form a large-pore zeolite without the need for the expensive organic compounds typically used to guide their architecture as they grow. The advance opens the way for cheaper catalysts. In yet another lab, researchers in Minnesota came up with a new route for making ultrathin zeolite membranes, which are likely to be useful as a wide variety of chemically selective filters.

This surge of molecular wizardry provides a vivid reminder that the creativity of chemists keeps their field ever young.

Related References and Web Sites

2011.12.23 View 13671