AT

-

Professor Byong-Guk Park Named Scientist of October

< Professor Byong-Guk Park >

Professor Byong-Guk Park from the Department of Materials Science and Engineering was selected as the ‘Scientist of the Month’ for October 2019 by the Ministry of Science and ICT and the National Research Foundation of Korea. Professor Park was recognized for his contributions to the advancement of spin-orbit torque (SOT)-based magnetic random access memory (MRAM) technology. He received 10 million KRW in prize money.

A next-generation, non-volatile memory device MRAM consists of thin magnetic films. It can be applied in “logic-in-memory” devices, in which logic and memory functionalities coexist, thus drastically improving the performance of complementary metal-oxide semiconductor (CMOS) processors. Conventional MRAM technology is limited in its ability to increase the operation speed of a memory device while maintaining a high density.

Professor Park tackled this challenge by introducing a new material, antiferromagnet (IrMn), that generates a sizable amount of SOT as well as an exchange-bias field, which makes successful data writing possible without an external magnetic field. This research outcome paved the way for the development of MRAM, which has a simple device structure but features high speeds and density.

Professor Park said, “I feel rewarded to have forwarded the feasibility and applicability of MRAM. I will continue devoting myself to studying further on the development of new materials that can help enhance the performance of memory devices."

(END)

2019.10.10 View 11783

Professor Byong-Guk Park Named Scientist of October

< Professor Byong-Guk Park >

Professor Byong-Guk Park from the Department of Materials Science and Engineering was selected as the ‘Scientist of the Month’ for October 2019 by the Ministry of Science and ICT and the National Research Foundation of Korea. Professor Park was recognized for his contributions to the advancement of spin-orbit torque (SOT)-based magnetic random access memory (MRAM) technology. He received 10 million KRW in prize money.

A next-generation, non-volatile memory device MRAM consists of thin magnetic films. It can be applied in “logic-in-memory” devices, in which logic and memory functionalities coexist, thus drastically improving the performance of complementary metal-oxide semiconductor (CMOS) processors. Conventional MRAM technology is limited in its ability to increase the operation speed of a memory device while maintaining a high density.

Professor Park tackled this challenge by introducing a new material, antiferromagnet (IrMn), that generates a sizable amount of SOT as well as an exchange-bias field, which makes successful data writing possible without an external magnetic field. This research outcome paved the way for the development of MRAM, which has a simple device structure but features high speeds and density.

Professor Park said, “I feel rewarded to have forwarded the feasibility and applicability of MRAM. I will continue devoting myself to studying further on the development of new materials that can help enhance the performance of memory devices."

(END)

2019.10.10 View 11783 -

Object Identification and Interaction with a Smartphone Knock

(Professor Lee (far right) demonstrate 'Knocker' with his students.)

A KAIST team has featured a new technology, “Knocker”, which identifies objects and executes actions just by knocking on it with the smartphone. Software powered by machine learning of sounds, vibrations, and other reactions will perform the users’ directions.

What separates Knocker from existing technology is the sensor fusion of sound and motion. Previously, object identification used either computer vision technology with cameras or hardware such as RFID (Radio Frequency Identification) tags. These solutions all have their limitations. For computer vision technology, users need to take pictures of every item. Even worse, the technology will not work well in poor lighting situations. Using hardware leads to additional costs and labor burdens.

Knocker, on the other hand, can identify objects even in dark environments only with a smartphone, without requiring any specialized hardware or using a camera. Knocker utilizes the smartphone’s built-in sensors such as a microphone, an accelerometer, and a gyroscope to capture a unique set of responses generated when a smartphone is knocked against an object. Machine learning is used to analyze these responses and classify and identify objects.

The research team under Professor Sung-Ju Lee from the School of Computing confirmed the applicability of Knocker technology using 23 everyday objects such as books, laptop computers, water bottles, and bicycles. In noisy environments such as a busy café or on the side of a road, it achieved 83% identification accuracy. In a quiet indoor environment, the accuracy rose to 98%.

The team believes Knocker will open a new paradigm of object interaction. For instance, by knocking on an empty water bottle, a smartphone can automatically order new water bottles from a merchant app. When integrated with IoT devices, knocking on a bed’s headboard before going to sleep could turn off the lights and set an alarm. The team suggested and implemented 15 application cases in the paper, presented during the 2019 ACM International Joint Conference on Pervasive and Ubiquitous Computing (UbiComp 2019) held in London last month.

Professor Sung-Ju Lee said, “This new technology does not require any specialized sensor or hardware. It simply uses the built-in sensors on smartphones and takes advantage of the power of machine learning. It’s a software solution that everyday smartphone users could immediately benefit from.” He continued, “This technology enables users to conveniently interact with their favorite objects.”

The research was supported in part by the Next-Generation Information Computing Development Program through the National Research Foundation of Korea funded by the Ministry of Science and ICT and an Institute for Information & Communications Technology Promotion (IITP) grant funded by the Ministry of Science and ICT.

Figure: An example knock on a bottle. Knocker identifies the object by analyzing a unique set of responses from the knock, and automatically launches a proper application or service.

2019.10.02 View 30167

Object Identification and Interaction with a Smartphone Knock

(Professor Lee (far right) demonstrate 'Knocker' with his students.)

A KAIST team has featured a new technology, “Knocker”, which identifies objects and executes actions just by knocking on it with the smartphone. Software powered by machine learning of sounds, vibrations, and other reactions will perform the users’ directions.

What separates Knocker from existing technology is the sensor fusion of sound and motion. Previously, object identification used either computer vision technology with cameras or hardware such as RFID (Radio Frequency Identification) tags. These solutions all have their limitations. For computer vision technology, users need to take pictures of every item. Even worse, the technology will not work well in poor lighting situations. Using hardware leads to additional costs and labor burdens.

Knocker, on the other hand, can identify objects even in dark environments only with a smartphone, without requiring any specialized hardware or using a camera. Knocker utilizes the smartphone’s built-in sensors such as a microphone, an accelerometer, and a gyroscope to capture a unique set of responses generated when a smartphone is knocked against an object. Machine learning is used to analyze these responses and classify and identify objects.

The research team under Professor Sung-Ju Lee from the School of Computing confirmed the applicability of Knocker technology using 23 everyday objects such as books, laptop computers, water bottles, and bicycles. In noisy environments such as a busy café or on the side of a road, it achieved 83% identification accuracy. In a quiet indoor environment, the accuracy rose to 98%.

The team believes Knocker will open a new paradigm of object interaction. For instance, by knocking on an empty water bottle, a smartphone can automatically order new water bottles from a merchant app. When integrated with IoT devices, knocking on a bed’s headboard before going to sleep could turn off the lights and set an alarm. The team suggested and implemented 15 application cases in the paper, presented during the 2019 ACM International Joint Conference on Pervasive and Ubiquitous Computing (UbiComp 2019) held in London last month.

Professor Sung-Ju Lee said, “This new technology does not require any specialized sensor or hardware. It simply uses the built-in sensors on smartphones and takes advantage of the power of machine learning. It’s a software solution that everyday smartphone users could immediately benefit from.” He continued, “This technology enables users to conveniently interact with their favorite objects.”

The research was supported in part by the Next-Generation Information Computing Development Program through the National Research Foundation of Korea funded by the Ministry of Science and ICT and an Institute for Information & Communications Technology Promotion (IITP) grant funded by the Ministry of Science and ICT.

Figure: An example knock on a bottle. Knocker identifies the object by analyzing a unique set of responses from the knock, and automatically launches a proper application or service.

2019.10.02 View 30167 -

Professor Hyun Gyu Park Appointed as Associate Editor for Biosensors and Bioelectronics

Professor Hyun Gyu Park from the Department of Chemical and Biomolecular Engineering was appointed as an associate editor for Biosensors and Bioelectronics, an international journal published by Elsevier.

Biosensors and Bioelectronics is one of the top SCI journals in the fields of chemistry and analytical science (IF 9.518 as of 2018). Professor Park was recognized and appointed as the associate editor for this journal due to his outstanding research achievements in the fields of nucleic acid engineering, biosensors, and nanobiotechnology.

Professor Park will serve as the associate editor from this October until December 2021.

(END)

2019.10.01 View 8846

Professor Hyun Gyu Park Appointed as Associate Editor for Biosensors and Bioelectronics

Professor Hyun Gyu Park from the Department of Chemical and Biomolecular Engineering was appointed as an associate editor for Biosensors and Bioelectronics, an international journal published by Elsevier.

Biosensors and Bioelectronics is one of the top SCI journals in the fields of chemistry and analytical science (IF 9.518 as of 2018). Professor Park was recognized and appointed as the associate editor for this journal due to his outstanding research achievements in the fields of nucleic acid engineering, biosensors, and nanobiotechnology.

Professor Park will serve as the associate editor from this October until December 2021.

(END)

2019.10.01 View 8846 -

Professor Ki-Jun Yoon selected as the 2019 SUHF Young Investigator

< Professor Ki-Jun Yoon >

Professor Ki-Jun Yoon from the Department of Biological Sciences was named one of four recipients of the 2019 Suh Kyung-Bae Science Foundation (SUHF) Young Investigator Awards.

The SUHF is a non-profit organization established in 2016 and funded by a personal donation of 300 billion KRW in shares from Chairman and CEO Kyung-Bae Suh of the Amorepacific Group. The primary purpose of the foundation is to serve as a platform to nurture and provide comprehensive long-term support for creative and passionate young Korean scientists committed to pursuing research in the field of life sciences. The SUHF selects three to five scientists through an open recruiting process every year, and grants each scientist a maximum of 2.5 billion KRW over a period of up to five years.

Since January this year, the foundation received 83 research proposals from scientists across the nation, especially from those who had less than five years of experience as professors, and selected the four recipients, including Professor Yoon.

Professor Yoon was recognized for his contributions to the advancement of research on how post-transcriptional mechanisms may modulate stem cell properties. His research project involves deciphering the molecular mechanisms controlling RNA metabolism in neural stem cells during normal development, and how alterations in RNA regulatory programs lead to human brain disorders.

< (From left) Professor Joo-Hong Park, Professor Yuree Lee, Chairman and CEO Kyung-Bae Suh, Professor Eunjung Lee, Professor Ki-Jun Yoon, ⓒ Amorepacific Group >

The other awards were given to Professor Joo-Hong Park and Professor Yuree Lee of Seoul National University, and Professor Eunjung Lee of Boston Children's Hospital and Harvard Medical School.

The awards ceremony was held on September 18 at the Amorepacific Headquarters in Seoul.

With these four new awardees, a total of 14 scientists have been named as SUHF Young Investigators to date.

(END)

2019.09.23 View 10375

Professor Ki-Jun Yoon selected as the 2019 SUHF Young Investigator

< Professor Ki-Jun Yoon >

Professor Ki-Jun Yoon from the Department of Biological Sciences was named one of four recipients of the 2019 Suh Kyung-Bae Science Foundation (SUHF) Young Investigator Awards.

The SUHF is a non-profit organization established in 2016 and funded by a personal donation of 300 billion KRW in shares from Chairman and CEO Kyung-Bae Suh of the Amorepacific Group. The primary purpose of the foundation is to serve as a platform to nurture and provide comprehensive long-term support for creative and passionate young Korean scientists committed to pursuing research in the field of life sciences. The SUHF selects three to five scientists through an open recruiting process every year, and grants each scientist a maximum of 2.5 billion KRW over a period of up to five years.

Since January this year, the foundation received 83 research proposals from scientists across the nation, especially from those who had less than five years of experience as professors, and selected the four recipients, including Professor Yoon.

Professor Yoon was recognized for his contributions to the advancement of research on how post-transcriptional mechanisms may modulate stem cell properties. His research project involves deciphering the molecular mechanisms controlling RNA metabolism in neural stem cells during normal development, and how alterations in RNA regulatory programs lead to human brain disorders.

< (From left) Professor Joo-Hong Park, Professor Yuree Lee, Chairman and CEO Kyung-Bae Suh, Professor Eunjung Lee, Professor Ki-Jun Yoon, ⓒ Amorepacific Group >

The other awards were given to Professor Joo-Hong Park and Professor Yuree Lee of Seoul National University, and Professor Eunjung Lee of Boston Children's Hospital and Harvard Medical School.

The awards ceremony was held on September 18 at the Amorepacific Headquarters in Seoul.

With these four new awardees, a total of 14 scientists have been named as SUHF Young Investigators to date.

(END)

2019.09.23 View 10375 -

KAIST to Transfer Core Tech to Domestic Companies amid Japan's Export Curbs

< Associate Vice President Kyung-Cheol Choi of the Office of University-Industry Cooperation (OUIC) at KAIST >

KAIST will transfer four core technologies related to materials, parts, and equipment to domestic companies to help them combat the latest export curbs triggered by Korea’s removal from Japan’s ‘white list’ of preferential trade partners. In addition, KAIST’s five patented technologies in the field of artificial intelligence (AI) and materials and parts will also be transferred to the companies in order to reduce the reliance on Japan and achieve technological independence through the ‘localization’ of key technologies.

KAIST announced these university-industry cooperation promotion plans at the ‘2019 KAIST Core Tech Transfer Day Conference’ held in Seoul on September 17. More than 200 entrepreneurs and investors attended the briefing and on-site consulting sessions delivered by nine KAIST professors who led the development of the technologies.

The four technologies were presented at the conference as those that can replace Japanese technologies subject to the export curbs. They include:

1. ‘Transparent fluorinated polyimide with low thermal expansion’ developed by Professor Sang-Youl Kim of the Department of Chemistry

2. ‘A non-destructive electromagnetic performance testing system’ developed by Professor Jung-Ryul Lee of the Department of Aerospace Engineering

3. ‘A nanotechnology-based electrode material for use in advanced secondary batteries’ developed by Professor Do-Kyung Kim of the Department of Materials Science and Engineering

4. ‘A high-resolution photoresist’ developed by Professor Emeritus Jin-Baek Kim of the Department of Chemistry.

Of particular interest is the non-destructive electromagnetic performance testing system technology developed by Professor Jung-Ryul Lee. This new cost-effective technology enables tests that were impossible to carry out using conventional technologies and yields a cost reduction of more than 50 percent compared to foreign technologies.

By introducing Professor Do-Kyung Kim’s new electrode material technology, the efficiency of electric vehicles can be increased. As this technology uses relatively low-cost sodium ion batteries, industries can prepare for the possible jump from the more expensive lithium batteries currently being used.

Another five patented AI and materials and parts technologies disclosed at the conference include:

1. ‘Enhanced HTTP adaptive streaming with CNN-based super-resolution’ developed by Professor Dong-soo Han of the School of Electrical Engineering

2. ‘Method and apparatus of brain-computer interface design for estimating choice behavior and decision strategy’ developed by Professor Sang-Wan Lee of the Department of Bio and Brain Engineering

3. ‘Eco-friendly fabrication of metal oxide nanoparticles and fabrication of non-toxic polymer sunscreen ingredients by electron irradiation’ developed by Professor Sung-Oh Cho of the Department of Nuclear and Quantum Engineering

4. ‘High-density nanofiber yarn-based coloricmetric gas sensors’ developed by Professor Il-Doo Kim of the Department of Materials Science and Engineering

5. ‘Silicon-pocket energy storage electrode with high energy density and its manufacturing technology’ developed by Professor Jeung-Ku Kang of the Graduate school of EEWS.

The patented nanofiber-based coloricmetric gas sensor technology developed by Professor Il-Doo Kim allows for the diagnosis of diseases by only using the patient’s respiration. Due to its high productivity and processability, it is expected to be applied to various fields in the fast-growing disease diagnosis sensor market, which includes mobile devices and wearable sensors.

Moreover, Professor Dong-soo Han’s patented adaptive streaming technology attracted attention along with the ever-growing Over The Top (OTT) and Video On Demand (VOD) service markets, since it has significant potential for improving the streaming quality of videos and reducing costs for video providers.

Professor Kyung-Cheol Choi, the Associate Vice President of the Office of University-Industry Cooperation (OUIC) at KAIST, said, “KAIST OUIC and KAIST Advisors on Materials and Parts (KAMP) have been working tirelessly to help Korean companies cope with the recent Japanese export restrictions. KAIST’s efforts will enhance the competitiveness and growth of the Korean industry and economy, turning this national crisis into opportunity.”

(END)

2019.09.20 View 7950

KAIST to Transfer Core Tech to Domestic Companies amid Japan's Export Curbs

< Associate Vice President Kyung-Cheol Choi of the Office of University-Industry Cooperation (OUIC) at KAIST >

KAIST will transfer four core technologies related to materials, parts, and equipment to domestic companies to help them combat the latest export curbs triggered by Korea’s removal from Japan’s ‘white list’ of preferential trade partners. In addition, KAIST’s five patented technologies in the field of artificial intelligence (AI) and materials and parts will also be transferred to the companies in order to reduce the reliance on Japan and achieve technological independence through the ‘localization’ of key technologies.

KAIST announced these university-industry cooperation promotion plans at the ‘2019 KAIST Core Tech Transfer Day Conference’ held in Seoul on September 17. More than 200 entrepreneurs and investors attended the briefing and on-site consulting sessions delivered by nine KAIST professors who led the development of the technologies.

The four technologies were presented at the conference as those that can replace Japanese technologies subject to the export curbs. They include:

1. ‘Transparent fluorinated polyimide with low thermal expansion’ developed by Professor Sang-Youl Kim of the Department of Chemistry

2. ‘A non-destructive electromagnetic performance testing system’ developed by Professor Jung-Ryul Lee of the Department of Aerospace Engineering

3. ‘A nanotechnology-based electrode material for use in advanced secondary batteries’ developed by Professor Do-Kyung Kim of the Department of Materials Science and Engineering

4. ‘A high-resolution photoresist’ developed by Professor Emeritus Jin-Baek Kim of the Department of Chemistry.

Of particular interest is the non-destructive electromagnetic performance testing system technology developed by Professor Jung-Ryul Lee. This new cost-effective technology enables tests that were impossible to carry out using conventional technologies and yields a cost reduction of more than 50 percent compared to foreign technologies.

By introducing Professor Do-Kyung Kim’s new electrode material technology, the efficiency of electric vehicles can be increased. As this technology uses relatively low-cost sodium ion batteries, industries can prepare for the possible jump from the more expensive lithium batteries currently being used.

Another five patented AI and materials and parts technologies disclosed at the conference include:

1. ‘Enhanced HTTP adaptive streaming with CNN-based super-resolution’ developed by Professor Dong-soo Han of the School of Electrical Engineering

2. ‘Method and apparatus of brain-computer interface design for estimating choice behavior and decision strategy’ developed by Professor Sang-Wan Lee of the Department of Bio and Brain Engineering

3. ‘Eco-friendly fabrication of metal oxide nanoparticles and fabrication of non-toxic polymer sunscreen ingredients by electron irradiation’ developed by Professor Sung-Oh Cho of the Department of Nuclear and Quantum Engineering

4. ‘High-density nanofiber yarn-based coloricmetric gas sensors’ developed by Professor Il-Doo Kim of the Department of Materials Science and Engineering

5. ‘Silicon-pocket energy storage electrode with high energy density and its manufacturing technology’ developed by Professor Jeung-Ku Kang of the Graduate school of EEWS.

The patented nanofiber-based coloricmetric gas sensor technology developed by Professor Il-Doo Kim allows for the diagnosis of diseases by only using the patient’s respiration. Due to its high productivity and processability, it is expected to be applied to various fields in the fast-growing disease diagnosis sensor market, which includes mobile devices and wearable sensors.

Moreover, Professor Dong-soo Han’s patented adaptive streaming technology attracted attention along with the ever-growing Over The Top (OTT) and Video On Demand (VOD) service markets, since it has significant potential for improving the streaming quality of videos and reducing costs for video providers.

Professor Kyung-Cheol Choi, the Associate Vice President of the Office of University-Industry Cooperation (OUIC) at KAIST, said, “KAIST OUIC and KAIST Advisors on Materials and Parts (KAMP) have been working tirelessly to help Korean companies cope with the recent Japanese export restrictions. KAIST’s efforts will enhance the competitiveness and growth of the Korean industry and economy, turning this national crisis into opportunity.”

(END)

2019.09.20 View 7950 -

Sungjoon Park Named Google PhD Fellow

PhD candidate Sungjoon Park from the School of Computing was named a 2019 Google PhD Fellow in the field of natural language processing. The Google PhD fellowship program has recognized and supported outstanding graduate students in computer science and related fields since 2009. Park is one of three Korean students chosen as the recipients of Google Fellowships this year. A total of 54 students across the world in 12 fields were awarded this fellowship.

Park’s research on computational psychotherapy using natural language processing (NLP) powered by machine learning earned him this year’s fellowship. He presented of learning distributed representations in Korean and their interpretations during the 2017 Annual Conference of the Association for Computational Linguistics and the 2018 Conference on Empirical Methods in Natural Language Processing. He also applied machine learning-based natural language processing into computational psychotherapy so that a trained machine learning model could categorize client's verbal responses in a counseling dialogue. This was presented at the Annual Conference of the North American Chapter of the Association for Computational Linguistics.

More recently, he has been developing on neural response generation model and the prediction and extraction of complex emotion in text, and computational psychotherapy applications.

2019.09.17 View 10515

Sungjoon Park Named Google PhD Fellow

PhD candidate Sungjoon Park from the School of Computing was named a 2019 Google PhD Fellow in the field of natural language processing. The Google PhD fellowship program has recognized and supported outstanding graduate students in computer science and related fields since 2009. Park is one of three Korean students chosen as the recipients of Google Fellowships this year. A total of 54 students across the world in 12 fields were awarded this fellowship.

Park’s research on computational psychotherapy using natural language processing (NLP) powered by machine learning earned him this year’s fellowship. He presented of learning distributed representations in Korean and their interpretations during the 2017 Annual Conference of the Association for Computational Linguistics and the 2018 Conference on Empirical Methods in Natural Language Processing. He also applied machine learning-based natural language processing into computational psychotherapy so that a trained machine learning model could categorize client's verbal responses in a counseling dialogue. This was presented at the Annual Conference of the North American Chapter of the Association for Computational Linguistics.

More recently, he has been developing on neural response generation model and the prediction and extraction of complex emotion in text, and computational psychotherapy applications.

2019.09.17 View 10515 -

Two More Cross-generation Collaborative Labs Open

< President Sung-Chul Shin (sixth from the left) and Professor Sun Chang Kim (seventh from the left) at the signboard ceremony of KAIST BioDesigneering Laboratory >

KAIST opened two more cross-generation collaborative labs last month. KAIST BioDesigneering Laboratory headed by Professor Sun Chang Kim from the Department of Biological Sciences and Nanophotonics Laboratory led by Professor Yong-Hee Lee from the Department of Physics have been selected to receive 500 million KRW funding for five years.

A four-member selection committee including the former President of ETH Zürich Professor Emeritus Ralph Eichler and Professor Kwang-Soo Kim of Harvard Medical School conducted a three-month review and evaluation for this selection to be made. With these two new labs onboard, a total of six cross-generation collaborative labs will be operated on campus.

The operation of cross-generation collaborative labs has been in trial since March last year, as one of the KAIST’s Vision 2031 research innovation initiatives. This novel approach is to pair up senior and junior faculty members for sustaining research and academic achievements even after the senior researcher retires, so that the spectrum of knowledge and research competitiveness can be extended to future generations. The selected labs will be funded for five years, and the funding will be extended if necessary. KAIST will continue to select new labs every year.

One of this year’s selectees Professor Sun Chang Kim will be teamed up with Professor Byung-Kwan Cho from the same department and Professor Jung Kyoon Choi from the Department of Bio and Brain Engineering to collaborate in the fields of synthetic biology, systems biology, and genetic engineering. This group mainly aims at designing and synthesizing optimal genomes that can efficiently manufacture protein drug and biomedical active materials. They will also strive to secure large amounts of high-functioning natural active substances, new adhesive antibacterial peptides, and eco-friendly ecological restoration materials. It is expected that collaboration between these three multigenerational professors will help innovate their bio-convergence technology and further strengthen their international competitiveness in the global bio-market.

Another world-renowned scholar Professor Yong-Hee Lee of photonic crystal laser study will be joined by Professor Minkyo Seo from the same department and Professor Hansuek Lee from the Graduate School of Nanoscience and Technology. They will explore the extreme limits of light-material interaction based on optical micro/nano resonators, with the goal of developing future nonlinear optoelectronic and quantum optical devices. The knowledge and technology newly gained from the research are expected to provide an important platform for a diverse range of fields from quantum communications to biophysics.

(END)

2019.09.06 View 12163

Two More Cross-generation Collaborative Labs Open

< President Sung-Chul Shin (sixth from the left) and Professor Sun Chang Kim (seventh from the left) at the signboard ceremony of KAIST BioDesigneering Laboratory >

KAIST opened two more cross-generation collaborative labs last month. KAIST BioDesigneering Laboratory headed by Professor Sun Chang Kim from the Department of Biological Sciences and Nanophotonics Laboratory led by Professor Yong-Hee Lee from the Department of Physics have been selected to receive 500 million KRW funding for five years.

A four-member selection committee including the former President of ETH Zürich Professor Emeritus Ralph Eichler and Professor Kwang-Soo Kim of Harvard Medical School conducted a three-month review and evaluation for this selection to be made. With these two new labs onboard, a total of six cross-generation collaborative labs will be operated on campus.

The operation of cross-generation collaborative labs has been in trial since March last year, as one of the KAIST’s Vision 2031 research innovation initiatives. This novel approach is to pair up senior and junior faculty members for sustaining research and academic achievements even after the senior researcher retires, so that the spectrum of knowledge and research competitiveness can be extended to future generations. The selected labs will be funded for five years, and the funding will be extended if necessary. KAIST will continue to select new labs every year.

One of this year’s selectees Professor Sun Chang Kim will be teamed up with Professor Byung-Kwan Cho from the same department and Professor Jung Kyoon Choi from the Department of Bio and Brain Engineering to collaborate in the fields of synthetic biology, systems biology, and genetic engineering. This group mainly aims at designing and synthesizing optimal genomes that can efficiently manufacture protein drug and biomedical active materials. They will also strive to secure large amounts of high-functioning natural active substances, new adhesive antibacterial peptides, and eco-friendly ecological restoration materials. It is expected that collaboration between these three multigenerational professors will help innovate their bio-convergence technology and further strengthen their international competitiveness in the global bio-market.

Another world-renowned scholar Professor Yong-Hee Lee of photonic crystal laser study will be joined by Professor Minkyo Seo from the same department and Professor Hansuek Lee from the Graduate School of Nanoscience and Technology. They will explore the extreme limits of light-material interaction based on optical micro/nano resonators, with the goal of developing future nonlinear optoelectronic and quantum optical devices. The knowledge and technology newly gained from the research are expected to provide an important platform for a diverse range of fields from quantum communications to biophysics.

(END)

2019.09.06 View 12163 -

Algorithm Identifies Optimal Pairs for Composing Metal-Organic Frameworks

The integration of metal-organic frameworks (MOFs) and other metal nanoparticles has increasingly led to the creation of new multifunctional materials. Many researchers have integrated MOFs with other classes of materials to produce new structures with synergetic properties.

Despite there being over 70,000 collections of synthesized MOFs that can be used as building blocks, the precise nature of the interaction and the bonding at the interface between the two materials still remains unknown. The question is how to sort out the right matching pairs out of 70,000 MOFs.

An algorithmic study published in Nature Communications by a KAIST research team presents a clue for finding the perfect pairs. The team, led by Professor Ji-Han Kim from the Department of Chemical and Biomolecular Engineering, developed a joint computational and experimental approach to rationally design MOF@MOFs, a composite of MOFs where an MOF is grown on a different MOF.

Professor Kim’s team, in collaboration with UNIST, noted that the metal node of one MOF can coordinately bond with the linker of a different MOF and the precisely matched interface configurations at atomic and molecular levels can enhance the likelihood of synthesizing MOF@MOFs.

They screened thousands of MOFs and identified optimal MOF pairs that can seamlessly connect to one another by taking advantage of the fact that the metal node of one MOF can form coordination bonds with the linkers of the second MOF. Six pairs predicted from the computational algorithm successfully grew into single crystals.

This computational workflow can readily extend into other classes of materials and can lead to the rapid exploration of the composite MOFs arena for accelerated materials development. Even more, the workflow can enhance the likelihood of synthesizing MOF@MOFs in the form of large single crystals, and thereby demonstrated the utility of rationally designing the MOF@MOFs.

This study is the first algorithm for predicting the synthesis of composite MOFs, to the best of their knowledge. Professor Kim said, “The number of predicted pairs can increase even more with the more general 2D lattice matching, and it is worth investigating in the future.”

This study was supported by Samsung Research Funding & Incubation Center of Samsung Electronics.

(Figure: An example of a rationally synthesized MOF@MOFs (cubic HKUST-1@MOF-5 ))

2019.08.30 View 18099

Algorithm Identifies Optimal Pairs for Composing Metal-Organic Frameworks

The integration of metal-organic frameworks (MOFs) and other metal nanoparticles has increasingly led to the creation of new multifunctional materials. Many researchers have integrated MOFs with other classes of materials to produce new structures with synergetic properties.

Despite there being over 70,000 collections of synthesized MOFs that can be used as building blocks, the precise nature of the interaction and the bonding at the interface between the two materials still remains unknown. The question is how to sort out the right matching pairs out of 70,000 MOFs.

An algorithmic study published in Nature Communications by a KAIST research team presents a clue for finding the perfect pairs. The team, led by Professor Ji-Han Kim from the Department of Chemical and Biomolecular Engineering, developed a joint computational and experimental approach to rationally design MOF@MOFs, a composite of MOFs where an MOF is grown on a different MOF.

Professor Kim’s team, in collaboration with UNIST, noted that the metal node of one MOF can coordinately bond with the linker of a different MOF and the precisely matched interface configurations at atomic and molecular levels can enhance the likelihood of synthesizing MOF@MOFs.

They screened thousands of MOFs and identified optimal MOF pairs that can seamlessly connect to one another by taking advantage of the fact that the metal node of one MOF can form coordination bonds with the linkers of the second MOF. Six pairs predicted from the computational algorithm successfully grew into single crystals.

This computational workflow can readily extend into other classes of materials and can lead to the rapid exploration of the composite MOFs arena for accelerated materials development. Even more, the workflow can enhance the likelihood of synthesizing MOF@MOFs in the form of large single crystals, and thereby demonstrated the utility of rationally designing the MOF@MOFs.

This study is the first algorithm for predicting the synthesis of composite MOFs, to the best of their knowledge. Professor Kim said, “The number of predicted pairs can increase even more with the more general 2D lattice matching, and it is worth investigating in the future.”

This study was supported by Samsung Research Funding & Incubation Center of Samsung Electronics.

(Figure: An example of a rationally synthesized MOF@MOFs (cubic HKUST-1@MOF-5 ))

2019.08.30 View 18099 -

Researchers Describe a Mechanism Inducing Self-Killing of Cancer Cells

(Professor Kim (left) and lead author Lee)

Researchers have described a new mechanism which induces the self-killing of cancer cells by perturbing ion homeostasis. A research team from the Department of Biochemical Engineering has developed helical polypeptide potassium ionophores that lead to the onset of programmed cell death. The ionophores increase the active oxygen concentration to stress endoplasmic reticulum to the point of cellular death.

The electrochemical gradient between extracellular and intracellular conditions plays an important role in cell growth and metabolism. When a cell’s ion homeostasis is disturbed, critical functions accelerating the activation of apoptosis are inhibited in the cell.

Although ionophores have been intensively used as an ion homeostasis disturber, the mechanisms of cell death have been unclear and the bio-applicability has been limited. In the study featured at Advanced Science, the team presented an alpha helical peptide-based anticancer agent that is capable of transporting potassium ions with water solubility. The cationic, hydrophilic, and potassium ionic groups were combined at the end of the peptide side chain to provide both ion transport and hydrophilic properties.

These peptide-based ionophores reduce the intracellular potassium concentration and at the same time increase the intracellular calcium concentration. Increased intracellular calcium concentrations produce intracellular reactive oxygen species, causing endoplasmic reticulum stress, and ultimately leading to apoptosis.

Anticancer effects were evaluated using tumor-bearing mice to confirm the therapeutic effect, even in animal models. It was found that tumor growth was strongly inhibited by endoplasmic stress-mediated apoptosis.

Lead author Dr. Dae-Yong Lee said, “A peptide-based ionophore is more effective than conventional chemotherapeutic agents because it induces apoptosis via elevated reactive oxygen species levels. Professor Yeu-Chun Kim said he expects this new mechanism to be widely used as a new chemotherapeutic strategy. This research was funded by the National Research Foundation.

2019.08.28 View 22093

Researchers Describe a Mechanism Inducing Self-Killing of Cancer Cells

(Professor Kim (left) and lead author Lee)

Researchers have described a new mechanism which induces the self-killing of cancer cells by perturbing ion homeostasis. A research team from the Department of Biochemical Engineering has developed helical polypeptide potassium ionophores that lead to the onset of programmed cell death. The ionophores increase the active oxygen concentration to stress endoplasmic reticulum to the point of cellular death.

The electrochemical gradient between extracellular and intracellular conditions plays an important role in cell growth and metabolism. When a cell’s ion homeostasis is disturbed, critical functions accelerating the activation of apoptosis are inhibited in the cell.

Although ionophores have been intensively used as an ion homeostasis disturber, the mechanisms of cell death have been unclear and the bio-applicability has been limited. In the study featured at Advanced Science, the team presented an alpha helical peptide-based anticancer agent that is capable of transporting potassium ions with water solubility. The cationic, hydrophilic, and potassium ionic groups were combined at the end of the peptide side chain to provide both ion transport and hydrophilic properties.

These peptide-based ionophores reduce the intracellular potassium concentration and at the same time increase the intracellular calcium concentration. Increased intracellular calcium concentrations produce intracellular reactive oxygen species, causing endoplasmic reticulum stress, and ultimately leading to apoptosis.

Anticancer effects were evaluated using tumor-bearing mice to confirm the therapeutic effect, even in animal models. It was found that tumor growth was strongly inhibited by endoplasmic stress-mediated apoptosis.

Lead author Dr. Dae-Yong Lee said, “A peptide-based ionophore is more effective than conventional chemotherapeutic agents because it induces apoptosis via elevated reactive oxygen species levels. Professor Yeu-Chun Kim said he expects this new mechanism to be widely used as a new chemotherapeutic strategy. This research was funded by the National Research Foundation.

2019.08.28 View 22093 -

Distinguished Professor Sukbok Chang Donates His Prize Money

The honoree of the 2019 Korea Best Scientist and Technologist Award, Distinguished Professor Sukbok Chang donated his prize money of one hundred million KRW to the Chemistry Department Scholarship Fund and the Lyu Keun-Chul Sports Complex Management Fund during a donation ceremony last week.

Professor Chang won the award last month in recognition of his pioneering achievements and lifetime contributions to the development of carbon-hydrogen activation strategies, especially for carbon-carbon, carbon-nitrogen, and carbon-oxygen formations. Professor Chang, a world renowned chemist, has been recognized for his highly selective catalytic systems, allowing the controlled defunctionalization of bio-derived platform substrates under mild conditions and opening a new avenue for the utilization of biomass-derived platform chemicals.

“All my achievements are the results of my students’ hard work and dedication. I feel very fortunate to have such talented team members. I want to express my sincere gratitude for such a great research environment that we have worked together in so far,” said Professor Chang at the ceremony.

KAIST President Sung-Chul Shin said, “Not only will Professor Chang’s donation make a significant contribution to the Department of Chemistry, but also to the improvement of the Lyu Keun-Chul Sports Complex’s management, which directly links to the health and welfare of the KAIST community.”

Professor Chang currently holds the position of distinguished professor at KAIST and director of the Center for Catalytic Hydrocarbon Functionalizations in the Institute for Basic Science (IBS). He previously received the Kyung-Ahm Academic Award in 2013 and the Korea Toray Science Award in 2018. All these prize money also went to the school.

(END)

2019.08.26 View 9448

Distinguished Professor Sukbok Chang Donates His Prize Money

The honoree of the 2019 Korea Best Scientist and Technologist Award, Distinguished Professor Sukbok Chang donated his prize money of one hundred million KRW to the Chemistry Department Scholarship Fund and the Lyu Keun-Chul Sports Complex Management Fund during a donation ceremony last week.

Professor Chang won the award last month in recognition of his pioneering achievements and lifetime contributions to the development of carbon-hydrogen activation strategies, especially for carbon-carbon, carbon-nitrogen, and carbon-oxygen formations. Professor Chang, a world renowned chemist, has been recognized for his highly selective catalytic systems, allowing the controlled defunctionalization of bio-derived platform substrates under mild conditions and opening a new avenue for the utilization of biomass-derived platform chemicals.

“All my achievements are the results of my students’ hard work and dedication. I feel very fortunate to have such talented team members. I want to express my sincere gratitude for such a great research environment that we have worked together in so far,” said Professor Chang at the ceremony.

KAIST President Sung-Chul Shin said, “Not only will Professor Chang’s donation make a significant contribution to the Department of Chemistry, but also to the improvement of the Lyu Keun-Chul Sports Complex’s management, which directly links to the health and welfare of the KAIST community.”

Professor Chang currently holds the position of distinguished professor at KAIST and director of the Center for Catalytic Hydrocarbon Functionalizations in the Institute for Basic Science (IBS). He previously received the Kyung-Ahm Academic Award in 2013 and the Korea Toray Science Award in 2018. All these prize money also went to the school.

(END)

2019.08.26 View 9448 -

Artificial Muscles Bloom, Dance, and Wave

Wearing a flower brooch that blooms before your eyes sounds like magic. KAIST researchers have made it real with robotic muscles.

Researchers have developed an ultrathin, artificial muscle for soft robotics. The advancement, recently reported in the journal Science Robotics, was demonstrated with a robotic blooming flower brooch, dancing robotic butterflies and fluttering tree leaves on a kinetic art piece.

The robotic equivalent of a muscle that can move is called an actuator. The actuator expands, contracts or rotates like muscle fibers using a stimulus such as electricity. Engineers around the world are striving to develop more dynamic actuators that respond quickly, can bend without breaking, and are very durable. Soft, robotic muscles could have a wide variety of applications, from wearable electronics to advanced prosthetics.

The team from KAIST’s Creative Research Initiative Center for Functionally Antagonistic Nano-Engineering developed a very thin, responsive, flexible and durable artificial muscle. The actuator looks like a skinny strip of paper about an inch long. They used a particular type of material called MXene, which is class of compounds that have layers only a few atoms thick.

Their chosen MXene material (T3C2Tx) is made of thin layers of titanium and carbon compounds. It was not flexible by itself; sheets of material would flake off the actuator when bent in a loop. That changed when the MXene was “ionically cross-linked” — connected through an ionic bond — to a synthetic polymer. The combination of materials made the actuator flexible, while still maintaining strength and conductivity, which is critical for movements driven by electricity.

Their particular combination performed better than others reported. Their actuator responded very quickly to low voltage, and lasted for more than five hours moving continuously.

To prove the tiny robotic muscle works, the team incorporated the actuator into wearable art: an origami-inspired brooch mimics how a narcissus flower unfolds its petals when a small amount of electricity is applied. They also designed robotic butterflies that move their wings up and down, and made the leaves of a tree sculpture flutter.

“Wearable robotics and kinetic art demonstrate how robotic muscles can have fun and beautiful applications,” said Il-Kwon Oh, lead paper author and professor of mechanical engineering. “It also shows the enormous potential for small, artificial muscles for a variety of uses, such as haptic feedback systems and active biomedical devices.”

The team next plans to investigate more practical applications of MXene-based soft actuators and other engineering applications of MXene 2D nanomaterials.

2019.08.22 View 26433

Artificial Muscles Bloom, Dance, and Wave

Wearing a flower brooch that blooms before your eyes sounds like magic. KAIST researchers have made it real with robotic muscles.

Researchers have developed an ultrathin, artificial muscle for soft robotics. The advancement, recently reported in the journal Science Robotics, was demonstrated with a robotic blooming flower brooch, dancing robotic butterflies and fluttering tree leaves on a kinetic art piece.

The robotic equivalent of a muscle that can move is called an actuator. The actuator expands, contracts or rotates like muscle fibers using a stimulus such as electricity. Engineers around the world are striving to develop more dynamic actuators that respond quickly, can bend without breaking, and are very durable. Soft, robotic muscles could have a wide variety of applications, from wearable electronics to advanced prosthetics.

The team from KAIST’s Creative Research Initiative Center for Functionally Antagonistic Nano-Engineering developed a very thin, responsive, flexible and durable artificial muscle. The actuator looks like a skinny strip of paper about an inch long. They used a particular type of material called MXene, which is class of compounds that have layers only a few atoms thick.

Their chosen MXene material (T3C2Tx) is made of thin layers of titanium and carbon compounds. It was not flexible by itself; sheets of material would flake off the actuator when bent in a loop. That changed when the MXene was “ionically cross-linked” — connected through an ionic bond — to a synthetic polymer. The combination of materials made the actuator flexible, while still maintaining strength and conductivity, which is critical for movements driven by electricity.

Their particular combination performed better than others reported. Their actuator responded very quickly to low voltage, and lasted for more than five hours moving continuously.

To prove the tiny robotic muscle works, the team incorporated the actuator into wearable art: an origami-inspired brooch mimics how a narcissus flower unfolds its petals when a small amount of electricity is applied. They also designed robotic butterflies that move their wings up and down, and made the leaves of a tree sculpture flutter.

“Wearable robotics and kinetic art demonstrate how robotic muscles can have fun and beautiful applications,” said Il-Kwon Oh, lead paper author and professor of mechanical engineering. “It also shows the enormous potential for small, artificial muscles for a variety of uses, such as haptic feedback systems and active biomedical devices.”

The team next plans to investigate more practical applications of MXene-based soft actuators and other engineering applications of MXene 2D nanomaterials.

2019.08.22 View 26433 -

Highly Uniform and Low Hysteresis Pressure Sensor to Increase Practical Applicability

< Professor Steve Park (left) and the First Author Mr. Jinwon Oh (right) >

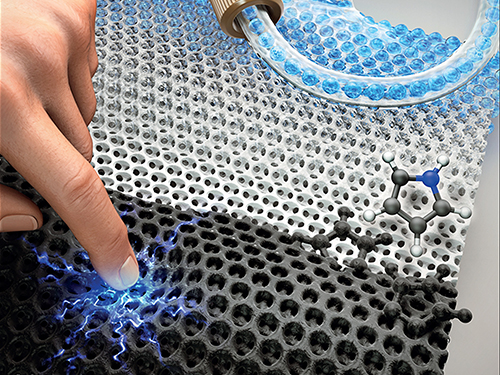

Researchers have designed a flexible pressure sensor that is expected to have a much wider applicability. A KAIST research team fabricated a piezoresistive pressure sensor of high uniformity with low hysteresis by chemically grafting a conductive polymer onto a porous elastomer template.

The team discovered that the uniformity of pore size and shape is directly related to the uniformity of the sensor. The team noted that by increasing pore size and shape variability, the variability of the sensor characteristics also increases.

Researchers led by Professor Steve Park from the Department of Materials Science and Engineering confirmed that compared to other sensors composed of randomly sized and shaped pores, which had a coefficient of variation in relative resistance change of 69.65%, their newly developed sensor exhibited much higher uniformity with a coefficient of variation of 2.43%. This study was reported in Small as the cover article on August 16.

Flexible pressure sensors have been actively researched and widely applied in electronic equipment such as touch screens, robots, wearable healthcare devices, electronic skin, and human-machine interfaces. In particular, piezoresistive pressure sensors based on elastomer‐conductive material composites hold significant potential due to their many advantages including a simple and low-cost fabrication process.

Various research results have been reported for ways to improve the performance of piezoresistive pressure sensors, most of which have been focused on increasing the sensitivity. Despite its significance, maximizing the sensitivity of composite-based piezoresistive pressure sensors is not necessary for many applications. On the other hand, sensor-to-sensor uniformity and hysteresis are two properties that are of critical importance to realize any application.

The importance of sensor-to-sensor uniformity is obvious. If the sensors manufactured under the same conditions have different properties, measurement reliability is compromised, and therefore the sensor cannot be used in a practical setting.

In addition, low hysteresis is also essential for improved measurement reliability. Hysteresis is a phenomenon in which the electrical readings differ depending on how fast or slow the sensor is being pressed, whether pressure is being released or applied, and how long and to what degree the sensor has been pressed. When a sensor has high hysteresis, the electrical readings will differ even under the same pressure, making the measurements unreliable.

Researchers said they observed a negligible hysteresis degree which was only 2%. This was attributed to the strong chemical bonding between the conductive polymer and the elastomer template, which prevents their relative sliding and displacement, and the porosity of the elastomer that enhances elastic behavior.

“This technology brings forth insight into how to address the two critical issues in pressure sensors: uniformity and hysteresis. We expect our technology to play an important role in increasing practical applications and the commercialization of pressure sensors in the near future,” said Professor Park.

This work was conducted as part of the KAIST‐funded Global Singularity Research Program for 2019, and also supported by the KUSTAR‐KAIST Institute.

Figure 1. Image of a porous elastomer template with uniform pore size and shape (left), Graph showing high uniformity in the sensors’ performance (right).

Figure 2. Hysteresis loops of the sensor at different pressure levels (left), and after a different number of cycles (right).

Figure 3. The cover page of Small Journal, Volume 15, Issue 33.

Publication:

Jinwon Oh, Jin‐Oh Kim, Yunjoo Kim, Han Byul Choi, Jun Chang Yang, Serin Lee, Mikhail Pyatykh, Jung Kim, Joo Yong Sim, and Steve Park. 2019. Highly Uniform and Low Hysteresis Piezoresistive Pressure Sensors Based on Chemical Grafting of Polypyrrole on Elastomer Template with Uniform Pore Size. Small. Wiley-VCH Verlag GmbH & Co. KgaA, Weinheim, Germany, Volume No. 15, Issue No. 33, Full Paper No. 201901744, 8 pages. https://doi.org/10.1002/smll.201901744

Profile: Prof. Steve Park, MS, PhD

stevepark@kaist.ac.kr

http://steveparklab.kaist.ac.kr/

Assistant Professor

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Mr. Jinwon Oh, MS

jwoh1701@gmail.com

http://steveparklab.kaist.ac.kr/

Researcher

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Prof. Jung Kim, MS, PhD

jungkim@kaist.ac.kr

http://medev.kaist.ac.kr/

Professor

Biorobotics Laboratory

Department of Mechanical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Joo Yong Sim, PhD

jsim@etri.re.kr

Researcher

Bio-Medical IT Convergence Research Department

Electronics and Telecommunications Research Institute (ETRI)

https://www.etri.re.krDaejeon 34129, Korea

(END)

2019.08.19 View 29654

Highly Uniform and Low Hysteresis Pressure Sensor to Increase Practical Applicability

< Professor Steve Park (left) and the First Author Mr. Jinwon Oh (right) >

Researchers have designed a flexible pressure sensor that is expected to have a much wider applicability. A KAIST research team fabricated a piezoresistive pressure sensor of high uniformity with low hysteresis by chemically grafting a conductive polymer onto a porous elastomer template.

The team discovered that the uniformity of pore size and shape is directly related to the uniformity of the sensor. The team noted that by increasing pore size and shape variability, the variability of the sensor characteristics also increases.

Researchers led by Professor Steve Park from the Department of Materials Science and Engineering confirmed that compared to other sensors composed of randomly sized and shaped pores, which had a coefficient of variation in relative resistance change of 69.65%, their newly developed sensor exhibited much higher uniformity with a coefficient of variation of 2.43%. This study was reported in Small as the cover article on August 16.

Flexible pressure sensors have been actively researched and widely applied in electronic equipment such as touch screens, robots, wearable healthcare devices, electronic skin, and human-machine interfaces. In particular, piezoresistive pressure sensors based on elastomer‐conductive material composites hold significant potential due to their many advantages including a simple and low-cost fabrication process.

Various research results have been reported for ways to improve the performance of piezoresistive pressure sensors, most of which have been focused on increasing the sensitivity. Despite its significance, maximizing the sensitivity of composite-based piezoresistive pressure sensors is not necessary for many applications. On the other hand, sensor-to-sensor uniformity and hysteresis are two properties that are of critical importance to realize any application.

The importance of sensor-to-sensor uniformity is obvious. If the sensors manufactured under the same conditions have different properties, measurement reliability is compromised, and therefore the sensor cannot be used in a practical setting.

In addition, low hysteresis is also essential for improved measurement reliability. Hysteresis is a phenomenon in which the electrical readings differ depending on how fast or slow the sensor is being pressed, whether pressure is being released or applied, and how long and to what degree the sensor has been pressed. When a sensor has high hysteresis, the electrical readings will differ even under the same pressure, making the measurements unreliable.

Researchers said they observed a negligible hysteresis degree which was only 2%. This was attributed to the strong chemical bonding between the conductive polymer and the elastomer template, which prevents their relative sliding and displacement, and the porosity of the elastomer that enhances elastic behavior.

“This technology brings forth insight into how to address the two critical issues in pressure sensors: uniformity and hysteresis. We expect our technology to play an important role in increasing practical applications and the commercialization of pressure sensors in the near future,” said Professor Park.

This work was conducted as part of the KAIST‐funded Global Singularity Research Program for 2019, and also supported by the KUSTAR‐KAIST Institute.

Figure 1. Image of a porous elastomer template with uniform pore size and shape (left), Graph showing high uniformity in the sensors’ performance (right).

Figure 2. Hysteresis loops of the sensor at different pressure levels (left), and after a different number of cycles (right).

Figure 3. The cover page of Small Journal, Volume 15, Issue 33.

Publication:

Jinwon Oh, Jin‐Oh Kim, Yunjoo Kim, Han Byul Choi, Jun Chang Yang, Serin Lee, Mikhail Pyatykh, Jung Kim, Joo Yong Sim, and Steve Park. 2019. Highly Uniform and Low Hysteresis Piezoresistive Pressure Sensors Based on Chemical Grafting of Polypyrrole on Elastomer Template with Uniform Pore Size. Small. Wiley-VCH Verlag GmbH & Co. KgaA, Weinheim, Germany, Volume No. 15, Issue No. 33, Full Paper No. 201901744, 8 pages. https://doi.org/10.1002/smll.201901744

Profile: Prof. Steve Park, MS, PhD

stevepark@kaist.ac.kr

http://steveparklab.kaist.ac.kr/

Assistant Professor

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Mr. Jinwon Oh, MS

jwoh1701@gmail.com

http://steveparklab.kaist.ac.kr/

Researcher

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Prof. Jung Kim, MS, PhD

jungkim@kaist.ac.kr

http://medev.kaist.ac.kr/

Professor

Biorobotics Laboratory

Department of Mechanical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Joo Yong Sim, PhD

jsim@etri.re.kr

Researcher

Bio-Medical IT Convergence Research Department

Electronics and Telecommunications Research Institute (ETRI)

https://www.etri.re.krDaejeon 34129, Korea

(END)

2019.08.19 View 29654