Park

-

Wearable Strain Sensor Using Light Transmittance Helps Measure Physical Signals Better

KAIST researchers have developed a novel wearable strain sensor based on the modulation of optical transmittance of a carbon nanotube (CNT)-embedded elastomer. The sensor is capable of sensitive, stable, and continuous measurement of physical signals. This technology, featured in the March 4th issue of ACS Applied Materials & Interfaces as a front cover article, shows great potential for the detection of subtle human motions and the real-time monitoring of body postures for healthcare applications.

A wearable strain sensor must have high sensitivity, flexibility, and stretchability, as well as low cost. Those used especially for health monitoring should also be tied to long-term solid performance, and be environmentally stable. Various stretchable strain sensors based on piezo-resistive and capacitive principles have been developed to meet all these requirements.

Conventional piezo-resistive strain sensors using functional nanomaterials, including CNTs as the most common example, have shown high sensitivity and great sensing performance. However, they suffer from poor long-term stability and linearity, as well as considerable signal hysteresis. As an alternative, piezo-capacitive strain sensors with better stability, lower hysteresis, and higher stretchability have been suggested. But due to the fact that piezo-capacitive strain sensors exhibit limited sensitivity and strong electromagnetic interference caused by the conductive objects in the surrounding environment, these conventional stretchable strain sensors are still facing limitations that are yet to be resolved.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering suggested that an optical-type stretchable strain sensor can be a good alternative to resolve the limitations of conventional piezo-resistive and piezo-capacitive strain sensors, because they have high stability and are less affected by environmental disturbances. The team then introduced an optical wearable strain sensor based on the light transmittance changes of a CNT-embedded elastomer, which further addresses the low sensitivity problem of conventional optical stretchable strain sensors.

In order to achieve a large dynamic range for the sensor, Professor Park and his researchers chose Ecoflex as an elastomeric substrate with good mechanical durability, flexibility, and attachability on human skin, and the new optical wearable strain sensor developed by the research group actually shows a wide dynamic range of 0 to 400%.

In addition, the researchers propagated the microcracks under tensile strain within the film of multi-walled CNTs embedded in the Ecoflex substrate, changing the optical transmittance of the film. By doing so, it was possible for them to develop a wearable strain sensor having a sensitivity 10 times higher than conventional optical stretchable strain sensors.

The proposed sensor has also passed the durability test with excellent results. The sensor’s response after 13,000 sets of cyclic loading was stable without any noticeable drift. This suggests that the sensor response can be used without degradation, even if the sensor is repeatedly used for a long time and in various environmental conditions.

Using the developed sensor, the research team could measure the finger bending motion and used it for robot control. They also developed a three-axes sensor array for body posture monitoring. The sensor was able to monitor human motions with small strains such as a pulse near the carotid artery and muscle movement around the mouth during pronunciation.

Professor Park said, “In this study, our group developed a new wearable strain sensor platform that overcomes many limitations of previously developed resistive, capacitive, and optical-type stretchable strain sensors. Our sensor could be widely used in a variety of fields including soft robotics, wearable electronics, electronic skin, healthcare, and even entertainment.”

This work was supported by the National Research Foundation (NRF) of Korea.

Publication:

Jimin Gu, Donguk Kwon, Junseong Ahn, and Inkyu Park. (2020) “Wearable Strain sensors Using Light Transmittance Change of Carbon Nanotube-Embedded Elastomers with Microcracks” ACS Applied Materials & Interfaces. Volume 12. Issue 9. Available online at https://doi.org/10.1021/acsami.9b18069

Profile:

Inkyu Park

Professor

inkyu@kaist.ac.kr

http://mintlab1.kaist.ac.kr

Micro/Nano Transducers Laboratory (MINT Lab)

Department of Mechanical Engineering (ME)Korea Advanced Institute of Science and Technology (KAIST)

Profile:

Jimin Gu

Ph.D. Candidate

mint9411@kaist.ac.kr

http://mintlab1.kaist.ac.kr

MINT Lab

KAIST ME

(END)

2020.03.20 View 21379

Wearable Strain Sensor Using Light Transmittance Helps Measure Physical Signals Better

KAIST researchers have developed a novel wearable strain sensor based on the modulation of optical transmittance of a carbon nanotube (CNT)-embedded elastomer. The sensor is capable of sensitive, stable, and continuous measurement of physical signals. This technology, featured in the March 4th issue of ACS Applied Materials & Interfaces as a front cover article, shows great potential for the detection of subtle human motions and the real-time monitoring of body postures for healthcare applications.

A wearable strain sensor must have high sensitivity, flexibility, and stretchability, as well as low cost. Those used especially for health monitoring should also be tied to long-term solid performance, and be environmentally stable. Various stretchable strain sensors based on piezo-resistive and capacitive principles have been developed to meet all these requirements.

Conventional piezo-resistive strain sensors using functional nanomaterials, including CNTs as the most common example, have shown high sensitivity and great sensing performance. However, they suffer from poor long-term stability and linearity, as well as considerable signal hysteresis. As an alternative, piezo-capacitive strain sensors with better stability, lower hysteresis, and higher stretchability have been suggested. But due to the fact that piezo-capacitive strain sensors exhibit limited sensitivity and strong electromagnetic interference caused by the conductive objects in the surrounding environment, these conventional stretchable strain sensors are still facing limitations that are yet to be resolved.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering suggested that an optical-type stretchable strain sensor can be a good alternative to resolve the limitations of conventional piezo-resistive and piezo-capacitive strain sensors, because they have high stability and are less affected by environmental disturbances. The team then introduced an optical wearable strain sensor based on the light transmittance changes of a CNT-embedded elastomer, which further addresses the low sensitivity problem of conventional optical stretchable strain sensors.

In order to achieve a large dynamic range for the sensor, Professor Park and his researchers chose Ecoflex as an elastomeric substrate with good mechanical durability, flexibility, and attachability on human skin, and the new optical wearable strain sensor developed by the research group actually shows a wide dynamic range of 0 to 400%.

In addition, the researchers propagated the microcracks under tensile strain within the film of multi-walled CNTs embedded in the Ecoflex substrate, changing the optical transmittance of the film. By doing so, it was possible for them to develop a wearable strain sensor having a sensitivity 10 times higher than conventional optical stretchable strain sensors.

The proposed sensor has also passed the durability test with excellent results. The sensor’s response after 13,000 sets of cyclic loading was stable without any noticeable drift. This suggests that the sensor response can be used without degradation, even if the sensor is repeatedly used for a long time and in various environmental conditions.

Using the developed sensor, the research team could measure the finger bending motion and used it for robot control. They also developed a three-axes sensor array for body posture monitoring. The sensor was able to monitor human motions with small strains such as a pulse near the carotid artery and muscle movement around the mouth during pronunciation.

Professor Park said, “In this study, our group developed a new wearable strain sensor platform that overcomes many limitations of previously developed resistive, capacitive, and optical-type stretchable strain sensors. Our sensor could be widely used in a variety of fields including soft robotics, wearable electronics, electronic skin, healthcare, and even entertainment.”

This work was supported by the National Research Foundation (NRF) of Korea.

Publication:

Jimin Gu, Donguk Kwon, Junseong Ahn, and Inkyu Park. (2020) “Wearable Strain sensors Using Light Transmittance Change of Carbon Nanotube-Embedded Elastomers with Microcracks” ACS Applied Materials & Interfaces. Volume 12. Issue 9. Available online at https://doi.org/10.1021/acsami.9b18069

Profile:

Inkyu Park

Professor

inkyu@kaist.ac.kr

http://mintlab1.kaist.ac.kr

Micro/Nano Transducers Laboratory (MINT Lab)

Department of Mechanical Engineering (ME)Korea Advanced Institute of Science and Technology (KAIST)

Profile:

Jimin Gu

Ph.D. Candidate

mint9411@kaist.ac.kr

http://mintlab1.kaist.ac.kr

MINT Lab

KAIST ME

(END)

2020.03.20 View 21379 -

‘OSK Rising Stars 30’ Recognizes Four KAISTians

Four KAISTians were selected as star researchers to brighten the future of optics in commemoration of the 30th anniversary of the Optical Society of Korea (OSK). As ‘OSK Rising Stars 30’, the OSK named 27 domestic researchers under the age of 40 who have made significant contributions and will continue contributing to the development of Korea’s optics academia and industry.

Professor YongKeun Park from the Department of Physics was selected in recognition of his contributions to the field of biomedical optics. Professor Park focuses on developing novel optical methods for understanding, diagnosing, and treating human diseases, based on light scattering, light manipulation, and interferometry. As a member of numerous international optics societies including the OSA and the SPIE and a co-founder of two start-up companies, Professor Park continues to broaden his boundaries as a leading opticist and entrepreneur.

Professor Jonghwa Shin from the Department of Materials Science and Engineering was recognized for blazing a trail in the field of broadband metamaterials. Professor Shin’s research on the broadband enhancement of the electric permittivity and refractive index of metamaterials has great potential in both academia and industry.

Professor Hongki Yoo from the Department of Mechanical Engineering is expected to create a significant ripple effect in the diagnosis of cardiovascular disorders through the development of new optical imaging techniques and applications.

Finally, Dr. Sejeong Kim, a KAIST graduate and a Chancellor’s postdoctoral research fellow at the University of Technology Sydney (UTS), was acknowledged for her optical device research utilizing two-dimensional materials. Dr. Kim’s research at UTS now focuses on the introduction of micro/nano cavities for new materials.

(END)

2020.03.16 View 12615

‘OSK Rising Stars 30’ Recognizes Four KAISTians

Four KAISTians were selected as star researchers to brighten the future of optics in commemoration of the 30th anniversary of the Optical Society of Korea (OSK). As ‘OSK Rising Stars 30’, the OSK named 27 domestic researchers under the age of 40 who have made significant contributions and will continue contributing to the development of Korea’s optics academia and industry.

Professor YongKeun Park from the Department of Physics was selected in recognition of his contributions to the field of biomedical optics. Professor Park focuses on developing novel optical methods for understanding, diagnosing, and treating human diseases, based on light scattering, light manipulation, and interferometry. As a member of numerous international optics societies including the OSA and the SPIE and a co-founder of two start-up companies, Professor Park continues to broaden his boundaries as a leading opticist and entrepreneur.

Professor Jonghwa Shin from the Department of Materials Science and Engineering was recognized for blazing a trail in the field of broadband metamaterials. Professor Shin’s research on the broadband enhancement of the electric permittivity and refractive index of metamaterials has great potential in both academia and industry.

Professor Hongki Yoo from the Department of Mechanical Engineering is expected to create a significant ripple effect in the diagnosis of cardiovascular disorders through the development of new optical imaging techniques and applications.

Finally, Dr. Sejeong Kim, a KAIST graduate and a Chancellor’s postdoctoral research fellow at the University of Technology Sydney (UTS), was acknowledged for her optical device research utilizing two-dimensional materials. Dr. Kim’s research at UTS now focuses on the introduction of micro/nano cavities for new materials.

(END)

2020.03.16 View 12615 -

Blood-Based Multiplexed Diagnostic Sensor Helps to Accurately Detect Alzheimer’s Disease

A research team at KAIST reported clinically accurate multiplexed electrical biosensor for detecting Alzheimer’s disease by measuring its core biomarkers using densely aligned carbon nanotubes.

Alzheimer’s disease is the most prevalent neurodegenerative disorder, affecting one in ten aged over 65 years. Early diagnosis can reduce the risk of suffering the disease by one-third, according to recent reports. However, its early diagnosis remains challenging due to the low accuracy but high cost of diagnosis.

Research team led by Professors Chan Beum Park and Steve Park described an ultrasensitive detection of multiple Alzheimer's disease core biomarker in human plasma. The team have designed the sensor array by employing a densely aligned single-walled carbon nanotube thin films as a transducer.

The representative biomarkers of Alzheimer's disease are beta-amyloid42, beta-amyloid40, total tau protein, phosphorylated tau protein and the concentrations of these biomarkers in human plasma are directly correlated with the pathology of Alzheimer’s disease.

The research team developed a highly sensitive resistive biosensor based on densely aligned carbon nanotubes fabricated by Langmuir-Blodgett method with a low manufacturing cost.

Aligned carbon nanotubes with high density minimizes the tube-to-tube junction resistance compared with randomly distributed carbon nanotubes, which leads to the improvement of sensor sensitivity. To be more specific, this resistive sensor with densely aligned carbon nanotubes exhibits a sensitivity over 100 times higher than that of conventional carbon nanotube-based biosensors.

By measuring the concentrations of four Alzheimer’s disease biomarkers simultaneously Alzheimer patients can be discriminated from health controls with an average sensitivity of 90.0%, a selectivity of 90.0% and an average accuracy of 88.6%.

This work, titled “Clinically accurate diagnosis of Alzheimer’s disease via multiplexed sensing of core biomarkers in human plasma”, were published in Nature Communications on January 8th 2020. The authors include PhD candidate Kayoung Kim and MS candidate Min-Ji Kim.

Professor Steve Park said, “This study was conducted on patients who are already confirmed with Alzheimer’s Disease. For further use in practical setting, it is necessary to test the patients with mild cognitive impairment.” He also emphasized that, “It is essential to establish a nationwide infrastructure, such as mild cognitive impairment cohort study and a dementia cohort study. This would enable the establishment of world-wide research network, and will help various private and public institutions.”

This research was supported by the Ministry of Science and ICT, Human Resource Bank of Chungnam National University Hospital and Chungbuk National University Hospital.

< A schematic diagram of a high-density aligned carbon nanotube-based resistive sensor that distinguishes patients with Alzheimer’s Disease by measuring the concentration of four biomarkers in the blood. >

Profile:

Professor Steve Park

stevepark@kaist.ac.kr

Department of Materials Science and Engineering

http://steveparklab.kaist.ac.kr/

KAIST

Profile:

Professor Chan Beum Park

parkcb at kaist.ac.kr

Department of Materials Science and Engineering

http://biomaterials.kaist.ac.kr/

KAIST

2020.02.07 View 12273

Blood-Based Multiplexed Diagnostic Sensor Helps to Accurately Detect Alzheimer’s Disease

A research team at KAIST reported clinically accurate multiplexed electrical biosensor for detecting Alzheimer’s disease by measuring its core biomarkers using densely aligned carbon nanotubes.

Alzheimer’s disease is the most prevalent neurodegenerative disorder, affecting one in ten aged over 65 years. Early diagnosis can reduce the risk of suffering the disease by one-third, according to recent reports. However, its early diagnosis remains challenging due to the low accuracy but high cost of diagnosis.

Research team led by Professors Chan Beum Park and Steve Park described an ultrasensitive detection of multiple Alzheimer's disease core biomarker in human plasma. The team have designed the sensor array by employing a densely aligned single-walled carbon nanotube thin films as a transducer.

The representative biomarkers of Alzheimer's disease are beta-amyloid42, beta-amyloid40, total tau protein, phosphorylated tau protein and the concentrations of these biomarkers in human plasma are directly correlated with the pathology of Alzheimer’s disease.

The research team developed a highly sensitive resistive biosensor based on densely aligned carbon nanotubes fabricated by Langmuir-Blodgett method with a low manufacturing cost.

Aligned carbon nanotubes with high density minimizes the tube-to-tube junction resistance compared with randomly distributed carbon nanotubes, which leads to the improvement of sensor sensitivity. To be more specific, this resistive sensor with densely aligned carbon nanotubes exhibits a sensitivity over 100 times higher than that of conventional carbon nanotube-based biosensors.

By measuring the concentrations of four Alzheimer’s disease biomarkers simultaneously Alzheimer patients can be discriminated from health controls with an average sensitivity of 90.0%, a selectivity of 90.0% and an average accuracy of 88.6%.

This work, titled “Clinically accurate diagnosis of Alzheimer’s disease via multiplexed sensing of core biomarkers in human plasma”, were published in Nature Communications on January 8th 2020. The authors include PhD candidate Kayoung Kim and MS candidate Min-Ji Kim.

Professor Steve Park said, “This study was conducted on patients who are already confirmed with Alzheimer’s Disease. For further use in practical setting, it is necessary to test the patients with mild cognitive impairment.” He also emphasized that, “It is essential to establish a nationwide infrastructure, such as mild cognitive impairment cohort study and a dementia cohort study. This would enable the establishment of world-wide research network, and will help various private and public institutions.”

This research was supported by the Ministry of Science and ICT, Human Resource Bank of Chungnam National University Hospital and Chungbuk National University Hospital.

< A schematic diagram of a high-density aligned carbon nanotube-based resistive sensor that distinguishes patients with Alzheimer’s Disease by measuring the concentration of four biomarkers in the blood. >

Profile:

Professor Steve Park

stevepark@kaist.ac.kr

Department of Materials Science and Engineering

http://steveparklab.kaist.ac.kr/

KAIST

Profile:

Professor Chan Beum Park

parkcb at kaist.ac.kr

Department of Materials Science and Engineering

http://biomaterials.kaist.ac.kr/

KAIST

2020.02.07 View 12273 -

Rachmaninoff the most innovative of 18th and 19th century composers according to network science

Rachmaninoff, followed by Bach, Brahms and Mendelssohn, was the most innovative of the composers who worked during the Baroque, Classical and Romantic eras of music (1700 to 1900) according to a study published in the open access journal EPJ Data Science.

A team of researchers from KAIST (Korea Advanced Institute of Science and Technology), calculated novelty scores for 900 classical piano compositions written by 19 composers between approximately 1700 and 1900. The scores were based on how musical compositions differed from all prior pieces of piano music and how they differed from previous piano works by the same composer. The authors found that composers from the Romantic era (1820 to 1910) tended to have high novelty scores.

The authors from the Graduate School of Culture Technology at KAIST created a computer model which divided each composition into segments called ‘codewords’. Each ‘codeword’ consisted of all of the notes played together at a given time. Sequences of ‘codewords’ were then compared between compositions. The similarities between the sequences were used to create novelty scores for each composer and to determine the extent to which composers influenced each other.

Juyong Park, the corresponding author, said: “Our model allows us to calculate the degree of shared melodies and harmonies between past and future works and to observe the evolution of western musical styles by demonstrating how prominent composers may have influenced each other. The period of music we studied is widely credited for having produced many musical styles that are still influential today.”

The model distinguished each new musical period from the one before it by the rise of newly dominant and highly influential composers that indicated dramatic shifts in musical styles. The authors found that compositions from the Classical period (1750 to 1820) tended to have the lowest novelty scores. During this period Haydn and Mozart were highly influential but were later overtaken by Beethoven during the Classical-to-Romantic transitional period.

The most innovative composer, indicated by the highest combined novelty score, was Rachmaninoff. His work during the Romantic era was novel when compared to the compositions of the other 18 composers included in the study, and his later works were novel compared to his earlier works.

Lower novelty did not necessarily correlate with low influence. Beethoven was ranked in the lower half of novelty scores yet was the most influential composer during the Romantic period (1820 to 1910) and is widely considered one of the greatest composers of all time.

Dr. Park said: “While novelty is necessary in a creative work it cannot account for all the creative and artistic qualities that go into creating melodies and harmonies that spread to later generations of composers. That may be why being more novel did not necessarily result in composers being more influential.”

The authors suggest that their method could be applied to narrative or visual artworks by creating codewords from groups of words or colours and shapes. However, they caution that as only piano compositions were included in their analysis, it is unknown whether including all works by the 19 composers would have resulted in another composer being identified as the most original.

Profile: Prof. Juyong Park, PhD

juyongp@kaist.ac.kr

Graduate School of Culture Technology (CT)

Korea Advanced Institute of Science and Technology (KAIST)

https://www.kaist.ac.kr

Daejeon 34141, Korea

(END)

2020.01.31 View 5743

Rachmaninoff the most innovative of 18th and 19th century composers according to network science

Rachmaninoff, followed by Bach, Brahms and Mendelssohn, was the most innovative of the composers who worked during the Baroque, Classical and Romantic eras of music (1700 to 1900) according to a study published in the open access journal EPJ Data Science.

A team of researchers from KAIST (Korea Advanced Institute of Science and Technology), calculated novelty scores for 900 classical piano compositions written by 19 composers between approximately 1700 and 1900. The scores were based on how musical compositions differed from all prior pieces of piano music and how they differed from previous piano works by the same composer. The authors found that composers from the Romantic era (1820 to 1910) tended to have high novelty scores.

The authors from the Graduate School of Culture Technology at KAIST created a computer model which divided each composition into segments called ‘codewords’. Each ‘codeword’ consisted of all of the notes played together at a given time. Sequences of ‘codewords’ were then compared between compositions. The similarities between the sequences were used to create novelty scores for each composer and to determine the extent to which composers influenced each other.

Juyong Park, the corresponding author, said: “Our model allows us to calculate the degree of shared melodies and harmonies between past and future works and to observe the evolution of western musical styles by demonstrating how prominent composers may have influenced each other. The period of music we studied is widely credited for having produced many musical styles that are still influential today.”

The model distinguished each new musical period from the one before it by the rise of newly dominant and highly influential composers that indicated dramatic shifts in musical styles. The authors found that compositions from the Classical period (1750 to 1820) tended to have the lowest novelty scores. During this period Haydn and Mozart were highly influential but were later overtaken by Beethoven during the Classical-to-Romantic transitional period.

The most innovative composer, indicated by the highest combined novelty score, was Rachmaninoff. His work during the Romantic era was novel when compared to the compositions of the other 18 composers included in the study, and his later works were novel compared to his earlier works.

Lower novelty did not necessarily correlate with low influence. Beethoven was ranked in the lower half of novelty scores yet was the most influential composer during the Romantic period (1820 to 1910) and is widely considered one of the greatest composers of all time.

Dr. Park said: “While novelty is necessary in a creative work it cannot account for all the creative and artistic qualities that go into creating melodies and harmonies that spread to later generations of composers. That may be why being more novel did not necessarily result in composers being more influential.”

The authors suggest that their method could be applied to narrative or visual artworks by creating codewords from groups of words or colours and shapes. However, they caution that as only piano compositions were included in their analysis, it is unknown whether including all works by the 19 composers would have resulted in another composer being identified as the most original.

Profile: Prof. Juyong Park, PhD

juyongp@kaist.ac.kr

Graduate School of Culture Technology (CT)

Korea Advanced Institute of Science and Technology (KAIST)

https://www.kaist.ac.kr

Daejeon 34141, Korea

(END)

2020.01.31 View 5743 -

KAIST Vaccine for Tick-Borne Disease ‘SFTS’ Protects Against Lethal Infection

A KAIST research team reported the development of a DNA vaccine for Severe Fever with Thrombocytopenia Syndrome Virus (SFTSV) which completely protects against lethal infection in ferrets. The team confirmed that ferrets immunized with DNA vaccines encoding all SFTSV proteins showed 100% survival rate without detectable viremia and did not develop any clinical symptoms. This study was published in Nature Communications on August 23.

Severe Fever with Thrombocytopenia Syndrome (SFTS) is a newly emerging tick-borne infectious disease. The disease causes fever, severe thrombocytopenia, leukocytopenia as well as vomiting and diarrhea. Severe cases end up with organ system failure often accompanied by hemorrhages, and its mortality rate stands at 10–20%.

The viral disease has been endemic to East Asia but the spread of the tick vector to North America increases the likelihood of potential outbreak beyond the Far East Asia. The World Health Organization (WHO) has also put SFTSV into the priority pathogen requiring urgent attention category. Currently, no vaccine has been available to prevent SFTS.

The research team led by Professor Su-Hyung Park noted that DNA vaccines induce broader immunity to multiple antigens than traditional ones. Moreover, DNA vaccines stimulate both T cell and antibody immunity, which make them suitable for vaccine development.

They constructed DNA vaccines that encode full-length Gn, Gc, N, NS, and RNA polymerase genes based on common sequences of 31 SFTSV strains isolated from patients. Their vaccine candidates induced both neutralizing antibody response and multifunctional SFTSV-specific T cell response in mice and ferrets.

To investigate the vaccine’s efficacy in vivo, the research team applied a recently developed ferret model that recapitulates fatal clinical symptoms in SFTSV infection in humans. Vaccinated ferrets were completely protected from lethal SFTSV challenge without SFTSV detection in their blood, whereas all control ferrets died within 10 days’ post-infection.

The KAIST team found that anti-envelope antibodies play an important role in protective immunity, suggesting that envelope glycoproteins of SFTSV may be the most effective antigens for inducing protective immunity. Moreover, the study revealed that T cell responses specific to non-envelope proteins of SFTSV also can contribute to protection against SFTSV infection.

Professor Park said, “This is the first study demonstrating complete protection against lethal SFTSV challenge using an immunocompetent, middle-sized animal model with clinical manifestations of SFTSV infection. We believe this study provides valuable insights into designing preventive vaccines for SFTSV.”

2020.01.31 View 5883

KAIST Vaccine for Tick-Borne Disease ‘SFTS’ Protects Against Lethal Infection

A KAIST research team reported the development of a DNA vaccine for Severe Fever with Thrombocytopenia Syndrome Virus (SFTSV) which completely protects against lethal infection in ferrets. The team confirmed that ferrets immunized with DNA vaccines encoding all SFTSV proteins showed 100% survival rate without detectable viremia and did not develop any clinical symptoms. This study was published in Nature Communications on August 23.

Severe Fever with Thrombocytopenia Syndrome (SFTS) is a newly emerging tick-borne infectious disease. The disease causes fever, severe thrombocytopenia, leukocytopenia as well as vomiting and diarrhea. Severe cases end up with organ system failure often accompanied by hemorrhages, and its mortality rate stands at 10–20%.

The viral disease has been endemic to East Asia but the spread of the tick vector to North America increases the likelihood of potential outbreak beyond the Far East Asia. The World Health Organization (WHO) has also put SFTSV into the priority pathogen requiring urgent attention category. Currently, no vaccine has been available to prevent SFTS.

The research team led by Professor Su-Hyung Park noted that DNA vaccines induce broader immunity to multiple antigens than traditional ones. Moreover, DNA vaccines stimulate both T cell and antibody immunity, which make them suitable for vaccine development.

They constructed DNA vaccines that encode full-length Gn, Gc, N, NS, and RNA polymerase genes based on common sequences of 31 SFTSV strains isolated from patients. Their vaccine candidates induced both neutralizing antibody response and multifunctional SFTSV-specific T cell response in mice and ferrets.

To investigate the vaccine’s efficacy in vivo, the research team applied a recently developed ferret model that recapitulates fatal clinical symptoms in SFTSV infection in humans. Vaccinated ferrets were completely protected from lethal SFTSV challenge without SFTSV detection in their blood, whereas all control ferrets died within 10 days’ post-infection.

The KAIST team found that anti-envelope antibodies play an important role in protective immunity, suggesting that envelope glycoproteins of SFTSV may be the most effective antigens for inducing protective immunity. Moreover, the study revealed that T cell responses specific to non-envelope proteins of SFTSV also can contribute to protection against SFTSV infection.

Professor Park said, “This is the first study demonstrating complete protection against lethal SFTSV challenge using an immunocompetent, middle-sized animal model with clinical manifestations of SFTSV infection. We believe this study provides valuable insights into designing preventive vaccines for SFTSV.”

2020.01.31 View 5883 -

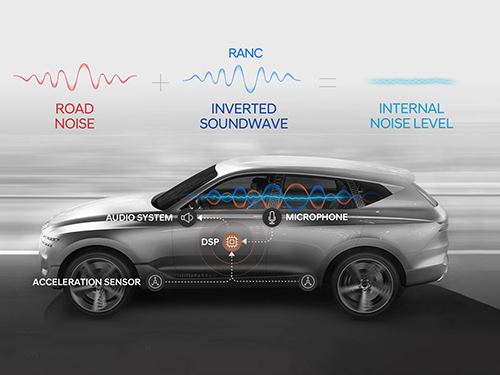

A System Controlling Road Active Noise to Hit the Road

The research team led by Professor Youngjin Park of the Department of Mechanical Engineering has developed a road noise active noise control (RANC) system to be commercialized in partnership with Hyundai Motor Group.

On December 11, Hyundai Motor Group announced the successful development of the RANC system, which significantly reduces the road noise flowing into cars. The carmaker has completed the domestic and American patent applications for the location of sensors and the signal selection method, the core technology of RANC.

RANC is a technology for reducing road noise during driving. This system consists of an acceleration sensor, digital signal processor (the control computer to analyze sound signals), microphone, amplifier, and audio system. To make the system as simple as possible, the audio system utilizes the original audio system embedded in the car instead of a separate system.

The acceleration sensor first calculates the vibration from the road into the car. The location of the sensor is important for accurately identifying the vibration path. The research team was able to find the optimal sensor location through a number of tests.

The System Dynamics and Applied Control Laboratory of Professor Park researched ways to significantly reduce road noise with Hyundai Motor Group for four years from 1993 as a G7 national project and published the results in international journals. In 2002, the researchers published an article titled “Noise Quietens Driving” in Nature, where they announced the first success in reducing road noise in actual cars. The achievement did not lead to commercialization, however, due to the lack of auxiliary technologies at the time, digital amplifiers and DSP for cars for example, and pricing issues.

Since 2013, Professor Park’s research team has participated in one technology transfer and eight university-industry projects. Based on these efforts, the team was able to successfully develop the RANC system with domestic technology in partnership with Hyundai’s NVH Research Lab (Research Fellow, Dr. Gangdeok Lee; Ph.D. in aviation engineering, 1996), Optomech (Founder, Professor Gyeongsu Kim; Ph.D. in mechanical engineering, 1999), ARE (CEO Hyeonseok Kim; Ph.D. in mechanical engineering, 1998), WeAcom, and BurnYoung.

Professor Park’s team led the project by performing theory-based research during the commercialization stage in collaboration with Hyundai Motor Group.

For the commercialization of the RANC system, Hyundai Motor Group is planning to collaborate with the global car audio company Harman to increase the degree of completion and apply the RANC system to the GV 80, the first SUV model of the Genesis brand.

“I am very delighted as an engineer to see the research I worked on from my early days at KAIST be commercialized after 20 years,” noted Professor Park. “I am thrilled to make a contribution to such commercialization with my students in my lab.”

2019.12.27 View 13172

A System Controlling Road Active Noise to Hit the Road

The research team led by Professor Youngjin Park of the Department of Mechanical Engineering has developed a road noise active noise control (RANC) system to be commercialized in partnership with Hyundai Motor Group.

On December 11, Hyundai Motor Group announced the successful development of the RANC system, which significantly reduces the road noise flowing into cars. The carmaker has completed the domestic and American patent applications for the location of sensors and the signal selection method, the core technology of RANC.

RANC is a technology for reducing road noise during driving. This system consists of an acceleration sensor, digital signal processor (the control computer to analyze sound signals), microphone, amplifier, and audio system. To make the system as simple as possible, the audio system utilizes the original audio system embedded in the car instead of a separate system.

The acceleration sensor first calculates the vibration from the road into the car. The location of the sensor is important for accurately identifying the vibration path. The research team was able to find the optimal sensor location through a number of tests.

The System Dynamics and Applied Control Laboratory of Professor Park researched ways to significantly reduce road noise with Hyundai Motor Group for four years from 1993 as a G7 national project and published the results in international journals. In 2002, the researchers published an article titled “Noise Quietens Driving” in Nature, where they announced the first success in reducing road noise in actual cars. The achievement did not lead to commercialization, however, due to the lack of auxiliary technologies at the time, digital amplifiers and DSP for cars for example, and pricing issues.

Since 2013, Professor Park’s research team has participated in one technology transfer and eight university-industry projects. Based on these efforts, the team was able to successfully develop the RANC system with domestic technology in partnership with Hyundai’s NVH Research Lab (Research Fellow, Dr. Gangdeok Lee; Ph.D. in aviation engineering, 1996), Optomech (Founder, Professor Gyeongsu Kim; Ph.D. in mechanical engineering, 1999), ARE (CEO Hyeonseok Kim; Ph.D. in mechanical engineering, 1998), WeAcom, and BurnYoung.

Professor Park’s team led the project by performing theory-based research during the commercialization stage in collaboration with Hyundai Motor Group.

For the commercialization of the RANC system, Hyundai Motor Group is planning to collaborate with the global car audio company Harman to increase the degree of completion and apply the RANC system to the GV 80, the first SUV model of the Genesis brand.

“I am very delighted as an engineer to see the research I worked on from my early days at KAIST be commercialized after 20 years,” noted Professor Park. “I am thrilled to make a contribution to such commercialization with my students in my lab.”

2019.12.27 View 13172 -

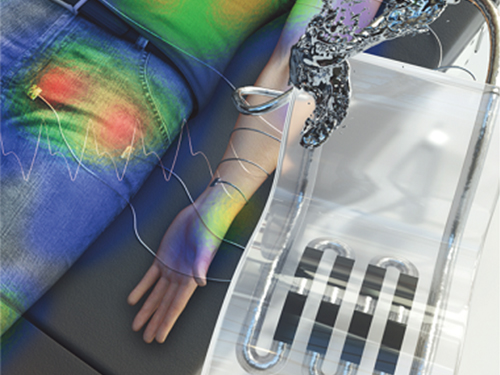

New Liquid Metal Wearable Pressure Sensor Created for Health Monitoring Applications

Soft pressure sensors have received significant research attention in a variety of fields, including soft robotics, electronic skin, and wearable electronics. Wearable soft pressure sensors have great potential for the real-time health monitoring and for the early diagnosis of diseases.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering developed a highly sensitive wearable pressure sensor for health monitoring applications. This work was reported in Advanced Healthcare Materials on November 21 as a front cover article.

This technology is capable of sensitive, precise, and continuous measurement of physiological and physical signals and shows great potential for health monitoring applications and the early diagnosis of diseases.

A soft pressure sensor is required to have high compliance, high sensitivity, low cost, long-term performance stability, and environmental stability in order to be employed for continuous health monitoring. Conventional solid-state soft pressure sensors using functional materials including carbon nanotubes and graphene have showed great sensing performance. However, these sensors suffer from limited stretchability, signal drifting, and long-term instability due to the distance between the stretchable substrate and the functional materials.

To overcome these issues, liquid-state electronics using liquid metal have been introduced for various wearable applications. Of these materials, Galinstan, a eutectic metal alloy of gallium, indium, and tin, has great mechanical and electrical properties that can be employed in wearable applications. But today’s liquid metal-based pressure sensors have low-pressure sensitivity, limiting their applicability for health monitoring devices.

The research team developed a 3D-printed rigid microbump array-integrated, liquid metal-based soft pressure sensor. With the help of 3D printing, the integration of a rigid microbump array and the master mold for a liquid metal microchannel could be achieved simultaneously, reducing the complexity of the manufacturing process. Through the integration of the rigid microbump and the microchannel, the new pressure sensor has an extremely low detection limit and enhanced pressure sensitivity compared to previously reported liquid metal-based pressure sensors. The proposed sensor also has a negligible signal drift over 10,000 cycles of pressure, bending, and stretching and exhibited excellent stability when subjected to various environmental conditions.

These performance outcomes make it an excellent sensor for various health monitoring devices. First, the research team demonstrated a wearable wristband device that can continuously monitor one’s pulse during exercise and be employed in a noninvasive cuffless BP monitoring system based on PTT calculations. Then, they introduced a wireless wearable heel pressure monitoring system that integrates three 3D-BLiPS with a wireless communication module.

Professor Park said, “It was possible to measure health indicators including pulse and blood pressure continuously as well as pressure of body parts using our proposed soft pressure sensor. We expect it to be used in health care applications, such as the prevention and the monitoring of the pressure-driven diseases such as pressure ulcers in the near future. There will be more opportunities for future research including a whole-body pressure monitoring system related to other physical parameters.”

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Ministry of Science and ICT.

< Figure 1. The front cover image of Advanced Healthcare Materials, Volume 8, Issue 22. >

< Figure 2. Highly sensitive liquid metal-based soft pressure sensor integrated with 3D-printed microbump array. >

< Figure 3. High pressure sensitivity and reliable sensing performances of the proposed sensor and wireless heel pressure monitoring application. >

-ProfileProfessor Inkyu ParkMicro/Nano Transducers Laboratoryhttp://mintlab1.kaist.ac.kr/

Department of Mechanical EngineeringKAIST

2019.12.20 View 16209

New Liquid Metal Wearable Pressure Sensor Created for Health Monitoring Applications

Soft pressure sensors have received significant research attention in a variety of fields, including soft robotics, electronic skin, and wearable electronics. Wearable soft pressure sensors have great potential for the real-time health monitoring and for the early diagnosis of diseases.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering developed a highly sensitive wearable pressure sensor for health monitoring applications. This work was reported in Advanced Healthcare Materials on November 21 as a front cover article.

This technology is capable of sensitive, precise, and continuous measurement of physiological and physical signals and shows great potential for health monitoring applications and the early diagnosis of diseases.

A soft pressure sensor is required to have high compliance, high sensitivity, low cost, long-term performance stability, and environmental stability in order to be employed for continuous health monitoring. Conventional solid-state soft pressure sensors using functional materials including carbon nanotubes and graphene have showed great sensing performance. However, these sensors suffer from limited stretchability, signal drifting, and long-term instability due to the distance between the stretchable substrate and the functional materials.

To overcome these issues, liquid-state electronics using liquid metal have been introduced for various wearable applications. Of these materials, Galinstan, a eutectic metal alloy of gallium, indium, and tin, has great mechanical and electrical properties that can be employed in wearable applications. But today’s liquid metal-based pressure sensors have low-pressure sensitivity, limiting their applicability for health monitoring devices.

The research team developed a 3D-printed rigid microbump array-integrated, liquid metal-based soft pressure sensor. With the help of 3D printing, the integration of a rigid microbump array and the master mold for a liquid metal microchannel could be achieved simultaneously, reducing the complexity of the manufacturing process. Through the integration of the rigid microbump and the microchannel, the new pressure sensor has an extremely low detection limit and enhanced pressure sensitivity compared to previously reported liquid metal-based pressure sensors. The proposed sensor also has a negligible signal drift over 10,000 cycles of pressure, bending, and stretching and exhibited excellent stability when subjected to various environmental conditions.

These performance outcomes make it an excellent sensor for various health monitoring devices. First, the research team demonstrated a wearable wristband device that can continuously monitor one’s pulse during exercise and be employed in a noninvasive cuffless BP monitoring system based on PTT calculations. Then, they introduced a wireless wearable heel pressure monitoring system that integrates three 3D-BLiPS with a wireless communication module.

Professor Park said, “It was possible to measure health indicators including pulse and blood pressure continuously as well as pressure of body parts using our proposed soft pressure sensor. We expect it to be used in health care applications, such as the prevention and the monitoring of the pressure-driven diseases such as pressure ulcers in the near future. There will be more opportunities for future research including a whole-body pressure monitoring system related to other physical parameters.”

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Ministry of Science and ICT.

< Figure 1. The front cover image of Advanced Healthcare Materials, Volume 8, Issue 22. >

< Figure 2. Highly sensitive liquid metal-based soft pressure sensor integrated with 3D-printed microbump array. >

< Figure 3. High pressure sensitivity and reliable sensing performances of the proposed sensor and wireless heel pressure monitoring application. >

-ProfileProfessor Inkyu ParkMicro/Nano Transducers Laboratoryhttp://mintlab1.kaist.ac.kr/

Department of Mechanical EngineeringKAIST

2019.12.20 View 16209 -

Professor Byong-Guk Park Named Scientist of October

< Professor Byong-Guk Park >

Professor Byong-Guk Park from the Department of Materials Science and Engineering was selected as the ‘Scientist of the Month’ for October 2019 by the Ministry of Science and ICT and the National Research Foundation of Korea. Professor Park was recognized for his contributions to the advancement of spin-orbit torque (SOT)-based magnetic random access memory (MRAM) technology. He received 10 million KRW in prize money.

A next-generation, non-volatile memory device MRAM consists of thin magnetic films. It can be applied in “logic-in-memory” devices, in which logic and memory functionalities coexist, thus drastically improving the performance of complementary metal-oxide semiconductor (CMOS) processors. Conventional MRAM technology is limited in its ability to increase the operation speed of a memory device while maintaining a high density.

Professor Park tackled this challenge by introducing a new material, antiferromagnet (IrMn), that generates a sizable amount of SOT as well as an exchange-bias field, which makes successful data writing possible without an external magnetic field. This research outcome paved the way for the development of MRAM, which has a simple device structure but features high speeds and density.

Professor Park said, “I feel rewarded to have forwarded the feasibility and applicability of MRAM. I will continue devoting myself to studying further on the development of new materials that can help enhance the performance of memory devices."

(END)

2019.10.10 View 11554

Professor Byong-Guk Park Named Scientist of October

< Professor Byong-Guk Park >

Professor Byong-Guk Park from the Department of Materials Science and Engineering was selected as the ‘Scientist of the Month’ for October 2019 by the Ministry of Science and ICT and the National Research Foundation of Korea. Professor Park was recognized for his contributions to the advancement of spin-orbit torque (SOT)-based magnetic random access memory (MRAM) technology. He received 10 million KRW in prize money.

A next-generation, non-volatile memory device MRAM consists of thin magnetic films. It can be applied in “logic-in-memory” devices, in which logic and memory functionalities coexist, thus drastically improving the performance of complementary metal-oxide semiconductor (CMOS) processors. Conventional MRAM technology is limited in its ability to increase the operation speed of a memory device while maintaining a high density.

Professor Park tackled this challenge by introducing a new material, antiferromagnet (IrMn), that generates a sizable amount of SOT as well as an exchange-bias field, which makes successful data writing possible without an external magnetic field. This research outcome paved the way for the development of MRAM, which has a simple device structure but features high speeds and density.

Professor Park said, “I feel rewarded to have forwarded the feasibility and applicability of MRAM. I will continue devoting myself to studying further on the development of new materials that can help enhance the performance of memory devices."

(END)

2019.10.10 View 11554 -

Professor Hyun Gyu Park Appointed as Associate Editor for Biosensors and Bioelectronics

Professor Hyun Gyu Park from the Department of Chemical and Biomolecular Engineering was appointed as an associate editor for Biosensors and Bioelectronics, an international journal published by Elsevier.

Biosensors and Bioelectronics is one of the top SCI journals in the fields of chemistry and analytical science (IF 9.518 as of 2018). Professor Park was recognized and appointed as the associate editor for this journal due to his outstanding research achievements in the fields of nucleic acid engineering, biosensors, and nanobiotechnology.

Professor Park will serve as the associate editor from this October until December 2021.

(END)

2019.10.01 View 8704

Professor Hyun Gyu Park Appointed as Associate Editor for Biosensors and Bioelectronics

Professor Hyun Gyu Park from the Department of Chemical and Biomolecular Engineering was appointed as an associate editor for Biosensors and Bioelectronics, an international journal published by Elsevier.

Biosensors and Bioelectronics is one of the top SCI journals in the fields of chemistry and analytical science (IF 9.518 as of 2018). Professor Park was recognized and appointed as the associate editor for this journal due to his outstanding research achievements in the fields of nucleic acid engineering, biosensors, and nanobiotechnology.

Professor Park will serve as the associate editor from this October until December 2021.

(END)

2019.10.01 View 8704 -

Sungjoon Park Named Google PhD Fellow

PhD candidate Sungjoon Park from the School of Computing was named a 2019 Google PhD Fellow in the field of natural language processing. The Google PhD fellowship program has recognized and supported outstanding graduate students in computer science and related fields since 2009. Park is one of three Korean students chosen as the recipients of Google Fellowships this year. A total of 54 students across the world in 12 fields were awarded this fellowship.

Park’s research on computational psychotherapy using natural language processing (NLP) powered by machine learning earned him this year’s fellowship. He presented of learning distributed representations in Korean and their interpretations during the 2017 Annual Conference of the Association for Computational Linguistics and the 2018 Conference on Empirical Methods in Natural Language Processing. He also applied machine learning-based natural language processing into computational psychotherapy so that a trained machine learning model could categorize client's verbal responses in a counseling dialogue. This was presented at the Annual Conference of the North American Chapter of the Association for Computational Linguistics.

More recently, he has been developing on neural response generation model and the prediction and extraction of complex emotion in text, and computational psychotherapy applications.

2019.09.17 View 10320

Sungjoon Park Named Google PhD Fellow

PhD candidate Sungjoon Park from the School of Computing was named a 2019 Google PhD Fellow in the field of natural language processing. The Google PhD fellowship program has recognized and supported outstanding graduate students in computer science and related fields since 2009. Park is one of three Korean students chosen as the recipients of Google Fellowships this year. A total of 54 students across the world in 12 fields were awarded this fellowship.

Park’s research on computational psychotherapy using natural language processing (NLP) powered by machine learning earned him this year’s fellowship. He presented of learning distributed representations in Korean and their interpretations during the 2017 Annual Conference of the Association for Computational Linguistics and the 2018 Conference on Empirical Methods in Natural Language Processing. He also applied machine learning-based natural language processing into computational psychotherapy so that a trained machine learning model could categorize client's verbal responses in a counseling dialogue. This was presented at the Annual Conference of the North American Chapter of the Association for Computational Linguistics.

More recently, he has been developing on neural response generation model and the prediction and extraction of complex emotion in text, and computational psychotherapy applications.

2019.09.17 View 10320 -

Professor Park at UPC-Barcelona Tech Receives Jeong Hun Cho Award

Professor Hyuk Park was honored to be the recipient of the Jeong Hun Cho Award which was presented at the Universitat Politècnica de Catalunya Barcelona Tech. The award recognizes young scientists in the field of aerospace engineering.

Professor Park, a graduate of KAIST’s Department of Mechanical Engineering in 2001, earned his MS and PhD at the Gwangju Institute of Science and Technology, and works at the Castelldefels School of Telecommunications and Aerospace Engineering at UPC-Barcelona Tech. He won this year’s award, which honors former PhD candidate Jeong Hun Cho at the Aerospace Engineering Department who died in a lab accident in 2003. Professor Park also received 25 million KRW prize money. Cho’s family endowed the award and scholarship in his memory. Since 2005, the scholarship has selected three young scholars every year who specialize in aerospace engineering from Cho’s alma maters of KAIST, Korea University, and Kongju National University High School.

Professor Park was selected as this year’s awardee in recognition of his studies of synthetic-aperture radar (SAR) satellite radiometer system, remote sensing radio frequency interference reduction system development, and 3CAT series research.

The Award Committee also chose three students for scholarships: PhD candidate Sang-Woo Chung from the Department of Aerospace Engineering at KAIST with 4 million KRW, PhD candidate Eun-Hee Kang from the School of Mechanical Engineering at Korea University with 4 million KRW, and Chan-Ho Song from Kongju National University High School with 3 million KRW.

2019.05.14 View 9144

Professor Park at UPC-Barcelona Tech Receives Jeong Hun Cho Award

Professor Hyuk Park was honored to be the recipient of the Jeong Hun Cho Award which was presented at the Universitat Politècnica de Catalunya Barcelona Tech. The award recognizes young scientists in the field of aerospace engineering.

Professor Park, a graduate of KAIST’s Department of Mechanical Engineering in 2001, earned his MS and PhD at the Gwangju Institute of Science and Technology, and works at the Castelldefels School of Telecommunications and Aerospace Engineering at UPC-Barcelona Tech. He won this year’s award, which honors former PhD candidate Jeong Hun Cho at the Aerospace Engineering Department who died in a lab accident in 2003. Professor Park also received 25 million KRW prize money. Cho’s family endowed the award and scholarship in his memory. Since 2005, the scholarship has selected three young scholars every year who specialize in aerospace engineering from Cho’s alma maters of KAIST, Korea University, and Kongju National University High School.

Professor Park was selected as this year’s awardee in recognition of his studies of synthetic-aperture radar (SAR) satellite radiometer system, remote sensing radio frequency interference reduction system development, and 3CAT series research.

The Award Committee also chose three students for scholarships: PhD candidate Sang-Woo Chung from the Department of Aerospace Engineering at KAIST with 4 million KRW, PhD candidate Eun-Hee Kang from the School of Mechanical Engineering at Korea University with 4 million KRW, and Chan-Ho Song from Kongju National University High School with 3 million KRW.

2019.05.14 View 9144 -

Stretchable Multi-functional Fiber for Energy Harvesting and Strain Sensing

(from left: Professor Steve Park, Jeongjae Ryu and Professor Seungbum Hong)

Fiber-based electronics are expected to play a vital role in next-generation wearable electronics. Woven into textiles, they can provide higher durability, comfort, and integrated multi-functionality. A KAIST team has developed a stretchable multi-functional fiber (SMF) that can harvest energy and detect strain, which can be applied to future wearable electronics.

With wearable electronics, health and physical conditions can be assessed by analyzing biological signals from the human body, such as pulse and muscle movements. Fibers are highly suitable for future wearable electronics because they can be easily integrated into textiles, which are designed to be conformable to curvilinear surfaces and comfortable to wear. Moreover, their weave structures offer support that makes them resistant to fatigue. Many research groups have developed fiber-based strain sensors to sense external biological signals. However, their sensitivities were relatively low.

The applicability of wearable devices is currently limited by their power source, as the size, weight, and lifetime of the battery lessens their versatility. Harvesting mechanical energy from the human body is a promising solution to overcome such limitations by utilizing various types of motions like bending, stretching, and pressing. However, previously reported, fiber-based energy harvesters were not stretchable and could not fully harvest the available mechanical energy.

Professor Seungbum Hong and Professor Steve Park from the Department of Materials Science and Engineering and their team fabricated a stretchable fiber by using a ferroelectric layer composed of P(VDF-TrFE)/PDMS sandwiched between stretchable electrodes composed of a composite of multi-walled carbon nanotubes (MWCNT) and poly 3,4-ethylenedioxythiophene polystyrenesulfonate (PEDOT:PSS).

Cracks formed in MWCNT/PEDOT:PSS layer help the fiber show high sensitivity compared to the previously reported fiber strain sensors. Furthermore, the new fiber can harvest mechanical energy under various mechanical stimuli such as stretching, tapping, and injecting water into the fiber using the piezoelectric effect of the P(VDF-TrFE)/PDMS layer.

Professor Hong said, “This new fiber has various functionalities and makes the device simple and compact. It is a core technology for developing wearable devices with energy harvesting and strain sensing capabilities.”

This article, led by PhD candidate Jeongjae Ryu, was published in the January 2019 issue of Nano Energy.

Figure 1.Schematic illustration of an SMF fiber and its piezoelectric voltage output and response to strain.

Figure 2. Photographs of a stretchable multi-functional fiber being stretched by 100%, bent, and twisted.

2019.01.31 View 9668

Stretchable Multi-functional Fiber for Energy Harvesting and Strain Sensing

(from left: Professor Steve Park, Jeongjae Ryu and Professor Seungbum Hong)

Fiber-based electronics are expected to play a vital role in next-generation wearable electronics. Woven into textiles, they can provide higher durability, comfort, and integrated multi-functionality. A KAIST team has developed a stretchable multi-functional fiber (SMF) that can harvest energy and detect strain, which can be applied to future wearable electronics.

With wearable electronics, health and physical conditions can be assessed by analyzing biological signals from the human body, such as pulse and muscle movements. Fibers are highly suitable for future wearable electronics because they can be easily integrated into textiles, which are designed to be conformable to curvilinear surfaces and comfortable to wear. Moreover, their weave structures offer support that makes them resistant to fatigue. Many research groups have developed fiber-based strain sensors to sense external biological signals. However, their sensitivities were relatively low.

The applicability of wearable devices is currently limited by their power source, as the size, weight, and lifetime of the battery lessens their versatility. Harvesting mechanical energy from the human body is a promising solution to overcome such limitations by utilizing various types of motions like bending, stretching, and pressing. However, previously reported, fiber-based energy harvesters were not stretchable and could not fully harvest the available mechanical energy.

Professor Seungbum Hong and Professor Steve Park from the Department of Materials Science and Engineering and their team fabricated a stretchable fiber by using a ferroelectric layer composed of P(VDF-TrFE)/PDMS sandwiched between stretchable electrodes composed of a composite of multi-walled carbon nanotubes (MWCNT) and poly 3,4-ethylenedioxythiophene polystyrenesulfonate (PEDOT:PSS).

Cracks formed in MWCNT/PEDOT:PSS layer help the fiber show high sensitivity compared to the previously reported fiber strain sensors. Furthermore, the new fiber can harvest mechanical energy under various mechanical stimuli such as stretching, tapping, and injecting water into the fiber using the piezoelectric effect of the P(VDF-TrFE)/PDMS layer.

Professor Hong said, “This new fiber has various functionalities and makes the device simple and compact. It is a core technology for developing wearable devices with energy harvesting and strain sensing capabilities.”

This article, led by PhD candidate Jeongjae Ryu, was published in the January 2019 issue of Nano Energy.

Figure 1.Schematic illustration of an SMF fiber and its piezoelectric voltage output and response to strain.

Figure 2. Photographs of a stretchable multi-functional fiber being stretched by 100%, bent, and twisted.

2019.01.31 View 9668