society

-

Fabrication of Shape-conformable Batteries with 3D-Printing

(from left: Dr. Bok Yeop Ahn, Dr. Chanhoon Kim, Professor Il-Doo Kim and Professor Jennifer A. Lewis)

Flexible, wireless electronic devices are rapidly emerging and have reached the level of commercialization; nevertheless, most of battery shapes are limited to either spherical and/or rectangular structures, which results in inefficient space use. Professor Il-Doo Kim’s team from the Department of Materials Science at KAIST has successfully developed technology to significantly enhance the variability of battery design through collaboration research with Professor Jennifer A. Lewis and her team from the School of Engineering and Applied Sciences at Harvard University.

Most of the battery shapes today are optimized for coin cell and/or pouch cells. Since the battery as an energy storage device occupies most of the space in microelectronic devices with different designs, new technology to freely change the shape of the battery is required.

The KAIST-Harvard research collaboration team has successfully manufactured various kinds of battery shapes, such as ring-type, H, and U shape, using 3D printing technology. And through the research collaboration with Dr. Youngmin Choi at the Korea Research Institute of Chemical Technology (KRICT), 3D-printed batteries were applied to small-scale wearable electronic devices (wearable light sensor rings).

The research group has adopted environmentally friendly aqueous Zn-ion batteries to make customized battery packs. This system, which uses Zn2+ instead of Li+ as charge carriers, is much safer compared with the conventional lithium rechargeable batteries that use highly inflammable organic electrolytes. Moreover, the processing conditions of lithium-ion batteries are very complicated because organic solvents can ignite upon exposure to moisture and oxygen.

As the aqueous Zn-ion batteries adopted by the research team are stable upon contact with atmospheric moisture and oxygen, they can be fabricated in the ambient air condition, and have advantages in packaging since packaged plastic does not dissolve in water even when plastic packaging is applied using a 3D printer.

To fabricate a stable cathode that can be modulated in various forms and allows high charge-discharge, the research team fabricated a carbon fiber current collector using electrospinning process and uniformly coated electrochemically active polyaniline conductive polymer on the surface of carbon fiber for a current collector-active layer integrated cathode. The cathode, based on conductive polyaniline consisting of a 3D structure, exhibits very fast charging speeds (50% of the charge in two minutes) and can be fabricated without the detachment of active cathode materials, so various battery forms with high mechanical stability can be manufactured.

Prof. Kim said, “Zn-ion batteries employing aqueous electrolytes have the advantage of fabrication under ambient conditions, so it is easy to fabricate the customized battery packs using 3D printing.”

“3D-printed batteries can be easily applied for niche applications such as wearable, personalized, miniaturized micro-robots, and implantable medical devices or microelectronic storage devices with unique designs,” added Professor Lewis.

With Dr. Chanhoon Kim in the Department of Materials Science and Engineering at KAIST and Dr. Bok Yeop Ahn School of Engineering and Applied Sciences at Harvard University participating as equally contributing first authors, this work was published in the December issue of ACS Nano.

This work was financially supported by the Global Research Laboratory (NRF-2015K1A1A2029679) and Wearable Platform Materials Technology Center (2016R1A5A1009926).

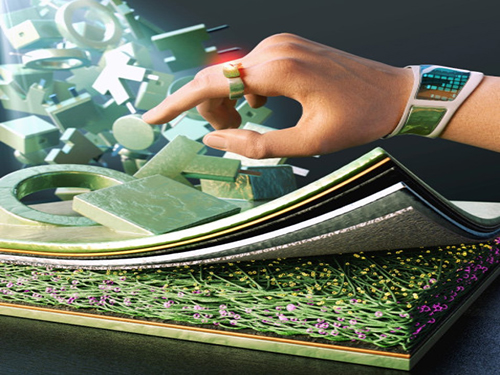

Figure 1.Fabrication of shape-conformable batteries based on 3D-printing technology and the application of polyaniline carbon nanofiber cathodes and wearable electronic devices

Figure 2.Fabricated shape-conformable batteries based on a 3D-printing method

Meanwhile, Professor Il-Doo Kim was recently appointed as an Associate Editor of ACS Nano, a highly renowned journal in the field of nanoscience.

Professor Kim said, “It is my great honor to be an Associate Editor of the highly renowned journal ACS Nano, which has an impact factor reaching 13.709 with 134,596 citations as of 2017. Through the editorial activities in the fields of energy, I will dedicate myself to improving the prominence of KAIST and expanding the scope of Korea’s science and technology. I will also contribute to carrying out more international collaborations with world-leading research groups.”

(Associate Editor of ACS Nano Professor Il-Doo Kim)

2018.12.20 View 10446

Fabrication of Shape-conformable Batteries with 3D-Printing

(from left: Dr. Bok Yeop Ahn, Dr. Chanhoon Kim, Professor Il-Doo Kim and Professor Jennifer A. Lewis)

Flexible, wireless electronic devices are rapidly emerging and have reached the level of commercialization; nevertheless, most of battery shapes are limited to either spherical and/or rectangular structures, which results in inefficient space use. Professor Il-Doo Kim’s team from the Department of Materials Science at KAIST has successfully developed technology to significantly enhance the variability of battery design through collaboration research with Professor Jennifer A. Lewis and her team from the School of Engineering and Applied Sciences at Harvard University.

Most of the battery shapes today are optimized for coin cell and/or pouch cells. Since the battery as an energy storage device occupies most of the space in microelectronic devices with different designs, new technology to freely change the shape of the battery is required.

The KAIST-Harvard research collaboration team has successfully manufactured various kinds of battery shapes, such as ring-type, H, and U shape, using 3D printing technology. And through the research collaboration with Dr. Youngmin Choi at the Korea Research Institute of Chemical Technology (KRICT), 3D-printed batteries were applied to small-scale wearable electronic devices (wearable light sensor rings).

The research group has adopted environmentally friendly aqueous Zn-ion batteries to make customized battery packs. This system, which uses Zn2+ instead of Li+ as charge carriers, is much safer compared with the conventional lithium rechargeable batteries that use highly inflammable organic electrolytes. Moreover, the processing conditions of lithium-ion batteries are very complicated because organic solvents can ignite upon exposure to moisture and oxygen.

As the aqueous Zn-ion batteries adopted by the research team are stable upon contact with atmospheric moisture and oxygen, they can be fabricated in the ambient air condition, and have advantages in packaging since packaged plastic does not dissolve in water even when plastic packaging is applied using a 3D printer.

To fabricate a stable cathode that can be modulated in various forms and allows high charge-discharge, the research team fabricated a carbon fiber current collector using electrospinning process and uniformly coated electrochemically active polyaniline conductive polymer on the surface of carbon fiber for a current collector-active layer integrated cathode. The cathode, based on conductive polyaniline consisting of a 3D structure, exhibits very fast charging speeds (50% of the charge in two minutes) and can be fabricated without the detachment of active cathode materials, so various battery forms with high mechanical stability can be manufactured.

Prof. Kim said, “Zn-ion batteries employing aqueous electrolytes have the advantage of fabrication under ambient conditions, so it is easy to fabricate the customized battery packs using 3D printing.”

“3D-printed batteries can be easily applied for niche applications such as wearable, personalized, miniaturized micro-robots, and implantable medical devices or microelectronic storage devices with unique designs,” added Professor Lewis.

With Dr. Chanhoon Kim in the Department of Materials Science and Engineering at KAIST and Dr. Bok Yeop Ahn School of Engineering and Applied Sciences at Harvard University participating as equally contributing first authors, this work was published in the December issue of ACS Nano.

This work was financially supported by the Global Research Laboratory (NRF-2015K1A1A2029679) and Wearable Platform Materials Technology Center (2016R1A5A1009926).

Figure 1.Fabrication of shape-conformable batteries based on 3D-printing technology and the application of polyaniline carbon nanofiber cathodes and wearable electronic devices

Figure 2.Fabricated shape-conformable batteries based on a 3D-printing method

Meanwhile, Professor Il-Doo Kim was recently appointed as an Associate Editor of ACS Nano, a highly renowned journal in the field of nanoscience.

Professor Kim said, “It is my great honor to be an Associate Editor of the highly renowned journal ACS Nano, which has an impact factor reaching 13.709 with 134,596 citations as of 2017. Through the editorial activities in the fields of energy, I will dedicate myself to improving the prominence of KAIST and expanding the scope of Korea’s science and technology. I will also contribute to carrying out more international collaborations with world-leading research groups.”

(Associate Editor of ACS Nano Professor Il-Doo Kim)

2018.12.20 View 10446 -

Professor Baik Awarded Sangsan Young Mathematician Prize

(Professor Hyungryul Baik)

Professor Hyungryul Baik from the Department of Mathematical Sciences was honored as the recipient of the 2018 Sangsan Prize for Young Mathematicians by the Korean Mathematical Society (KMS).

The Sangsan Prize recognizes young mathematicians who finished their degree within the previous five years and have begun an outstanding research career. Professor Baik was recognized for his studies in the fields of low-dimensional topology, geophysical mathematics, and geometric theory. In particular, his Ph.D. dissertation presented a new criterion that completely identifies the hyperbolic surface group, making an inference about the nature of the hyperbolic manifold group.

Recently, Professor Baik co-published a paper entitled Spaces of Invariant Circular Orders of Groups with Professor Eric Samperton at the University of California Santa Barbara in the renowned academic journal Groups, Geometry, and Dynamics in 2018.

Professor Baik earned his BS at KAIST and finished his MS and Ph.D. in mathematics in 2014 at Cornell University. He joined KAIST as a faculty member last year.

2018.10.30 View 6391

Professor Baik Awarded Sangsan Young Mathematician Prize

(Professor Hyungryul Baik)

Professor Hyungryul Baik from the Department of Mathematical Sciences was honored as the recipient of the 2018 Sangsan Prize for Young Mathematicians by the Korean Mathematical Society (KMS).

The Sangsan Prize recognizes young mathematicians who finished their degree within the previous five years and have begun an outstanding research career. Professor Baik was recognized for his studies in the fields of low-dimensional topology, geophysical mathematics, and geometric theory. In particular, his Ph.D. dissertation presented a new criterion that completely identifies the hyperbolic surface group, making an inference about the nature of the hyperbolic manifold group.

Recently, Professor Baik co-published a paper entitled Spaces of Invariant Circular Orders of Groups with Professor Eric Samperton at the University of California Santa Barbara in the renowned academic journal Groups, Geometry, and Dynamics in 2018.

Professor Baik earned his BS at KAIST and finished his MS and Ph.D. in mathematics in 2014 at Cornell University. He joined KAIST as a faculty member last year.

2018.10.30 View 6391 -

Washing and Enrichment of Micro-Particles Encapsulated in Droplets

Researchers developed microfluidic technology for the washing and enrichment of in-droplet micro-particles. They presented the technology using a microfluidic chip based on surface acoustic wave (SAW)-driven acoustic radiation force (ARF).

The team demonstrated the first instance of acoustic in-droplet micro-particle washing with a particle recovery rate of approximately 90 percent. They further extended the applicability of the proposed method to in-droplet particle enrichment with the unprecedented abilities to increase the in-droplet particle quantity and exchange the droplet dispersed phase.

This proposed method enabled on-chip, label-free, continuous, and selective in-droplet micro-particle manipulation. The team demonstrated the first instance of in-droplet micro-particle washing between two types of alternating droplets in a simple microchannel, proving that the method can increase the particle quantity, which has not been achieved by previously reported methods.

The study aimed to develop an in-droplet micro-particle washing and enrichment method based on SAW-driven ARF. When a droplet containing particles is exposed to an acoustic field, both the droplet and suspended particles experience ARF arising from inhomogeneous wave scattering at the liquid-liquid and liquid-solid interfaces. Unlike previous in-droplet particle manipulation methods, this method allows simultaneous and precise control over the droplets and suspended particles. Moreover, the proposed acoustic method does not require labelled particles, such as magnetic particles, and employs a simple microchannel geometry.

Microfluidic sample washing has emerged as an alternative to centrifugation because the limitations of centrifugation-based washing methods can be addressed using continuous washing processes. It also has considerable potential and importance in a variety of applications such as single-cell/particle assays, high-throughput screening of rare samples, and cell culture medium exchange.

Compared to continuous flow-based microfluidic methods, droplet-based microfluidic sample washing has been rarely explored due to technological difficulties. On-chip, in-droplet sample washing requires sample transfer across the droplet interface composed of two immiscible fluids. This process involves simultaneous and precise control over the encapsulated sample and droplet interface during the medium exchange of the in-droplet sample.

Sample encapsulation within individual microscale droplets offers isolated microenvironments for the samples. Experimental uncertainties due to cross-contamination and Taylor dispersion between multiple reagents can be reduced in droplet-based microfluidics.

This is the first research achievement made by the Acousto-Microfluidics Research Center for Next-Generation Healthcare, the cross-generation collaborative lab KAIST opened in May. This novel approach pairs senior and junior faculty members for sustaining the research legacy even after the senior researcher retires. The research center, which paired Chair Professor Hyung Jin Sung and Professors Hyoungsoo Kim and Yeunwoo Cho, made a breakthrough in microfluidics along with PhD candidate Jinsoo Park. The study was featured as the cover of Lab on a Chip published by Royal Society of Chemistry.

Jinsoo Park, first author of the study, believes this technology will may serve as an in-droplet sample preparation platform with in-line integration of other droplet microfluidic components. Chair Professor Sung said, “The proposed acoustic method will offer new perspectives on sample washing and enrichment by performing the operation in microscale droplets.”

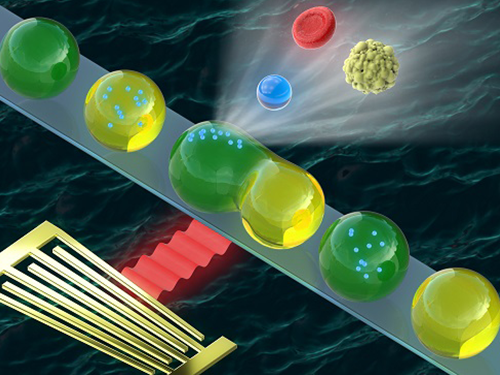

Figure 1. (a) A microfluidic device for in-droplet micro-particle washing and enrichment; (b) alternatingly produced droplets of two kinds at a double T-junction; (c) a droplet and encapsulated micro-particles exposed to surface acoustic wave-driven acoustic radiation force; (d-h) sequential processes of in-droplet micro-particle washing and enrichment operation.

2018.10.19 View 7550

Washing and Enrichment of Micro-Particles Encapsulated in Droplets

Researchers developed microfluidic technology for the washing and enrichment of in-droplet micro-particles. They presented the technology using a microfluidic chip based on surface acoustic wave (SAW)-driven acoustic radiation force (ARF).

The team demonstrated the first instance of acoustic in-droplet micro-particle washing with a particle recovery rate of approximately 90 percent. They further extended the applicability of the proposed method to in-droplet particle enrichment with the unprecedented abilities to increase the in-droplet particle quantity and exchange the droplet dispersed phase.

This proposed method enabled on-chip, label-free, continuous, and selective in-droplet micro-particle manipulation. The team demonstrated the first instance of in-droplet micro-particle washing between two types of alternating droplets in a simple microchannel, proving that the method can increase the particle quantity, which has not been achieved by previously reported methods.

The study aimed to develop an in-droplet micro-particle washing and enrichment method based on SAW-driven ARF. When a droplet containing particles is exposed to an acoustic field, both the droplet and suspended particles experience ARF arising from inhomogeneous wave scattering at the liquid-liquid and liquid-solid interfaces. Unlike previous in-droplet particle manipulation methods, this method allows simultaneous and precise control over the droplets and suspended particles. Moreover, the proposed acoustic method does not require labelled particles, such as magnetic particles, and employs a simple microchannel geometry.

Microfluidic sample washing has emerged as an alternative to centrifugation because the limitations of centrifugation-based washing methods can be addressed using continuous washing processes. It also has considerable potential and importance in a variety of applications such as single-cell/particle assays, high-throughput screening of rare samples, and cell culture medium exchange.

Compared to continuous flow-based microfluidic methods, droplet-based microfluidic sample washing has been rarely explored due to technological difficulties. On-chip, in-droplet sample washing requires sample transfer across the droplet interface composed of two immiscible fluids. This process involves simultaneous and precise control over the encapsulated sample and droplet interface during the medium exchange of the in-droplet sample.

Sample encapsulation within individual microscale droplets offers isolated microenvironments for the samples. Experimental uncertainties due to cross-contamination and Taylor dispersion between multiple reagents can be reduced in droplet-based microfluidics.

This is the first research achievement made by the Acousto-Microfluidics Research Center for Next-Generation Healthcare, the cross-generation collaborative lab KAIST opened in May. This novel approach pairs senior and junior faculty members for sustaining the research legacy even after the senior researcher retires. The research center, which paired Chair Professor Hyung Jin Sung and Professors Hyoungsoo Kim and Yeunwoo Cho, made a breakthrough in microfluidics along with PhD candidate Jinsoo Park. The study was featured as the cover of Lab on a Chip published by Royal Society of Chemistry.

Jinsoo Park, first author of the study, believes this technology will may serve as an in-droplet sample preparation platform with in-line integration of other droplet microfluidic components. Chair Professor Sung said, “The proposed acoustic method will offer new perspectives on sample washing and enrichment by performing the operation in microscale droplets.”

Figure 1. (a) A microfluidic device for in-droplet micro-particle washing and enrichment; (b) alternatingly produced droplets of two kinds at a double T-junction; (c) a droplet and encapsulated micro-particles exposed to surface acoustic wave-driven acoustic radiation force; (d-h) sequential processes of in-droplet micro-particle washing and enrichment operation.

2018.10.19 View 7550 -

Spray Coated Tactile Sensor on a 3-D Surface for Robotic Skin

Robots will be able to conduct a wide variety of tasks as well as humans if they can be given tactile sensing capabilities.

A KAIST research team has reported a stretchable pressure insensitive strain sensor by using an all solution-based process. The solution-based process is easily scalable to accommodate for large areas and can be coated as a thin-film on 3-dimensional irregularly shaped objects via spray coating. These conditions make their processing technique unique and highly suitable for robotic electronic skin or wearable electronic applications.

The making of electronic skin to mimic the tactile sensing properties of human skin is an active area of research for various applications such as wearable electronics, robotics, and prosthetics. One of the major challenges in electronic skin research is differentiating various external stimuli, particularly between strain and pressure. Another issue is uniformly depositing electrical skin on 3-dimensional irregularly shaped objects.

To overcome these issues, the research team led by Professor Steve Park from the Department of Materials Science and Engineering and Professor Jung Kim from the Department of Mechanical Engineering developed electronic skin that can be uniformly coated on 3-dimensional surfaces and distinguish mechanical stimuli. The new electronic skin can also distinguish mechanical stimuli analogous to human skin. The structure of the electronic skin was designed to respond differently under applied pressure and strain. Under applied strain, conducting pathways undergo significant conformational changes, considerably changing the resistance. On the other hand, under applied pressure, negligible conformational change in the conducting pathway occurs; e-skin is therefore non-responsive to pressure. The research team is currently working on strain insensitive pressure sensors to use with the developed strain sensors.

The research team also spatially mapped the local strain without the use of patterned electrode arrays utilizing electrical impedance tomography (EIT). By using EIT, it is possible to minimize the number of electrodes, increase durability, and enable facile fabrication onto 3-dimensional surfaces.

Professor Park said, “Our electronic skin can be mass produced at a low cost and can easily be coated onto complex 3-dimensional surfaces. It is a key technology that can bring us closer to the commercialization of electronic skin for various applications in the near future.”

The result of this work entitled “Pressure Insensitive Strain Sensor with Facile Solution-based Process for Tactile Sensing Applications” was published in the August issue of ACS Nano as a cover article.

(Figure: Detecting mechanical stimuli using electrical impedance tomography.)

2018.09.21 View 8325

Spray Coated Tactile Sensor on a 3-D Surface for Robotic Skin

Robots will be able to conduct a wide variety of tasks as well as humans if they can be given tactile sensing capabilities.

A KAIST research team has reported a stretchable pressure insensitive strain sensor by using an all solution-based process. The solution-based process is easily scalable to accommodate for large areas and can be coated as a thin-film on 3-dimensional irregularly shaped objects via spray coating. These conditions make their processing technique unique and highly suitable for robotic electronic skin or wearable electronic applications.

The making of electronic skin to mimic the tactile sensing properties of human skin is an active area of research for various applications such as wearable electronics, robotics, and prosthetics. One of the major challenges in electronic skin research is differentiating various external stimuli, particularly between strain and pressure. Another issue is uniformly depositing electrical skin on 3-dimensional irregularly shaped objects.

To overcome these issues, the research team led by Professor Steve Park from the Department of Materials Science and Engineering and Professor Jung Kim from the Department of Mechanical Engineering developed electronic skin that can be uniformly coated on 3-dimensional surfaces and distinguish mechanical stimuli. The new electronic skin can also distinguish mechanical stimuli analogous to human skin. The structure of the electronic skin was designed to respond differently under applied pressure and strain. Under applied strain, conducting pathways undergo significant conformational changes, considerably changing the resistance. On the other hand, under applied pressure, negligible conformational change in the conducting pathway occurs; e-skin is therefore non-responsive to pressure. The research team is currently working on strain insensitive pressure sensors to use with the developed strain sensors.

The research team also spatially mapped the local strain without the use of patterned electrode arrays utilizing electrical impedance tomography (EIT). By using EIT, it is possible to minimize the number of electrodes, increase durability, and enable facile fabrication onto 3-dimensional surfaces.

Professor Park said, “Our electronic skin can be mass produced at a low cost and can easily be coated onto complex 3-dimensional surfaces. It is a key technology that can bring us closer to the commercialization of electronic skin for various applications in the near future.”

The result of this work entitled “Pressure Insensitive Strain Sensor with Facile Solution-based Process for Tactile Sensing Applications” was published in the August issue of ACS Nano as a cover article.

(Figure: Detecting mechanical stimuli using electrical impedance tomography.)

2018.09.21 View 8325 -

KAIST Develops VRFB with Longer Durability

(from left: PhD candidate Soohyun Kim, Professor Hee-Tak Kim and PhD candidate Junghoon Choi)

There has been growing demand for large-scale storage for energy produced from renewable energy sources in an efficient and stable way. To meet this demand, a KAIST research team developed a new vanadium redox-flow battery (VRFB) with 15 times greater capacity retention and five times longer durability. This VRFB battery can be an excellent candidate for a large-scale rechargeable battery with no risk of explosion.

The VRFB has received much attention for its high efficiency and reliability with the absence of cross-contamination. However, it has the limitation of having insufficient charge and discharge efficiency and a low capacity retention rate because its perfluorinated membrane is very permeable to any active materials. To minimize energy loss, it needs a membrane that has low vanadium ion permeability and high ion conductivity. Hence, there was an attempt to incorporate a hydrocarbon membrane that has low cost and high ion selectivity but it turned out that the VO₂+ caused chemical degradation, which led to shortening the battery life drastically.

To develop a membrane with pore sizes smaller than the hydrated size of vanadium ions yet larger than that of the protons, a research team co-led by Professor Hee-Tae Jung and Professor Hee-Tak Kim from the Department of Chemical and Biomolecular Engineering implemented a graphene-oxide framework (GOF) membrane by cross-linking graphene oxide nanosheets. They believed that GOF, having strong ion selectivity, would be a good candidate for the membrane component for the VRFB. The interlayer spacing between the GO sheets limited moisture expansion and provided selective ion permeation.

The GOF membrane increased the capacity retention of the VRFB, which showed a 15 times higher rate than that of perfluorinated membranes. Its cycling stability was also enhanced up to five times, compared to conventional hydrocarbon membranes.

These pore-sized-tuned graphene oxide frameworks will allow pore-sized tuning of membranes and will be applicable to electrochemical systems that utilize ions of various sizes, such as rechargeable batteries and sensors.

Professor Kim said, “Developing a membrane that prevents the mixing of positive and negative active materials has been a chronic issue in the field of redox-flow batteries. Through this research, we showed that nanotechnology can prevent this crossover issue and membrane degradation. I believe that this technology can be applied to various rechargeable batteries requiring large-scale storage.”

This research was published in Nano Letters on May 3.

Figure 1. Electrochemical performances of the VRFBs with Nafion 115, SPAES (sulfonated poly), and GOF/SPAES: discharge capacity

Figure 2. Schematic of the selective ion transfer of hydrated vanadium ions and protons in the GOF membrane and the molecular structure of the GOF membrane, showing that the GO nanosheets are cross-linked with EDA (ethylenediamine)

2018.09.20 View 7285

KAIST Develops VRFB with Longer Durability

(from left: PhD candidate Soohyun Kim, Professor Hee-Tak Kim and PhD candidate Junghoon Choi)

There has been growing demand for large-scale storage for energy produced from renewable energy sources in an efficient and stable way. To meet this demand, a KAIST research team developed a new vanadium redox-flow battery (VRFB) with 15 times greater capacity retention and five times longer durability. This VRFB battery can be an excellent candidate for a large-scale rechargeable battery with no risk of explosion.

The VRFB has received much attention for its high efficiency and reliability with the absence of cross-contamination. However, it has the limitation of having insufficient charge and discharge efficiency and a low capacity retention rate because its perfluorinated membrane is very permeable to any active materials. To minimize energy loss, it needs a membrane that has low vanadium ion permeability and high ion conductivity. Hence, there was an attempt to incorporate a hydrocarbon membrane that has low cost and high ion selectivity but it turned out that the VO₂+ caused chemical degradation, which led to shortening the battery life drastically.

To develop a membrane with pore sizes smaller than the hydrated size of vanadium ions yet larger than that of the protons, a research team co-led by Professor Hee-Tae Jung and Professor Hee-Tak Kim from the Department of Chemical and Biomolecular Engineering implemented a graphene-oxide framework (GOF) membrane by cross-linking graphene oxide nanosheets. They believed that GOF, having strong ion selectivity, would be a good candidate for the membrane component for the VRFB. The interlayer spacing between the GO sheets limited moisture expansion and provided selective ion permeation.

The GOF membrane increased the capacity retention of the VRFB, which showed a 15 times higher rate than that of perfluorinated membranes. Its cycling stability was also enhanced up to five times, compared to conventional hydrocarbon membranes.

These pore-sized-tuned graphene oxide frameworks will allow pore-sized tuning of membranes and will be applicable to electrochemical systems that utilize ions of various sizes, such as rechargeable batteries and sensors.

Professor Kim said, “Developing a membrane that prevents the mixing of positive and negative active materials has been a chronic issue in the field of redox-flow batteries. Through this research, we showed that nanotechnology can prevent this crossover issue and membrane degradation. I believe that this technology can be applied to various rechargeable batteries requiring large-scale storage.”

This research was published in Nano Letters on May 3.

Figure 1. Electrochemical performances of the VRFBs with Nafion 115, SPAES (sulfonated poly), and GOF/SPAES: discharge capacity

Figure 2. Schematic of the selective ion transfer of hydrated vanadium ions and protons in the GOF membrane and the molecular structure of the GOF membrane, showing that the GO nanosheets are cross-linked with EDA (ethylenediamine)

2018.09.20 View 7285 -

Transfering Nanowires onto a Flexible Substrate

(from left: PhD Min-Ho Seo and Professor Jun-Bo Yoon)

Boasting excellent physical and chemical properties, nanowires (NWs) are suitable for fabricating flexible electronics; therefore, technology to transfer well-aligned wires plays a crucial role in enhancing performance of the devices. A KAIST research team succeeded in developing NW-transfer technology that is expected to enhance the existing chemical reaction-based NW fabrication technology that has this far showed low performance in applicability and productivity.

NWs, one of the most well-known nanomaterials, have the structural advantage of being small and lightweight. Hence, NW-transfer technology has drawn attention because it can fabricate high-performance, flexible nanodevices with high simplicity and throughput.

A conventional nanowire-fabrication method generally has an irregularity issue since it mixes chemically synthesized nanowires in a solution and randomly distributes the NWs onto flexible substrates. Hence, numerous nanofabrication processes have emerged, and one of them is master-mold-based, which enables the fabrication of highly ordered NW arrays embedded onto substrates in a simple and cost-effective manner, but its employment is limited to only some materials because of its chemistry-based NW-transfer mechanism, which is complex and time consuming. For the successful transfer, it requires that adequate chemicals controlling the chemical interfacial adhesion between the master mold, NWs, and flexible substrate be present.

Here, Professor Jun-Bo Yoon and his team from the School of Electrical Engineering introduced a material-independent mechanical-interlocking-based nanowire-transfer (MINT) method to fabricate ultralong and fully aligned NWs on a large flexible substrate in a highly robust manner.

This method involves sequentially forming a nanosacrificial layer and NWs on a nanograting substrate that becomes the master mold for the transfer, then weakening the structure of the nanosacrificial layer through a dry etching process. The nanosacrificial layer very weakly holds the nanowires on the master mold. Therefore, when using a flexible substrate material, the nanowires are very easily transferred from the master mold to the substrate, just like a piece of tape lifting dust off a carpet.

This technology uses common physical vapor deposition and does not rely on NW materials, making it easy to fabricate NWs onto the flexible substrates.

Using this technology, the team was able to fabricate a variety of metal and metal-oxide NWs, including gold, platinum, and copper – all perfectly aligned on a flexible substrate. They also confirmed that it can be applied to creating stable and applicable devices in everyday life by successfully applying it to flexible heaters and gas sensors.

PhD Min-Ho Seo who led this research said, “We have successfully aligned various metals and semiconductor NWs with excellent physical properties onto flexible substrates and applied them to fabricated devices. As a platform-technology, it will contribute to developing high-performing and stable electronic devices.”

This research was published in ACS Nano on May 24.

Figure 1. Photograph of the fabricated wafer-scale fully aligned and ultralong Au nanowire array on a flexible substrate

2018.09.17 View 6112

Transfering Nanowires onto a Flexible Substrate

(from left: PhD Min-Ho Seo and Professor Jun-Bo Yoon)

Boasting excellent physical and chemical properties, nanowires (NWs) are suitable for fabricating flexible electronics; therefore, technology to transfer well-aligned wires plays a crucial role in enhancing performance of the devices. A KAIST research team succeeded in developing NW-transfer technology that is expected to enhance the existing chemical reaction-based NW fabrication technology that has this far showed low performance in applicability and productivity.

NWs, one of the most well-known nanomaterials, have the structural advantage of being small and lightweight. Hence, NW-transfer technology has drawn attention because it can fabricate high-performance, flexible nanodevices with high simplicity and throughput.

A conventional nanowire-fabrication method generally has an irregularity issue since it mixes chemically synthesized nanowires in a solution and randomly distributes the NWs onto flexible substrates. Hence, numerous nanofabrication processes have emerged, and one of them is master-mold-based, which enables the fabrication of highly ordered NW arrays embedded onto substrates in a simple and cost-effective manner, but its employment is limited to only some materials because of its chemistry-based NW-transfer mechanism, which is complex and time consuming. For the successful transfer, it requires that adequate chemicals controlling the chemical interfacial adhesion between the master mold, NWs, and flexible substrate be present.

Here, Professor Jun-Bo Yoon and his team from the School of Electrical Engineering introduced a material-independent mechanical-interlocking-based nanowire-transfer (MINT) method to fabricate ultralong and fully aligned NWs on a large flexible substrate in a highly robust manner.

This method involves sequentially forming a nanosacrificial layer and NWs on a nanograting substrate that becomes the master mold for the transfer, then weakening the structure of the nanosacrificial layer through a dry etching process. The nanosacrificial layer very weakly holds the nanowires on the master mold. Therefore, when using a flexible substrate material, the nanowires are very easily transferred from the master mold to the substrate, just like a piece of tape lifting dust off a carpet.

This technology uses common physical vapor deposition and does not rely on NW materials, making it easy to fabricate NWs onto the flexible substrates.

Using this technology, the team was able to fabricate a variety of metal and metal-oxide NWs, including gold, platinum, and copper – all perfectly aligned on a flexible substrate. They also confirmed that it can be applied to creating stable and applicable devices in everyday life by successfully applying it to flexible heaters and gas sensors.

PhD Min-Ho Seo who led this research said, “We have successfully aligned various metals and semiconductor NWs with excellent physical properties onto flexible substrates and applied them to fabricated devices. As a platform-technology, it will contribute to developing high-performing and stable electronic devices.”

This research was published in ACS Nano on May 24.

Figure 1. Photograph of the fabricated wafer-scale fully aligned and ultralong Au nanowire array on a flexible substrate

2018.09.17 View 6112 -

Potential Drug to Cure Ciliopathies

(from left: Professor Joon Kim and PhD candidate Yong Joon Kim)

Ciliopathies are rare disorders involving functional and structural abnormalities of cilia. Although they are rare, they may reach 1 in 1,000 births. Unfortunately, there are no small-molecule drugs for treating ciliary defects. A KAIST research team conducted successful research that introduces a potential treatment that will be a foundation for developing drugs to treat the disease as well as a platform for developing small-molecule drugs for similar genetic disorders.

It was found that mutations in genes required for the formation or function of primary cilia cause ciliopathies and they result in cerebellar disorders, kidney dysfunction, and retinal degeneration.

Primary cilia are cell organelles playing a crucial role in the human body. They participate in intercellular signal transduction during embryonic development and allow retinal photoreceptor cells to function.

Currently, there are no approved drugs available for treating most ciliopathies. In fact, this is the case for most of the rare genetic disorders involving functional abnormalities through genetic mutation, and gene therapy is usually the only treatment available.

To tackle this issue, a team led by Professor Joon Kim from the Graduate School of Medical Science and Engineering and Ho Jeong Kwon from Yonsei University constructed a cell that mimics a gene-mutated CEP290, one of the main causes of ciliopathies, through genome editing. They then used cell-based compound library screening to obtain a natural small-molecule compound capable of relieving defects in ciliogenesis, the production of cilia.

The CEP290 protein forms a complex with a ciliopathy protein called NPHP5 to support the function of the ciliary transition zone. In cases where the CEP290 protein is not formed due to a genetic mutation, NPHP5 will not function normally. Here, the compound was confirmed to partially restore the function of the complex by normalizing the function of NPHP5.

The team also identified that the compound is capable of retarding retinal degeneration by injecting the compound into animal models.

As a result, they discovered a lead compound for developing medication to treat ciliopathy patients involving retinal degeneration. Hence, the findings imply that chemical compounds that target other proteins interacting with the disease protein can mitigate shortages of a disease protein in recessive genetic disorders.

PhD candidate Yong Joon Kim stated, “This study shows how genetic disorders caused by genetic mutation can be treated with small-molecule drugs.”

Professor Kim said, “Since the efficacy of the candidate drug has been verified through animal testing, a follow-up study will also be conducted to demonstrate the effect on humans.”

This research was published in the Journal of Clinical Investigation on July 23.

Figure 1. Identification of compounds that rescue ciliogenesis defects caused by CEP290 knockout

Figure 2. Eupatilin injection ameliorates M-opsin trafficking and electrophysiological response of cone photoreceptors in rd16 mice

2018.08.30 View 8138

Potential Drug to Cure Ciliopathies

(from left: Professor Joon Kim and PhD candidate Yong Joon Kim)

Ciliopathies are rare disorders involving functional and structural abnormalities of cilia. Although they are rare, they may reach 1 in 1,000 births. Unfortunately, there are no small-molecule drugs for treating ciliary defects. A KAIST research team conducted successful research that introduces a potential treatment that will be a foundation for developing drugs to treat the disease as well as a platform for developing small-molecule drugs for similar genetic disorders.

It was found that mutations in genes required for the formation or function of primary cilia cause ciliopathies and they result in cerebellar disorders, kidney dysfunction, and retinal degeneration.

Primary cilia are cell organelles playing a crucial role in the human body. They participate in intercellular signal transduction during embryonic development and allow retinal photoreceptor cells to function.

Currently, there are no approved drugs available for treating most ciliopathies. In fact, this is the case for most of the rare genetic disorders involving functional abnormalities through genetic mutation, and gene therapy is usually the only treatment available.

To tackle this issue, a team led by Professor Joon Kim from the Graduate School of Medical Science and Engineering and Ho Jeong Kwon from Yonsei University constructed a cell that mimics a gene-mutated CEP290, one of the main causes of ciliopathies, through genome editing. They then used cell-based compound library screening to obtain a natural small-molecule compound capable of relieving defects in ciliogenesis, the production of cilia.

The CEP290 protein forms a complex with a ciliopathy protein called NPHP5 to support the function of the ciliary transition zone. In cases where the CEP290 protein is not formed due to a genetic mutation, NPHP5 will not function normally. Here, the compound was confirmed to partially restore the function of the complex by normalizing the function of NPHP5.

The team also identified that the compound is capable of retarding retinal degeneration by injecting the compound into animal models.

As a result, they discovered a lead compound for developing medication to treat ciliopathy patients involving retinal degeneration. Hence, the findings imply that chemical compounds that target other proteins interacting with the disease protein can mitigate shortages of a disease protein in recessive genetic disorders.

PhD candidate Yong Joon Kim stated, “This study shows how genetic disorders caused by genetic mutation can be treated with small-molecule drugs.”

Professor Kim said, “Since the efficacy of the candidate drug has been verified through animal testing, a follow-up study will also be conducted to demonstrate the effect on humans.”

This research was published in the Journal of Clinical Investigation on July 23.

Figure 1. Identification of compounds that rescue ciliogenesis defects caused by CEP290 knockout

Figure 2. Eupatilin injection ameliorates M-opsin trafficking and electrophysiological response of cone photoreceptors in rd16 mice

2018.08.30 View 8138 -

Rh Ensemble Catalyst for Effective Automobile Exhaust Treatment

(from left: Professor Hyunjoo Lee and PhD candidate Hojin Jeong)

A KAIST research team has developed a fully dispersed Rh ensemble catalyst (ENS) that shows better performance than commercial diesel oxidation catalyst (DOC). This newly developed ENSs could improve low-temperature automobile exhaust treatment.

Precious metals have been used for various heterogeneous reactions, but it is crucial to maximize efficiency of catalysts due to their high cost. Single-atom catalysts (SACs) have received much attention because it is possible for all of the metal atoms to be used for reactions, yet they do not show catalytic activity for reactions that require ensemble sites.

Meanwhile, hydrocarbons, such as propylene (C3H6) and propane (C3H8) are typical automobile exhaust gas pollutants and must be converted to carbon dioxide (CO2) and water (H2O) before they are released as exhaust. Since the hydrocarbon oxidation reaction proceeds only during carbon-carbon (C-C) or carbon-hydrogen (C-H) bond cleavage, it is essential to secure the metal ensemble site for the catalytic reaction. Therefore, precious metal catalysts with high dispersion and ensemble sites are greatly needed.

To solve this issue, Professor Hyunjoo Lee from the Department of Chemical and Biomolecular Engineering and Professor Jeong Woo Han from POSTECH developed an Rh ensemble catalyst with 100% dispersion, and applied it to automobile after-treatment. Having a 100% dispersion means that every metal atom is used for the reaction since it is exposed on the surface.

SACs also have 100% dispersion, but the difference is that ENSs have the unique advantage of having an ensemble site with two or more atoms.

As a result of the experiment, the ENSs showed excellent catalytic performance in CO, NO, propylene, and propane oxidation at low temperatures. This complements the disadvantage of nanoparticle catalyst (NPs) that perform catalysis poorly at low temperatures due to low metal dispersion, or SACs without hydrocarbon oxidation.

In particular, the ENSs have superior low-temperature activity even better than commercial DOC, hence they are expected to be applied to automobile exhaust treatment.

Professor Lee said, “I believe that the ENSs have given academic contribution for proposing a new concept of metal catalysts, differentiating from conventional SACs and NPs. At the same time, they are of great value in the industry of exhaust treatment catalysts.”

This research, led by PhD candidate Hojin Jeong, was published in the Journal of the American Chemical Society on July 5.

Figure 1. Concept of Rh ensemble catalyst for automobile exhaust treatment

Figure 2. Structure and performance comparison of single-atom catalyst and ensemble catalyst

Figure 3. Energy-dispersive X-ray spectroscopy (EDS) mapping images for SAC, ENS, and NP, respectively (green, Eh; red, Ce)

2018.08.29 View 7138

Rh Ensemble Catalyst for Effective Automobile Exhaust Treatment

(from left: Professor Hyunjoo Lee and PhD candidate Hojin Jeong)

A KAIST research team has developed a fully dispersed Rh ensemble catalyst (ENS) that shows better performance than commercial diesel oxidation catalyst (DOC). This newly developed ENSs could improve low-temperature automobile exhaust treatment.

Precious metals have been used for various heterogeneous reactions, but it is crucial to maximize efficiency of catalysts due to their high cost. Single-atom catalysts (SACs) have received much attention because it is possible for all of the metal atoms to be used for reactions, yet they do not show catalytic activity for reactions that require ensemble sites.

Meanwhile, hydrocarbons, such as propylene (C3H6) and propane (C3H8) are typical automobile exhaust gas pollutants and must be converted to carbon dioxide (CO2) and water (H2O) before they are released as exhaust. Since the hydrocarbon oxidation reaction proceeds only during carbon-carbon (C-C) or carbon-hydrogen (C-H) bond cleavage, it is essential to secure the metal ensemble site for the catalytic reaction. Therefore, precious metal catalysts with high dispersion and ensemble sites are greatly needed.

To solve this issue, Professor Hyunjoo Lee from the Department of Chemical and Biomolecular Engineering and Professor Jeong Woo Han from POSTECH developed an Rh ensemble catalyst with 100% dispersion, and applied it to automobile after-treatment. Having a 100% dispersion means that every metal atom is used for the reaction since it is exposed on the surface.

SACs also have 100% dispersion, but the difference is that ENSs have the unique advantage of having an ensemble site with two or more atoms.

As a result of the experiment, the ENSs showed excellent catalytic performance in CO, NO, propylene, and propane oxidation at low temperatures. This complements the disadvantage of nanoparticle catalyst (NPs) that perform catalysis poorly at low temperatures due to low metal dispersion, or SACs without hydrocarbon oxidation.

In particular, the ENSs have superior low-temperature activity even better than commercial DOC, hence they are expected to be applied to automobile exhaust treatment.

Professor Lee said, “I believe that the ENSs have given academic contribution for proposing a new concept of metal catalysts, differentiating from conventional SACs and NPs. At the same time, they are of great value in the industry of exhaust treatment catalysts.”

This research, led by PhD candidate Hojin Jeong, was published in the Journal of the American Chemical Society on July 5.

Figure 1. Concept of Rh ensemble catalyst for automobile exhaust treatment

Figure 2. Structure and performance comparison of single-atom catalyst and ensemble catalyst

Figure 3. Energy-dispersive X-ray spectroscopy (EDS) mapping images for SAC, ENS, and NP, respectively (green, Eh; red, Ce)

2018.08.29 View 7138 -

Levitating 2D Semiconductor for Better Performance

(from top: Professor Yeon Sik Jung and PhD candidate Soomin Yim)

Atomically thin 2D semiconductors have been drawing attention for their superior physical properties over silicon semiconductors; nevertheless, they are not the most appealing materials due to their structural instability and costly manufacturing process. To shed some light on these limitations, a KAIST research team suspended a 2D semiconductor on a dome-shaped nanostructure to produce a highly efficient semiconductor at a low cost.

2D semiconducting materials have emerged as alternatives for silicon-based semiconductors because of their inherent flexibility, high transparency, and excellent carrier transport properties, which are the important characteristics for flexible electronics.

Despite their outstanding physical and chemical properties, they are oversensitive to their environment due to their extremely thin nature. Hence, any irregularities in the supporting surface can affect the properties of 2D semiconductors and make it more difficult to produce reliable and well performing devices. In particular, it can result in serious degradation of charge-carrier mobility or light-emission yield.

To solve this problem, there have been continued efforts to fundamentally block the substrate effects. One way is to suspend a 2D semiconductor; however, this method will degrade mechanical durability due to the absence of a supporter underneath the 2D semiconducting materials.

Professor Yeon Sik Jung from the Department of Materials Science and Engineering and his team came up with a new strategy based on the insertion of high-density topographic patterns as a nanogap-containing supporter between 2D materials and the substrate in order to mitigate their contact and to block the substrate-induced unwanted effects.

More than 90% of the dome-shaped supporter is simply an empty space because of its nanometer scale size. Placing a 2D semiconductor on this structure creates a similar effect to levitating the layer. Hence, this method secures the mechanical durability of the device while minimizing the undesired effects from the substrate. By applying this method to the 2D semiconductor, the charge-carrier mobility was more than doubled, showing a significant improvement of the performance of the 2D semiconductor.

Additionally, the team reduced the price of manufacturing the semiconductor. In general, constructing an ultra-fine dome structure on a surface generally involves costly equipment to create individual patterns on the surface. However, the team employed a method of self-assembling nanopatterns in which molecules assemble themselves to form a nanostructure. This method led to reducing production costs and showed good compatibility with conventional semiconductor manufacturing processes.

Professor Jung said, “This research can be applied to improve devices using various 2D semiconducting materials as well as devices using graphene, a metallic 2D material. It will be useful in a broad range of applications, such as the material for the high speed transistor channels for next-generation flexible displays or for the active layer in light detectors.”

This research, led by PhD candidate Soomin Yim, was published in Nano Letters in April.

Figure 1. Image of a 2D semiconductor using dome structures

2018.08.28 View 6555

Levitating 2D Semiconductor for Better Performance

(from top: Professor Yeon Sik Jung and PhD candidate Soomin Yim)

Atomically thin 2D semiconductors have been drawing attention for their superior physical properties over silicon semiconductors; nevertheless, they are not the most appealing materials due to their structural instability and costly manufacturing process. To shed some light on these limitations, a KAIST research team suspended a 2D semiconductor on a dome-shaped nanostructure to produce a highly efficient semiconductor at a low cost.

2D semiconducting materials have emerged as alternatives for silicon-based semiconductors because of their inherent flexibility, high transparency, and excellent carrier transport properties, which are the important characteristics for flexible electronics.

Despite their outstanding physical and chemical properties, they are oversensitive to their environment due to their extremely thin nature. Hence, any irregularities in the supporting surface can affect the properties of 2D semiconductors and make it more difficult to produce reliable and well performing devices. In particular, it can result in serious degradation of charge-carrier mobility or light-emission yield.

To solve this problem, there have been continued efforts to fundamentally block the substrate effects. One way is to suspend a 2D semiconductor; however, this method will degrade mechanical durability due to the absence of a supporter underneath the 2D semiconducting materials.

Professor Yeon Sik Jung from the Department of Materials Science and Engineering and his team came up with a new strategy based on the insertion of high-density topographic patterns as a nanogap-containing supporter between 2D materials and the substrate in order to mitigate their contact and to block the substrate-induced unwanted effects.

More than 90% of the dome-shaped supporter is simply an empty space because of its nanometer scale size. Placing a 2D semiconductor on this structure creates a similar effect to levitating the layer. Hence, this method secures the mechanical durability of the device while minimizing the undesired effects from the substrate. By applying this method to the 2D semiconductor, the charge-carrier mobility was more than doubled, showing a significant improvement of the performance of the 2D semiconductor.

Additionally, the team reduced the price of manufacturing the semiconductor. In general, constructing an ultra-fine dome structure on a surface generally involves costly equipment to create individual patterns on the surface. However, the team employed a method of self-assembling nanopatterns in which molecules assemble themselves to form a nanostructure. This method led to reducing production costs and showed good compatibility with conventional semiconductor manufacturing processes.

Professor Jung said, “This research can be applied to improve devices using various 2D semiconducting materials as well as devices using graphene, a metallic 2D material. It will be useful in a broad range of applications, such as the material for the high speed transistor channels for next-generation flexible displays or for the active layer in light detectors.”

This research, led by PhD candidate Soomin Yim, was published in Nano Letters in April.

Figure 1. Image of a 2D semiconductor using dome structures

2018.08.28 View 6555 -

Professor YongKeun Park Wins the 2018 Fumio Okano Award

(Professor Park)

Professor YongKeun Park from the Department of Physics won the 2018 Fumio Okano Award in recognition of his contributions to 3D display technology development during the annual conference of the International Society for Optics and Photonics (SPIE) held last month in Orlando, Florida in the US.

The Fumio Okano Best 3D Paper Prize is presented annually in memory of Dr. Fumio Okano, a pioneer and innovator of 3D displays who passed away in 2013, for his contributions to the field of 3D TVs and displays. The award is sponsored by NHK-ES.

Professor Park and his team are developing novel technology for measuring and visualizing 3D images by applying random light scattering. He has published numerous papers on 3D holographic camera technology and 3000x enhanced performance of 3D holographic displays in renowned international journals such as Nature Photonics, Nature Communications, and Science Advances. His technology has drawn international attention from renowned media outlets including Newsweek and Forbes.

He has established two startups to commercialize his technology. Tomocube specializes in 3D imaging microscopes using holotomographic technology and the company exports their products to several countries including the US and Japan. The.Wave.Talk is exploring technology for examining pre-existing bacteria anywhere and anytime.

Professor Park’s innovations have already been recognized in and out of KAIST. In February, he was selected as the KAISTian of the Year for his outstanding research, commercialization, and startups. He was also decorated with the National Science Award in April by the Ministry of Science and ICT and the Hong Jin-Ki Innovation Award later in May by the Yumin Cultural Foundation.

Professor Park said, “3D holography is emerging as a significant technology with growing potential and positive impacts on our daily lives. However, the current technology lags far behind the levels displayed in SF movies. We will do our utmost to reach this level with more commercialization."

2018.05.31 View 10477

Professor YongKeun Park Wins the 2018 Fumio Okano Award

(Professor Park)

Professor YongKeun Park from the Department of Physics won the 2018 Fumio Okano Award in recognition of his contributions to 3D display technology development during the annual conference of the International Society for Optics and Photonics (SPIE) held last month in Orlando, Florida in the US.

The Fumio Okano Best 3D Paper Prize is presented annually in memory of Dr. Fumio Okano, a pioneer and innovator of 3D displays who passed away in 2013, for his contributions to the field of 3D TVs and displays. The award is sponsored by NHK-ES.

Professor Park and his team are developing novel technology for measuring and visualizing 3D images by applying random light scattering. He has published numerous papers on 3D holographic camera technology and 3000x enhanced performance of 3D holographic displays in renowned international journals such as Nature Photonics, Nature Communications, and Science Advances. His technology has drawn international attention from renowned media outlets including Newsweek and Forbes.

He has established two startups to commercialize his technology. Tomocube specializes in 3D imaging microscopes using holotomographic technology and the company exports their products to several countries including the US and Japan. The.Wave.Talk is exploring technology for examining pre-existing bacteria anywhere and anytime.

Professor Park’s innovations have already been recognized in and out of KAIST. In February, he was selected as the KAISTian of the Year for his outstanding research, commercialization, and startups. He was also decorated with the National Science Award in April by the Ministry of Science and ICT and the Hong Jin-Ki Innovation Award later in May by the Yumin Cultural Foundation.

Professor Park said, “3D holography is emerging as a significant technology with growing potential and positive impacts on our daily lives. However, the current technology lags far behind the levels displayed in SF movies. We will do our utmost to reach this level with more commercialization."

2018.05.31 View 10477 -

Platinum Catalyst Has Price Lowed and Durability Doubled

(Professor Cho in the Department of Materials Science and Engineering)

Professor EunAe Cho in the Department of Materials Science and Engineering reported a fuel cell catalyst that shows 12 times higher performance and twice the durability than previously used platinum catalyst.

Fuel cells, eco-friendly power generators, are said to be running air purifiers. A hydrogen vehicle powered by fuel cells can allegedly purify more than 98 percent of the particulate matter and ultrafine particles from the amount of air that 70 adults breathe.

Despite this peculiarity, the high price of platinum, which is used as an electrode catalyst, remains a big challenge to accelerating commercialization. In addition, recently developed ‘nano-structured platinum catalysts’ have not yet commercialized due to its meager oxygen reduction reaction and durability in fuel cell.

Addressing all those challenges, Professor Cho’s team reported a platinum catalyst costing 30 percent less but boasting 12 times higher performance.

The research team, to this end, combined the platinum with nickel, then applied various metallic elements for making the most efficient performance. Among others, they found that the addition of gallium can modulate the oxygen intermediate binding energy, leading to enhanced catalytic activity of the oxygen reduction reaction.

They made octahedron nanoparticle platinum-nickel alloy and could efficiently achieve 12-times high performance with the platinum catalyst by adding gallium to the surface of octahedron.

Existing fuel cell catalysts have issues in practical fuel cell applications. However, Professor Cho’s team experimentally proved the high performance of the catalyst even in the fuel cell, and is expected to be practically applied to the existing procedure.

First author JeongHoon Lim said their work demonstrates the gallium-added octahedral nanoparticles can be utilized as a highly active and durable oxygen reduction reaction catalyst in practical fuel cell applications. It will make it feasible for the mass production of the catalysts.

Professor Cho also said, “Our study realized the two main goals: an affordable price and increased performance of fuel cells. We hope this will make a contribution to the market competitiveness of fuel cell electric vehicles.”

This research was described in Nano Letters in April and was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP), the National Research Foundation (NRF), and the Agency for Defense Development (ADD).

(Figure: HAADF STEM images with EDX analyses and line scanning profiles of (a) Ga-PtNi/C and (b) PtNi/C during the voltage-cycling tests. The composition changes of Ni, Pt, and Ga atoms in the nanoparticles were determined by EDX (inset in the EDX mapping results)).

2018.05.15 View 7476

Platinum Catalyst Has Price Lowed and Durability Doubled

(Professor Cho in the Department of Materials Science and Engineering)

Professor EunAe Cho in the Department of Materials Science and Engineering reported a fuel cell catalyst that shows 12 times higher performance and twice the durability than previously used platinum catalyst.

Fuel cells, eco-friendly power generators, are said to be running air purifiers. A hydrogen vehicle powered by fuel cells can allegedly purify more than 98 percent of the particulate matter and ultrafine particles from the amount of air that 70 adults breathe.

Despite this peculiarity, the high price of platinum, which is used as an electrode catalyst, remains a big challenge to accelerating commercialization. In addition, recently developed ‘nano-structured platinum catalysts’ have not yet commercialized due to its meager oxygen reduction reaction and durability in fuel cell.

Addressing all those challenges, Professor Cho’s team reported a platinum catalyst costing 30 percent less but boasting 12 times higher performance.

The research team, to this end, combined the platinum with nickel, then applied various metallic elements for making the most efficient performance. Among others, they found that the addition of gallium can modulate the oxygen intermediate binding energy, leading to enhanced catalytic activity of the oxygen reduction reaction.

They made octahedron nanoparticle platinum-nickel alloy and could efficiently achieve 12-times high performance with the platinum catalyst by adding gallium to the surface of octahedron.

Existing fuel cell catalysts have issues in practical fuel cell applications. However, Professor Cho’s team experimentally proved the high performance of the catalyst even in the fuel cell, and is expected to be practically applied to the existing procedure.

First author JeongHoon Lim said their work demonstrates the gallium-added octahedral nanoparticles can be utilized as a highly active and durable oxygen reduction reaction catalyst in practical fuel cell applications. It will make it feasible for the mass production of the catalysts.

Professor Cho also said, “Our study realized the two main goals: an affordable price and increased performance of fuel cells. We hope this will make a contribution to the market competitiveness of fuel cell electric vehicles.”

This research was described in Nano Letters in April and was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP), the National Research Foundation (NRF), and the Agency for Defense Development (ADD).

(Figure: HAADF STEM images with EDX analyses and line scanning profiles of (a) Ga-PtNi/C and (b) PtNi/C during the voltage-cycling tests. The composition changes of Ni, Pt, and Ga atoms in the nanoparticles were determined by EDX (inset in the EDX mapping results)).

2018.05.15 View 7476 -

Capillary Forces at Work for Lithium-Sulfur Batteries

Professor Do Kyung Kim from the KAIST Department of Materials Science and Engineering and his team succeeded in developing high-areal-capacity lithium sulfur batteries (Li-S batteries) by capturing polysulfide with carbon nanofibers. This research will provide new batteries to replace existing lithium rechargeable batteries, shifting the commercialization of related technologies ahead.

Electrical vehicles and large-scale energy storage systems necessitate the development of batteries with high energy density and cost effectiveness, and Li-S batteries are known to be one of the promising alternatives to the predominant lithium ion batteries.

With six times as much energy density, Li-S batteries theoretically thrust electric vehicle to twice the distance of lithium ion batteries. Therefore, they have been spotlighted as next-generation lithium rechargeable batteries because they can go up to 400km once charged.

However, several issues make it challenging to readily commercialize Li-S batteries. The low electrical conductivity of sulfur, volumetric expansion and contraction of the battery during charge and discharge, and permanent damage of the electrode caused by the dissolution of the lithium polysulfide into the electrolyte – known as the “shuttle effect” – are three of the biggest obstacles to commercial-grade Li-S batteries.

While there have been numerous attempts to curb, avoid, or alleviate these issues — such as the physical encapsulation of sulfur using various metal oxides or carbonaceous matrices — most of them entail utilizing zero-dimensional (0D) carbon materials. This encapsulation method has been somewhat effective in enhancing the electrical conductivity of sulfur while simultaneously tolerating some volumetric alterations and suppressing the shuttle effect. The downside of 0D carbon material-based encapsulation methods is their complicated synthetic processing and the limited mass loading of sulfur.

With this in mind, the team set out to employ one-dimensional (1D) carbon materials instead. Unlike the 0D case, 1D carbon materials render a large surface area and a long-range conduction path for electrons and lithium ions. Being 1D also solves the undesirable high-contact resistance problem frequently encountered by 0D carbon material-based encapsulation.

The key to developing the proposed material was to exploit the capillary force to decrease the energy associated with the dissolution of polysulfides. As such, carbon nanofibers (CNFs) were found to be suitable for high-areal-capacity lithium-sulfur batteries since capillary force acting between CNFs can take advantage of the high electrical conductivity with the suppressed dissolution of sulfides.

The research findings show that sulfur was successfully contained in between the CNFs by wetting due to the capillary force without the need for complicated synthetic processing, as in the 0D case. The research results indicate that the sulfur contained per unit area (mg/cm2) is five times greater for the newly implemented method, which then enabled the lithium-sulfur battery to achieve an areal capacity of 7 mAh/cm2, which amounts to as much as at most seven times that of conventional lithium ion batteries.

First author Jong Hyuk Yun stated that the unprecedented methods utilized in this study will help further and widen the progress of lithium batteries in general. Meanwhile, Professor Kim said, “This study brought us closer to commercial-grade high-capacity Li-S batteries, which are applicable for a wide variety of products, including electric vehicles, unmanned aerial vehicles (UAVs), and drones.”

This research, led by PhD candidate Yun, was published in the 18th issue of this year’s Nano Letters.

Figure 1. Electrochemical reaction leading to the containment of the sulfur within the carbon nanofiber and the corresponding specific capacity of the battery over a number of charge-discharge cycles

Figure 2. SEM images of the first discharged electrode containing lithium sulfide at the junction between the nanofibers, and the first charged electrode

Figure 3. carbon nanofiber effectively absorbing liquid based lithium polysulfide

2018.05.14 View 7826

Capillary Forces at Work for Lithium-Sulfur Batteries

Professor Do Kyung Kim from the KAIST Department of Materials Science and Engineering and his team succeeded in developing high-areal-capacity lithium sulfur batteries (Li-S batteries) by capturing polysulfide with carbon nanofibers. This research will provide new batteries to replace existing lithium rechargeable batteries, shifting the commercialization of related technologies ahead.

Electrical vehicles and large-scale energy storage systems necessitate the development of batteries with high energy density and cost effectiveness, and Li-S batteries are known to be one of the promising alternatives to the predominant lithium ion batteries.

With six times as much energy density, Li-S batteries theoretically thrust electric vehicle to twice the distance of lithium ion batteries. Therefore, they have been spotlighted as next-generation lithium rechargeable batteries because they can go up to 400km once charged.

However, several issues make it challenging to readily commercialize Li-S batteries. The low electrical conductivity of sulfur, volumetric expansion and contraction of the battery during charge and discharge, and permanent damage of the electrode caused by the dissolution of the lithium polysulfide into the electrolyte – known as the “shuttle effect” – are three of the biggest obstacles to commercial-grade Li-S batteries.

While there have been numerous attempts to curb, avoid, or alleviate these issues — such as the physical encapsulation of sulfur using various metal oxides or carbonaceous matrices — most of them entail utilizing zero-dimensional (0D) carbon materials. This encapsulation method has been somewhat effective in enhancing the electrical conductivity of sulfur while simultaneously tolerating some volumetric alterations and suppressing the shuttle effect. The downside of 0D carbon material-based encapsulation methods is their complicated synthetic processing and the limited mass loading of sulfur.

With this in mind, the team set out to employ one-dimensional (1D) carbon materials instead. Unlike the 0D case, 1D carbon materials render a large surface area and a long-range conduction path for electrons and lithium ions. Being 1D also solves the undesirable high-contact resistance problem frequently encountered by 0D carbon material-based encapsulation.

The key to developing the proposed material was to exploit the capillary force to decrease the energy associated with the dissolution of polysulfides. As such, carbon nanofibers (CNFs) were found to be suitable for high-areal-capacity lithium-sulfur batteries since capillary force acting between CNFs can take advantage of the high electrical conductivity with the suppressed dissolution of sulfides.

The research findings show that sulfur was successfully contained in between the CNFs by wetting due to the capillary force without the need for complicated synthetic processing, as in the 0D case. The research results indicate that the sulfur contained per unit area (mg/cm2) is five times greater for the newly implemented method, which then enabled the lithium-sulfur battery to achieve an areal capacity of 7 mAh/cm2, which amounts to as much as at most seven times that of conventional lithium ion batteries.

First author Jong Hyuk Yun stated that the unprecedented methods utilized in this study will help further and widen the progress of lithium batteries in general. Meanwhile, Professor Kim said, “This study brought us closer to commercial-grade high-capacity Li-S batteries, which are applicable for a wide variety of products, including electric vehicles, unmanned aerial vehicles (UAVs), and drones.”

This research, led by PhD candidate Yun, was published in the 18th issue of this year’s Nano Letters.

Figure 1. Electrochemical reaction leading to the containment of the sulfur within the carbon nanofiber and the corresponding specific capacity of the battery over a number of charge-discharge cycles

Figure 2. SEM images of the first discharged electrode containing lithium sulfide at the junction between the nanofibers, and the first charged electrode

Figure 3. carbon nanofiber effectively absorbing liquid based lithium polysulfide

2018.05.14 View 7826