CO

-

Professor Junil Choi Receives Stephen O. Rice Prize

< Professor Junil Choi (second from the left) >

Professor Junil Choi from the School of Electrical Engineering received the Stephen O. Rice Prize at the Global Communications Conference (GLOBECOM) hosted by the Institute of Electrical and Electronics Engineers (IEEE) in Hawaii on December 10, 2019.

The Stephen O. Rice Prize is awarded to only one paper of exceptional merit every year. The IEEE Communications Society evaluates all papers published in the IEEE Transactions on Communications journal within the last three years, and marks each paper by aggregating its scores on originality, the number of citations, impact, and peer evaluation.

Professor Choi won the prize for his research on one-bit analog-to-digital converters (ADCs) for multiuser massive multiple-input and multiple-output (MIMO) antenna systems published in 2016. In his paper, Professor Choi proposed a technology that can drastically reduce the power consumption of the multiuser massive MIMO antenna systems, which are the core technology for 5G and future wireless communication. Professor Choi’s paper has been cited more than 230 times in various academic journals and conference papers since its publication, and multiple follow-up studies are actively ongoing.

In 2015, Professor Choi received the IEEE Signal Processing Society Best Paper Award, an award equals to the Stephen O. Rice Prize. He was also selected as the winner of the 15th Haedong Young Engineering Researcher Award presented by the Korean Institute of Communications and Information Sciences (KICS) on December 6, 2019 for his outstanding academic achievements, including 34 international journal publications and 26 US patent registrations.

(END)

2019.12.23 View 13231

Professor Junil Choi Receives Stephen O. Rice Prize

< Professor Junil Choi (second from the left) >

Professor Junil Choi from the School of Electrical Engineering received the Stephen O. Rice Prize at the Global Communications Conference (GLOBECOM) hosted by the Institute of Electrical and Electronics Engineers (IEEE) in Hawaii on December 10, 2019.

The Stephen O. Rice Prize is awarded to only one paper of exceptional merit every year. The IEEE Communications Society evaluates all papers published in the IEEE Transactions on Communications journal within the last three years, and marks each paper by aggregating its scores on originality, the number of citations, impact, and peer evaluation.

Professor Choi won the prize for his research on one-bit analog-to-digital converters (ADCs) for multiuser massive multiple-input and multiple-output (MIMO) antenna systems published in 2016. In his paper, Professor Choi proposed a technology that can drastically reduce the power consumption of the multiuser massive MIMO antenna systems, which are the core technology for 5G and future wireless communication. Professor Choi’s paper has been cited more than 230 times in various academic journals and conference papers since its publication, and multiple follow-up studies are actively ongoing.

In 2015, Professor Choi received the IEEE Signal Processing Society Best Paper Award, an award equals to the Stephen O. Rice Prize. He was also selected as the winner of the 15th Haedong Young Engineering Researcher Award presented by the Korean Institute of Communications and Information Sciences (KICS) on December 6, 2019 for his outstanding academic achievements, including 34 international journal publications and 26 US patent registrations.

(END)

2019.12.23 View 13231 -

Professor Sung Yong Kim Elected as the Chair of PICES MONITOR

< Professor Sung Yong Kim >

Professor Sung Yong Kim from the Department of Mechanical Engineering was elected as the chair of the Technical Committee on Monitoring (MONITOR) of the North Pacific Marine Science Organization (PICES).

PICES is an intergovernmental marine science organization that was established in 1992 through a collaboration between six North Pacific nations including South Korea, Russia, the United States, Japan, China, and Canada to exchange and discuss research on the Pacific waters. Its headquarters is located in Canada and the organization consists of seven affiliated maritime science and marine technology committees.

Professor Kim was elected as the chair of the technical committee that focuses on monitoring and will be part of the Science Board as an ex-officio member. His term will last three years from November 2019.

Professor Kim was recognized for his academic excellence, expertise, and leadership among oceanographers both domestically and internationally.

Professor Kim will also participate as an academia civilian committee member of the Maritime and Fisheries Science and Technology Committee under the Korean Ministry of Oceans and Fisheries for two years from December 18, 2019.

He stated, “I will give my full efforts to broaden Korean oceanography research by participating in maritime leadership positions at home and abroad, and help South Korea become a maritime powerhouse.”

(END)

2019.12.22 View 11353

Professor Sung Yong Kim Elected as the Chair of PICES MONITOR

< Professor Sung Yong Kim >

Professor Sung Yong Kim from the Department of Mechanical Engineering was elected as the chair of the Technical Committee on Monitoring (MONITOR) of the North Pacific Marine Science Organization (PICES).

PICES is an intergovernmental marine science organization that was established in 1992 through a collaboration between six North Pacific nations including South Korea, Russia, the United States, Japan, China, and Canada to exchange and discuss research on the Pacific waters. Its headquarters is located in Canada and the organization consists of seven affiliated maritime science and marine technology committees.

Professor Kim was elected as the chair of the technical committee that focuses on monitoring and will be part of the Science Board as an ex-officio member. His term will last three years from November 2019.

Professor Kim was recognized for his academic excellence, expertise, and leadership among oceanographers both domestically and internationally.

Professor Kim will also participate as an academia civilian committee member of the Maritime and Fisheries Science and Technology Committee under the Korean Ministry of Oceans and Fisheries for two years from December 18, 2019.

He stated, “I will give my full efforts to broaden Korean oceanography research by participating in maritime leadership positions at home and abroad, and help South Korea become a maritime powerhouse.”

(END)

2019.12.22 View 11353 -

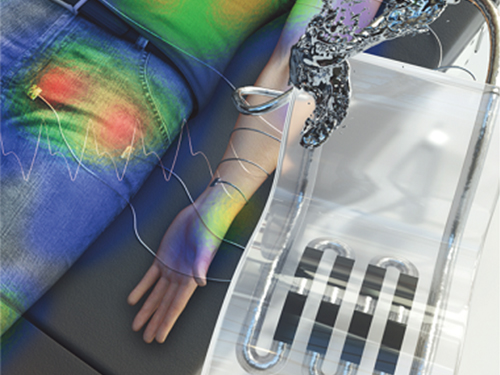

New Liquid Metal Wearable Pressure Sensor Created for Health Monitoring Applications

Soft pressure sensors have received significant research attention in a variety of fields, including soft robotics, electronic skin, and wearable electronics. Wearable soft pressure sensors have great potential for the real-time health monitoring and for the early diagnosis of diseases.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering developed a highly sensitive wearable pressure sensor for health monitoring applications. This work was reported in Advanced Healthcare Materials on November 21 as a front cover article.

This technology is capable of sensitive, precise, and continuous measurement of physiological and physical signals and shows great potential for health monitoring applications and the early diagnosis of diseases.

A soft pressure sensor is required to have high compliance, high sensitivity, low cost, long-term performance stability, and environmental stability in order to be employed for continuous health monitoring. Conventional solid-state soft pressure sensors using functional materials including carbon nanotubes and graphene have showed great sensing performance. However, these sensors suffer from limited stretchability, signal drifting, and long-term instability due to the distance between the stretchable substrate and the functional materials.

To overcome these issues, liquid-state electronics using liquid metal have been introduced for various wearable applications. Of these materials, Galinstan, a eutectic metal alloy of gallium, indium, and tin, has great mechanical and electrical properties that can be employed in wearable applications. But today’s liquid metal-based pressure sensors have low-pressure sensitivity, limiting their applicability for health monitoring devices.

The research team developed a 3D-printed rigid microbump array-integrated, liquid metal-based soft pressure sensor. With the help of 3D printing, the integration of a rigid microbump array and the master mold for a liquid metal microchannel could be achieved simultaneously, reducing the complexity of the manufacturing process. Through the integration of the rigid microbump and the microchannel, the new pressure sensor has an extremely low detection limit and enhanced pressure sensitivity compared to previously reported liquid metal-based pressure sensors. The proposed sensor also has a negligible signal drift over 10,000 cycles of pressure, bending, and stretching and exhibited excellent stability when subjected to various environmental conditions.

These performance outcomes make it an excellent sensor for various health monitoring devices. First, the research team demonstrated a wearable wristband device that can continuously monitor one’s pulse during exercise and be employed in a noninvasive cuffless BP monitoring system based on PTT calculations. Then, they introduced a wireless wearable heel pressure monitoring system that integrates three 3D-BLiPS with a wireless communication module.

Professor Park said, “It was possible to measure health indicators including pulse and blood pressure continuously as well as pressure of body parts using our proposed soft pressure sensor. We expect it to be used in health care applications, such as the prevention and the monitoring of the pressure-driven diseases such as pressure ulcers in the near future. There will be more opportunities for future research including a whole-body pressure monitoring system related to other physical parameters.”

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Ministry of Science and ICT.

< Figure 1. The front cover image of Advanced Healthcare Materials, Volume 8, Issue 22. >

< Figure 2. Highly sensitive liquid metal-based soft pressure sensor integrated with 3D-printed microbump array. >

< Figure 3. High pressure sensitivity and reliable sensing performances of the proposed sensor and wireless heel pressure monitoring application. >

-ProfileProfessor Inkyu ParkMicro/Nano Transducers Laboratoryhttp://mintlab1.kaist.ac.kr/

Department of Mechanical EngineeringKAIST

2019.12.20 View 16330

New Liquid Metal Wearable Pressure Sensor Created for Health Monitoring Applications

Soft pressure sensors have received significant research attention in a variety of fields, including soft robotics, electronic skin, and wearable electronics. Wearable soft pressure sensors have great potential for the real-time health monitoring and for the early diagnosis of diseases.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering developed a highly sensitive wearable pressure sensor for health monitoring applications. This work was reported in Advanced Healthcare Materials on November 21 as a front cover article.

This technology is capable of sensitive, precise, and continuous measurement of physiological and physical signals and shows great potential for health monitoring applications and the early diagnosis of diseases.

A soft pressure sensor is required to have high compliance, high sensitivity, low cost, long-term performance stability, and environmental stability in order to be employed for continuous health monitoring. Conventional solid-state soft pressure sensors using functional materials including carbon nanotubes and graphene have showed great sensing performance. However, these sensors suffer from limited stretchability, signal drifting, and long-term instability due to the distance between the stretchable substrate and the functional materials.

To overcome these issues, liquid-state electronics using liquid metal have been introduced for various wearable applications. Of these materials, Galinstan, a eutectic metal alloy of gallium, indium, and tin, has great mechanical and electrical properties that can be employed in wearable applications. But today’s liquid metal-based pressure sensors have low-pressure sensitivity, limiting their applicability for health monitoring devices.

The research team developed a 3D-printed rigid microbump array-integrated, liquid metal-based soft pressure sensor. With the help of 3D printing, the integration of a rigid microbump array and the master mold for a liquid metal microchannel could be achieved simultaneously, reducing the complexity of the manufacturing process. Through the integration of the rigid microbump and the microchannel, the new pressure sensor has an extremely low detection limit and enhanced pressure sensitivity compared to previously reported liquid metal-based pressure sensors. The proposed sensor also has a negligible signal drift over 10,000 cycles of pressure, bending, and stretching and exhibited excellent stability when subjected to various environmental conditions.

These performance outcomes make it an excellent sensor for various health monitoring devices. First, the research team demonstrated a wearable wristband device that can continuously monitor one’s pulse during exercise and be employed in a noninvasive cuffless BP monitoring system based on PTT calculations. Then, they introduced a wireless wearable heel pressure monitoring system that integrates three 3D-BLiPS with a wireless communication module.

Professor Park said, “It was possible to measure health indicators including pulse and blood pressure continuously as well as pressure of body parts using our proposed soft pressure sensor. We expect it to be used in health care applications, such as the prevention and the monitoring of the pressure-driven diseases such as pressure ulcers in the near future. There will be more opportunities for future research including a whole-body pressure monitoring system related to other physical parameters.”

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Ministry of Science and ICT.

< Figure 1. The front cover image of Advanced Healthcare Materials, Volume 8, Issue 22. >

< Figure 2. Highly sensitive liquid metal-based soft pressure sensor integrated with 3D-printed microbump array. >

< Figure 3. High pressure sensitivity and reliable sensing performances of the proposed sensor and wireless heel pressure monitoring application. >

-ProfileProfessor Inkyu ParkMicro/Nano Transducers Laboratoryhttp://mintlab1.kaist.ac.kr/

Department of Mechanical EngineeringKAIST

2019.12.20 View 16330 -

Team Geumo Wins Consecutive Victories in K-Cyber Security Challenge

< Professor Sang Kil Cha >

< Masters Candidate Kangsu Kim and Researcher Corentin Soulet >

Team Geumo, led by Professor Sang Kil Cha from the Graduate School of Information Security, won the K-Cyber Security Challenge in the AI-based automatic vulnerability detection division for two consecutive years in 2018 and 2019.

The K-Cyber Security Challenge is an inter-machine hacking competition. Participants develop and operate AI-based systems that are capable of independently identifying software vulnerabilities and gaining operating rights through hacking. The K-Cyber Security Challenge, inspired by the US Cyber Grand Challenge launched by the Defense Advanced Research Projects Agency (DARPA), is hosted by the Ministry of Science and ICT and organized by the Korea Internet and Security Agency.

Researcher Corentin Soulet of the School of Computing and master’s student Kangsu Kim of the Graduate School of Information Security teamed up for the competition. Professor Cha, who has led the research on software and systems security since his days at Carnegie Mellon University, succeeded in establishing a world-class system using domestic technology.

In a recent collaboration with the Cyber Security Research Center, Professor Cha achieved a ten-fold increase in the speed of binary analysis engines, a key component of AI-based hacking systems. For this accomplishment, he received the Best Paper Award at the 2019 Network and Distributed System Security Workshop on Binary Analysis Research (NDSS BAR).

Kangsu Kim said, "It is a great honor to win the competition two years in a row. I will continue to work hard and apply my knowledge to serve society.”

(END)

2019.12.20 View 11529

Team Geumo Wins Consecutive Victories in K-Cyber Security Challenge

< Professor Sang Kil Cha >

< Masters Candidate Kangsu Kim and Researcher Corentin Soulet >

Team Geumo, led by Professor Sang Kil Cha from the Graduate School of Information Security, won the K-Cyber Security Challenge in the AI-based automatic vulnerability detection division for two consecutive years in 2018 and 2019.

The K-Cyber Security Challenge is an inter-machine hacking competition. Participants develop and operate AI-based systems that are capable of independently identifying software vulnerabilities and gaining operating rights through hacking. The K-Cyber Security Challenge, inspired by the US Cyber Grand Challenge launched by the Defense Advanced Research Projects Agency (DARPA), is hosted by the Ministry of Science and ICT and organized by the Korea Internet and Security Agency.

Researcher Corentin Soulet of the School of Computing and master’s student Kangsu Kim of the Graduate School of Information Security teamed up for the competition. Professor Cha, who has led the research on software and systems security since his days at Carnegie Mellon University, succeeded in establishing a world-class system using domestic technology.

In a recent collaboration with the Cyber Security Research Center, Professor Cha achieved a ten-fold increase in the speed of binary analysis engines, a key component of AI-based hacking systems. For this accomplishment, he received the Best Paper Award at the 2019 Network and Distributed System Security Workshop on Binary Analysis Research (NDSS BAR).

Kangsu Kim said, "It is a great honor to win the competition two years in a row. I will continue to work hard and apply my knowledge to serve society.”

(END)

2019.12.20 View 11529 -

Korea Policy Center for the Fourth Industrial Revolution Opens

The World Economic Forum’s Center for the Fourth Industrial Revolution opened its Korean affiliate center at KAIST on December 10. The Korea Policy Center for the 4th Industrial Revolution (KPC4IR) will develop policy norms and frameworks for accelerating the benefits of emerging technologies.

Many dignitaries including KAIST President Sung-Chul Shin, National Assemblyman Sang-Min Lee, Daejeon City Mayor Her Tae-Jeong, and Managing Director of the WEF Center for the Fourth Industrial Revolution Murat Sonmez attended the opening ceremony.

The center will play a vital role in helping to shape the development of national Fourth Industrial Revolution strategies and public-private initiatives. The Center will actively engage with the government on policy design and piloting activities.

The Center is the result of KAIST’s close partnership with the WEF and its Center for the Fourth Industrial Revolution in San Francisco. KAIST signed an MOU with the WEF in 2017 for this collaboration. Dr. Klaus Schwab expressed his high hopes many times regarding Korea’s potential in responding to the Fourth Industrial Revolution. In addition, he said that KAIST and the City of Daejeon would play a significant role in helping the Fourth Industrial Revolution move forward.

During a meeting with President Moon Jae-In last June, Dr. Schwab expressed his strong desire to collaborate with Korea, and the Korean government designated KAIST as an affiliate center of the WEF.

The KPC4IR had already begun conducting policy research in the areas of block chain and precision medicine even before making a partnership with the WEF. The director of the Center, Distinguished Professor Sang Yup Lee, said, “We have focused on the development of technology but rarely talk about governance. Technology should come with policy. We will conduct policy development on how to ensure inclusive growth capitalizing on emerging technologies. We will also make policy guidelines for technological applications after considering all the ethical perspectives.

President Shin also said in his opening remarks, “Korea has been a fast follower over the past decades in making economic development and innovations. I believe that the Fourth Industrial Revolution gives us the best opportunity to play the role of ‘first mover.’ I look forward to the KPC4IR serving as a ‘Think and Do’ tank, not limiting itself to the role of ‘think tank.’ We will continue to work closely with the WEF in the fields of AI, blockchain, and precision medicine.

2019.12.10 View 9810

Korea Policy Center for the Fourth Industrial Revolution Opens

The World Economic Forum’s Center for the Fourth Industrial Revolution opened its Korean affiliate center at KAIST on December 10. The Korea Policy Center for the 4th Industrial Revolution (KPC4IR) will develop policy norms and frameworks for accelerating the benefits of emerging technologies.

Many dignitaries including KAIST President Sung-Chul Shin, National Assemblyman Sang-Min Lee, Daejeon City Mayor Her Tae-Jeong, and Managing Director of the WEF Center for the Fourth Industrial Revolution Murat Sonmez attended the opening ceremony.

The center will play a vital role in helping to shape the development of national Fourth Industrial Revolution strategies and public-private initiatives. The Center will actively engage with the government on policy design and piloting activities.

The Center is the result of KAIST’s close partnership with the WEF and its Center for the Fourth Industrial Revolution in San Francisco. KAIST signed an MOU with the WEF in 2017 for this collaboration. Dr. Klaus Schwab expressed his high hopes many times regarding Korea’s potential in responding to the Fourth Industrial Revolution. In addition, he said that KAIST and the City of Daejeon would play a significant role in helping the Fourth Industrial Revolution move forward.

During a meeting with President Moon Jae-In last June, Dr. Schwab expressed his strong desire to collaborate with Korea, and the Korean government designated KAIST as an affiliate center of the WEF.

The KPC4IR had already begun conducting policy research in the areas of block chain and precision medicine even before making a partnership with the WEF. The director of the Center, Distinguished Professor Sang Yup Lee, said, “We have focused on the development of technology but rarely talk about governance. Technology should come with policy. We will conduct policy development on how to ensure inclusive growth capitalizing on emerging technologies. We will also make policy guidelines for technological applications after considering all the ethical perspectives.

President Shin also said in his opening remarks, “Korea has been a fast follower over the past decades in making economic development and innovations. I believe that the Fourth Industrial Revolution gives us the best opportunity to play the role of ‘first mover.’ I look forward to the KPC4IR serving as a ‘Think and Do’ tank, not limiting itself to the role of ‘think tank.’ We will continue to work closely with the WEF in the fields of AI, blockchain, and precision medicine.

2019.12.10 View 9810 -

New Members of KAST 2020

< Professor Zong-Tae Bae (Left) and Professor Sang Ouk Kim (Right) >

Professor Zong-Tae Bae from the School of Management Engineering and Professor Sang Ouk Kim from the Department of Materials Science and Engineering became new fellows of the Korean Academy of Science and Technology (KAST) along with 22 other scientists in Korea.

On November 22, KAST announced 24 new members for the year 2020. This includes seven scientists from the field of natural sciences, six from engineering, four from medical sciences, another four from policy research, and three from agriculture and fishery.

The new fellows will begin their term from January next year, and their fellowships wll be conferred during the KAST’s New Year Reception to be held on January 14 in Seoul.

(END)

2019.12.09 View 14440

New Members of KAST 2020

< Professor Zong-Tae Bae (Left) and Professor Sang Ouk Kim (Right) >

Professor Zong-Tae Bae from the School of Management Engineering and Professor Sang Ouk Kim from the Department of Materials Science and Engineering became new fellows of the Korean Academy of Science and Technology (KAST) along with 22 other scientists in Korea.

On November 22, KAST announced 24 new members for the year 2020. This includes seven scientists from the field of natural sciences, six from engineering, four from medical sciences, another four from policy research, and three from agriculture and fishery.

The new fellows will begin their term from January next year, and their fellowships wll be conferred during the KAST’s New Year Reception to be held on January 14 in Seoul.

(END)

2019.12.09 View 14440 -

KAIST Awarded the IPBC R&D Institution Team of the Year

KAIST was awarded the R&D Institution Team of the Year during the annual IPBC (Intellectual Property Business Congress) Asia 2019 held in Tokyo October 28-30. IPBC is a conference dedicated to IP value creation strategies hosted by IAM Media, a world’s leading IP business media platform.

IPBC Asia 2019 recognized the institutions and businesses that employed innovative IP strategies and management to produce the greatest IP value in 11 categories covering automotive, electronics, healthcare and biotechnology, internet and software, R&D institutions, semiconductors, industrials, mobile and telecommunications, Asia IP deals, Asia teams, and Asia individuals. This year, KAIST was recognized as one of the most active patentees in the Asia-Pacific region by significantly increasing its IP value through licensing and tech transfers.

Associate Vice President Kyung Cheol Choi of the Office of University-Industry Cooperation remarked, “We are so delighted to prove the strong research capacity of KAIST. This will help us accomplish our vision of being a leading university that creates global impact.”

2019.12.04 View 9265

KAIST Awarded the IPBC R&D Institution Team of the Year

KAIST was awarded the R&D Institution Team of the Year during the annual IPBC (Intellectual Property Business Congress) Asia 2019 held in Tokyo October 28-30. IPBC is a conference dedicated to IP value creation strategies hosted by IAM Media, a world’s leading IP business media platform.

IPBC Asia 2019 recognized the institutions and businesses that employed innovative IP strategies and management to produce the greatest IP value in 11 categories covering automotive, electronics, healthcare and biotechnology, internet and software, R&D institutions, semiconductors, industrials, mobile and telecommunications, Asia IP deals, Asia teams, and Asia individuals. This year, KAIST was recognized as one of the most active patentees in the Asia-Pacific region by significantly increasing its IP value through licensing and tech transfers.

Associate Vice President Kyung Cheol Choi of the Office of University-Industry Cooperation remarked, “We are so delighted to prove the strong research capacity of KAIST. This will help us accomplish our vision of being a leading university that creates global impact.”

2019.12.04 View 9265 -

KAIST and Google Jointly Develop AI Curricula

KAIST selected the two professors who will develop AI curriculum under the auspices of the KAIST-Google Partnership for AI Education and Research. The Graduate School of AI announced the two authors among the 20 applicants who will develop the curriculum next year. They will be provided 7,500 USD per subject.

Professor Changho Suh from the School of Electrical Engineering and Professor Yong-Jin Yoon from the Department of Mechanical Engineering will use Google technology such as TensorFlow, Google Cloud, and Android to create the curriculum.

Professor Suh’s “TensorFlow for Information Theory and Convex Optimization “will be used for curriculum in the graduate courses and Professor Yoon’s “AI Convergence Project Based Learning (PBL)” will be used for online courses. Professor Yoon’s course will explore and define problems by utilizing AI and experiencing the process of developing products that use AI through design thinking, which involves product design, production, and verification. Professor Suh’s course will discus“information theory and convergence,” which uses basic sciences and engineering as well as AI, machine learning, and deep learning.

2019.12.04 View 16373

KAIST and Google Jointly Develop AI Curricula

KAIST selected the two professors who will develop AI curriculum under the auspices of the KAIST-Google Partnership for AI Education and Research. The Graduate School of AI announced the two authors among the 20 applicants who will develop the curriculum next year. They will be provided 7,500 USD per subject.

Professor Changho Suh from the School of Electrical Engineering and Professor Yong-Jin Yoon from the Department of Mechanical Engineering will use Google technology such as TensorFlow, Google Cloud, and Android to create the curriculum.

Professor Suh’s “TensorFlow for Information Theory and Convex Optimization “will be used for curriculum in the graduate courses and Professor Yoon’s “AI Convergence Project Based Learning (PBL)” will be used for online courses. Professor Yoon’s course will explore and define problems by utilizing AI and experiencing the process of developing products that use AI through design thinking, which involves product design, production, and verification. Professor Suh’s course will discus“information theory and convergence,” which uses basic sciences and engineering as well as AI, machine learning, and deep learning.

2019.12.04 View 16373 -

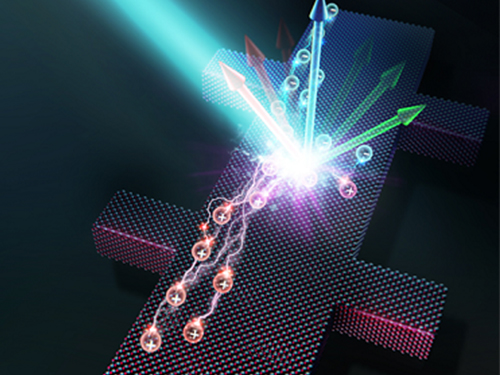

‘Carrier-Resolved Photo-Hall’ to Push Semiconductor Advances

(Professor Shin and Dr. Gunawan (left))

An IBM-KAIST research team described a breakthrough in a 140-year-old mystery in physics. The research reported in Nature last month unlocks the physical characteristics of semiconductors in much greater detail and aids in the development of new and improved semiconductor materials.

Research team under Professor Byungha Shin at the Department of Material Sciences and Engineering and Dr. Oki Gunawan at IBM discovered a new formula and technique that enables the simultaneous extraction of both majority and minority carrier information such as their density and mobility, as well as gain additional insights about carrier lifetimes, diffusion lengths, and the recombination process. This new discovery and technology will help push semiconductor advances in both existing and emerging technologies.

Semiconductors are the basic building blocks of today’s digital electronics age, providing us with a multitude of devices that benefit our modern life. To truly appreciate the physics of semiconductors, it is very important to understand the fundamental properties of the charge carriers inside the materials, whether those particles are positive or negative, their speed under an applied electric field, and how densely they are packed into the material.

Physicist Edwin Hall found a way to determine those properties in 1879, when he discovered that a magnetic field will deflect the movement of electronic charges inside a conductor and that the amount of deflection can be measured as a voltage perpendicular to the flow of the charge. Decades after Hall’s discovery, researchers also recognized that they can measure the Hall effect with light via “photo-Hall experiments”. During such experiments, the light generates multiple carriers or electron–hole pairs in the semiconductors.

Unfortunately, the basic Hall effect only provided insights into the dominant charge carrier (or majority carrier). Researchers were unable to extract the properties of both carriers (the majority and minority carriers) simultaneously. The property information of both carriers is crucial for many applications that involve light such as solar cells and other optoelectronic devices.

In the photo-Hall experiment by the KAIST-IBM team, both carriers contribute to changes in conductivity and the Hall coefficient. The key insight comes from measuring the conductivity and Hall coefficient as a function of light intensity. Hidden in the trajectory of the conductivity, the Hall coefficient curve reveals crucial new information: the difference in the mobility of both carriers. As discussed in the paper, this relationship can be expressed elegantly as: Δµ = d (σ²H)/dσ

The research team solved for both majority and minority carrier mobility and density as a function of light intensity, naming the new technique Carrier-Resolved Photo Hall (CRPH) measurement. With known light illumination intensity, the carrier lifetime can be established in a similar way.

Beyond advances in theoretical understanding, advances in experimental techniques were also critical for enabling this breakthrough. The technique requires a clean Hall signal measurement, which can be challenging for materials where the Hall signal is weak due to low mobility or when extra unwanted signals are present, such as under strong light illumination.

The newly developed photo-Hall technique allows the extraction of an astonishing amount of information from semiconductors. In contrast to only three parameters obtained in the classic Hall measurements, this new technique yields up to seven parameters at every tested level of light intensity. These include the mobility of both the electron and hole; their carrier density under light; the recombination lifetime; and the diffusion lengths for electrons, holes, and ambipolar types. All of these can be repeated N times (i.e. the number of light intensity settings used in the experiment).

Professor Shin said, “This novel technology sheds new light on understanding the physical characteristics of semiconductor materials in great detail.” Dr. Gunawan added, “This will will help accelerate the development of next-generation semiconductor technology such as better solar cells, better optoelectronics devices, and new materials and devices for artificial intelligence technology.”

Profile:

Professor Byungha Shin

Department of Materials Science and Engineering

KAIST

byungha@kaist.ac.kr

http://energymatlab.kaist.ac.kr/

2019.11.18 View 15777

‘Carrier-Resolved Photo-Hall’ to Push Semiconductor Advances

(Professor Shin and Dr. Gunawan (left))

An IBM-KAIST research team described a breakthrough in a 140-year-old mystery in physics. The research reported in Nature last month unlocks the physical characteristics of semiconductors in much greater detail and aids in the development of new and improved semiconductor materials.

Research team under Professor Byungha Shin at the Department of Material Sciences and Engineering and Dr. Oki Gunawan at IBM discovered a new formula and technique that enables the simultaneous extraction of both majority and minority carrier information such as their density and mobility, as well as gain additional insights about carrier lifetimes, diffusion lengths, and the recombination process. This new discovery and technology will help push semiconductor advances in both existing and emerging technologies.

Semiconductors are the basic building blocks of today’s digital electronics age, providing us with a multitude of devices that benefit our modern life. To truly appreciate the physics of semiconductors, it is very important to understand the fundamental properties of the charge carriers inside the materials, whether those particles are positive or negative, their speed under an applied electric field, and how densely they are packed into the material.

Physicist Edwin Hall found a way to determine those properties in 1879, when he discovered that a magnetic field will deflect the movement of electronic charges inside a conductor and that the amount of deflection can be measured as a voltage perpendicular to the flow of the charge. Decades after Hall’s discovery, researchers also recognized that they can measure the Hall effect with light via “photo-Hall experiments”. During such experiments, the light generates multiple carriers or electron–hole pairs in the semiconductors.

Unfortunately, the basic Hall effect only provided insights into the dominant charge carrier (or majority carrier). Researchers were unable to extract the properties of both carriers (the majority and minority carriers) simultaneously. The property information of both carriers is crucial for many applications that involve light such as solar cells and other optoelectronic devices.

In the photo-Hall experiment by the KAIST-IBM team, both carriers contribute to changes in conductivity and the Hall coefficient. The key insight comes from measuring the conductivity and Hall coefficient as a function of light intensity. Hidden in the trajectory of the conductivity, the Hall coefficient curve reveals crucial new information: the difference in the mobility of both carriers. As discussed in the paper, this relationship can be expressed elegantly as: Δµ = d (σ²H)/dσ

The research team solved for both majority and minority carrier mobility and density as a function of light intensity, naming the new technique Carrier-Resolved Photo Hall (CRPH) measurement. With known light illumination intensity, the carrier lifetime can be established in a similar way.

Beyond advances in theoretical understanding, advances in experimental techniques were also critical for enabling this breakthrough. The technique requires a clean Hall signal measurement, which can be challenging for materials where the Hall signal is weak due to low mobility or when extra unwanted signals are present, such as under strong light illumination.

The newly developed photo-Hall technique allows the extraction of an astonishing amount of information from semiconductors. In contrast to only three parameters obtained in the classic Hall measurements, this new technique yields up to seven parameters at every tested level of light intensity. These include the mobility of both the electron and hole; their carrier density under light; the recombination lifetime; and the diffusion lengths for electrons, holes, and ambipolar types. All of these can be repeated N times (i.e. the number of light intensity settings used in the experiment).

Professor Shin said, “This novel technology sheds new light on understanding the physical characteristics of semiconductor materials in great detail.” Dr. Gunawan added, “This will will help accelerate the development of next-generation semiconductor technology such as better solar cells, better optoelectronics devices, and new materials and devices for artificial intelligence technology.”

Profile:

Professor Byungha Shin

Department of Materials Science and Engineering

KAIST

byungha@kaist.ac.kr

http://energymatlab.kaist.ac.kr/

2019.11.18 View 15777 -

KAIST Alumnus NYU Professor Supports Female AI Researchers

A KAIST alumnus and an associate professor at New York University (NYU), Dr. Kyunghyun Cho donated 3,000 USD to the KAIST Graduate School of AI to support female AI researchers.

Professor Cho spoke as a guest lecturer at the 2019 Samsung AI Forum on November 4 and received 3,000 USD as an honorarium. He donated this honorarium to the KAIST Graduate School of AI with a special request to support the school’s female PhD students attending the 2020 International Conference on Learning Representations (ICLR), where he serves as a program co-chair.

Professor Cho received his BS degree from KAIST’s School of Computing in 2009 and is now serving as an associate professor at NYU’s Computer Science Department and Center for Data Science. His research mainly covers machine learning and natural language processing.

Professor Cho said that he decided to make this donation because “In Korea and even in the US, women in science, technology, engineering, and mathematics (STEM) lack opportunities and environments that allow them to excel.”

Professor Song Chong, the Head of the KAIST Graduate School of AI, responded, “We are so grateful for Professor Kyunghyun Cho’s contribution and we will also use funds from the school in addition to the donation to support our female PhD students who will attend the ICLR.”

(END)

2019.11.15 View 10452

KAIST Alumnus NYU Professor Supports Female AI Researchers

A KAIST alumnus and an associate professor at New York University (NYU), Dr. Kyunghyun Cho donated 3,000 USD to the KAIST Graduate School of AI to support female AI researchers.

Professor Cho spoke as a guest lecturer at the 2019 Samsung AI Forum on November 4 and received 3,000 USD as an honorarium. He donated this honorarium to the KAIST Graduate School of AI with a special request to support the school’s female PhD students attending the 2020 International Conference on Learning Representations (ICLR), where he serves as a program co-chair.

Professor Cho received his BS degree from KAIST’s School of Computing in 2009 and is now serving as an associate professor at NYU’s Computer Science Department and Center for Data Science. His research mainly covers machine learning and natural language processing.

Professor Cho said that he decided to make this donation because “In Korea and even in the US, women in science, technology, engineering, and mathematics (STEM) lack opportunities and environments that allow them to excel.”

Professor Song Chong, the Head of the KAIST Graduate School of AI, responded, “We are so grateful for Professor Kyunghyun Cho’s contribution and we will also use funds from the school in addition to the donation to support our female PhD students who will attend the ICLR.”

(END)

2019.11.15 View 10452 -

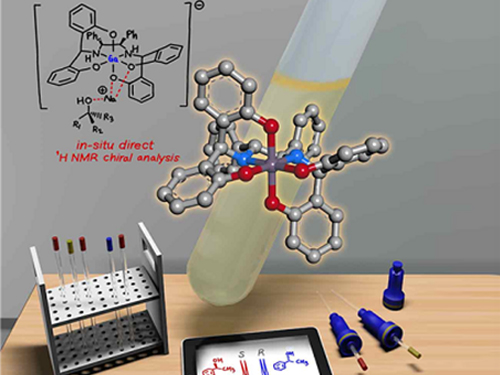

Gallium-Based Solvating Agent Efficiently Analyzes Optically Active Alcohols

A KAIST research team has developed a gallium-based metal complex enabling the rapid chiral analysis of alcohols. A team working under Professor Hyunwoo Kim reported the efficient new alcohol analysis method using nuclear magnetic resonance (NMR) spectroscopy in iScience.

Enantiopure chiral alcohols are ubiquitous in nature and widely utilized as pharmaceuticals. This importance of chirality in synthetic and medicinal chemistry has advanced the search for rapid and facile methods to determine the enantiomeric purities of compounds. To date, chiral analysis has been performed using high-performance liquid chromatography (HPLC) with chiral columns.

Along with the HPLC technique, chiral analysis using NMR spectroscopy has gained tremendous attention as an alternative to traditionally employed chromatographic methods due to its simplicity and rapid detection for real-time measurement. However, this method carries drawbacks such as line-broadening, narrow substrate scope, and poor resolution. Thus, compared with popular methods of chromatographic analysis, NMR spectroscopy is infrequently used for chiral analysis.

In principle, a chiral solvating agent is additionally required for the NMR measurement of chiral alcohols to obtain two distinct signals. However, NMR analysis of chiral alcohols has been challenging due to weak binding interactions with chiral solvating agents. To overcome the intrinsic difficulty of relatively weak molecular interactions that are common for alcohols, many researchers have used multifunctional alcohols to enhance interactions with solvating agents.

Instead, the KAIST team successfully varied the physical properties of metal complexes to induce stronger interactions with alcohols rather than the strategy of using multifunctional analytes, in the hopes of developing a universal chiral solvating agent for alcohols. Compared to the current method of chiral analysis used in the pharmaceutical industry, alcohols that do not possess chromophores can also be directly analyzed with the gallium complexes.

Professor Kim said that this method could be a complementary chiral analysis technique at the industry level in the near future. He added that since the developed gallium complex can determine enantiomeric excess within minutes, it can be further utilized to monitor asymmetric synthesis. This feature will benefit a large number of researchers in the organic chemistry community, as well as the pharmaceutical industry.

(Figure: Schematic view of the in-situ direct 1H NMR chiral analysis.)

-Profile:

Professor Hyunwoo Kim

Department of Chemistry

KAIST

http://mdos.kaist.ac.kr

hwk34@kaist.ac.kr

For more on this article,

please go to https://doi.org/10.1016/j.isci2019.07051

2019.11.14 View 12357

Gallium-Based Solvating Agent Efficiently Analyzes Optically Active Alcohols

A KAIST research team has developed a gallium-based metal complex enabling the rapid chiral analysis of alcohols. A team working under Professor Hyunwoo Kim reported the efficient new alcohol analysis method using nuclear magnetic resonance (NMR) spectroscopy in iScience.

Enantiopure chiral alcohols are ubiquitous in nature and widely utilized as pharmaceuticals. This importance of chirality in synthetic and medicinal chemistry has advanced the search for rapid and facile methods to determine the enantiomeric purities of compounds. To date, chiral analysis has been performed using high-performance liquid chromatography (HPLC) with chiral columns.

Along with the HPLC technique, chiral analysis using NMR spectroscopy has gained tremendous attention as an alternative to traditionally employed chromatographic methods due to its simplicity and rapid detection for real-time measurement. However, this method carries drawbacks such as line-broadening, narrow substrate scope, and poor resolution. Thus, compared with popular methods of chromatographic analysis, NMR spectroscopy is infrequently used for chiral analysis.

In principle, a chiral solvating agent is additionally required for the NMR measurement of chiral alcohols to obtain two distinct signals. However, NMR analysis of chiral alcohols has been challenging due to weak binding interactions with chiral solvating agents. To overcome the intrinsic difficulty of relatively weak molecular interactions that are common for alcohols, many researchers have used multifunctional alcohols to enhance interactions with solvating agents.

Instead, the KAIST team successfully varied the physical properties of metal complexes to induce stronger interactions with alcohols rather than the strategy of using multifunctional analytes, in the hopes of developing a universal chiral solvating agent for alcohols. Compared to the current method of chiral analysis used in the pharmaceutical industry, alcohols that do not possess chromophores can also be directly analyzed with the gallium complexes.

Professor Kim said that this method could be a complementary chiral analysis technique at the industry level in the near future. He added that since the developed gallium complex can determine enantiomeric excess within minutes, it can be further utilized to monitor asymmetric synthesis. This feature will benefit a large number of researchers in the organic chemistry community, as well as the pharmaceutical industry.

(Figure: Schematic view of the in-situ direct 1H NMR chiral analysis.)

-Profile:

Professor Hyunwoo Kim

Department of Chemistry

KAIST

http://mdos.kaist.ac.kr

hwk34@kaist.ac.kr

For more on this article,

please go to https://doi.org/10.1016/j.isci2019.07051

2019.11.14 View 12357 -

AI to Determine When to Intervene with Your Driving

(Professor Uichin Lee (left) and PhD candidate Auk Kim)

Can your AI agent judge when to talk to you while you are driving? According to a KAIST research team, their in-vehicle conservation service technology will judge when it is appropriate to contact you to ensure your safety.

Professor Uichin Lee from the Department of Industrial and Systems Engineering at KAIST and his research team have developed AI technology that automatically detects safe moments for AI agents to provide conversation services to drivers.

Their research focuses on solving the potential problems of distraction created by in-vehicle conversation services. If an AI agent talks to a driver at an inopportune moment, such as while making a turn, a car accident will be more likely to occur.

In-vehicle conversation services need to be convenient as well as safe. However, the cognitive burden of multitasking negatively influences the quality of the service. Users tend to be more distracted during certain traffic conditions. To address this long-standing challenge of the in-vehicle conversation services, the team introduced a composite cognitive model that considers both safe driving and auditory-verbal service performance and used a machine-learning model for all collected data.

The combination of these individual measures is able to determine the appropriate moments for conversation and most appropriate types of conversational services. For instance, in the case of delivering simple-context information, such as a weather forecast, driver safety alone would be the most appropriate consideration. Meanwhile, when delivering information that requires a driver response, such as a “Yes” or “No,” the combination of driver safety and auditory-verbal performance should be considered.

The research team developed a prototype of an in-vehicle conversation service based on a navigation app that can be used in real driving environments. The app was also connected to the vehicle to collect in-vehicle OBD-II/CAN data, such as the steering wheel angle and brake pedal position, and mobility and environmental data such as the distance between successive cars and traffic flow.

Using pseudo-conversation services, the research team collected a real-world driving dataset consisting of 1,388 interactions and sensor data from 29 drivers who interacted with AI conversational agents. Machine learning analysis based on the dataset demonstrated that the opportune moments for driver interruption could be correctly inferred with 87% accuracy.

The safety enhancement technology developed by the team is expected to minimize driver distractions caused by in-vehicle conversation services. This technology can be directly applied to current in-vehicle systems that provide conversation services. It can also be extended and applied to the real-time detection of driver distraction problems caused by the use of a smartphone while driving.

Professor Lee said, “In the near future, cars will proactively deliver various in-vehicle conversation services. This technology will certainly help vehicles interact with their drivers safely as it can fairly accurately determine when to provide conversation services using only basic sensor data generated by cars.”

The researchers presented their findings at the ACM International Joint Conference on Pervasive and Ubiquitous Computing (Ubicomp’19) in London, UK. This research was supported in part by Hyundai NGV and by the Next-Generation Information Computing Development Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT.

(Figure: Visual description of safe enhancement technology for in-vehicle conversation services)

2019.11.13 View 19708

AI to Determine When to Intervene with Your Driving

(Professor Uichin Lee (left) and PhD candidate Auk Kim)

Can your AI agent judge when to talk to you while you are driving? According to a KAIST research team, their in-vehicle conservation service technology will judge when it is appropriate to contact you to ensure your safety.

Professor Uichin Lee from the Department of Industrial and Systems Engineering at KAIST and his research team have developed AI technology that automatically detects safe moments for AI agents to provide conversation services to drivers.

Their research focuses on solving the potential problems of distraction created by in-vehicle conversation services. If an AI agent talks to a driver at an inopportune moment, such as while making a turn, a car accident will be more likely to occur.

In-vehicle conversation services need to be convenient as well as safe. However, the cognitive burden of multitasking negatively influences the quality of the service. Users tend to be more distracted during certain traffic conditions. To address this long-standing challenge of the in-vehicle conversation services, the team introduced a composite cognitive model that considers both safe driving and auditory-verbal service performance and used a machine-learning model for all collected data.

The combination of these individual measures is able to determine the appropriate moments for conversation and most appropriate types of conversational services. For instance, in the case of delivering simple-context information, such as a weather forecast, driver safety alone would be the most appropriate consideration. Meanwhile, when delivering information that requires a driver response, such as a “Yes” or “No,” the combination of driver safety and auditory-verbal performance should be considered.

The research team developed a prototype of an in-vehicle conversation service based on a navigation app that can be used in real driving environments. The app was also connected to the vehicle to collect in-vehicle OBD-II/CAN data, such as the steering wheel angle and brake pedal position, and mobility and environmental data such as the distance between successive cars and traffic flow.

Using pseudo-conversation services, the research team collected a real-world driving dataset consisting of 1,388 interactions and sensor data from 29 drivers who interacted with AI conversational agents. Machine learning analysis based on the dataset demonstrated that the opportune moments for driver interruption could be correctly inferred with 87% accuracy.

The safety enhancement technology developed by the team is expected to minimize driver distractions caused by in-vehicle conversation services. This technology can be directly applied to current in-vehicle systems that provide conversation services. It can also be extended and applied to the real-time detection of driver distraction problems caused by the use of a smartphone while driving.

Professor Lee said, “In the near future, cars will proactively deliver various in-vehicle conversation services. This technology will certainly help vehicles interact with their drivers safely as it can fairly accurately determine when to provide conversation services using only basic sensor data generated by cars.”

The researchers presented their findings at the ACM International Joint Conference on Pervasive and Ubiquitous Computing (Ubicomp’19) in London, UK. This research was supported in part by Hyundai NGV and by the Next-Generation Information Computing Development Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT.

(Figure: Visual description of safe enhancement technology for in-vehicle conversation services)

2019.11.13 View 19708