optics

-

Scholarship in Memory of Professor Shin Endowed by His Family

Professor Joong-Hoon Shin of the Graduate School of Nanoscience and Technology was touted as a genius young scientist who would take the lead in nanoscience technology. After earning degrees from Harvard and the Caltech, he was appointed at KAIST at age 27. He was the youngest professor ever appointed in Korea.

Professor Shin’s outstanding research in the field of semiconductor nano-optics led him to be named as the ‘Scientist of the Year’ for three consecutive years from 2004 by the most prestigious scientist and technology organizations including the Korean Academy Science and Technology, the National Research Foundation of Korea, and the Korean government. However, a fatal car accident last September on the way home from a seminar in Gangwon Province took his life and a promising scholar’s research was left unfinished. He was 47 years old.

Mrs. Young-Eun Hong, the widow of the late Professor Shin, made a 100 million KRW gift to KAIST to establish the ‘Joong-Hoon Shin Scholarship’ on April 7. The scholarship will provide financial assistance to outstanding students of physics and nanoscience.

At the donation ceremony attended by President Sung-Chul Shin, Professor Shin’s colleagues and students, and family members, Mrs. Hong said, “My family would like to help young students achieve their dreams on behalf of my husband. I hope students will remember my husband’s passion and dedication toward his studies for a long time. He was a very hard worker.”

Working at KAIST, Professor Shin made significant achievements in field of semiconductor nano-optics, specializing in silicon photonics and silicon nanocrystal structures. In particular, his research team gained attention reproducing the structure of ‘Morpho butterfly’ wings, which produce the same colors from various angles, using external light as a light source without extra power. Their research led to the creation of original technology dubbed the biomimetics reflective display and was published in Nature in 2012.

Professor Shin’s legacy still endures. In February, a research team under Professor Shin-Hyun Kim of the Department of Chemical and Biomolecular Engineering includingthe late Professor Shin’s doctoral student Seung Yeol Lee, posthumously dedicated their research published on Advanced Materials to Professor Shin. ( click )

KAIST President Sung-Chul Shin, who is also a physicist, said “His passing is a great loss to the whole scientific and technology community, at home and abroad. But Joong-Hoon Shin scholarship will enable the growth and ensure the strength of nanoscience and its education at KAIST. We will uphold Professor Shin’s legacy by doing our best to make KAIST a world-leading university which can create global value.”

Mrs. Hong said she will continue her husband’s academic legacy at his alma maters, Harvard and the Caltech, where he earned his BS in physics and his Ph.D. in applied physics respectively. She said she will start fundraising to establish the Joong-Hoon Shin Scholarship at Harvard and Caltech from July.

(Mrs. Hong poses with President Sung-Chul Shin after donating 100 million KRW for establishing 'Joong-Hoon Shin Scholarship' in memory of her husband on April 7.)

2017.04.10 View 8988

Scholarship in Memory of Professor Shin Endowed by His Family

Professor Joong-Hoon Shin of the Graduate School of Nanoscience and Technology was touted as a genius young scientist who would take the lead in nanoscience technology. After earning degrees from Harvard and the Caltech, he was appointed at KAIST at age 27. He was the youngest professor ever appointed in Korea.

Professor Shin’s outstanding research in the field of semiconductor nano-optics led him to be named as the ‘Scientist of the Year’ for three consecutive years from 2004 by the most prestigious scientist and technology organizations including the Korean Academy Science and Technology, the National Research Foundation of Korea, and the Korean government. However, a fatal car accident last September on the way home from a seminar in Gangwon Province took his life and a promising scholar’s research was left unfinished. He was 47 years old.

Mrs. Young-Eun Hong, the widow of the late Professor Shin, made a 100 million KRW gift to KAIST to establish the ‘Joong-Hoon Shin Scholarship’ on April 7. The scholarship will provide financial assistance to outstanding students of physics and nanoscience.

At the donation ceremony attended by President Sung-Chul Shin, Professor Shin’s colleagues and students, and family members, Mrs. Hong said, “My family would like to help young students achieve their dreams on behalf of my husband. I hope students will remember my husband’s passion and dedication toward his studies for a long time. He was a very hard worker.”

Working at KAIST, Professor Shin made significant achievements in field of semiconductor nano-optics, specializing in silicon photonics and silicon nanocrystal structures. In particular, his research team gained attention reproducing the structure of ‘Morpho butterfly’ wings, which produce the same colors from various angles, using external light as a light source without extra power. Their research led to the creation of original technology dubbed the biomimetics reflective display and was published in Nature in 2012.

Professor Shin’s legacy still endures. In February, a research team under Professor Shin-Hyun Kim of the Department of Chemical and Biomolecular Engineering includingthe late Professor Shin’s doctoral student Seung Yeol Lee, posthumously dedicated their research published on Advanced Materials to Professor Shin. ( click )

KAIST President Sung-Chul Shin, who is also a physicist, said “His passing is a great loss to the whole scientific and technology community, at home and abroad. But Joong-Hoon Shin scholarship will enable the growth and ensure the strength of nanoscience and its education at KAIST. We will uphold Professor Shin’s legacy by doing our best to make KAIST a world-leading university which can create global value.”

Mrs. Hong said she will continue her husband’s academic legacy at his alma maters, Harvard and the Caltech, where he earned his BS in physics and his Ph.D. in applied physics respectively. She said she will start fundraising to establish the Joong-Hoon Shin Scholarship at Harvard and Caltech from July.

(Mrs. Hong poses with President Sung-Chul Shin after donating 100 million KRW for establishing 'Joong-Hoon Shin Scholarship' in memory of her husband on April 7.)

2017.04.10 View 8988 -

Fast, Accurate 3D Imaging to Track Optically-Trapped Particles

KAIST researchers published an article on the development of a novel technique to precisely track the 3-D positions of optically-trapped particles having complicated geometry in high speed in the April 2015 issue of Optica.

Optical tweezers have been used as an invaluable tool for exerting micro-scale force on microscopic particles and manipulating three-dimensional (3-D) positions of particles. Optical tweezers employ a tightly-focused laser whose beam diameter is smaller than one micrometer (1/100 of hair thickness), which generates attractive force on neighboring microscopic particles moving toward the beam focus. Controlling the positions of the beam focus enabled researchers to hold the particles and move them freely to other locations so they coined the name “optical tweezers.”

To locate the optically-trapped particles by a laser beam, optical microscopes have usually been employed. Optical microscopes measure light signals scattered by the optically-trapped microscopic particles and the positions of the particles in two dimensions. However, it was difficult to quantify the particles’ precise positions along the optic axis, the direction of the beam, from a single image, which is analogous to the difficulty of determining the front and rear positions of objects when closing an eye due to a lack of depth perception. Furthermore, it became more difficult to measure precisely 3-D positions of particles when scattered light signals were distorted by optically-trapped particles having complicated shapes or other particles occlude the target object along the optic axis.

Professor YongKeun Park and his research team in the Department of Physics at the Korea Advanced Institute of Science and Technology (KAIST) employed an optical diffraction tomography (ODT) technique to measure 3-D positions of optically-trapped particles in high speed. The principle of ODT is similar to X-ray CT imaging commonly used in hospitals for visualizing the internal organs of patients. Like X-ray CT imaging, which takes several images from various illumination angles, ODT measures 3-D images of optically-trapped particles by illuminating them with a laser beam in various incidence angles.

The KAIST team used optical tweezers to trap a glass bead with a diameter of 2 micrometers, and moved the bead toward a white blood cell having complicated internal structures. The team measured the 3-D dynamics of the white blood cell as it responded to an approaching glass bead via ODT in the high acquisition rate of 60 images per second. Since the white blood cell screens the glass bead along an optic axis, a conventionally-used optical microscope could not determine the 3-D positions of the glass bead. In contrast, the present method employing ODT localized the 3-D positions of the bead precisely as well as measured the composition of the internal materials of the bead and the white blood cell simultaneously.

Professor Park said, “Our technique has the advantage of measuring the 3-D positions and internal structures of optically-trapped particles in high speed without labelling exogenous fluorescent agents and can be applied in various fields including physics, optics, nanotechnology, and medical science.”

Kyoohyun Kim, the lead author of this paper (“Simultaneous 3D Visualization and Position Tracking of Optically Trapped Particles Using Optical Diffraction Tomography”), added, “This ODT technique can also apply to cellular-level surgeries where optical tweezers are used to manipulate intracellular organelles and to display in real time and in 3-D the images of the reaction of the cell membrane and nucleus during the operation or monitoring the recovery process of the cells from the surgery.”

The research results were published as the cover article in the April 2014 issue of Optica, the newest journal launched last year by the Optical Society of America (OSA) for rapid dissemination of high-impact results related to optics.

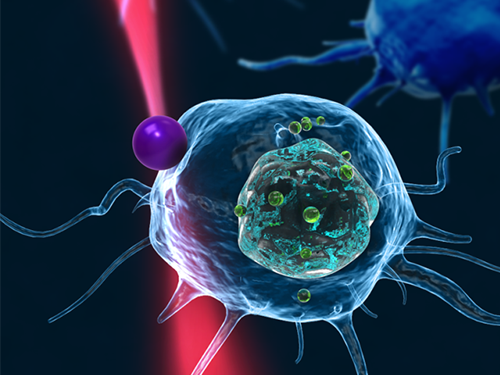

Figure 1: This picture shows the concept image of tweezing an optically-trapped glass bead on the cellular membrane of a white blood cell.

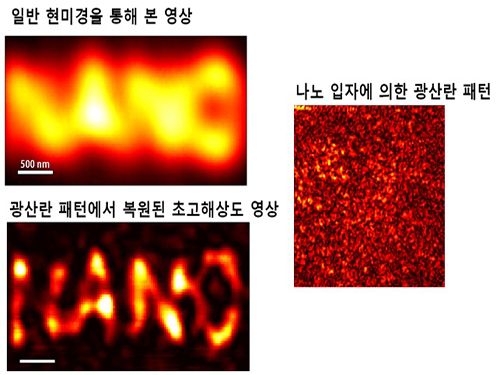

Figure 2: High-speed 3-D images produced from optical diffraction tomography technique

2015.04.24 View 12783

Fast, Accurate 3D Imaging to Track Optically-Trapped Particles

KAIST researchers published an article on the development of a novel technique to precisely track the 3-D positions of optically-trapped particles having complicated geometry in high speed in the April 2015 issue of Optica.

Optical tweezers have been used as an invaluable tool for exerting micro-scale force on microscopic particles and manipulating three-dimensional (3-D) positions of particles. Optical tweezers employ a tightly-focused laser whose beam diameter is smaller than one micrometer (1/100 of hair thickness), which generates attractive force on neighboring microscopic particles moving toward the beam focus. Controlling the positions of the beam focus enabled researchers to hold the particles and move them freely to other locations so they coined the name “optical tweezers.”

To locate the optically-trapped particles by a laser beam, optical microscopes have usually been employed. Optical microscopes measure light signals scattered by the optically-trapped microscopic particles and the positions of the particles in two dimensions. However, it was difficult to quantify the particles’ precise positions along the optic axis, the direction of the beam, from a single image, which is analogous to the difficulty of determining the front and rear positions of objects when closing an eye due to a lack of depth perception. Furthermore, it became more difficult to measure precisely 3-D positions of particles when scattered light signals were distorted by optically-trapped particles having complicated shapes or other particles occlude the target object along the optic axis.

Professor YongKeun Park and his research team in the Department of Physics at the Korea Advanced Institute of Science and Technology (KAIST) employed an optical diffraction tomography (ODT) technique to measure 3-D positions of optically-trapped particles in high speed. The principle of ODT is similar to X-ray CT imaging commonly used in hospitals for visualizing the internal organs of patients. Like X-ray CT imaging, which takes several images from various illumination angles, ODT measures 3-D images of optically-trapped particles by illuminating them with a laser beam in various incidence angles.

The KAIST team used optical tweezers to trap a glass bead with a diameter of 2 micrometers, and moved the bead toward a white blood cell having complicated internal structures. The team measured the 3-D dynamics of the white blood cell as it responded to an approaching glass bead via ODT in the high acquisition rate of 60 images per second. Since the white blood cell screens the glass bead along an optic axis, a conventionally-used optical microscope could not determine the 3-D positions of the glass bead. In contrast, the present method employing ODT localized the 3-D positions of the bead precisely as well as measured the composition of the internal materials of the bead and the white blood cell simultaneously.

Professor Park said, “Our technique has the advantage of measuring the 3-D positions and internal structures of optically-trapped particles in high speed without labelling exogenous fluorescent agents and can be applied in various fields including physics, optics, nanotechnology, and medical science.”

Kyoohyun Kim, the lead author of this paper (“Simultaneous 3D Visualization and Position Tracking of Optically Trapped Particles Using Optical Diffraction Tomography”), added, “This ODT technique can also apply to cellular-level surgeries where optical tweezers are used to manipulate intracellular organelles and to display in real time and in 3-D the images of the reaction of the cell membrane and nucleus during the operation or monitoring the recovery process of the cells from the surgery.”

The research results were published as the cover article in the April 2014 issue of Optica, the newest journal launched last year by the Optical Society of America (OSA) for rapid dissemination of high-impact results related to optics.

Figure 1: This picture shows the concept image of tweezing an optically-trapped glass bead on the cellular membrane of a white blood cell.

Figure 2: High-speed 3-D images produced from optical diffraction tomography technique

2015.04.24 View 12783 -

Ultra-high Resolution 2-dimentional Real-time Image Capture with Super Lens

Ultra-high Resolution 2-dimentional Real-time Image Capture with Super Lens

Applications to high-precision semiconductor processing or intracellular structures observation are possible.

A joint research team led by Professors Yongkeun Park and Yong-Hoon Cho from the Department of Physics, KAIST, has succeeded in capturing real-time 2D images at a resolution of 100 nm (nanometers), which was impossible with optical lens due to the diffraction limit of light until now. Its future application includes high-precision semiconductor manufacturing process or observation of intracellular structures.

This research follows the past research of the super-lens developed by Professor Park last April, using paint spray to observe images that have three times higher resolution than those discovered by conventional optical lens.

Since optical lens utilize the refraction of light, the diffraction limit, which prevents achieving focus smaller than the wavelength of light, has always been a barrier for acquiring high-resolution images. In the past, it was impossible to observe objects less than the size of 200 to 300 nm in the visible light spectrum.

In order to solve the problem of near-field extinction due to scattering of light, the research team used spray paint consisting of nano-particles massed with dense scattering materials to obtain high-resolution information.

Then, by calculating and restoring the first scattering shape of light using the time reversibility of light, the researchers were able to overcome the diffraction limit. The original position of an object to be observed is obtained by deriving the complex trajectory of the light, and reversing the time to locate the particular position of the object.

Professor Park said, “This new technology can be used as the core technology in all fields which require optical measurement and control. The existing electron microscopy cannot observe cells without destroying them, but the new technology allows us to visualize at ultra-high resolution without destruction.”

The research results were published online in the 9th edition of Physical Review Letters, a prestigious international journal in the field of physics.

2014.09.23 View 11304

Ultra-high Resolution 2-dimentional Real-time Image Capture with Super Lens

Ultra-high Resolution 2-dimentional Real-time Image Capture with Super Lens

Applications to high-precision semiconductor processing or intracellular structures observation are possible.

A joint research team led by Professors Yongkeun Park and Yong-Hoon Cho from the Department of Physics, KAIST, has succeeded in capturing real-time 2D images at a resolution of 100 nm (nanometers), which was impossible with optical lens due to the diffraction limit of light until now. Its future application includes high-precision semiconductor manufacturing process or observation of intracellular structures.

This research follows the past research of the super-lens developed by Professor Park last April, using paint spray to observe images that have three times higher resolution than those discovered by conventional optical lens.

Since optical lens utilize the refraction of light, the diffraction limit, which prevents achieving focus smaller than the wavelength of light, has always been a barrier for acquiring high-resolution images. In the past, it was impossible to observe objects less than the size of 200 to 300 nm in the visible light spectrum.

In order to solve the problem of near-field extinction due to scattering of light, the research team used spray paint consisting of nano-particles massed with dense scattering materials to obtain high-resolution information.

Then, by calculating and restoring the first scattering shape of light using the time reversibility of light, the researchers were able to overcome the diffraction limit. The original position of an object to be observed is obtained by deriving the complex trajectory of the light, and reversing the time to locate the particular position of the object.

Professor Park said, “This new technology can be used as the core technology in all fields which require optical measurement and control. The existing electron microscopy cannot observe cells without destroying them, but the new technology allows us to visualize at ultra-high resolution without destruction.”

The research results were published online in the 9th edition of Physical Review Letters, a prestigious international journal in the field of physics.

2014.09.23 View 11304 -

Nanoparticle based Super Lens selected as 2013 Science and Technology News

Professor Yong-keun Park

"Nanoparticle-based Super Lens", an article by KAIST Physics Department’s Professor Yong-keun Park and Professor Yong-hoon Cho’s joint research team, has been selected as one of the ten representative 2013 Science and Technology News, by the Korea Federation of Science and Technology Societies.

This new concept super lens uses the scattering of light, which can yield over three times more superior resolution of previous optical lenses.

Unlike the conventional optical lens that utilizes refraction of the light, the super lens can give the image of viruses and structure within the cell at 100㎚. This lens is also applicable to state-of-the-art optical and semiconductor processes.

In addition, this year's research achievements also include the successful launch of Naro, a new technology to remove the brain cell membrane which gives a more transparent view of the brain, a new drug to inhibit cancer metastasis, as well as the development of ultra-wide-angle insect eye camera technology.

Articles for 2013 Science and Technology News are chosen in three trial reviews by committee and online voting by 5,437 people over the course of [two weeks]14 days, from November 21st to December 4th.

2013.12.14 View 11851

Nanoparticle based Super Lens selected as 2013 Science and Technology News

Professor Yong-keun Park

"Nanoparticle-based Super Lens", an article by KAIST Physics Department’s Professor Yong-keun Park and Professor Yong-hoon Cho’s joint research team, has been selected as one of the ten representative 2013 Science and Technology News, by the Korea Federation of Science and Technology Societies.

This new concept super lens uses the scattering of light, which can yield over three times more superior resolution of previous optical lenses.

Unlike the conventional optical lens that utilizes refraction of the light, the super lens can give the image of viruses and structure within the cell at 100㎚. This lens is also applicable to state-of-the-art optical and semiconductor processes.

In addition, this year's research achievements also include the successful launch of Naro, a new technology to remove the brain cell membrane which gives a more transparent view of the brain, a new drug to inhibit cancer metastasis, as well as the development of ultra-wide-angle insect eye camera technology.

Articles for 2013 Science and Technology News are chosen in three trial reviews by committee and online voting by 5,437 people over the course of [two weeks]14 days, from November 21st to December 4th.

2013.12.14 View 11851 -

Technology Developed to Control Light Scattering Using Holography

Published on May 29th Nature Scientific Reports online

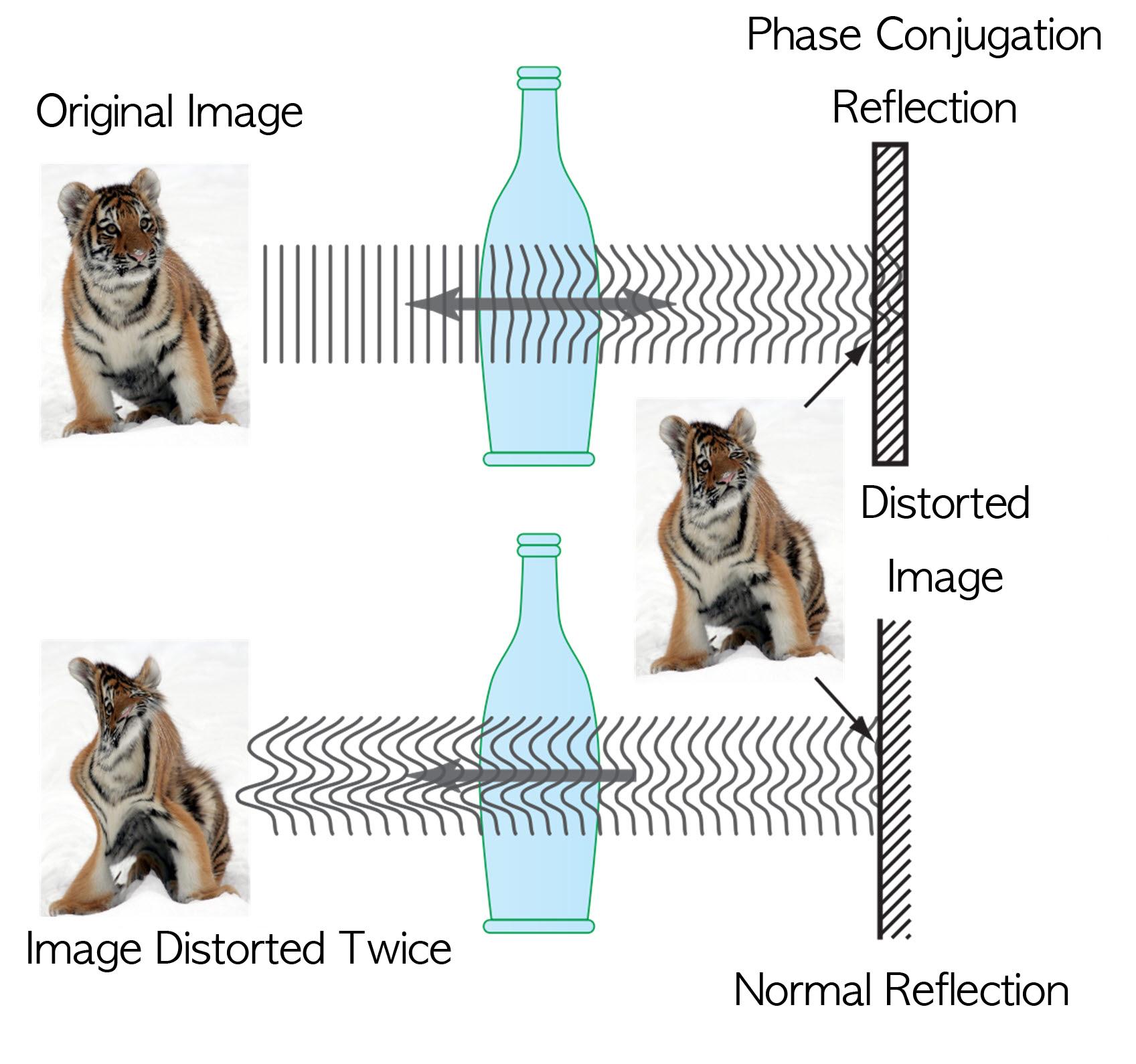

Recently, a popular article demonstrated that an opaque glass becomes transparent as transparent tape is applied to the glass. The scientific principle is that light is less scattered as the rough surface of the opaque glass is filled by transparent tape, thereby making things behind the opaque glass look clearer.

Professor Yong-Keun Park from KAIST’s Department of Physics, in a joint research with MIT Spectroscopy Lab, has developed a technology to easily control light scattering using holography. Their results are published on Nature’s Scientific Reports May 29th online edition.

This technology allows us to see things behind visual obstructions such as cloud and smoke, or even human skin that is highly scattering, optically thick materials. The research team applied the holography technology that records both the direction and intensity of light, and controlled light scattering of obstacles lied between an observer and a target image. The team was able to retrieve the original image by recording the information of scattered light and reflecting the light precisely to the other side.This phenomenon is known as “phase conjugation” in physics. Professor Park’s team applied phase conjugation and digital holography to observe two-dimensional image behind a highly scattering wall. “This technology will be utilized in many fields of physics, optics, nanotechnology, medical science, and even military science,” said Professor Park. “This is different from what is commonly known as penetrating camera or invisible clothes.” He nevertheless drew the line at over-interpreting the technology, “Currently, the significance is on the development of the technology itself that allows us to accurately control the scattering of light."

Figure I. Observed Images

Figure II. Light Scattering Control

2013.07.19 View 10003

Technology Developed to Control Light Scattering Using Holography

Published on May 29th Nature Scientific Reports online

Recently, a popular article demonstrated that an opaque glass becomes transparent as transparent tape is applied to the glass. The scientific principle is that light is less scattered as the rough surface of the opaque glass is filled by transparent tape, thereby making things behind the opaque glass look clearer.

Professor Yong-Keun Park from KAIST’s Department of Physics, in a joint research with MIT Spectroscopy Lab, has developed a technology to easily control light scattering using holography. Their results are published on Nature’s Scientific Reports May 29th online edition.

This technology allows us to see things behind visual obstructions such as cloud and smoke, or even human skin that is highly scattering, optically thick materials. The research team applied the holography technology that records both the direction and intensity of light, and controlled light scattering of obstacles lied between an observer and a target image. The team was able to retrieve the original image by recording the information of scattered light and reflecting the light precisely to the other side.This phenomenon is known as “phase conjugation” in physics. Professor Park’s team applied phase conjugation and digital holography to observe two-dimensional image behind a highly scattering wall. “This technology will be utilized in many fields of physics, optics, nanotechnology, medical science, and even military science,” said Professor Park. “This is different from what is commonly known as penetrating camera or invisible clothes.” He nevertheless drew the line at over-interpreting the technology, “Currently, the significance is on the development of the technology itself that allows us to accurately control the scattering of light."

Figure I. Observed Images

Figure II. Light Scattering Control

2013.07.19 View 10003 -

Technology for Non-Breaking Smartphone Display Developed

High-strength plastic display has been developed by applying a glass-fiber fabric.

“Will bring about innovation to the field by replacing glass substrates”

It is now possible to manufacture non-breaking smartphone display. Heavy glass substrates of large-screen televisions will be replaced with light plastic films.

Professor Choon Sup Yoon from KAIST’s Department of Physics and KAIST Institute for Information Technology Convergence has developed the technology for high-strength plastic substrates to replace glass displays.

The plastic substrate created by Professor Yoon and his research team have greatly enhanced needed properties of heat resistance, transparency, flexibility, inner chemical capability, and tensile strength. Although the material retains flexibility as a native advantage of plastic film, its tensile strength is three times greater than that of normal glass, which is a degree similar to tempered glass. In addition, Professor Yoon’s substrate is as colorless and transparent as glass and resists heat up to 450℃, while its thermal expansivity is only 10% to 20% of existing plastics.

Glass substrates are currently used in practically every display such as mobile phone screens, televisions, and computer monitors for having smooth surface and satisfying basic conditions for display substrates. However, as glass substrates are heavy and easily broken, researchers studied colorless and transparent plastic polyimide films to replace glass substrates for their excellent thermal and chemical stability.

Nonetheless, colorless and transparent polyimide films do not have sufficient heat resistance and mechanical solidity. To resolve this problem, polyimide films are impregnated with glass-fiber fabrics, but it was far from commercialization as the impregnation exacerbates the roughness of surface and light transmittance. The roughness of the surface increases as the solvent evaporates in the impregnation process, resulting in surface roughness of around 0.4μm. The downturn in light transmittance is due to light scattering effect by the discording refractive index of polyimide film and glass-fiber fabric.

Professor Yoon’s research team resolved these issues by tuning the refractive indices of transparent polyimide film and glass-fiber fabric up to four decimal places, and by developing the technology of flattening the film’s surface roughness to a few nanometers. As a result, the research team achieved heat expansivity of 11ppm/℃, surface roughness of 0.9nm, tensile strength of 250MPa, bending curvature radius of 2mm, and light transmittance at 90% with a 110μm-thick glass-fiber fabric impregnated transparent polyimide film substrate.

“The developed substrate can not only replace the traditional glass substrate but also be applied as flexible display substrate,” said Professor Yoon in prospect, “it will bring about technological innovation in display industry as it can fundamentally resolve the issue of shattering mobile phone displays, reduce the weight and thickness of large-area televisions, and apply Roll to Roll process in display manufacture.”

Supported by the Ministry of Knowledge Economy for five years, the technology has applied for 3 patents and is in discussion for technology transfer with related business.

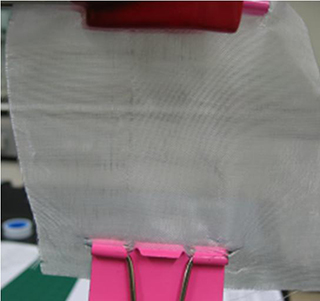

Figure 1. The according (left) and discording (right) refractive indices of glass-fiber fabric and polyimide film. The characters on the left are sharp and clear, but the characters on the right appear foggy.

Figure 2. Picture of the developed glass-fiber fabric

2013.06.09 View 10145

Technology for Non-Breaking Smartphone Display Developed

High-strength plastic display has been developed by applying a glass-fiber fabric.

“Will bring about innovation to the field by replacing glass substrates”

It is now possible to manufacture non-breaking smartphone display. Heavy glass substrates of large-screen televisions will be replaced with light plastic films.

Professor Choon Sup Yoon from KAIST’s Department of Physics and KAIST Institute for Information Technology Convergence has developed the technology for high-strength plastic substrates to replace glass displays.

The plastic substrate created by Professor Yoon and his research team have greatly enhanced needed properties of heat resistance, transparency, flexibility, inner chemical capability, and tensile strength. Although the material retains flexibility as a native advantage of plastic film, its tensile strength is three times greater than that of normal glass, which is a degree similar to tempered glass. In addition, Professor Yoon’s substrate is as colorless and transparent as glass and resists heat up to 450℃, while its thermal expansivity is only 10% to 20% of existing plastics.

Glass substrates are currently used in practically every display such as mobile phone screens, televisions, and computer monitors for having smooth surface and satisfying basic conditions for display substrates. However, as glass substrates are heavy and easily broken, researchers studied colorless and transparent plastic polyimide films to replace glass substrates for their excellent thermal and chemical stability.

Nonetheless, colorless and transparent polyimide films do not have sufficient heat resistance and mechanical solidity. To resolve this problem, polyimide films are impregnated with glass-fiber fabrics, but it was far from commercialization as the impregnation exacerbates the roughness of surface and light transmittance. The roughness of the surface increases as the solvent evaporates in the impregnation process, resulting in surface roughness of around 0.4μm. The downturn in light transmittance is due to light scattering effect by the discording refractive index of polyimide film and glass-fiber fabric.

Professor Yoon’s research team resolved these issues by tuning the refractive indices of transparent polyimide film and glass-fiber fabric up to four decimal places, and by developing the technology of flattening the film’s surface roughness to a few nanometers. As a result, the research team achieved heat expansivity of 11ppm/℃, surface roughness of 0.9nm, tensile strength of 250MPa, bending curvature radius of 2mm, and light transmittance at 90% with a 110μm-thick glass-fiber fabric impregnated transparent polyimide film substrate.

“The developed substrate can not only replace the traditional glass substrate but also be applied as flexible display substrate,” said Professor Yoon in prospect, “it will bring about technological innovation in display industry as it can fundamentally resolve the issue of shattering mobile phone displays, reduce the weight and thickness of large-area televisions, and apply Roll to Roll process in display manufacture.”

Supported by the Ministry of Knowledge Economy for five years, the technology has applied for 3 patents and is in discussion for technology transfer with related business.

Figure 1. The according (left) and discording (right) refractive indices of glass-fiber fabric and polyimide film. The characters on the left are sharp and clear, but the characters on the right appear foggy.

Figure 2. Picture of the developed glass-fiber fabric

2013.06.09 View 10145 -

The control of light at the nano-level

Professor Min Bumki

Professor Min Bumki’s research team from the Department of Mechanical Engineering at KAIST have successfully gained control of the transmittance of light in optical devices using graphene* and artificial 2-dimensional metamaterials**.

* Graphene : a thin membrane composed of pure carbon, with atoms arranged in a regular hexagonal pattern

** Metamaterials : artificial materials engineered to have properties that may not be found in nature

The research results were published in the recent online edition (September 30th) of Nature Materials, a sister journal of the world renowned Nature journal, under the title ‘Terahertz waves with gate-controlled active graphene metamaterials’

Since the discovery of graphene in 2004 by Professors Novoselov and Geim from the University of Manchester (2010 Nobel Prize winners in Physics), it has been dubbed “the dream material” because of its outstanding physical properties.

Graphene has been especially praised for its ability to absorb approximately 2.3% of near infrared and visible rays due to its characteristic electron structure. This property allows graphene to be used as a transparent electrode, which is a vital electrical component used in touch screens and solar batteries. However, graphene’s optical transmittance was largely ignored by researchers due to its limited control using electrical methods and its small optical modulation in data transfer.

Professor Min’s team combined 0.34 nanometer-thick graphene with metamaterials to allow a more effective control of light transmittance and greater optical modulation. This graphene metamaterial can be integrated in to a thin and flexible macromolecule substrate which allows the control of transmittance using electric signals.

This research experimentally showed that graphene metamaterials can not only effective control optical transmittance, but can also be used in graphene optical memory devices using electrical hysteresis.

Professor Min said that “this research allows the effective control of light at the nanometer level” and that “this research will help in the development of microscopic optical modulators or memory disks”.

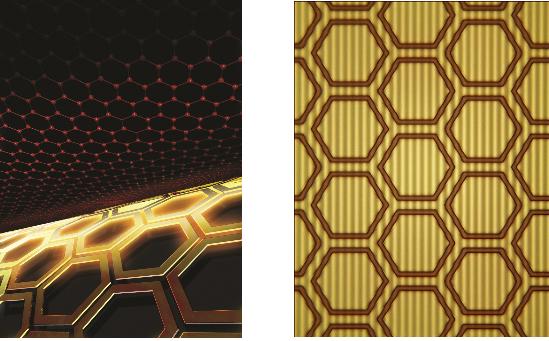

figure 1. The working drawing of graphene metamaterials

figure 2. Conceptual diagram (Left) and microscopic photo (right) of graphene metamaterials

2012.11.23 View 11781

The control of light at the nano-level

Professor Min Bumki

Professor Min Bumki’s research team from the Department of Mechanical Engineering at KAIST have successfully gained control of the transmittance of light in optical devices using graphene* and artificial 2-dimensional metamaterials**.

* Graphene : a thin membrane composed of pure carbon, with atoms arranged in a regular hexagonal pattern

** Metamaterials : artificial materials engineered to have properties that may not be found in nature

The research results were published in the recent online edition (September 30th) of Nature Materials, a sister journal of the world renowned Nature journal, under the title ‘Terahertz waves with gate-controlled active graphene metamaterials’

Since the discovery of graphene in 2004 by Professors Novoselov and Geim from the University of Manchester (2010 Nobel Prize winners in Physics), it has been dubbed “the dream material” because of its outstanding physical properties.

Graphene has been especially praised for its ability to absorb approximately 2.3% of near infrared and visible rays due to its characteristic electron structure. This property allows graphene to be used as a transparent electrode, which is a vital electrical component used in touch screens and solar batteries. However, graphene’s optical transmittance was largely ignored by researchers due to its limited control using electrical methods and its small optical modulation in data transfer.

Professor Min’s team combined 0.34 nanometer-thick graphene with metamaterials to allow a more effective control of light transmittance and greater optical modulation. This graphene metamaterial can be integrated in to a thin and flexible macromolecule substrate which allows the control of transmittance using electric signals.

This research experimentally showed that graphene metamaterials can not only effective control optical transmittance, but can also be used in graphene optical memory devices using electrical hysteresis.

Professor Min said that “this research allows the effective control of light at the nanometer level” and that “this research will help in the development of microscopic optical modulators or memory disks”.

figure 1. The working drawing of graphene metamaterials

figure 2. Conceptual diagram (Left) and microscopic photo (right) of graphene metamaterials

2012.11.23 View 11781