robotics

-

KAIST to showcase a pack of KAIST Start-ups at CES 2023

- KAIST is to run an Exclusive Booth at the Venetian Expo (Hall G) in Eureka Park, at CES 2023, to be held in Las Vegas from Thursday, January 5th through Sunday, the 8th.

- Twelve businesses recently put together by KAIST faculty, alumni, and the start-ups given legal usage of KAIST technologies will be showcased.

- Out of the participating start-ups, the products by Fluiz and Hills Robotics were selected as the “CES Innovation Award 2023 Honoree”, scoring top in their respective categories.

On January 3, KAIST announced that there will be a KAIST booth at Consumer Electronics Show (CES) 2023, the most influential tech event in the world, to be held in Las Vegas from January 3 to 8.

At this exclusive corner, KAIST will introduce the technologies of KAIST start-ups over the exhibition period.

KAIST first started holding its exclusive booth in CES 2019 with five start-up businesses, following up at CES 2020 with 12 start-ups and at CES 2022 with 10 start-ups. At CES 2023, which would be KAIST’s fourth conference, KAIST will be accompanying 12 businesses including start-ups by the faculty members, alumni, and technology transfer companies that just began their businesses with technologies from their research findings that stands a head above others.

To maximize the publicity opportunity, KAIST will support each company’s marketing strategies through cooperation with the Korea International Trade Association (KITA), and provide an opportunity for the school and each startup to create global identity and exhibit the excellence of their technologies at the convention.

The following companies will be at the KAIST Booth in Eureka Park:

The twelve startups mentioned above aim to achieve global technology commecialization in their respective fields of expertise spanning from eXtended Reality (XR) and gaming, to AI and robotics, vehicle and transport, mobile platform, smart city, autonomous driving, healthcare, internet of thing (IoT), through joint research and development, technology transfer and investment attraction from world’s leading institutions and enterprises.

In particular, Fluiz and Hills Robotics won the CES Innovation Award as 2023 Honorees and is expected to attain greater achievements in the future.

A staff member from the KAIST Institute of Technology Value Creation said, “The KAIST Showcase for CES 2023 has prepared a new pitching space for each of the companies for their own IR efforts, and we hope that KAIST startups will actively and effectively market their products and technologies while they are at the convention. We hope it will help them utilize their time here to establish their name in presence here which will eventually serve as a good foothold for them and their predecessors to further global commercialization goals.”

2023.01.04 View 18947

KAIST to showcase a pack of KAIST Start-ups at CES 2023

- KAIST is to run an Exclusive Booth at the Venetian Expo (Hall G) in Eureka Park, at CES 2023, to be held in Las Vegas from Thursday, January 5th through Sunday, the 8th.

- Twelve businesses recently put together by KAIST faculty, alumni, and the start-ups given legal usage of KAIST technologies will be showcased.

- Out of the participating start-ups, the products by Fluiz and Hills Robotics were selected as the “CES Innovation Award 2023 Honoree”, scoring top in their respective categories.

On January 3, KAIST announced that there will be a KAIST booth at Consumer Electronics Show (CES) 2023, the most influential tech event in the world, to be held in Las Vegas from January 3 to 8.

At this exclusive corner, KAIST will introduce the technologies of KAIST start-ups over the exhibition period.

KAIST first started holding its exclusive booth in CES 2019 with five start-up businesses, following up at CES 2020 with 12 start-ups and at CES 2022 with 10 start-ups. At CES 2023, which would be KAIST’s fourth conference, KAIST will be accompanying 12 businesses including start-ups by the faculty members, alumni, and technology transfer companies that just began their businesses with technologies from their research findings that stands a head above others.

To maximize the publicity opportunity, KAIST will support each company’s marketing strategies through cooperation with the Korea International Trade Association (KITA), and provide an opportunity for the school and each startup to create global identity and exhibit the excellence of their technologies at the convention.

The following companies will be at the KAIST Booth in Eureka Park:

The twelve startups mentioned above aim to achieve global technology commecialization in their respective fields of expertise spanning from eXtended Reality (XR) and gaming, to AI and robotics, vehicle and transport, mobile platform, smart city, autonomous driving, healthcare, internet of thing (IoT), through joint research and development, technology transfer and investment attraction from world’s leading institutions and enterprises.

In particular, Fluiz and Hills Robotics won the CES Innovation Award as 2023 Honorees and is expected to attain greater achievements in the future.

A staff member from the KAIST Institute of Technology Value Creation said, “The KAIST Showcase for CES 2023 has prepared a new pitching space for each of the companies for their own IR efforts, and we hope that KAIST startups will actively and effectively market their products and technologies while they are at the convention. We hope it will help them utilize their time here to establish their name in presence here which will eventually serve as a good foothold for them and their predecessors to further global commercialization goals.”

2023.01.04 View 18947 -

A Quick but Clingy Creepy-Crawler that will MARVEL You

Engineered by KAIST Mechanics, a quadrupedal robot climbs steel walls and crawls across metal ceilings at the fastest speed that the world has ever seen.

< Photo 1. (From left) KAIST ME Prof. Hae-Won Park, Ph.D. Student Yong Um, Ph.D. Student Seungwoo Hong >

- Professor Hae-Won Park's team at the Department of Mechanical Engineering developed a quadrupedal robot that can move at a high speed on ferrous walls and ceilings.

- It is expected to make a wide variety of contributions as it is to be used to conduct inspections and repairs of large steel structures such as ships, bridges, and transmission towers, offering an alternative to dangerous or risky activities required in hazardous environments while maintaining productivity and efficiency through automation and unmanning of such operations.

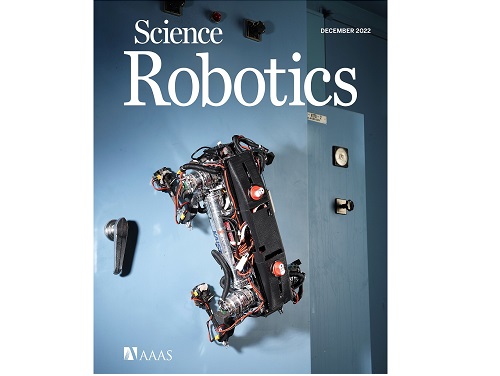

- The study was published as the cover paper of the December issue of Science Robotics.

KAIST (President Kwang Hyung Lee) announced on the 26th that a research team led by Professor Hae-Won Park of the Department of Mechanical Engineering developed a quadrupedal walking robot that can move at high speed on steel walls and ceilings named M.A.R.V.E.L. - rightly so as it is a Magnetically Adhesive Robot for Versatile and Expeditious Locomotion as described in their paper, “Agile and Versatile Climbing on Ferromagnetic Surfaces with a Quadrupedal Robot.” (DOI: 10.1126/scirobotics.add1017)

To make this happen, Professor Park's research team developed a foot pad that can quickly turn the magnetic adhesive force on and off while retaining high adhesive force even on an uneven surface through the use of the Electro-Permanent Magnet (EPM), a device that can magnetize and demagnetize an electromagnet with little power, and the Magneto-Rheological Elastomer (MRE), an elastic material made by mixing a magnetic response factor, such as iron powder, with an elastic material, such as rubber, which they mounted on a small quadrupedal robot they made in-house, at their own laboratory. These walking robots are expected to be put into a wide variety of usage, including being programmed to perform inspections, repairs, and maintenance tasks on large structures made of steel, such as ships, bridges, transmission towers, large storage areas, and construction sites.

This study, in which Seungwoo Hong and Yong Um of the Department of Mechanical Engineering participated as co-first authors, was published as the cover paper in the December issue of Science Robotics.

< Image on the Cover of 2022 December issue of Science Robotics >

Existing wall-climbing robots use wheels or endless tracks, so their mobility is limited on surfaces with steps or irregularities. On the other hand, walking robots for climbing can expect improved mobility in obstacle terrain, but have disadvantages in that they have significantly slower moving speeds or cannot perform various movements.

In order to enable fast movement of the walking robot, the sole of the foot must have strong adhesion force and be able to control the adhesion to quickly switch from sticking to the surface or to be off of it. In addition, it is necessary to maintain the adhesion force even on a rough or uneven surface.

To solve this problem, the research team used the EPM and MRE for the first time in designing the soles of walking robots. An EPM is a magnet that can turn on and off the electromagnetic force with a short current pulse. Unlike general electromagnets, it has the advantage that it does not require energy to maintain the magnetic force. The research team proposed a new EPM with a rectangular structure arrangement, enabling faster switching while significantly lowering the voltage required for switching compared to existing electromagnets.

In addition, the research team was able to increase the frictional force without significantly reducing the magnetic force of the sole by covering the sole with an MRE. The proposed sole weighs only 169 g, but provides a vertical gripping force of about *535 Newtons (N) and a frictional force of 445 N, which is sufficient gripping force for a quadrupedal robot weighing 8 kg.

* 535 N converted to kg is 54.5 kg, and 445 N is 45.4 kg. In other words, even if an external force of up to 54.5 kg in the vertical direction and up to 45.4 kg in the horizontal direction is applied (or even if a corresponding weight is hung), the sole of the foot does not come off the steel plate.

MARVEL climbed up a vertical wall at high speed at a speed of 70 cm per second, and was able to walk while hanging upside down from the ceiling at a maximum speed of 50 cm per second. This is the world's fastest speed for a walking climbing robot. In addition, the research team demonstrated that the robot can climb at a speed of up to 35 cm even on a surface that is painted, dirty with dust and the rust-tainted surfaces of water tanks, proving the robot's performance in a real environment. It was experimentally demonstrated that the robot not only exhibited high speed, but also can switch from floor to wall and from wall to ceiling, and overcome 5-cm high obstacles protruding from walls without difficulty.

The new climbing quadrupedal robot is expected to be widely used for inspection, repair, and maintenance of large steel structures such as ships, bridges, transmission towers, oil pipelines, large storage areas, and construction sites. As the works required in these places involves risks such as falls, suffocation and other accidents that may result in serious injuries or casualties, the need for automation is of utmost urgency.

One of the first co-authors of the paper, a Ph.D. student, Yong Um of KAIST’s Department of Mechanical Engineering, said, "By the use of the magnetic soles made up of the EPM and MRE and the non-linear model predictive controller suitable for climbing, the robot can speedily move through a variety of ferromagnetic surfaces including walls and ceilings, not just level grounds. We believe this would become a cornerstone that will expand the mobility and the places of pedal-mobile robots can venture into." He added, “These robots can be put into good use in executing dangerous and difficult tasks on steel structures in places like the shipbuilding yards.”

This research was carried out with support from the National Research Foundation of Korea's Basic Research in Science & Engineering Program for Mid-Career Researchers and Korea Shipbuilding & Offshore Engineering Co., Ltd..

< Figure 1. The quadrupedal robot (MARVEL) walking over various ferrous surfaces. (A) vertical wall (B) ceiling. (C) over obstacles on a vertical wall (D) making floor-to-wall and wall-to-ceiling transitions (E) moving over a storage tank (F) walking on a wall with a 2-kg weight and over a ceiling with a 3-kg load. >

< Figure 2. Description of the magnetic foot (A) Components of the magnet sole: ankle, Square Eletro-Permanent Magnet(S-EPM), MRE footpad. (B) Components of the S-EPM and MRE footpad. (C) Working principle of the S-EPM. When the magnetization direction is aligned as shown in the left figure, magnetic flux comes out of the keeper and circulates through the steel plate, generating holding force (ON state). Conversely, if the magnetization direction is aligned as shown in the figure on the right, the magnetic flux circulates inside the S-EPM and the holding force disappears (OFF state). >

Video Introduction: Agile and versatile climbing on ferromagnetic surfaces with a quadrupedal robot - YouTube

2022.12.30 View 20058

A Quick but Clingy Creepy-Crawler that will MARVEL You

Engineered by KAIST Mechanics, a quadrupedal robot climbs steel walls and crawls across metal ceilings at the fastest speed that the world has ever seen.

< Photo 1. (From left) KAIST ME Prof. Hae-Won Park, Ph.D. Student Yong Um, Ph.D. Student Seungwoo Hong >

- Professor Hae-Won Park's team at the Department of Mechanical Engineering developed a quadrupedal robot that can move at a high speed on ferrous walls and ceilings.

- It is expected to make a wide variety of contributions as it is to be used to conduct inspections and repairs of large steel structures such as ships, bridges, and transmission towers, offering an alternative to dangerous or risky activities required in hazardous environments while maintaining productivity and efficiency through automation and unmanning of such operations.

- The study was published as the cover paper of the December issue of Science Robotics.

KAIST (President Kwang Hyung Lee) announced on the 26th that a research team led by Professor Hae-Won Park of the Department of Mechanical Engineering developed a quadrupedal walking robot that can move at high speed on steel walls and ceilings named M.A.R.V.E.L. - rightly so as it is a Magnetically Adhesive Robot for Versatile and Expeditious Locomotion as described in their paper, “Agile and Versatile Climbing on Ferromagnetic Surfaces with a Quadrupedal Robot.” (DOI: 10.1126/scirobotics.add1017)

To make this happen, Professor Park's research team developed a foot pad that can quickly turn the magnetic adhesive force on and off while retaining high adhesive force even on an uneven surface through the use of the Electro-Permanent Magnet (EPM), a device that can magnetize and demagnetize an electromagnet with little power, and the Magneto-Rheological Elastomer (MRE), an elastic material made by mixing a magnetic response factor, such as iron powder, with an elastic material, such as rubber, which they mounted on a small quadrupedal robot they made in-house, at their own laboratory. These walking robots are expected to be put into a wide variety of usage, including being programmed to perform inspections, repairs, and maintenance tasks on large structures made of steel, such as ships, bridges, transmission towers, large storage areas, and construction sites.

This study, in which Seungwoo Hong and Yong Um of the Department of Mechanical Engineering participated as co-first authors, was published as the cover paper in the December issue of Science Robotics.

< Image on the Cover of 2022 December issue of Science Robotics >

Existing wall-climbing robots use wheels or endless tracks, so their mobility is limited on surfaces with steps or irregularities. On the other hand, walking robots for climbing can expect improved mobility in obstacle terrain, but have disadvantages in that they have significantly slower moving speeds or cannot perform various movements.

In order to enable fast movement of the walking robot, the sole of the foot must have strong adhesion force and be able to control the adhesion to quickly switch from sticking to the surface or to be off of it. In addition, it is necessary to maintain the adhesion force even on a rough or uneven surface.

To solve this problem, the research team used the EPM and MRE for the first time in designing the soles of walking robots. An EPM is a magnet that can turn on and off the electromagnetic force with a short current pulse. Unlike general electromagnets, it has the advantage that it does not require energy to maintain the magnetic force. The research team proposed a new EPM with a rectangular structure arrangement, enabling faster switching while significantly lowering the voltage required for switching compared to existing electromagnets.

In addition, the research team was able to increase the frictional force without significantly reducing the magnetic force of the sole by covering the sole with an MRE. The proposed sole weighs only 169 g, but provides a vertical gripping force of about *535 Newtons (N) and a frictional force of 445 N, which is sufficient gripping force for a quadrupedal robot weighing 8 kg.

* 535 N converted to kg is 54.5 kg, and 445 N is 45.4 kg. In other words, even if an external force of up to 54.5 kg in the vertical direction and up to 45.4 kg in the horizontal direction is applied (or even if a corresponding weight is hung), the sole of the foot does not come off the steel plate.

MARVEL climbed up a vertical wall at high speed at a speed of 70 cm per second, and was able to walk while hanging upside down from the ceiling at a maximum speed of 50 cm per second. This is the world's fastest speed for a walking climbing robot. In addition, the research team demonstrated that the robot can climb at a speed of up to 35 cm even on a surface that is painted, dirty with dust and the rust-tainted surfaces of water tanks, proving the robot's performance in a real environment. It was experimentally demonstrated that the robot not only exhibited high speed, but also can switch from floor to wall and from wall to ceiling, and overcome 5-cm high obstacles protruding from walls without difficulty.

The new climbing quadrupedal robot is expected to be widely used for inspection, repair, and maintenance of large steel structures such as ships, bridges, transmission towers, oil pipelines, large storage areas, and construction sites. As the works required in these places involves risks such as falls, suffocation and other accidents that may result in serious injuries or casualties, the need for automation is of utmost urgency.

One of the first co-authors of the paper, a Ph.D. student, Yong Um of KAIST’s Department of Mechanical Engineering, said, "By the use of the magnetic soles made up of the EPM and MRE and the non-linear model predictive controller suitable for climbing, the robot can speedily move through a variety of ferromagnetic surfaces including walls and ceilings, not just level grounds. We believe this would become a cornerstone that will expand the mobility and the places of pedal-mobile robots can venture into." He added, “These robots can be put into good use in executing dangerous and difficult tasks on steel structures in places like the shipbuilding yards.”

This research was carried out with support from the National Research Foundation of Korea's Basic Research in Science & Engineering Program for Mid-Career Researchers and Korea Shipbuilding & Offshore Engineering Co., Ltd..

< Figure 1. The quadrupedal robot (MARVEL) walking over various ferrous surfaces. (A) vertical wall (B) ceiling. (C) over obstacles on a vertical wall (D) making floor-to-wall and wall-to-ceiling transitions (E) moving over a storage tank (F) walking on a wall with a 2-kg weight and over a ceiling with a 3-kg load. >

< Figure 2. Description of the magnetic foot (A) Components of the magnet sole: ankle, Square Eletro-Permanent Magnet(S-EPM), MRE footpad. (B) Components of the S-EPM and MRE footpad. (C) Working principle of the S-EPM. When the magnetization direction is aligned as shown in the left figure, magnetic flux comes out of the keeper and circulates through the steel plate, generating holding force (ON state). Conversely, if the magnetization direction is aligned as shown in the figure on the right, the magnetic flux circulates inside the S-EPM and the holding force disappears (OFF state). >

Video Introduction: Agile and versatile climbing on ferromagnetic surfaces with a quadrupedal robot - YouTube

2022.12.30 View 20058 -

KI-Robotics Wins the 2021 Hyundai Motor Autonomous Driving Challenge

Professor Hyunchul Shim’s autonomous driving team topped the challenge

KI-Robotics, a KAIST autonomous driving research team led by Professor Hyunchul Shim from the School of Electric Engineering won the 2021 Hyundai Motor Autonomous Driving Challenge held in Seoul on November 29. The KI-Robotics team received 100 million won in prize money and a field trip to the US.

Out of total 23 teams, the six teams competed in the finals by simultaneously driving through a 4km section within the test operation region, where other traffic was constrained. The challenge included avoiding and overtaking vehicles, crossing intersections, and keeping to traffic laws including traffic lights, lanes, speed limit, and school zones. The contestants were ranked by their order of course completion, but points were deducted every time they violated a traffic rule. A driver and an invigilator rode in each car in case of an emergency, and the race was broadcasted live on a large screen on stage and via YouTube.

In the first round, KI-Robotics came in first with a score of 11 minutes and 27 seconds after a tight race with Incheon University. Although the team’s result in the second round exceeded 16 minutes due to traffic conditions like traffic lights, the 11 minutes and 27 seconds ultimately ranked first out of the six universities. It is worth noting that KI-Robotics focused on its vehicle’s perception and judgement rather than speed when building its algorithm. Out of the six universities that made it to the final round, KI-Robotics was the only team that excluded GPS from the vehicle to minimize its risk.

The team considered the fact that GPS signals are not accurate in urban settings, meaning location errors can cause problems while driving. As an alternative, the team added three radar sensors and cameras in the front and the back of the vehicle. They also used the urban-specific SLAM technology they developed to construct a precise map and were more successful in location determination.

As opposed to other teams that focused on speed, the KAIST team also developed overtaking route construction technology, taking into consideration the locations of surrounding cars, which gave them an advantage in responding to obstacles while keeping to real urban traffic rules. Through this, the KAIST team could score highest in rounds one and two combined.

Professor Shim said, “I am very glad that the autonomous driving technology our research team has been developing over the last ten years has borne fruit. I would like to thank the leader, Daegyu Lee, and all the students that participated in the development, as they did more than their best under difficult conditions.”

Dae-Gyu Lee, the leader of KI-Robotics and a Ph.D. candidate in the School of Electrical Engineering, explained, “Since we came in fourth in the preliminary round, we were further behind than we expected. But we were able to overtake the cars ahead of us and shorten our record.”

2021.12.07 View 8254

KI-Robotics Wins the 2021 Hyundai Motor Autonomous Driving Challenge

Professor Hyunchul Shim’s autonomous driving team topped the challenge

KI-Robotics, a KAIST autonomous driving research team led by Professor Hyunchul Shim from the School of Electric Engineering won the 2021 Hyundai Motor Autonomous Driving Challenge held in Seoul on November 29. The KI-Robotics team received 100 million won in prize money and a field trip to the US.

Out of total 23 teams, the six teams competed in the finals by simultaneously driving through a 4km section within the test operation region, where other traffic was constrained. The challenge included avoiding and overtaking vehicles, crossing intersections, and keeping to traffic laws including traffic lights, lanes, speed limit, and school zones. The contestants were ranked by their order of course completion, but points were deducted every time they violated a traffic rule. A driver and an invigilator rode in each car in case of an emergency, and the race was broadcasted live on a large screen on stage and via YouTube.

In the first round, KI-Robotics came in first with a score of 11 minutes and 27 seconds after a tight race with Incheon University. Although the team’s result in the second round exceeded 16 minutes due to traffic conditions like traffic lights, the 11 minutes and 27 seconds ultimately ranked first out of the six universities. It is worth noting that KI-Robotics focused on its vehicle’s perception and judgement rather than speed when building its algorithm. Out of the six universities that made it to the final round, KI-Robotics was the only team that excluded GPS from the vehicle to minimize its risk.

The team considered the fact that GPS signals are not accurate in urban settings, meaning location errors can cause problems while driving. As an alternative, the team added three radar sensors and cameras in the front and the back of the vehicle. They also used the urban-specific SLAM technology they developed to construct a precise map and were more successful in location determination.

As opposed to other teams that focused on speed, the KAIST team also developed overtaking route construction technology, taking into consideration the locations of surrounding cars, which gave them an advantage in responding to obstacles while keeping to real urban traffic rules. Through this, the KAIST team could score highest in rounds one and two combined.

Professor Shim said, “I am very glad that the autonomous driving technology our research team has been developing over the last ten years has borne fruit. I would like to thank the leader, Daegyu Lee, and all the students that participated in the development, as they did more than their best under difficult conditions.”

Dae-Gyu Lee, the leader of KI-Robotics and a Ph.D. candidate in the School of Electrical Engineering, explained, “Since we came in fourth in the preliminary round, we were further behind than we expected. But we were able to overtake the cars ahead of us and shorten our record.”

2021.12.07 View 8254 -

Hubo Professor Jun-Ho Oh Donates Startup Shares Worth 5 Billion KRW

Rainbow Robotics stock used to endow the development fund

Emeritus Professor Jun-Ho Oh, who developed the 2015 DARPA Challenge winning humanoid robot DRC-Hubo, donated 5 billion KRW on October 25 during a ceremony held at the KAIST campus in Daejeon.

Professor Oh donated his 20% share (400 shares) of his startup Rainbow Robotics, which was established in 2011. Rainbow Robotics was listed on the KOSDAQ this February. The 400 shares were converted to 200,000 shares with a value of approximately 5 billion KRW when listed this year.

KAIST sold the stocks and endowed the Jun-Ho Oh Fund, which will be used for the development of the university. He was the 39th faculty member who launched a startup with technology from his lab and became the biggest faculty entrepreneur donor.

“I have received huge support and funding for my research. Fortunately, the research had a good result and led to the startup. Now I am very delighted to pay back the university. I feel that I have played a part in building the school’s startup ecosystem and creating a virtuous circle,” said Professor Oh during the ceremony.

KAIST President Kwang Hyung Lee declared, “Professor Oh has been a very impressive exemplary model for our aspiring faculty and student tech startups. We will spare no effort to support startups at KAIST.”

Professor Oh, who retired from the Department of Mechanical Engineering last year, now serves as the CTO at Rainbow Robotics. The company is developing humanoid bipedal robots and collaborative robots, and advancing robot technology including parts for astronomical observations.

Professor Hae-Won Park and Professor Je Min Hwangbo, who are now responsible for the Hubo Lab, also joined the ceremony along with employees of Rainbow Robotics.

2021.10.26 View 11494

Hubo Professor Jun-Ho Oh Donates Startup Shares Worth 5 Billion KRW

Rainbow Robotics stock used to endow the development fund

Emeritus Professor Jun-Ho Oh, who developed the 2015 DARPA Challenge winning humanoid robot DRC-Hubo, donated 5 billion KRW on October 25 during a ceremony held at the KAIST campus in Daejeon.

Professor Oh donated his 20% share (400 shares) of his startup Rainbow Robotics, which was established in 2011. Rainbow Robotics was listed on the KOSDAQ this February. The 400 shares were converted to 200,000 shares with a value of approximately 5 billion KRW when listed this year.

KAIST sold the stocks and endowed the Jun-Ho Oh Fund, which will be used for the development of the university. He was the 39th faculty member who launched a startup with technology from his lab and became the biggest faculty entrepreneur donor.

“I have received huge support and funding for my research. Fortunately, the research had a good result and led to the startup. Now I am very delighted to pay back the university. I feel that I have played a part in building the school’s startup ecosystem and creating a virtuous circle,” said Professor Oh during the ceremony.

KAIST President Kwang Hyung Lee declared, “Professor Oh has been a very impressive exemplary model for our aspiring faculty and student tech startups. We will spare no effort to support startups at KAIST.”

Professor Oh, who retired from the Department of Mechanical Engineering last year, now serves as the CTO at Rainbow Robotics. The company is developing humanoid bipedal robots and collaborative robots, and advancing robot technology including parts for astronomical observations.

Professor Hae-Won Park and Professor Je Min Hwangbo, who are now responsible for the Hubo Lab, also joined the ceremony along with employees of Rainbow Robotics.

2021.10.26 View 11494 -

‘WalkON Suit 4’ Releases Paraplegics from Wheelchairs

- KAIST Athletes in ‘WalkON Suit 4’ Dominated the Cybathlon 2020 Global Edition. -

Paraplegic athletes Byeong-Uk Kim and Joohyun Lee from KAIST’s Team Angel Robotics won a gold and a bronze medal respectively at the Cybathlon 2020 Global Edition last week. ‘WalkON Suit 4,’ a wearable robot developed by the Professor Kyoungchul Kong’s team from the Department of Mechanical Engineering topped the standings at the event with double medal success.

Kim, the former bronze medallist, clinched his gold medal by finishing all six tasks in 3 minutes and 47 seconds, whereas Lee came in third with a time of 5 minutes and 51 seconds. TWIICE, a Swiss team, lagged 53 seconds behind Kim’s winning time to be the runner-up.

Cybathlon is a global championship, organized by ETH Zurich, which brings together people with physical disabilities to compete using state-of-the-art assistive technologies to perform everyday tasks. The first championship was held in 2016 in Zurich, Switzerland.

Due to the COVID-19 pandemic, the second championship was postponed twice and held in a new format in a decentralized setting. A total of 51 teams from 20 countries across the world performed the events in their home bases in different time zones instead of traveling to Zurich. Under the supervision of a referee and timekeeper, all races were filmed and then reviewed by judges.

KAIST’s Team Angel Robotics participated in the Powered Exoskeleton Race category, where nine pilots representing five nations including Korea, Switzerland, the US, Russia, and France competed against each other.

The team installed their own arena and raced at the KAIST Main Campus in Daejeon according to the framework, tasks, and rules defined by the competition committee. The two paraplegic pilots were each equipped with exoskeletal devices, the WalkON Suit 4, and undertook six tasks related to daily activities.

The WalkON Suit 4 recorded the fastest walking speed for a complete paraplegic ever reported. For a continuous walk, it achieved a maximum speed of 40 meters per minute. This is comparable to the average walking pace of a non-disabled person, which is around two to four kilometers per hour.

The research team raised the functionality of the robot by adding technology that can observe the user’s level of anxiety and external factors like the state of the walking surface, so it can control itself intelligently. The assistive functions a robot should provide vary greatly with the environment, and the WalkON Suit 4 made it possible to analyze the pace of the user within 30 steps and provide a personally optimized walking pattern, enabling a high walking speed.

The six tasks that Kim and Lee had to complete were:1) sitting and standing back up, 2) navigating around obstacles while avoiding collisions, 3) stepping over obstacles on the ground, 4) going up and down stairs, 5) walking across a tilted path, and 6) climbing a steep slope, opening and closing a door, and descending a steep slope.

Points were given based on the accuracy of each completed task, and the final scores were calculated by adding all of the points that were gained in each attempt, which lasted 10 minutes. Each pilot was given three opportunities and used his/her highest score. Should pilots have the same final score, the pilot who completed the race in the shortest amount of time would win.

Kim said in his victory speech that he was so thrilled to see all his and fellow researchers’ years of hard work paying off. “This will be a good opportunity to show how outstanding Korean wearable robot technologies are,” he added.

Lee, who participated in the competition for the first time, said, “By showing that I can overcome my physical disabilities with robot technology, I’d like to send out a message of hope to everyone who is tired because of COVID-19”.

Professor Kong’s team collaborated in technology development and pilot training with their colleagues from Angel Robotics Co., Ltd., Severance Rehabilitation Hospital, Yeungnam University, Stalks, and the Institute of Rehabilitation Technology.

Footage from the competition is available at the Cybathlon’s official website.

(END)

2020.11.20 View 11831

‘WalkON Suit 4’ Releases Paraplegics from Wheelchairs

- KAIST Athletes in ‘WalkON Suit 4’ Dominated the Cybathlon 2020 Global Edition. -

Paraplegic athletes Byeong-Uk Kim and Joohyun Lee from KAIST’s Team Angel Robotics won a gold and a bronze medal respectively at the Cybathlon 2020 Global Edition last week. ‘WalkON Suit 4,’ a wearable robot developed by the Professor Kyoungchul Kong’s team from the Department of Mechanical Engineering topped the standings at the event with double medal success.

Kim, the former bronze medallist, clinched his gold medal by finishing all six tasks in 3 minutes and 47 seconds, whereas Lee came in third with a time of 5 minutes and 51 seconds. TWIICE, a Swiss team, lagged 53 seconds behind Kim’s winning time to be the runner-up.

Cybathlon is a global championship, organized by ETH Zurich, which brings together people with physical disabilities to compete using state-of-the-art assistive technologies to perform everyday tasks. The first championship was held in 2016 in Zurich, Switzerland.

Due to the COVID-19 pandemic, the second championship was postponed twice and held in a new format in a decentralized setting. A total of 51 teams from 20 countries across the world performed the events in their home bases in different time zones instead of traveling to Zurich. Under the supervision of a referee and timekeeper, all races were filmed and then reviewed by judges.

KAIST’s Team Angel Robotics participated in the Powered Exoskeleton Race category, where nine pilots representing five nations including Korea, Switzerland, the US, Russia, and France competed against each other.

The team installed their own arena and raced at the KAIST Main Campus in Daejeon according to the framework, tasks, and rules defined by the competition committee. The two paraplegic pilots were each equipped with exoskeletal devices, the WalkON Suit 4, and undertook six tasks related to daily activities.

The WalkON Suit 4 recorded the fastest walking speed for a complete paraplegic ever reported. For a continuous walk, it achieved a maximum speed of 40 meters per minute. This is comparable to the average walking pace of a non-disabled person, which is around two to four kilometers per hour.

The research team raised the functionality of the robot by adding technology that can observe the user’s level of anxiety and external factors like the state of the walking surface, so it can control itself intelligently. The assistive functions a robot should provide vary greatly with the environment, and the WalkON Suit 4 made it possible to analyze the pace of the user within 30 steps and provide a personally optimized walking pattern, enabling a high walking speed.

The six tasks that Kim and Lee had to complete were:1) sitting and standing back up, 2) navigating around obstacles while avoiding collisions, 3) stepping over obstacles on the ground, 4) going up and down stairs, 5) walking across a tilted path, and 6) climbing a steep slope, opening and closing a door, and descending a steep slope.

Points were given based on the accuracy of each completed task, and the final scores were calculated by adding all of the points that were gained in each attempt, which lasted 10 minutes. Each pilot was given three opportunities and used his/her highest score. Should pilots have the same final score, the pilot who completed the race in the shortest amount of time would win.

Kim said in his victory speech that he was so thrilled to see all his and fellow researchers’ years of hard work paying off. “This will be a good opportunity to show how outstanding Korean wearable robot technologies are,” he added.

Lee, who participated in the competition for the first time, said, “By showing that I can overcome my physical disabilities with robot technology, I’d like to send out a message of hope to everyone who is tired because of COVID-19”.

Professor Kong’s team collaborated in technology development and pilot training with their colleagues from Angel Robotics Co., Ltd., Severance Rehabilitation Hospital, Yeungnam University, Stalks, and the Institute of Rehabilitation Technology.

Footage from the competition is available at the Cybathlon’s official website.

(END)

2020.11.20 View 11831 -

Professor Jee-Hwan Ryu Receives IEEE ICRA 2020 Outstanding Reviewer Award

Professor Jee-Hwan Ryu from the Department of Civil and Environmental Engineering was selected as this year’s winner of the Outstanding Reviewer Award presented by the Institute of Electrical and Electronics Engineers International Conference on Robotics and Automation (IEEE ICRA). The award ceremony took place on June 5 during the conference that is being held online May 31 through August 31 for three months.

The IEEE ICRA Outstanding Reviewer Award is given every year to the top reviewers who have provided constructive and high-quality thesis reviews, and contributed to improving the quality of papers published as results of the conference.

Professor Ryu was one of the four winners of this year’s award. He was selected from 9,425 candidates, which was approximately three times bigger than the candidate pool in previous years. He was strongly recommended by the editorial committee of the conference.

(END)

2020.06.10 View 11497

Professor Jee-Hwan Ryu Receives IEEE ICRA 2020 Outstanding Reviewer Award

Professor Jee-Hwan Ryu from the Department of Civil and Environmental Engineering was selected as this year’s winner of the Outstanding Reviewer Award presented by the Institute of Electrical and Electronics Engineers International Conference on Robotics and Automation (IEEE ICRA). The award ceremony took place on June 5 during the conference that is being held online May 31 through August 31 for three months.

The IEEE ICRA Outstanding Reviewer Award is given every year to the top reviewers who have provided constructive and high-quality thesis reviews, and contributed to improving the quality of papers published as results of the conference.

Professor Ryu was one of the four winners of this year’s award. He was selected from 9,425 candidates, which was approximately three times bigger than the candidate pool in previous years. He was strongly recommended by the editorial committee of the conference.

(END)

2020.06.10 View 11497 -

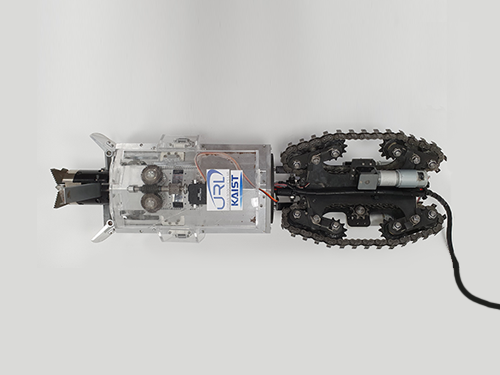

‘Mole-bot’ Optimized for Underground and Space Exploration

Biomimetic drilling robot provides new insights into the development of efficient drilling technologies

Mole-bot, a drilling biomimetic robot designed by KAIST, boasts a stout scapula, a waist inclinable on all sides, and powerful forelimbs. Most of all, the powerful torque from the expandable drilling bit mimicking the chiseling ability of a mole’s front teeth highlights the best feature of the drilling robot.

The Mole-bot is expected to be used for space exploration and mining for underground resources such as coalbed methane and Rare Earth Elements (REE), which require highly advanced drilling technologies in complex environments.

The research team, led by Professor Hyun Myung from the School of Electrical Engineering, found inspiration for their drilling bot from two striking features of the African mole-rat and European mole.

“The crushing power of the African mole-rat’s teeth is so powerful that they can dig a hole with 48 times more power than their body weight. We used this characteristic for building the main excavation tool. And its expandable drill is designed not to collide with its forelimbs,” said Professor Myung.

The 25-cm wide and 84-cm long Mole-bot can excavate three times faster with six times higher directional accuracy than conventional models. The Mole-bot weighs 26 kg.

After digging, the robot removes the excavated soil and debris using its forelimbs. This embedded muscle feature, inspired by the European mole’s scapula, converts linear motion into a powerful rotational force. For directional drilling, the robot’s elongated waist changes its direction 360° like living mammals.

For exploring underground environments, the research team developed and applied new sensor systems and algorithms to identify the robot’s position and orientation using graph-based 3D Simultaneous Localization and Mapping (SLAM) technology that matches the Earth’s magnetic field sequence, which enables 3D autonomous navigation underground.

According to Market & Market’s survey, the directional drilling market in 2016 is estimated to be 83.3 billion USD and is expected to grow to 103 billion USD in 2021. The growth of the drilling market, starting with the Shale Revolution, is likely to expand into the future development of space and polar resources. As initiated by Space X recently, more attention for planetary exploration will be on the rise and its related technology and equipment market will also increase.

The Mole-bot is a huge step forward for efficient underground drilling and exploration technologies. Unlike conventional drilling processes that use environmentally unfriendly mud compounds for cleaning debris, Mole-bot can mitigate environmental destruction. The researchers said their system saves on cost and labor and does not require additional pipelines or other ancillary equipment.

“We look forward to a more efficient resource exploration with this type of drilling robot. We also hope Mole-bot will have a very positive impact on the robotics market in terms of its extensive application spectra and economic feasibility,” said Professor Myung.

This research, made in collaboration with Professor Jung-Wuk Hong and Professor Tae-Hyuk Kwon’s team in the Department of Civil and Environmental Engineering for robot structure analysis and geotechnical experiments, was supported by the Ministry of Trade, Industry and Energy’s Industrial Technology Innovation Project.

Profile

Professor Hyun Myung

Urban Robotics Lab

http://urobot.kaist.ac.kr/

School of Electrical Engineering

KAIST

2020.06.05 View 12946

‘Mole-bot’ Optimized for Underground and Space Exploration

Biomimetic drilling robot provides new insights into the development of efficient drilling technologies

Mole-bot, a drilling biomimetic robot designed by KAIST, boasts a stout scapula, a waist inclinable on all sides, and powerful forelimbs. Most of all, the powerful torque from the expandable drilling bit mimicking the chiseling ability of a mole’s front teeth highlights the best feature of the drilling robot.

The Mole-bot is expected to be used for space exploration and mining for underground resources such as coalbed methane and Rare Earth Elements (REE), which require highly advanced drilling technologies in complex environments.

The research team, led by Professor Hyun Myung from the School of Electrical Engineering, found inspiration for their drilling bot from two striking features of the African mole-rat and European mole.

“The crushing power of the African mole-rat’s teeth is so powerful that they can dig a hole with 48 times more power than their body weight. We used this characteristic for building the main excavation tool. And its expandable drill is designed not to collide with its forelimbs,” said Professor Myung.

The 25-cm wide and 84-cm long Mole-bot can excavate three times faster with six times higher directional accuracy than conventional models. The Mole-bot weighs 26 kg.

After digging, the robot removes the excavated soil and debris using its forelimbs. This embedded muscle feature, inspired by the European mole’s scapula, converts linear motion into a powerful rotational force. For directional drilling, the robot’s elongated waist changes its direction 360° like living mammals.

For exploring underground environments, the research team developed and applied new sensor systems and algorithms to identify the robot’s position and orientation using graph-based 3D Simultaneous Localization and Mapping (SLAM) technology that matches the Earth’s magnetic field sequence, which enables 3D autonomous navigation underground.

According to Market & Market’s survey, the directional drilling market in 2016 is estimated to be 83.3 billion USD and is expected to grow to 103 billion USD in 2021. The growth of the drilling market, starting with the Shale Revolution, is likely to expand into the future development of space and polar resources. As initiated by Space X recently, more attention for planetary exploration will be on the rise and its related technology and equipment market will also increase.

The Mole-bot is a huge step forward for efficient underground drilling and exploration technologies. Unlike conventional drilling processes that use environmentally unfriendly mud compounds for cleaning debris, Mole-bot can mitigate environmental destruction. The researchers said their system saves on cost and labor and does not require additional pipelines or other ancillary equipment.

“We look forward to a more efficient resource exploration with this type of drilling robot. We also hope Mole-bot will have a very positive impact on the robotics market in terms of its extensive application spectra and economic feasibility,” said Professor Myung.

This research, made in collaboration with Professor Jung-Wuk Hong and Professor Tae-Hyuk Kwon’s team in the Department of Civil and Environmental Engineering for robot structure analysis and geotechnical experiments, was supported by the Ministry of Trade, Industry and Energy’s Industrial Technology Innovation Project.

Profile

Professor Hyun Myung

Urban Robotics Lab

http://urobot.kaist.ac.kr/

School of Electrical Engineering

KAIST

2020.06.05 View 12946 -

Hubo Debuts as a News Anchor

HUBO, a humanoid robot developed by Professor Jun-Ho Oh’s team, made its debut as a co-anchor during the TJB prime time news 8 on May 14.

“Un-contact" became the new normal after Covid-19 and many business solutions are being transformed using robotics. HUBO made two news reports on contactless services using robots in medical, manufacturing, and logistics industries. HUBO 2, the second generation of HUBO, appeared as a special anchor on the local broadcasting network’s special program in celebration of its 25th anniversary.

HUBO is the champion of the 2015 DARPA Robotics Challenge held in the USA. Its FX-2 riding robot also participated in the Olympic torch relay during the 2018 PyeongChang Winter Olympics.

Click here to watch a full video of HUBO anchoring the news.

(END)

2020.05.14 View 14496

Hubo Debuts as a News Anchor

HUBO, a humanoid robot developed by Professor Jun-Ho Oh’s team, made its debut as a co-anchor during the TJB prime time news 8 on May 14.

“Un-contact" became the new normal after Covid-19 and many business solutions are being transformed using robotics. HUBO made two news reports on contactless services using robots in medical, manufacturing, and logistics industries. HUBO 2, the second generation of HUBO, appeared as a special anchor on the local broadcasting network’s special program in celebration of its 25th anniversary.

HUBO is the champion of the 2015 DARPA Robotics Challenge held in the USA. Its FX-2 riding robot also participated in the Olympic torch relay during the 2018 PyeongChang Winter Olympics.

Click here to watch a full video of HUBO anchoring the news.

(END)

2020.05.14 View 14496 -

Wearable Strain Sensor Using Light Transmittance Helps Measure Physical Signals Better

KAIST researchers have developed a novel wearable strain sensor based on the modulation of optical transmittance of a carbon nanotube (CNT)-embedded elastomer. The sensor is capable of sensitive, stable, and continuous measurement of physical signals. This technology, featured in the March 4th issue of ACS Applied Materials & Interfaces as a front cover article, shows great potential for the detection of subtle human motions and the real-time monitoring of body postures for healthcare applications.

A wearable strain sensor must have high sensitivity, flexibility, and stretchability, as well as low cost. Those used especially for health monitoring should also be tied to long-term solid performance, and be environmentally stable. Various stretchable strain sensors based on piezo-resistive and capacitive principles have been developed to meet all these requirements.

Conventional piezo-resistive strain sensors using functional nanomaterials, including CNTs as the most common example, have shown high sensitivity and great sensing performance. However, they suffer from poor long-term stability and linearity, as well as considerable signal hysteresis. As an alternative, piezo-capacitive strain sensors with better stability, lower hysteresis, and higher stretchability have been suggested. But due to the fact that piezo-capacitive strain sensors exhibit limited sensitivity and strong electromagnetic interference caused by the conductive objects in the surrounding environment, these conventional stretchable strain sensors are still facing limitations that are yet to be resolved.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering suggested that an optical-type stretchable strain sensor can be a good alternative to resolve the limitations of conventional piezo-resistive and piezo-capacitive strain sensors, because they have high stability and are less affected by environmental disturbances. The team then introduced an optical wearable strain sensor based on the light transmittance changes of a CNT-embedded elastomer, which further addresses the low sensitivity problem of conventional optical stretchable strain sensors.

In order to achieve a large dynamic range for the sensor, Professor Park and his researchers chose Ecoflex as an elastomeric substrate with good mechanical durability, flexibility, and attachability on human skin, and the new optical wearable strain sensor developed by the research group actually shows a wide dynamic range of 0 to 400%.

In addition, the researchers propagated the microcracks under tensile strain within the film of multi-walled CNTs embedded in the Ecoflex substrate, changing the optical transmittance of the film. By doing so, it was possible for them to develop a wearable strain sensor having a sensitivity 10 times higher than conventional optical stretchable strain sensors.

The proposed sensor has also passed the durability test with excellent results. The sensor’s response after 13,000 sets of cyclic loading was stable without any noticeable drift. This suggests that the sensor response can be used without degradation, even if the sensor is repeatedly used for a long time and in various environmental conditions.

Using the developed sensor, the research team could measure the finger bending motion and used it for robot control. They also developed a three-axes sensor array for body posture monitoring. The sensor was able to monitor human motions with small strains such as a pulse near the carotid artery and muscle movement around the mouth during pronunciation.

Professor Park said, “In this study, our group developed a new wearable strain sensor platform that overcomes many limitations of previously developed resistive, capacitive, and optical-type stretchable strain sensors. Our sensor could be widely used in a variety of fields including soft robotics, wearable electronics, electronic skin, healthcare, and even entertainment.”

This work was supported by the National Research Foundation (NRF) of Korea.

Publication:

Jimin Gu, Donguk Kwon, Junseong Ahn, and Inkyu Park. (2020) “Wearable Strain sensors Using Light Transmittance Change of Carbon Nanotube-Embedded Elastomers with Microcracks” ACS Applied Materials & Interfaces. Volume 12. Issue 9. Available online at https://doi.org/10.1021/acsami.9b18069

Profile:

Inkyu Park

Professor

inkyu@kaist.ac.kr

http://mintlab1.kaist.ac.kr

Micro/Nano Transducers Laboratory (MINT Lab)

Department of Mechanical Engineering (ME)Korea Advanced Institute of Science and Technology (KAIST)

Profile:

Jimin Gu

Ph.D. Candidate

mint9411@kaist.ac.kr

http://mintlab1.kaist.ac.kr

MINT Lab

KAIST ME

(END)

2020.03.20 View 22774

Wearable Strain Sensor Using Light Transmittance Helps Measure Physical Signals Better

KAIST researchers have developed a novel wearable strain sensor based on the modulation of optical transmittance of a carbon nanotube (CNT)-embedded elastomer. The sensor is capable of sensitive, stable, and continuous measurement of physical signals. This technology, featured in the March 4th issue of ACS Applied Materials & Interfaces as a front cover article, shows great potential for the detection of subtle human motions and the real-time monitoring of body postures for healthcare applications.

A wearable strain sensor must have high sensitivity, flexibility, and stretchability, as well as low cost. Those used especially for health monitoring should also be tied to long-term solid performance, and be environmentally stable. Various stretchable strain sensors based on piezo-resistive and capacitive principles have been developed to meet all these requirements.

Conventional piezo-resistive strain sensors using functional nanomaterials, including CNTs as the most common example, have shown high sensitivity and great sensing performance. However, they suffer from poor long-term stability and linearity, as well as considerable signal hysteresis. As an alternative, piezo-capacitive strain sensors with better stability, lower hysteresis, and higher stretchability have been suggested. But due to the fact that piezo-capacitive strain sensors exhibit limited sensitivity and strong electromagnetic interference caused by the conductive objects in the surrounding environment, these conventional stretchable strain sensors are still facing limitations that are yet to be resolved.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering suggested that an optical-type stretchable strain sensor can be a good alternative to resolve the limitations of conventional piezo-resistive and piezo-capacitive strain sensors, because they have high stability and are less affected by environmental disturbances. The team then introduced an optical wearable strain sensor based on the light transmittance changes of a CNT-embedded elastomer, which further addresses the low sensitivity problem of conventional optical stretchable strain sensors.

In order to achieve a large dynamic range for the sensor, Professor Park and his researchers chose Ecoflex as an elastomeric substrate with good mechanical durability, flexibility, and attachability on human skin, and the new optical wearable strain sensor developed by the research group actually shows a wide dynamic range of 0 to 400%.

In addition, the researchers propagated the microcracks under tensile strain within the film of multi-walled CNTs embedded in the Ecoflex substrate, changing the optical transmittance of the film. By doing so, it was possible for them to develop a wearable strain sensor having a sensitivity 10 times higher than conventional optical stretchable strain sensors.

The proposed sensor has also passed the durability test with excellent results. The sensor’s response after 13,000 sets of cyclic loading was stable without any noticeable drift. This suggests that the sensor response can be used without degradation, even if the sensor is repeatedly used for a long time and in various environmental conditions.

Using the developed sensor, the research team could measure the finger bending motion and used it for robot control. They also developed a three-axes sensor array for body posture monitoring. The sensor was able to monitor human motions with small strains such as a pulse near the carotid artery and muscle movement around the mouth during pronunciation.

Professor Park said, “In this study, our group developed a new wearable strain sensor platform that overcomes many limitations of previously developed resistive, capacitive, and optical-type stretchable strain sensors. Our sensor could be widely used in a variety of fields including soft robotics, wearable electronics, electronic skin, healthcare, and even entertainment.”

This work was supported by the National Research Foundation (NRF) of Korea.

Publication:

Jimin Gu, Donguk Kwon, Junseong Ahn, and Inkyu Park. (2020) “Wearable Strain sensors Using Light Transmittance Change of Carbon Nanotube-Embedded Elastomers with Microcracks” ACS Applied Materials & Interfaces. Volume 12. Issue 9. Available online at https://doi.org/10.1021/acsami.9b18069

Profile:

Inkyu Park

Professor

inkyu@kaist.ac.kr

http://mintlab1.kaist.ac.kr

Micro/Nano Transducers Laboratory (MINT Lab)

Department of Mechanical Engineering (ME)Korea Advanced Institute of Science and Technology (KAIST)

Profile:

Jimin Gu

Ph.D. Candidate

mint9411@kaist.ac.kr

http://mintlab1.kaist.ac.kr

MINT Lab

KAIST ME

(END)

2020.03.20 View 22774 -

Two Professors Receive Awards from the Korea Robotics Society

< Professor Jee-Hwan Ryu and Professor Ayoung Kim >

The Korea Robotics Society (KROS) conferred awards onto two KAIST professors from the Department of Civil and Environmental Engineering in recognition of their achievements and contributions to the development of the robotics industry in 2019. Professor Jee-Hwan Ryu has been actively engaged in researching the field of teleoperation, and this led him to win the KROS Robotics Innovation (KRI) Award. The KRI Award was newly established in 2019 by the KROS, in order to encourage researchers who have made innovative achievements in robotics. Professor Ryu shared the honor of being the first winner of this award with Professor Jaeheung Park of Seoul National University. Professor Ayoung Kim, from the same department, received the Young Investigator Award presented to emerging robitics researchers under 40 years of age. (END)

2019.12.19 View 13086

Two Professors Receive Awards from the Korea Robotics Society

< Professor Jee-Hwan Ryu and Professor Ayoung Kim >

The Korea Robotics Society (KROS) conferred awards onto two KAIST professors from the Department of Civil and Environmental Engineering in recognition of their achievements and contributions to the development of the robotics industry in 2019. Professor Jee-Hwan Ryu has been actively engaged in researching the field of teleoperation, and this led him to win the KROS Robotics Innovation (KRI) Award. The KRI Award was newly established in 2019 by the KROS, in order to encourage researchers who have made innovative achievements in robotics. Professor Ryu shared the honor of being the first winner of this award with Professor Jaeheung Park of Seoul National University. Professor Ayoung Kim, from the same department, received the Young Investigator Award presented to emerging robitics researchers under 40 years of age. (END)

2019.12.19 View 13086 -

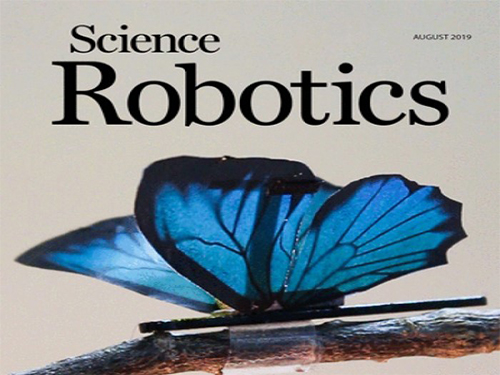

Artificial Muscles Bloom, Dance, and Wave

Wearing a flower brooch that blooms before your eyes sounds like magic. KAIST researchers have made it real with robotic muscles.

Researchers have developed an ultrathin, artificial muscle for soft robotics. The advancement, recently reported in the journal Science Robotics, was demonstrated with a robotic blooming flower brooch, dancing robotic butterflies and fluttering tree leaves on a kinetic art piece.

The robotic equivalent of a muscle that can move is called an actuator. The actuator expands, contracts or rotates like muscle fibers using a stimulus such as electricity. Engineers around the world are striving to develop more dynamic actuators that respond quickly, can bend without breaking, and are very durable. Soft, robotic muscles could have a wide variety of applications, from wearable electronics to advanced prosthetics.

The team from KAIST’s Creative Research Initiative Center for Functionally Antagonistic Nano-Engineering developed a very thin, responsive, flexible and durable artificial muscle. The actuator looks like a skinny strip of paper about an inch long. They used a particular type of material called MXene, which is class of compounds that have layers only a few atoms thick.

Their chosen MXene material (T3C2Tx) is made of thin layers of titanium and carbon compounds. It was not flexible by itself; sheets of material would flake off the actuator when bent in a loop. That changed when the MXene was “ionically cross-linked” — connected through an ionic bond — to a synthetic polymer. The combination of materials made the actuator flexible, while still maintaining strength and conductivity, which is critical for movements driven by electricity.

Their particular combination performed better than others reported. Their actuator responded very quickly to low voltage, and lasted for more than five hours moving continuously.

To prove the tiny robotic muscle works, the team incorporated the actuator into wearable art: an origami-inspired brooch mimics how a narcissus flower unfolds its petals when a small amount of electricity is applied. They also designed robotic butterflies that move their wings up and down, and made the leaves of a tree sculpture flutter.

“Wearable robotics and kinetic art demonstrate how robotic muscles can have fun and beautiful applications,” said Il-Kwon Oh, lead paper author and professor of mechanical engineering. “It also shows the enormous potential for small, artificial muscles for a variety of uses, such as haptic feedback systems and active biomedical devices.”

The team next plans to investigate more practical applications of MXene-based soft actuators and other engineering applications of MXene 2D nanomaterials.

2019.08.22 View 26802

Artificial Muscles Bloom, Dance, and Wave

Wearing a flower brooch that blooms before your eyes sounds like magic. KAIST researchers have made it real with robotic muscles.

Researchers have developed an ultrathin, artificial muscle for soft robotics. The advancement, recently reported in the journal Science Robotics, was demonstrated with a robotic blooming flower brooch, dancing robotic butterflies and fluttering tree leaves on a kinetic art piece.

The robotic equivalent of a muscle that can move is called an actuator. The actuator expands, contracts or rotates like muscle fibers using a stimulus such as electricity. Engineers around the world are striving to develop more dynamic actuators that respond quickly, can bend without breaking, and are very durable. Soft, robotic muscles could have a wide variety of applications, from wearable electronics to advanced prosthetics.

The team from KAIST’s Creative Research Initiative Center for Functionally Antagonistic Nano-Engineering developed a very thin, responsive, flexible and durable artificial muscle. The actuator looks like a skinny strip of paper about an inch long. They used a particular type of material called MXene, which is class of compounds that have layers only a few atoms thick.

Their chosen MXene material (T3C2Tx) is made of thin layers of titanium and carbon compounds. It was not flexible by itself; sheets of material would flake off the actuator when bent in a loop. That changed when the MXene was “ionically cross-linked” — connected through an ionic bond — to a synthetic polymer. The combination of materials made the actuator flexible, while still maintaining strength and conductivity, which is critical for movements driven by electricity.

Their particular combination performed better than others reported. Their actuator responded very quickly to low voltage, and lasted for more than five hours moving continuously.

To prove the tiny robotic muscle works, the team incorporated the actuator into wearable art: an origami-inspired brooch mimics how a narcissus flower unfolds its petals when a small amount of electricity is applied. They also designed robotic butterflies that move their wings up and down, and made the leaves of a tree sculpture flutter.

“Wearable robotics and kinetic art demonstrate how robotic muscles can have fun and beautiful applications,” said Il-Kwon Oh, lead paper author and professor of mechanical engineering. “It also shows the enormous potential for small, artificial muscles for a variety of uses, such as haptic feedback systems and active biomedical devices.”

The team next plans to investigate more practical applications of MXene-based soft actuators and other engineering applications of MXene 2D nanomaterials.

2019.08.22 View 26802 -

Wearable Robot 'WalkON Suit' Off to Cybathlon 2020

Standing upright and walking alone are very simple but noble motions that separate humans from many other creatures. Wearable and prosthetic technologies have emerged to augment human function in locomotion and manipulation. However, advances in wearable robot technology have been especially momentous to Byoung-Wook Kim, a triplegic for 22 years following a devastating car accident.

Kim rejoiced after standing upright and walking again by putting on the ‘WalkON Suit,’ the wearable robot developed by Professor Kyoungchul Kong’s team. Even more, Kim won third prize in the powered exoskeleton race at Cybathlon 2016, an international cyborg Olympics hosted by ETH Zurich.

Now Kim and Professor Kong’s team are all geared up for the Cybathlon Championship 2020. Professor Kong and his startup, Angel Robotics, held a kickoff ceremony for Cybathlon 2020 at KAIST on June 24. The 2020 championship will take place in Switzerland.

Only pilots with complete paralysis of the legs resulting from spinal cord injuries are eligible to participate in the Cybathlon, which takes place every four years. Pilots compete against each other while completing everyday tasks using technical assistance systems in six different disciplines: a brain-computer interface race, a functional electrical stimulation bike race, a powered arm prosthesis race, a powered leg prosthesis race, a powered exoskeleton race, and a powered wheelchair race. The 2016 championship drew 66 pilots from 56 teams representing 25 countries.

In the powered exoskeleton race, pilots complete everyday activities such as getting up from a sofa and overcoming obstacles such as stairs, ramps, or slopes and up to four pilots compete simultaneously on tracks to solve six tasks; and the pilot that solves the most tasks in the least amount of time wins the race.

(Kim, a triplegic for 22 years demonstrates walking and climbing the stairs (below photo) wearing the WalkOn Suit during the media day on June 21 at KAIST.)

Kim, who demonstrated walking and climbing the stairs wearing the WalkON Suit during the media day for the Cybathlon 2020 kickoff ceremony on June 21 at KAIST, said, “I have been confined to a wheelchair for more than 20 years. I am used to it so I feel like the wheelchair is one of my body parts. Actually, I don’t feel any big difficulties in doing everyday tasks in wheelchair. But whenever I face the fact that I will never be able to stand up with my own two legs again, I am so devastated.” He continued, “I still remember the day when I stood up with my own two legs by myself after 22 years. It was beyond description.”

The market for wearable robots, especially for exoskeleton robots, is continuing to grow as the aging population has been a major challenge in almost every advanced country. The global market for these robots expects to see annual growth of 41.2% to 8.3 billion US dollars by 2025. Healthcare wearable robots for the elderly and rehabilitation take up the half of the market share followed by wearable robots for industrial and defense purposes.

Professor Kong from the Department of Mechanical Engineering and his colleagues have developed two wearable robot systems in 2014: The "WalkON Suit" for complete paraplegics and “Angel Suit” for those with partial impairment in walking ability such as the elderly and rehabilitation patients.

Professor Kong said after 15 years of basic research, the team is now able to develop its own distinct technologies. He said their robots are powered by non-resistant precision drives with algorithms recognizing the user’s moving intention. Incorporated with prosthetic devices technology from the Severance Rehabilitation Hospital, their control technology has led to the production of a customizable robot suit optimized for each user’s physical condition.

The WalkON Suit, which boasts a maximum force of 250 Nm and maximum rotation speed of 45 RPM, gives the user high-energy efficiency modeled after the physiology of the human leg. It allows users to walk on flat ground and down stairs, climb up and down inclines, and sit and lie down. Currently the battery lasts five to six hours for locomotion and the approximate 25 kg of robot weight still remains a technical challenge to upgrade.

Professor Kong’s team has grafted AR glass technology into the WalkOn Suit that one of his pilots put on for the torch relay of the PyongChang Paralympics in 2018. His team is now upgrading the WalkON Suit 4.0 for next year’s competition. Severance Rehabilitation Hospital will help the seven pilots with their training.

Professor Kong said his goal is to make robots that can make people with disabilities much more independent. He stressed, “Wearable robots should be designed for each single user. We provide a very good graphical user interface so that we can design, check, and also verify our optimized design for users’ best performance.”

(Seven pilots and Professor Kong (fifth from left in second row) pose with guests who joined the Cybathlon 2020 kickoff ceremony. President Shin (fifth from right) made a congratulatory remarks during the ceremony.)

2019.06.25 View 43269

Wearable Robot 'WalkON Suit' Off to Cybathlon 2020

Standing upright and walking alone are very simple but noble motions that separate humans from many other creatures. Wearable and prosthetic technologies have emerged to augment human function in locomotion and manipulation. However, advances in wearable robot technology have been especially momentous to Byoung-Wook Kim, a triplegic for 22 years following a devastating car accident.

Kim rejoiced after standing upright and walking again by putting on the ‘WalkON Suit,’ the wearable robot developed by Professor Kyoungchul Kong’s team. Even more, Kim won third prize in the powered exoskeleton race at Cybathlon 2016, an international cyborg Olympics hosted by ETH Zurich.

Now Kim and Professor Kong’s team are all geared up for the Cybathlon Championship 2020. Professor Kong and his startup, Angel Robotics, held a kickoff ceremony for Cybathlon 2020 at KAIST on June 24. The 2020 championship will take place in Switzerland.

Only pilots with complete paralysis of the legs resulting from spinal cord injuries are eligible to participate in the Cybathlon, which takes place every four years. Pilots compete against each other while completing everyday tasks using technical assistance systems in six different disciplines: a brain-computer interface race, a functional electrical stimulation bike race, a powered arm prosthesis race, a powered leg prosthesis race, a powered exoskeleton race, and a powered wheelchair race. The 2016 championship drew 66 pilots from 56 teams representing 25 countries.

In the powered exoskeleton race, pilots complete everyday activities such as getting up from a sofa and overcoming obstacles such as stairs, ramps, or slopes and up to four pilots compete simultaneously on tracks to solve six tasks; and the pilot that solves the most tasks in the least amount of time wins the race.

(Kim, a triplegic for 22 years demonstrates walking and climbing the stairs (below photo) wearing the WalkOn Suit during the media day on June 21 at KAIST.)

Kim, who demonstrated walking and climbing the stairs wearing the WalkON Suit during the media day for the Cybathlon 2020 kickoff ceremony on June 21 at KAIST, said, “I have been confined to a wheelchair for more than 20 years. I am used to it so I feel like the wheelchair is one of my body parts. Actually, I don’t feel any big difficulties in doing everyday tasks in wheelchair. But whenever I face the fact that I will never be able to stand up with my own two legs again, I am so devastated.” He continued, “I still remember the day when I stood up with my own two legs by myself after 22 years. It was beyond description.”

The market for wearable robots, especially for exoskeleton robots, is continuing to grow as the aging population has been a major challenge in almost every advanced country. The global market for these robots expects to see annual growth of 41.2% to 8.3 billion US dollars by 2025. Healthcare wearable robots for the elderly and rehabilitation take up the half of the market share followed by wearable robots for industrial and defense purposes.

Professor Kong from the Department of Mechanical Engineering and his colleagues have developed two wearable robot systems in 2014: The "WalkON Suit" for complete paraplegics and “Angel Suit” for those with partial impairment in walking ability such as the elderly and rehabilitation patients.

Professor Kong said after 15 years of basic research, the team is now able to develop its own distinct technologies. He said their robots are powered by non-resistant precision drives with algorithms recognizing the user’s moving intention. Incorporated with prosthetic devices technology from the Severance Rehabilitation Hospital, their control technology has led to the production of a customizable robot suit optimized for each user’s physical condition.

The WalkON Suit, which boasts a maximum force of 250 Nm and maximum rotation speed of 45 RPM, gives the user high-energy efficiency modeled after the physiology of the human leg. It allows users to walk on flat ground and down stairs, climb up and down inclines, and sit and lie down. Currently the battery lasts five to six hours for locomotion and the approximate 25 kg of robot weight still remains a technical challenge to upgrade.

Professor Kong’s team has grafted AR glass technology into the WalkOn Suit that one of his pilots put on for the torch relay of the PyongChang Paralympics in 2018. His team is now upgrading the WalkON Suit 4.0 for next year’s competition. Severance Rehabilitation Hospital will help the seven pilots with their training.

Professor Kong said his goal is to make robots that can make people with disabilities much more independent. He stressed, “Wearable robots should be designed for each single user. We provide a very good graphical user interface so that we can design, check, and also verify our optimized design for users’ best performance.”

(Seven pilots and Professor Kong (fifth from left in second row) pose with guests who joined the Cybathlon 2020 kickoff ceremony. President Shin (fifth from right) made a congratulatory remarks during the ceremony.)

2019.06.25 View 43269