microbial

-

Engineered Microbial Production of Grape Flavoring

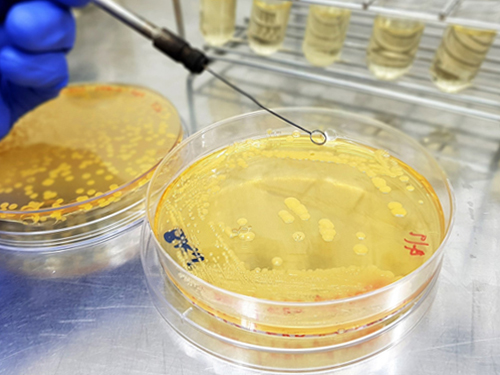

(Image 1: Engineered bacteria that produce grape flavoring.)

Researchers report a microbial method for producing an artificial grape flavor. Methyl anthranilate (MANT) is a common grape flavoring and odorant compound currently produced through a petroleum-based process that uses large volumes of toxic acid catalysts.

Professor Sang-Yup Lee’s team at the Department of Chemical and Biomolecular Engineering demonstrated production of MANT, a naturally occurring compound, via engineered bacteria. The authors engineered strains of Escherichia coli and Corynebacetrium glutamicum to produce MANT through a plant-based engineered metabolic pathway.

The authors tuned the bacterial metabolic pathway by optimizing the levels of AAMT1, the key enzyme in the process. To maximize production of MANT, the authors tested six strategies, including increasing the supply of a precursor compound and enhancing the availability of a co-substrate. The most productive strategy proved to be a two-phase extractive culture, in which MANT was extracted into a solvent. This strategy produced MANT on the scale of 4.47 to 5.74 grams per liter, a significant amount, considering that engineered microbes produce most natural products at a scale of milligrams or micrograms per liter.

According to the authors, the results suggest that MANT and other related molecules produced through industrial processes can be produced at scale by engineered microbes in a manner that would allow them to be marketed as natural one, instead of artificial one.

This study, featured at the Proceeding of the National Academy of Sciences of the USA on May 13, was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT.

(Image 2. Overview of the strategies applied for the microbial production of grape flavoring.)

2019.05.15 View 57256

Engineered Microbial Production of Grape Flavoring

(Image 1: Engineered bacteria that produce grape flavoring.)

Researchers report a microbial method for producing an artificial grape flavor. Methyl anthranilate (MANT) is a common grape flavoring and odorant compound currently produced through a petroleum-based process that uses large volumes of toxic acid catalysts.

Professor Sang-Yup Lee’s team at the Department of Chemical and Biomolecular Engineering demonstrated production of MANT, a naturally occurring compound, via engineered bacteria. The authors engineered strains of Escherichia coli and Corynebacetrium glutamicum to produce MANT through a plant-based engineered metabolic pathway.

The authors tuned the bacterial metabolic pathway by optimizing the levels of AAMT1, the key enzyme in the process. To maximize production of MANT, the authors tested six strategies, including increasing the supply of a precursor compound and enhancing the availability of a co-substrate. The most productive strategy proved to be a two-phase extractive culture, in which MANT was extracted into a solvent. This strategy produced MANT on the scale of 4.47 to 5.74 grams per liter, a significant amount, considering that engineered microbes produce most natural products at a scale of milligrams or micrograms per liter.

According to the authors, the results suggest that MANT and other related molecules produced through industrial processes can be produced at scale by engineered microbes in a manner that would allow them to be marketed as natural one, instead of artificial one.

This study, featured at the Proceeding of the National Academy of Sciences of the USA on May 13, was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT.

(Image 2. Overview of the strategies applied for the microbial production of grape flavoring.)

2019.05.15 View 57256 -

Distinguished Professor Sang Yup Lee Honored with the 23rd NAEK Award

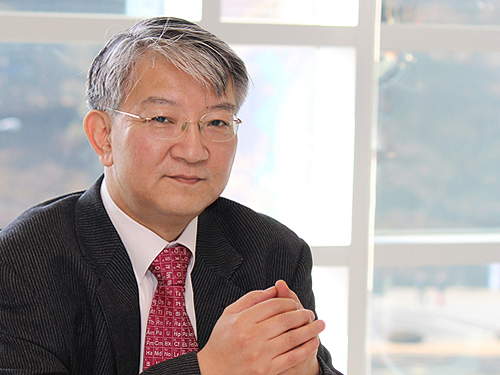

(Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering)

Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering was honored to be the laureate of the 23rd NAEK Award.

The NAEK (National Academy of Engineering of Korea) Award was instituted in 1997 to honor and recognize engineers who have made significant contributions to the development of the engineering and technology field at universities, industries, and institutions. Every year, it is conferred to only one person who has achieved original and world-leading research that has led to national development.

Distinguished Professor Lee is a pioneering scholar of the field of systems metabolic engineering and he was recognized for his significant achievements in the biochemical industry by developing novel microbial bioprocesses. In particular, he is globally renowned for biological plastic synthesis, making or decomposing polymers with microorganisms instead of using fossil resources.

He has produced numerous high-quality research breakthroughs in metabolic and systems engineering. In 2016, he produced an easily degradable plastic with Escherichia coli (E. coli). In 2018, he successfully produced aromatic polyesters, the main material for PET (poly ethylene terephthalate) from E. coli strains. He also identified microorganism structures for PET degradation and improved its degradability with a novel variant.

His research was ranked number one in the research and development division of Top Ten Science and Technology News 2018 announced by Korean Federation of Science & Technology Societies. He is one of highly cited researchers (HCR) ranked in the top 1% by citations for their field by the Clarivate Analytics.

2019.03.21 View 9733

Distinguished Professor Sang Yup Lee Honored with the 23rd NAEK Award

(Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering)

Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering was honored to be the laureate of the 23rd NAEK Award.

The NAEK (National Academy of Engineering of Korea) Award was instituted in 1997 to honor and recognize engineers who have made significant contributions to the development of the engineering and technology field at universities, industries, and institutions. Every year, it is conferred to only one person who has achieved original and world-leading research that has led to national development.

Distinguished Professor Lee is a pioneering scholar of the field of systems metabolic engineering and he was recognized for his significant achievements in the biochemical industry by developing novel microbial bioprocesses. In particular, he is globally renowned for biological plastic synthesis, making or decomposing polymers with microorganisms instead of using fossil resources.

He has produced numerous high-quality research breakthroughs in metabolic and systems engineering. In 2016, he produced an easily degradable plastic with Escherichia coli (E. coli). In 2018, he successfully produced aromatic polyesters, the main material for PET (poly ethylene terephthalate) from E. coli strains. He also identified microorganism structures for PET degradation and improved its degradability with a novel variant.

His research was ranked number one in the research and development division of Top Ten Science and Technology News 2018 announced by Korean Federation of Science & Technology Societies. He is one of highly cited researchers (HCR) ranked in the top 1% by citations for their field by the Clarivate Analytics.

2019.03.21 View 9733 -

Distinguished Professor Lee Receives 2018 George Washington Carver Award

(Distinguished Professor Lee)

Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering will become the 11th recipient of the George Washington Carver Award. The award ceremony will be held during the 2018 Biotechnology Innovation Organization (BIO) World Congress on Industrial Biotechnology from July 16 through 19 at the Pennsylvania Convention Center in Philadelphia.

The annual Carver award recognizes an individual who has made a significant contribution to building the bio-based economy by applying industrial biotechnology to create environmentally sustainable products. It serves as a lasting memorial to the original vision of George Washington Carver who, over a century ago, pioneered bio-based products, materials, and energy derived from renewable agricultural feedstock. Previous recipients include the founder and CEO of POET Jeff Broin, the CEO of DuPont Ellen Kullman, and Professor Gregory Stephanopoulos at MIT.

Professor Lee is a pioneering scholar of systems metabolic engineering, leveraging technology to develop microbial bioprocesses for the sustainable and environment-friendly production of chemicals, fuels, and materials from non-food renewable biomass. He also serves as the dean of the multi-and interdisciplinary research center hub, KAIST Institute.Through his work, Professor Lee has garnered countless achievements, including being one of only 13 people in the world elected as a foreign member of both the National Academy of Sciences USA and the National Academy of Engineering USA.

He has actively promoted the importance of industrial biotechnology through engagement with the public, policymakers, and decision makers around the world. He currently serves as the co-chairman of the Global Future Council on Biotechnology for the World Economic Forum and served as the Chairman of the Emerging Technologies Council and Biotechnology Council for the World Economic Forum.

Upon the award announcement, Dr. Brent Erickson, executive vice president of BIO’s Industrial & Environmental Section lauded Professor Lee’s achievement, saying “Dr. Lee has advanced the bio-based economy by developing innovative products and processes that are sustainable and environmentally friendly. In doing so, he has become a leader in advocating on the importance of industrial biotechnology. His contributions to the advancement of the industry are a continuation of the legacy left behind by George Washington Carver.”

Professor Lee thanked his research team who has worked together for the past few decades, adding, “Industrial biotechnology is becoming increasingly important to help achieve the UN’s Sustainable Development Goals. We should continue to work together to advance the field and establish a solid foundation for the sustainable future.”

The George Washington Carver Award is sponsored by the Iowa Biotechnology Association. Joe Hrdlicka, executive director of the Iowa Biotechnology Association, said, “Dr. Sang Yup Lee’s significant contributions to the advancement of industrial biotechnology make him the perfect recipient for the George Washington Carver Award. Having published more than 575 peer-reviewed papers, contributed to 82 books, and holding 636 patents, the culmination of Dr. Lee’s work has led to the establishment of sustainable systems for bio-based production of chemicals, fuels, and materials, thus reducing environmental impact and improving quality of life for all.”

2018.07.12 View 13686

Distinguished Professor Lee Receives 2018 George Washington Carver Award

(Distinguished Professor Lee)

Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering will become the 11th recipient of the George Washington Carver Award. The award ceremony will be held during the 2018 Biotechnology Innovation Organization (BIO) World Congress on Industrial Biotechnology from July 16 through 19 at the Pennsylvania Convention Center in Philadelphia.

The annual Carver award recognizes an individual who has made a significant contribution to building the bio-based economy by applying industrial biotechnology to create environmentally sustainable products. It serves as a lasting memorial to the original vision of George Washington Carver who, over a century ago, pioneered bio-based products, materials, and energy derived from renewable agricultural feedstock. Previous recipients include the founder and CEO of POET Jeff Broin, the CEO of DuPont Ellen Kullman, and Professor Gregory Stephanopoulos at MIT.

Professor Lee is a pioneering scholar of systems metabolic engineering, leveraging technology to develop microbial bioprocesses for the sustainable and environment-friendly production of chemicals, fuels, and materials from non-food renewable biomass. He also serves as the dean of the multi-and interdisciplinary research center hub, KAIST Institute.Through his work, Professor Lee has garnered countless achievements, including being one of only 13 people in the world elected as a foreign member of both the National Academy of Sciences USA and the National Academy of Engineering USA.

He has actively promoted the importance of industrial biotechnology through engagement with the public, policymakers, and decision makers around the world. He currently serves as the co-chairman of the Global Future Council on Biotechnology for the World Economic Forum and served as the Chairman of the Emerging Technologies Council and Biotechnology Council for the World Economic Forum.

Upon the award announcement, Dr. Brent Erickson, executive vice president of BIO’s Industrial & Environmental Section lauded Professor Lee’s achievement, saying “Dr. Lee has advanced the bio-based economy by developing innovative products and processes that are sustainable and environmentally friendly. In doing so, he has become a leader in advocating on the importance of industrial biotechnology. His contributions to the advancement of the industry are a continuation of the legacy left behind by George Washington Carver.”

Professor Lee thanked his research team who has worked together for the past few decades, adding, “Industrial biotechnology is becoming increasingly important to help achieve the UN’s Sustainable Development Goals. We should continue to work together to advance the field and establish a solid foundation for the sustainable future.”

The George Washington Carver Award is sponsored by the Iowa Biotechnology Association. Joe Hrdlicka, executive director of the Iowa Biotechnology Association, said, “Dr. Sang Yup Lee’s significant contributions to the advancement of industrial biotechnology make him the perfect recipient for the George Washington Carver Award. Having published more than 575 peer-reviewed papers, contributed to 82 books, and holding 636 patents, the culmination of Dr. Lee’s work has led to the establishment of sustainable systems for bio-based production of chemicals, fuels, and materials, thus reducing environmental impact and improving quality of life for all.”

2018.07.12 View 13686 -

Material-Independent Nanocoating Antimicrobial Spray Significantly Extends the Shelf Life of Produce

The edible coating on produce has drawn a great deal of attention in the food and agricultural industry. It could not only prolong postharvest shelf life of produce against external changes in the environment but also provide additional nutrients to be useful for human health. However, most versions of the coating have had intrinsic limitations in their practical application. First, highly specific interactions between coating materials and target surfaces are required for a stable and durable coating. Even further, the coating of bulk substrates, such as fruits, is time consuming or is not achievable in the conventional solution-based coating. In this respect, material-independent and rapid coating strategies are highly demanded.

The research team led by Professor Insung Choi of the Department of Chemistry developed a sprayable nanocoating technique using plant-derived polyphenol that can be applied to any surface. This new nanocoating process can be completed in seconds to form nanometer-thick films, allowing for the coating of commodity goods, such as shoe insoles and fruits, in a controlled fashion. For example, spray-coated mandarin oranges and strawberries show significantly-prolonged postharvest shelf life, suggesting the practical potential in edible coatings of perishable produce.

The technology has been patented and is currently being commercialized for widespread use as a means of preserving produce. The research results have recently been published in Scientific Reports on Aug 1.

Polyphenols, a metabolite of photosynthesis, possess several hydroxyl groups and are found in a large number of plants showing excellent antioxidant properties. They have been widely used as a nontoxic food additive and are known to exhibit antibacterial, as well as potential anti-carcinogenic capabilities. Polyphenols can also be used with iron ions, which are naturally found in the body, to form an adhesive complex, which has been used in leather tanning, ink, etc.

The research team combined these chemical properties of polyphenol-iron complexes with spray techniques to develop their nanocoating technology. Compared to conventional immersion coating methods, which dip substrates in specialized coating solutions, this spray technique can coat the select areas more quickly. The spray also prevents cross contamination, which is a big concern for immersion methods. The research team has showcased the spray’s ability to coat a variety of different materials, including metals, plastics, glass, as well as textile fabrics. The polyphenol complex has been used to form antifogging films on corrective lenses, as well as antifungal treatments for shoe soles, demonstrating the versatility of their technique.

Furthermore, the spray has been used to coat produce with a naturally antibacterial, edible film. The coatings significantly improved the shelf life of tangerines and strawberries, preserving freshness beyond 28 days and 58 hours, respectively. (Uncoated fruit decomposed and became moldy under the same conditions). See the image below.

a –I, II: Uncoated and coated tangerines incubated for 14 and 28 days in daily-life settings

b –I: Uncoated and coated strawberries incubated for 58 hours in daily-life settings

b –II: Statistical investigation of the resulting edibility.

Professor Choi said, “Nanocoating technologies are still in their infancy, but they have untapped potential for exciting applications. As we have shown, nanocoatings can be easily adapted for several different uses, and the creative combination of existing nanomaterials and coating methods can synergize to unlock this potential.”

2017.08.10 View 10064

Material-Independent Nanocoating Antimicrobial Spray Significantly Extends the Shelf Life of Produce

The edible coating on produce has drawn a great deal of attention in the food and agricultural industry. It could not only prolong postharvest shelf life of produce against external changes in the environment but also provide additional nutrients to be useful for human health. However, most versions of the coating have had intrinsic limitations in their practical application. First, highly specific interactions between coating materials and target surfaces are required for a stable and durable coating. Even further, the coating of bulk substrates, such as fruits, is time consuming or is not achievable in the conventional solution-based coating. In this respect, material-independent and rapid coating strategies are highly demanded.

The research team led by Professor Insung Choi of the Department of Chemistry developed a sprayable nanocoating technique using plant-derived polyphenol that can be applied to any surface. This new nanocoating process can be completed in seconds to form nanometer-thick films, allowing for the coating of commodity goods, such as shoe insoles and fruits, in a controlled fashion. For example, spray-coated mandarin oranges and strawberries show significantly-prolonged postharvest shelf life, suggesting the practical potential in edible coatings of perishable produce.

The technology has been patented and is currently being commercialized for widespread use as a means of preserving produce. The research results have recently been published in Scientific Reports on Aug 1.

Polyphenols, a metabolite of photosynthesis, possess several hydroxyl groups and are found in a large number of plants showing excellent antioxidant properties. They have been widely used as a nontoxic food additive and are known to exhibit antibacterial, as well as potential anti-carcinogenic capabilities. Polyphenols can also be used with iron ions, which are naturally found in the body, to form an adhesive complex, which has been used in leather tanning, ink, etc.

The research team combined these chemical properties of polyphenol-iron complexes with spray techniques to develop their nanocoating technology. Compared to conventional immersion coating methods, which dip substrates in specialized coating solutions, this spray technique can coat the select areas more quickly. The spray also prevents cross contamination, which is a big concern for immersion methods. The research team has showcased the spray’s ability to coat a variety of different materials, including metals, plastics, glass, as well as textile fabrics. The polyphenol complex has been used to form antifogging films on corrective lenses, as well as antifungal treatments for shoe soles, demonstrating the versatility of their technique.

Furthermore, the spray has been used to coat produce with a naturally antibacterial, edible film. The coatings significantly improved the shelf life of tangerines and strawberries, preserving freshness beyond 28 days and 58 hours, respectively. (Uncoated fruit decomposed and became moldy under the same conditions). See the image below.

a –I, II: Uncoated and coated tangerines incubated for 14 and 28 days in daily-life settings

b –I: Uncoated and coated strawberries incubated for 58 hours in daily-life settings

b –II: Statistical investigation of the resulting edibility.

Professor Choi said, “Nanocoating technologies are still in their infancy, but they have untapped potential for exciting applications. As we have shown, nanocoatings can be easily adapted for several different uses, and the creative combination of existing nanomaterials and coating methods can synergize to unlock this potential.”

2017.08.10 View 10064 -

Distinguished Professor Lee Elected to the NAS

Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering was elected as a foreign associate to the US National Academy of Sciences (NAS) on May 2. The National Academy of Sciences elected 84 new members and 21 foreign associates in recognition of their distinguished and continuing achievements in their original research. Election to the Academy is widely regarded as one of the highest honors that a scientist can receive.

Professor Lee was also elected in 2010 as a member of the US National Academy of Engineering (NAE) for his leadership in microbial biotechnology and metabolic engineering, including the development of fermentation processes for biodegradable polymers and organic acids. Until 2016, there are only 12 people worldwide who are foreign associates of both NAS and NAE.

He is the first Korean elected to both prestigious academies, the NAS and the NAE in the US. Professor Lee is currently the dean of KAIST Institutes, the world leading institute for multi-and interdisciplinary research. He is also serving as co-chair of the Global Council on Biotechnology and member of the Global Future Council on the Fourth Industrial Revolution, the World Economic Forum.

2017.05.16 View 11166

Distinguished Professor Lee Elected to the NAS

Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering was elected as a foreign associate to the US National Academy of Sciences (NAS) on May 2. The National Academy of Sciences elected 84 new members and 21 foreign associates in recognition of their distinguished and continuing achievements in their original research. Election to the Academy is widely regarded as one of the highest honors that a scientist can receive.

Professor Lee was also elected in 2010 as a member of the US National Academy of Engineering (NAE) for his leadership in microbial biotechnology and metabolic engineering, including the development of fermentation processes for biodegradable polymers and organic acids. Until 2016, there are only 12 people worldwide who are foreign associates of both NAS and NAE.

He is the first Korean elected to both prestigious academies, the NAS and the NAE in the US. Professor Lee is currently the dean of KAIST Institutes, the world leading institute for multi-and interdisciplinary research. He is also serving as co-chair of the Global Council on Biotechnology and member of the Global Future Council on the Fourth Industrial Revolution, the World Economic Forum.

2017.05.16 View 11166 -

KAIST announced a novel technology to produce gasoline by a metabolically engineered microorganism

A major scientific breakthrough in the development of renewable energy sources and other important chemicals; The research team succeeded in producing 580 mg of gasoline per liter of cultured broth by converting in vivo generated fatty acids

For many decades, we have been relying on fossil resources to produce liquid fuels such as gasoline, diesel, and many industrial and consumer chemicals for daily use. However, increasing strains on natural resources as well as environmental issues including global warming have triggered a strong interest in developing sustainable ways to obtain fuels and chemicals.

Gasoline, the petroleum-derived product that is most widely used as a fuel for transportation, is a mixture of hydrocarbons, additives, and blending agents. The hydrocarbons, called alkanes, consist only of carbon and hydrogen atoms. Gasoline has a combination of straight-chain and branched-chain alkanes (hydrocarbons) consisted of 4-12 carbon atoms linked by direct carbon-carbon bonds.

Previously, through metabolic engineering of Escherichia coli (E. coli), there have been a few research results on the production of long-chain alkanes, which consist of 13-17 carbon atoms, suitable for replacing diesel. However, there has been no report on the microbial production of short-chain alkanes, a possible substitute for gasoline.

In the paper (entitled "Microbial Production of Short-chain Alkanes") published online in Nature on September 29, a Korean research team led by Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering at the Korea Advanced Institute of Science and Technology (KAIST) reported, for the first time, the development of a novel strategy for microbial gasoline production through metabolic engineering of E. coli.

The research team engineered the fatty acid metabolism to provide the fatty acid derivatives that are shorter than normal intracellular fatty acid metabolites, and introduced a novel synthetic pathway for the biosynthesis of short-chain alkanes. This allowed the development of platform E. coli strain capable of producing gasoline for the first time. Furthermore, this platform strain, if desired, can be modified to produce other products such as short-chain fatty esters and short-chain fatty alcohols.

In this paper, the Korean researchers described detailed strategies for 1) screening of enzymes associated with the production of fatty acids, 2) engineering of enzymes and fatty acid biosynthetic pathways to concentrate carbon flux towards the short-chain fatty acid production, and 3) converting short-chain fatty acids to their corresponding alkanes (gasoline) by introducing a novel synthetic pathway and optimization of culture conditions. Furthermore, the research team showed the possibility of producing fatty esters and alcohols by introducing responsible enzymes into the same platform strain.

Professor Sang Yup Lee said, "It is only the beginning of the work towards sustainable production of gasoline. The titer is rather low due to the low metabolic flux towards the formation of short-chain fatty acids and their derivatives. We are currently working on increasing the titer, yield and productivity of bio-gasoline. Nonetheless, we are pleased to report, for the first time, the production of gasoline through the metabolic engineering of E. coli, which we hope will serve as a basis for the metabolic engineering of microorganisms to produce fuels and chemicals from renewable resources."

This research was supported by the Advanced Biomass Research and Development Center of Korea (ABC-2010-0029799) through the Global Frontier Research Program of the Ministry of Science, ICT and Future Planning (MSIP) through the National Research Foundation (NRF), Republic of Korea. Systems metabolic engineering work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries (NRF-2012-C1AAA001-2012M1A2A2026556) by MSIP through NRF.

Short-Chain Alkanes Generated from Renewable Biomass

This diagram shows the metabolic engineering of Escherichia coli for the production of short-chain alkanes (gasoline) from renewable biomass.

Nature Cover Page (September 29th, 2013)

2013.11.04 View 13489

KAIST announced a novel technology to produce gasoline by a metabolically engineered microorganism

A major scientific breakthrough in the development of renewable energy sources and other important chemicals; The research team succeeded in producing 580 mg of gasoline per liter of cultured broth by converting in vivo generated fatty acids

For many decades, we have been relying on fossil resources to produce liquid fuels such as gasoline, diesel, and many industrial and consumer chemicals for daily use. However, increasing strains on natural resources as well as environmental issues including global warming have triggered a strong interest in developing sustainable ways to obtain fuels and chemicals.

Gasoline, the petroleum-derived product that is most widely used as a fuel for transportation, is a mixture of hydrocarbons, additives, and blending agents. The hydrocarbons, called alkanes, consist only of carbon and hydrogen atoms. Gasoline has a combination of straight-chain and branched-chain alkanes (hydrocarbons) consisted of 4-12 carbon atoms linked by direct carbon-carbon bonds.

Previously, through metabolic engineering of Escherichia coli (E. coli), there have been a few research results on the production of long-chain alkanes, which consist of 13-17 carbon atoms, suitable for replacing diesel. However, there has been no report on the microbial production of short-chain alkanes, a possible substitute for gasoline.

In the paper (entitled "Microbial Production of Short-chain Alkanes") published online in Nature on September 29, a Korean research team led by Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering at the Korea Advanced Institute of Science and Technology (KAIST) reported, for the first time, the development of a novel strategy for microbial gasoline production through metabolic engineering of E. coli.

The research team engineered the fatty acid metabolism to provide the fatty acid derivatives that are shorter than normal intracellular fatty acid metabolites, and introduced a novel synthetic pathway for the biosynthesis of short-chain alkanes. This allowed the development of platform E. coli strain capable of producing gasoline for the first time. Furthermore, this platform strain, if desired, can be modified to produce other products such as short-chain fatty esters and short-chain fatty alcohols.

In this paper, the Korean researchers described detailed strategies for 1) screening of enzymes associated with the production of fatty acids, 2) engineering of enzymes and fatty acid biosynthetic pathways to concentrate carbon flux towards the short-chain fatty acid production, and 3) converting short-chain fatty acids to their corresponding alkanes (gasoline) by introducing a novel synthetic pathway and optimization of culture conditions. Furthermore, the research team showed the possibility of producing fatty esters and alcohols by introducing responsible enzymes into the same platform strain.

Professor Sang Yup Lee said, "It is only the beginning of the work towards sustainable production of gasoline. The titer is rather low due to the low metabolic flux towards the formation of short-chain fatty acids and their derivatives. We are currently working on increasing the titer, yield and productivity of bio-gasoline. Nonetheless, we are pleased to report, for the first time, the production of gasoline through the metabolic engineering of E. coli, which we hope will serve as a basis for the metabolic engineering of microorganisms to produce fuels and chemicals from renewable resources."

This research was supported by the Advanced Biomass Research and Development Center of Korea (ABC-2010-0029799) through the Global Frontier Research Program of the Ministry of Science, ICT and Future Planning (MSIP) through the National Research Foundation (NRF), Republic of Korea. Systems metabolic engineering work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries (NRF-2012-C1AAA001-2012M1A2A2026556) by MSIP through NRF.

Short-Chain Alkanes Generated from Renewable Biomass

This diagram shows the metabolic engineering of Escherichia coli for the production of short-chain alkanes (gasoline) from renewable biomass.

Nature Cover Page (September 29th, 2013)

2013.11.04 View 13489 -

A powerful strategy for developing microbial cell factories by employing synthetic small RNAs

The current systems for the production of chemicals, fuels and materials heavily rely on the use of fossil resources. Due to the increasing concerns on climate change and other environmental problems, however, there has been much interest in developing biorefineries for the production of such chemicals, fuels and materials from renewable resources. For the biorefineries to be competitive with the traditional fossil resource-based refineries, development of high performance microorganisms is the most important as it will affect the overall economics of the process most significantly. Metabolic engineering, which can be defined as purposeful modification of cellular metabolic and regulatory networks with an aim to improve the production of a desired product, has been successfully employed to improve the performance of the cell. However, it is not trivial to engineer the cellular metabolism and regulatory circuits in the cell due to their high complexity.

In metabolic engineering, it is important to find the genes that need to be amplified and attenuated in order to increase the product formation rate while minimizing the production of undesirable byproducts. Gene knock-out experiments are often performed to delete those metabolic fluxes that will consequently result in the increase of the desired product formation. However, gene knock-out experiments require much effort and time to perform, and are difficult to do for a large number of genes. Furthermore, the gene knock-out experiments performed in one strain cannot be transferred to another organism and thus the whole experimental process has to be repeated. This is a big problem in developing a high performance microbial cell factory because it is required to find the best platform strain among many different strains. Therefore, researchers have been eager to develop a strategy that allows rapid identification of multiple genes to be attenuated in multiple strains at the same time.

A Korean research team led by Distinguished Professor Sang Yup Lee at the Department of Chemical and Biomolecular Engineering from the Korea Advanced Institute of Science and Technology (KAIST) reported the development of a strategy for efficiently developing microbial cell factories by employing synthetic small RNAs (sRNAs). They first reported the development of such system in Nature Biotechnology last February. This strategy of employing synthetic sRNAs in metabolic engineering has been receiving great interest worldwide as it allows easy, rapid, high-throughput, tunable, and un-doable knock-down of multiple genes in multiple strains at the same time. The research team published a paper online on August 8 as a cover page (September issue) in Nature Protocols, describing the detailed strategy and protocol to employ synthetic sRNAs for metabolic engineering.

In this paper, researchers described the detailed step-by-step protocol for synthetic sRNA-based gene expression control, including the sRNA design principles. Tailor-made synthetic sRNAs can be easily manipulated by using conventional gene cloning method. The use of synthetic sRNAs for gene expression regulation provides several advantages such as portability, conditionality, and tunability in high-throughput experiments. Plasmid-based synthetic sRNA expression system does not leave any scar on the chromosome, and can be easily transferred to many other host strains to be examined. Thus, the construction of libraries and examination of different host strains are much easier than the conventional hard-coded gene manipulation systems. Also, the expression of genes can be conditionally repressed by controlling the production of synthetic sRNAs. Synthetic sRNAs possessing different repression efficiencies make it possible to finely tune the gene expression levels as well. Furthermore, synthetic sRNAs allow knock-down of the expression of essential genes, which was not possible by conventional gene knock-out experiments.

Synthetic sRNAs can be utilized for diverse experiments where gene expression regulation is needed. One of promising applications is high-throughput screening of the target genes to be manipulated and multiple strains simultaneously to enhance the production of chemicals and materials of interest. Such simultaneous optimization of gene targets and strains has been one of the big challenges in metabolic engineering. Another application is to fine tune the expression of the screened genes for flux optimization, which would enhance chemical production further by balancing the flux between biomass formation and target chemical production. Synthetic sRNAs can also be applied to finely regulating genetic interactions in a circuit or network, which is essential in synthetic biology. Once a sRNA scaffold-harboring plasmid is constructed, tailor-made, synthetic sRNAs can be made within 3-4 days, followed by the desired application experiments.

Dr. Eytan Zlotorynski, an editor at Nature Protocols, said "This paper describes the detailed protocol for the design and applications of synthetic sRNA. The method, which has many advantages, is likely to become common practice, and prove useful for metabolic engineering and synthetic biology studies."

This paper published in Nature Protocols will be useful for all researchers in academia and industry who are interested in the use of synthetic sRNAs for fundamental and applied biological and biotechnological studies.

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries (NRF-2012-C1AAA001-2012M1A2A2026556) and the Intelligent Synthetic Biology Center through the Global Frontier Project (2011-0031963) of the Ministry of Science, ICT and Future Planning through the National Research Foundation of Korea.

2013.10.31 View 10981

A powerful strategy for developing microbial cell factories by employing synthetic small RNAs

The current systems for the production of chemicals, fuels and materials heavily rely on the use of fossil resources. Due to the increasing concerns on climate change and other environmental problems, however, there has been much interest in developing biorefineries for the production of such chemicals, fuels and materials from renewable resources. For the biorefineries to be competitive with the traditional fossil resource-based refineries, development of high performance microorganisms is the most important as it will affect the overall economics of the process most significantly. Metabolic engineering, which can be defined as purposeful modification of cellular metabolic and regulatory networks with an aim to improve the production of a desired product, has been successfully employed to improve the performance of the cell. However, it is not trivial to engineer the cellular metabolism and regulatory circuits in the cell due to their high complexity.

In metabolic engineering, it is important to find the genes that need to be amplified and attenuated in order to increase the product formation rate while minimizing the production of undesirable byproducts. Gene knock-out experiments are often performed to delete those metabolic fluxes that will consequently result in the increase of the desired product formation. However, gene knock-out experiments require much effort and time to perform, and are difficult to do for a large number of genes. Furthermore, the gene knock-out experiments performed in one strain cannot be transferred to another organism and thus the whole experimental process has to be repeated. This is a big problem in developing a high performance microbial cell factory because it is required to find the best platform strain among many different strains. Therefore, researchers have been eager to develop a strategy that allows rapid identification of multiple genes to be attenuated in multiple strains at the same time.

A Korean research team led by Distinguished Professor Sang Yup Lee at the Department of Chemical and Biomolecular Engineering from the Korea Advanced Institute of Science and Technology (KAIST) reported the development of a strategy for efficiently developing microbial cell factories by employing synthetic small RNAs (sRNAs). They first reported the development of such system in Nature Biotechnology last February. This strategy of employing synthetic sRNAs in metabolic engineering has been receiving great interest worldwide as it allows easy, rapid, high-throughput, tunable, and un-doable knock-down of multiple genes in multiple strains at the same time. The research team published a paper online on August 8 as a cover page (September issue) in Nature Protocols, describing the detailed strategy and protocol to employ synthetic sRNAs for metabolic engineering.

In this paper, researchers described the detailed step-by-step protocol for synthetic sRNA-based gene expression control, including the sRNA design principles. Tailor-made synthetic sRNAs can be easily manipulated by using conventional gene cloning method. The use of synthetic sRNAs for gene expression regulation provides several advantages such as portability, conditionality, and tunability in high-throughput experiments. Plasmid-based synthetic sRNA expression system does not leave any scar on the chromosome, and can be easily transferred to many other host strains to be examined. Thus, the construction of libraries and examination of different host strains are much easier than the conventional hard-coded gene manipulation systems. Also, the expression of genes can be conditionally repressed by controlling the production of synthetic sRNAs. Synthetic sRNAs possessing different repression efficiencies make it possible to finely tune the gene expression levels as well. Furthermore, synthetic sRNAs allow knock-down of the expression of essential genes, which was not possible by conventional gene knock-out experiments.

Synthetic sRNAs can be utilized for diverse experiments where gene expression regulation is needed. One of promising applications is high-throughput screening of the target genes to be manipulated and multiple strains simultaneously to enhance the production of chemicals and materials of interest. Such simultaneous optimization of gene targets and strains has been one of the big challenges in metabolic engineering. Another application is to fine tune the expression of the screened genes for flux optimization, which would enhance chemical production further by balancing the flux between biomass formation and target chemical production. Synthetic sRNAs can also be applied to finely regulating genetic interactions in a circuit or network, which is essential in synthetic biology. Once a sRNA scaffold-harboring plasmid is constructed, tailor-made, synthetic sRNAs can be made within 3-4 days, followed by the desired application experiments.

Dr. Eytan Zlotorynski, an editor at Nature Protocols, said "This paper describes the detailed protocol for the design and applications of synthetic sRNA. The method, which has many advantages, is likely to become common practice, and prove useful for metabolic engineering and synthetic biology studies."

This paper published in Nature Protocols will be useful for all researchers in academia and industry who are interested in the use of synthetic sRNAs for fundamental and applied biological and biotechnological studies.

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries (NRF-2012-C1AAA001-2012M1A2A2026556) and the Intelligent Synthetic Biology Center through the Global Frontier Project (2011-0031963) of the Ministry of Science, ICT and Future Planning through the National Research Foundation of Korea.

2013.10.31 View 10981 -

New drug targeting method for microbial pathogens developed using in silico cell

A ripple effect is expected on the new antibacterial discovery using “in silico” cells

Featured as a journal cover paper of Molecular BioSystems

A research team of Distinguished Professor Sang Yup Lee at KAIST recently constructed an in silico cell of a microbial pathogen that is resistant to antibiotics and developed a new drug targeting method that could effectively disrupt the pathogen"s growth using the in silico cell.

Hyun Uk Kim, a graduate research assistant at the Department of Chemical and Biomolecular Engineering, KAIST, conducted this study as a part of his thesis research, and the study was featured as a journal cover paper in the February issue of Molecular BioSystems this year, published by The Royal Society of Chemistry based in Europe.

It was relatively easy to treat infectious microbes using antibiotics in the past. However, the overdose of antibiotics has caused pathogens to increase their resistance to various antibiotics, and it has become more difficult to cure infectious diseases these days.

A representative microbial pathogen is Acinetobacter baumannaii. Originally isolated from soils and water, this microorganism did not have resistance to antibiotics, and hence it was easy to eradicate them if infected. However, within a decade, this miroorganism has transformed into a dreadful super-bacterium resistant to antibiotics and caused many casualties among the U.S. and French soldiers who were injured from the recent Iraqi war and infected with Acinetobacter baumannaii.

Professor Lee’s group constructed an in silico cell of this A. baumannii by computationally collecting, integrating, and analyzing the biological information of the bacterium, scattered over various databases and literatures, in order to study this organism"s genomic features and system-wide metabolic characteristics. Furthermore, they employed this in silico cell for integrative approaches, including several network analysis and analysis of essential reactions and metabolites, to predict drug targets that effectively disrupt the pathogen"s growth. Final drug targets are the ones that selectively kill pathogens without harming human body.

Here, essential reactions refer to enzymatic reactions required for normal metabolic functioning in organisms, while essential metabolites indicate chemical compounds required in the metabolism for proper functioning, and their removal brings about the effect of simultaneously disrupting their associated enzymes that interact with them.

This study attempted to predict highly reliable drug targets by systematically scanning biological components, including metabolic genes, enzymatic reactions, that constitute an in silico cell in a short period of time.

This research achievement is highly regarded as it, for the first time, systematically scanned essential metabolites for the effective drug targets using the concept of systems biology, and paved the way for a new antibacterial discovery. This study is also expected to contribute to elucidating the infectious mechanism caused by pathogens.

"Although tons of genomic information is poured in at this moment, application research that efficiently converts this preliminary information into actually useful information is still lagged behind. In this regard, this study is meaningful in that medically useful information is generated from the genomic information of Acinetobacter baumannii," says Professor Lee. "In particular, development of this organism"s in silico cell allows generation of new knowledge regarding essential genes and enzymatic reactions under specific conditions," he added.

This study was supported by the Korean Systems Biology Project of the Ministry of Education, Science and Technology, and the patent for the development of in silico cells of microbial pathogens and drug targeting methods has been filed.

[Picture 1 Cells in silico]

[Picture 2 A process of generating drug targets without harming human body while effectively disrupting the growth of a pathogen, after predicting metabolites from in silico cells]

2010.04.05 View 19357

New drug targeting method for microbial pathogens developed using in silico cell

A ripple effect is expected on the new antibacterial discovery using “in silico” cells

Featured as a journal cover paper of Molecular BioSystems

A research team of Distinguished Professor Sang Yup Lee at KAIST recently constructed an in silico cell of a microbial pathogen that is resistant to antibiotics and developed a new drug targeting method that could effectively disrupt the pathogen"s growth using the in silico cell.

Hyun Uk Kim, a graduate research assistant at the Department of Chemical and Biomolecular Engineering, KAIST, conducted this study as a part of his thesis research, and the study was featured as a journal cover paper in the February issue of Molecular BioSystems this year, published by The Royal Society of Chemistry based in Europe.

It was relatively easy to treat infectious microbes using antibiotics in the past. However, the overdose of antibiotics has caused pathogens to increase their resistance to various antibiotics, and it has become more difficult to cure infectious diseases these days.

A representative microbial pathogen is Acinetobacter baumannaii. Originally isolated from soils and water, this microorganism did not have resistance to antibiotics, and hence it was easy to eradicate them if infected. However, within a decade, this miroorganism has transformed into a dreadful super-bacterium resistant to antibiotics and caused many casualties among the U.S. and French soldiers who were injured from the recent Iraqi war and infected with Acinetobacter baumannaii.

Professor Lee’s group constructed an in silico cell of this A. baumannii by computationally collecting, integrating, and analyzing the biological information of the bacterium, scattered over various databases and literatures, in order to study this organism"s genomic features and system-wide metabolic characteristics. Furthermore, they employed this in silico cell for integrative approaches, including several network analysis and analysis of essential reactions and metabolites, to predict drug targets that effectively disrupt the pathogen"s growth. Final drug targets are the ones that selectively kill pathogens without harming human body.

Here, essential reactions refer to enzymatic reactions required for normal metabolic functioning in organisms, while essential metabolites indicate chemical compounds required in the metabolism for proper functioning, and their removal brings about the effect of simultaneously disrupting their associated enzymes that interact with them.

This study attempted to predict highly reliable drug targets by systematically scanning biological components, including metabolic genes, enzymatic reactions, that constitute an in silico cell in a short period of time.

This research achievement is highly regarded as it, for the first time, systematically scanned essential metabolites for the effective drug targets using the concept of systems biology, and paved the way for a new antibacterial discovery. This study is also expected to contribute to elucidating the infectious mechanism caused by pathogens.

"Although tons of genomic information is poured in at this moment, application research that efficiently converts this preliminary information into actually useful information is still lagged behind. In this regard, this study is meaningful in that medically useful information is generated from the genomic information of Acinetobacter baumannii," says Professor Lee. "In particular, development of this organism"s in silico cell allows generation of new knowledge regarding essential genes and enzymatic reactions under specific conditions," he added.

This study was supported by the Korean Systems Biology Project of the Ministry of Education, Science and Technology, and the patent for the development of in silico cells of microbial pathogens and drug targeting methods has been filed.

[Picture 1 Cells in silico]

[Picture 2 A process of generating drug targets without harming human body while effectively disrupting the growth of a pathogen, after predicting metabolites from in silico cells]

2010.04.05 View 19357 -

International Science Journal Spotlights Korean Biotechnology

Biotechnology Journal published by German-based Wiley-VCH, one of the world"s major scientific and technical publishers, devoted its entire special edition for May to biotechnology in Korea.

The monthly journal"s special issue was planned by KAIST Professor Sang-Yup Lee of the Chemical and Biomolecular Engineering Department who is one of the journal"s two editors-in-chief.

The special issue outlines the current status and future prospect of biotechnology in Korea, and presents five review papers and eight original papers by leading Korean biotech researchers to showcase recent developments in Korean biotechnology. Among these papers, a review by Dr. Byung-Hwan Hyeon and his colleagues describes in detail the Korean biotechnology strategies represented by "Bio-Vision 2016," and another by Dr. Ji-Hyun Kim and his collaborators presents recent progress in microbial genome projects in Korea.

In the editorial of the journal, Prof. Lee said, "Heavy industry and IT industry have been the two drivers of Korean economic growth. Korea is now considering biotechnology as its next generation growth engine."

Underscoring the growing importance of fusion research, he mentioned that integration of biotechnology with information technology and nanotechnology is advancing rapidly in Korea. Another special edition of Biotechnology Journal focusing on these exciting biotech developments in Korea is planned for the future.

2008.05.20 View 16492

International Science Journal Spotlights Korean Biotechnology

Biotechnology Journal published by German-based Wiley-VCH, one of the world"s major scientific and technical publishers, devoted its entire special edition for May to biotechnology in Korea.

The monthly journal"s special issue was planned by KAIST Professor Sang-Yup Lee of the Chemical and Biomolecular Engineering Department who is one of the journal"s two editors-in-chief.

The special issue outlines the current status and future prospect of biotechnology in Korea, and presents five review papers and eight original papers by leading Korean biotech researchers to showcase recent developments in Korean biotechnology. Among these papers, a review by Dr. Byung-Hwan Hyeon and his colleagues describes in detail the Korean biotechnology strategies represented by "Bio-Vision 2016," and another by Dr. Ji-Hyun Kim and his collaborators presents recent progress in microbial genome projects in Korea.

In the editorial of the journal, Prof. Lee said, "Heavy industry and IT industry have been the two drivers of Korean economic growth. Korea is now considering biotechnology as its next generation growth engine."

Underscoring the growing importance of fusion research, he mentioned that integration of biotechnology with information technology and nanotechnology is advancing rapidly in Korea. Another special edition of Biotechnology Journal focusing on these exciting biotech developments in Korea is planned for the future.

2008.05.20 View 16492