college+of+engineering

-

Rechargeable Lithium Sulfur Battery for Greater Battery Capacity

Professor Do Kyung Kim from the Department of Material Science and Engineering and Professor Jang Wook Choi from the Graduate School of EEWS have been featured in the lead story of the renowned nanoscience journal Advanced Materials for their research on the lithium sulfur battery. This new type of battery developed by Professor Kim is expected to have a longer life battery life and [higher] energy density than currently commercial batteries.

With ample energy density up to 2100Wh/kg—almost 5.4 times that of lithium ion batteries—lithium sulfur batteries can withstand the sharp decrease in energy capacity resulting from charging and discharging—which has been considered the inherent limitation of the conventional batteries.

Professor Kim and his research team used one-dimensional, vertical alignment of 75nm tick, 15μm long sulfur nanowires to maximize electric conductivity. Then, to prevent loss of battery life, they carbon-coated each nanowire and prohibited direct contact between the sulfur and electrolyte.

The result was one of the most powerful batteries in terms of both energy performance and density. Compared to conventional batteries which suffer from continuous decrease in energy capacity after being discharged, the lithium sulfur battery maintained 99.2% of its initial capacity after being charged and discharged 300 times and up to 70% even after 1000 times.

Professor Kim claims that his new battery is an important step forward towards a high-performance rechargeable battery which is a vital technology for unmanned vehicles, electric automobiles and energy storage. He hopes that his research can solve the problems of battery-capacity loss and contribute to South Korea’s leading position in battery technology. Professor Kim’s research team has filed applications for one domestic and international patent for their research.

2013.12.11 View 14602

Rechargeable Lithium Sulfur Battery for Greater Battery Capacity

Professor Do Kyung Kim from the Department of Material Science and Engineering and Professor Jang Wook Choi from the Graduate School of EEWS have been featured in the lead story of the renowned nanoscience journal Advanced Materials for their research on the lithium sulfur battery. This new type of battery developed by Professor Kim is expected to have a longer life battery life and [higher] energy density than currently commercial batteries.

With ample energy density up to 2100Wh/kg—almost 5.4 times that of lithium ion batteries—lithium sulfur batteries can withstand the sharp decrease in energy capacity resulting from charging and discharging—which has been considered the inherent limitation of the conventional batteries.

Professor Kim and his research team used one-dimensional, vertical alignment of 75nm tick, 15μm long sulfur nanowires to maximize electric conductivity. Then, to prevent loss of battery life, they carbon-coated each nanowire and prohibited direct contact between the sulfur and electrolyte.

The result was one of the most powerful batteries in terms of both energy performance and density. Compared to conventional batteries which suffer from continuous decrease in energy capacity after being discharged, the lithium sulfur battery maintained 99.2% of its initial capacity after being charged and discharged 300 times and up to 70% even after 1000 times.

Professor Kim claims that his new battery is an important step forward towards a high-performance rechargeable battery which is a vital technology for unmanned vehicles, electric automobiles and energy storage. He hopes that his research can solve the problems of battery-capacity loss and contribute to South Korea’s leading position in battery technology. Professor Kim’s research team has filed applications for one domestic and international patent for their research.

2013.12.11 View 14602 -

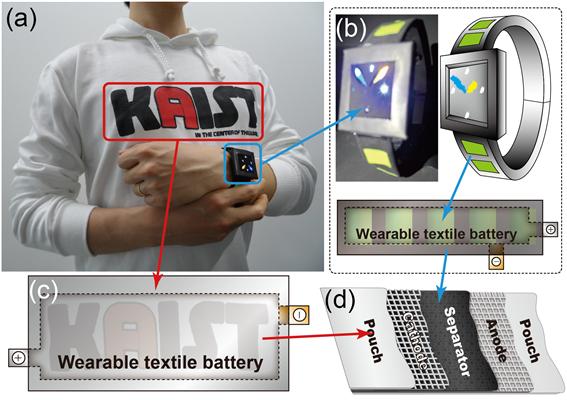

Technology Developed for Flexible, Foldable & Rechargeable Battery

Flexible, Foldable & Rechargeable Battery

The research group of professors Jang-Wook Choi & Jung-Yong Lee from the Graduate School of EEWS and Taek-Soo Kim from the Department of Mechanical Engineering at KAIST has developed technology for flexible and foldable batteries which are rechargeable using solar energy. The research result was published in the online issue of Nano Letters on November 5.

Trial versions of flexible and wearable electronics are being developed and introduced in the market such as Galaxy Gear, Apple’s i-Watch, and Google Glass. Research is being conducted to make the batteries softer and more wearable and to compete in the fast-growing market for flexible electronics.

This new technology is expected to be applied to the development of wearable computers as well as winter outdoor clothing since it is flexible and light. The research group expects that the new technology can be applied to current battery production lines without additional investment.

Professor Choi said, “It can be used as a core-source technology in the rechargeable battery industry in the future. Various wearable mobile electronic products can be developed through cooperation and collaboration within the industry.”

2013.11.21 View 13318

Technology Developed for Flexible, Foldable & Rechargeable Battery

Flexible, Foldable & Rechargeable Battery

The research group of professors Jang-Wook Choi & Jung-Yong Lee from the Graduate School of EEWS and Taek-Soo Kim from the Department of Mechanical Engineering at KAIST has developed technology for flexible and foldable batteries which are rechargeable using solar energy. The research result was published in the online issue of Nano Letters on November 5.

Trial versions of flexible and wearable electronics are being developed and introduced in the market such as Galaxy Gear, Apple’s i-Watch, and Google Glass. Research is being conducted to make the batteries softer and more wearable and to compete in the fast-growing market for flexible electronics.

This new technology is expected to be applied to the development of wearable computers as well as winter outdoor clothing since it is flexible and light. The research group expects that the new technology can be applied to current battery production lines without additional investment.

Professor Choi said, “It can be used as a core-source technology in the rechargeable battery industry in the future. Various wearable mobile electronic products can be developed through cooperation and collaboration within the industry.”

2013.11.21 View 13318 -

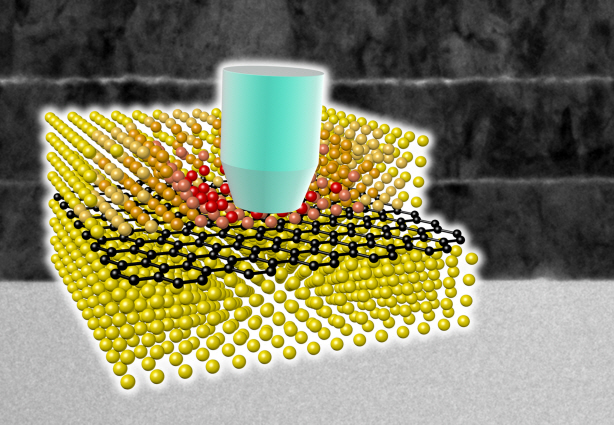

Ultra-High Strength Metamaterial Developed Using Graphene

New metamaterial has been developed, exhibiting hundreds of times greater strength than pure metals.

Professor Seung Min, Han and Yoo Sung, Jeong (Graduate School of Energy, Environment, Water, and Sustainability (EEWS)) and Professor Seok Woo, Jeon (Department of Material Science and Engineering) have developed a composite nanomaterial. The nanomaterial consists of graphene inserted in copper and nickel and exhibits strengths 500 times and 180 times, respectively, greater than that of pure metals. The result of the research was published on the July 2nd online edition in Nature Communications journal.

Graphene displays strengths 200 times greater than that of steel, is stretchable, and is flexible. The U.S. Army Armaments Research, Development and Engineering Center developed a graphene-metal nanomaterial but failed to drastically improve the strength of the material.

To maximize the strength increased by the addition of graphene, the KAIST research team created a layered structure of metal and graphene. Using CVD (Chemical Vapor Deposition), the team grew a single layer of graphene on a metal deposited substrate and then deposited another metal layer. They repeated this process to produce a metal-graphene multilayer composite material, utilizing a single layer of graphene. Micro-compression tests within Transmission Electronic Microscope and Molecular Dynamics simulations effectively showed the strength enhancing effect and the dislocation movement in grain boundaries of graphene on an atomic level.

The mechanical characteristics of the graphene layer within the metal-graphene composite material successfully blocked the dislocations and cracks from external damage from traveling inwards. Therefore the composite material displayed strength beyond conventional metal-metal multilayer materials. The copper-graphene multilayer material with an interplanar distance of 70nm exhibited 500 times greater (1.5GPa) strength than pure copper. Nickel-graphene multilayer material with an interplanar distance of 100nm showed 180 times greater (4.0GPa) strength than pure nickel.

It was found that there is a clear relationship between the interplanar distance and the strength of the multilayer material. A smaller interplanar distance made the dislocation movement more difficult and therefore increased the strength of the material. Professor Han, who led the research, commented, “the result is astounding as 0.00004% in weight of graphene increased the strength of the materials by hundreds of times” and “improvements based on this success, especially mass production with roll-to-roll process or metal sintering process in the production of ultra-high strength, lightweight parts for automobile and spacecraft, may become possible.” In addition, Professor Han mentioned that “the new material can be applied to coating materials for nuclear reactor construction or other structural materials requiring high reliability.”

The research project received support from National Research Foundation, Global Frontier Program, KAIST EEWS-KINC Program and KISTI Supercomputer and was a collaborative effort with KISTI (Korea Institute of Science and Technology Information), KBSI (Korea Basic Science Institute), Stanford University, and Columbia University.

A schematic diagram shows the structure of metal-graphene multi-layers. The metal-graphene multi-layered composite materials, containing a single-layered graphene, block the dislocation movement of graphene layers, resulting in a greater strength in the materials.

2013.08.23 View 18298

Ultra-High Strength Metamaterial Developed Using Graphene

New metamaterial has been developed, exhibiting hundreds of times greater strength than pure metals.

Professor Seung Min, Han and Yoo Sung, Jeong (Graduate School of Energy, Environment, Water, and Sustainability (EEWS)) and Professor Seok Woo, Jeon (Department of Material Science and Engineering) have developed a composite nanomaterial. The nanomaterial consists of graphene inserted in copper and nickel and exhibits strengths 500 times and 180 times, respectively, greater than that of pure metals. The result of the research was published on the July 2nd online edition in Nature Communications journal.

Graphene displays strengths 200 times greater than that of steel, is stretchable, and is flexible. The U.S. Army Armaments Research, Development and Engineering Center developed a graphene-metal nanomaterial but failed to drastically improve the strength of the material.

To maximize the strength increased by the addition of graphene, the KAIST research team created a layered structure of metal and graphene. Using CVD (Chemical Vapor Deposition), the team grew a single layer of graphene on a metal deposited substrate and then deposited another metal layer. They repeated this process to produce a metal-graphene multilayer composite material, utilizing a single layer of graphene. Micro-compression tests within Transmission Electronic Microscope and Molecular Dynamics simulations effectively showed the strength enhancing effect and the dislocation movement in grain boundaries of graphene on an atomic level.

The mechanical characteristics of the graphene layer within the metal-graphene composite material successfully blocked the dislocations and cracks from external damage from traveling inwards. Therefore the composite material displayed strength beyond conventional metal-metal multilayer materials. The copper-graphene multilayer material with an interplanar distance of 70nm exhibited 500 times greater (1.5GPa) strength than pure copper. Nickel-graphene multilayer material with an interplanar distance of 100nm showed 180 times greater (4.0GPa) strength than pure nickel.

It was found that there is a clear relationship between the interplanar distance and the strength of the multilayer material. A smaller interplanar distance made the dislocation movement more difficult and therefore increased the strength of the material. Professor Han, who led the research, commented, “the result is astounding as 0.00004% in weight of graphene increased the strength of the materials by hundreds of times” and “improvements based on this success, especially mass production with roll-to-roll process or metal sintering process in the production of ultra-high strength, lightweight parts for automobile and spacecraft, may become possible.” In addition, Professor Han mentioned that “the new material can be applied to coating materials for nuclear reactor construction or other structural materials requiring high reliability.”

The research project received support from National Research Foundation, Global Frontier Program, KAIST EEWS-KINC Program and KISTI Supercomputer and was a collaborative effort with KISTI (Korea Institute of Science and Technology Information), KBSI (Korea Basic Science Institute), Stanford University, and Columbia University.

A schematic diagram shows the structure of metal-graphene multi-layers. The metal-graphene multi-layered composite materials, containing a single-layered graphene, block the dislocation movement of graphene layers, resulting in a greater strength in the materials.

2013.08.23 View 18298 -

Professor Hwang Kyu Young and Professor Yang Dong Yeol Receives Engineer of Korea Award

Emeritus Professor Hwang Kyu Young (Department of Computer Sciences) and Professor Yang Dong Yeol (Department of Mechanical Engineering) were named as the 2012 Engineer of Korea by the Ministry of Education, Science, and Technology and Korea Science Foundation.

The Engineer of Korea Award is awarded biannually to scientists and engineers that have contributed to the development of Korea’s science and technology and national economy.

Professor Hwang’s work with DBMS and close coupling architecture of information search and overall new theories and application technology development in the field of database system has aided the opening and expansion of IT software industry development and the advent of internet information culture era.

Professor Yang is a word renowned scholar in the field of net shape manufacturing and is considered to have opened a new page in the field of nano-molding technique.

In addition, Professor Eum Sang Il (Department of Mathematical Science) has been selected as the 2012 Young Scientist Award.

2013.01.22 View 13531

Professor Hwang Kyu Young and Professor Yang Dong Yeol Receives Engineer of Korea Award

Emeritus Professor Hwang Kyu Young (Department of Computer Sciences) and Professor Yang Dong Yeol (Department of Mechanical Engineering) were named as the 2012 Engineer of Korea by the Ministry of Education, Science, and Technology and Korea Science Foundation.

The Engineer of Korea Award is awarded biannually to scientists and engineers that have contributed to the development of Korea’s science and technology and national economy.

Professor Hwang’s work with DBMS and close coupling architecture of information search and overall new theories and application technology development in the field of database system has aided the opening and expansion of IT software industry development and the advent of internet information culture era.

Professor Yang is a word renowned scholar in the field of net shape manufacturing and is considered to have opened a new page in the field of nano-molding technique.

In addition, Professor Eum Sang Il (Department of Mathematical Science) has been selected as the 2012 Young Scientist Award.

2013.01.22 View 13531 -

KAIST Professors win 2012 Korea Engineering Award

Distinguished Professor Hwang Gyu Young (Department of Computer Science) and Professor Yang Dong Yol (Department of Mechanical Engineering) from KAIST received the 2012 ‘Korea Engineering Award’ hosted by the Ministry of Education, Science and Technology and the Korea Research Foundation.

The ‘Korea Engineering Award’ is given biennially to researchers who have accomplished world class research and have contributed greatly to Korea’s development in the field of Science and Technology. The award started in 1994 and a total of 24 recipients were recognized in various fields such as electronics, mechanics, chemistry, construction, etc. The recipients of the award areawarded the Presidential award as well as 50million won as prize money.

Professor Hwang was recognized for his research on DBMS close-coupling architecture as well as other new data base system theories, contributing to the development of the IT software industry in Korea. Professor Yang was praised for his work in precision shape creation and manufacturing, especially for his work in the nano-stereolithography process.

In addition, Professor Oum Sang-il from the Deparment of Mathematical Science received the 2012 ‘Young Scientist Award’ hosted by the Ministry of Education, Science and Technology and the Korean Academy of Science and Technology.

The ceremony for ‘Korea Engineering Award’ and the ‘Young Scientist Award’ was held in Seoul Press Center Press Club on the 21st of December.

2012.12.26 View 15377

KAIST Professors win 2012 Korea Engineering Award

Distinguished Professor Hwang Gyu Young (Department of Computer Science) and Professor Yang Dong Yol (Department of Mechanical Engineering) from KAIST received the 2012 ‘Korea Engineering Award’ hosted by the Ministry of Education, Science and Technology and the Korea Research Foundation.

The ‘Korea Engineering Award’ is given biennially to researchers who have accomplished world class research and have contributed greatly to Korea’s development in the field of Science and Technology. The award started in 1994 and a total of 24 recipients were recognized in various fields such as electronics, mechanics, chemistry, construction, etc. The recipients of the award areawarded the Presidential award as well as 50million won as prize money.

Professor Hwang was recognized for his research on DBMS close-coupling architecture as well as other new data base system theories, contributing to the development of the IT software industry in Korea. Professor Yang was praised for his work in precision shape creation and manufacturing, especially for his work in the nano-stereolithography process.

In addition, Professor Oum Sang-il from the Deparment of Mathematical Science received the 2012 ‘Young Scientist Award’ hosted by the Ministry of Education, Science and Technology and the Korean Academy of Science and Technology.

The ceremony for ‘Korea Engineering Award’ and the ‘Young Scientist Award’ was held in Seoul Press Center Press Club on the 21st of December.

2012.12.26 View 15377 -

KAIST shocks the world with its creativity

Researchers at KAIST yielded great results at the world’s leading international Human Computer Interaction Society.

Professor Lee Gi Hyuk’s (Department of Computer Sciences) and Professor Bae Seok Hyung’ (Department of Industrial Design) respective teams received awards in two criteria in student innovation contest and was the only domestic university that presented their thesis at the ACM Symposium on User Interface Software.

The ACM UIST holds a student innovation contest prior to its opening. This year’s topic was the pressure sensing multi touch pad of Synaptics and involved 27 prestigious universities including MIT and CMU.

The KAIST team (Ki Son Joon Ph.D. candidate, Son Jeong Min M.A. candidate of Department of Computer Sciences and Woo Soo Jin M.A. candidate of Department of Industrial Design) designed a system that allows modulated control by attaching a simple structure to the pressure sensing multi touch pad.

The second KAIST team (Huh Seong Guk Ph.D. candidate, Han Jae Hyun Ph.D. candidate, Koo Ji Sung Ph.D. candidate at the Department of Computer Sciences, and Choi Ha Yan M.A. candidate at Department of Industrial Design) designed a system that utilizes a highly elastic fiber to allow the sensing of lateral forces. They also created a slingshot game application which was the second most popular system.

In the thesis session Professor Bae’s team (Lee DaWhee Ph.D. candidate, Son Kyung Hee Ph.D. candidate, Lee Joon Hyup M.A. candidate at Department of Industrial Design) presented a thesis that dealt with the technology that innovated the table pen for displays.

The new ‘phantom pen’ solved the issue arising from the hiding effect of the pen’s contact point and the display error due to the thickness of the display. In addition the ‘phantom pen’ has the ability to show the same effects as crayons or markers in a digital environment.

2012.11.29 View 12744

KAIST shocks the world with its creativity

Researchers at KAIST yielded great results at the world’s leading international Human Computer Interaction Society.

Professor Lee Gi Hyuk’s (Department of Computer Sciences) and Professor Bae Seok Hyung’ (Department of Industrial Design) respective teams received awards in two criteria in student innovation contest and was the only domestic university that presented their thesis at the ACM Symposium on User Interface Software.

The ACM UIST holds a student innovation contest prior to its opening. This year’s topic was the pressure sensing multi touch pad of Synaptics and involved 27 prestigious universities including MIT and CMU.

The KAIST team (Ki Son Joon Ph.D. candidate, Son Jeong Min M.A. candidate of Department of Computer Sciences and Woo Soo Jin M.A. candidate of Department of Industrial Design) designed a system that allows modulated control by attaching a simple structure to the pressure sensing multi touch pad.

The second KAIST team (Huh Seong Guk Ph.D. candidate, Han Jae Hyun Ph.D. candidate, Koo Ji Sung Ph.D. candidate at the Department of Computer Sciences, and Choi Ha Yan M.A. candidate at Department of Industrial Design) designed a system that utilizes a highly elastic fiber to allow the sensing of lateral forces. They also created a slingshot game application which was the second most popular system.

In the thesis session Professor Bae’s team (Lee DaWhee Ph.D. candidate, Son Kyung Hee Ph.D. candidate, Lee Joon Hyup M.A. candidate at Department of Industrial Design) presented a thesis that dealt with the technology that innovated the table pen for displays.

The new ‘phantom pen’ solved the issue arising from the hiding effect of the pen’s contact point and the display error due to the thickness of the display. In addition the ‘phantom pen’ has the ability to show the same effects as crayons or markers in a digital environment.

2012.11.29 View 12744