School+of+Electrical+Engineering

-

Transfering Nanowires onto a Flexible Substrate

(from left: PhD Min-Ho Seo and Professor Jun-Bo Yoon)

Boasting excellent physical and chemical properties, nanowires (NWs) are suitable for fabricating flexible electronics; therefore, technology to transfer well-aligned wires plays a crucial role in enhancing performance of the devices. A KAIST research team succeeded in developing NW-transfer technology that is expected to enhance the existing chemical reaction-based NW fabrication technology that has this far showed low performance in applicability and productivity.

NWs, one of the most well-known nanomaterials, have the structural advantage of being small and lightweight. Hence, NW-transfer technology has drawn attention because it can fabricate high-performance, flexible nanodevices with high simplicity and throughput.

A conventional nanowire-fabrication method generally has an irregularity issue since it mixes chemically synthesized nanowires in a solution and randomly distributes the NWs onto flexible substrates. Hence, numerous nanofabrication processes have emerged, and one of them is master-mold-based, which enables the fabrication of highly ordered NW arrays embedded onto substrates in a simple and cost-effective manner, but its employment is limited to only some materials because of its chemistry-based NW-transfer mechanism, which is complex and time consuming. For the successful transfer, it requires that adequate chemicals controlling the chemical interfacial adhesion between the master mold, NWs, and flexible substrate be present.

Here, Professor Jun-Bo Yoon and his team from the School of Electrical Engineering introduced a material-independent mechanical-interlocking-based nanowire-transfer (MINT) method to fabricate ultralong and fully aligned NWs on a large flexible substrate in a highly robust manner.

This method involves sequentially forming a nanosacrificial layer and NWs on a nanograting substrate that becomes the master mold for the transfer, then weakening the structure of the nanosacrificial layer through a dry etching process. The nanosacrificial layer very weakly holds the nanowires on the master mold. Therefore, when using a flexible substrate material, the nanowires are very easily transferred from the master mold to the substrate, just like a piece of tape lifting dust off a carpet.

This technology uses common physical vapor deposition and does not rely on NW materials, making it easy to fabricate NWs onto the flexible substrates.

Using this technology, the team was able to fabricate a variety of metal and metal-oxide NWs, including gold, platinum, and copper – all perfectly aligned on a flexible substrate. They also confirmed that it can be applied to creating stable and applicable devices in everyday life by successfully applying it to flexible heaters and gas sensors.

PhD Min-Ho Seo who led this research said, “We have successfully aligned various metals and semiconductor NWs with excellent physical properties onto flexible substrates and applied them to fabricated devices. As a platform-technology, it will contribute to developing high-performing and stable electronic devices.”

This research was published in ACS Nano on May 24.

Figure 1. Photograph of the fabricated wafer-scale fully aligned and ultralong Au nanowire array on a flexible substrate

2018.09.17 View 6752

Transfering Nanowires onto a Flexible Substrate

(from left: PhD Min-Ho Seo and Professor Jun-Bo Yoon)

Boasting excellent physical and chemical properties, nanowires (NWs) are suitable for fabricating flexible electronics; therefore, technology to transfer well-aligned wires plays a crucial role in enhancing performance of the devices. A KAIST research team succeeded in developing NW-transfer technology that is expected to enhance the existing chemical reaction-based NW fabrication technology that has this far showed low performance in applicability and productivity.

NWs, one of the most well-known nanomaterials, have the structural advantage of being small and lightweight. Hence, NW-transfer technology has drawn attention because it can fabricate high-performance, flexible nanodevices with high simplicity and throughput.

A conventional nanowire-fabrication method generally has an irregularity issue since it mixes chemically synthesized nanowires in a solution and randomly distributes the NWs onto flexible substrates. Hence, numerous nanofabrication processes have emerged, and one of them is master-mold-based, which enables the fabrication of highly ordered NW arrays embedded onto substrates in a simple and cost-effective manner, but its employment is limited to only some materials because of its chemistry-based NW-transfer mechanism, which is complex and time consuming. For the successful transfer, it requires that adequate chemicals controlling the chemical interfacial adhesion between the master mold, NWs, and flexible substrate be present.

Here, Professor Jun-Bo Yoon and his team from the School of Electrical Engineering introduced a material-independent mechanical-interlocking-based nanowire-transfer (MINT) method to fabricate ultralong and fully aligned NWs on a large flexible substrate in a highly robust manner.

This method involves sequentially forming a nanosacrificial layer and NWs on a nanograting substrate that becomes the master mold for the transfer, then weakening the structure of the nanosacrificial layer through a dry etching process. The nanosacrificial layer very weakly holds the nanowires on the master mold. Therefore, when using a flexible substrate material, the nanowires are very easily transferred from the master mold to the substrate, just like a piece of tape lifting dust off a carpet.

This technology uses common physical vapor deposition and does not rely on NW materials, making it easy to fabricate NWs onto the flexible substrates.

Using this technology, the team was able to fabricate a variety of metal and metal-oxide NWs, including gold, platinum, and copper – all perfectly aligned on a flexible substrate. They also confirmed that it can be applied to creating stable and applicable devices in everyday life by successfully applying it to flexible heaters and gas sensors.

PhD Min-Ho Seo who led this research said, “We have successfully aligned various metals and semiconductor NWs with excellent physical properties onto flexible substrates and applied them to fabricated devices. As a platform-technology, it will contribute to developing high-performing and stable electronic devices.”

This research was published in ACS Nano on May 24.

Figure 1. Photograph of the fabricated wafer-scale fully aligned and ultralong Au nanowire array on a flexible substrate

2018.09.17 View 6752 -

2018 KAIST Research Day Honors Outstanding Research Achievements

(KAIST President Sung-Chul Shin and Professor Jong-Hwan Kim) Professor Jong-Hwan Kim from the School of Electrical Engineering was recognized at the 2018 KAIST Research Day as the Research Grand Prize Awardee. The ten most distinguished research achievements of the past year were also recognized.

The Research Grand Prize recognizes the professor whose comprehensive research performance evaluation indicator was the highest over the past five years. The indicator combines the number of research contracts, IPR and royalty income.

During the May 25th ceremony, Professor Hyochoong Bang from the Department of Aerospace Engineering and Professor In so Kweon from the School of Electrical Engineering also won the Best Research Award prize.

This year, the Research Innovation Award went to Professor Dong Soo Han from the School of Computing. The Research Innovation Award combines scores in the categories of foreign patent registrations, contracts of technological transfer, and income from technology fees, technology consultations, and startups.

The Convergence Research Award was given to Professor Junmo Kim from the School of Electrical Engineering and Professor Hyun Myung from the Department of Civil & Environmental Engineering. The Convergence Research Award recognizes the most outstanding research team that created innovative research results over a one-year period.

President Sung-Chul Shin said, “KAIST has selected the ten most outstanding research achievements of 2017 conducted by our faculty and researchers. All of them demonstrated exceptional creativity, which opens new research paths in each field though their novelty, innovation, and impact.”

KAIST hosts Research Day every year to introduce major research performances at KAIST and share knowledge about the research and development.

During Research Day, KAIST also announced the ten most distinguished research achievements contributed by KAIST professors during the previous year. They are listed below.

▲ High-Speed Motion Core Technology for Magnetic Memory by Professor Kab-Jin Kim from the Department of Physics

▲ A Double Well Potential System by Professor Jaeyoung Byeon from the Department of Mathematical Sciences

▲ Cheap and Efficient Dehydrogenation of Alkanes by Professor Mu-Hyun Baik from the Department of Chemistry

▲ A Dynamic LPS Transfer Mechanism for Innate Immune Activation by Professor Ho Min Kim from the Graduate School of Medical Science and Engineering

▲ A Memristive Functional Device and Circuit on Fabric for Fibertronics by Professor Yang-Kyu Choi and Professor Sung-Yool Choi from the School of Electrical Engineering

▲ A Hippocampal Morphology Study Based on a Progressive Template Deformable Model by Professor Jinah Park from the School of Computing

▲ The Development of a 6-DOF Dynamic Response Measurement System for Civil Infrastructure Monitoring by Professor Hoon Sohn from the Department of Civil and Environmental Engineering

▲ Cooperative Tumour Cell Membrane Targeted Phototherapy by Professor Ji-Ho Park from the Department of Bio and Brain Engineering

▲ HUMICOTTA: A 3D-Printed Terracotta Humidifier by Professor Sangmin Bae from the Department of Industrial Design

▲ Ultrathin, Cross-Linked Ionic Polymer Thin Films by Professor Sung Gap Im from the Department of Chemical and Biomolecular Engineering

2018.05.28 View 12771

2018 KAIST Research Day Honors Outstanding Research Achievements

(KAIST President Sung-Chul Shin and Professor Jong-Hwan Kim) Professor Jong-Hwan Kim from the School of Electrical Engineering was recognized at the 2018 KAIST Research Day as the Research Grand Prize Awardee. The ten most distinguished research achievements of the past year were also recognized.

The Research Grand Prize recognizes the professor whose comprehensive research performance evaluation indicator was the highest over the past five years. The indicator combines the number of research contracts, IPR and royalty income.

During the May 25th ceremony, Professor Hyochoong Bang from the Department of Aerospace Engineering and Professor In so Kweon from the School of Electrical Engineering also won the Best Research Award prize.

This year, the Research Innovation Award went to Professor Dong Soo Han from the School of Computing. The Research Innovation Award combines scores in the categories of foreign patent registrations, contracts of technological transfer, and income from technology fees, technology consultations, and startups.

The Convergence Research Award was given to Professor Junmo Kim from the School of Electrical Engineering and Professor Hyun Myung from the Department of Civil & Environmental Engineering. The Convergence Research Award recognizes the most outstanding research team that created innovative research results over a one-year period.

President Sung-Chul Shin said, “KAIST has selected the ten most outstanding research achievements of 2017 conducted by our faculty and researchers. All of them demonstrated exceptional creativity, which opens new research paths in each field though their novelty, innovation, and impact.”

KAIST hosts Research Day every year to introduce major research performances at KAIST and share knowledge about the research and development.

During Research Day, KAIST also announced the ten most distinguished research achievements contributed by KAIST professors during the previous year. They are listed below.

▲ High-Speed Motion Core Technology for Magnetic Memory by Professor Kab-Jin Kim from the Department of Physics

▲ A Double Well Potential System by Professor Jaeyoung Byeon from the Department of Mathematical Sciences

▲ Cheap and Efficient Dehydrogenation of Alkanes by Professor Mu-Hyun Baik from the Department of Chemistry

▲ A Dynamic LPS Transfer Mechanism for Innate Immune Activation by Professor Ho Min Kim from the Graduate School of Medical Science and Engineering

▲ A Memristive Functional Device and Circuit on Fabric for Fibertronics by Professor Yang-Kyu Choi and Professor Sung-Yool Choi from the School of Electrical Engineering

▲ A Hippocampal Morphology Study Based on a Progressive Template Deformable Model by Professor Jinah Park from the School of Computing

▲ The Development of a 6-DOF Dynamic Response Measurement System for Civil Infrastructure Monitoring by Professor Hoon Sohn from the Department of Civil and Environmental Engineering

▲ Cooperative Tumour Cell Membrane Targeted Phototherapy by Professor Ji-Ho Park from the Department of Bio and Brain Engineering

▲ HUMICOTTA: A 3D-Printed Terracotta Humidifier by Professor Sangmin Bae from the Department of Industrial Design

▲ Ultrathin, Cross-Linked Ionic Polymer Thin Films by Professor Sung Gap Im from the Department of Chemical and Biomolecular Engineering

2018.05.28 View 12771 -

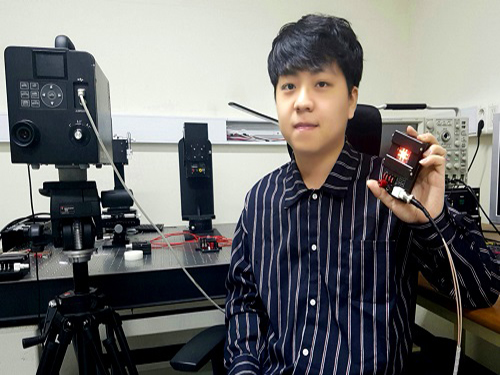

Get Treatment Anywhere and Any Time with Wearable PBM Patch

(PhD Candidate Yongmin Jeon)

There have been many cases in which OLEDs are applied to electronic devices, and now they have even been extended to therapeutic fields. A KAIST research team succeeded in developing a wearable photobiomodulation (PBM) patch to treat wounds. This technology will allow injuries to be treated regardless of location or time.

Professor KyungCheol Choi from the School of Electrical Engineering, in collaboration with Seoul National University Bundang Hospital’s team, conducted research on PBMs which are a clinical method widely used in hospitals. They are considered to be a safe, noninvasive, and nonsurgical method that require relatively low light power.

Conventionally, light-emitting diodes (LEDs) have been used in PBM applications; however, LED devices are usually inflexible and difficult to irradiate light uniformly. They may also produce localized heat. Due to these constraints, it was difficult to enhance the clinical effects of LED devices as they cannot stick to the human body.

Choi’s team developed a wearable patch using flexible OLEDs, allowing people to be treated outside of hospitals. A thin film has been developed for the patch, containing not only flexible OLEDs but also batteries and anti-superheating devices.

Moreover, its thickness is less than 1mm and its weight is less than 1g. This lightweight and ultra-thin patch with a bending radius is 20mm can be used more than 300 hours.

These patches are usable at a temperature below 42℃ to eliminate the risk of low-temperature burns. They also meet the safety regulations of the International Organization for Standardization (ISO) at red wavelengths (600–700 nm).

The wearable PBM patches showed excellent effects with in vitro wounds because they stimulated cell proliferation over 58% of control as well as cell migration over 46% of control under various conditions.

Yongmin Jeon, who led this research, said, “The wearable PBM is effective and convenient, so people can simply purchase it at a pharmacy without having to visit a hospital. If we can adjust the power and wavelength of the OLEDs, its application can be extended to skin care, cancer treatment, Alzheimer’s disease treatment, and mental healthcare.”

Professor Choi added, “We have applied the advantages of flexible OLEDs, which are often used for fabricating displays, to PBMs. This technology will open the way to commercialize portable and highly-efficient wearable photobiomodulation devices.”

This research was published in the front cover of Advanced Materials Technologies on May, 2018.

Figure 1. The patch attached to a human face, a hand and examples of treatment applications

Figure 2. The migration of cells into the scratched area

2018.05.25 View 8026

Get Treatment Anywhere and Any Time with Wearable PBM Patch

(PhD Candidate Yongmin Jeon)

There have been many cases in which OLEDs are applied to electronic devices, and now they have even been extended to therapeutic fields. A KAIST research team succeeded in developing a wearable photobiomodulation (PBM) patch to treat wounds. This technology will allow injuries to be treated regardless of location or time.

Professor KyungCheol Choi from the School of Electrical Engineering, in collaboration with Seoul National University Bundang Hospital’s team, conducted research on PBMs which are a clinical method widely used in hospitals. They are considered to be a safe, noninvasive, and nonsurgical method that require relatively low light power.

Conventionally, light-emitting diodes (LEDs) have been used in PBM applications; however, LED devices are usually inflexible and difficult to irradiate light uniformly. They may also produce localized heat. Due to these constraints, it was difficult to enhance the clinical effects of LED devices as they cannot stick to the human body.

Choi’s team developed a wearable patch using flexible OLEDs, allowing people to be treated outside of hospitals. A thin film has been developed for the patch, containing not only flexible OLEDs but also batteries and anti-superheating devices.

Moreover, its thickness is less than 1mm and its weight is less than 1g. This lightweight and ultra-thin patch with a bending radius is 20mm can be used more than 300 hours.

These patches are usable at a temperature below 42℃ to eliminate the risk of low-temperature burns. They also meet the safety regulations of the International Organization for Standardization (ISO) at red wavelengths (600–700 nm).

The wearable PBM patches showed excellent effects with in vitro wounds because they stimulated cell proliferation over 58% of control as well as cell migration over 46% of control under various conditions.

Yongmin Jeon, who led this research, said, “The wearable PBM is effective and convenient, so people can simply purchase it at a pharmacy without having to visit a hospital. If we can adjust the power and wavelength of the OLEDs, its application can be extended to skin care, cancer treatment, Alzheimer’s disease treatment, and mental healthcare.”

Professor Choi added, “We have applied the advantages of flexible OLEDs, which are often used for fabricating displays, to PBMs. This technology will open the way to commercialize portable and highly-efficient wearable photobiomodulation devices.”

This research was published in the front cover of Advanced Materials Technologies on May, 2018.

Figure 1. The patch attached to a human face, a hand and examples of treatment applications

Figure 2. The migration of cells into the scratched area

2018.05.25 View 8026 -

KAIST Welcomes Global Participants to AI World Cup 2018

KAIST will host the AI (Artificial Intelligence) World Cup 2018 in August, and this time it is open to the international community. AI World Cup 2018 will be a very exciting challenge for extending the limit of academic and industrial applications based on AI technology.

KAIST, after launching its AI World Cup 2017 for domestic participants, is now hosting the AI World Cup 2018 for everyone. The AI World Cup will be comprised of three events: 1) Five on five AI Soccer 2) AI Commentator and 3) AI Reporter. Winner of each category, runner-up of AI Soccer, and 2nd runner-up of AI Soccer will receive awards with cash prizes.

For AI Soccer in which AI controlled robots team up to compete, the preliminary rounds will be held in July in a league format, and the final rounds will be played on August 20-22.

For AI Commentator and AI Reporter, eight finalists will be selected for each category based on scoring criteria, and their performance will be evaluated by the judges to select the winner from each category on August 22.

During the final rounds, a variety of events will also take place at KAIST, including tutorial sessions on AI technology, a poster session where students present their research works on AI, not necessarily limited to the scope of AI Soccer, AI Commentator, and AI Reporter, and panel discussions by prominent experts in the field of AI.

Moreover, renowned experts on AI will deliver their keynote addresses. The Cyberbotics CEO Olivier Michel will address his keynote speech on the topic ‘Simulation benchmarks and competitions: a fundamental tool to foster robotics research.’

The AI World Cup was established by the College of Engineering at KAIST to show that AI technology can be further extended to sports, soccer in particular.

Professor Jong-Hwan Kim, the inventor of AI World Cup and chairman of the organizing committee said, “I hope that this event will offer a great chance to develop AI technology for use in the coming years. I wish many people can enjoy the AI World Cup 2018. I would recommend that prospective teams not worry about the technical barrier when deciding whether to participate in the games. Participants from academia and industry can test whether their code runs well in the competition simulator; this way, they will know their level of play and perhaps they can further develop their algorithms.”

“We will also broadcast the final round of AI Soccer online so that people in remote areas can also enjoy watching the games. I am looking forward to seeing all of you at the AI World Cup. Any participant with a passion to prove excellence in AI technology is welcomed with open arms,” he added.

Anyone interested in the AI World Cup 2018 can register online via aiworldcup.org . Registration starts from April 1. The deadline for registration and final code submission is June 30.

(Cubical players in the figure for domestic AI Soccer competition have been replaced with cylindrical players for more agile movements while playing)

(Opening ceremony of AI World Cup 2017)

(Trophy and prize)

(Interview of participant)

(Casters commentating on game playing)

2018.03.30 View 9199

KAIST Welcomes Global Participants to AI World Cup 2018

KAIST will host the AI (Artificial Intelligence) World Cup 2018 in August, and this time it is open to the international community. AI World Cup 2018 will be a very exciting challenge for extending the limit of academic and industrial applications based on AI technology.

KAIST, after launching its AI World Cup 2017 for domestic participants, is now hosting the AI World Cup 2018 for everyone. The AI World Cup will be comprised of three events: 1) Five on five AI Soccer 2) AI Commentator and 3) AI Reporter. Winner of each category, runner-up of AI Soccer, and 2nd runner-up of AI Soccer will receive awards with cash prizes.

For AI Soccer in which AI controlled robots team up to compete, the preliminary rounds will be held in July in a league format, and the final rounds will be played on August 20-22.

For AI Commentator and AI Reporter, eight finalists will be selected for each category based on scoring criteria, and their performance will be evaluated by the judges to select the winner from each category on August 22.

During the final rounds, a variety of events will also take place at KAIST, including tutorial sessions on AI technology, a poster session where students present their research works on AI, not necessarily limited to the scope of AI Soccer, AI Commentator, and AI Reporter, and panel discussions by prominent experts in the field of AI.

Moreover, renowned experts on AI will deliver their keynote addresses. The Cyberbotics CEO Olivier Michel will address his keynote speech on the topic ‘Simulation benchmarks and competitions: a fundamental tool to foster robotics research.’

The AI World Cup was established by the College of Engineering at KAIST to show that AI technology can be further extended to sports, soccer in particular.

Professor Jong-Hwan Kim, the inventor of AI World Cup and chairman of the organizing committee said, “I hope that this event will offer a great chance to develop AI technology for use in the coming years. I wish many people can enjoy the AI World Cup 2018. I would recommend that prospective teams not worry about the technical barrier when deciding whether to participate in the games. Participants from academia and industry can test whether their code runs well in the competition simulator; this way, they will know their level of play and perhaps they can further develop their algorithms.”

“We will also broadcast the final round of AI Soccer online so that people in remote areas can also enjoy watching the games. I am looking forward to seeing all of you at the AI World Cup. Any participant with a passion to prove excellence in AI technology is welcomed with open arms,” he added.

Anyone interested in the AI World Cup 2018 can register online via aiworldcup.org . Registration starts from April 1. The deadline for registration and final code submission is June 30.

(Cubical players in the figure for domestic AI Soccer competition have been replaced with cylindrical players for more agile movements while playing)

(Opening ceremony of AI World Cup 2017)

(Trophy and prize)

(Interview of participant)

(Casters commentating on game playing)

2018.03.30 View 9199 -

Recognizing Seven Different Face Emotions on a Mobile Platform

(Professor Hoi-Jun Yoo)

A KAIST research team succeeded in achieving face emotion recognition on a mobile platform by developing an AI semiconductor IC that processes two neural networks on a single chip.

Professor Hoi-Jun Yoo and his team (Primary researcher: Jinmook Lee Ph. D. student) from the School of Electrical Engineering developed a unified deep neural network processing unit (UNPU).

Deep learning is a technology for machine learning based on artificial neural networks, which allows a computer to learn by itself, just like a human.

The developed chip adjusts the weight precision (from 1 bit to 16 bit) of a neural network inside of the semiconductor in order to optimize energy efficiency and accuracy. With a single chip, it can process a convolutional neural network (CNN) and recurrent neural network (RNN) simultaneously. CNN is used for categorizing and recognizing images while RNN is for action recognition and speech recognition, such as time-series information.

Moreover, it enables an adjustment in energy efficiency and accuracy dynamically while recognizing objects. To realize mobile AI technology, it needs to process high-speed operations with low energy, otherwise the battery can run out quickly due to processing massive amounts of information at once. According to the team, this chip has better operation performance compared to world-class level mobile AI chips such as Google TPU. The energy efficiency of the new chip is 4 times higher than the TPU.

In order to demonstrate its high performance, the team installed UNPU in a smartphone to facilitate automatic face emotion recognition on the smartphone. This system displays a user’s emotions in real time. The research results for this system were presented at the 2018 International Solid-State Circuits Conference (ISSCC) in San Francisco on February 13.

Professor Yoo said, “We have developed a semiconductor that accelerates with low power requirements in order to realize AI on mobile platforms. We are hoping that this technology will be applied in various areas, such as object recognition, emotion recognition, action recognition, and automatic translation. Within one year, we will commercialize this technology.”

2018.03.09 View 7603

Recognizing Seven Different Face Emotions on a Mobile Platform

(Professor Hoi-Jun Yoo)

A KAIST research team succeeded in achieving face emotion recognition on a mobile platform by developing an AI semiconductor IC that processes two neural networks on a single chip.

Professor Hoi-Jun Yoo and his team (Primary researcher: Jinmook Lee Ph. D. student) from the School of Electrical Engineering developed a unified deep neural network processing unit (UNPU).

Deep learning is a technology for machine learning based on artificial neural networks, which allows a computer to learn by itself, just like a human.

The developed chip adjusts the weight precision (from 1 bit to 16 bit) of a neural network inside of the semiconductor in order to optimize energy efficiency and accuracy. With a single chip, it can process a convolutional neural network (CNN) and recurrent neural network (RNN) simultaneously. CNN is used for categorizing and recognizing images while RNN is for action recognition and speech recognition, such as time-series information.

Moreover, it enables an adjustment in energy efficiency and accuracy dynamically while recognizing objects. To realize mobile AI technology, it needs to process high-speed operations with low energy, otherwise the battery can run out quickly due to processing massive amounts of information at once. According to the team, this chip has better operation performance compared to world-class level mobile AI chips such as Google TPU. The energy efficiency of the new chip is 4 times higher than the TPU.

In order to demonstrate its high performance, the team installed UNPU in a smartphone to facilitate automatic face emotion recognition on the smartphone. This system displays a user’s emotions in real time. The research results for this system were presented at the 2018 International Solid-State Circuits Conference (ISSCC) in San Francisco on February 13.

Professor Yoo said, “We have developed a semiconductor that accelerates with low power requirements in order to realize AI on mobile platforms. We are hoping that this technology will be applied in various areas, such as object recognition, emotion recognition, action recognition, and automatic translation. Within one year, we will commercialize this technology.”

2018.03.09 View 7603 -

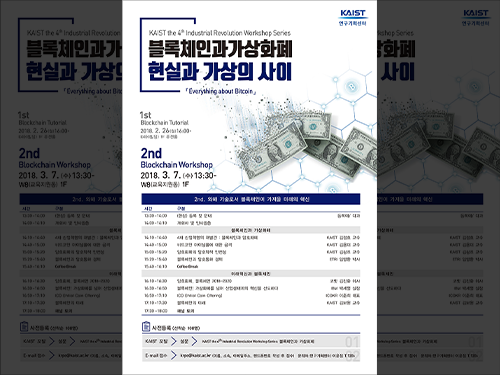

Blockchain and Cryptocurrency: Between Reality and Virtuality

A workshop on blockchain and cryptocurrency, one of the 4th Industrial Revolution Workshop Series, was held at the KAIST main campus on March 7.

Experts from industry, academia, and research gathered and shared their opinions about blockchain technology, which is currently gaining huge attention along with cryptocurrency.

During the workshop, four KAIST professors and four experts from institutes and business examined the scope on the possibility of blockchain, technology for the Fourth Industrial Revolution.

Moreover, they discussed a variety of issues including mining, wallets, cryptocurrency, information security, smart contracts, and ICOs.

In a previous blockchain tutorial, Professor Yongdae Kim from the School of Electrical Engineering at KAIST and Professor Hyoungshick Kim from Sungkyunkwan University opened up a blockchain tutorial which provided a technical understanding of blockchain, such as the birth of cryptocurrency, algorithm design, and exchange methods.

Professor Jungho Kim, who is in charge of this event, said, “This workshop will broaden the understanding of blockchain, which can provide a foundation for a national growth engine.”

2018.03.07 View 8733

Blockchain and Cryptocurrency: Between Reality and Virtuality

A workshop on blockchain and cryptocurrency, one of the 4th Industrial Revolution Workshop Series, was held at the KAIST main campus on March 7.

Experts from industry, academia, and research gathered and shared their opinions about blockchain technology, which is currently gaining huge attention along with cryptocurrency.

During the workshop, four KAIST professors and four experts from institutes and business examined the scope on the possibility of blockchain, technology for the Fourth Industrial Revolution.

Moreover, they discussed a variety of issues including mining, wallets, cryptocurrency, information security, smart contracts, and ICOs.

In a previous blockchain tutorial, Professor Yongdae Kim from the School of Electrical Engineering at KAIST and Professor Hyoungshick Kim from Sungkyunkwan University opened up a blockchain tutorial which provided a technical understanding of blockchain, such as the birth of cryptocurrency, algorithm design, and exchange methods.

Professor Jungho Kim, who is in charge of this event, said, “This workshop will broaden the understanding of blockchain, which can provide a foundation for a national growth engine.”

2018.03.07 View 8733 -

Low-power, Flexible Memristor Circuit for Mobile and Wearable Devices

(from left: Yunyong Nam, Professor Sung-Yool Choi and Byung Chul Jang)

A KAIST research team succeeded in developing an energy efficient, nonvolatile logic-in-memory circuit by using a memristor. This novel technology can be used as an energy efficient computing architecture for battery-powered flexible electronic systems, such as mobile and wearable devices.

Professor Sung-Yool Choi from the School of Electrical Engineering and Professor Sang-Hee Ko Park from the Department of Materials Science and Engineering developed a memristive nonvolatile logic-in-memory circuit.

Transistor-based conventional electronic systems have issues with battery supply and a long standby period due to their volatile computing architecture. The standby power consumption caused by subthreshold leakage current limits their potential applications for mobile electronic devices. Also, their physical separation of memory and processor causes power consumption and time delay during data transfer.

In order to solve this problem, the team developed a logic-in-memory circuit that enables data storage as well as logic operation simultaneously. It can minimize energy consumption and time delay because it does not require data transfer between memory and processor.

The team employed nonvolatile, polymer-based memristors and flexible back-to-back Schottky diode selector devices on plastic substrates. Unlike the conventional architecture, this memristive nonvolatile logic-in-memory is a novel computing architecture that consumes a minimal amount of standby power. This one-selector-one memristor (1S-1M) solved the issue of undesirable leakage currents, known as ‘sneak currents’.

They also implemented single-instruction multiple-data (SIMD) to calculate multiple values at once.

The proposed parallel computing method using a memristive nonvolatile logic-in-memory circuit can provide a low-power circuit platform for battery-powered flexible electronic systems with a variety of potential applications.

Professor Choi said, “Flexible logic-in-memory circuits integrating memristor and selector device can provide flexibility, low power, memory with logic functions. This will be a core technology that will bring innovation to mobile and wearable electronic systems.”

This research, collaborated with Ph.D. candidates Byung Chul Jang and Yunyong Nam, was published and chosen as the cover of Advanced Functional Materials on January 10.

Figure 1. Cover of the Advanced Functional Materials

Figure 2. Schematic illustration and cross-sectional TEM image of flexible memristive nonvolatile logic-in-memory circuit

Figure 3. Test performance

Figure 4. Parallel logic operation within 1S-1M memristor array

2018.02.21 View 7129

Low-power, Flexible Memristor Circuit for Mobile and Wearable Devices

(from left: Yunyong Nam, Professor Sung-Yool Choi and Byung Chul Jang)

A KAIST research team succeeded in developing an energy efficient, nonvolatile logic-in-memory circuit by using a memristor. This novel technology can be used as an energy efficient computing architecture for battery-powered flexible electronic systems, such as mobile and wearable devices.

Professor Sung-Yool Choi from the School of Electrical Engineering and Professor Sang-Hee Ko Park from the Department of Materials Science and Engineering developed a memristive nonvolatile logic-in-memory circuit.

Transistor-based conventional electronic systems have issues with battery supply and a long standby period due to their volatile computing architecture. The standby power consumption caused by subthreshold leakage current limits their potential applications for mobile electronic devices. Also, their physical separation of memory and processor causes power consumption and time delay during data transfer.

In order to solve this problem, the team developed a logic-in-memory circuit that enables data storage as well as logic operation simultaneously. It can minimize energy consumption and time delay because it does not require data transfer between memory and processor.

The team employed nonvolatile, polymer-based memristors and flexible back-to-back Schottky diode selector devices on plastic substrates. Unlike the conventional architecture, this memristive nonvolatile logic-in-memory is a novel computing architecture that consumes a minimal amount of standby power. This one-selector-one memristor (1S-1M) solved the issue of undesirable leakage currents, known as ‘sneak currents’.

They also implemented single-instruction multiple-data (SIMD) to calculate multiple values at once.

The proposed parallel computing method using a memristive nonvolatile logic-in-memory circuit can provide a low-power circuit platform for battery-powered flexible electronic systems with a variety of potential applications.

Professor Choi said, “Flexible logic-in-memory circuits integrating memristor and selector device can provide flexibility, low power, memory with logic functions. This will be a core technology that will bring innovation to mobile and wearable electronic systems.”

This research, collaborated with Ph.D. candidates Byung Chul Jang and Yunyong Nam, was published and chosen as the cover of Advanced Functional Materials on January 10.

Figure 1. Cover of the Advanced Functional Materials

Figure 2. Schematic illustration and cross-sectional TEM image of flexible memristive nonvolatile logic-in-memory circuit

Figure 3. Test performance

Figure 4. Parallel logic operation within 1S-1M memristor array

2018.02.21 View 7129 -

Fiber OLEDs, Thinner Than a Hair

(Seonil Kwon, PhD Candidate)

Professor Kyung Cheol Choi from the School of Electrical Engineering and his team succeeded in fabricating highly efficient Organic Light-Emitting Diodes (OLEDs) on an ultra-thin fiber.

The team expects the technology, which produces high-efficiency, long-lasting OLEDs, can be widely utilized in wearable displays.

Existing fiber-based wearable displays’ OLEDs show much lower performance compared to those fabricated on planar substrates. This low performance caused a limitation for applying it to actual wearable displays.

In order to solve this problem, the team designed a structure of OLEDs compatible to fiber and used a dip-coating method in a three-dimensional structure of fibers. Through this method, the team successfully developed efficient OLEDs that are designed to last a lifetime and are still equivalent to those on planar substrates.

The team identified that solution process planar OLEDs can be applied to fibers without any reduction in performance through the technology. This fiber OLEDs exhibited luminance and current efficiency values of over 10,000 cd/m^2(candela/square meter) and 11 cd/A (candela/ampere).

The team also verified that the fiber OLEDs withstood tensile strains of up to 4.3% while retaining more than 90% of their current efficiency. In addition, they could be woven into textiles and knitted clothes without causing any problems.

Moreover, the technology allows for fabricating OLEDs on fibers with diameters ranging from 300㎛ down to 90㎛, thinner than a human hair, which attests to the scalability of the proposed fabrication scheme.

Noting that every process is carried out at a low temperature (~105℃), fibers vulnerable to high temperatures can also employ this fabrication scheme.

Professor Choi said, “Existing fiber-based wearable displays had limitations for applicability due to their low performance. However, this technology can fabricate OLEDs with high performance on fibers. This simple, low-cost process opens a way to commercialize fiber-based wearable displays.”

This research led by a PhD candidate Seonil Kwon was published online in the international journal for nanoscience, Nano Letters, on December 6.

(Fiber-based OLEDs woven into knitted clothes)

This work was funded by the Engineering Research Center of Excellence Program (Grant No. NRF-2017R1A5A1014708) and Nano-Material Technology Development Program (Grant No. NRF-2016M3A7B4910635) by the National Research Foundation of Korea, the Ministry of Science and ICT of Korea.

2018.01.09 View 14478

Fiber OLEDs, Thinner Than a Hair

(Seonil Kwon, PhD Candidate)

Professor Kyung Cheol Choi from the School of Electrical Engineering and his team succeeded in fabricating highly efficient Organic Light-Emitting Diodes (OLEDs) on an ultra-thin fiber.

The team expects the technology, which produces high-efficiency, long-lasting OLEDs, can be widely utilized in wearable displays.

Existing fiber-based wearable displays’ OLEDs show much lower performance compared to those fabricated on planar substrates. This low performance caused a limitation for applying it to actual wearable displays.

In order to solve this problem, the team designed a structure of OLEDs compatible to fiber and used a dip-coating method in a three-dimensional structure of fibers. Through this method, the team successfully developed efficient OLEDs that are designed to last a lifetime and are still equivalent to those on planar substrates.

The team identified that solution process planar OLEDs can be applied to fibers without any reduction in performance through the technology. This fiber OLEDs exhibited luminance and current efficiency values of over 10,000 cd/m^2(candela/square meter) and 11 cd/A (candela/ampere).

The team also verified that the fiber OLEDs withstood tensile strains of up to 4.3% while retaining more than 90% of their current efficiency. In addition, they could be woven into textiles and knitted clothes without causing any problems.

Moreover, the technology allows for fabricating OLEDs on fibers with diameters ranging from 300㎛ down to 90㎛, thinner than a human hair, which attests to the scalability of the proposed fabrication scheme.

Noting that every process is carried out at a low temperature (~105℃), fibers vulnerable to high temperatures can also employ this fabrication scheme.

Professor Choi said, “Existing fiber-based wearable displays had limitations for applicability due to their low performance. However, this technology can fabricate OLEDs with high performance on fibers. This simple, low-cost process opens a way to commercialize fiber-based wearable displays.”

This research led by a PhD candidate Seonil Kwon was published online in the international journal for nanoscience, Nano Letters, on December 6.

(Fiber-based OLEDs woven into knitted clothes)

This work was funded by the Engineering Research Center of Excellence Program (Grant No. NRF-2017R1A5A1014708) and Nano-Material Technology Development Program (Grant No. NRF-2016M3A7B4910635) by the National Research Foundation of Korea, the Ministry of Science and ICT of Korea.

2018.01.09 View 14478 -

Ultra-Low Power Flexible Memory Using 2D Materials

(Professor Choi and Ph.D. candidate Jang)

KAIST research team led by Professor Sung-Yool Choi at School of Electrical Engineering and Professor Sung Gap Im at the Department of Chemical and Biomolecular Engineering developed high-density, ultra-low power, non-volatile, flexible memory technology using 2D materials. The team used ultrathin molybdenum disulfide (MoS2) with atomic-scale thickness as the channel material and high-performance polymeric insulator film as the tunneling dielectric material. This research was published on the cover of Advanced Functional Materials on November 17. KAIST graduate Myung Hun Woo, a researcher at Samsung Electronics and Ph.D. candidate Byung Chul Jang are first authors.

The surge of new technologies such as Internet of Things (IoT), Artificial Intelligence (AI), and cloud server led to the paradigm shift from processor-centric computing to memory-centric computing in the industry, as well as the increase in demand of wearable devices. This led to an increased need for high-density, ultra-low power, non-volatile flexible memory. In particular, ultrathin MoS2 as semiconductor material has been recently regarded as post-silicon material. This is due to its ultrathin thickness of atomic-scale which suppresses short channel effect observed in conventional silicon material, leading to advantages in high- density and low-power consumption. Further, this thickness allows the material to be flexible, and thus the material is applicable to wearable devices.

However, due to the dangling-bond free surface of MoS2 semiconductor material, it is difficult to deposit the thin insulator film to be uniform and stable over a large area via the conventional atomic layer deposition process. Further, the currently used solution process makes it difficult to deposit uniformly low dielectric constant (k) polymeric insulator film with sub-10 nm thickness on a large area, thus indicating that the memory device utilizing the conventional solution-processed polymer insulator film cannot be operated at low-operating voltage and is not compatible with photolithography.

The research team tried to overcome the hurdles and develop high-density, ultra-low power, non-volatile flexible memory by employing a low-temperature, solvent-free, and all-dry vapor phase technique named initiated chemical vapor deposition (iCVD) process. Using iCVD process, tunneling polymeric insulator film with 10 nm thickness was deposited uniformly on MoS2 semiconductor material without being restricted by the dangling bond-free surface of MoS2. The team observed that the newly developed MoS2-based non-volatile memory can be operated at low-voltage (around 10V), in contrast to the conventional MoS2-based non-volatile memory that requires over 20V.

Professor Choi said, “As the basis for the Fourth Industrial revolution technologies including AI and IoT, semiconductor device technology needs to have characteristics of low-power and flexibility, in clear contrast to conventional memory devices.” He continued, “This new technology is significant in developing source technology in terms of materials, processes, and devices to contribute to achieve these characteristics.”

This research was supported by the Global Frontier Center for Advanced Soft Electronics and the Creative Materials Discovery Program by funded the National Research Foundation of Korea of Ministry of Science and ICT.

( Figure 1. Cover of Advanced Functional Materials)

(Figure 2. Concept map for the developed non-volatile memory material and high-resolution transmission electron microscopy image for material cross-section )

2018.01.02 View 10232

Ultra-Low Power Flexible Memory Using 2D Materials

(Professor Choi and Ph.D. candidate Jang)

KAIST research team led by Professor Sung-Yool Choi at School of Electrical Engineering and Professor Sung Gap Im at the Department of Chemical and Biomolecular Engineering developed high-density, ultra-low power, non-volatile, flexible memory technology using 2D materials. The team used ultrathin molybdenum disulfide (MoS2) with atomic-scale thickness as the channel material and high-performance polymeric insulator film as the tunneling dielectric material. This research was published on the cover of Advanced Functional Materials on November 17. KAIST graduate Myung Hun Woo, a researcher at Samsung Electronics and Ph.D. candidate Byung Chul Jang are first authors.

The surge of new technologies such as Internet of Things (IoT), Artificial Intelligence (AI), and cloud server led to the paradigm shift from processor-centric computing to memory-centric computing in the industry, as well as the increase in demand of wearable devices. This led to an increased need for high-density, ultra-low power, non-volatile flexible memory. In particular, ultrathin MoS2 as semiconductor material has been recently regarded as post-silicon material. This is due to its ultrathin thickness of atomic-scale which suppresses short channel effect observed in conventional silicon material, leading to advantages in high- density and low-power consumption. Further, this thickness allows the material to be flexible, and thus the material is applicable to wearable devices.

However, due to the dangling-bond free surface of MoS2 semiconductor material, it is difficult to deposit the thin insulator film to be uniform and stable over a large area via the conventional atomic layer deposition process. Further, the currently used solution process makes it difficult to deposit uniformly low dielectric constant (k) polymeric insulator film with sub-10 nm thickness on a large area, thus indicating that the memory device utilizing the conventional solution-processed polymer insulator film cannot be operated at low-operating voltage and is not compatible with photolithography.

The research team tried to overcome the hurdles and develop high-density, ultra-low power, non-volatile flexible memory by employing a low-temperature, solvent-free, and all-dry vapor phase technique named initiated chemical vapor deposition (iCVD) process. Using iCVD process, tunneling polymeric insulator film with 10 nm thickness was deposited uniformly on MoS2 semiconductor material without being restricted by the dangling bond-free surface of MoS2. The team observed that the newly developed MoS2-based non-volatile memory can be operated at low-voltage (around 10V), in contrast to the conventional MoS2-based non-volatile memory that requires over 20V.

Professor Choi said, “As the basis for the Fourth Industrial revolution technologies including AI and IoT, semiconductor device technology needs to have characteristics of low-power and flexibility, in clear contrast to conventional memory devices.” He continued, “This new technology is significant in developing source technology in terms of materials, processes, and devices to contribute to achieve these characteristics.”

This research was supported by the Global Frontier Center for Advanced Soft Electronics and the Creative Materials Discovery Program by funded the National Research Foundation of Korea of Ministry of Science and ICT.

( Figure 1. Cover of Advanced Functional Materials)

(Figure 2. Concept map for the developed non-volatile memory material and high-resolution transmission electron microscopy image for material cross-section )

2018.01.02 View 10232 -

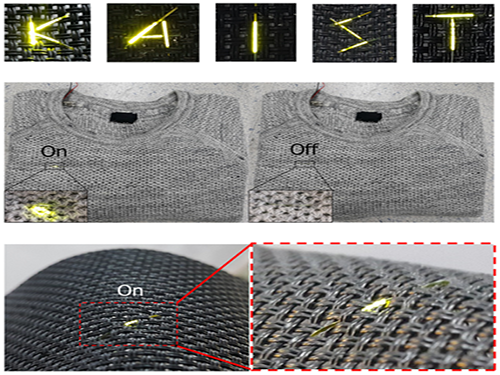

The Medici Effect: Highly Flexible, Wearable Displays Born in KAIST

(Ph.D. candidate Seungyeop Choi)

How do you feel when technology you saw in a movie is made into reality? Collaboration between the electrical engineering and textile industries has made TVs or smartphone screens displaying on clothing a reality.

A research team led by Professor Kyung Cheol Choi at the School of Electrical Engineering presented wearable displays for various applications including fashion, IT, and healthcare. Integrating OLED (organic light-emitting diode) into fabrics, the team developed the most highly flexible and reliable technology for wearable displays in the world.

Recently, information displays have become increasingly important as they construct the external part of smart devices for the next generation. As world trends are focusing on the Internet of Things (IoTs) and wearable technology, the team drew a lot of attention by making great progress towards commercializing clothing-shaped ‘wearable displays’.

The research for realizing displays on clothing gained considerable attention from academia as well as industry when research on luminescence formed in fabrics was introduced in 2011; however, there was no technology for commercializing it due to its surface roughness and flexibility.

Because of this technical limitation, clothing-shaped wearable displays were thought to be unreachable technology. However, the KAIST team recently succeeded in developing the world’s most highly efficient, light-emitting clothes that can be commercialized.

The research team used two different approaches, fabric-type and fiber-type, in order to realize clothing-shaped wearable displays. In 2015, the team successfully laminated a thin planarization sheet thermally onto fabric to form a surface that is compatible with the OLEDs approximately 200 hundred nanometers thick. Also, the team reported their research outcomes on enhancing the reliability of operating fiber-based OLEDs. In 2016, the team introduced a dip-coating method, capable of uniformly depositing layers, to develop polymer light-emitting diodes, which show high luminance even on thin fabric.

Based on the research performance in 2015 and 2016, Ph.D. candidate Seungyeop Choi took the lead in the research team and succeeded in realizing fabric-based OLEDs, showing high luminance and efficiency while maintaining the flexibility of the fabric.

The long-term reliability of this wearable device that has the world’s best electrical and optical characteristics was verified through their self-developed, organic and inorganic encapsulation technology. According to the team, their wearable device facilitates the operation of OLEDs even at a bending radius of 2mm.

According to Choi, “Having wavy structures and empty spaces, fiber plays a significant role in lowering the mechanical stress on the OLEDs.”

“Screen displayed on our daily clothing is no longer a future technology,” said Professor Choi. “Light-emitting clothes will have considerable influence on not only the e-textile industry but also the automobile and healthcare industries.”

Moreover, the research team remarked, “It means a lot to realize clothing-shaped OLEDs that have the world’s best luminance and efficiency. It is the most flexible fabric-based light-emitting device among those reported. Moreover, noting that this research carried out an in-depth analysis of the mechanical characteristics of the clothing-spared, light-emitting device, the research performance will become a guideline for developing the fabric-based electronics industry.”

This research was funded by the Ministry of Trade, Industry and Energy and collaborated with KOLON Glotech, INC. The research performance was published in Scientific Reports in July.

(OLEDs operating in fabrics)

(Current-voltage-luminance and efficiency of the highly flexible, fabric-based OLEDs;Image of OLEDs after repetitive bending tests;Verification of flexibility through mechanical simulation)

2017.08.24 View 16485

The Medici Effect: Highly Flexible, Wearable Displays Born in KAIST

(Ph.D. candidate Seungyeop Choi)

How do you feel when technology you saw in a movie is made into reality? Collaboration between the electrical engineering and textile industries has made TVs or smartphone screens displaying on clothing a reality.

A research team led by Professor Kyung Cheol Choi at the School of Electrical Engineering presented wearable displays for various applications including fashion, IT, and healthcare. Integrating OLED (organic light-emitting diode) into fabrics, the team developed the most highly flexible and reliable technology for wearable displays in the world.

Recently, information displays have become increasingly important as they construct the external part of smart devices for the next generation. As world trends are focusing on the Internet of Things (IoTs) and wearable technology, the team drew a lot of attention by making great progress towards commercializing clothing-shaped ‘wearable displays’.

The research for realizing displays on clothing gained considerable attention from academia as well as industry when research on luminescence formed in fabrics was introduced in 2011; however, there was no technology for commercializing it due to its surface roughness and flexibility.

Because of this technical limitation, clothing-shaped wearable displays were thought to be unreachable technology. However, the KAIST team recently succeeded in developing the world’s most highly efficient, light-emitting clothes that can be commercialized.

The research team used two different approaches, fabric-type and fiber-type, in order to realize clothing-shaped wearable displays. In 2015, the team successfully laminated a thin planarization sheet thermally onto fabric to form a surface that is compatible with the OLEDs approximately 200 hundred nanometers thick. Also, the team reported their research outcomes on enhancing the reliability of operating fiber-based OLEDs. In 2016, the team introduced a dip-coating method, capable of uniformly depositing layers, to develop polymer light-emitting diodes, which show high luminance even on thin fabric.

Based on the research performance in 2015 and 2016, Ph.D. candidate Seungyeop Choi took the lead in the research team and succeeded in realizing fabric-based OLEDs, showing high luminance and efficiency while maintaining the flexibility of the fabric.

The long-term reliability of this wearable device that has the world’s best electrical and optical characteristics was verified through their self-developed, organic and inorganic encapsulation technology. According to the team, their wearable device facilitates the operation of OLEDs even at a bending radius of 2mm.

According to Choi, “Having wavy structures and empty spaces, fiber plays a significant role in lowering the mechanical stress on the OLEDs.”

“Screen displayed on our daily clothing is no longer a future technology,” said Professor Choi. “Light-emitting clothes will have considerable influence on not only the e-textile industry but also the automobile and healthcare industries.”

Moreover, the research team remarked, “It means a lot to realize clothing-shaped OLEDs that have the world’s best luminance and efficiency. It is the most flexible fabric-based light-emitting device among those reported. Moreover, noting that this research carried out an in-depth analysis of the mechanical characteristics of the clothing-spared, light-emitting device, the research performance will become a guideline for developing the fabric-based electronics industry.”

This research was funded by the Ministry of Trade, Industry and Energy and collaborated with KOLON Glotech, INC. The research performance was published in Scientific Reports in July.

(OLEDs operating in fabrics)

(Current-voltage-luminance and efficiency of the highly flexible, fabric-based OLEDs;Image of OLEDs after repetitive bending tests;Verification of flexibility through mechanical simulation)

2017.08.24 View 16485 -

Professor Dan Keun Sung Endows Scholarship in Honor of His Retirement

Professor Dan Keun Sung in the School of Electrical Engineering contributed a 100 million KRW scholarship fund this month to KAIST to mark his retirement after more than three decades of work.

“As my retirement date comes closer, I have been thinking about what I could do for the school. I wanted to leave something behind, even though it’s small, for my lifelong school and students. I am hoping that this scholarship fund will benefit the members of KAIST.”

This isn’t his first time making a donation to KAIST. In 2013, Professor Sung donated ten million KRW, which was his cash prize from the 9th Haedong Academic Award of The Korean Institute of Communications and Information Sciences (KICS). At that time, Professor Sung had the chance to create a scholarship fund in his name; however, he wanted to highlight that the scholarship fund was for ‘someone,’ not created by ‘someone.’ In that sense, his scholarship fund was created with no name to benefit students in the School of Electrical Engineering. His colleagues and students supported his idea. Professor Seonghwan Cho, students, and alumni also participated in fund raising efforts, which reached 55 million KRW in total.

Professor Sung emphasized, “Donations should always be remembered, no matter how small they are.” He then explained his purpose for creating the scholarship fund by saying, “Fundraising can be truly meaningful to contributors, knowing that their money is going to supporting the school and students.”

Professor Sung, a fellow of the Institute of Electrical and Electronics Engineers (IEEE) Communication Society, started his post at KAIST in 1986. For the past 30 years, he has devoted himself to fostering young scholars and studying in the area of information and communication. He also participated in developing technologies for the resource management of various future cellular components, such as satellites, switchboards, and signaling networks.

2017.08.11 View 10509

Professor Dan Keun Sung Endows Scholarship in Honor of His Retirement

Professor Dan Keun Sung in the School of Electrical Engineering contributed a 100 million KRW scholarship fund this month to KAIST to mark his retirement after more than three decades of work.

“As my retirement date comes closer, I have been thinking about what I could do for the school. I wanted to leave something behind, even though it’s small, for my lifelong school and students. I am hoping that this scholarship fund will benefit the members of KAIST.”

This isn’t his first time making a donation to KAIST. In 2013, Professor Sung donated ten million KRW, which was his cash prize from the 9th Haedong Academic Award of The Korean Institute of Communications and Information Sciences (KICS). At that time, Professor Sung had the chance to create a scholarship fund in his name; however, he wanted to highlight that the scholarship fund was for ‘someone,’ not created by ‘someone.’ In that sense, his scholarship fund was created with no name to benefit students in the School of Electrical Engineering. His colleagues and students supported his idea. Professor Seonghwan Cho, students, and alumni also participated in fund raising efforts, which reached 55 million KRW in total.

Professor Sung emphasized, “Donations should always be remembered, no matter how small they are.” He then explained his purpose for creating the scholarship fund by saying, “Fundraising can be truly meaningful to contributors, knowing that their money is going to supporting the school and students.”

Professor Sung, a fellow of the Institute of Electrical and Electronics Engineers (IEEE) Communication Society, started his post at KAIST in 1986. For the past 30 years, he has devoted himself to fostering young scholars and studying in the area of information and communication. He also participated in developing technologies for the resource management of various future cellular components, such as satellites, switchboards, and signaling networks.

2017.08.11 View 10509 -

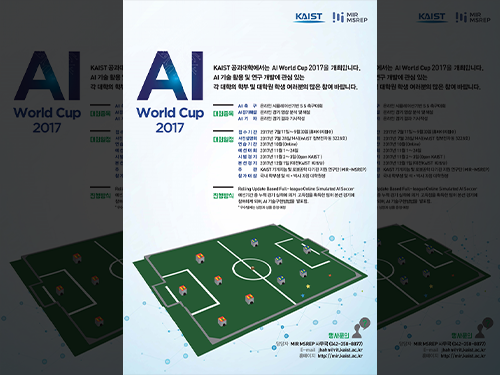

KAIST to Host the 2017 AI World Cup in November

KAIST, the birthplace of the Robot World Cup in 1996, now presents a new technology matchup, the AI World Cup this November, which will be held at KAIST. The event is being organized by the Machine Intelligence and Robotics Multi-Sponsored Research and Education Platform (MIR-MSREP) of KAIST. The online, simulated AI soccer game, based on rolling updates, will be a draw for avid online gamers and tech-savvy university students from around the nation.

The tournament is comprised of three events: ▲A 5 on 5 AI soccer match to be played after self-learning using AI technology in an online simulation environment ▲Commentary in which online soccer videos are analyzed and commented on, and ▲Game reporters who will write articles on online soccer event results.

The participants will undergo a month-long online practice period in October and compete in preliminary matches from November 1 through 24. The top teams that scored the highest accumulated points will compete in the finals on December 1. In the finals, each team’s AI technology implementation method will be evaluated to select the final winning team. To ensure a successful event, KAIST will host a briefing session for participants on July 28.

Technological prowess and early exposure to AI accumulated at KAIST led to the launching of this tournament. Professor Jong-Hwan Kim, the chair of the Organizing Committee of the AI World Cup, hosted the first ever Robot World Cup back in 1996. His concept has now evolved into the emerging technology of AI and the members of the Organizing Committee encompass the professors from the various departments of electrical engineering, computing, industrial and systems engineering, aerospace engineering, civil and environmental engineering, and the graduate schools of Green Transportation, Cultural Technology, and Science and Technology Policy.

In particular, ongoing convergence research initiatives incorporating AI into a wide arrays of disciplines such as bio, nano, and IT, played a crucial role for making this AI World Cup happen. Professor Kim said, “The winner of this year’s competition will be awarded a certificate and a small gift. In 2018, we aim to expand the event to an international scale by allowing international teams.”

Any undergraduate or graduate student in Korea can apply to participate in the ‘AI World Cup 2017’. KAIST will host a public trial event during the ‘Open KAIST’ event period to be held November 2-3 to help participating students understand the event better. ‘Open KAIST’ allows the general public to personally visit and experience what goes on in engineering departments and laboratories on the KAIST main campus. It is hosted by the College of Engineering every two years and is the largest event hosted by KAIST.

To participate in the ‘AI World Cup 2017,’ teams consisting of Korean undergraduates or graduate students can fill out application forms and submit them by September 30 on http://mir.kaist.ac.kr .

2017.07.14 View 13083

KAIST to Host the 2017 AI World Cup in November

KAIST, the birthplace of the Robot World Cup in 1996, now presents a new technology matchup, the AI World Cup this November, which will be held at KAIST. The event is being organized by the Machine Intelligence and Robotics Multi-Sponsored Research and Education Platform (MIR-MSREP) of KAIST. The online, simulated AI soccer game, based on rolling updates, will be a draw for avid online gamers and tech-savvy university students from around the nation.

The tournament is comprised of three events: ▲A 5 on 5 AI soccer match to be played after self-learning using AI technology in an online simulation environment ▲Commentary in which online soccer videos are analyzed and commented on, and ▲Game reporters who will write articles on online soccer event results.

The participants will undergo a month-long online practice period in October and compete in preliminary matches from November 1 through 24. The top teams that scored the highest accumulated points will compete in the finals on December 1. In the finals, each team’s AI technology implementation method will be evaluated to select the final winning team. To ensure a successful event, KAIST will host a briefing session for participants on July 28.

Technological prowess and early exposure to AI accumulated at KAIST led to the launching of this tournament. Professor Jong-Hwan Kim, the chair of the Organizing Committee of the AI World Cup, hosted the first ever Robot World Cup back in 1996. His concept has now evolved into the emerging technology of AI and the members of the Organizing Committee encompass the professors from the various departments of electrical engineering, computing, industrial and systems engineering, aerospace engineering, civil and environmental engineering, and the graduate schools of Green Transportation, Cultural Technology, and Science and Technology Policy.

In particular, ongoing convergence research initiatives incorporating AI into a wide arrays of disciplines such as bio, nano, and IT, played a crucial role for making this AI World Cup happen. Professor Kim said, “The winner of this year’s competition will be awarded a certificate and a small gift. In 2018, we aim to expand the event to an international scale by allowing international teams.”

Any undergraduate or graduate student in Korea can apply to participate in the ‘AI World Cup 2017’. KAIST will host a public trial event during the ‘Open KAIST’ event period to be held November 2-3 to help participating students understand the event better. ‘Open KAIST’ allows the general public to personally visit and experience what goes on in engineering departments and laboratories on the KAIST main campus. It is hosted by the College of Engineering every two years and is the largest event hosted by KAIST.

To participate in the ‘AI World Cup 2017,’ teams consisting of Korean undergraduates or graduate students can fill out application forms and submit them by September 30 on http://mir.kaist.ac.kr .

2017.07.14 View 13083