Engineering

-

Inexpensive Separation Method of Graphene Developed

The problem with commercializing graphene that is synthesized onto metals over a wide area is that it can not be separated from the metal. However, a groundbreaking separation technology which is both cheap and environment friendly has been developed.

Prof. Taek soo Kim and Prof. Byung Jin Cho"s research teams have conducted this research under the support of the Global Frontier program and Researcher Support Program initiated by The Ministry of Education and Science and Korea Research Foundation. The research results have been posted on the online news flash of Nano Letters on februrary 29th. (Thesis title: Direct Measurement of Adhesion Energy of Monolayer Graphene As-Grown on Copper and Its Application to Renewable Transfer Process)

The research has generated exact results on the interfacial adhesive energy of graphene and its surface material for the first time. Through this, the catalyst metal are no longer to be used just once, but will be used for an infinite number of times, thereby being ecofriendly and efficient.

Wide area graphine synthesized onto the catalyst meatal are used in various ways such as for display and for solar cells. There has been much research going on in this field. However, in order to use this wide area graphene, the graphene must be removed from the catalyst metal without damage.

Until now, the metal had been melted away through the use of chemical substances in order to separate the graphene. However, this method has been very problematic. The metal can not be reused, the costs are very high, much harmful wastes were created in the process of melting the metals, and the process was very complicated.

The research teams of Professors Taek Su Kim and Byung Jin Cho measured the interfacial adhesive energy of the synthesized graphene and learned that it could be easily removed.

Also, the mechanically removed graphene was successfully used in creating molecular electronic devices directly. This has thus innovatively shortened the graphene manufacturing process. Also, it has been confirmed that the metalic board can be reused multiple times after the graphene is removed. A new, ecofriendly and cost friendly method of graphene manufacturing has been paved.

Through this discovery, it is expected that graphene will become easier to manufacture and that the period til the commercialization date of graphene will therefore be greatly reduced

Prof. Cho stated " This reserach has much academical meaning significance in that it has successfully defined the surfacial adhesive energy between the graphene and its catalyst material and it should receive much attention in that it solved the largest technical problem involved in the production of graphene.

2012.04.04 View 14164

Inexpensive Separation Method of Graphene Developed

The problem with commercializing graphene that is synthesized onto metals over a wide area is that it can not be separated from the metal. However, a groundbreaking separation technology which is both cheap and environment friendly has been developed.

Prof. Taek soo Kim and Prof. Byung Jin Cho"s research teams have conducted this research under the support of the Global Frontier program and Researcher Support Program initiated by The Ministry of Education and Science and Korea Research Foundation. The research results have been posted on the online news flash of Nano Letters on februrary 29th. (Thesis title: Direct Measurement of Adhesion Energy of Monolayer Graphene As-Grown on Copper and Its Application to Renewable Transfer Process)

The research has generated exact results on the interfacial adhesive energy of graphene and its surface material for the first time. Through this, the catalyst metal are no longer to be used just once, but will be used for an infinite number of times, thereby being ecofriendly and efficient.

Wide area graphine synthesized onto the catalyst meatal are used in various ways such as for display and for solar cells. There has been much research going on in this field. However, in order to use this wide area graphene, the graphene must be removed from the catalyst metal without damage.

Until now, the metal had been melted away through the use of chemical substances in order to separate the graphene. However, this method has been very problematic. The metal can not be reused, the costs are very high, much harmful wastes were created in the process of melting the metals, and the process was very complicated.

The research teams of Professors Taek Su Kim and Byung Jin Cho measured the interfacial adhesive energy of the synthesized graphene and learned that it could be easily removed.

Also, the mechanically removed graphene was successfully used in creating molecular electronic devices directly. This has thus innovatively shortened the graphene manufacturing process. Also, it has been confirmed that the metalic board can be reused multiple times after the graphene is removed. A new, ecofriendly and cost friendly method of graphene manufacturing has been paved.

Through this discovery, it is expected that graphene will become easier to manufacture and that the period til the commercialization date of graphene will therefore be greatly reduced

Prof. Cho stated " This reserach has much academical meaning significance in that it has successfully defined the surfacial adhesive energy between the graphene and its catalyst material and it should receive much attention in that it solved the largest technical problem involved in the production of graphene.

2012.04.04 View 14164 -

Future of Petrochemical Industry: The Age of Bio-Refineries

The concept of bio-refinery is based on using biomass from seaweeds and non-edible plant sources to produce various materials.

Bio-refineries has been looked into with increasing interest in modern times due to the advent of global warming (and the subsequent changes in the atmosphere) and the exhaustion of natural resources.

However past 20 years of research in metabolic engineering had a crucial limitation; the need to improve the efficiency of the microorganisms that actually go about converting biomass into biochemical materials.

In order to compensate for the inefficiency, Professor Lee Sang Yeop combined systems biology, composite biology, evolutionary engineering to form ‘systems metabolic engineering’.

This allows combining various data to explain the organism’s state in a multi-dimensional scope and respond accordingly by controlling the metabolism.

The result of the experiment is set as the cover dissertation of ‘Trends in Biotechnology’ magazine’s August edition.

2011.07.28 View 11820

Future of Petrochemical Industry: The Age of Bio-Refineries

The concept of bio-refinery is based on using biomass from seaweeds and non-edible plant sources to produce various materials.

Bio-refineries has been looked into with increasing interest in modern times due to the advent of global warming (and the subsequent changes in the atmosphere) and the exhaustion of natural resources.

However past 20 years of research in metabolic engineering had a crucial limitation; the need to improve the efficiency of the microorganisms that actually go about converting biomass into biochemical materials.

In order to compensate for the inefficiency, Professor Lee Sang Yeop combined systems biology, composite biology, evolutionary engineering to form ‘systems metabolic engineering’.

This allows combining various data to explain the organism’s state in a multi-dimensional scope and respond accordingly by controlling the metabolism.

The result of the experiment is set as the cover dissertation of ‘Trends in Biotechnology’ magazine’s August edition.

2011.07.28 View 11820 -

New Scientist: Wind power harnesses the energy of galloping, June 2, 2011

Researchers from the Civil and Environmental Engineering Department, KAIST, released their research results in Smart Materials and Structures on ways to “harness strange properties of turbulent airs.” They built a prototype that produces energy using a specific type of unstable airflow called “wake galloping.” New Scientist wrote an article about the paper, which appeared on June 2, 2011. For the article, please follow the link below.

http://www.newscientist.com/article/mg21028145.700-wind-power-harnesses-the-energy-of-galloping.html?full=true&print=true

2011.06.04 View 9076

New Scientist: Wind power harnesses the energy of galloping, June 2, 2011

Researchers from the Civil and Environmental Engineering Department, KAIST, released their research results in Smart Materials and Structures on ways to “harness strange properties of turbulent airs.” They built a prototype that produces energy using a specific type of unstable airflow called “wake galloping.” New Scientist wrote an article about the paper, which appeared on June 2, 2011. For the article, please follow the link below.

http://www.newscientist.com/article/mg21028145.700-wind-power-harnesses-the-energy-of-galloping.html?full=true&print=true

2011.06.04 View 9076 -

2011 International Web Science Symposium Held

The 2011 International Web Science Symposium was held in Seoul on the 24th of March hosted by Web Science Engineering College.

The symposium dealt with the technological development and the social impact of web science and the future of the Web.

A special guest was invited to the symposium this year; the founder of web science, Wendy Hall’s lecture on ‘Web Science: New Frontier’. The numerous experts from abroad was unanimous in stating their outlook of web science affecting the competitiveness of IT companies and ultimately become the driving force in new businesses.

The main research in web science are web platforms and contents production, human based web research, and web SW engineering and web science has to do with pulling together various webs all around the world to create new industries.

2011.04.01 View 7509

2011 International Web Science Symposium Held

The 2011 International Web Science Symposium was held in Seoul on the 24th of March hosted by Web Science Engineering College.

The symposium dealt with the technological development and the social impact of web science and the future of the Web.

A special guest was invited to the symposium this year; the founder of web science, Wendy Hall’s lecture on ‘Web Science: New Frontier’. The numerous experts from abroad was unanimous in stating their outlook of web science affecting the competitiveness of IT companies and ultimately become the driving force in new businesses.

The main research in web science are web platforms and contents production, human based web research, and web SW engineering and web science has to do with pulling together various webs all around the world to create new industries.

2011.04.01 View 7509 -

KAIST Design Week 2011 Held

KAIST designated a week (from March 27th to April 2nd) as KAIST Design Week 2011 and will be hosting a series of international conferences on engineering designs.

The 21st CIRP Design Conference, the 6th International Conference on Axiomatic Design, and the 1st Design in Civil and Environmental Engineering Workshop will be held in Fusion hall in the KI Building from the 27th of March.

The CIRP Design Conference was held on the 27th and the 28th and annually provides an opportunity for researchers and industry developers to exchange information and knowledge.

The International Conference on Axiomatic Design was held on the 30th to the 31st and dealt with various presentations and discussions on the axiomatic design theory. The Axiomatic Design Theory was thought up by KAIST President Seo Nam Pyo and deals with analyzing the wants of the consumers and solves the problems associated with the product through making altercations on the product design.

Last The Design in Civil and environmental Engineering Workshop will be held on the 1st and 2nd of April and will deal with sustainable city design and development.

The Design Week will also be featuring humanoid robot HUBO, the Online Electric Vehicle that can charge its battery wirelessly, and the Mobile Harbor, and therefore show off KAIST’s achievements.

2011.04.01 View 10292

KAIST Design Week 2011 Held

KAIST designated a week (from March 27th to April 2nd) as KAIST Design Week 2011 and will be hosting a series of international conferences on engineering designs.

The 21st CIRP Design Conference, the 6th International Conference on Axiomatic Design, and the 1st Design in Civil and Environmental Engineering Workshop will be held in Fusion hall in the KI Building from the 27th of March.

The CIRP Design Conference was held on the 27th and the 28th and annually provides an opportunity for researchers and industry developers to exchange information and knowledge.

The International Conference on Axiomatic Design was held on the 30th to the 31st and dealt with various presentations and discussions on the axiomatic design theory. The Axiomatic Design Theory was thought up by KAIST President Seo Nam Pyo and deals with analyzing the wants of the consumers and solves the problems associated with the product through making altercations on the product design.

Last The Design in Civil and environmental Engineering Workshop will be held on the 1st and 2nd of April and will deal with sustainable city design and development.

The Design Week will also be featuring humanoid robot HUBO, the Online Electric Vehicle that can charge its battery wirelessly, and the Mobile Harbor, and therefore show off KAIST’s achievements.

2011.04.01 View 10292 -

Late Dr. Ryu Geun Chul's Achievements and Generous Contributions

First Doctor in the field of Korean Traditional Medicine

The late Dr. Ryu was born in 1926 and is the father figure of Korea’s Traditional Medicine and is its First Doctor (1976 Kyung Hee University), and was the vice-professor of Kyung Hee University of Medicine, Vice-Director of Kyung Hee Institute of Korean Traditional Medicine, and was the first chairman of the Association of Korea Oriental Medicine. He developed the painless acupuncture administering device for the first time in Korea in 1962, and succeeded in anesthetizing a patient for cesarean procedure using acupuncture in 1972.

He even was the first to receive a medical engineering doctorate degree from the Moscow National Engineering School in April of 1996 and developed a stroke rehabilitation machine.

Korea’s Most Generous Donor

Dr. Ryu surprised the world by donating 57.8billion Won worth of real estate to KAIST in August of 2008. Dr. Ryu revealed that his reason for donating such a huge sum to KAIST was due to its focused students giving him the belief that the future of Korea is at KAIST and that the development of science and technology is necessary for Korea to develop into a world class nation and KAIST is the institute most suitable to lead Korea in the field.

Dr. Ryu lived on KAIST campus after donating his entire fortune and even established ‘KAIST scholars and spacemen health research center’ and ‘Dr. Ryu Health Clinic’ as he also wanted to donate his knowledge.

Even when he was a professor at Moscow National Engineering University in the late 1990s he carried out free medical work throughout Korea and in recognition of his devoted work, he was named honorary citizen from Chun Ahn city, San Chung city, and DaeJeon city. In 2007 he donated 450million Won to Cheon Dong Elementary School in Chun Ahn city to build a gymnasium and an indoor golf practice range.

Role as Science and Technology Public Relations Officer

Dr. Ryu volunteered to numerous lectures and interviews after donation to advertise science and technology. His belief that the development of science and technology is necessary for Korea’s development was the driving force behind his efforts at increasing interest and support for the field of science and technology.

In addition, through interviews with MBC, KBS, SBS, KTV, Joong Ang Newspapers, Dong Ah Newspaper and other media mediums, Dr. Ryu improved the public perception on donations whilst increasing the pride of scientists and researchers by highlighting their importance and the importance of science and technology.

In recognition of Dr. Ryu’s efforts, he received the 43rd Science Day Science and Technology Creation Award, 2010 MBC Social Service Special Award, and 2010 ‘Proud Chung Cheong Citizen’ Award.

2011.03.22 View 17749

Late Dr. Ryu Geun Chul's Achievements and Generous Contributions

First Doctor in the field of Korean Traditional Medicine

The late Dr. Ryu was born in 1926 and is the father figure of Korea’s Traditional Medicine and is its First Doctor (1976 Kyung Hee University), and was the vice-professor of Kyung Hee University of Medicine, Vice-Director of Kyung Hee Institute of Korean Traditional Medicine, and was the first chairman of the Association of Korea Oriental Medicine. He developed the painless acupuncture administering device for the first time in Korea in 1962, and succeeded in anesthetizing a patient for cesarean procedure using acupuncture in 1972.

He even was the first to receive a medical engineering doctorate degree from the Moscow National Engineering School in April of 1996 and developed a stroke rehabilitation machine.

Korea’s Most Generous Donor

Dr. Ryu surprised the world by donating 57.8billion Won worth of real estate to KAIST in August of 2008. Dr. Ryu revealed that his reason for donating such a huge sum to KAIST was due to its focused students giving him the belief that the future of Korea is at KAIST and that the development of science and technology is necessary for Korea to develop into a world class nation and KAIST is the institute most suitable to lead Korea in the field.

Dr. Ryu lived on KAIST campus after donating his entire fortune and even established ‘KAIST scholars and spacemen health research center’ and ‘Dr. Ryu Health Clinic’ as he also wanted to donate his knowledge.

Even when he was a professor at Moscow National Engineering University in the late 1990s he carried out free medical work throughout Korea and in recognition of his devoted work, he was named honorary citizen from Chun Ahn city, San Chung city, and DaeJeon city. In 2007 he donated 450million Won to Cheon Dong Elementary School in Chun Ahn city to build a gymnasium and an indoor golf practice range.

Role as Science and Technology Public Relations Officer

Dr. Ryu volunteered to numerous lectures and interviews after donation to advertise science and technology. His belief that the development of science and technology is necessary for Korea’s development was the driving force behind his efforts at increasing interest and support for the field of science and technology.

In addition, through interviews with MBC, KBS, SBS, KTV, Joong Ang Newspapers, Dong Ah Newspaper and other media mediums, Dr. Ryu improved the public perception on donations whilst increasing the pride of scientists and researchers by highlighting their importance and the importance of science and technology.

In recognition of Dr. Ryu’s efforts, he received the 43rd Science Day Science and Technology Creation Award, 2010 MBC Social Service Special Award, and 2010 ‘Proud Chung Cheong Citizen’ Award.

2011.03.22 View 17749 -

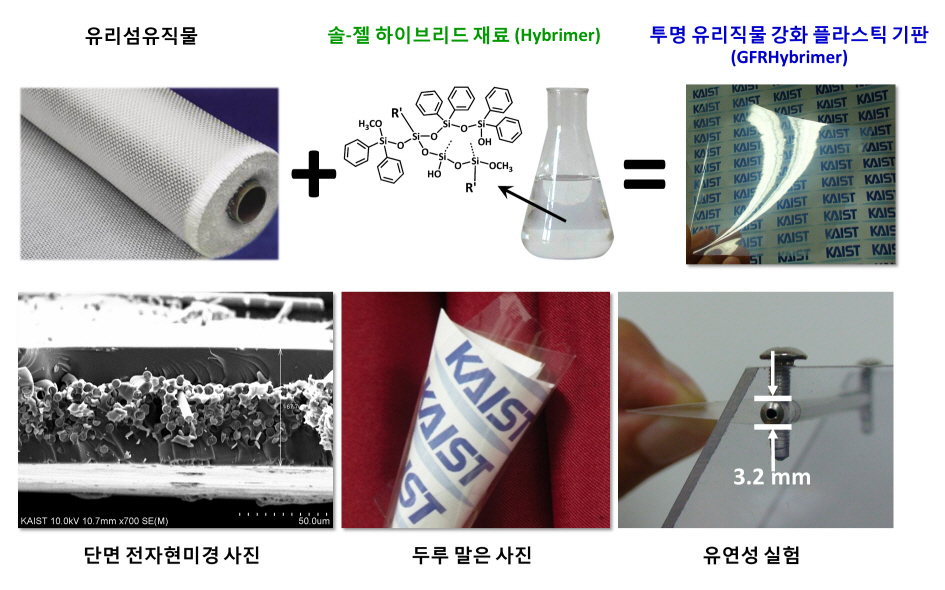

KAIST paves the way to commercialize flexible display screens

Source: IDTechEX, Feb. 28, 2011

KAIST paves the way to commercialize flexible display screens

28 Feb 2011

Transparent plastic and glass cloths, which have a limited thermal expansion needed for the production of flexible display screens and solar power cells, were developed by researchers at KAIST (Korea Advance Institute of Science & Technology).

The research, led by KAIST"s Professor Byoung-Soo Bae, was funded by the Engineering Research Center under the initiative of the Ministry of Education, Science and Technology and the National Research Foundation. The research result was printed as the cover paper of "Advanced Materials".

Professor Bae"s team developed a hybrid material with the same properties as fiber glass. With the material, they created a transparent, plastic film sheet resistant to heat. Transparent plastic film sheets were used by researchers all over the world to develop devices such as flexible displays or solar power cells that can be fit into various living spaces. However, plastic films are heat sensitive and tend to expand as temperature increases, thereby making it difficult to produce displays or solar power cells.

The new transparent, plastic film screen shows that heat expansion index (13ppm/oC) similar to that of glass fiber (9ppm/oC) due to the presence of glass fibers; its heat resistance allows to be used for displays and solar power cells over 250oC.

Professor Bae"s team succeeded in producing a flexible thin plastic film available for use in LCD or AMOLED screens and thin solar power cells.

Professor Bae commented, "Not only the newly developed plastic film has superior qualities, compared to the old models, but also it is cheap to produce, potentially bringing forward the day when flexible displays and solar panels become commonplace. With the cooperation of various industries, research institutes and universities, we will strive to improve the existing design and develop it further."

http://www.printedelectronicsworld.com/articles/kaist_paves_the_way_to_commercialize_flexible_display_screens_00003144.asp?sessionid=1

2011.03.01 View 14144

KAIST paves the way to commercialize flexible display screens

Source: IDTechEX, Feb. 28, 2011

KAIST paves the way to commercialize flexible display screens

28 Feb 2011

Transparent plastic and glass cloths, which have a limited thermal expansion needed for the production of flexible display screens and solar power cells, were developed by researchers at KAIST (Korea Advance Institute of Science & Technology).

The research, led by KAIST"s Professor Byoung-Soo Bae, was funded by the Engineering Research Center under the initiative of the Ministry of Education, Science and Technology and the National Research Foundation. The research result was printed as the cover paper of "Advanced Materials".

Professor Bae"s team developed a hybrid material with the same properties as fiber glass. With the material, they created a transparent, plastic film sheet resistant to heat. Transparent plastic film sheets were used by researchers all over the world to develop devices such as flexible displays or solar power cells that can be fit into various living spaces. However, plastic films are heat sensitive and tend to expand as temperature increases, thereby making it difficult to produce displays or solar power cells.

The new transparent, plastic film screen shows that heat expansion index (13ppm/oC) similar to that of glass fiber (9ppm/oC) due to the presence of glass fibers; its heat resistance allows to be used for displays and solar power cells over 250oC.

Professor Bae"s team succeeded in producing a flexible thin plastic film available for use in LCD or AMOLED screens and thin solar power cells.

Professor Bae commented, "Not only the newly developed plastic film has superior qualities, compared to the old models, but also it is cheap to produce, potentially bringing forward the day when flexible displays and solar panels become commonplace. With the cooperation of various industries, research institutes and universities, we will strive to improve the existing design and develop it further."

http://www.printedelectronicsworld.com/articles/kaist_paves_the_way_to_commercialize_flexible_display_screens_00003144.asp?sessionid=1

2011.03.01 View 14144 -

Success in differentiating Functional Vascular Progenitor Cells (VPC)

KAIST’s Professor Han Yong Man successfully differentiated vascular progenitor cells from human embryonic stem cells and reversed differentiated stem cells.

The research went beyond the current method of synthesis of embryonic body or mice cell ball culture and used the careful alteration of signal transmission system of the human embryonic stem cells to differentiate the formation of vascular progenitor cells.

The team controlled the MEK/ERK and BMP signal transmission system that serves an important role in the self replication of human embryonic stem cells and successfully differentiated 20% of the cells experimented on to vascular progenitor cells.

The vascular progenitor cells produced with such a method successfully differentiated into cells forming the endodermis of the blood vessel, vascular smooth muscle cells and hematopoietic cells in an environment outside of the human body and also successfully differentiated into blood vessels in nude mice.

In addition, the vascular progenitor cell derived from human embryonic cells successfully formed blood vessels or secreted vascular growth factors and increased the blood flow and the necrosis of blood vessels when injected into an animal with limb ischemic illness.

The research was funded by the Ministry of Education, Science and Technology, 21st Century Frontier Research and Development Institution’s Cell Application Research Department and Professor Ko Kyu Young (KAIST), Professor Choi Chul Hee (KAIST), Professor Jeong Hyung Min (Cha Medical School) and Doctor Jo Lee Sook (Researcher in Korea Bio Engineering Institute) participated in it.

The results of the research was published as the cover paper of the September edition of “Blood (IF:10.55)”, the American Blood Journal and has been patented domestically and has finished registration of foreign PCT.

The results of the experiment opened the possibility of providing a patient specific cure using stem cells in the field of blood vessel illness.

2011.01.18 View 14283

Success in differentiating Functional Vascular Progenitor Cells (VPC)

KAIST’s Professor Han Yong Man successfully differentiated vascular progenitor cells from human embryonic stem cells and reversed differentiated stem cells.

The research went beyond the current method of synthesis of embryonic body or mice cell ball culture and used the careful alteration of signal transmission system of the human embryonic stem cells to differentiate the formation of vascular progenitor cells.

The team controlled the MEK/ERK and BMP signal transmission system that serves an important role in the self replication of human embryonic stem cells and successfully differentiated 20% of the cells experimented on to vascular progenitor cells.

The vascular progenitor cells produced with such a method successfully differentiated into cells forming the endodermis of the blood vessel, vascular smooth muscle cells and hematopoietic cells in an environment outside of the human body and also successfully differentiated into blood vessels in nude mice.

In addition, the vascular progenitor cell derived from human embryonic cells successfully formed blood vessels or secreted vascular growth factors and increased the blood flow and the necrosis of blood vessels when injected into an animal with limb ischemic illness.

The research was funded by the Ministry of Education, Science and Technology, 21st Century Frontier Research and Development Institution’s Cell Application Research Department and Professor Ko Kyu Young (KAIST), Professor Choi Chul Hee (KAIST), Professor Jeong Hyung Min (Cha Medical School) and Doctor Jo Lee Sook (Researcher in Korea Bio Engineering Institute) participated in it.

The results of the research was published as the cover paper of the September edition of “Blood (IF:10.55)”, the American Blood Journal and has been patented domestically and has finished registration of foreign PCT.

The results of the experiment opened the possibility of providing a patient specific cure using stem cells in the field of blood vessel illness.

2011.01.18 View 14283 -

Professor Kang Suk Joong receives 'Korea Engineering Award.'

KAIST”s Professor Kang Suk Joong of the Department of Material Science and Engineering received ‘Korea Engineering Award’ from the Ministry of Education, Science and Technology and Korea Research Foundation. The award is given to those professors who have accomplished world class research and results.

Professor Kang has potentially redirected the direction of research in the field of the microstructure of materials by explaining the fundamental principle behind how the microstructure of a material that affects the physical properties of the polycrystalline structure and changes through processing. Professor Kang applied the results of his findings in the manufacture of new materials and made significant contributions to Korean Material Engineering Industry and was consequently awarded the award.

The ‘Korea Engineering Award’ was thought of in 1994 and a total of 24 recipients were recognized through the award in various fields like electronics, mechanics, chemistry, construction, etc. The recipient is awarded in addition the President’s award and 50million won as prize money.

The ceremony for ‘Korea Engineering Award’ and the ‘Young Scientist Award’ was held in Seoul Press Center Press Club on the 22nd of December at 3pm. The Minister of Education, Science and Technology (Lee Joo Ho), member of Board of Directors of the Korea Research Foundation (Kim Byoung Gook), Director of Korea Science and Technology Archive (Jeong Gil Seng), along with the recipients attended the ceremony.

In addition, Professor Kang was appointed as Distinguished Professor in March 2010 in recognition of his research accomplishments.

2011.01.18 View 11859

Professor Kang Suk Joong receives 'Korea Engineering Award.'

KAIST”s Professor Kang Suk Joong of the Department of Material Science and Engineering received ‘Korea Engineering Award’ from the Ministry of Education, Science and Technology and Korea Research Foundation. The award is given to those professors who have accomplished world class research and results.

Professor Kang has potentially redirected the direction of research in the field of the microstructure of materials by explaining the fundamental principle behind how the microstructure of a material that affects the physical properties of the polycrystalline structure and changes through processing. Professor Kang applied the results of his findings in the manufacture of new materials and made significant contributions to Korean Material Engineering Industry and was consequently awarded the award.

The ‘Korea Engineering Award’ was thought of in 1994 and a total of 24 recipients were recognized through the award in various fields like electronics, mechanics, chemistry, construction, etc. The recipient is awarded in addition the President’s award and 50million won as prize money.

The ceremony for ‘Korea Engineering Award’ and the ‘Young Scientist Award’ was held in Seoul Press Center Press Club on the 22nd of December at 3pm. The Minister of Education, Science and Technology (Lee Joo Ho), member of Board of Directors of the Korea Research Foundation (Kim Byoung Gook), Director of Korea Science and Technology Archive (Jeong Gil Seng), along with the recipients attended the ceremony.

In addition, Professor Kang was appointed as Distinguished Professor in March 2010 in recognition of his research accomplishments.

2011.01.18 View 11859 -

KAIST developed a plastic film board less sensitive to heat.

The research result was made the cover of magazine, Advanced Materials and is accredited to paving the way to commercialize flexible display screens and solar power cells.

Transparent plastic and glass cloths, which have a limited thermal expansion needed for the production of flexible display screens and solar power cells, were developed by Korean researchers.

The research, led by KAIST’s Professor Byoung-Soo Bae, was funded by the Engineering Research Center under the initiative of the Ministry of Education, Science and Technology and the National Research Foundation. The research result was printed as the cover paper of ‘Advanced Materials’ which is the leading magazine in the field of materials science.

Professor Bae’s team developed a hybrid material with the same properties as fiber glass. With the material, they created a transparent, plastic film sheet resistant to heat. Transparent plastic film sheets were used by researchers all over the world to develop devices such as flexible displays or solar power cells that can be fit into various living spaces. However, plastic films are heat sensitive and tend to expand as temperature increases, thereby making it difficult to produce displays or solar power cells.

The new transparent, plastic film screen shows that heat expansion index (13ppm/oC) similar to that of glass fiber (9ppm/oC) due to the presence of glass fibers; its heat resistance allows to be used for displays and solar power cells over 250oC.

Professor Bae’s team succeeded in producing a flexible thin plastic film available for use in LCD or AMOLED screens and thin solar power cells.

Professor Bae commented, “Not only the newly developed plastic film has superior qualities, compared to the old models, but also it is cheap to produce, potentially bringing forward the day when flexible displays and solar panels become commonplace. With the cooperation of various industries, research institutes and universities, we will strive to improve the existing design and develop it further.”

2011.01.05 View 14775

KAIST developed a plastic film board less sensitive to heat.

The research result was made the cover of magazine, Advanced Materials and is accredited to paving the way to commercialize flexible display screens and solar power cells.

Transparent plastic and glass cloths, which have a limited thermal expansion needed for the production of flexible display screens and solar power cells, were developed by Korean researchers.

The research, led by KAIST’s Professor Byoung-Soo Bae, was funded by the Engineering Research Center under the initiative of the Ministry of Education, Science and Technology and the National Research Foundation. The research result was printed as the cover paper of ‘Advanced Materials’ which is the leading magazine in the field of materials science.

Professor Bae’s team developed a hybrid material with the same properties as fiber glass. With the material, they created a transparent, plastic film sheet resistant to heat. Transparent plastic film sheets were used by researchers all over the world to develop devices such as flexible displays or solar power cells that can be fit into various living spaces. However, plastic films are heat sensitive and tend to expand as temperature increases, thereby making it difficult to produce displays or solar power cells.

The new transparent, plastic film screen shows that heat expansion index (13ppm/oC) similar to that of glass fiber (9ppm/oC) due to the presence of glass fibers; its heat resistance allows to be used for displays and solar power cells over 250oC.

Professor Bae’s team succeeded in producing a flexible thin plastic film available for use in LCD or AMOLED screens and thin solar power cells.

Professor Bae commented, “Not only the newly developed plastic film has superior qualities, compared to the old models, but also it is cheap to produce, potentially bringing forward the day when flexible displays and solar panels become commonplace. With the cooperation of various industries, research institutes and universities, we will strive to improve the existing design and develop it further.”

2011.01.05 View 14775 -

KAIST sells eight HUBO 2 robots to US and Singapore.

HUBO, a humanoid robot developed by KAIST, has made its journey to the US and Singapore for the development of robotics engineering in those nations. Details on the movements of HOBO being exported aboard, please click the link of the news article:

http://www.slashgear.com/kaist-sells-eight-hubo-2-robots-to-us-and-singapore-14119320/

2010.12.20 View 11202

KAIST sells eight HUBO 2 robots to US and Singapore.

HUBO, a humanoid robot developed by KAIST, has made its journey to the US and Singapore for the development of robotics engineering in those nations. Details on the movements of HOBO being exported aboard, please click the link of the news article:

http://www.slashgear.com/kaist-sells-eight-hubo-2-robots-to-us-and-singapore-14119320/

2010.12.20 View 11202 -

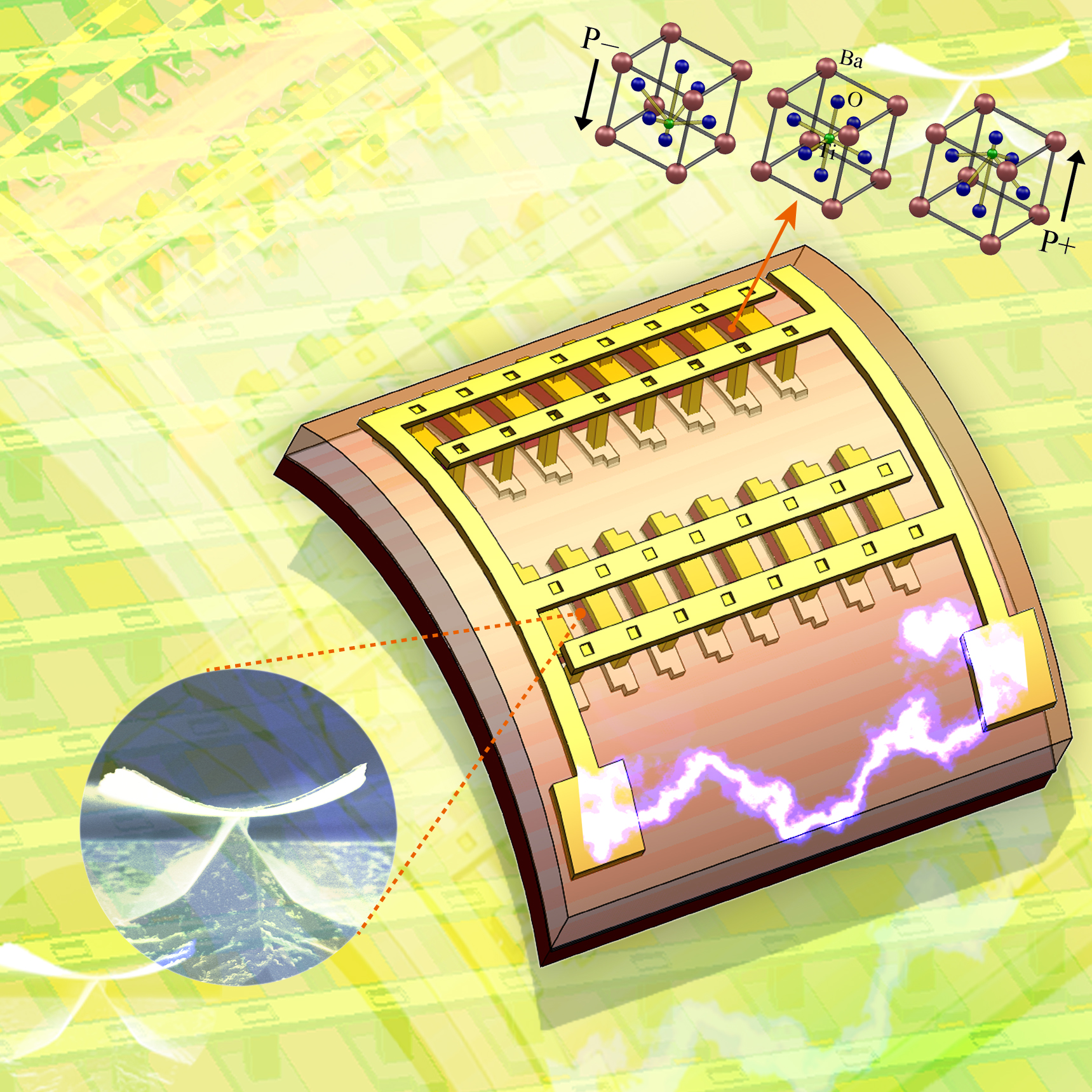

The KAIST & GIT team developed a power generation technology using bendable thin film nano-materials.

Figure description: Flexible thin film nanomaterials produce electricity.

Can a heart implanted micro robot operate permanently?

Can cell phones and tiny robots implanted in the heart operate permanently without having their batteries charged?

It might sound like science fiction, but these things seem to be possible in the near future. The team of Prof. Keon Jae Lee (KAIST, Dept. of Materials Science and Engineering) and Prof. Zhong Lin Wang (Georgia Institute of Technology, Dept. of Materials Science and Engineering) has developed new forms of highly efficient, flexible nanogenerator technology using the freely bendable piezoelectric ceramic thin film nano-materials that can convert tiny movements of the human body (such as heart beats and blood flow) into electrical energy.

The piezoelectric effect refers to voltage generation when pressure or bending strength is applied to piezoelectric materials. The ceramics, containing a perovskite structure, have a high piezoelectric efficiency. Until now, it has been very difficult to use these ceramic materials to fabricate flexible electronic systems due to their brittle property.

The research team, however, has succeeded in developing a bio-eco-friendly ceramic thin film nanogenerator that is freely bendable without breakdown.

Nanogenerator technology, a power generating system without wires or batteries, combines nanotechnology with piezoelectrics that can be used not only in personal mobile electronics but also in bio-implantable sensors or as an energy source for micro robots. Energy sources in nature (wind, vibration, and sound) and biomechanical forces produced by the human body (heart beats, blood flow, and muscle contraction/relaxation) can infinitely produce nonpolluting energy. (Nanogenerator produces electricity by external forces: http://www.youtube.com/watch?v=tvj0SsBqpBw)

Prof. Keon Jae Lee (KAIST) was involved in the first co-invention of “High Performance Flexible Single Crystal Electronics” during his PhD course at the University of Illinois at Urbana-Champaign. This nanogenerator technology, based on the previous invention, utilized the similar protocol of transferring ceramic thin film nano-materials on flexible substrates and produced voltage generation between electrodes.

Prof. Zhong Lin Wang (Georgia Tech, inventor of the nanogenerator) said, “This technology can be used to turn on an LED by slightly modifying circuits and operate touchable flexible displays. In addition, thin film nano-materials (‘barium titanate’) of this research have the property of both high efficiency and lead-free bio compatibility, which can be used in future medical applications.” This result is published in November online issue of ‘Nano Letters’ ACS journal.

<Video>

Youtube link: http://www.youtube.com/watch?v=tvj0SsBqpBw

Thin Film Nanogenerator produces electricity by external forces.

2010.11.23 View 15524

The KAIST & GIT team developed a power generation technology using bendable thin film nano-materials.

Figure description: Flexible thin film nanomaterials produce electricity.

Can a heart implanted micro robot operate permanently?

Can cell phones and tiny robots implanted in the heart operate permanently without having their batteries charged?

It might sound like science fiction, but these things seem to be possible in the near future. The team of Prof. Keon Jae Lee (KAIST, Dept. of Materials Science and Engineering) and Prof. Zhong Lin Wang (Georgia Institute of Technology, Dept. of Materials Science and Engineering) has developed new forms of highly efficient, flexible nanogenerator technology using the freely bendable piezoelectric ceramic thin film nano-materials that can convert tiny movements of the human body (such as heart beats and blood flow) into electrical energy.

The piezoelectric effect refers to voltage generation when pressure or bending strength is applied to piezoelectric materials. The ceramics, containing a perovskite structure, have a high piezoelectric efficiency. Until now, it has been very difficult to use these ceramic materials to fabricate flexible electronic systems due to their brittle property.

The research team, however, has succeeded in developing a bio-eco-friendly ceramic thin film nanogenerator that is freely bendable without breakdown.

Nanogenerator technology, a power generating system without wires or batteries, combines nanotechnology with piezoelectrics that can be used not only in personal mobile electronics but also in bio-implantable sensors or as an energy source for micro robots. Energy sources in nature (wind, vibration, and sound) and biomechanical forces produced by the human body (heart beats, blood flow, and muscle contraction/relaxation) can infinitely produce nonpolluting energy. (Nanogenerator produces electricity by external forces: http://www.youtube.com/watch?v=tvj0SsBqpBw)

Prof. Keon Jae Lee (KAIST) was involved in the first co-invention of “High Performance Flexible Single Crystal Electronics” during his PhD course at the University of Illinois at Urbana-Champaign. This nanogenerator technology, based on the previous invention, utilized the similar protocol of transferring ceramic thin film nano-materials on flexible substrates and produced voltage generation between electrodes.

Prof. Zhong Lin Wang (Georgia Tech, inventor of the nanogenerator) said, “This technology can be used to turn on an LED by slightly modifying circuits and operate touchable flexible displays. In addition, thin film nano-materials (‘barium titanate’) of this research have the property of both high efficiency and lead-free bio compatibility, which can be used in future medical applications.” This result is published in November online issue of ‘Nano Letters’ ACS journal.

<Video>

Youtube link: http://www.youtube.com/watch?v=tvj0SsBqpBw

Thin Film Nanogenerator produces electricity by external forces.

2010.11.23 View 15524