catalysts

-

Platinum Catalyst Has Price Lowed and Durability Doubled

(Professor Cho in the Department of Materials Science and Engineering)

Professor EunAe Cho in the Department of Materials Science and Engineering reported a fuel cell catalyst that shows 12 times higher performance and twice the durability than previously used platinum catalyst.

Fuel cells, eco-friendly power generators, are said to be running air purifiers. A hydrogen vehicle powered by fuel cells can allegedly purify more than 98 percent of the particulate matter and ultrafine particles from the amount of air that 70 adults breathe.

Despite this peculiarity, the high price of platinum, which is used as an electrode catalyst, remains a big challenge to accelerating commercialization. In addition, recently developed ‘nano-structured platinum catalysts’ have not yet commercialized due to its meager oxygen reduction reaction and durability in fuel cell.

Addressing all those challenges, Professor Cho’s team reported a platinum catalyst costing 30 percent less but boasting 12 times higher performance.

The research team, to this end, combined the platinum with nickel, then applied various metallic elements for making the most efficient performance. Among others, they found that the addition of gallium can modulate the oxygen intermediate binding energy, leading to enhanced catalytic activity of the oxygen reduction reaction.

They made octahedron nanoparticle platinum-nickel alloy and could efficiently achieve 12-times high performance with the platinum catalyst by adding gallium to the surface of octahedron.

Existing fuel cell catalysts have issues in practical fuel cell applications. However, Professor Cho’s team experimentally proved the high performance of the catalyst even in the fuel cell, and is expected to be practically applied to the existing procedure.

First author JeongHoon Lim said their work demonstrates the gallium-added octahedral nanoparticles can be utilized as a highly active and durable oxygen reduction reaction catalyst in practical fuel cell applications. It will make it feasible for the mass production of the catalysts.

Professor Cho also said, “Our study realized the two main goals: an affordable price and increased performance of fuel cells. We hope this will make a contribution to the market competitiveness of fuel cell electric vehicles.”

This research was described in Nano Letters in April and was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP), the National Research Foundation (NRF), and the Agency for Defense Development (ADD).

(Figure: HAADF STEM images with EDX analyses and line scanning profiles of (a) Ga-PtNi/C and (b) PtNi/C during the voltage-cycling tests. The composition changes of Ni, Pt, and Ga atoms in the nanoparticles were determined by EDX (inset in the EDX mapping results)).

2018.05.15 View 8191

Platinum Catalyst Has Price Lowed and Durability Doubled

(Professor Cho in the Department of Materials Science and Engineering)

Professor EunAe Cho in the Department of Materials Science and Engineering reported a fuel cell catalyst that shows 12 times higher performance and twice the durability than previously used platinum catalyst.

Fuel cells, eco-friendly power generators, are said to be running air purifiers. A hydrogen vehicle powered by fuel cells can allegedly purify more than 98 percent of the particulate matter and ultrafine particles from the amount of air that 70 adults breathe.

Despite this peculiarity, the high price of platinum, which is used as an electrode catalyst, remains a big challenge to accelerating commercialization. In addition, recently developed ‘nano-structured platinum catalysts’ have not yet commercialized due to its meager oxygen reduction reaction and durability in fuel cell.

Addressing all those challenges, Professor Cho’s team reported a platinum catalyst costing 30 percent less but boasting 12 times higher performance.

The research team, to this end, combined the platinum with nickel, then applied various metallic elements for making the most efficient performance. Among others, they found that the addition of gallium can modulate the oxygen intermediate binding energy, leading to enhanced catalytic activity of the oxygen reduction reaction.

They made octahedron nanoparticle platinum-nickel alloy and could efficiently achieve 12-times high performance with the platinum catalyst by adding gallium to the surface of octahedron.

Existing fuel cell catalysts have issues in practical fuel cell applications. However, Professor Cho’s team experimentally proved the high performance of the catalyst even in the fuel cell, and is expected to be practically applied to the existing procedure.

First author JeongHoon Lim said their work demonstrates the gallium-added octahedral nanoparticles can be utilized as a highly active and durable oxygen reduction reaction catalyst in practical fuel cell applications. It will make it feasible for the mass production of the catalysts.

Professor Cho also said, “Our study realized the two main goals: an affordable price and increased performance of fuel cells. We hope this will make a contribution to the market competitiveness of fuel cell electric vehicles.”

This research was described in Nano Letters in April and was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP), the National Research Foundation (NRF), and the Agency for Defense Development (ADD).

(Figure: HAADF STEM images with EDX analyses and line scanning profiles of (a) Ga-PtNi/C and (b) PtNi/C during the voltage-cycling tests. The composition changes of Ni, Pt, and Ga atoms in the nanoparticles were determined by EDX (inset in the EDX mapping results)).

2018.05.15 View 8191 -

Producing 50x More Stable Adsorbent

A KAIST research team developed a technology to increase the stability of amine-containing adsorbents by fifty times, moving one step further toward commercializing stable adsorbents that last longer.

Professor Minkee Choi from the Department of Chemical and Biomolecular Engineering and his team succeeded in developing amine-containing adsorbents that show high oxidative stability.

The capture of the greenhouse gas carbon dioxide is an active ongoing research field, and some of the latest advancements point to amine-containing adsorbents as an efficient and environment-friendly way to capture carbon dioxide. However, existing amine-containing adsorbents are known to be unstable under oxidation, which chemically breaks down the adsorbent, thereby making it difficult to rely on amine-containing adsorbents for repeated and continued use.

The researchers have discovered that the miniscule amount of iron and copper present in the amine accelerate the oxidative breakdown of the amine-containing adsorbent. Upon this discovery, they proposed the use of a chelator substance, which essentially suppresses the activation of the impurities.

The team demonstrates that the proposed method renders the adsorbent up to 50 times slower in its deactivation rate due to oxidation, compared to conventional polyethyleneimine (PEI) / silica adsorbents. Figure 1 illustrates the superior performance of this oxidation-stable amine-containing adsorbent (shown in black squares), whose carbon dioxide-capturing capacity deteriorates by only a small amount (~8%). Meanwhile, the carbon dioxide-capturing capacity of the PEI/silica adsorbent (shown in red diamonds) degrades dramatically after being exposed to oxidative aging for 30 days.

This stability under oxidation is expected to have brought amine-containing adsorbents one step closer to commercialization. As such, first author Woosung Choi describes the significance of this study as “having brought solid carbon dioxide adsorbents to commercializable standards”. In fact, Professor Choi explains that commercialization steps for his team’s carbon dioxide adsorbents are already underway. He further set forth his aim to “develop the world’s best carbon dioxide capture adsorbent”.

This research, led by the PhD candidate Woosung Choi, was published online in Nature Communications on February 20.

Figure 1. Carbon dioxide working capacity against oxidative aging time. Performance of the proposed method (black) degrades much more slowly (~50x) than that of existing methods. The novel adsorbent is thus shown to be more robust to oxidation.

2018.04.16 View 6496

Producing 50x More Stable Adsorbent

A KAIST research team developed a technology to increase the stability of amine-containing adsorbents by fifty times, moving one step further toward commercializing stable adsorbents that last longer.

Professor Minkee Choi from the Department of Chemical and Biomolecular Engineering and his team succeeded in developing amine-containing adsorbents that show high oxidative stability.

The capture of the greenhouse gas carbon dioxide is an active ongoing research field, and some of the latest advancements point to amine-containing adsorbents as an efficient and environment-friendly way to capture carbon dioxide. However, existing amine-containing adsorbents are known to be unstable under oxidation, which chemically breaks down the adsorbent, thereby making it difficult to rely on amine-containing adsorbents for repeated and continued use.

The researchers have discovered that the miniscule amount of iron and copper present in the amine accelerate the oxidative breakdown of the amine-containing adsorbent. Upon this discovery, they proposed the use of a chelator substance, which essentially suppresses the activation of the impurities.

The team demonstrates that the proposed method renders the adsorbent up to 50 times slower in its deactivation rate due to oxidation, compared to conventional polyethyleneimine (PEI) / silica adsorbents. Figure 1 illustrates the superior performance of this oxidation-stable amine-containing adsorbent (shown in black squares), whose carbon dioxide-capturing capacity deteriorates by only a small amount (~8%). Meanwhile, the carbon dioxide-capturing capacity of the PEI/silica adsorbent (shown in red diamonds) degrades dramatically after being exposed to oxidative aging for 30 days.

This stability under oxidation is expected to have brought amine-containing adsorbents one step closer to commercialization. As such, first author Woosung Choi describes the significance of this study as “having brought solid carbon dioxide adsorbents to commercializable standards”. In fact, Professor Choi explains that commercialization steps for his team’s carbon dioxide adsorbents are already underway. He further set forth his aim to “develop the world’s best carbon dioxide capture adsorbent”.

This research, led by the PhD candidate Woosung Choi, was published online in Nature Communications on February 20.

Figure 1. Carbon dioxide working capacity against oxidative aging time. Performance of the proposed method (black) degrades much more slowly (~50x) than that of existing methods. The novel adsorbent is thus shown to be more robust to oxidation.

2018.04.16 View 6496 -

Platinum Single Atom Catalysts for 'Direct Formic Acid Fuel Cells'

(Professor Hyunjoo Lee (left) and Ph.D. candidate Jiwhan Kim)

A research team co-led by Professor Hyunjoo Lee at the Department of Chemical and Biomolecular Engineering at KAIST and Professor Jeong Woo Han from the University of Seoul synthesized highly stable high-Pt-content single atom catalysts for direct formic acid fuel cells. The amount of platinum can be reduced to 1/10 of that of conventional platinum nanoparticle catalysts.

Platinum (Pt) catalysts have been used in various catalytic reactions due to their high activity and stability. However, because Pt is rare and expensive, it is important to reduce the amount of Pt used. Pt single atom catalysts can reduce the size of the Pt particles to the size of an atom. Thus, the cost of Pt catalysts can be minimized because all of the Pt atoms can participate in the catalytic reactions. Additionally, single atom catalysts have no ensemble site in which two or more atoms are attached, and thus, the reaction selectivity is different from that of nanoparticle catalysts.

Despite these advantages, single atom catalysts are easily aggregated and less stable due to their low coordination number and high surface free energy. It is difficult to develop a single atom catalyst with high content and high stability, and thus, its application in practical devices is limited.

Direct formic acid fuel cells can be an energy source for next-generation portable devices because liquid formic acid as a fuel is safer and easier to store and transport than high-pressure hydrogen gas.

To improve the stability of Pt single atom catalysts, Professor Lee’s group developed a Pt-Sn single atom alloy structure on an antimony-doped tin oxide (ATO) support. This structure has been proven by computational calculations which show that Pt single atoms substitute antimony sites in the antimony-tin alloy structure and are thermodynamically stable. This catalyst has been shown to have a higher activity up to 50 times per weight of Pt than that of the commercial catalyst, Pt/C, in the oxidation of formic acid, and the stability of the catalyst was also remarkably high.

Professor Lee’s group also used a single atomic catalyst in a 'direct formic acid fuel cell’ consisting of membranes and electrodes. It is the first attempt to apply a single atomic catalyst to a full cell. In this case, an output similar to that of the commercial catalyst could be obtained by using 1/10 of the platinum compared to the commercial Pt/C catalyst.

Ph.D. candidate Jiwhan Kim from KAIST was the first author of the research. This research was published online on September 11 in Advanced Energy Materials.

This research was carried out with the support of the Samsung Electronics Future Technology Development Center.

(Figure 1. Concept photograph for Pt single atom catalysts.)

(Figure 2. Pt single atom catalysts by HAADF-STEM analysis (bright white circles))

2017.10.31 View 8106

Platinum Single Atom Catalysts for 'Direct Formic Acid Fuel Cells'

(Professor Hyunjoo Lee (left) and Ph.D. candidate Jiwhan Kim)

A research team co-led by Professor Hyunjoo Lee at the Department of Chemical and Biomolecular Engineering at KAIST and Professor Jeong Woo Han from the University of Seoul synthesized highly stable high-Pt-content single atom catalysts for direct formic acid fuel cells. The amount of platinum can be reduced to 1/10 of that of conventional platinum nanoparticle catalysts.

Platinum (Pt) catalysts have been used in various catalytic reactions due to their high activity and stability. However, because Pt is rare and expensive, it is important to reduce the amount of Pt used. Pt single atom catalysts can reduce the size of the Pt particles to the size of an atom. Thus, the cost of Pt catalysts can be minimized because all of the Pt atoms can participate in the catalytic reactions. Additionally, single atom catalysts have no ensemble site in which two or more atoms are attached, and thus, the reaction selectivity is different from that of nanoparticle catalysts.

Despite these advantages, single atom catalysts are easily aggregated and less stable due to their low coordination number and high surface free energy. It is difficult to develop a single atom catalyst with high content and high stability, and thus, its application in practical devices is limited.

Direct formic acid fuel cells can be an energy source for next-generation portable devices because liquid formic acid as a fuel is safer and easier to store and transport than high-pressure hydrogen gas.

To improve the stability of Pt single atom catalysts, Professor Lee’s group developed a Pt-Sn single atom alloy structure on an antimony-doped tin oxide (ATO) support. This structure has been proven by computational calculations which show that Pt single atoms substitute antimony sites in the antimony-tin alloy structure and are thermodynamically stable. This catalyst has been shown to have a higher activity up to 50 times per weight of Pt than that of the commercial catalyst, Pt/C, in the oxidation of formic acid, and the stability of the catalyst was also remarkably high.

Professor Lee’s group also used a single atomic catalyst in a 'direct formic acid fuel cell’ consisting of membranes and electrodes. It is the first attempt to apply a single atomic catalyst to a full cell. In this case, an output similar to that of the commercial catalyst could be obtained by using 1/10 of the platinum compared to the commercial Pt/C catalyst.

Ph.D. candidate Jiwhan Kim from KAIST was the first author of the research. This research was published online on September 11 in Advanced Energy Materials.

This research was carried out with the support of the Samsung Electronics Future Technology Development Center.

(Figure 1. Concept photograph for Pt single atom catalysts.)

(Figure 2. Pt single atom catalysts by HAADF-STEM analysis (bright white circles))

2017.10.31 View 8106 -

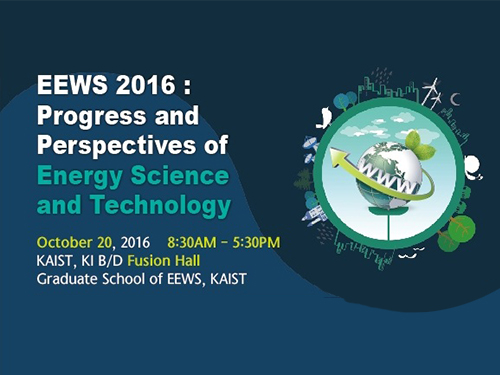

2016 KAIST EEWS Workshop

The Energy, Environment, Water and Sustainability (EEWS) Graduate School of KAIST hosted a workshop entitled “Progress and Perspectives of Energy Science and Technology” on October 20, 2016. The workshop took place at the Fusion Hall of the KAIST Institute on campus.

About 400 experts in energy science and engineering participated in the event. Eight globally recognized scientists introduced the latest research trends in nanomaterials, energy theory, catalysts, and photocatalysts and led discussions on the current status and prospects of EEWS.

Professors Yi Cui of Stanford University, an expert in nanomaterials, and William A. Goddard of California Institute of Technology presented their research experiments on materials design and recent results on the direction of theory under the topics of energy and environment.

Dr. Miquel Salmeron, a former head of the Material Science Division of Lawrence Berkeley National Laboratory, and Professor Yuichi Ikuhara of Tokyo University introduced their analysis of catalysts and energy matters at an atomic scale.

Professor Sukbok Chang of the Chemistry Department at KAIST, a deputy editor of ACS Catalysis and the head of the Center for Catalytic Hydrocarbon Functionalizations at the Institute of Basic Science, and Professor Yang-Kook Sun of Energy Engineering at Hanyang University, who is also a deputy editor of ACS Energy Letters, presented their latest research results on new catalytic reaction development and energy storage.

The workshop consisted of three sections which addressed the design of energy and environment materials; analysis of energy and catalytic materials; and energy conversion and catalysts.

The EEWS Graduate School was established in 2008 with the sponsorship of the Korean government’s World Class University (WCU) project to support science education in Korea. Professor J. Fraser Stoddart, the winner of the 2016 Nobel Prize in Chemistry, was previously worked at the KAIST EEWS Graduate School as a WCU visiting professor for two years, from 2011 to 2013. Professor Ali Coskun, who was a postdoctoral researcher in the laboratory of Professor Stoddart, now teaches and conducts research as a full-time professor at the graduate school.

Dean Yousung Jung of the EEWS Graduate School said:

“This workshop has provided us with a meaningful opportunity to engage in discussions on energy science and technology with world-class scholars from all around the world. It is also a good venue for our graduate school to share with them what we have been doing in research and education.”

2016.10.20 View 14557

2016 KAIST EEWS Workshop

The Energy, Environment, Water and Sustainability (EEWS) Graduate School of KAIST hosted a workshop entitled “Progress and Perspectives of Energy Science and Technology” on October 20, 2016. The workshop took place at the Fusion Hall of the KAIST Institute on campus.

About 400 experts in energy science and engineering participated in the event. Eight globally recognized scientists introduced the latest research trends in nanomaterials, energy theory, catalysts, and photocatalysts and led discussions on the current status and prospects of EEWS.

Professors Yi Cui of Stanford University, an expert in nanomaterials, and William A. Goddard of California Institute of Technology presented their research experiments on materials design and recent results on the direction of theory under the topics of energy and environment.

Dr. Miquel Salmeron, a former head of the Material Science Division of Lawrence Berkeley National Laboratory, and Professor Yuichi Ikuhara of Tokyo University introduced their analysis of catalysts and energy matters at an atomic scale.

Professor Sukbok Chang of the Chemistry Department at KAIST, a deputy editor of ACS Catalysis and the head of the Center for Catalytic Hydrocarbon Functionalizations at the Institute of Basic Science, and Professor Yang-Kook Sun of Energy Engineering at Hanyang University, who is also a deputy editor of ACS Energy Letters, presented their latest research results on new catalytic reaction development and energy storage.

The workshop consisted of three sections which addressed the design of energy and environment materials; analysis of energy and catalytic materials; and energy conversion and catalysts.

The EEWS Graduate School was established in 2008 with the sponsorship of the Korean government’s World Class University (WCU) project to support science education in Korea. Professor J. Fraser Stoddart, the winner of the 2016 Nobel Prize in Chemistry, was previously worked at the KAIST EEWS Graduate School as a WCU visiting professor for two years, from 2011 to 2013. Professor Ali Coskun, who was a postdoctoral researcher in the laboratory of Professor Stoddart, now teaches and conducts research as a full-time professor at the graduate school.

Dean Yousung Jung of the EEWS Graduate School said:

“This workshop has provided us with a meaningful opportunity to engage in discussions on energy science and technology with world-class scholars from all around the world. It is also a good venue for our graduate school to share with them what we have been doing in research and education.”

2016.10.20 View 14557