piezoelectric

-

AI-Driven Wearable Blood Pressure Sensor for Continuous Health Monitoring – Published in Nature Reviews Cardiology

A KAIST research team led by Professor Keon Jae Lee has proposed an innovative theoretical framework and research strategies for AI-based wearable blood pressure sensors, paving the way for continuous and non-invasive cardiovascular monitoring.

Hypertension is a leading chronic disease affecting over a billion people worldwide and is a major risk factor for severe cardiovascular conditions such as myocardial infarction, stroke, and heart failure. Traditional blood pressure measurement relies on intermittent, cuff-based methods, which fail to capture real-time fluctuations and present challenges in continuous patient monitoring.

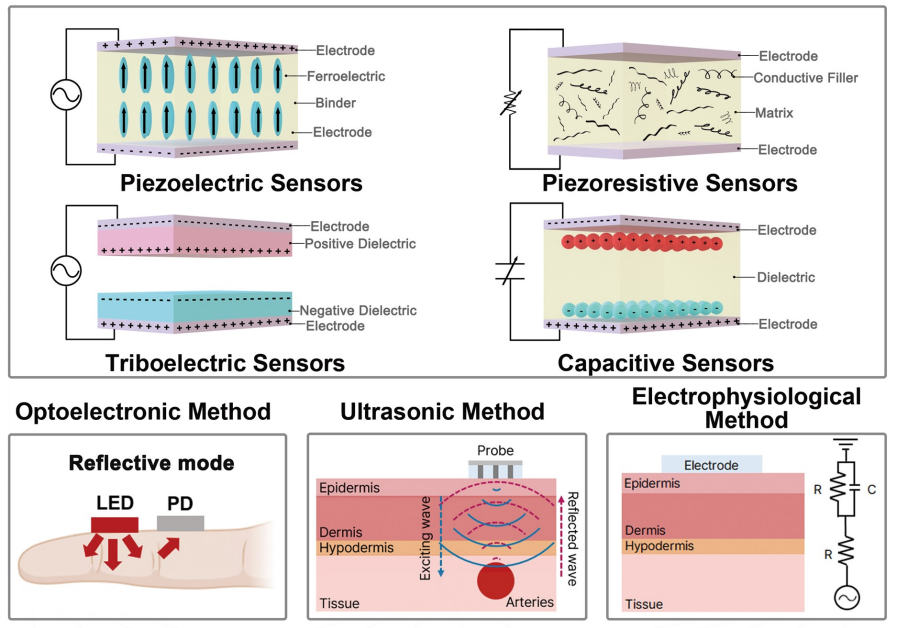

Wearable blood pressure sensors offer a non-invasive solution for continuous blood pressure monitoring, enabling real-time tracking and personalized cardiovascular health management. However, current technologies lack the accuracy and reliability required for medical applications, limiting their practical use. To address these challenges, advancements in high-sensitivity sensor technology and AI signal processing algorithms are essential.

Building on their previous study in Advanced Materials (doi.org/10.1002/adma.202301627), which validated the clinical feasibility of flexible piezoelectric blood pressure sensors, Professor Lee’s team conducted an in-depth review of the latest advancements in cuffless wearable sensors, focusing on key technical and clinical challenges. Their review highlights clinical aspects of clinical implementation, real-time data transmission, signal quality degradation, and AI algorithm accuracy.

Professor Keon Jae Lee said, “This paper systematically demonstrates the feasibility of medical-grade wearable blood pressure sensors, overcoming what was previously considered an insurmountable challenge. We propose theoretical strategies to address technical barriers, opening new possibilities for future innovations in this field. With continued advancements, we expect these sensors to gain trust and be commercialized soon, significantly improving quality of life.”

This review entitled “Wearable blood pressure sensors for cardiovascular monitoring and machine learning algorithms for blood pressure estimation” was published in the February 18 issue of Nature Reviews Cardiology (Impact Factor: 41.7). (doi.org/10.1038/s41569-025-01127-0)

< Figure 1. Overview of wearable blood pressure sensor technologies for cardiovascular health care >

[Reference] Min S. et al., (2025) “Wearable blood pressure sensors for

cardiovascular monitoring and machine learning algorithms for blood pressure estimation.” Nature Reviews Cardiology

(doi.org/10.1038/s41569-025-01127-0)

[Main Author] Seongwook Min (Korea Advanced Institute of Science and Technology), Jaehun An (Korea Advanced Institute of Science and Technology), Jae Hee Lee (Northwestern University),

* Contact email : Professor Keon Jae Lee (keonlee@kaist.ac.kr)

2025.03.04 View 3951

AI-Driven Wearable Blood Pressure Sensor for Continuous Health Monitoring – Published in Nature Reviews Cardiology

A KAIST research team led by Professor Keon Jae Lee has proposed an innovative theoretical framework and research strategies for AI-based wearable blood pressure sensors, paving the way for continuous and non-invasive cardiovascular monitoring.

Hypertension is a leading chronic disease affecting over a billion people worldwide and is a major risk factor for severe cardiovascular conditions such as myocardial infarction, stroke, and heart failure. Traditional blood pressure measurement relies on intermittent, cuff-based methods, which fail to capture real-time fluctuations and present challenges in continuous patient monitoring.

Wearable blood pressure sensors offer a non-invasive solution for continuous blood pressure monitoring, enabling real-time tracking and personalized cardiovascular health management. However, current technologies lack the accuracy and reliability required for medical applications, limiting their practical use. To address these challenges, advancements in high-sensitivity sensor technology and AI signal processing algorithms are essential.

Building on their previous study in Advanced Materials (doi.org/10.1002/adma.202301627), which validated the clinical feasibility of flexible piezoelectric blood pressure sensors, Professor Lee’s team conducted an in-depth review of the latest advancements in cuffless wearable sensors, focusing on key technical and clinical challenges. Their review highlights clinical aspects of clinical implementation, real-time data transmission, signal quality degradation, and AI algorithm accuracy.

Professor Keon Jae Lee said, “This paper systematically demonstrates the feasibility of medical-grade wearable blood pressure sensors, overcoming what was previously considered an insurmountable challenge. We propose theoretical strategies to address technical barriers, opening new possibilities for future innovations in this field. With continued advancements, we expect these sensors to gain trust and be commercialized soon, significantly improving quality of life.”

This review entitled “Wearable blood pressure sensors for cardiovascular monitoring and machine learning algorithms for blood pressure estimation” was published in the February 18 issue of Nature Reviews Cardiology (Impact Factor: 41.7). (doi.org/10.1038/s41569-025-01127-0)

< Figure 1. Overview of wearable blood pressure sensor technologies for cardiovascular health care >

[Reference] Min S. et al., (2025) “Wearable blood pressure sensors for

cardiovascular monitoring and machine learning algorithms for blood pressure estimation.” Nature Reviews Cardiology

(doi.org/10.1038/s41569-025-01127-0)

[Main Author] Seongwook Min (Korea Advanced Institute of Science and Technology), Jaehun An (Korea Advanced Institute of Science and Technology), Jae Hee Lee (Northwestern University),

* Contact email : Professor Keon Jae Lee (keonlee@kaist.ac.kr)

2025.03.04 View 3951 -

A KAIST Research Team Develops a Novel “Bone Bandage” Material for Cracked Bones

Bone regeneration is a complex process, and existing methods to aid regeneration including transplants and growth factor transmissions face limitations such as the high cost. But recently, a piezoelectric material that can promote the growth of bone tissue has been developed.

A KAIST research team led by Professor Seungbum Hong from the Department of Materials Science and Engineering (DMSE) announced on January 25 the development of a biomimetic scaffold that generates electrical signals upon the application of pressure by utilizing the unique osteogenic ability of hydroxyapatite (HAp). This research was conducted in collaboration with a team led by Professor Jangho Kim from the Department of Convergence Biosystems Engineering at Chonnam National University.

HAp is a basic calcium phosphate material found in bones and teeth. This biocompatible mineral substance is also known to prevent tooth decay and is often used in toothpaste.

Previous studies on piezoelectric scaffolds confirmed the effects of piezoelectricity on promoting bone regeneration and improving bone fusion in various polymer-based materials, but were limited in simulating the complex cellular environment required for optimal bone tissue regeneration. However, this research suggests a new method for utilizing the unique osteogenic abilities of HAp to develop a material that mimics the environment for bone tissue in a living body.

< Figure 1. Design and characterization of piezoelectrically and topographically originated biomimetic scaffolds. (a) Schematic representation of the enhanced bone regeneration mechanism through electrical and topographical cues provided by HAp-incorporated P(VDF-TrFE) scaffolds. (b) Schematic diagram of the fabrication process. >

The research team developed a manufacturing process that fuses HAp with a polymer film. The flexible and free-standing scaffold developed through this process demonstrated its remarkable potential for promoting bone regeneration through in-vitro and in-vivo experiments in rats.

The team also identified the principles of bone regeneration that their scaffold is based on. Using atomic force microscopy (AFM), they analysed the electrical properties of the scaffold and evaluated the detailed surface properties related to cell shape and cell skeletal protein formation. They also investigated the effects of piezoelectricity and surface properties on the expression of growth factors.

Professor Hong from KAIST’s DMSE said, “We have developed a HAp-based piezoelectric composite material that can act like a ‘bone bandage’ through its ability to accelerate bone regeneration.” He added, “This research not only suggests a new direction for designing biomaterials, but is also significant in having explored the effects of piezoelectricity and surface properties on bone regeneration.”

This research, conducted by co-first authors Soyun Joo and Soyeon Kim from Professor Hong’s group, was published on ACS Applied Materials & Interfaces on January 4 under the title “Piezoelectrically and Topographically Engineered Scaffolds for Accelerating Bone Regeneration”. From Professor Kim’s group, Ph.D. candidate Yonghyun Gwon also participated as co-first author, and Professor Kim himself as a corresponding author.

< Figure 2. Analysis of piezoelectric and surface properties of the biomimetic scaffolds using atomic force microscopy. (a) PFM amplitude and phase images of box-poled composite scaffolds. The white bar represents 2 μm. (b) 3D representations of composite scaffolds paired with typical 2D line sections. (c) In vivo bone regeneration micro-CT analysis, (d) schematic representation of filler-derived electrical origins in bone regeneration. >

This research was supported by the KAIST Research and Development Team, the KUSTAR-KAIST Joint Research Center, the KAIST Global Singularity Project, and the government-funded Basic Research Project by the National Research Foundation of Korea.

2024.02.01 View 8474

A KAIST Research Team Develops a Novel “Bone Bandage” Material for Cracked Bones

Bone regeneration is a complex process, and existing methods to aid regeneration including transplants and growth factor transmissions face limitations such as the high cost. But recently, a piezoelectric material that can promote the growth of bone tissue has been developed.

A KAIST research team led by Professor Seungbum Hong from the Department of Materials Science and Engineering (DMSE) announced on January 25 the development of a biomimetic scaffold that generates electrical signals upon the application of pressure by utilizing the unique osteogenic ability of hydroxyapatite (HAp). This research was conducted in collaboration with a team led by Professor Jangho Kim from the Department of Convergence Biosystems Engineering at Chonnam National University.

HAp is a basic calcium phosphate material found in bones and teeth. This biocompatible mineral substance is also known to prevent tooth decay and is often used in toothpaste.

Previous studies on piezoelectric scaffolds confirmed the effects of piezoelectricity on promoting bone regeneration and improving bone fusion in various polymer-based materials, but were limited in simulating the complex cellular environment required for optimal bone tissue regeneration. However, this research suggests a new method for utilizing the unique osteogenic abilities of HAp to develop a material that mimics the environment for bone tissue in a living body.

< Figure 1. Design and characterization of piezoelectrically and topographically originated biomimetic scaffolds. (a) Schematic representation of the enhanced bone regeneration mechanism through electrical and topographical cues provided by HAp-incorporated P(VDF-TrFE) scaffolds. (b) Schematic diagram of the fabrication process. >

The research team developed a manufacturing process that fuses HAp with a polymer film. The flexible and free-standing scaffold developed through this process demonstrated its remarkable potential for promoting bone regeneration through in-vitro and in-vivo experiments in rats.

The team also identified the principles of bone regeneration that their scaffold is based on. Using atomic force microscopy (AFM), they analysed the electrical properties of the scaffold and evaluated the detailed surface properties related to cell shape and cell skeletal protein formation. They also investigated the effects of piezoelectricity and surface properties on the expression of growth factors.

Professor Hong from KAIST’s DMSE said, “We have developed a HAp-based piezoelectric composite material that can act like a ‘bone bandage’ through its ability to accelerate bone regeneration.” He added, “This research not only suggests a new direction for designing biomaterials, but is also significant in having explored the effects of piezoelectricity and surface properties on bone regeneration.”

This research, conducted by co-first authors Soyun Joo and Soyeon Kim from Professor Hong’s group, was published on ACS Applied Materials & Interfaces on January 4 under the title “Piezoelectrically and Topographically Engineered Scaffolds for Accelerating Bone Regeneration”. From Professor Kim’s group, Ph.D. candidate Yonghyun Gwon also participated as co-first author, and Professor Kim himself as a corresponding author.

< Figure 2. Analysis of piezoelectric and surface properties of the biomimetic scaffolds using atomic force microscopy. (a) PFM amplitude and phase images of box-poled composite scaffolds. The white bar represents 2 μm. (b) 3D representations of composite scaffolds paired with typical 2D line sections. (c) In vivo bone regeneration micro-CT analysis, (d) schematic representation of filler-derived electrical origins in bone regeneration. >

This research was supported by the KAIST Research and Development Team, the KUSTAR-KAIST Joint Research Center, the KAIST Global Singularity Project, and the government-funded Basic Research Project by the National Research Foundation of Korea.

2024.02.01 View 8474 -

KAIST Team Develops Highly-Sensitive Wearable Piezoelectric Blood Pressure Sensor for Continuous Health Monitoring

- A collaborative research team led by KAIST Professor Keon Jae Lee verifies the accuracy of the highly-sensitive sensor through clinical trials

- Commercialization of the watch and patch-type sensor is in progress

A KAIST research team led by Professor Keon Jae Lee from the Department of Materials Science and Engineering and the College of Medicine of the Catholic University of Korea has developed a highly sensitive, wearable piezoelectric blood pressure sensor.

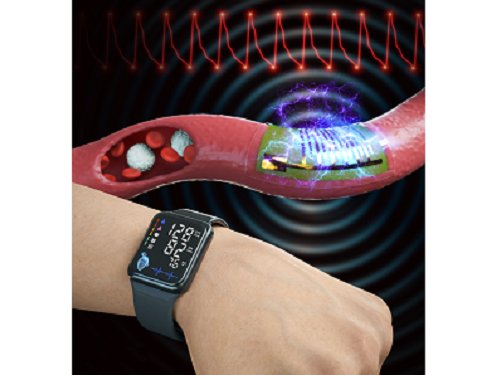

Blood pressure is a critical indicator for assessing general health and predicting stroke or heart failure. In particular, cardiovascular disease is the leading cause of global death, therefore, periodic measurement of blood pressure is crucial for personal healthcare.

Recently, there has been a growing interest in healthcare devices for continuous blood pressure monitoring. Although smart watches using LED-based photoplethysmography (PPG) technology have been on market, these devices have been limited by the accuracy constraints of optical sensors, making it hard to meet the international standards of automatic sphygmomanometers.

Professor Lee’s team has developed the wearable piezoelectric blood pressure sensor by transferring a highly sensitive, inorganic piezoelectric membrane from bulk sapphire substrates to flexible substrates. Ultrathin piezoelectric sensors with a thickness of several micrometers (one hundredth of the human hair) exhibit conformal contact with the skin to successfully collect accurate blood pressure from the subtle pulsation of the blood vessels.

Clinical trial at the St. Mary’s Hospital of the Catholic University validated the accuracy of blood pressure sensor at par with international standard with errors within ±5 mmHg and a standard deviation under 8 mmHg for both systolic and diastolic blood pressure. In addition, the research team successfully embedded the sensor on a watch-type product to enable continuous monitoring of blood pressure.

Prof. Keon Jae Lee said, “Major target of our healthcare devices is hypertensive patients for their daily medical check-up. We plan to develop a comfortable patch-type sensor to monitor blood pressure during sleep and have a start-up company commercialize these watch and patch-type products soon.”

This result titled “Clinical validation of wearable piezoelectric blood pressure sensor for health monitoring” was published in the online issue of Advanced Materials on March 24th, 2023. (DOI: 10.1002/adma.202301627)

Figure 1. Schematic illustration of the overall concept for a wearable piezoelectric blood pressure sensor (WPBPS).

Figure 2. Wearable piezoelectric blood pressure sensor (WPBPS) mounted on a watch (a) Schematic design of the WPBPS-embedded wristwatch. (b) Block diagram of the wireless communication circuit, which filters, amplifies, and transmits wireless data to portable devices. (c) Pulse waveforms transmitted from the wristwatch to the portable device by the wireless communication circuit. The inset shows a photograph of monitoring a user’s beat-to-beat pulses and their corresponding BP values in real time using the developed WPBPS-mounted wristwatch.

2023.04.17 View 9672

KAIST Team Develops Highly-Sensitive Wearable Piezoelectric Blood Pressure Sensor for Continuous Health Monitoring

- A collaborative research team led by KAIST Professor Keon Jae Lee verifies the accuracy of the highly-sensitive sensor through clinical trials

- Commercialization of the watch and patch-type sensor is in progress

A KAIST research team led by Professor Keon Jae Lee from the Department of Materials Science and Engineering and the College of Medicine of the Catholic University of Korea has developed a highly sensitive, wearable piezoelectric blood pressure sensor.

Blood pressure is a critical indicator for assessing general health and predicting stroke or heart failure. In particular, cardiovascular disease is the leading cause of global death, therefore, periodic measurement of blood pressure is crucial for personal healthcare.

Recently, there has been a growing interest in healthcare devices for continuous blood pressure monitoring. Although smart watches using LED-based photoplethysmography (PPG) technology have been on market, these devices have been limited by the accuracy constraints of optical sensors, making it hard to meet the international standards of automatic sphygmomanometers.

Professor Lee’s team has developed the wearable piezoelectric blood pressure sensor by transferring a highly sensitive, inorganic piezoelectric membrane from bulk sapphire substrates to flexible substrates. Ultrathin piezoelectric sensors with a thickness of several micrometers (one hundredth of the human hair) exhibit conformal contact with the skin to successfully collect accurate blood pressure from the subtle pulsation of the blood vessels.

Clinical trial at the St. Mary’s Hospital of the Catholic University validated the accuracy of blood pressure sensor at par with international standard with errors within ±5 mmHg and a standard deviation under 8 mmHg for both systolic and diastolic blood pressure. In addition, the research team successfully embedded the sensor on a watch-type product to enable continuous monitoring of blood pressure.

Prof. Keon Jae Lee said, “Major target of our healthcare devices is hypertensive patients for their daily medical check-up. We plan to develop a comfortable patch-type sensor to monitor blood pressure during sleep and have a start-up company commercialize these watch and patch-type products soon.”

This result titled “Clinical validation of wearable piezoelectric blood pressure sensor for health monitoring” was published in the online issue of Advanced Materials on March 24th, 2023. (DOI: 10.1002/adma.202301627)

Figure 1. Schematic illustration of the overall concept for a wearable piezoelectric blood pressure sensor (WPBPS).

Figure 2. Wearable piezoelectric blood pressure sensor (WPBPS) mounted on a watch (a) Schematic design of the WPBPS-embedded wristwatch. (b) Block diagram of the wireless communication circuit, which filters, amplifies, and transmits wireless data to portable devices. (c) Pulse waveforms transmitted from the wristwatch to the portable device by the wireless communication circuit. The inset shows a photograph of monitoring a user’s beat-to-beat pulses and their corresponding BP values in real time using the developed WPBPS-mounted wristwatch.

2023.04.17 View 9672 -

Biomimetic Resonant Acoustic Sensor Detecting Far-Distant Voices Accurately to Hit the Market

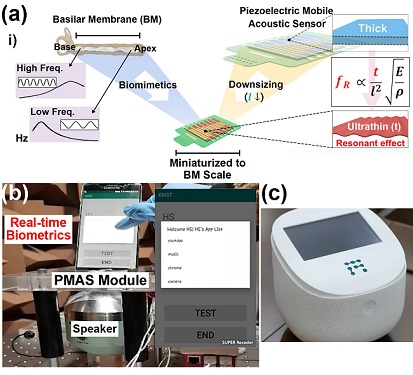

A KAIST research team led by Professor Keon Jae Lee from the Department of Materials Science and Engineering has developed a bioinspired flexible piezoelectric acoustic sensor with multi-resonant ultrathin piezoelectric membrane mimicking the basilar membrane of the human cochlea. The flexible acoustic sensor has been miniaturized for embedding into smartphones and the first commercial prototype is ready for accurate and far-distant voice detection.

In 2018, Professor Lee presented the first concept of a flexible piezoelectric acoustic sensor, inspired by the fact that humans can accurately detect far-distant voices using a multi-resonant trapezoidal membrane with 20,000 hair cells. However, previous acoustic sensors could not be integrated into commercial products like smartphones and AI speakers due to their large device size.

In this work, the research team fabricated a mobile-sized acoustic sensor by adopting ultrathin piezoelectric membranes with high sensitivity. Simulation studies proved that the ultrathin polymer underneath inorganic piezoelectric thin film can broaden the resonant bandwidth to cover the entire voice frequency range using seven channels. Based on this theory, the research team successfully demonstrated the miniaturized acoustic sensor mounted in commercial smartphones and AI speakers for machine learning-based biometric authentication and voice processing. (Please refer to the explanatory movie KAIST Flexible Piezoelectric Mobile Acoustic Sensor).

The resonant mobile acoustic sensor has superior sensitivity and multi-channel signals compared to conventional condenser microphones with a single channel, and it has shown highly accurate and far-distant speaker identification with a small amount of voice training data. The error rate of speaker identification was significantly reduced by 56% (with 150 training datasets) and 75% (with 2,800 training datasets) compared to that of a MEMS condenser device.

Professor Lee said, “Recently, Google has been targeting the ‘Wolverine Project’ on far-distant voice separation from multi-users for next-generation AI user interfaces. I expect that our multi-channel resonant acoustic sensor with abundant voice information is the best fit for this application. Currently, the mass production process is on the verge of completion, so we hope that this will be used in our daily lives very soon.”

Professor Lee also established a startup company called Fronics Inc., located both in Korea and U.S. (branch office) to commercialize this flexible acoustic sensor and is seeking collaborations with global AI companies.

These research results entitled “Biomimetic and Flexible Piezoelectric Mobile Acoustic Sensors with Multi-Resonant Ultrathin Structures for Machine Learning Biometrics” were published in Science Advances in 2021 (7, eabe5683).

-Publication

“Biomimetic and flexible piezoelectric mobile acoustic sensors with multiresonant ultrathin structures for machine learning biometrics,” Science Advances (DOI: 10.1126/sciadv.abe5683)

-Profile

Professor Keon Jae Lee

Department of Materials Science and Engineering

Flexible and Nanobio Device Lab

http://fand.kaist.ac.kr/

KAIST

2021.06.14 View 11113

Biomimetic Resonant Acoustic Sensor Detecting Far-Distant Voices Accurately to Hit the Market

A KAIST research team led by Professor Keon Jae Lee from the Department of Materials Science and Engineering has developed a bioinspired flexible piezoelectric acoustic sensor with multi-resonant ultrathin piezoelectric membrane mimicking the basilar membrane of the human cochlea. The flexible acoustic sensor has been miniaturized for embedding into smartphones and the first commercial prototype is ready for accurate and far-distant voice detection.

In 2018, Professor Lee presented the first concept of a flexible piezoelectric acoustic sensor, inspired by the fact that humans can accurately detect far-distant voices using a multi-resonant trapezoidal membrane with 20,000 hair cells. However, previous acoustic sensors could not be integrated into commercial products like smartphones and AI speakers due to their large device size.

In this work, the research team fabricated a mobile-sized acoustic sensor by adopting ultrathin piezoelectric membranes with high sensitivity. Simulation studies proved that the ultrathin polymer underneath inorganic piezoelectric thin film can broaden the resonant bandwidth to cover the entire voice frequency range using seven channels. Based on this theory, the research team successfully demonstrated the miniaturized acoustic sensor mounted in commercial smartphones and AI speakers for machine learning-based biometric authentication and voice processing. (Please refer to the explanatory movie KAIST Flexible Piezoelectric Mobile Acoustic Sensor).

The resonant mobile acoustic sensor has superior sensitivity and multi-channel signals compared to conventional condenser microphones with a single channel, and it has shown highly accurate and far-distant speaker identification with a small amount of voice training data. The error rate of speaker identification was significantly reduced by 56% (with 150 training datasets) and 75% (with 2,800 training datasets) compared to that of a MEMS condenser device.

Professor Lee said, “Recently, Google has been targeting the ‘Wolverine Project’ on far-distant voice separation from multi-users for next-generation AI user interfaces. I expect that our multi-channel resonant acoustic sensor with abundant voice information is the best fit for this application. Currently, the mass production process is on the verge of completion, so we hope that this will be used in our daily lives very soon.”

Professor Lee also established a startup company called Fronics Inc., located both in Korea and U.S. (branch office) to commercialize this flexible acoustic sensor and is seeking collaborations with global AI companies.

These research results entitled “Biomimetic and Flexible Piezoelectric Mobile Acoustic Sensors with Multi-Resonant Ultrathin Structures for Machine Learning Biometrics” were published in Science Advances in 2021 (7, eabe5683).

-Publication

“Biomimetic and flexible piezoelectric mobile acoustic sensors with multiresonant ultrathin structures for machine learning biometrics,” Science Advances (DOI: 10.1126/sciadv.abe5683)

-Profile

Professor Keon Jae Lee

Department of Materials Science and Engineering

Flexible and Nanobio Device Lab

http://fand.kaist.ac.kr/

KAIST

2021.06.14 View 11113 -

Highly Deformable Piezoelectric Nanotruss for Tactile Electronics

With the importance of non-contact environments growing due to COVID-19, tactile electronic devices using haptic technology are gaining traction as new mediums of communication.

Haptic technology is being applied in a wide array of fields such as robotics or interactive displays. haptic gloves are being used for augmented information communication technology. Efficient piezoelectric materials that can convert various mechanical stimuli into electrical signals and vice versa are a prerequisite for advancing high-performing haptic technology.

A research team led by Professor Seungbum Hong confirmed the potential of tactile devices by developing ceramic piezoelectric materials that are three times more deformable. For the fabrication of highly deformable nanomaterials, the research team built a zinc oxide hollow nanostructure using proximity field nanopatterning and atomic layered deposition. The piezoelectric coefficient was measured to be approximately 9.2 pm/V and the nanopillar compression test showed an elastic strain limit of approximately 10%, which is more than three times greater than that of the bulk zinc oxide one.

Piezoelectric ceramics have a high piezoelectric coefficient with a low elastic strain limit, whereas the opposite is true for piezoelectric polymers. Therefore, it has been very challenging to obtain good performance in both high piezoelectric coefficients as well as high elastic strain limits. To break the elastic limit of piezoelectric ceramics, the research team introduced a 3D truss-like hollow nanostructure with nanometer-scale thin walls.

According to the Griffith criterion, the fracture strength of a material is inversely proportional to the square root of the preexisting flaw size. However, a large flaw is less likely to occur in a small structure, which, in turn, enhances the strength of the material. Therefore, implementing the form of a 3D truss-like hollow nanostructure with nanometer-scale thin walls can extend the elastic limit of the material. Furthermore, a monolithic 3D structure can withstand large strains in all directions while simultaneously preventing the loss from the bottleneck. Previously, the fracture property of piezoelectric ceramic materials was difficult to control, owing to the large variance in crack sizes. However, the research team structurally limited the crack sizes to manage the fracture properties.

Professor Hong’s results demonstrate the potential for the development of highly deformable ceramic piezoelectric materials by improving the elastic limit using a 3D hollow nanostructure. Since zinc oxide has a relatively low piezoelectric coefficient compared to other piezoelectric ceramic materials, applying the proposed structure to such components promised better results in terms of the piezoelectric activity.

“With the advent of the non-contact era, the importance of emotional communication is increasing. Through the development of novel tactile interaction technologies, in addition to the current visual and auditory communication, mankind will enter a new era where they can communicate with anyone using all five senses regardless of location as if they are with them in person,” Professor Hong said.

“While additional research must be conducted to realize the application of the proposed designs for haptic enhancement devices, this study holds high value in that it resolves one of the most challenging issues in the use of piezoelectric ceramics, specifically opening new possibilities for their application by overcoming their mechanical constraints.

The research was reported in Nano Energy and supported by the Ministry of Science and ICT, the Korea Research Foundation, and the KAIST Global Singularity Research Project.

-Profile: Professor Seungbum Hong

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

2021.02.02 View 12308

Highly Deformable Piezoelectric Nanotruss for Tactile Electronics

With the importance of non-contact environments growing due to COVID-19, tactile electronic devices using haptic technology are gaining traction as new mediums of communication.

Haptic technology is being applied in a wide array of fields such as robotics or interactive displays. haptic gloves are being used for augmented information communication technology. Efficient piezoelectric materials that can convert various mechanical stimuli into electrical signals and vice versa are a prerequisite for advancing high-performing haptic technology.

A research team led by Professor Seungbum Hong confirmed the potential of tactile devices by developing ceramic piezoelectric materials that are three times more deformable. For the fabrication of highly deformable nanomaterials, the research team built a zinc oxide hollow nanostructure using proximity field nanopatterning and atomic layered deposition. The piezoelectric coefficient was measured to be approximately 9.2 pm/V and the nanopillar compression test showed an elastic strain limit of approximately 10%, which is more than three times greater than that of the bulk zinc oxide one.

Piezoelectric ceramics have a high piezoelectric coefficient with a low elastic strain limit, whereas the opposite is true for piezoelectric polymers. Therefore, it has been very challenging to obtain good performance in both high piezoelectric coefficients as well as high elastic strain limits. To break the elastic limit of piezoelectric ceramics, the research team introduced a 3D truss-like hollow nanostructure with nanometer-scale thin walls.

According to the Griffith criterion, the fracture strength of a material is inversely proportional to the square root of the preexisting flaw size. However, a large flaw is less likely to occur in a small structure, which, in turn, enhances the strength of the material. Therefore, implementing the form of a 3D truss-like hollow nanostructure with nanometer-scale thin walls can extend the elastic limit of the material. Furthermore, a monolithic 3D structure can withstand large strains in all directions while simultaneously preventing the loss from the bottleneck. Previously, the fracture property of piezoelectric ceramic materials was difficult to control, owing to the large variance in crack sizes. However, the research team structurally limited the crack sizes to manage the fracture properties.

Professor Hong’s results demonstrate the potential for the development of highly deformable ceramic piezoelectric materials by improving the elastic limit using a 3D hollow nanostructure. Since zinc oxide has a relatively low piezoelectric coefficient compared to other piezoelectric ceramic materials, applying the proposed structure to such components promised better results in terms of the piezoelectric activity.

“With the advent of the non-contact era, the importance of emotional communication is increasing. Through the development of novel tactile interaction technologies, in addition to the current visual and auditory communication, mankind will enter a new era where they can communicate with anyone using all five senses regardless of location as if they are with them in person,” Professor Hong said.

“While additional research must be conducted to realize the application of the proposed designs for haptic enhancement devices, this study holds high value in that it resolves one of the most challenging issues in the use of piezoelectric ceramics, specifically opening new possibilities for their application by overcoming their mechanical constraints.

The research was reported in Nano Energy and supported by the Ministry of Science and ICT, the Korea Research Foundation, and the KAIST Global Singularity Research Project.

-Profile: Professor Seungbum Hong

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

2021.02.02 View 12308 -

Sturdy Fabric-Based Piezoelectric Energy Harvester Takes Us One Step Closer to Wearable Electronics

KAIST researchers presented a highly flexible but sturdy wearable piezoelectric harvester using the simple and easy fabrication process of hot pressing and tape casting. This energy harvester, which has record high interfacial adhesion strength, will take us one step closer to being able to manufacture embedded wearable electronics.

A research team led by Professor Seungbum Hong said that the novelty of this result lies in its simplicity, applicability, durability, and its new characterization of wearable electronic devices.

Wearable devices are increasingly being used in a wide array of applications from small electronics to embedded devices such as sensors, actuators, displays, and energy harvesters.

Despite their many advantages, high costs and complex fabrication processes remained challenges for reaching commercialization. In addition, their durability was frequently questioned. To address these issues, Professor Hong’s team developed a new fabrication process and analysis technology for testing the mechanical properties of affordable wearable devices.

For this process, the research team used a hot pressing and tape casting procedure to connect the fabric structures of polyester and a polymer film. Hot pressing has usually been used when making batteries and fuel cells due to its high adhesiveness. Above all, the process takes only two to three minutes.

The newly developed fabrication process will enable the direct application of a device into general garments using hot pressing just as graphic patches can be attached to garments using a heat press.

In particular, when the polymer film is hot pressed onto a fabric below its crystallization temperature, it transforms into an amorphous state. In this state, it compactly attaches to the concave surface of the fabric and infiltrates into the gaps between the transverse wefts and longitudinal warps. These features result in high interfacial adhesion strength. For this reason, hot pressing has the potential to reduce the cost of fabrication through the direct application of fabric-based wearable devices to common garments.

In addition to the conventional durability test of bending cycles, the newly introduced surface and interfacial cutting analysis system proved the high mechanical durability of the fabric-based wearable device by measuring the high interfacial adhesion strength between the fabric and the polymer film. Professor Hong said the study lays a new foundation for the manufacturing process and analysis of wearable devices using fabrics and polymers.

He added that his team first used the surface and interfacial cutting analysis system (SAICAS) in the field of wearable electronics to test the mechanical properties of polymer-based wearable devices. Their surface and interfacial cutting analysis system is more precise than conventional methods (peel test, tape test, and microstretch test) because it qualitatively and quantitatively measures the adhesion strength.

Professor Hong explained, “This study could enable the commercialization of highly durable wearable devices based on the analysis of their interfacial adhesion strength. Our study lays a new foundation for the manufacturing process and analysis of other devices using fabrics and polymers. We look forward to fabric-based wearable electronics hitting the market very soon.”

The results of this study were registered as a domestic patent in Korea last year, and published in Nano Energy this month. This study has been conducted through collaboration with Professor Yong Min Lee in the Department of Energy Science and Engineering at DGIST, Professor Kwangsoo No in the Department of Materials Science and Engineering at KAIST, and Professor Seunghwa Ryu in the Department of Mechanical Engineering at KAIST.

This study was supported by the High-Risk High-Return Project and the Global Singularity Research Project at KAIST, the National Research Foundation, and the Ministry of Science and ICT in Korea.

-Publication:

Jaegyu Kim, Seoungwoo Byun, Sangryun Lee, Jeongjae Ryu, Seongwoo Cho, Chungik Oh, Hongjun Kim, Kwangsoo No, Seunghwa Ryu, Yong Min Lee, Seungbum Hong*, Nano Energy 75 (2020), 104992.

https://doi.org/10.1016/j.nanoen.2020.104992

-Profile: Professor Seungbum Hong

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

2020.09.17 View 15067

Sturdy Fabric-Based Piezoelectric Energy Harvester Takes Us One Step Closer to Wearable Electronics

KAIST researchers presented a highly flexible but sturdy wearable piezoelectric harvester using the simple and easy fabrication process of hot pressing and tape casting. This energy harvester, which has record high interfacial adhesion strength, will take us one step closer to being able to manufacture embedded wearable electronics.

A research team led by Professor Seungbum Hong said that the novelty of this result lies in its simplicity, applicability, durability, and its new characterization of wearable electronic devices.

Wearable devices are increasingly being used in a wide array of applications from small electronics to embedded devices such as sensors, actuators, displays, and energy harvesters.

Despite their many advantages, high costs and complex fabrication processes remained challenges for reaching commercialization. In addition, their durability was frequently questioned. To address these issues, Professor Hong’s team developed a new fabrication process and analysis technology for testing the mechanical properties of affordable wearable devices.

For this process, the research team used a hot pressing and tape casting procedure to connect the fabric structures of polyester and a polymer film. Hot pressing has usually been used when making batteries and fuel cells due to its high adhesiveness. Above all, the process takes only two to three minutes.

The newly developed fabrication process will enable the direct application of a device into general garments using hot pressing just as graphic patches can be attached to garments using a heat press.

In particular, when the polymer film is hot pressed onto a fabric below its crystallization temperature, it transforms into an amorphous state. In this state, it compactly attaches to the concave surface of the fabric and infiltrates into the gaps between the transverse wefts and longitudinal warps. These features result in high interfacial adhesion strength. For this reason, hot pressing has the potential to reduce the cost of fabrication through the direct application of fabric-based wearable devices to common garments.

In addition to the conventional durability test of bending cycles, the newly introduced surface and interfacial cutting analysis system proved the high mechanical durability of the fabric-based wearable device by measuring the high interfacial adhesion strength between the fabric and the polymer film. Professor Hong said the study lays a new foundation for the manufacturing process and analysis of wearable devices using fabrics and polymers.

He added that his team first used the surface and interfacial cutting analysis system (SAICAS) in the field of wearable electronics to test the mechanical properties of polymer-based wearable devices. Their surface and interfacial cutting analysis system is more precise than conventional methods (peel test, tape test, and microstretch test) because it qualitatively and quantitatively measures the adhesion strength.

Professor Hong explained, “This study could enable the commercialization of highly durable wearable devices based on the analysis of their interfacial adhesion strength. Our study lays a new foundation for the manufacturing process and analysis of other devices using fabrics and polymers. We look forward to fabric-based wearable electronics hitting the market very soon.”

The results of this study were registered as a domestic patent in Korea last year, and published in Nano Energy this month. This study has been conducted through collaboration with Professor Yong Min Lee in the Department of Energy Science and Engineering at DGIST, Professor Kwangsoo No in the Department of Materials Science and Engineering at KAIST, and Professor Seunghwa Ryu in the Department of Mechanical Engineering at KAIST.

This study was supported by the High-Risk High-Return Project and the Global Singularity Research Project at KAIST, the National Research Foundation, and the Ministry of Science and ICT in Korea.

-Publication:

Jaegyu Kim, Seoungwoo Byun, Sangryun Lee, Jeongjae Ryu, Seongwoo Cho, Chungik Oh, Hongjun Kim, Kwangsoo No, Seunghwa Ryu, Yong Min Lee, Seungbum Hong*, Nano Energy 75 (2020), 104992.

https://doi.org/10.1016/j.nanoen.2020.104992

-Profile: Professor Seungbum Hong

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

2020.09.17 View 15067 -

Stretchable Multi-functional Fiber for Energy Harvesting and Strain Sensing

(from left: Professor Steve Park, Jeongjae Ryu and Professor Seungbum Hong)

Fiber-based electronics are expected to play a vital role in next-generation wearable electronics. Woven into textiles, they can provide higher durability, comfort, and integrated multi-functionality. A KAIST team has developed a stretchable multi-functional fiber (SMF) that can harvest energy and detect strain, which can be applied to future wearable electronics.

With wearable electronics, health and physical conditions can be assessed by analyzing biological signals from the human body, such as pulse and muscle movements. Fibers are highly suitable for future wearable electronics because they can be easily integrated into textiles, which are designed to be conformable to curvilinear surfaces and comfortable to wear. Moreover, their weave structures offer support that makes them resistant to fatigue. Many research groups have developed fiber-based strain sensors to sense external biological signals. However, their sensitivities were relatively low.

The applicability of wearable devices is currently limited by their power source, as the size, weight, and lifetime of the battery lessens their versatility. Harvesting mechanical energy from the human body is a promising solution to overcome such limitations by utilizing various types of motions like bending, stretching, and pressing. However, previously reported, fiber-based energy harvesters were not stretchable and could not fully harvest the available mechanical energy.

Professor Seungbum Hong and Professor Steve Park from the Department of Materials Science and Engineering and their team fabricated a stretchable fiber by using a ferroelectric layer composed of P(VDF-TrFE)/PDMS sandwiched between stretchable electrodes composed of a composite of multi-walled carbon nanotubes (MWCNT) and poly 3,4-ethylenedioxythiophene polystyrenesulfonate (PEDOT:PSS).

Cracks formed in MWCNT/PEDOT:PSS layer help the fiber show high sensitivity compared to the previously reported fiber strain sensors. Furthermore, the new fiber can harvest mechanical energy under various mechanical stimuli such as stretching, tapping, and injecting water into the fiber using the piezoelectric effect of the P(VDF-TrFE)/PDMS layer.

Professor Hong said, “This new fiber has various functionalities and makes the device simple and compact. It is a core technology for developing wearable devices with energy harvesting and strain sensing capabilities.”

This article, led by PhD candidate Jeongjae Ryu, was published in the January 2019 issue of Nano Energy.

Figure 1.Schematic illustration of an SMF fiber and its piezoelectric voltage output and response to strain.

Figure 2. Photographs of a stretchable multi-functional fiber being stretched by 100%, bent, and twisted.

2019.01.31 View 9716

Stretchable Multi-functional Fiber for Energy Harvesting and Strain Sensing

(from left: Professor Steve Park, Jeongjae Ryu and Professor Seungbum Hong)

Fiber-based electronics are expected to play a vital role in next-generation wearable electronics. Woven into textiles, they can provide higher durability, comfort, and integrated multi-functionality. A KAIST team has developed a stretchable multi-functional fiber (SMF) that can harvest energy and detect strain, which can be applied to future wearable electronics.

With wearable electronics, health and physical conditions can be assessed by analyzing biological signals from the human body, such as pulse and muscle movements. Fibers are highly suitable for future wearable electronics because they can be easily integrated into textiles, which are designed to be conformable to curvilinear surfaces and comfortable to wear. Moreover, their weave structures offer support that makes them resistant to fatigue. Many research groups have developed fiber-based strain sensors to sense external biological signals. However, their sensitivities were relatively low.

The applicability of wearable devices is currently limited by their power source, as the size, weight, and lifetime of the battery lessens their versatility. Harvesting mechanical energy from the human body is a promising solution to overcome such limitations by utilizing various types of motions like bending, stretching, and pressing. However, previously reported, fiber-based energy harvesters were not stretchable and could not fully harvest the available mechanical energy.

Professor Seungbum Hong and Professor Steve Park from the Department of Materials Science and Engineering and their team fabricated a stretchable fiber by using a ferroelectric layer composed of P(VDF-TrFE)/PDMS sandwiched between stretchable electrodes composed of a composite of multi-walled carbon nanotubes (MWCNT) and poly 3,4-ethylenedioxythiophene polystyrenesulfonate (PEDOT:PSS).

Cracks formed in MWCNT/PEDOT:PSS layer help the fiber show high sensitivity compared to the previously reported fiber strain sensors. Furthermore, the new fiber can harvest mechanical energy under various mechanical stimuli such as stretching, tapping, and injecting water into the fiber using the piezoelectric effect of the P(VDF-TrFE)/PDMS layer.

Professor Hong said, “This new fiber has various functionalities and makes the device simple and compact. It is a core technology for developing wearable devices with energy harvesting and strain sensing capabilities.”

This article, led by PhD candidate Jeongjae Ryu, was published in the January 2019 issue of Nano Energy.

Figure 1.Schematic illustration of an SMF fiber and its piezoelectric voltage output and response to strain.

Figure 2. Photographs of a stretchable multi-functional fiber being stretched by 100%, bent, and twisted.

2019.01.31 View 9716 -

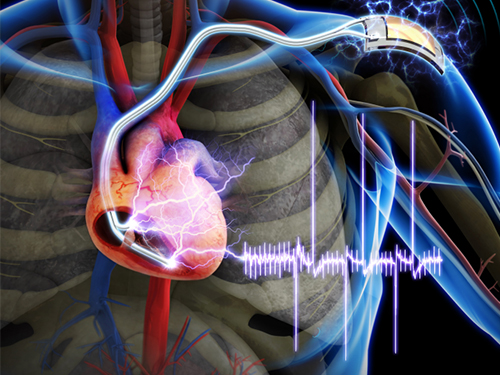

The First Demonstration of a Self-powered Cardiac Pacemaker

As the number of pacemakers implanted each year reaches into the millions worldwide, improving the lifespan of pacemaker batteries has been of great concern for developers and manufacturers. Currently, pacemaker batteries last seven years on average, requiring frequent replacements, which may pose patients to a potential risk involved in medical procedures.

A research team from the Korea Advanced Institute of Science and Technology (KAIST), headed by Professor Keon Jae Lee of the Department of Materials Science and Engineering at KAIST and Professor Boyoung Joung, M.D. of the Division of Cardiology at Severance Hospital of Yonsei University, has developed a self-powered artificial cardiac pacemaker that is operated semi-permanently by a flexible piezoelectric nanogenerator.

The artificial cardiac pacemaker is widely acknowledged as medical equipment that is integrated into the human body to regulate the heartbeats through electrical stimulation to contract the cardiac muscles of people who suffer from arrhythmia. However, repeated surgeries to replace pacemaker batteries have exposed elderly patients to health risks such as infections or severe bleeding during operations.

The team’s newly designed flexible piezoelectric nanogenerator directly stimulated a living rat’s heart using electrical energy converted from the small body movements of the rat. This technology could facilitate the use of self-powered flexible energy harvesters, not only prolonging the lifetime of cardiac pacemakers but also realizing real-time heart monitoring.

The research team fabricated high-performance flexible nanogenerators utilizing a bulk single-crystal PMN-PT thin film (iBULe Photonics). The harvested energy reached up to 8.2 V and 0.22 mA by bending and pushing motions, which were high enough values to directly stimulate the rat’s heart.

Professor Keon Jae Lee said:

“For clinical purposes, the current achievement will benefit the development of self-powered cardiac pacemakers as well as prevent heart attacks via the real-time diagnosis of heart arrhythmia. In addition, the flexible piezoelectric nanogenerator could also be utilized as an electrical source for various implantable medical devices.”

This research result was described in the April online issue of Advanced Materials (“Self-Powered Cardiac Pacemaker Enabled by Flexible Single Crystalline PMN-PT Piezoelectric Energy Harvester”: http://onlinelibrary.wiley.com/doi/10.1002/adma.201400562/abstract).

Youtube link: http://www.youtube.com/watch?v=ZWYT2cU_Mog&feature=youtu.be

Picture Caption: A self-powered cardiac pacemaker is enabled by a flexible piezoelectric energy harvester.

2014.06.25 View 18121

The First Demonstration of a Self-powered Cardiac Pacemaker

As the number of pacemakers implanted each year reaches into the millions worldwide, improving the lifespan of pacemaker batteries has been of great concern for developers and manufacturers. Currently, pacemaker batteries last seven years on average, requiring frequent replacements, which may pose patients to a potential risk involved in medical procedures.

A research team from the Korea Advanced Institute of Science and Technology (KAIST), headed by Professor Keon Jae Lee of the Department of Materials Science and Engineering at KAIST and Professor Boyoung Joung, M.D. of the Division of Cardiology at Severance Hospital of Yonsei University, has developed a self-powered artificial cardiac pacemaker that is operated semi-permanently by a flexible piezoelectric nanogenerator.

The artificial cardiac pacemaker is widely acknowledged as medical equipment that is integrated into the human body to regulate the heartbeats through electrical stimulation to contract the cardiac muscles of people who suffer from arrhythmia. However, repeated surgeries to replace pacemaker batteries have exposed elderly patients to health risks such as infections or severe bleeding during operations.

The team’s newly designed flexible piezoelectric nanogenerator directly stimulated a living rat’s heart using electrical energy converted from the small body movements of the rat. This technology could facilitate the use of self-powered flexible energy harvesters, not only prolonging the lifetime of cardiac pacemakers but also realizing real-time heart monitoring.

The research team fabricated high-performance flexible nanogenerators utilizing a bulk single-crystal PMN-PT thin film (iBULe Photonics). The harvested energy reached up to 8.2 V and 0.22 mA by bending and pushing motions, which were high enough values to directly stimulate the rat’s heart.

Professor Keon Jae Lee said:

“For clinical purposes, the current achievement will benefit the development of self-powered cardiac pacemakers as well as prevent heart attacks via the real-time diagnosis of heart arrhythmia. In addition, the flexible piezoelectric nanogenerator could also be utilized as an electrical source for various implantable medical devices.”

This research result was described in the April online issue of Advanced Materials (“Self-Powered Cardiac Pacemaker Enabled by Flexible Single Crystalline PMN-PT Piezoelectric Energy Harvester”: http://onlinelibrary.wiley.com/doi/10.1002/adma.201400562/abstract).

Youtube link: http://www.youtube.com/watch?v=ZWYT2cU_Mog&feature=youtu.be

Picture Caption: A self-powered cardiac pacemaker is enabled by a flexible piezoelectric energy harvester.

2014.06.25 View 18121 -

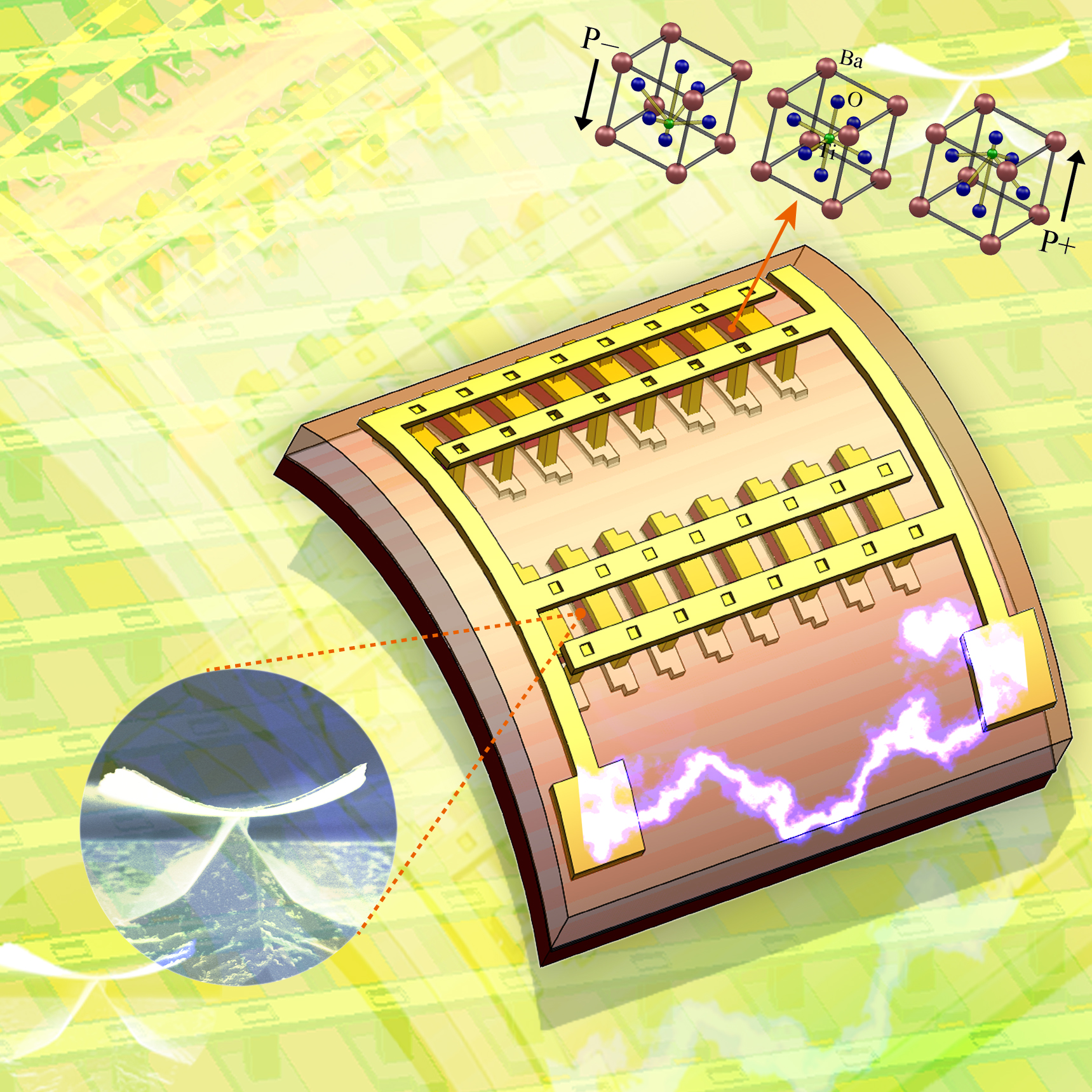

Flexible Nanogenerator Technology

KAIST research team successfully developed the foundation technology that will enable to fabrication of low cost, large area nanogenerator.

Professor Lee Gun Jae’s team (Department of Materials Science and Engineering) published a dissertation on a nanogenerator using nanocomplexes as the cover dissertation of the June edition of Advanced Materials.

The developed technology is receiving rave reviews for having overcome the complex and size limitations of the nanogenerator fabrication process.

A nanogenerator is an electricity generator that uses materials in the nanoscale and uses piezoelectricity that creates electricity with the application of physical force.

The generation technology using piezoelectricity was appointed as one of top 10 promising technologies by MIT in 2009 and was included in the 45 innovative technologies that will shake the world by Popular Science Magazine in 2010.

The only nanogenerator thus far was the ZnO model suggested by Georgia Tech’s Professor Zhong Lin Wang in 2005.

Professor Lee’s team used ceramic thin film material BaTiO3 which has 15~20 times greater piezoelectric capacity than ZnO and thus improved the overall performance of the device. The use of a nanocomplex allows large scale production and the simplification of the fabrication process itself.

The team created a mixture of PDMS (polydimethylsiloxane) with BaTiO3 and either of CNT (Carbon Nanotube) or RGO (Reduced Graphene Oxide) which has high electrical conductivity and applied this mixture to create a large scale nanogenerator.

2012.06.18 View 15277

Flexible Nanogenerator Technology

KAIST research team successfully developed the foundation technology that will enable to fabrication of low cost, large area nanogenerator.

Professor Lee Gun Jae’s team (Department of Materials Science and Engineering) published a dissertation on a nanogenerator using nanocomplexes as the cover dissertation of the June edition of Advanced Materials.

The developed technology is receiving rave reviews for having overcome the complex and size limitations of the nanogenerator fabrication process.

A nanogenerator is an electricity generator that uses materials in the nanoscale and uses piezoelectricity that creates electricity with the application of physical force.

The generation technology using piezoelectricity was appointed as one of top 10 promising technologies by MIT in 2009 and was included in the 45 innovative technologies that will shake the world by Popular Science Magazine in 2010.

The only nanogenerator thus far was the ZnO model suggested by Georgia Tech’s Professor Zhong Lin Wang in 2005.

Professor Lee’s team used ceramic thin film material BaTiO3 which has 15~20 times greater piezoelectric capacity than ZnO and thus improved the overall performance of the device. The use of a nanocomplex allows large scale production and the simplification of the fabrication process itself.

The team created a mixture of PDMS (polydimethylsiloxane) with BaTiO3 and either of CNT (Carbon Nanotube) or RGO (Reduced Graphene Oxide) which has high electrical conductivity and applied this mixture to create a large scale nanogenerator.

2012.06.18 View 15277 -

The KAIST & GIT team developed a power generation technology using bendable thin film nano-materials.

Figure description: Flexible thin film nanomaterials produce electricity.

Can a heart implanted micro robot operate permanently?

Can cell phones and tiny robots implanted in the heart operate permanently without having their batteries charged?

It might sound like science fiction, but these things seem to be possible in the near future. The team of Prof. Keon Jae Lee (KAIST, Dept. of Materials Science and Engineering) and Prof. Zhong Lin Wang (Georgia Institute of Technology, Dept. of Materials Science and Engineering) has developed new forms of highly efficient, flexible nanogenerator technology using the freely bendable piezoelectric ceramic thin film nano-materials that can convert tiny movements of the human body (such as heart beats and blood flow) into electrical energy.

The piezoelectric effect refers to voltage generation when pressure or bending strength is applied to piezoelectric materials. The ceramics, containing a perovskite structure, have a high piezoelectric efficiency. Until now, it has been very difficult to use these ceramic materials to fabricate flexible electronic systems due to their brittle property.

The research team, however, has succeeded in developing a bio-eco-friendly ceramic thin film nanogenerator that is freely bendable without breakdown.

Nanogenerator technology, a power generating system without wires or batteries, combines nanotechnology with piezoelectrics that can be used not only in personal mobile electronics but also in bio-implantable sensors or as an energy source for micro robots. Energy sources in nature (wind, vibration, and sound) and biomechanical forces produced by the human body (heart beats, blood flow, and muscle contraction/relaxation) can infinitely produce nonpolluting energy. (Nanogenerator produces electricity by external forces: http://www.youtube.com/watch?v=tvj0SsBqpBw)

Prof. Keon Jae Lee (KAIST) was involved in the first co-invention of “High Performance Flexible Single Crystal Electronics” during his PhD course at the University of Illinois at Urbana-Champaign. This nanogenerator technology, based on the previous invention, utilized the similar protocol of transferring ceramic thin film nano-materials on flexible substrates and produced voltage generation between electrodes.

Prof. Zhong Lin Wang (Georgia Tech, inventor of the nanogenerator) said, “This technology can be used to turn on an LED by slightly modifying circuits and operate touchable flexible displays. In addition, thin film nano-materials (‘barium titanate’) of this research have the property of both high efficiency and lead-free bio compatibility, which can be used in future medical applications.” This result is published in November online issue of ‘Nano Letters’ ACS journal.

<Video>

Youtube link: http://www.youtube.com/watch?v=tvj0SsBqpBw

Thin Film Nanogenerator produces electricity by external forces.

2010.11.23 View 17377

The KAIST & GIT team developed a power generation technology using bendable thin film nano-materials.

Figure description: Flexible thin film nanomaterials produce electricity.

Can a heart implanted micro robot operate permanently?

Can cell phones and tiny robots implanted in the heart operate permanently without having their batteries charged?

It might sound like science fiction, but these things seem to be possible in the near future. The team of Prof. Keon Jae Lee (KAIST, Dept. of Materials Science and Engineering) and Prof. Zhong Lin Wang (Georgia Institute of Technology, Dept. of Materials Science and Engineering) has developed new forms of highly efficient, flexible nanogenerator technology using the freely bendable piezoelectric ceramic thin film nano-materials that can convert tiny movements of the human body (such as heart beats and blood flow) into electrical energy.

The piezoelectric effect refers to voltage generation when pressure or bending strength is applied to piezoelectric materials. The ceramics, containing a perovskite structure, have a high piezoelectric efficiency. Until now, it has been very difficult to use these ceramic materials to fabricate flexible electronic systems due to their brittle property.

The research team, however, has succeeded in developing a bio-eco-friendly ceramic thin film nanogenerator that is freely bendable without breakdown.

Nanogenerator technology, a power generating system without wires or batteries, combines nanotechnology with piezoelectrics that can be used not only in personal mobile electronics but also in bio-implantable sensors or as an energy source for micro robots. Energy sources in nature (wind, vibration, and sound) and biomechanical forces produced by the human body (heart beats, blood flow, and muscle contraction/relaxation) can infinitely produce nonpolluting energy. (Nanogenerator produces electricity by external forces: http://www.youtube.com/watch?v=tvj0SsBqpBw)

Prof. Keon Jae Lee (KAIST) was involved in the first co-invention of “High Performance Flexible Single Crystal Electronics” during his PhD course at the University of Illinois at Urbana-Champaign. This nanogenerator technology, based on the previous invention, utilized the similar protocol of transferring ceramic thin film nano-materials on flexible substrates and produced voltage generation between electrodes.

Prof. Zhong Lin Wang (Georgia Tech, inventor of the nanogenerator) said, “This technology can be used to turn on an LED by slightly modifying circuits and operate touchable flexible displays. In addition, thin film nano-materials (‘barium titanate’) of this research have the property of both high efficiency and lead-free bio compatibility, which can be used in future medical applications.” This result is published in November online issue of ‘Nano Letters’ ACS journal.

<Video>

Youtube link: http://www.youtube.com/watch?v=tvj0SsBqpBw

Thin Film Nanogenerator produces electricity by external forces.

2010.11.23 View 17377