mask

-

A KAIST Team Develops Face-Conforming LED Mask Showing 340% Improved Efficacy in Deep Skin Elasticity

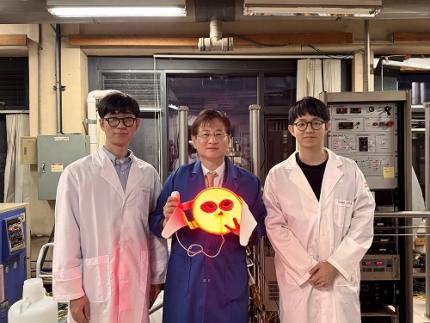

- A KAIST research team led by Professor Keon Jae Lee has developed a deep skin-stimulating LED mask which has been verified in clinical trials to improve dermis elasticity by 340%.

< Figure 1. Overall concept of face-fit surface-lighting micro-LEDs (FSLED) mask. a. Optical image of the FSLED mask showing uniform surface-lighting. schematic illustration of the FSLED mask. The 2D to 3D transformation procedure b. Difference in cosmetic effect on deep skin elasticity, wrinkles, and sagging between FSLED mask and CLED mask. (improvement percentage in eight weeks) >

Conventional LED masks, with their rigid design, fail to conform closely to the skin's contours. This limitation causes substantial light reflection, with up to 90% reflected over a distance of 2 cm, reducing light penetration and limiting stimulation of the deep skin layers essential for effective skin rejuvenation.

To address these challenges, Professor Lee's team developed a face-conforming surface lighting micro-LED (FSLED) mask, which can provide uniform photostimulation to the dermis. The key technology lies in the mask's ability to deliver uniform light to deep skin tissues while maintaining a conformal skin attachment. This is achieved through a 3D origami structure, integrated with 3,770 micro-LEDs and flexible surface light-diffusion layer, minimizing the gaps between the light source and the skin.

In clinical trials involving 33 participants, the FSLED mask demonstrated a 340% improvement in deep skin elasticity compared to conventional LED masks, proving its efficacy in significantly reducing skin wrinkles, sagging and aging.

Professor Keon Jae Lee said, “The FSLED mask provides cosmetic benefits to the entire facial dermis without the side effects of low-temperature burns, making home-care anti-aging treatment that enhances the quality of human life possible. The product is being manufactured by Fronics, KAIST startup company, and will be distributed globally through Amorepacific's network, with sales starting in November.”

This result titled “Clinical Validation of Face-fit Surface-lighting Micro Light-emitting Diode Mask for Skin Anti-aging Treatment”, in which Min Seo Kim, a student of the Master-Doctorate integrated program, and Jaehun An, a Ph.D. candidate, in the Department of Materials Science and Engineering of KAIST, took part as co-first authors, was published in Advanced Materials on October 22nd, 2024 (DOI: 10.1002/adma.202411651).

Introductory Video: Face-conforming surface LED mask for skin anti-aging ( https://www.youtube.com/watch?v=kSccLwx8N_w )

2024.10.29 View 7526

A KAIST Team Develops Face-Conforming LED Mask Showing 340% Improved Efficacy in Deep Skin Elasticity

- A KAIST research team led by Professor Keon Jae Lee has developed a deep skin-stimulating LED mask which has been verified in clinical trials to improve dermis elasticity by 340%.

< Figure 1. Overall concept of face-fit surface-lighting micro-LEDs (FSLED) mask. a. Optical image of the FSLED mask showing uniform surface-lighting. schematic illustration of the FSLED mask. The 2D to 3D transformation procedure b. Difference in cosmetic effect on deep skin elasticity, wrinkles, and sagging between FSLED mask and CLED mask. (improvement percentage in eight weeks) >

Conventional LED masks, with their rigid design, fail to conform closely to the skin's contours. This limitation causes substantial light reflection, with up to 90% reflected over a distance of 2 cm, reducing light penetration and limiting stimulation of the deep skin layers essential for effective skin rejuvenation.

To address these challenges, Professor Lee's team developed a face-conforming surface lighting micro-LED (FSLED) mask, which can provide uniform photostimulation to the dermis. The key technology lies in the mask's ability to deliver uniform light to deep skin tissues while maintaining a conformal skin attachment. This is achieved through a 3D origami structure, integrated with 3,770 micro-LEDs and flexible surface light-diffusion layer, minimizing the gaps between the light source and the skin.

In clinical trials involving 33 participants, the FSLED mask demonstrated a 340% improvement in deep skin elasticity compared to conventional LED masks, proving its efficacy in significantly reducing skin wrinkles, sagging and aging.

Professor Keon Jae Lee said, “The FSLED mask provides cosmetic benefits to the entire facial dermis without the side effects of low-temperature burns, making home-care anti-aging treatment that enhances the quality of human life possible. The product is being manufactured by Fronics, KAIST startup company, and will be distributed globally through Amorepacific's network, with sales starting in November.”

This result titled “Clinical Validation of Face-fit Surface-lighting Micro Light-emitting Diode Mask for Skin Anti-aging Treatment”, in which Min Seo Kim, a student of the Master-Doctorate integrated program, and Jaehun An, a Ph.D. candidate, in the Department of Materials Science and Engineering of KAIST, took part as co-first authors, was published in Advanced Materials on October 22nd, 2024 (DOI: 10.1002/adma.202411651).

Introductory Video: Face-conforming surface LED mask for skin anti-aging ( https://www.youtube.com/watch?v=kSccLwx8N_w )

2024.10.29 View 7526 -

Professor Il-Doo Kim Receives the Science Minister’s Award

Professor Il-Doo Kim from the Department of Materials Science and Engineering received the Science and ICT Minister’s Award in recognition of his commercialization and technology transfer achievements during the Day of IP celebration.

Professor Kim, who has made over 222 patents application and registration home and abroad, has advanced toxic gas detection and breath gas sensor technology by arraying nanosensor fibers. His technological advances in micro-electro-mechanical systems (MEMS) helped to advance the commercialization of the MEMS-related sensor and improve its overall competitiveness.

He founded the Il-Doo Kim Research Center in 2019 and focuses on the commercialization of nanofiber manufacturing through electrospinning and highly efficient nanofiber filters. For instance, he succeeded in manufacturing a nano-filter recyclable mask that maintains excellent filtering efficiency even after hand washing through the development of proprietary technology that aligns nanofibers with a diameter of 100~500 nanometers in orthogonal or unidirectional directions.

Professor Kim also serves as an associate editor at ACS Nano. He said, “The importance of IP goes without saying. I look forward to the registration and application of more KAIST patents leading to commercialization, paving the way for national technological competitiveness.”

2021.09.15 View 8017

Professor Il-Doo Kim Receives the Science Minister’s Award

Professor Il-Doo Kim from the Department of Materials Science and Engineering received the Science and ICT Minister’s Award in recognition of his commercialization and technology transfer achievements during the Day of IP celebration.

Professor Kim, who has made over 222 patents application and registration home and abroad, has advanced toxic gas detection and breath gas sensor technology by arraying nanosensor fibers. His technological advances in micro-electro-mechanical systems (MEMS) helped to advance the commercialization of the MEMS-related sensor and improve its overall competitiveness.

He founded the Il-Doo Kim Research Center in 2019 and focuses on the commercialization of nanofiber manufacturing through electrospinning and highly efficient nanofiber filters. For instance, he succeeded in manufacturing a nano-filter recyclable mask that maintains excellent filtering efficiency even after hand washing through the development of proprietary technology that aligns nanofibers with a diameter of 100~500 nanometers in orthogonal or unidirectional directions.

Professor Kim also serves as an associate editor at ACS Nano. He said, “The importance of IP goes without saying. I look forward to the registration and application of more KAIST patents leading to commercialization, paving the way for national technological competitiveness.”

2021.09.15 View 8017 -

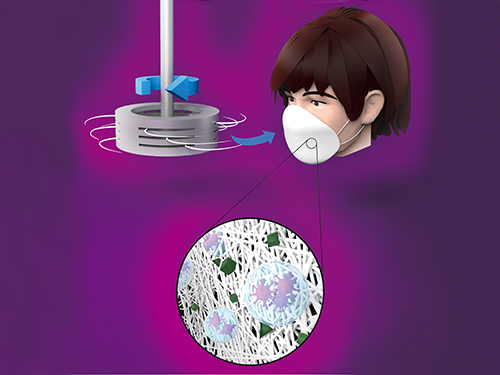

Centrifugal Multispun Nanofibers Put a New Spin on COVID-19 Masks

KAIST researchers have developed a novel nanofiber production technique called ‘centrifugal multispinning’ that will open the door for the safe and cost-effective mass production of high-performance polymer nanofibers. This new technique, which has shown up to a 300 times higher nanofiber production rate per hour than that of the conventional electrospinning method, has many potential applications including the development of face mask filters for coronavirus protection.

Nanofibers make good face mask filters because their mechanical interactions with aerosol particles give them a greater ability to capture more than 90% of harmful particles such as fine dust and virus-containing droplets.

The impact of the COVID-19 pandemic has further accelerated the growing demand in recent years for a better kind of face mask. A polymer nanofiber-based mask filter that can more effectively block harmful particles has also been in higher demand as the pandemic continues.

‘Electrospinning’ has been a common process used to prepare fine and uniform polymer nanofibers, but in terms of safety, cost-effectiveness, and mass production, it has several drawbacks. The electrospinning method requires a high-voltage electric field and electrically conductive target, and this hinders the safe and cost-effective mass production of polymer nanofibers.

In response to this shortcoming, ‘centrifugal spinning’ that utilizes centrifugal force instead of high voltage to produce polymer nanofibers has been suggested as a safer and more cost-effective alternative to the electrospinning. Easy scalability is another advantage, as this technology only requires a rotating spinneret and a collector.

However, since the existing centrifugal force-based spinning technology employs only a single rotating spinneret, productivity is limited and not much higher than that of some advanced electrospinning technologies such as ‘multi-nozzle electrospinning’ and ‘nozzleless electrospinning.’ This problem persists even when the size of the spinneret is increased.

Inspired by these limitations, a research team led by Professor Do Hyun Kim from the Department of Chemical and Biomolecular Engineering at KAIST developed a centrifugal multispinning spinneret with mass-producibility, by sectioning a rotating spinneret into three sub-disks. This study was published as a front cover article of ACS Macro Letters, Volume 10, Issue 3 in March 2021.

Using this new centrifugal multispinning spinneret with three sub-disks, the lead author of the paper PhD candidate Byeong Eun Kwak and his fellow researchers Hyo Jeong Yoo and Eungjun Lee demonstrated the gram-scale production of various polymer nanofibers with a maximum production rate of up to 25 grams per hour, which is approximately 300 times higher than that of the conventional electrospinning system. The production rate of up to 25 grams of polymer nanofibers per hour corresponds to the production rate of about 30 face mask filters per day in a lab-scale manufacturing system.

By integrating the mass-produced polymer nanofibers into the form of a mask filter, the researchers were able to fabricate face masks that have comparable filtration performance with the KF80 and KF94 face masks that are currently available in the Korean market. The KF80 and KF94 masks have been approved by the Ministry of Food and Drug Safety of Korea to filter out at least 80% and 94% of harmful particles respectively.

“When our system is scaled up from the lab scale to an industrial scale, the large-scale production of centrifugal multispun polymer nanofibers will be made possible, and the cost of polymer nanofiber-based face mask filters will also be lowered dramatically,” Kwak explained.

This work was supported by the KAIST-funded Global Singularity Research Program for 2020.

Publication:

Byeong Eun Kwak, Hyo Jeong Yoo, Eungjun Lee, and Do Hyun Kim. (2021) Large-Scale Centrifugal Multispinning Production of Polymer Micro- and Nanofibers for Mask Filter Application with a Potential of Cospinning Mixed Multicomponent Fibers. ACS Macro Letters, Volume No. 10, Issue No. 3, pp. 382-388. Available online at https://doi.org/10.1021/acsmacrolett.0c00829

Profile:

Do Hyun Kim, Sc.D.

Professor

dohyun.kim@kaist.edu

http://procal.kaist.ac.kr/

Process Analysis Laboratory

Department of Chemical and Biomolecular Engineering

https:/kaist.ac.kr/en/

Korea Advanced Institute of Science and Technology (KAIST)Daejeon 34141, Korea

(END)

2021.04.12 View 14071

Centrifugal Multispun Nanofibers Put a New Spin on COVID-19 Masks

KAIST researchers have developed a novel nanofiber production technique called ‘centrifugal multispinning’ that will open the door for the safe and cost-effective mass production of high-performance polymer nanofibers. This new technique, which has shown up to a 300 times higher nanofiber production rate per hour than that of the conventional electrospinning method, has many potential applications including the development of face mask filters for coronavirus protection.

Nanofibers make good face mask filters because their mechanical interactions with aerosol particles give them a greater ability to capture more than 90% of harmful particles such as fine dust and virus-containing droplets.

The impact of the COVID-19 pandemic has further accelerated the growing demand in recent years for a better kind of face mask. A polymer nanofiber-based mask filter that can more effectively block harmful particles has also been in higher demand as the pandemic continues.

‘Electrospinning’ has been a common process used to prepare fine and uniform polymer nanofibers, but in terms of safety, cost-effectiveness, and mass production, it has several drawbacks. The electrospinning method requires a high-voltage electric field and electrically conductive target, and this hinders the safe and cost-effective mass production of polymer nanofibers.

In response to this shortcoming, ‘centrifugal spinning’ that utilizes centrifugal force instead of high voltage to produce polymer nanofibers has been suggested as a safer and more cost-effective alternative to the electrospinning. Easy scalability is another advantage, as this technology only requires a rotating spinneret and a collector.

However, since the existing centrifugal force-based spinning technology employs only a single rotating spinneret, productivity is limited and not much higher than that of some advanced electrospinning technologies such as ‘multi-nozzle electrospinning’ and ‘nozzleless electrospinning.’ This problem persists even when the size of the spinneret is increased.

Inspired by these limitations, a research team led by Professor Do Hyun Kim from the Department of Chemical and Biomolecular Engineering at KAIST developed a centrifugal multispinning spinneret with mass-producibility, by sectioning a rotating spinneret into three sub-disks. This study was published as a front cover article of ACS Macro Letters, Volume 10, Issue 3 in March 2021.

Using this new centrifugal multispinning spinneret with three sub-disks, the lead author of the paper PhD candidate Byeong Eun Kwak and his fellow researchers Hyo Jeong Yoo and Eungjun Lee demonstrated the gram-scale production of various polymer nanofibers with a maximum production rate of up to 25 grams per hour, which is approximately 300 times higher than that of the conventional electrospinning system. The production rate of up to 25 grams of polymer nanofibers per hour corresponds to the production rate of about 30 face mask filters per day in a lab-scale manufacturing system.

By integrating the mass-produced polymer nanofibers into the form of a mask filter, the researchers were able to fabricate face masks that have comparable filtration performance with the KF80 and KF94 face masks that are currently available in the Korean market. The KF80 and KF94 masks have been approved by the Ministry of Food and Drug Safety of Korea to filter out at least 80% and 94% of harmful particles respectively.

“When our system is scaled up from the lab scale to an industrial scale, the large-scale production of centrifugal multispun polymer nanofibers will be made possible, and the cost of polymer nanofiber-based face mask filters will also be lowered dramatically,” Kwak explained.

This work was supported by the KAIST-funded Global Singularity Research Program for 2020.

Publication:

Byeong Eun Kwak, Hyo Jeong Yoo, Eungjun Lee, and Do Hyun Kim. (2021) Large-Scale Centrifugal Multispinning Production of Polymer Micro- and Nanofibers for Mask Filter Application with a Potential of Cospinning Mixed Multicomponent Fibers. ACS Macro Letters, Volume No. 10, Issue No. 3, pp. 382-388. Available online at https://doi.org/10.1021/acsmacrolett.0c00829

Profile:

Do Hyun Kim, Sc.D.

Professor

dohyun.kim@kaist.edu

http://procal.kaist.ac.kr/

Process Analysis Laboratory

Department of Chemical and Biomolecular Engineering

https:/kaist.ac.kr/en/

Korea Advanced Institute of Science and Technology (KAIST)Daejeon 34141, Korea

(END)

2021.04.12 View 14071 -

Antivirus Industry the Centerpiece of New Deal R&D Initiatives

- KAIST launches post-COVID-19 R&D initiatives for smart mobile medical systems. -

KAIST will make the antivirus industry the centerpiece of what it is touting as the KAIST New Deal R&D initiative, which will drive new growth engines for preparing for the post-coronavirus era.

According to the new initiative, KAIST will concentrate on creating antivirus technologies, infectious disease-related big data management, and non-contact services platforms as key future R&D projects.

President Sung-Chul Shin launched the COVID-19 R&D Initiative task force last month, composed of more than 50 professors from the Graduate School of Medical Science and Engineering, the Department of Biological Sciences, the College of Engineering, and the Department of Industrial Design. The task force came up with key research agendas that will promote smart mobile medical systems in the years ahead.

“We will devote all of our R&D capacities to pursue a smart healthcare society,” said President Shin. “Our competitiveness in the fields of AI, ICT, materials, and bio-technology holds significant potential for building a healthy society powered by smart medical systems in Korea,” he added.

The smart medical systems focus mainly on building an Epidemic Mitigating Mobile Module (EMMM). The EMMM will manage epidemics via the three phases of prevention, emergency response, and treatment, with the development of each phase’s technological modules. The EMMM will also build an AI big data platform to assist with clinical applications and epidemic management.

Technologies applicable for the prevention phase include developing recyclable antivirus masks, plasma virus sterilizers, and smart breathable protective gowns. KAIST researchers will also focus on developing diagnosis modules that will identify epidemics more quickly and accurately.

Most significantly, KAIST aims to develop technologies for anti-infection medical services such as the transformable negative pressure ambulance module and negative pressure room, which are specially developed for respiratory infections.

The new R&D initiatives will center on virus therapies and treatments, specifically pushing forward vaccine and robotics studies. As caring robots and delivery robots will become common as main caregivers via noncontact services, research focusing on robotics will be significantly enhanced.

Even before launching the new R&D initiatives, researchers have started to present new technologies to help address the pandemic. Professor Il-Doo Kim’s team in the Department of Materials Science and Engineering developed a washable nano-fiber filtered face mask that is preparing for commercialization.

GPS tracking of infections has expanded comprehensively to detect both indoor and outdoor activities of infected patients. Professor Dong-Soo Han from the School of Computing developed Wi-Fi positioning software built into mobile phones that can trace both activities and is now preparing to roll it out.

Virologist Ui-Cheol Shin from the Graduate School of Medical Science and Engineering is carrying out research on a universal T-cell vaccine that can block the Betacoronaviruses. It is reported that that new epidemics such as SARS, MERS, and COVID-19 carry Betacoronaviruses.

Research teams in the Graduate School of AI are conducting various research projects on building prediction models for outbreaks and spreads using big data.

(END)

2020.05.20 View 14156

Antivirus Industry the Centerpiece of New Deal R&D Initiatives

- KAIST launches post-COVID-19 R&D initiatives for smart mobile medical systems. -

KAIST will make the antivirus industry the centerpiece of what it is touting as the KAIST New Deal R&D initiative, which will drive new growth engines for preparing for the post-coronavirus era.

According to the new initiative, KAIST will concentrate on creating antivirus technologies, infectious disease-related big data management, and non-contact services platforms as key future R&D projects.

President Sung-Chul Shin launched the COVID-19 R&D Initiative task force last month, composed of more than 50 professors from the Graduate School of Medical Science and Engineering, the Department of Biological Sciences, the College of Engineering, and the Department of Industrial Design. The task force came up with key research agendas that will promote smart mobile medical systems in the years ahead.

“We will devote all of our R&D capacities to pursue a smart healthcare society,” said President Shin. “Our competitiveness in the fields of AI, ICT, materials, and bio-technology holds significant potential for building a healthy society powered by smart medical systems in Korea,” he added.

The smart medical systems focus mainly on building an Epidemic Mitigating Mobile Module (EMMM). The EMMM will manage epidemics via the three phases of prevention, emergency response, and treatment, with the development of each phase’s technological modules. The EMMM will also build an AI big data platform to assist with clinical applications and epidemic management.

Technologies applicable for the prevention phase include developing recyclable antivirus masks, plasma virus sterilizers, and smart breathable protective gowns. KAIST researchers will also focus on developing diagnosis modules that will identify epidemics more quickly and accurately.

Most significantly, KAIST aims to develop technologies for anti-infection medical services such as the transformable negative pressure ambulance module and negative pressure room, which are specially developed for respiratory infections.

The new R&D initiatives will center on virus therapies and treatments, specifically pushing forward vaccine and robotics studies. As caring robots and delivery robots will become common as main caregivers via noncontact services, research focusing on robotics will be significantly enhanced.

Even before launching the new R&D initiatives, researchers have started to present new technologies to help address the pandemic. Professor Il-Doo Kim’s team in the Department of Materials Science and Engineering developed a washable nano-fiber filtered face mask that is preparing for commercialization.

GPS tracking of infections has expanded comprehensively to detect both indoor and outdoor activities of infected patients. Professor Dong-Soo Han from the School of Computing developed Wi-Fi positioning software built into mobile phones that can trace both activities and is now preparing to roll it out.

Virologist Ui-Cheol Shin from the Graduate School of Medical Science and Engineering is carrying out research on a universal T-cell vaccine that can block the Betacoronaviruses. It is reported that that new epidemics such as SARS, MERS, and COVID-19 carry Betacoronaviruses.

Research teams in the Graduate School of AI are conducting various research projects on building prediction models for outbreaks and spreads using big data.

(END)

2020.05.20 View 14156 -

Wafer-Scale Multilayer Fabrication of Silk Fibroin-Based Microelectronics

A KAIST research team developed a novel fabrication method for the multilayer processing of silk-based microelectronics. This technology for creating a biodegradable silk fibroin film allows microfabrication with polymer or metal structures manufactured from photolithography. It can be a key technology in the implementation of silk fibroin-based biodegradable electronic devices or localized drug delivery through silk fibroin patterns.

Silk fibroins are biocompatible, biodegradable, transparent, and flexible, which makes them excellent candidates for implantable biomedical devices, and they have also been used as biodegradable films and functional microstructures in biomedical applications. However, conventional microfabrication processes require strong etching solutions and solvents to modify the structure of silk fibroins.

To prevent the silk fibroin from being damaged during the process, Professor Hyunjoo J. Lee from the School of Electrical Engineering and her team came up with a novel process, named aluminum hard mask on silk fibroin (AMoS), which is capable of micropatterning multiple layers composed of both fibroin and inorganic materials, such as metal and dielectrics with high-precision microscale alignment. The AMoS process can make silk fibroin patterns on devices, or make patterns on silk fibroin thin films with other materials by using photolithography, which is a core technology in the current microfabrication process.

The team successfully cultured primary neurons on the processed silk fibroin micro-patterns, and confirmed that silk fibroin has excellent biocompatibility before and after the fabrication process and that it also can be applied to implanted biological devices.

Through this technology, the team realized the multilayer micropatterning of fibroin films on a silk fibroin substrate and fabricated a biodegradable microelectric circuit consisting of resistors and silk fibroin dielectric capacitors in a silicon wafer with large areas.

They also used this technology to position the micro-pattern of the silk fibroin thin film closer to the flexible polymer-based brain electrode, and confirmed the dye molecules mounted on the silk fibroin were transferred successfully from the micropatterns.

Professor Lee said, “This technology facilitates wafer-scale, large-area processing of sensitive materials. We expect it to be applied to a wide range of biomedical devices in the future. Using the silk fibroin with micro-patterned brain electrodes can open up many new possibilities in research on brain circuits by mounting drugs that restrict or promote brain cell activities.”

This research, in collaboration with Dr. Nakwon Choi from KIST and led by PhD candidate Geon Kook, was published in ACS AMI (10.1021/acsami.8b13170) on January 16, 2019.

Figure 1. The cover page of ACS AMI

Figure 2. Fibroin microstructures and metal patterns on a fibroin produced by using the AMoS mask.

Figure 3. Biocompatibility assessment of the AMoS Process. Top: Schematics image of a) fibroin-coated silicon b) fibroin-pattered silicon and c) gold-patterned fibroin. Bottom: Representative confocal microscopy images of live (green) and dead (red) primary cortical neurons cultured on the substrates.

2019.03.15 View 23412

Wafer-Scale Multilayer Fabrication of Silk Fibroin-Based Microelectronics

A KAIST research team developed a novel fabrication method for the multilayer processing of silk-based microelectronics. This technology for creating a biodegradable silk fibroin film allows microfabrication with polymer or metal structures manufactured from photolithography. It can be a key technology in the implementation of silk fibroin-based biodegradable electronic devices or localized drug delivery through silk fibroin patterns.

Silk fibroins are biocompatible, biodegradable, transparent, and flexible, which makes them excellent candidates for implantable biomedical devices, and they have also been used as biodegradable films and functional microstructures in biomedical applications. However, conventional microfabrication processes require strong etching solutions and solvents to modify the structure of silk fibroins.

To prevent the silk fibroin from being damaged during the process, Professor Hyunjoo J. Lee from the School of Electrical Engineering and her team came up with a novel process, named aluminum hard mask on silk fibroin (AMoS), which is capable of micropatterning multiple layers composed of both fibroin and inorganic materials, such as metal and dielectrics with high-precision microscale alignment. The AMoS process can make silk fibroin patterns on devices, or make patterns on silk fibroin thin films with other materials by using photolithography, which is a core technology in the current microfabrication process.

The team successfully cultured primary neurons on the processed silk fibroin micro-patterns, and confirmed that silk fibroin has excellent biocompatibility before and after the fabrication process and that it also can be applied to implanted biological devices.

Through this technology, the team realized the multilayer micropatterning of fibroin films on a silk fibroin substrate and fabricated a biodegradable microelectric circuit consisting of resistors and silk fibroin dielectric capacitors in a silicon wafer with large areas.

They also used this technology to position the micro-pattern of the silk fibroin thin film closer to the flexible polymer-based brain electrode, and confirmed the dye molecules mounted on the silk fibroin were transferred successfully from the micropatterns.

Professor Lee said, “This technology facilitates wafer-scale, large-area processing of sensitive materials. We expect it to be applied to a wide range of biomedical devices in the future. Using the silk fibroin with micro-patterned brain electrodes can open up many new possibilities in research on brain circuits by mounting drugs that restrict or promote brain cell activities.”

This research, in collaboration with Dr. Nakwon Choi from KIST and led by PhD candidate Geon Kook, was published in ACS AMI (10.1021/acsami.8b13170) on January 16, 2019.

Figure 1. The cover page of ACS AMI

Figure 2. Fibroin microstructures and metal patterns on a fibroin produced by using the AMoS mask.

Figure 3. Biocompatibility assessment of the AMoS Process. Top: Schematics image of a) fibroin-coated silicon b) fibroin-pattered silicon and c) gold-patterned fibroin. Bottom: Representative confocal microscopy images of live (green) and dead (red) primary cortical neurons cultured on the substrates.

2019.03.15 View 23412