Seungbum+Hong

-

KAIST Scientifically Identifies a Method to Prevent Dental Erosion from Carbonated Drinks

A Korean research team, which had previously visualized and scientifically proven the harmful effects of carbonated drinks like cola on dental health using nanotechnology, has now identified a mechanism for an effective method to prevent tooth damage caused by these beverages.

KAIST (represented by President Kwang Hyung Lee) announced on the 5th of December that a team led by Professor Seungbum Hong from the Department of Materials Science and Engineering, in collaboration with Seoul National University's School of Dentistry (Departments of Pediatric Dentistry and Oral Microbiology) and Professor Hye Ryung Byon’s research team from the Department of Chemistry, has revealed through nanotechnology that silver diamine fluoride (SDF)* forms a fluoride-containing protective layer on the tooth surface, effectively inhibiting cola-induced erosion.

*SDF (Silver Diamine Fluoride): A dental agent primarily used for the treatment and prevention of tooth decay. SDF strengthens carious lesions, suppresses bacterial growth, and halts the progression of cavities.

The team analyzed the surface morphology and mechanical properties of tooth enamel on a nanoscale using atomic force microscopy (AFM). They also examined the chemical properties of the nano-film formed by SDF treatment using X-ray photoelectron spectroscopy (XPS)* and Fourier-transform infrared spectroscopy (FTIR)*.

*XPS (X-ray Photoelectron Spectroscopy): A powerful surface analysis technique used to investigate the chemical composition and electronic structure of materials.

*FTIR (Fourier-Transform Infrared Spectroscopy): An analytical method that identifies the molecular structure and composition of materials by analyzing how they absorb or transmit infrared light.

The findings showed significant differences in surface roughness and elastic modulus between teeth exposed to cola with and without SDF treatment. Teeth treated with SDF exhibited minimal changes in surface roughness due to erosion (from 64 nm to 70 nm) and maintained a high elastic modulus (from 215 GPa to 205 GPa).

This was attributed to the formation of a fluoroapatite* layer by SDF, which acted as a protective shield.

*Fluoroapatite: A phosphate mineral with the chemical formula Ca₅(PO₄)₃F (calcium fluoro-phosphate). It can occur naturally or be synthesized biologically/artificially and plays a crucial role in strengthening teeth and bones.

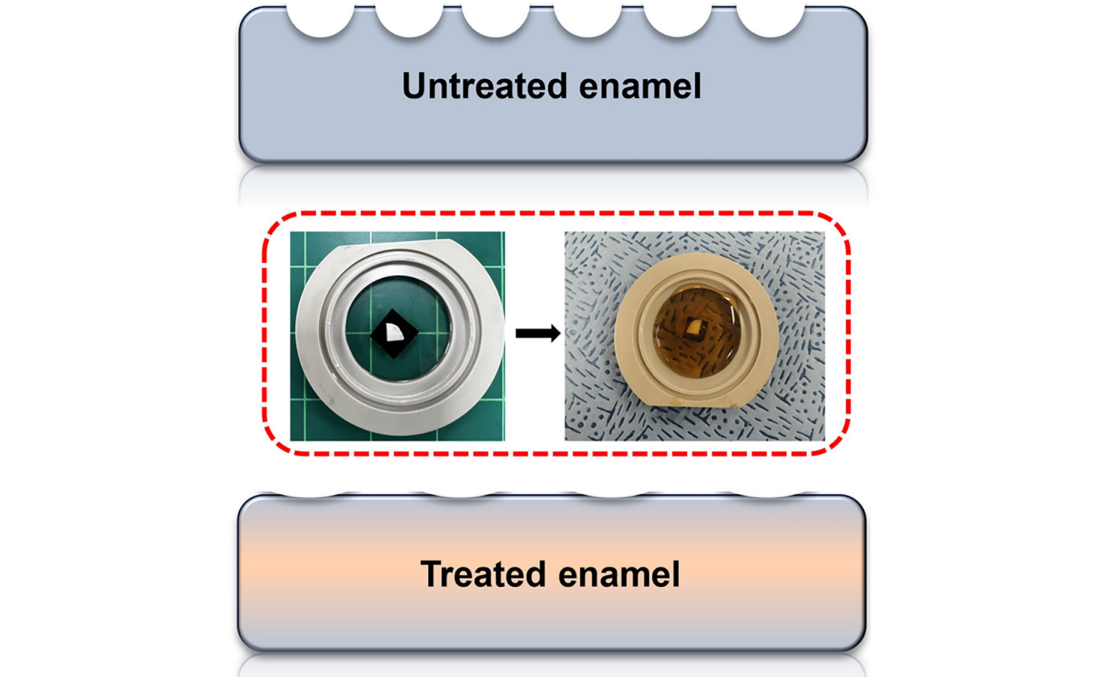

< Figure 1. Schematic of the workflow. Surface morphology and mechanical properties of untreated and treated silver diamine fluoride (SDF) treated enamel exposed to cola were analyzed over time using atomic force microscopy (AFM). >

Professor Young J. Kim from Seoul National University's Department of Pediatric Dentistry noted, "This technology could be applied to prevent dental erosion and strengthen teeth for both children and adults. It is a cost-effective and accessible dental treatment."

< Figure 2. Changes in surface roughness and elastic modulus according to time of exposure to cola for SDF untreated and treated teeth. After 1 hour, the surface roughness of the SDF untreated teeth rapidly became rougher from 83 nm to 287 nm and the elastic modulus weakened from 125 GPa to 13 GPa, whereas the surface roughness of the SDF treated teeth changed only slightly from 64 nm to 70 nm and the elastic modulus barely changed from 215 GPa to 205 GPa, maintaining a similar state to the initial state. >

Professor Seungbum Hong emphasized, "Dental health significantly impacts quality of life. This research offers an effective non-invasive method to prevent early dental erosion, moving beyond traditional surgical treatments. By simply applying SDF, dental erosion can be prevented and enamel strengthened, potentially reducing pain and costs associated with treatment."

This study, led by the first author Aditi Saha, a PhD student in KAIST’s Department of Materials Science and Engineering, was published in the international journal Biomaterials Research on November 7 under the title "Nanoscale Study on Noninvasive Prevention of Dental Erosion of Enamel by Silver Diamine Fluoride". The research was supported by the National Research Foundation of Korea.

2024.12.11 View 3643

KAIST Scientifically Identifies a Method to Prevent Dental Erosion from Carbonated Drinks

A Korean research team, which had previously visualized and scientifically proven the harmful effects of carbonated drinks like cola on dental health using nanotechnology, has now identified a mechanism for an effective method to prevent tooth damage caused by these beverages.

KAIST (represented by President Kwang Hyung Lee) announced on the 5th of December that a team led by Professor Seungbum Hong from the Department of Materials Science and Engineering, in collaboration with Seoul National University's School of Dentistry (Departments of Pediatric Dentistry and Oral Microbiology) and Professor Hye Ryung Byon’s research team from the Department of Chemistry, has revealed through nanotechnology that silver diamine fluoride (SDF)* forms a fluoride-containing protective layer on the tooth surface, effectively inhibiting cola-induced erosion.

*SDF (Silver Diamine Fluoride): A dental agent primarily used for the treatment and prevention of tooth decay. SDF strengthens carious lesions, suppresses bacterial growth, and halts the progression of cavities.

The team analyzed the surface morphology and mechanical properties of tooth enamel on a nanoscale using atomic force microscopy (AFM). They also examined the chemical properties of the nano-film formed by SDF treatment using X-ray photoelectron spectroscopy (XPS)* and Fourier-transform infrared spectroscopy (FTIR)*.

*XPS (X-ray Photoelectron Spectroscopy): A powerful surface analysis technique used to investigate the chemical composition and electronic structure of materials.

*FTIR (Fourier-Transform Infrared Spectroscopy): An analytical method that identifies the molecular structure and composition of materials by analyzing how they absorb or transmit infrared light.

The findings showed significant differences in surface roughness and elastic modulus between teeth exposed to cola with and without SDF treatment. Teeth treated with SDF exhibited minimal changes in surface roughness due to erosion (from 64 nm to 70 nm) and maintained a high elastic modulus (from 215 GPa to 205 GPa).

This was attributed to the formation of a fluoroapatite* layer by SDF, which acted as a protective shield.

*Fluoroapatite: A phosphate mineral with the chemical formula Ca₅(PO₄)₃F (calcium fluoro-phosphate). It can occur naturally or be synthesized biologically/artificially and plays a crucial role in strengthening teeth and bones.

< Figure 1. Schematic of the workflow. Surface morphology and mechanical properties of untreated and treated silver diamine fluoride (SDF) treated enamel exposed to cola were analyzed over time using atomic force microscopy (AFM). >

Professor Young J. Kim from Seoul National University's Department of Pediatric Dentistry noted, "This technology could be applied to prevent dental erosion and strengthen teeth for both children and adults. It is a cost-effective and accessible dental treatment."

< Figure 2. Changes in surface roughness and elastic modulus according to time of exposure to cola for SDF untreated and treated teeth. After 1 hour, the surface roughness of the SDF untreated teeth rapidly became rougher from 83 nm to 287 nm and the elastic modulus weakened from 125 GPa to 13 GPa, whereas the surface roughness of the SDF treated teeth changed only slightly from 64 nm to 70 nm and the elastic modulus barely changed from 215 GPa to 205 GPa, maintaining a similar state to the initial state. >

Professor Seungbum Hong emphasized, "Dental health significantly impacts quality of life. This research offers an effective non-invasive method to prevent early dental erosion, moving beyond traditional surgical treatments. By simply applying SDF, dental erosion can be prevented and enamel strengthened, potentially reducing pain and costs associated with treatment."

This study, led by the first author Aditi Saha, a PhD student in KAIST’s Department of Materials Science and Engineering, was published in the international journal Biomaterials Research on November 7 under the title "Nanoscale Study on Noninvasive Prevention of Dental Erosion of Enamel by Silver Diamine Fluoride". The research was supported by the National Research Foundation of Korea.

2024.12.11 View 3643 -

KAIST Employs Image-recognition AI to Determine Battery Composition and Conditions

An international collaborative research team has developed an image recognition technology that can accurately determine the elemental composition and the number of charge and discharge cycles of a battery by examining only its surface morphology using AI learning.

KAIST (President Kwang-Hyung Lee) announced on July 2nd that Professor Seungbum Hong from the Department of Materials Science and Engineering, in collaboration with the Electronics and Telecommunications Research Institute (ETRI) and Drexel University in the United States, has developed a method to predict the major elemental composition and charge-discharge state of NCM cathode materials with 99.6% accuracy using convolutional neural networks (CNN)*.

*Convolutional Neural Network (CNN): A type of multi-layer, feed-forward, artificial neural network used for analyzing visual images.

The research team noted that while scanning electron microscopy (SEM) is used in semiconductor manufacturing to inspect wafer defects, it is rarely used in battery inspections. SEM is used for batteries to analyze the size of particles only at research sites, and reliability is predicted from the broken particles and the shape of the breakage in the case of deteriorated battery materials.

The research team decided that it would be groundbreaking if an automated SEM can be used in the process of battery production, just like in the semiconductor manufacturing, to inspect the surface of the cathode material to determine whether it was synthesized according to the desired composition and that the lifespan would be reliable, thereby reducing the defect rate.

< Figure 1. Example images of true cases and their grad-CAM overlays from the best trained network. >

The researchers trained a CNN-based AI applicable to autonomous vehicles to learn the surface images of battery materials, enabling it to predict the major elemental composition and charge-discharge cycle states of the cathode materials. They found that while the method could accurately predict the composition of materials with additives, it had lower accuracy for predicting charge-discharge states. The team plans to further train the AI with various battery material morphologies produced through different processes and ultimately use it for inspecting the compositional uniformity and predicting the lifespan of next-generation batteries.

Professor Joshua C. Agar, one of the collaborating researchers of the project from the Department of Mechanical Engineering and Mechanics of Drexel University, said, "In the future, artificial intelligence is expected to be applied not only to battery materials but also to various dynamic processes in functional materials synthesis, clean energy generation in fusion, and understanding foundations of particles and the universe."

Professor Seungbum Hong from KAIST, who led the research, stated, "This research is significant as it is the first in the world to develop an AI-based methodology that can quickly and accurately predict the major elemental composition and the state of the battery from the structural data of micron-scale SEM images. The methodology developed in this study for identifying the composition and state of battery materials based on microscopic images is expected to play a crucial role in improving the performance and quality of battery materials in the future."

< Figure 2. Accuracies of CNN Model predictions on SEM images of NCM cathode materials with additives under various conditions. >

This research was conducted by KAIST’s Materials Science and Engineering Department graduates Dr. Jimin Oh and Dr. Jiwon Yeom, the co-first authors, in collaboration with Professor Josh Agar and Dr. Kwang Man Kim from ETRI. It was supported by the National Research Foundation of Korea, the KAIST Global Singularity project, and international collaboration with the US research team. The results were published in the international journal npj Computational Materials on May 4. (Paper Title: “Composition and state prediction of lithium-ion cathode via convolutional neural network trained on scanning electron microscopy images”)

2024.07.02 View 5552

KAIST Employs Image-recognition AI to Determine Battery Composition and Conditions

An international collaborative research team has developed an image recognition technology that can accurately determine the elemental composition and the number of charge and discharge cycles of a battery by examining only its surface morphology using AI learning.

KAIST (President Kwang-Hyung Lee) announced on July 2nd that Professor Seungbum Hong from the Department of Materials Science and Engineering, in collaboration with the Electronics and Telecommunications Research Institute (ETRI) and Drexel University in the United States, has developed a method to predict the major elemental composition and charge-discharge state of NCM cathode materials with 99.6% accuracy using convolutional neural networks (CNN)*.

*Convolutional Neural Network (CNN): A type of multi-layer, feed-forward, artificial neural network used for analyzing visual images.

The research team noted that while scanning electron microscopy (SEM) is used in semiconductor manufacturing to inspect wafer defects, it is rarely used in battery inspections. SEM is used for batteries to analyze the size of particles only at research sites, and reliability is predicted from the broken particles and the shape of the breakage in the case of deteriorated battery materials.

The research team decided that it would be groundbreaking if an automated SEM can be used in the process of battery production, just like in the semiconductor manufacturing, to inspect the surface of the cathode material to determine whether it was synthesized according to the desired composition and that the lifespan would be reliable, thereby reducing the defect rate.

< Figure 1. Example images of true cases and their grad-CAM overlays from the best trained network. >

The researchers trained a CNN-based AI applicable to autonomous vehicles to learn the surface images of battery materials, enabling it to predict the major elemental composition and charge-discharge cycle states of the cathode materials. They found that while the method could accurately predict the composition of materials with additives, it had lower accuracy for predicting charge-discharge states. The team plans to further train the AI with various battery material morphologies produced through different processes and ultimately use it for inspecting the compositional uniformity and predicting the lifespan of next-generation batteries.

Professor Joshua C. Agar, one of the collaborating researchers of the project from the Department of Mechanical Engineering and Mechanics of Drexel University, said, "In the future, artificial intelligence is expected to be applied not only to battery materials but also to various dynamic processes in functional materials synthesis, clean energy generation in fusion, and understanding foundations of particles and the universe."

Professor Seungbum Hong from KAIST, who led the research, stated, "This research is significant as it is the first in the world to develop an AI-based methodology that can quickly and accurately predict the major elemental composition and the state of the battery from the structural data of micron-scale SEM images. The methodology developed in this study for identifying the composition and state of battery materials based on microscopic images is expected to play a crucial role in improving the performance and quality of battery materials in the future."

< Figure 2. Accuracies of CNN Model predictions on SEM images of NCM cathode materials with additives under various conditions. >

This research was conducted by KAIST’s Materials Science and Engineering Department graduates Dr. Jimin Oh and Dr. Jiwon Yeom, the co-first authors, in collaboration with Professor Josh Agar and Dr. Kwang Man Kim from ETRI. It was supported by the National Research Foundation of Korea, the KAIST Global Singularity project, and international collaboration with the US research team. The results were published in the international journal npj Computational Materials on May 4. (Paper Title: “Composition and state prediction of lithium-ion cathode via convolutional neural network trained on scanning electron microscopy images”)

2024.07.02 View 5552 -

A KAIST Research Team Develops a Novel “Bone Bandage” Material for Cracked Bones

Bone regeneration is a complex process, and existing methods to aid regeneration including transplants and growth factor transmissions face limitations such as the high cost. But recently, a piezoelectric material that can promote the growth of bone tissue has been developed.

A KAIST research team led by Professor Seungbum Hong from the Department of Materials Science and Engineering (DMSE) announced on January 25 the development of a biomimetic scaffold that generates electrical signals upon the application of pressure by utilizing the unique osteogenic ability of hydroxyapatite (HAp). This research was conducted in collaboration with a team led by Professor Jangho Kim from the Department of Convergence Biosystems Engineering at Chonnam National University.

HAp is a basic calcium phosphate material found in bones and teeth. This biocompatible mineral substance is also known to prevent tooth decay and is often used in toothpaste.

Previous studies on piezoelectric scaffolds confirmed the effects of piezoelectricity on promoting bone regeneration and improving bone fusion in various polymer-based materials, but were limited in simulating the complex cellular environment required for optimal bone tissue regeneration. However, this research suggests a new method for utilizing the unique osteogenic abilities of HAp to develop a material that mimics the environment for bone tissue in a living body.

< Figure 1. Design and characterization of piezoelectrically and topographically originated biomimetic scaffolds. (a) Schematic representation of the enhanced bone regeneration mechanism through electrical and topographical cues provided by HAp-incorporated P(VDF-TrFE) scaffolds. (b) Schematic diagram of the fabrication process. >

The research team developed a manufacturing process that fuses HAp with a polymer film. The flexible and free-standing scaffold developed through this process demonstrated its remarkable potential for promoting bone regeneration through in-vitro and in-vivo experiments in rats.

The team also identified the principles of bone regeneration that their scaffold is based on. Using atomic force microscopy (AFM), they analysed the electrical properties of the scaffold and evaluated the detailed surface properties related to cell shape and cell skeletal protein formation. They also investigated the effects of piezoelectricity and surface properties on the expression of growth factors.

Professor Hong from KAIST’s DMSE said, “We have developed a HAp-based piezoelectric composite material that can act like a ‘bone bandage’ through its ability to accelerate bone regeneration.” He added, “This research not only suggests a new direction for designing biomaterials, but is also significant in having explored the effects of piezoelectricity and surface properties on bone regeneration.”

This research, conducted by co-first authors Soyun Joo and Soyeon Kim from Professor Hong’s group, was published on ACS Applied Materials & Interfaces on January 4 under the title “Piezoelectrically and Topographically Engineered Scaffolds for Accelerating Bone Regeneration”. From Professor Kim’s group, Ph.D. candidate Yonghyun Gwon also participated as co-first author, and Professor Kim himself as a corresponding author.

< Figure 2. Analysis of piezoelectric and surface properties of the biomimetic scaffolds using atomic force microscopy. (a) PFM amplitude and phase images of box-poled composite scaffolds. The white bar represents 2 μm. (b) 3D representations of composite scaffolds paired with typical 2D line sections. (c) In vivo bone regeneration micro-CT analysis, (d) schematic representation of filler-derived electrical origins in bone regeneration. >

This research was supported by the KAIST Research and Development Team, the KUSTAR-KAIST Joint Research Center, the KAIST Global Singularity Project, and the government-funded Basic Research Project by the National Research Foundation of Korea.

2024.02.01 View 7328

A KAIST Research Team Develops a Novel “Bone Bandage” Material for Cracked Bones

Bone regeneration is a complex process, and existing methods to aid regeneration including transplants and growth factor transmissions face limitations such as the high cost. But recently, a piezoelectric material that can promote the growth of bone tissue has been developed.

A KAIST research team led by Professor Seungbum Hong from the Department of Materials Science and Engineering (DMSE) announced on January 25 the development of a biomimetic scaffold that generates electrical signals upon the application of pressure by utilizing the unique osteogenic ability of hydroxyapatite (HAp). This research was conducted in collaboration with a team led by Professor Jangho Kim from the Department of Convergence Biosystems Engineering at Chonnam National University.

HAp is a basic calcium phosphate material found in bones and teeth. This biocompatible mineral substance is also known to prevent tooth decay and is often used in toothpaste.

Previous studies on piezoelectric scaffolds confirmed the effects of piezoelectricity on promoting bone regeneration and improving bone fusion in various polymer-based materials, but were limited in simulating the complex cellular environment required for optimal bone tissue regeneration. However, this research suggests a new method for utilizing the unique osteogenic abilities of HAp to develop a material that mimics the environment for bone tissue in a living body.

< Figure 1. Design and characterization of piezoelectrically and topographically originated biomimetic scaffolds. (a) Schematic representation of the enhanced bone regeneration mechanism through electrical and topographical cues provided by HAp-incorporated P(VDF-TrFE) scaffolds. (b) Schematic diagram of the fabrication process. >

The research team developed a manufacturing process that fuses HAp with a polymer film. The flexible and free-standing scaffold developed through this process demonstrated its remarkable potential for promoting bone regeneration through in-vitro and in-vivo experiments in rats.

The team also identified the principles of bone regeneration that their scaffold is based on. Using atomic force microscopy (AFM), they analysed the electrical properties of the scaffold and evaluated the detailed surface properties related to cell shape and cell skeletal protein formation. They also investigated the effects of piezoelectricity and surface properties on the expression of growth factors.

Professor Hong from KAIST’s DMSE said, “We have developed a HAp-based piezoelectric composite material that can act like a ‘bone bandage’ through its ability to accelerate bone regeneration.” He added, “This research not only suggests a new direction for designing biomaterials, but is also significant in having explored the effects of piezoelectricity and surface properties on bone regeneration.”

This research, conducted by co-first authors Soyun Joo and Soyeon Kim from Professor Hong’s group, was published on ACS Applied Materials & Interfaces on January 4 under the title “Piezoelectrically and Topographically Engineered Scaffolds for Accelerating Bone Regeneration”. From Professor Kim’s group, Ph.D. candidate Yonghyun Gwon also participated as co-first author, and Professor Kim himself as a corresponding author.

< Figure 2. Analysis of piezoelectric and surface properties of the biomimetic scaffolds using atomic force microscopy. (a) PFM amplitude and phase images of box-poled composite scaffolds. The white bar represents 2 μm. (b) 3D representations of composite scaffolds paired with typical 2D line sections. (c) In vivo bone regeneration micro-CT analysis, (d) schematic representation of filler-derived electrical origins in bone regeneration. >

This research was supported by the KAIST Research and Development Team, the KUSTAR-KAIST Joint Research Center, the KAIST Global Singularity Project, and the government-funded Basic Research Project by the National Research Foundation of Korea.

2024.02.01 View 7328 -

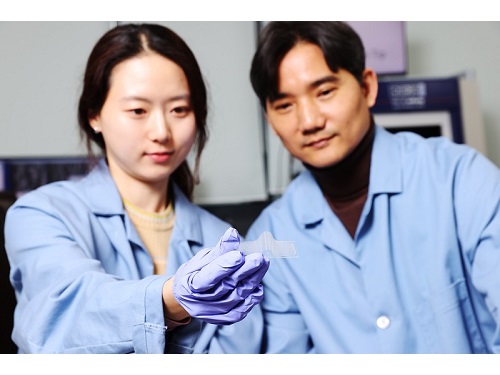

Streamlining the Process of Materials Discovery

The materials platform M3I3 reduces the time for materials discovery by reverse engineering future materials using multiscale/multimodal imaging and machine learning of the processing-structure-properties relationship

Developing new materials and novel processes has continued to change the world. The M3I3 Initiative at KAIST has led to new insights into advancing materials development by implementing breakthroughs in materials imaging that have created a paradigm shift in the discovery of materials. The Initiative features the multiscale modeling and imaging of structure and property relationships and materials hierarchies combined with the latest material-processing data.

The research team led by Professor Seungbum Hong analyzed the materials research projects reported by leading global institutes and research groups, and derived a quantitative model using machine learning with a scientific interpretation. This process embodies the research goal of the M3I3: Materials and Molecular Modeling, Imaging, Informatics and Integration.

The researchers discussed the role of multiscale materials and molecular imaging combined with machine learning and also presented a future outlook for developments and the major challenges of M3I3. By building this model, the research team envisions creating desired sets of properties for materials and obtaining the optimum processing recipes to synthesize them.

“The development of various microscopy and diffraction tools with the ability to map the structure, property, and performance of materials at multiscale levels and in real time enabled us to think that materials imaging could radically accelerate materials discovery and development,” says Professor Hong.

“We plan to build an M3I3 repository of searchable structural and property maps using FAIR (Findable, Accessible, Interoperable, and Reusable) principles to standardize best practices as well as streamline the training of early career researchers.”

One of the examples that shows the power of structure-property imaging at the nanoscale is the development of future materials for emerging nonvolatile memory devices. Specifically, the research team focused on microscopy using photons, electrons, and physical probes on the multiscale structural hierarchy, as well as structure-property relationships to enhance the performance of memory devices.

“M3I3 is an algorithm for performing the reverse engineering of future materials. Reverse engineering starts by analyzing the structure and composition of cutting-edge materials or products. Once the research team determines the performance of our targeted future materials, we need to know the candidate structures and compositions for producing the future materials.”

The research team has built a data-driven experimental design based on traditional NCM (nickel, cobalt, and manganese) cathode materials. With this, the research team expanded their future direction for achieving even higher discharge capacity, which can be realized via Li-rich cathodes.

However, one of the major challenges was the limitation of available data that describes the Li-rich cathode properties. To mitigate this problem, the researchers proposed two solutions: First, they should build a machine-learning-guided data generator for data augmentation. Second, they would use a machine-learning method based on ‘transfer learning.’ Since the NCM cathode database shares a common feature with a Li-rich cathode, one could consider repurposing the NCM trained model for assisting the Li-rich prediction. With the pretrained model and transfer learning, the team expects to achieve outstanding predictions for Li-rich cathodes even with the small data set.

With advances in experimental imaging and the availability of well-resolved information and big data, along with significant advances in high-performance computing and a worldwide thrust toward a general, collaborative, integrative, and on-demand research platform, there is a clear confluence in the required capabilities of advancing the M3I3 Initiative.

Professor Hong said, “Once we succeed in using the inverse “property−structure−processing” solver to develop cathode, anode, electrolyte, and membrane materials for high energy density Li-ion batteries, we will expand our scope of materials to battery/fuel cells, aerospace, automobiles, food, medicine, and cosmetic materials.”

The review was published in ACS Nano in March. This study was conducted through collaborations with Dr. Chi Hao Liow, Professor Jong Min Yuk, Professor Hye Ryung Byon, Professor Yongsoo Yang, Professor EunAe Cho, Professor Pyuck-Pa Choi, and Professor Hyuck Mo Lee at KAIST, Professor Joshua C. Agar at Lehigh University, Dr. Sergei V. Kalinin at Oak Ridge National Laboratory, Professor Peter W. Voorhees at Northwestern University, and Professor Peter Littlewood at the University of Chicago (Article title: Reducing Time to Discovery: Materials and Molecular Modeling, Imaging, Informatics, and Integration).This work was supported by the KAIST Global Singularity Research Program for 2019 and 2020.

Publication:

“Reducing Time to Discovery: Materials and Molecular Modeling, Imaging, Informatics and Integration,” S. Hong, C. H. Liow, J. M. Yuk, H. R. Byon, Y. Yang, E. Cho, J. Yeom, G. Park, H. Kang, S. Kim, Y. Shim, M. Na, C. Jeong, G. Hwang, H. Kim, H. Kim, S. Eom, S. Cho, H. Jun, Y. Lee, A. Baucour, K. Bang, M. Kim, S. Yun, J. Ryu, Y. Han, A. Jetybayeva, P.-P. Choi, J. C. Agar, S. V. Kalinin, P. W. Voorhees, P. Littlewood, and H. M. Lee, ACS Nano 15, 3, 3971–3995 (2021) https://doi.org/10.1021/acsnano.1c00211

Profile:

Seungbum Hong, PhD

Associate Professor

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr

Department of Materials Science and Engineering

KAIST

(END)

2021.04.05 View 14248

Streamlining the Process of Materials Discovery

The materials platform M3I3 reduces the time for materials discovery by reverse engineering future materials using multiscale/multimodal imaging and machine learning of the processing-structure-properties relationship

Developing new materials and novel processes has continued to change the world. The M3I3 Initiative at KAIST has led to new insights into advancing materials development by implementing breakthroughs in materials imaging that have created a paradigm shift in the discovery of materials. The Initiative features the multiscale modeling and imaging of structure and property relationships and materials hierarchies combined with the latest material-processing data.

The research team led by Professor Seungbum Hong analyzed the materials research projects reported by leading global institutes and research groups, and derived a quantitative model using machine learning with a scientific interpretation. This process embodies the research goal of the M3I3: Materials and Molecular Modeling, Imaging, Informatics and Integration.

The researchers discussed the role of multiscale materials and molecular imaging combined with machine learning and also presented a future outlook for developments and the major challenges of M3I3. By building this model, the research team envisions creating desired sets of properties for materials and obtaining the optimum processing recipes to synthesize them.

“The development of various microscopy and diffraction tools with the ability to map the structure, property, and performance of materials at multiscale levels and in real time enabled us to think that materials imaging could radically accelerate materials discovery and development,” says Professor Hong.

“We plan to build an M3I3 repository of searchable structural and property maps using FAIR (Findable, Accessible, Interoperable, and Reusable) principles to standardize best practices as well as streamline the training of early career researchers.”

One of the examples that shows the power of structure-property imaging at the nanoscale is the development of future materials for emerging nonvolatile memory devices. Specifically, the research team focused on microscopy using photons, electrons, and physical probes on the multiscale structural hierarchy, as well as structure-property relationships to enhance the performance of memory devices.

“M3I3 is an algorithm for performing the reverse engineering of future materials. Reverse engineering starts by analyzing the structure and composition of cutting-edge materials or products. Once the research team determines the performance of our targeted future materials, we need to know the candidate structures and compositions for producing the future materials.”

The research team has built a data-driven experimental design based on traditional NCM (nickel, cobalt, and manganese) cathode materials. With this, the research team expanded their future direction for achieving even higher discharge capacity, which can be realized via Li-rich cathodes.

However, one of the major challenges was the limitation of available data that describes the Li-rich cathode properties. To mitigate this problem, the researchers proposed two solutions: First, they should build a machine-learning-guided data generator for data augmentation. Second, they would use a machine-learning method based on ‘transfer learning.’ Since the NCM cathode database shares a common feature with a Li-rich cathode, one could consider repurposing the NCM trained model for assisting the Li-rich prediction. With the pretrained model and transfer learning, the team expects to achieve outstanding predictions for Li-rich cathodes even with the small data set.

With advances in experimental imaging and the availability of well-resolved information and big data, along with significant advances in high-performance computing and a worldwide thrust toward a general, collaborative, integrative, and on-demand research platform, there is a clear confluence in the required capabilities of advancing the M3I3 Initiative.

Professor Hong said, “Once we succeed in using the inverse “property−structure−processing” solver to develop cathode, anode, electrolyte, and membrane materials for high energy density Li-ion batteries, we will expand our scope of materials to battery/fuel cells, aerospace, automobiles, food, medicine, and cosmetic materials.”

The review was published in ACS Nano in March. This study was conducted through collaborations with Dr. Chi Hao Liow, Professor Jong Min Yuk, Professor Hye Ryung Byon, Professor Yongsoo Yang, Professor EunAe Cho, Professor Pyuck-Pa Choi, and Professor Hyuck Mo Lee at KAIST, Professor Joshua C. Agar at Lehigh University, Dr. Sergei V. Kalinin at Oak Ridge National Laboratory, Professor Peter W. Voorhees at Northwestern University, and Professor Peter Littlewood at the University of Chicago (Article title: Reducing Time to Discovery: Materials and Molecular Modeling, Imaging, Informatics, and Integration).This work was supported by the KAIST Global Singularity Research Program for 2019 and 2020.

Publication:

“Reducing Time to Discovery: Materials and Molecular Modeling, Imaging, Informatics and Integration,” S. Hong, C. H. Liow, J. M. Yuk, H. R. Byon, Y. Yang, E. Cho, J. Yeom, G. Park, H. Kang, S. Kim, Y. Shim, M. Na, C. Jeong, G. Hwang, H. Kim, H. Kim, S. Eom, S. Cho, H. Jun, Y. Lee, A. Baucour, K. Bang, M. Kim, S. Yun, J. Ryu, Y. Han, A. Jetybayeva, P.-P. Choi, J. C. Agar, S. V. Kalinin, P. W. Voorhees, P. Littlewood, and H. M. Lee, ACS Nano 15, 3, 3971–3995 (2021) https://doi.org/10.1021/acsnano.1c00211

Profile:

Seungbum Hong, PhD

Associate Professor

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr

Department of Materials Science and Engineering

KAIST

(END)

2021.04.05 View 14248 -

ACS Nano Special Edition Highlights Innovations at KAIST

- The collective intelligence and technological innovation of KAIST was highlighted with case studies including the Post-COVID-19 New Deal R&D Initiative Project. -

KAIST’s innovative academic achievements and R&D efforts for addressing the world’s greatest challenges such as the COVID-19 pandemic were featured in ACS Nano as part of its special virtual issue commemorating the 50th anniversary of KAIST. The issue consisted of 14 review articles contributed by KAIST faculty from five departments, including two from Professor Il-Doo Kim from the Department of Materials Science and Engineering, who serves as an associate editor of the ACS Nano.

ACS Nano, the leading international journal in nanoscience and nanotechnology, published a special virtual issue last month, titled ‘Celebrating 50 Years of KAIST: Collective Intelligence and Innovation for Confronting Contemporary Issues.’

This special virtual issue introduced KAIST’s vision of becoming a ‘global value-creative leading university’ and its progress toward this vision over the last 50 years. The issue explained how KAIST has served as the main hub for advanced scientific research and technological innovation in South Korea since its establishment in 1971, and how its faculty and over 69,000 graduates played a key role in propelling the nation’s rapid industrialization and economic development.

The issue also emphasized the need for KAIST to enhance global cooperation and the exchange of ideas in the years to come, especially during the post-COVID era intertwined with the Fourth Industrial Revolution (4IR). In this regard, the issue cited the first ‘KAIST Emerging Materials e-Symposium (EMS)’, which was held online for five days in September of last year with a global audience of over 10,000 participating live via Zoom and YouTube, as a successful example of what academic collaboration could look like in the post-COVID and 4IR eras.

In addition, the “Science & Technology New Deal Project for COVID-19 Response,” a project conducted by KAIST with support from the Ministry of Science and ICT (MSIT) of South Korea, was also introduced as another excellent case of KAIST’s collective intelligence and technological innovation. The issue highlighted some key achievements from this project for overcoming the pandemic-driven crisis, such as: reusable anti-virus filters, negative-pressure ambulances for integrated patient transport and hospitalization, and movable and expandable negative-pressure ward modules.

“We hold our expectations high for the outstanding achievements and progress KAIST will have made by its centennial,” said Professor Kim on the background of curating the 14 review articles contributed by KAIST faculty from the fields of Materials Science and Engineering (MSE), Chemical and Biomolecular Engineering (CBE), Nuclear and Quantum Engineering (NQE), Electrical Engineering (EE), and Chemistry (Chem).

Review articles discussing emerging materials and their properties covered photonic carbon dots (Professor Chan Beum Park, MSE), single-atom and ensemble catalysts (Professor Hyunjoo Lee, CBE), and metal/metal oxide electrocatalysts (Professor Sung-Yoon Chung, MSE).

Review articles discussing materials processing covered 2D layered materials synthesis based on interlayer engineering (Professor Kibum Kang, MSE), eco-friendly methods for solar cell production (Professor Bumjoon J. Kim, CBE), an ex-solution process for the synthesis of highly stable catalysts (Professor WooChul Jung, MSE), and 3D light-patterning synthesis of ordered nanostructures (Professor Seokwoo Jeon, MSE, and Professor Dongchan Jang, NQE).

Review articles discussing advanced analysis techniques covered operando materials analyses (Professor Jeong Yeong Park, Chem), graphene liquid cell transmission electron microscopy (Professor Jong Min Yuk, MSE), and multiscale modeling and visualization of materials systems (Professor Seungbum Hong, MSE).

Review articles discussing practical state-of-the-art devices covered chemiresistive hydrogen sensors (Professor Il-Doo Kim, MSE), patient-friendly diagnostics and implantable treatment devices (Professor Steve Park, MSE), triboelectric nanogenerators (Professor Yang-Kyu Choi, EE), and next-generation lithium-air batteries (Professor Hye Ryung Byon, Chem, and Professor Il-Doo Kim, MSE).

In addition to Professor Il-Doo Kim, post-doctoral researcher Dr. Jaewan Ahn from the KAIST Applied Science Research Institute, Dean of the College of Engineering at KAIST Professor Choongsik Bae, and ACS Nano Editor-in-Chief Professor Paul S. Weiss from the University of California, Los Angeles also contributed to the publication of this ACS Nano special virtual issue.

The issue can be viewed and downloaded from the ACS Nano website at https://doi.org/10.1021/acsnano.1c01101.

Image credit: KAIST

Image usage restrictions: News organizations may use or redistribute this image,with proper attribution, as part of news coverage of this paper only.

Publication:

Ahn, J., et al. (2021) Celebrating 50 Years of KAIST: Collective Intelligence and Innovation for Confronting Contemporary Issues. ACS Nano 15(3): 1895-1907. Available online at https://doi.org/10.1021/acsnano.1c01101

Profile:

Il-Doo Kim, Ph.D

Chair Professor

idkim@kaist.ac.kr

http://advnano.kaist.ac.kr

Advanced Nanomaterials and Energy Lab.

Department of Materials Science and Engineering

Membrane Innovation Center for Anti-Virus and Air-Quality Control

https://kaist.ac.kr/

Korea Advanced Institute of Science and Technology (KAIST) Daejeon, Republic of Korea

(END)

2021.03.05 View 31784

ACS Nano Special Edition Highlights Innovations at KAIST

- The collective intelligence and technological innovation of KAIST was highlighted with case studies including the Post-COVID-19 New Deal R&D Initiative Project. -

KAIST’s innovative academic achievements and R&D efforts for addressing the world’s greatest challenges such as the COVID-19 pandemic were featured in ACS Nano as part of its special virtual issue commemorating the 50th anniversary of KAIST. The issue consisted of 14 review articles contributed by KAIST faculty from five departments, including two from Professor Il-Doo Kim from the Department of Materials Science and Engineering, who serves as an associate editor of the ACS Nano.

ACS Nano, the leading international journal in nanoscience and nanotechnology, published a special virtual issue last month, titled ‘Celebrating 50 Years of KAIST: Collective Intelligence and Innovation for Confronting Contemporary Issues.’

This special virtual issue introduced KAIST’s vision of becoming a ‘global value-creative leading university’ and its progress toward this vision over the last 50 years. The issue explained how KAIST has served as the main hub for advanced scientific research and technological innovation in South Korea since its establishment in 1971, and how its faculty and over 69,000 graduates played a key role in propelling the nation’s rapid industrialization and economic development.

The issue also emphasized the need for KAIST to enhance global cooperation and the exchange of ideas in the years to come, especially during the post-COVID era intertwined with the Fourth Industrial Revolution (4IR). In this regard, the issue cited the first ‘KAIST Emerging Materials e-Symposium (EMS)’, which was held online for five days in September of last year with a global audience of over 10,000 participating live via Zoom and YouTube, as a successful example of what academic collaboration could look like in the post-COVID and 4IR eras.

In addition, the “Science & Technology New Deal Project for COVID-19 Response,” a project conducted by KAIST with support from the Ministry of Science and ICT (MSIT) of South Korea, was also introduced as another excellent case of KAIST’s collective intelligence and technological innovation. The issue highlighted some key achievements from this project for overcoming the pandemic-driven crisis, such as: reusable anti-virus filters, negative-pressure ambulances for integrated patient transport and hospitalization, and movable and expandable negative-pressure ward modules.

“We hold our expectations high for the outstanding achievements and progress KAIST will have made by its centennial,” said Professor Kim on the background of curating the 14 review articles contributed by KAIST faculty from the fields of Materials Science and Engineering (MSE), Chemical and Biomolecular Engineering (CBE), Nuclear and Quantum Engineering (NQE), Electrical Engineering (EE), and Chemistry (Chem).

Review articles discussing emerging materials and their properties covered photonic carbon dots (Professor Chan Beum Park, MSE), single-atom and ensemble catalysts (Professor Hyunjoo Lee, CBE), and metal/metal oxide electrocatalysts (Professor Sung-Yoon Chung, MSE).

Review articles discussing materials processing covered 2D layered materials synthesis based on interlayer engineering (Professor Kibum Kang, MSE), eco-friendly methods for solar cell production (Professor Bumjoon J. Kim, CBE), an ex-solution process for the synthesis of highly stable catalysts (Professor WooChul Jung, MSE), and 3D light-patterning synthesis of ordered nanostructures (Professor Seokwoo Jeon, MSE, and Professor Dongchan Jang, NQE).

Review articles discussing advanced analysis techniques covered operando materials analyses (Professor Jeong Yeong Park, Chem), graphene liquid cell transmission electron microscopy (Professor Jong Min Yuk, MSE), and multiscale modeling and visualization of materials systems (Professor Seungbum Hong, MSE).

Review articles discussing practical state-of-the-art devices covered chemiresistive hydrogen sensors (Professor Il-Doo Kim, MSE), patient-friendly diagnostics and implantable treatment devices (Professor Steve Park, MSE), triboelectric nanogenerators (Professor Yang-Kyu Choi, EE), and next-generation lithium-air batteries (Professor Hye Ryung Byon, Chem, and Professor Il-Doo Kim, MSE).

In addition to Professor Il-Doo Kim, post-doctoral researcher Dr. Jaewan Ahn from the KAIST Applied Science Research Institute, Dean of the College of Engineering at KAIST Professor Choongsik Bae, and ACS Nano Editor-in-Chief Professor Paul S. Weiss from the University of California, Los Angeles also contributed to the publication of this ACS Nano special virtual issue.

The issue can be viewed and downloaded from the ACS Nano website at https://doi.org/10.1021/acsnano.1c01101.

Image credit: KAIST

Image usage restrictions: News organizations may use or redistribute this image,with proper attribution, as part of news coverage of this paper only.

Publication:

Ahn, J., et al. (2021) Celebrating 50 Years of KAIST: Collective Intelligence and Innovation for Confronting Contemporary Issues. ACS Nano 15(3): 1895-1907. Available online at https://doi.org/10.1021/acsnano.1c01101

Profile:

Il-Doo Kim, Ph.D

Chair Professor

idkim@kaist.ac.kr

http://advnano.kaist.ac.kr

Advanced Nanomaterials and Energy Lab.

Department of Materials Science and Engineering

Membrane Innovation Center for Anti-Virus and Air-Quality Control

https://kaist.ac.kr/

Korea Advanced Institute of Science and Technology (KAIST) Daejeon, Republic of Korea

(END)

2021.03.05 View 31784 -

Highly Deformable Piezoelectric Nanotruss for Tactile Electronics

With the importance of non-contact environments growing due to COVID-19, tactile electronic devices using haptic technology are gaining traction as new mediums of communication.

Haptic technology is being applied in a wide array of fields such as robotics or interactive displays. haptic gloves are being used for augmented information communication technology. Efficient piezoelectric materials that can convert various mechanical stimuli into electrical signals and vice versa are a prerequisite for advancing high-performing haptic technology.

A research team led by Professor Seungbum Hong confirmed the potential of tactile devices by developing ceramic piezoelectric materials that are three times more deformable. For the fabrication of highly deformable nanomaterials, the research team built a zinc oxide hollow nanostructure using proximity field nanopatterning and atomic layered deposition. The piezoelectric coefficient was measured to be approximately 9.2 pm/V and the nanopillar compression test showed an elastic strain limit of approximately 10%, which is more than three times greater than that of the bulk zinc oxide one.

Piezoelectric ceramics have a high piezoelectric coefficient with a low elastic strain limit, whereas the opposite is true for piezoelectric polymers. Therefore, it has been very challenging to obtain good performance in both high piezoelectric coefficients as well as high elastic strain limits. To break the elastic limit of piezoelectric ceramics, the research team introduced a 3D truss-like hollow nanostructure with nanometer-scale thin walls.

According to the Griffith criterion, the fracture strength of a material is inversely proportional to the square root of the preexisting flaw size. However, a large flaw is less likely to occur in a small structure, which, in turn, enhances the strength of the material. Therefore, implementing the form of a 3D truss-like hollow nanostructure with nanometer-scale thin walls can extend the elastic limit of the material. Furthermore, a monolithic 3D structure can withstand large strains in all directions while simultaneously preventing the loss from the bottleneck. Previously, the fracture property of piezoelectric ceramic materials was difficult to control, owing to the large variance in crack sizes. However, the research team structurally limited the crack sizes to manage the fracture properties.

Professor Hong’s results demonstrate the potential for the development of highly deformable ceramic piezoelectric materials by improving the elastic limit using a 3D hollow nanostructure. Since zinc oxide has a relatively low piezoelectric coefficient compared to other piezoelectric ceramic materials, applying the proposed structure to such components promised better results in terms of the piezoelectric activity.

“With the advent of the non-contact era, the importance of emotional communication is increasing. Through the development of novel tactile interaction technologies, in addition to the current visual and auditory communication, mankind will enter a new era where they can communicate with anyone using all five senses regardless of location as if they are with them in person,” Professor Hong said.

“While additional research must be conducted to realize the application of the proposed designs for haptic enhancement devices, this study holds high value in that it resolves one of the most challenging issues in the use of piezoelectric ceramics, specifically opening new possibilities for their application by overcoming their mechanical constraints.

The research was reported in Nano Energy and supported by the Ministry of Science and ICT, the Korea Research Foundation, and the KAIST Global Singularity Research Project.

-Profile: Professor Seungbum Hong

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

2021.02.02 View 11427

Highly Deformable Piezoelectric Nanotruss for Tactile Electronics

With the importance of non-contact environments growing due to COVID-19, tactile electronic devices using haptic technology are gaining traction as new mediums of communication.

Haptic technology is being applied in a wide array of fields such as robotics or interactive displays. haptic gloves are being used for augmented information communication technology. Efficient piezoelectric materials that can convert various mechanical stimuli into electrical signals and vice versa are a prerequisite for advancing high-performing haptic technology.

A research team led by Professor Seungbum Hong confirmed the potential of tactile devices by developing ceramic piezoelectric materials that are three times more deformable. For the fabrication of highly deformable nanomaterials, the research team built a zinc oxide hollow nanostructure using proximity field nanopatterning and atomic layered deposition. The piezoelectric coefficient was measured to be approximately 9.2 pm/V and the nanopillar compression test showed an elastic strain limit of approximately 10%, which is more than three times greater than that of the bulk zinc oxide one.

Piezoelectric ceramics have a high piezoelectric coefficient with a low elastic strain limit, whereas the opposite is true for piezoelectric polymers. Therefore, it has been very challenging to obtain good performance in both high piezoelectric coefficients as well as high elastic strain limits. To break the elastic limit of piezoelectric ceramics, the research team introduced a 3D truss-like hollow nanostructure with nanometer-scale thin walls.

According to the Griffith criterion, the fracture strength of a material is inversely proportional to the square root of the preexisting flaw size. However, a large flaw is less likely to occur in a small structure, which, in turn, enhances the strength of the material. Therefore, implementing the form of a 3D truss-like hollow nanostructure with nanometer-scale thin walls can extend the elastic limit of the material. Furthermore, a monolithic 3D structure can withstand large strains in all directions while simultaneously preventing the loss from the bottleneck. Previously, the fracture property of piezoelectric ceramic materials was difficult to control, owing to the large variance in crack sizes. However, the research team structurally limited the crack sizes to manage the fracture properties.

Professor Hong’s results demonstrate the potential for the development of highly deformable ceramic piezoelectric materials by improving the elastic limit using a 3D hollow nanostructure. Since zinc oxide has a relatively low piezoelectric coefficient compared to other piezoelectric ceramic materials, applying the proposed structure to such components promised better results in terms of the piezoelectric activity.

“With the advent of the non-contact era, the importance of emotional communication is increasing. Through the development of novel tactile interaction technologies, in addition to the current visual and auditory communication, mankind will enter a new era where they can communicate with anyone using all five senses regardless of location as if they are with them in person,” Professor Hong said.

“While additional research must be conducted to realize the application of the proposed designs for haptic enhancement devices, this study holds high value in that it resolves one of the most challenging issues in the use of piezoelectric ceramics, specifically opening new possibilities for their application by overcoming their mechanical constraints.

The research was reported in Nano Energy and supported by the Ministry of Science and ICT, the Korea Research Foundation, and the KAIST Global Singularity Research Project.

-Profile: Professor Seungbum Hong

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

2021.02.02 View 11427 -

Sturdy Fabric-Based Piezoelectric Energy Harvester Takes Us One Step Closer to Wearable Electronics

KAIST researchers presented a highly flexible but sturdy wearable piezoelectric harvester using the simple and easy fabrication process of hot pressing and tape casting. This energy harvester, which has record high interfacial adhesion strength, will take us one step closer to being able to manufacture embedded wearable electronics.

A research team led by Professor Seungbum Hong said that the novelty of this result lies in its simplicity, applicability, durability, and its new characterization of wearable electronic devices.

Wearable devices are increasingly being used in a wide array of applications from small electronics to embedded devices such as sensors, actuators, displays, and energy harvesters.

Despite their many advantages, high costs and complex fabrication processes remained challenges for reaching commercialization. In addition, their durability was frequently questioned. To address these issues, Professor Hong’s team developed a new fabrication process and analysis technology for testing the mechanical properties of affordable wearable devices.

For this process, the research team used a hot pressing and tape casting procedure to connect the fabric structures of polyester and a polymer film. Hot pressing has usually been used when making batteries and fuel cells due to its high adhesiveness. Above all, the process takes only two to three minutes.

The newly developed fabrication process will enable the direct application of a device into general garments using hot pressing just as graphic patches can be attached to garments using a heat press.

In particular, when the polymer film is hot pressed onto a fabric below its crystallization temperature, it transforms into an amorphous state. In this state, it compactly attaches to the concave surface of the fabric and infiltrates into the gaps between the transverse wefts and longitudinal warps. These features result in high interfacial adhesion strength. For this reason, hot pressing has the potential to reduce the cost of fabrication through the direct application of fabric-based wearable devices to common garments.

In addition to the conventional durability test of bending cycles, the newly introduced surface and interfacial cutting analysis system proved the high mechanical durability of the fabric-based wearable device by measuring the high interfacial adhesion strength between the fabric and the polymer film. Professor Hong said the study lays a new foundation for the manufacturing process and analysis of wearable devices using fabrics and polymers.

He added that his team first used the surface and interfacial cutting analysis system (SAICAS) in the field of wearable electronics to test the mechanical properties of polymer-based wearable devices. Their surface and interfacial cutting analysis system is more precise than conventional methods (peel test, tape test, and microstretch test) because it qualitatively and quantitatively measures the adhesion strength.

Professor Hong explained, “This study could enable the commercialization of highly durable wearable devices based on the analysis of their interfacial adhesion strength. Our study lays a new foundation for the manufacturing process and analysis of other devices using fabrics and polymers. We look forward to fabric-based wearable electronics hitting the market very soon.”

The results of this study were registered as a domestic patent in Korea last year, and published in Nano Energy this month. This study has been conducted through collaboration with Professor Yong Min Lee in the Department of Energy Science and Engineering at DGIST, Professor Kwangsoo No in the Department of Materials Science and Engineering at KAIST, and Professor Seunghwa Ryu in the Department of Mechanical Engineering at KAIST.

This study was supported by the High-Risk High-Return Project and the Global Singularity Research Project at KAIST, the National Research Foundation, and the Ministry of Science and ICT in Korea.

-Publication:

Jaegyu Kim, Seoungwoo Byun, Sangryun Lee, Jeongjae Ryu, Seongwoo Cho, Chungik Oh, Hongjun Kim, Kwangsoo No, Seunghwa Ryu, Yong Min Lee, Seungbum Hong*, Nano Energy 75 (2020), 104992.

https://doi.org/10.1016/j.nanoen.2020.104992

-Profile: Professor Seungbum Hong

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

2020.09.17 View 14291

Sturdy Fabric-Based Piezoelectric Energy Harvester Takes Us One Step Closer to Wearable Electronics

KAIST researchers presented a highly flexible but sturdy wearable piezoelectric harvester using the simple and easy fabrication process of hot pressing and tape casting. This energy harvester, which has record high interfacial adhesion strength, will take us one step closer to being able to manufacture embedded wearable electronics.

A research team led by Professor Seungbum Hong said that the novelty of this result lies in its simplicity, applicability, durability, and its new characterization of wearable electronic devices.

Wearable devices are increasingly being used in a wide array of applications from small electronics to embedded devices such as sensors, actuators, displays, and energy harvesters.

Despite their many advantages, high costs and complex fabrication processes remained challenges for reaching commercialization. In addition, their durability was frequently questioned. To address these issues, Professor Hong’s team developed a new fabrication process and analysis technology for testing the mechanical properties of affordable wearable devices.

For this process, the research team used a hot pressing and tape casting procedure to connect the fabric structures of polyester and a polymer film. Hot pressing has usually been used when making batteries and fuel cells due to its high adhesiveness. Above all, the process takes only two to three minutes.

The newly developed fabrication process will enable the direct application of a device into general garments using hot pressing just as graphic patches can be attached to garments using a heat press.

In particular, when the polymer film is hot pressed onto a fabric below its crystallization temperature, it transforms into an amorphous state. In this state, it compactly attaches to the concave surface of the fabric and infiltrates into the gaps between the transverse wefts and longitudinal warps. These features result in high interfacial adhesion strength. For this reason, hot pressing has the potential to reduce the cost of fabrication through the direct application of fabric-based wearable devices to common garments.

In addition to the conventional durability test of bending cycles, the newly introduced surface and interfacial cutting analysis system proved the high mechanical durability of the fabric-based wearable device by measuring the high interfacial adhesion strength between the fabric and the polymer film. Professor Hong said the study lays a new foundation for the manufacturing process and analysis of wearable devices using fabrics and polymers.

He added that his team first used the surface and interfacial cutting analysis system (SAICAS) in the field of wearable electronics to test the mechanical properties of polymer-based wearable devices. Their surface and interfacial cutting analysis system is more precise than conventional methods (peel test, tape test, and microstretch test) because it qualitatively and quantitatively measures the adhesion strength.

Professor Hong explained, “This study could enable the commercialization of highly durable wearable devices based on the analysis of their interfacial adhesion strength. Our study lays a new foundation for the manufacturing process and analysis of other devices using fabrics and polymers. We look forward to fabric-based wearable electronics hitting the market very soon.”

The results of this study were registered as a domestic patent in Korea last year, and published in Nano Energy this month. This study has been conducted through collaboration with Professor Yong Min Lee in the Department of Energy Science and Engineering at DGIST, Professor Kwangsoo No in the Department of Materials Science and Engineering at KAIST, and Professor Seunghwa Ryu in the Department of Mechanical Engineering at KAIST.

This study was supported by the High-Risk High-Return Project and the Global Singularity Research Project at KAIST, the National Research Foundation, and the Ministry of Science and ICT in Korea.

-Publication:

Jaegyu Kim, Seoungwoo Byun, Sangryun Lee, Jeongjae Ryu, Seongwoo Cho, Chungik Oh, Hongjun Kim, Kwangsoo No, Seunghwa Ryu, Yong Min Lee, Seungbum Hong*, Nano Energy 75 (2020), 104992.

https://doi.org/10.1016/j.nanoen.2020.104992

-Profile: Professor Seungbum Hong

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

2020.09.17 View 14291 -

Atomic Force Microscopy Reveals Nanoscale Dental Erosion from Beverages

KAIST researchers used atomic force microscopy to quantitatively evaluate how acidic and sugary drinks affect human tooth enamel at the nanoscale level. This novel approach is useful for measuring mechanical and morphological changes that occur over time during enamel erosion induced by beverages.

Enamel is the hard-white substance that forms the outer part of a tooth. It is the hardest substance in the human body, even stronger than bone. Its resilient surface is 96 percent mineral, the highest percentage of any body tissue, making it durable and damage-resistant. The enamel acts as a barrier to protect the soft inner layers of the tooth, but can become susceptible to degradation by acids and sugars.

Enamel erosion occurs when the tooth enamel is overexposed to excessive consumption of acidic and sugary food and drinks. The loss of enamel, if left untreated, can lead to various tooth conditions including stains, fractures, sensitivity, and translucence. Once tooth enamel is damaged, it cannot be brought back. Therefore, thorough studies on how enamel erosion starts and develops, especially at the initial stages, are of high scientific and clinical relevance for dental health maintenance.

A research team led by Professor Seungbum Hong from the Department of Materials Science and Engineering at KAIST reported a new method of applying atomic force microscopy (AFM) techniques to study the nanoscale characterization of this early stage of enamel erosion. This study was introduced in the Journal of the Mechanical Behavior of Biomedical Materials (JMBBM) on June 29.

AFM is a very-high-resolution type of scanning probe microscopy (SPM), with demonstrated resolution on the order of fractions of a nanometer (nm) that is equal to one billionth of a meter. AFM generates images by scanning a small cantilever over the surface of a sample, and this can precisely measure the structure and mechanical properties of the sample, such as surface roughness and elastic modulus.

The co-lead authors of the study, Dr. Panpan Li and Dr. Chungik Oh, chose three commercially available popular beverages, Coca-Cola®, Sprite®, and Minute Maid® orange juice, and immersed tooth enamel in these drinks over time to analyze their impacts on human teeth and monitor the etching process on tooth enamel.

Five healthy human molars were obtained from volunteers between age 20 and 35 who visited the KAIST Clinic. After extraction, the teeth were preserved in distilled water before the experiment. The drinks were purchased and opened right before the immersion experiment, and the team utilized AFM to measure the surface topography and elastic modulus map.

The researchers observed that the surface roughness of the tooth enamel increased significantly as the immersion time increased, while the elastic modulus of the enamel surface decreased drastically. It was demonstrated that the enamel surface roughened five times more when it was immersed in beverages for 10 minutes, and that the elastic modulus of tooth enamel was five times lower after five minutes in the drinks.

Additionally, the research team found preferential etching in scratched tooth enamel. Brushing your teeth too hard and toothpastes with polishing particles that are advertised to remove dental biofilms can cause scratches on the enamel surface, which can be preferential sites for etching, the study revealed.

Professor Hong said, “Our study shows that AFM is a suitable technique to characterize variations in the morphology and mechanical properties of dental erosion quantitatively at the nanoscale level.”

This work was supported by the National Research Foundation (NRF), the Ministry of Science and ICT (MSIT), and the KUSTAR-KAIST Institute of Korea.

A dentist at the KAIST Clinic, Dr. Suebean Cho, Dr. Sangmin Shin from the Smile Well Dental, and Professor Kack-Kyun Kim at the Seoul National University School of Dentistry also collaborated in this project.

Publication:

Li, P., et al. (2020) ‘Nanoscale effects of beverages on enamel surface of human teeth: An atomic force microscopy study’. Journal of the Mechanical Behavior of Biomedical Materials (JMBBM), Volume 110. Article No. 103930. Available online at https://doi.org/10.1016/j.jmbbm.2020.103930

Profile: Seungbum Hong, Ph.D.

Associate Professor

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr/

Materials Imaging and Integration (MII) Lab.

Department of Materials Science and Engineering (MSE)

Korea Advanced Institute of Science and Technology (KAIST)

https://www.kaist.ac.kr

Daejeon 34141, Korea

(END)

2020.07.21 View 13297

Atomic Force Microscopy Reveals Nanoscale Dental Erosion from Beverages

KAIST researchers used atomic force microscopy to quantitatively evaluate how acidic and sugary drinks affect human tooth enamel at the nanoscale level. This novel approach is useful for measuring mechanical and morphological changes that occur over time during enamel erosion induced by beverages.

Enamel is the hard-white substance that forms the outer part of a tooth. It is the hardest substance in the human body, even stronger than bone. Its resilient surface is 96 percent mineral, the highest percentage of any body tissue, making it durable and damage-resistant. The enamel acts as a barrier to protect the soft inner layers of the tooth, but can become susceptible to degradation by acids and sugars.

Enamel erosion occurs when the tooth enamel is overexposed to excessive consumption of acidic and sugary food and drinks. The loss of enamel, if left untreated, can lead to various tooth conditions including stains, fractures, sensitivity, and translucence. Once tooth enamel is damaged, it cannot be brought back. Therefore, thorough studies on how enamel erosion starts and develops, especially at the initial stages, are of high scientific and clinical relevance for dental health maintenance.

A research team led by Professor Seungbum Hong from the Department of Materials Science and Engineering at KAIST reported a new method of applying atomic force microscopy (AFM) techniques to study the nanoscale characterization of this early stage of enamel erosion. This study was introduced in the Journal of the Mechanical Behavior of Biomedical Materials (JMBBM) on June 29.

AFM is a very-high-resolution type of scanning probe microscopy (SPM), with demonstrated resolution on the order of fractions of a nanometer (nm) that is equal to one billionth of a meter. AFM generates images by scanning a small cantilever over the surface of a sample, and this can precisely measure the structure and mechanical properties of the sample, such as surface roughness and elastic modulus.

The co-lead authors of the study, Dr. Panpan Li and Dr. Chungik Oh, chose three commercially available popular beverages, Coca-Cola®, Sprite®, and Minute Maid® orange juice, and immersed tooth enamel in these drinks over time to analyze their impacts on human teeth and monitor the etching process on tooth enamel.

Five healthy human molars were obtained from volunteers between age 20 and 35 who visited the KAIST Clinic. After extraction, the teeth were preserved in distilled water before the experiment. The drinks were purchased and opened right before the immersion experiment, and the team utilized AFM to measure the surface topography and elastic modulus map.

The researchers observed that the surface roughness of the tooth enamel increased significantly as the immersion time increased, while the elastic modulus of the enamel surface decreased drastically. It was demonstrated that the enamel surface roughened five times more when it was immersed in beverages for 10 minutes, and that the elastic modulus of tooth enamel was five times lower after five minutes in the drinks.

Additionally, the research team found preferential etching in scratched tooth enamel. Brushing your teeth too hard and toothpastes with polishing particles that are advertised to remove dental biofilms can cause scratches on the enamel surface, which can be preferential sites for etching, the study revealed.

Professor Hong said, “Our study shows that AFM is a suitable technique to characterize variations in the morphology and mechanical properties of dental erosion quantitatively at the nanoscale level.”

This work was supported by the National Research Foundation (NRF), the Ministry of Science and ICT (MSIT), and the KUSTAR-KAIST Institute of Korea.

A dentist at the KAIST Clinic, Dr. Suebean Cho, Dr. Sangmin Shin from the Smile Well Dental, and Professor Kack-Kyun Kim at the Seoul National University School of Dentistry also collaborated in this project.

Publication:

Li, P., et al. (2020) ‘Nanoscale effects of beverages on enamel surface of human teeth: An atomic force microscopy study’. Journal of the Mechanical Behavior of Biomedical Materials (JMBBM), Volume 110. Article No. 103930. Available online at https://doi.org/10.1016/j.jmbbm.2020.103930

Profile: Seungbum Hong, Ph.D.

Associate Professor

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr/

Materials Imaging and Integration (MII) Lab.

Department of Materials Science and Engineering (MSE)

Korea Advanced Institute of Science and Technology (KAIST)

https://www.kaist.ac.kr

Daejeon 34141, Korea

(END)

2020.07.21 View 13297 -

Visualization of Functional Components to Characterize Optimal Composite Electrodes

Researchers have developed a visualization method that will determine the distribution of components in battery electrodes using atomic force microscopy. The method provides insights into the optimal conditions of composite electrodes and takes us one step closer to being able to manufacture next-generation all-solid-state batteries.

Lithium-ion batteries are widely used in smart devices and vehicles. However, their flammability makes them a safety concern, arising from potential leakage of liquid electrolytes.

All-solid-state lithium ion batteries have emerged as an alternative because of their better safety and wider electrochemical stability. Despite their advantages, all-solid-state lithium ion batteries still have drawbacks such as limited ion conductivity, insufficient contact areas, and high interfacial resistance between the electrode and solid electrolyte.

To solve these issues, studies have been conducted on composite electrodes in which lithium ion conducting additives are dispersed as a medium to provide ion conductive paths at the interface and increase the overall ionic conductivity.

It is very important to identify the shape and distribution of the components used in active materials, ion conductors, binders, and conductive additives on a microscopic scale for significantly improving the battery operation performance.

The developed method is able to distinguish regions of each component based on detected signal sensitivity, by using various modes of atomic force microscopy on a multiscale basis, including electrochemical strain microscopy and lateral force microscopy.

For this research project, both conventional electrodes and composite electrodes were tested, and the results were compared. Individual regions were distinguished and nanoscale correlation between ion reactivity distribution and friction force distribution within a single region was determined to examine the effect of the distribution of binder on the electrochemical strain.

The research team explored the electrochemical strain microscopy amplitude/phase and lateral force microscopy friction force dependence on the AC drive voltage and the tip loading force, and used their sensitivities as markers for each component in the composite anode.

This method allows for direct multiscale observation of the composite electrode in ambient condition, distinguishing various components and measuring their properties simultaneously.

Lead author Dr. Hongjun Kim said, “It is easy to prepare the test sample for observation while providing much higher spatial resolution and intensity resolution for detected signals.” He added, “The method also has the advantage of providing 3D surface morphology information for the observed specimens.”

Professor Seungbum Hong from the Department of Material Sciences and Engineering said, “This analytical technique using atomic force microscopy will be useful for quantitatively understanding what role each component of a composite material plays in the final properties.”

“Our method not only will suggest the new direction for next-generation all-solid-state battery design on a multiscale basis but also lay the groundwork for innovation in the manufacturing process of other electrochemical materials.”

This study is published in ACS Applied Energy Materials and supported by the Big Science Research and Development Project under the Ministry of Science and ICT and the National Research Foundation of Korea, the Basic Research Project under the Wearable Platform Materials Technology Center, and KAIST Global Singularity Research Program for 2019 and 2020.