TR

-

KAIST Research Team Develops Electronic Ink for Room-Temperature Printing of High-Resolution, Variable-Stiffness Electronics

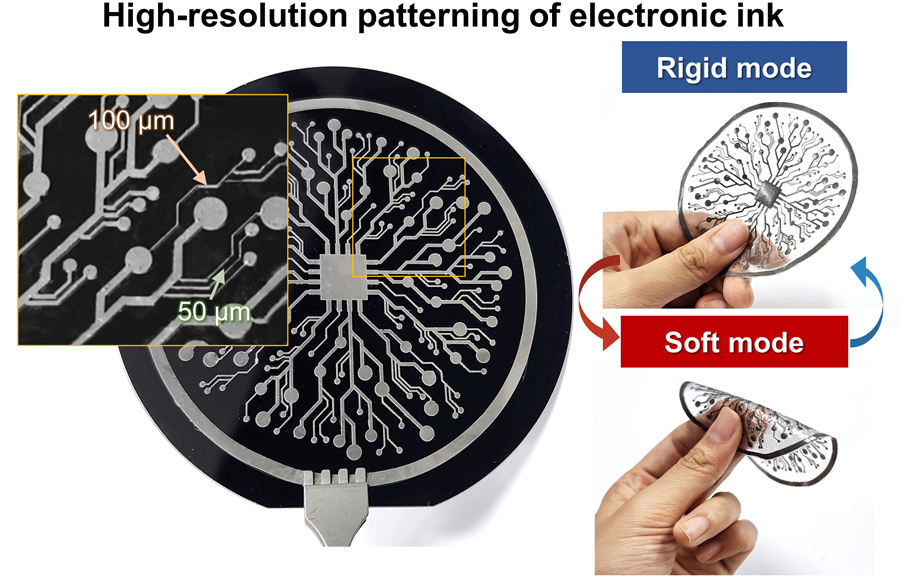

A team of researchers from KAIST and Seoul National University has developed a groundbreaking electronic ink that enables room-temperature printing of variable-stiffness circuits capable of switching between rigid and soft modes. This advancement marks a significant leap toward next-generation wearable, implantable, and robotic devices.

< Photo 1. (From left) Professor Jae-Woong Jeong and PhD candidate Simok Lee of the School of Electrical Engineering, (in separate bubbles, from left) Professor Gun-Hee Lee of Pusan National University, Professor Seongjun Park of Seoul National University, Professor Steve Park of the Department of Materials Science and Engineering>

Variable-stiffness electronics are at the forefront of adaptive technology, offering the ability for a single device to transition between rigid and soft modes depending on its use case. Gallium, a metal known for its high rigidity contrast between solid and liquid states, is a promising candidate for such applications. However, its use has been hindered by challenges including high surface tension, low viscosity, and undesirable phase transitions during manufacturing.

On June 4th, a research team led by Professor Jae-Woong Jeong from the School of Electrical Engineering at KAIST, Professor Seongjun Park from the Digital Healthcare Major at Seoul National University, and Professor Steve Park from the Department of Materials Science and Engineering at KAIST introduced a novel liquid metal electronic ink. This ink allows for micro-scale circuit printing – thinner than a human hair – at room temperature, with the ability to reversibly switch between rigid and soft modes depending on temperature.

The new ink combines printable viscosity with excellent electrical conductivity, enabling the creation of complex, high-resolution multilayer circuits comparable to commercial printed circuit boards (PCBs). These circuits can dynamically change stiffness in response to temperature, presenting new opportunities for multifunctional electronics, medical technologies, and robotics.

Conventional electronics typically have fixed form factors – either rigid for durability or soft for wearability. Rigid devices like smartphones and laptops offer robust performance but are uncomfortable when worn, while soft electronics are more comfortable but lack precise handling. As demand grows for devices that can adapt their stiffness to context, variable-stiffness electronics are becoming increasingly important.

< Figure 1. Fabrication process of stable, high-viscosity electronic ink by dispersing micro-sized gallium particles in a polymer matrix (left). High-resolution large-area circuit printing process through pH-controlled chemical sintering (right). >

To address this challenge, the researchers focused on gallium, which melts just below body temperature. Solid gallium is quite stiff, while its liquid form is fluid and soft. Despite its potential, gallium’s use in electronic printing has been limited by its high surface tension and instability when melted.

To overcome these issues, the team developed a pH-controlled liquid metal ink printing process. By dispersing micro-sized gallium particles into a hydrophilic polyurethane matrix using a neutral solvent (dimethyl sulfoxide, or DMSO), they created a stable, high-viscosity ink suitable for precision printing. During post-print heating, the DMSO decomposes to form an acidic environment, which removes the oxide layer on the gallium particles. This triggers the particles to coalesce into electrically conductive networks with tunable mechanical properties.

The resulting printed circuits exhibit fine feature sizes (~50 μm), high conductivity (2.27 × 10⁶ S/m), and a stiffness modulation ratio of up to 1,465 – allowing the material to shift from plastic-like rigidity to rubber-like softness. Furthermore, the ink is compatible with conventional printing techniques such as screen printing and dip coating, supporting large-area and 3D device fabrication.

< Figure 2. Key features of the electronic ink. (i) High-resolution printing and multilayer integration capability. (ii) Batch fabrication capability through large-area screen printing. (iii) Complex three-dimensional structure printing capability through dip coating. (iv) Excellent electrical conductivity and stiffness control capability.>

The team demonstrated this technology by developing a multi-functional device that operates as a rigid portable electronic under normal conditions but transforms into a soft wearable healthcare device when attached to the body. They also created a neural probe that remains stiff during surgical insertion for accurate positioning but softens once inside brain tissue to reduce inflammation – highlighting its potential for biomedical implants.

< Figure 3. Variable stiffness wearable electronics with high-resolution circuits and multilayer structure comparable to commercial printed circuit boards (PCBs). Functions as a rigid portable electronic device at room temperature, then transforms into a wearable healthcare device by softening at body temperature upon skin contact.>

“The core achievement of this research lies in overcoming the longstanding challenges of liquid metal printing through our innovative technology,” said Professor Jeong. “By controlling the ink’s acidity, we were able to electrically and mechanically connect printed gallium particles, enabling the room-temperature fabrication of high-resolution, large-area circuits with tunable stiffness. This opens up new possibilities for future personal electronics, medical devices, and robotics.”

< Figure 4. Body-temperature softening neural probe implemented by coating electronic ink on an optical waveguide structure. (Left) Remains rigid during surgery for precise manipulation and brain insertion, then softens after implantation to minimize mechanical stress on the brain and greatly enhance biocompatibility. (Right) >

This research was published in Science Advances under the title, “Phase-Change Metal Ink with pH-Controlled Chemical Sintering for Versatile and Scalable Fabrication of Variable Stiffness Electronics.” The work was supported by the National Research Foundation of Korea, the Boston-Korea Project, and the BK21 FOUR Program.

2025.06.04 View 259

KAIST Research Team Develops Electronic Ink for Room-Temperature Printing of High-Resolution, Variable-Stiffness Electronics

A team of researchers from KAIST and Seoul National University has developed a groundbreaking electronic ink that enables room-temperature printing of variable-stiffness circuits capable of switching between rigid and soft modes. This advancement marks a significant leap toward next-generation wearable, implantable, and robotic devices.

< Photo 1. (From left) Professor Jae-Woong Jeong and PhD candidate Simok Lee of the School of Electrical Engineering, (in separate bubbles, from left) Professor Gun-Hee Lee of Pusan National University, Professor Seongjun Park of Seoul National University, Professor Steve Park of the Department of Materials Science and Engineering>

Variable-stiffness electronics are at the forefront of adaptive technology, offering the ability for a single device to transition between rigid and soft modes depending on its use case. Gallium, a metal known for its high rigidity contrast between solid and liquid states, is a promising candidate for such applications. However, its use has been hindered by challenges including high surface tension, low viscosity, and undesirable phase transitions during manufacturing.

On June 4th, a research team led by Professor Jae-Woong Jeong from the School of Electrical Engineering at KAIST, Professor Seongjun Park from the Digital Healthcare Major at Seoul National University, and Professor Steve Park from the Department of Materials Science and Engineering at KAIST introduced a novel liquid metal electronic ink. This ink allows for micro-scale circuit printing – thinner than a human hair – at room temperature, with the ability to reversibly switch between rigid and soft modes depending on temperature.

The new ink combines printable viscosity with excellent electrical conductivity, enabling the creation of complex, high-resolution multilayer circuits comparable to commercial printed circuit boards (PCBs). These circuits can dynamically change stiffness in response to temperature, presenting new opportunities for multifunctional electronics, medical technologies, and robotics.

Conventional electronics typically have fixed form factors – either rigid for durability or soft for wearability. Rigid devices like smartphones and laptops offer robust performance but are uncomfortable when worn, while soft electronics are more comfortable but lack precise handling. As demand grows for devices that can adapt their stiffness to context, variable-stiffness electronics are becoming increasingly important.

< Figure 1. Fabrication process of stable, high-viscosity electronic ink by dispersing micro-sized gallium particles in a polymer matrix (left). High-resolution large-area circuit printing process through pH-controlled chemical sintering (right). >

To address this challenge, the researchers focused on gallium, which melts just below body temperature. Solid gallium is quite stiff, while its liquid form is fluid and soft. Despite its potential, gallium’s use in electronic printing has been limited by its high surface tension and instability when melted.

To overcome these issues, the team developed a pH-controlled liquid metal ink printing process. By dispersing micro-sized gallium particles into a hydrophilic polyurethane matrix using a neutral solvent (dimethyl sulfoxide, or DMSO), they created a stable, high-viscosity ink suitable for precision printing. During post-print heating, the DMSO decomposes to form an acidic environment, which removes the oxide layer on the gallium particles. This triggers the particles to coalesce into electrically conductive networks with tunable mechanical properties.

The resulting printed circuits exhibit fine feature sizes (~50 μm), high conductivity (2.27 × 10⁶ S/m), and a stiffness modulation ratio of up to 1,465 – allowing the material to shift from plastic-like rigidity to rubber-like softness. Furthermore, the ink is compatible with conventional printing techniques such as screen printing and dip coating, supporting large-area and 3D device fabrication.

< Figure 2. Key features of the electronic ink. (i) High-resolution printing and multilayer integration capability. (ii) Batch fabrication capability through large-area screen printing. (iii) Complex three-dimensional structure printing capability through dip coating. (iv) Excellent electrical conductivity and stiffness control capability.>

The team demonstrated this technology by developing a multi-functional device that operates as a rigid portable electronic under normal conditions but transforms into a soft wearable healthcare device when attached to the body. They also created a neural probe that remains stiff during surgical insertion for accurate positioning but softens once inside brain tissue to reduce inflammation – highlighting its potential for biomedical implants.

< Figure 3. Variable stiffness wearable electronics with high-resolution circuits and multilayer structure comparable to commercial printed circuit boards (PCBs). Functions as a rigid portable electronic device at room temperature, then transforms into a wearable healthcare device by softening at body temperature upon skin contact.>

“The core achievement of this research lies in overcoming the longstanding challenges of liquid metal printing through our innovative technology,” said Professor Jeong. “By controlling the ink’s acidity, we were able to electrically and mechanically connect printed gallium particles, enabling the room-temperature fabrication of high-resolution, large-area circuits with tunable stiffness. This opens up new possibilities for future personal electronics, medical devices, and robotics.”

< Figure 4. Body-temperature softening neural probe implemented by coating electronic ink on an optical waveguide structure. (Left) Remains rigid during surgery for precise manipulation and brain insertion, then softens after implantation to minimize mechanical stress on the brain and greatly enhance biocompatibility. (Right) >

This research was published in Science Advances under the title, “Phase-Change Metal Ink with pH-Controlled Chemical Sintering for Versatile and Scalable Fabrication of Variable Stiffness Electronics.” The work was supported by the National Research Foundation of Korea, the Boston-Korea Project, and the BK21 FOUR Program.

2025.06.04 View 259 -

RAIBO Runs over Walls with Feline Agility... Ready for Effortless Search over Mountaineous and Rough Terrains

< Photo 1. Research Team Photo (Professor Jemin Hwangbo, second from right in the front row) >

KAIST's quadrupedal robot, RAIBO, can now move at high speed across discontinuous and complex terrains such as stairs, gaps, walls, and debris. It has demonstrated its ability to run on vertical walls, leap over 1.3-meter-wide gaps, sprint at approximately 14.4 km/h over stepping stones, and move quickly and nimbly on terrain combining 30° slopes, stairs, and stepping stones. RaiBo is expected to be deployed soon for practical missions such as disaster site exploration and mountain searches.

Professor Jemin Hwangbo's research team in the Department of Mechanical Engineering at our university announced on June 3rd that they have developed a quadrupedal robot navigation framework capable of high-speed locomotion at 14.4 km/h (4m/s) even on discontinuous and complex terrains such as walls, stairs, and stepping stones.

The research team developed a quadrupedal navigation system that enables the robot to reach its target destination quickly and safely in complex and discontinuous terrain.

To achieve this, they approached the problem by breaking it down into two stages: first, developing a planner for planning foothold positions, and second, developing a tracker to accurately follow the planned foothold positions.

First, the planner module quickly searches for physically feasible foothold positions using a sampling-based optimization method with neural network-based heuristics and verifies the optimal path through simulation rollouts.

While existing methods considered various factors such as contact timing and robot posture in addition to foothold positions, this research significantly reduced computational complexity by setting only foothold positions as the search space. Furthermore, inspired by the walking method of cats, the introduction of a structure where the hind feet step on the same spots as the front feet further significantly reduced computational complexity.

< Figure 1. High-speed navigation across various discontinuous terrains >

Second, the tracker module is trained to accurately step on planned positions, and tracking training is conducted through a generative model that competes in environments of appropriate difficulty.

The tracker is trained through reinforcement learning to accurately step on planned plots, and during this process, a generative model called the 'map generator' provides the target distribution.

This generative model is trained simultaneously and adversarially with the tracker to allow the tracker to progressively adapt to more challenging difficulties. Subsequently, a sampling-based planner was designed to generate feasible foothold plans that can reflect the characteristics and performance of the trained tracker.

This hierarchical structure showed superior performance in both planning speed and stability compared to existing techniques, and experiments proved its high-speed locomotion capabilities across various obstacles and discontinuous terrains, as well as its general applicability to unseen terrains.

Professor Jemin Hwangbo stated, "We approached the problem of high-speed navigation in discontinuous terrain, which previously required a significantly large amount of computation, from the simple perspective of how to select the footprint positions. Inspired by the placements of cat's paw, allowing the hind feet to step where the front feet stepped drastically reduced computation. We expect this to significantly expand the range of discontinuous terrain that walking robots can overcome and enable them to traverse it at high speeds, contributing to the robot's ability to perform practical missions such as disaster site exploration and mountain searches."

This research achievement was published in the May 2025 issue of the international journal Science Robotics.

Paper Title: High-speed control and navigation for quadrupedal robots on complex and discrete terrain, (https://www.science.org/doi/10.1126/scirobotics.ads6192)YouTube Link: https://youtu.be/EZbM594T3c4?si=kfxLF2XnVUvYVIyk

2025.06.04 View 235

RAIBO Runs over Walls with Feline Agility... Ready for Effortless Search over Mountaineous and Rough Terrains

< Photo 1. Research Team Photo (Professor Jemin Hwangbo, second from right in the front row) >

KAIST's quadrupedal robot, RAIBO, can now move at high speed across discontinuous and complex terrains such as stairs, gaps, walls, and debris. It has demonstrated its ability to run on vertical walls, leap over 1.3-meter-wide gaps, sprint at approximately 14.4 km/h over stepping stones, and move quickly and nimbly on terrain combining 30° slopes, stairs, and stepping stones. RaiBo is expected to be deployed soon for practical missions such as disaster site exploration and mountain searches.

Professor Jemin Hwangbo's research team in the Department of Mechanical Engineering at our university announced on June 3rd that they have developed a quadrupedal robot navigation framework capable of high-speed locomotion at 14.4 km/h (4m/s) even on discontinuous and complex terrains such as walls, stairs, and stepping stones.

The research team developed a quadrupedal navigation system that enables the robot to reach its target destination quickly and safely in complex and discontinuous terrain.

To achieve this, they approached the problem by breaking it down into two stages: first, developing a planner for planning foothold positions, and second, developing a tracker to accurately follow the planned foothold positions.

First, the planner module quickly searches for physically feasible foothold positions using a sampling-based optimization method with neural network-based heuristics and verifies the optimal path through simulation rollouts.

While existing methods considered various factors such as contact timing and robot posture in addition to foothold positions, this research significantly reduced computational complexity by setting only foothold positions as the search space. Furthermore, inspired by the walking method of cats, the introduction of a structure where the hind feet step on the same spots as the front feet further significantly reduced computational complexity.

< Figure 1. High-speed navigation across various discontinuous terrains >

Second, the tracker module is trained to accurately step on planned positions, and tracking training is conducted through a generative model that competes in environments of appropriate difficulty.

The tracker is trained through reinforcement learning to accurately step on planned plots, and during this process, a generative model called the 'map generator' provides the target distribution.

This generative model is trained simultaneously and adversarially with the tracker to allow the tracker to progressively adapt to more challenging difficulties. Subsequently, a sampling-based planner was designed to generate feasible foothold plans that can reflect the characteristics and performance of the trained tracker.

This hierarchical structure showed superior performance in both planning speed and stability compared to existing techniques, and experiments proved its high-speed locomotion capabilities across various obstacles and discontinuous terrains, as well as its general applicability to unseen terrains.

Professor Jemin Hwangbo stated, "We approached the problem of high-speed navigation in discontinuous terrain, which previously required a significantly large amount of computation, from the simple perspective of how to select the footprint positions. Inspired by the placements of cat's paw, allowing the hind feet to step where the front feet stepped drastically reduced computation. We expect this to significantly expand the range of discontinuous terrain that walking robots can overcome and enable them to traverse it at high speeds, contributing to the robot's ability to perform practical missions such as disaster site exploration and mountain searches."

This research achievement was published in the May 2025 issue of the international journal Science Robotics.

Paper Title: High-speed control and navigation for quadrupedal robots on complex and discrete terrain, (https://www.science.org/doi/10.1126/scirobotics.ads6192)YouTube Link: https://youtu.be/EZbM594T3c4?si=kfxLF2XnVUvYVIyk

2025.06.04 View 235 -

Professor Hyun Myung's Team Wins Challenge at ICRA by IEEE

< Photo 1. (From left) Daebeom Kim (Team Leader, Ph.D. student), Seungjae Lee (Ph.D. student), Seoyeon Jang (Ph.D. student), Jei Gong (Master's student), Professor Hyun Myung >

The Urban Robotics Lab team, led by Professor Hyun Myung from the School of Electrical Engineering at our university, achieved a remarkable first-place overall victory in the Nothing Stands Still Challenge (NSS Challenge) 2025, held at the 2025 IEEE International Conference on Robotics and Automation (ICRA), the world's most prestigious robotics conference, from May 19 to 23 in Atlanta, USA.

The NSS Challenge was co-hosted by HILTI, a global construction company based in Liechtenstein, and Stanford University's Gradient Spaces Group. It is an expanded version of the HILTI SLAM (Simultaneous Localization and Mapping)* Challenge, which has been held since 2021, and is considered one of the most prominent challenges at 2025 IEEE ICRA.*SLAM: Refers to Simultaneous Localization and Mapping, a technology where robots, drones, autonomous vehicles, etc., determine their own position and simultaneously create a map of their surroundings.

< Photo 2. Oral Presentation on the Winning Team's Technology (Speakers: Seungjae Lee, Ph.D. student, and Seoyeon Jang, Ph.D. student) >

This challenge primarily evaluates how accurately and robustly LiDAR scan data, collected at various times, can be registered in situations with frequent structural changes, such as construction and industrial environments. In particular, it is regarded as a highly technical competition because it deals with multi-session localization and mapping (Multi-session SLAM) technology that responds to structural changes occurring over multiple timeframes, rather than just single-point registration accuracy.

The Urban Robotics Lab team secured first place overall, surpassing National Taiwan University (3rd place) and Northwestern Polytechnical University of China (2nd place) by a significant margin, with their unique localization and mapping technology that solves the problem of registering LiDAR data collected across multiple times and spaces. The winning team will be awarded a prize of $4,000.

< Figure 1. Example of Multiway-Registration for Registering Multiple Scans >

The Urban Robotics Lab team independently developed a multiway-registration framework that can robustly register multiple scans even without prior connection information. This framework consists of an algorithm for summarizing feature points within scans and finding correspondences (CubicFeat), an algorithm for performing global registration based on the found correspondences (Quatro), and an algorithm for refining results based on change detection (Chamelion). This combination of technologies ensures stable registration performance based on fixed structures, even in highly dynamic industrial environments.

< Figure 2. Example of Change Detection Using the Chamelion Algorithm>

LiDAR scan registration technology is a core component of SLAM (Simultaneous Localization And Mapping) in various autonomous systems such as autonomous vehicles, autonomous robots, autonomous walking systems, and autonomous flying vehicles.

Professor Hyun Myung of the School of Electrical Engineering stated, "This award-winning technology is evaluated as a case that simultaneously proves both academic value and industrial applicability by maximizing the performance of precisely estimating the relative positions between different scans even in complex environments. I am grateful to the students who challenged themselves and never gave up, even when many teams abandoned due to the high difficulty."

< Figure 3. Competition Result Board, Lower RMSE (Root Mean Squared Error) Indicates Higher Score (Unit: meters)>

Meanwhile, the Urban Robotics Lab team first participated in the SLAM Challenge in 2022, winning second place among academic teams, and in 2023, they secured first place overall in the LiDAR category and first place among academic teams in the vision category.

2025.05.30 View 197

Professor Hyun Myung's Team Wins Challenge at ICRA by IEEE

< Photo 1. (From left) Daebeom Kim (Team Leader, Ph.D. student), Seungjae Lee (Ph.D. student), Seoyeon Jang (Ph.D. student), Jei Gong (Master's student), Professor Hyun Myung >

The Urban Robotics Lab team, led by Professor Hyun Myung from the School of Electrical Engineering at our university, achieved a remarkable first-place overall victory in the Nothing Stands Still Challenge (NSS Challenge) 2025, held at the 2025 IEEE International Conference on Robotics and Automation (ICRA), the world's most prestigious robotics conference, from May 19 to 23 in Atlanta, USA.

The NSS Challenge was co-hosted by HILTI, a global construction company based in Liechtenstein, and Stanford University's Gradient Spaces Group. It is an expanded version of the HILTI SLAM (Simultaneous Localization and Mapping)* Challenge, which has been held since 2021, and is considered one of the most prominent challenges at 2025 IEEE ICRA.*SLAM: Refers to Simultaneous Localization and Mapping, a technology where robots, drones, autonomous vehicles, etc., determine their own position and simultaneously create a map of their surroundings.

< Photo 2. Oral Presentation on the Winning Team's Technology (Speakers: Seungjae Lee, Ph.D. student, and Seoyeon Jang, Ph.D. student) >

This challenge primarily evaluates how accurately and robustly LiDAR scan data, collected at various times, can be registered in situations with frequent structural changes, such as construction and industrial environments. In particular, it is regarded as a highly technical competition because it deals with multi-session localization and mapping (Multi-session SLAM) technology that responds to structural changes occurring over multiple timeframes, rather than just single-point registration accuracy.

The Urban Robotics Lab team secured first place overall, surpassing National Taiwan University (3rd place) and Northwestern Polytechnical University of China (2nd place) by a significant margin, with their unique localization and mapping technology that solves the problem of registering LiDAR data collected across multiple times and spaces. The winning team will be awarded a prize of $4,000.

< Figure 1. Example of Multiway-Registration for Registering Multiple Scans >

The Urban Robotics Lab team independently developed a multiway-registration framework that can robustly register multiple scans even without prior connection information. This framework consists of an algorithm for summarizing feature points within scans and finding correspondences (CubicFeat), an algorithm for performing global registration based on the found correspondences (Quatro), and an algorithm for refining results based on change detection (Chamelion). This combination of technologies ensures stable registration performance based on fixed structures, even in highly dynamic industrial environments.

< Figure 2. Example of Change Detection Using the Chamelion Algorithm>

LiDAR scan registration technology is a core component of SLAM (Simultaneous Localization And Mapping) in various autonomous systems such as autonomous vehicles, autonomous robots, autonomous walking systems, and autonomous flying vehicles.

Professor Hyun Myung of the School of Electrical Engineering stated, "This award-winning technology is evaluated as a case that simultaneously proves both academic value and industrial applicability by maximizing the performance of precisely estimating the relative positions between different scans even in complex environments. I am grateful to the students who challenged themselves and never gave up, even when many teams abandoned due to the high difficulty."

< Figure 3. Competition Result Board, Lower RMSE (Root Mean Squared Error) Indicates Higher Score (Unit: meters)>

Meanwhile, the Urban Robotics Lab team first participated in the SLAM Challenge in 2022, winning second place among academic teams, and in 2023, they secured first place overall in the LiDAR category and first place among academic teams in the vision category.

2025.05.30 View 197 -

KAIST to Develop a Korean-style ChatGPT Platform Specifically Geared Toward Medical Diagnosis and Drug Discovery

On May 23rd, KAIST (President Kwang-Hyung Lee) announced that its Digital Bio-Health AI Research Center (Director: Professor JongChul Ye of KAIST Kim Jaechul Graduate School of AI) has been selected for the Ministry of Science and ICT's 'AI Top-Tier Young Researcher Support Program (AI Star Fellowship Project).' With a total investment of ₩11.5 billion from May 2025 to December 2030, the center will embark on the full-scale development of AI technology and a platform capable of independently inferring and determining the kinds of diseases, and discovering new drugs.

< Photo. On May 20th, a kick-off meeting for the AI Star Fellowship Project was held at KAIST Kim Jaechul Graduate School of AI’s Yangjae Research Center with the KAIST research team and participating organizations of Samsung Medical Center, NAVER Cloud, and HITS. [From left to right in the front row] Professor Jaegul Joo (KAIST), Professor Yoonjae Choi (KAIST), Professor Woo Youn Kim (KAIST/HITS), Professor JongChul Ye (KAIST), Professor Sungsoo Ahn (KAIST), Dr. Haanju Yoo (NAVER Cloud), Yoonho Lee (KAIST), HyeYoon Moon (Samsung Medical Center), Dr. Su Min Kim (Samsung Medical Center) >

This project aims to foster an innovative AI research ecosystem centered on young researchers and develop an inferential AI agent that can utilize and automatically expand specialized knowledge systems in the bio and medical fields.

Professor JongChul Ye of the Kim Jaechul Graduate School of AI will serve as the lead researcher, with young researchers from KAIST including Professors Yoonjae Choi, Kimin Lee, Sungsoo Ahn, and Chanyoung Park, along with mid-career researchers like Professors Jaegul Joo and Woo Youn Kim, jointly undertaking the project. They will collaborate with various laboratories within KAIST to conduct comprehensive research covering the entire cycle from the theoretical foundations of AI inference to its practical application.

Specifically, the main goals include: - Building high-performance inference models that integrate diverse medical knowledge systems to enhance the precision and reliability of diagnosis and treatment. - Developing a convergence inference platform that efficiently combines symbol-based inference with neural network models. - Securing AI technology for new drug development and biomarker discovery based on 'cell ontology.'

Furthermore, through close collaboration with industry and medical institutions such as Samsung Medical Center, NAVER Cloud, and HITS Co., Ltd., the project aims to achieve: - Clinical diagnostic AI utilizing medical knowledge systems. - AI-based molecular target exploration for new drug development. - Commercialization of an extendible AI inference platform.

Professor JongChul Ye, Director of KAIST's Digital Bio-Health AI Research Center, stated, "At a time when competition in AI inference model development is intensifying, it is a great honor for KAIST to lead the development of AI technology specialized in the bio and medical fields with world-class young researchers." He added, "We will do our best to ensure that the participating young researchers reach a world-leading level in terms of research achievements after the completion of this seven-year project starting in 2025."

The AI Star Fellowship is a newly established program where post-doctoral researchers and faculty members within seven years of appointment participate as project leaders (PLs) to independently lead research. Multiple laboratories within a university and demand-side companies form a consortium to operate the program.

Through this initiative, KAIST plans to nurture bio-medical convergence AI talent and simultaneously promote the commercialization of core technologies in collaboration with Samsung Medical Center, NAVER Cloud, and HITS.

2025.05.26 View 913

KAIST to Develop a Korean-style ChatGPT Platform Specifically Geared Toward Medical Diagnosis and Drug Discovery

On May 23rd, KAIST (President Kwang-Hyung Lee) announced that its Digital Bio-Health AI Research Center (Director: Professor JongChul Ye of KAIST Kim Jaechul Graduate School of AI) has been selected for the Ministry of Science and ICT's 'AI Top-Tier Young Researcher Support Program (AI Star Fellowship Project).' With a total investment of ₩11.5 billion from May 2025 to December 2030, the center will embark on the full-scale development of AI technology and a platform capable of independently inferring and determining the kinds of diseases, and discovering new drugs.

< Photo. On May 20th, a kick-off meeting for the AI Star Fellowship Project was held at KAIST Kim Jaechul Graduate School of AI’s Yangjae Research Center with the KAIST research team and participating organizations of Samsung Medical Center, NAVER Cloud, and HITS. [From left to right in the front row] Professor Jaegul Joo (KAIST), Professor Yoonjae Choi (KAIST), Professor Woo Youn Kim (KAIST/HITS), Professor JongChul Ye (KAIST), Professor Sungsoo Ahn (KAIST), Dr. Haanju Yoo (NAVER Cloud), Yoonho Lee (KAIST), HyeYoon Moon (Samsung Medical Center), Dr. Su Min Kim (Samsung Medical Center) >

This project aims to foster an innovative AI research ecosystem centered on young researchers and develop an inferential AI agent that can utilize and automatically expand specialized knowledge systems in the bio and medical fields.

Professor JongChul Ye of the Kim Jaechul Graduate School of AI will serve as the lead researcher, with young researchers from KAIST including Professors Yoonjae Choi, Kimin Lee, Sungsoo Ahn, and Chanyoung Park, along with mid-career researchers like Professors Jaegul Joo and Woo Youn Kim, jointly undertaking the project. They will collaborate with various laboratories within KAIST to conduct comprehensive research covering the entire cycle from the theoretical foundations of AI inference to its practical application.

Specifically, the main goals include: - Building high-performance inference models that integrate diverse medical knowledge systems to enhance the precision and reliability of diagnosis and treatment. - Developing a convergence inference platform that efficiently combines symbol-based inference with neural network models. - Securing AI technology for new drug development and biomarker discovery based on 'cell ontology.'

Furthermore, through close collaboration with industry and medical institutions such as Samsung Medical Center, NAVER Cloud, and HITS Co., Ltd., the project aims to achieve: - Clinical diagnostic AI utilizing medical knowledge systems. - AI-based molecular target exploration for new drug development. - Commercialization of an extendible AI inference platform.

Professor JongChul Ye, Director of KAIST's Digital Bio-Health AI Research Center, stated, "At a time when competition in AI inference model development is intensifying, it is a great honor for KAIST to lead the development of AI technology specialized in the bio and medical fields with world-class young researchers." He added, "We will do our best to ensure that the participating young researchers reach a world-leading level in terms of research achievements after the completion of this seven-year project starting in 2025."

The AI Star Fellowship is a newly established program where post-doctoral researchers and faculty members within seven years of appointment participate as project leaders (PLs) to independently lead research. Multiple laboratories within a university and demand-side companies form a consortium to operate the program.

Through this initiative, KAIST plans to nurture bio-medical convergence AI talent and simultaneously promote the commercialization of core technologies in collaboration with Samsung Medical Center, NAVER Cloud, and HITS.

2025.05.26 View 913 -

KAIST’s Next-Generation Small Satellite-2 Completes a Two-Year Mission – the Successful Observation of Arctic and Forest Changes

KAIST (President Kwang-Hyung Lee) announced on the 25th of May that the Next-Generation Small Satellite-2 developed by the Satellite Technology Research Center (SaTReC, Director Jaeheung Han) and launched aboard the third Nuri rocket from the Naro Space Center at 18:24 on May 25, 2023, has successfully completed its two-year core mission of verifying homegrown Synthetic Aperture Radar (SAR) technology and conducting all-weather Earth observations.

The SAR system onboard the satellite was designed, manufactured, and tested domestically for the first time by KAIST’s Satellite Research Center. As of May 25, 2025, it has successfully completed its two-year in-orbit technology demonstration mission.

Particularly noteworthy is the fact that the SAR system was mounted on the 100 kg-class Next-Generation Small Satellite-2, marking a major step forward in the miniaturization and weight reduction of spaceborne radar systems and strengthening Korea’s competitiveness in satellite technology.

< Figure 1. Conceptual diagram of Earth observation by the Next-Generation Small Satellite No. 2's synthetic aperture radar >

The developed SAR is an active sensor that uses electromagnetic waves, allowing all-weather image acquisition regardless of time of day or weather conditions. This makes it especially useful for monitoring regions like the Korean Peninsula, which frequently experiences rain and cloud cover, as it can observe even in cloudy and rainy conditions or darkness.

Since its launch, the satellite has carried out three to four image acquisitions per day on average, undergoing functionality checks and technology verifications. To date, it has completed over 1,200 Earth observations and the SAR continues to perform stably, supporting ongoing observation tasks even beyond its designated mission lifespan.

< Photo 1. Researchers of the Next-Generation Small Satellite No. 2 at SatRec, taken at the KAIST ground station. (From left) Sung-Og Park, Jung-soo Lee, Hongyoung Park, TaeSeong Jang (Next-Generation Small Satellite No. 2 Project Manager), Seyeon Kim, Mi Young Park, Yongmin Kim, DongGuk Kim >

Although still in the domestic technology verification stage, KAIST’s Satellite Research Center has been collaborating with the Korea Polar Research Institute (Director Hyoung Chul Shin) and the Korea National Park Research Institute (Director Jin Tae Kim) since March 2024 to prioritize imaging of areas of interest related to Arctic ice changes and forest ecosystem monitoring.

KAIST’s Satellite Research Center is conducting repeated observations of Arctic sea ice, and the Remote Sensing and Cryosphere Information Center of the Korea Polar Research Institute is analyzing the results using time-series data to precisely track changes in sea ice area and structure due to climate change.

< Photo 2. Radar Images from Observations on July 24, 2024 - Around the Atchafalaya River in Louisiana, USA. The Wax Lake Delta is seen growing like a leaf. >

Recently, the Korea Polar Research Institute (KOPRI), by integrating observation data from the Next-Generation Small Satellite No. 2 and the European Space Agency's (ESA) Sentinel-1, detected a significant increase of 15 km² in the area of an ice lake behind Canada's Milne Ice Shelf (a massive, floating layer of ice where glaciers flow from land into the sea) between 2021 and 2025. This has exacerbated structural instability and is analyzed as an important sign indicating the acceleration of Arctic climate change.

Hyuncheol Kim, Director of the Remote Sensing and Cryosphere Information Center at the Korea Polar Research Institute, stated, “This research clearly demonstrates how vulnerable Arctic ice shelves are to climate change. We will continue to monitor and analyze Arctic environmental changes using the SAR aboard the Next-Generation Small Satellite-2 and promote international collaboration.” He added, “We also plan to present these findings at international academic conferences and expand educational and outreach efforts to raise public awareness about changes in the Arctic environment.”

< Photo 3. Sinduri Coastal Dune, Taean Coastal National Park, Taean-gun, Chungcheongnam-do >

In collaboration with the Climate Change Research Center of the National Park Research Institute, SAR imagery from the satellite is also being used to study phenological shifts due to climate change, the dieback of conifers in high-altitude zones, and landslide monitoring in forest ecosystems. Researchers are also analyzing the spatial distribution of carbon storage in forest areas using satellite data, comparing it with field measurements to improve accuracy.

Because SAR is unaffected by light and weather conditions, it can observe through fire and smoke during wildfires, making it an exceptionally effective tool for the regular monitoring of large protected areas. It is expected to play an important role in shaping future forest conservation policies.

In addition, KAIST’s Satellite Research Center is working on a system to convert the satellite’s technology demonstration data into standardized imagery products, with budget support from the Korea Aerospace Administration (Administrator Youngbin Yoon), making the data more accessible to research institutions and boosting the usability of the satellite’s observations.

< Photo 4. Jang Bogo Station, Antarctica >

Jaeheung Han, Director of the Satellite Research Center, said, “The significance of the Next-Generation Small Satellite-2 lies not only in the success of domestic development, but also in its direct contribution to real-world environmental analysis and national research efforts. We will continue to focus on expanding the application of SAR data from the satellite.”

KAIST President Kwang-Hyung Lee remarked, “This satellite is a product of KAIST’s advanced space technology and the innovation capacity of its researchers. Its success signals KAIST’s potential to lead in future space technology talent development and R&D, and we will continue to accelerate efforts in this direction.”

< Photo 5. Confirmation of changes in the expanded area of the Milne Ice Shelf lake using observation data from Next-Generation Small Satellite No. 2 and Sentinel-1 >

2025.05.25 View 411

KAIST’s Next-Generation Small Satellite-2 Completes a Two-Year Mission – the Successful Observation of Arctic and Forest Changes

KAIST (President Kwang-Hyung Lee) announced on the 25th of May that the Next-Generation Small Satellite-2 developed by the Satellite Technology Research Center (SaTReC, Director Jaeheung Han) and launched aboard the third Nuri rocket from the Naro Space Center at 18:24 on May 25, 2023, has successfully completed its two-year core mission of verifying homegrown Synthetic Aperture Radar (SAR) technology and conducting all-weather Earth observations.

The SAR system onboard the satellite was designed, manufactured, and tested domestically for the first time by KAIST’s Satellite Research Center. As of May 25, 2025, it has successfully completed its two-year in-orbit technology demonstration mission.

Particularly noteworthy is the fact that the SAR system was mounted on the 100 kg-class Next-Generation Small Satellite-2, marking a major step forward in the miniaturization and weight reduction of spaceborne radar systems and strengthening Korea’s competitiveness in satellite technology.

< Figure 1. Conceptual diagram of Earth observation by the Next-Generation Small Satellite No. 2's synthetic aperture radar >

The developed SAR is an active sensor that uses electromagnetic waves, allowing all-weather image acquisition regardless of time of day or weather conditions. This makes it especially useful for monitoring regions like the Korean Peninsula, which frequently experiences rain and cloud cover, as it can observe even in cloudy and rainy conditions or darkness.

Since its launch, the satellite has carried out three to four image acquisitions per day on average, undergoing functionality checks and technology verifications. To date, it has completed over 1,200 Earth observations and the SAR continues to perform stably, supporting ongoing observation tasks even beyond its designated mission lifespan.

< Photo 1. Researchers of the Next-Generation Small Satellite No. 2 at SatRec, taken at the KAIST ground station. (From left) Sung-Og Park, Jung-soo Lee, Hongyoung Park, TaeSeong Jang (Next-Generation Small Satellite No. 2 Project Manager), Seyeon Kim, Mi Young Park, Yongmin Kim, DongGuk Kim >

Although still in the domestic technology verification stage, KAIST’s Satellite Research Center has been collaborating with the Korea Polar Research Institute (Director Hyoung Chul Shin) and the Korea National Park Research Institute (Director Jin Tae Kim) since March 2024 to prioritize imaging of areas of interest related to Arctic ice changes and forest ecosystem monitoring.

KAIST’s Satellite Research Center is conducting repeated observations of Arctic sea ice, and the Remote Sensing and Cryosphere Information Center of the Korea Polar Research Institute is analyzing the results using time-series data to precisely track changes in sea ice area and structure due to climate change.

< Photo 2. Radar Images from Observations on July 24, 2024 - Around the Atchafalaya River in Louisiana, USA. The Wax Lake Delta is seen growing like a leaf. >

Recently, the Korea Polar Research Institute (KOPRI), by integrating observation data from the Next-Generation Small Satellite No. 2 and the European Space Agency's (ESA) Sentinel-1, detected a significant increase of 15 km² in the area of an ice lake behind Canada's Milne Ice Shelf (a massive, floating layer of ice where glaciers flow from land into the sea) between 2021 and 2025. This has exacerbated structural instability and is analyzed as an important sign indicating the acceleration of Arctic climate change.

Hyuncheol Kim, Director of the Remote Sensing and Cryosphere Information Center at the Korea Polar Research Institute, stated, “This research clearly demonstrates how vulnerable Arctic ice shelves are to climate change. We will continue to monitor and analyze Arctic environmental changes using the SAR aboard the Next-Generation Small Satellite-2 and promote international collaboration.” He added, “We also plan to present these findings at international academic conferences and expand educational and outreach efforts to raise public awareness about changes in the Arctic environment.”

< Photo 3. Sinduri Coastal Dune, Taean Coastal National Park, Taean-gun, Chungcheongnam-do >

In collaboration with the Climate Change Research Center of the National Park Research Institute, SAR imagery from the satellite is also being used to study phenological shifts due to climate change, the dieback of conifers in high-altitude zones, and landslide monitoring in forest ecosystems. Researchers are also analyzing the spatial distribution of carbon storage in forest areas using satellite data, comparing it with field measurements to improve accuracy.

Because SAR is unaffected by light and weather conditions, it can observe through fire and smoke during wildfires, making it an exceptionally effective tool for the regular monitoring of large protected areas. It is expected to play an important role in shaping future forest conservation policies.

In addition, KAIST’s Satellite Research Center is working on a system to convert the satellite’s technology demonstration data into standardized imagery products, with budget support from the Korea Aerospace Administration (Administrator Youngbin Yoon), making the data more accessible to research institutions and boosting the usability of the satellite’s observations.

< Photo 4. Jang Bogo Station, Antarctica >

Jaeheung Han, Director of the Satellite Research Center, said, “The significance of the Next-Generation Small Satellite-2 lies not only in the success of domestic development, but also in its direct contribution to real-world environmental analysis and national research efforts. We will continue to focus on expanding the application of SAR data from the satellite.”

KAIST President Kwang-Hyung Lee remarked, “This satellite is a product of KAIST’s advanced space technology and the innovation capacity of its researchers. Its success signals KAIST’s potential to lead in future space technology talent development and R&D, and we will continue to accelerate efforts in this direction.”

< Photo 5. Confirmation of changes in the expanded area of the Milne Ice Shelf lake using observation data from Next-Generation Small Satellite No. 2 and Sentinel-1 >

2025.05.25 View 411 -

KAIST and Mainz Researchers Unveil 3D Magnon Control, Charting a New Course for Neuromorphic and Quantum Technologies

< Professor Se Kwon Kim of the Department of Physics (left), Dr. Zarzuela of the University of Mainz, Germany (right) >

What if the magnon Hall effect, which processes information using magnons (spin waves) capable of current-free information transfer with magnets, could overcome its current limitation of being possible only on a 2D plane? If magnons could be utilized in 3D space, they would enable flexible design, including 3D circuits, and be applicable in various fields such as next-generation neuromorphic (brain-mimicking) computing structures, similar to human brain information processing. KAIST and an international joint research team have, for the first time in the world, predicted a 3D magnon Hall effect, demonstrating that magnons can move freely and complexly in 3D space, transcending the conventional concept of magnons.

KAIST (President Kwang Hyung Lee) announced on May 22nd that Professor Se Kwon Kim of the Department of Physics, in collaboration with Dr. Ricardo Zarzuela of the University of Mainz, Germany, has revealed that the interaction between magnons (spin waves) and solitons (spin vortices) within complex magnetic structures (topologically textured frustrated magnets) is not simple, but complex in a way that enables novel functionalities.

Magnons (spin waves), which can transmit information like electron movement, are garnering attention as a next-generation information processing technology that transmits information without using current, thus generating no heat. Until now, magnon research has focused on simple magnets where spins are neatly aligned in one direction, and the mathematics describing this was a relatively simple 'Abelian gauge theory.'

The research team demonstrated, for the first time in the world, that in complex spin structures like frustrated magnets, magnons interact and become entangled in complex ways from various directions. They applied an advanced mathematical framework, 'non-Abelian gauge theory,' to describe this movement, which is a groundbreaking achievement.

This research presents the possibility of future applications in low-power logic devices using magnons and topology-based quantum information processing technologies, indicating a potential paradigm shift in future information technology.

In conventional linear magnetic materials, the value representing the magnetic state (order parameter) is given as a vector. In magnonics research based on this, it has been interpreted that a U(1) Abelian gauge field is induced when magnons move in soliton structures like skyrmions. This means that the interaction between solitons and magnons has a structure similar to quantum electrodynamics (QED), which has successfully explained various experimental results such as the magnon Hall effect in 2D magnets.

< Figure. Schematic diagram of non-Abelian magnon quantum chromodynamics describing the dynamics of three types of magnons discovered for the first time in this study.>

However, through this research, the team theoretically revealed that in frustrated magnets, the order parameter must be expressed not as a simple vector but as a quaternion. As a result, the gauge field experienced by magnons resembles an SU(3) non-Abelian gauge field, rather than a simple U(1) Abelian gauge field.

This implies that within frustrated magnets, there are not one or two types of magnons seen in conventional magnets, but three distinct types of magnons, each interacting and intricately entangled with solitons. This structure is highly significant as it resembles quantum chromodynamics (QCD) that describes the strong interaction between quarks mediated by gluons rather than quantum electrodynamics (QED) that describes electromagnetic forces.

Professor Se Kwon Kim stated, "This research presents a powerful theoretical framework to explain the dynamics of magnons occurring within the complex order of frustrated magnets," adding, "By pioneering non-Abelian magnonics, it will be a conceptual turning point that can influence quantum magnetism research as a whole."

The research results, with Dr. Ricardo Zarzuela of the University of Mainz, Germany, as the first author, were published in the world-renowned physics journal Physical Review Letters on May 6th.※ Paper title: "Non-Abelian Gauge Theory for Magnons in Topologically Textured Frustrated Magnets," Phys. Rev. Lett. 134, 186701 (2025)DOI: https://doi.org/10.1103/PhysRevLett.134.186701

This research was supported by the Brain Pool Plus program of the National Research Foundation of Korea.

2025.05.22 View 1032

KAIST and Mainz Researchers Unveil 3D Magnon Control, Charting a New Course for Neuromorphic and Quantum Technologies

< Professor Se Kwon Kim of the Department of Physics (left), Dr. Zarzuela of the University of Mainz, Germany (right) >

What if the magnon Hall effect, which processes information using magnons (spin waves) capable of current-free information transfer with magnets, could overcome its current limitation of being possible only on a 2D plane? If magnons could be utilized in 3D space, they would enable flexible design, including 3D circuits, and be applicable in various fields such as next-generation neuromorphic (brain-mimicking) computing structures, similar to human brain information processing. KAIST and an international joint research team have, for the first time in the world, predicted a 3D magnon Hall effect, demonstrating that magnons can move freely and complexly in 3D space, transcending the conventional concept of magnons.

KAIST (President Kwang Hyung Lee) announced on May 22nd that Professor Se Kwon Kim of the Department of Physics, in collaboration with Dr. Ricardo Zarzuela of the University of Mainz, Germany, has revealed that the interaction between magnons (spin waves) and solitons (spin vortices) within complex magnetic structures (topologically textured frustrated magnets) is not simple, but complex in a way that enables novel functionalities.

Magnons (spin waves), which can transmit information like electron movement, are garnering attention as a next-generation information processing technology that transmits information without using current, thus generating no heat. Until now, magnon research has focused on simple magnets where spins are neatly aligned in one direction, and the mathematics describing this was a relatively simple 'Abelian gauge theory.'

The research team demonstrated, for the first time in the world, that in complex spin structures like frustrated magnets, magnons interact and become entangled in complex ways from various directions. They applied an advanced mathematical framework, 'non-Abelian gauge theory,' to describe this movement, which is a groundbreaking achievement.

This research presents the possibility of future applications in low-power logic devices using magnons and topology-based quantum information processing technologies, indicating a potential paradigm shift in future information technology.

In conventional linear magnetic materials, the value representing the magnetic state (order parameter) is given as a vector. In magnonics research based on this, it has been interpreted that a U(1) Abelian gauge field is induced when magnons move in soliton structures like skyrmions. This means that the interaction between solitons and magnons has a structure similar to quantum electrodynamics (QED), which has successfully explained various experimental results such as the magnon Hall effect in 2D magnets.

< Figure. Schematic diagram of non-Abelian magnon quantum chromodynamics describing the dynamics of three types of magnons discovered for the first time in this study.>

However, through this research, the team theoretically revealed that in frustrated magnets, the order parameter must be expressed not as a simple vector but as a quaternion. As a result, the gauge field experienced by magnons resembles an SU(3) non-Abelian gauge field, rather than a simple U(1) Abelian gauge field.

This implies that within frustrated magnets, there are not one or two types of magnons seen in conventional magnets, but three distinct types of magnons, each interacting and intricately entangled with solitons. This structure is highly significant as it resembles quantum chromodynamics (QCD) that describes the strong interaction between quarks mediated by gluons rather than quantum electrodynamics (QED) that describes electromagnetic forces.

Professor Se Kwon Kim stated, "This research presents a powerful theoretical framework to explain the dynamics of magnons occurring within the complex order of frustrated magnets," adding, "By pioneering non-Abelian magnonics, it will be a conceptual turning point that can influence quantum magnetism research as a whole."

The research results, with Dr. Ricardo Zarzuela of the University of Mainz, Germany, as the first author, were published in the world-renowned physics journal Physical Review Letters on May 6th.※ Paper title: "Non-Abelian Gauge Theory for Magnons in Topologically Textured Frustrated Magnets," Phys. Rev. Lett. 134, 186701 (2025)DOI: https://doi.org/10.1103/PhysRevLett.134.186701

This research was supported by the Brain Pool Plus program of the National Research Foundation of Korea.

2025.05.22 View 1032 -

2025 National Strategic Technology Innovation Forum Held - Seeking ROK-U.S. Cooperation

The Future Institute for National Strategic Technology and Policy (FINST&P) at KAIST will host the 'National Strategic Technology* Innovation Forum for 1st half of 2025' on Thursday, May 22, at the Chung Kunmo Conference Hall in the Academic and Culture Building (E9) at the KAIST Main Campus in Daejeon.

* National Strategic Technologies: Technologies recognized for their strategic importance in terms of diplomacy and security, with significant impact on the national economy and related industries, and serving as the foundation for future innovation, including the creation of new technologies and industries. Currently, 12 major technologies such as AI, advanced bio, quantum, and semiconductors, and 50 detailed key technologies are being selected and supported (「Special Act on Fostering National Strategic Technologies」).

This forum will examine the policy direction for fostering national strategic technologies in South Korea amidst rapidly changing international dynamics, such as escalating conflict between the United States and China and increasing global security uncertainties. Furthermore, it will discuss ways to strengthen technology innovation between South Korea and the United States to secure scientific and technological sovereignty and future growth engines.

The forum will feature: △An opening address by KAIST President Kwang-Hyung Lee △Congratulatory remarks by Minister Sang-im Yoo of the Ministry of Science and ICT △A keynote speech by Robert D. Atkinson, President of the Information Technology and Innovation Foundation (ITIF) of the U.S. Subsequently, △Part 1, ‘ROK-U.S. Science and Technology Cooperation,’ will share the latest global trends in national strategic technologies and discuss ROK-U.S. science and technology cooperation under the U.S.-China technology hegemony structure.

Following this, △Part 2, ‘ROK-U.S. Cooperation in Key Detailed Technology Fields,’ will analyze R&D trends and current issues focusing on major national strategic technologies, and derive action-oriented policy tasks that South Korea can pursue based on ROK-U.S. cooperation.

< National Strategic Technology Innovation Forum Poster >

Each session of Part 1 and Part 2 will consist of presentations by domestic and international experts, followed by a comprehensive discussion and Q&A with the audience, promising more in-depth discussions.

Robert D. Atkinson, President of the U.S. Information Technology and Innovation Foundation (ITIF), in his keynote speech ‘The Trump 2.0 Era: South Korea's New Growth Strategy,’ suggests that South Korea should shift from its existing export-oriented growth to a new growth strategy based on broad technological innovation, and promote technological innovation by improving "shadow regulations" imposed by social practices.

The first presenter in Part 1, Stephen Ezell, Vice President for Global Innovation Policy at ITIF, emphasizes in ‘U.S.-China Conflict: South Korea's Response and Global Implications’ that South Korea must overcome the crisis by improving overall national productivity and fostering a competitive service industry.

Following this, Kyungjin Song, Country Representative of The Asia Foundation Korea Office, suggests in ‘Strengthening ROK-U.S. Strategic Technology Partnership Cooperation’ that as global technological hegemony competition changes the diplomatic and security landscape, ROK-U.S. cooperation should advance towards an institutional and sustainable cooperation foundation through a multi-layered partnership structure involving both countries' parliaments, industries, academia, and civil society.

Jaemin Jung, Dean of the College of Humanities and Social Sciences at KAIST, in ‘The Value of Humanities, Social Sciences, and Arts in the Age of Artificial Intelligence,’ explains the role and importance of the KAIST College of Humanities and Social Sciences in connecting technological innovation with human-centered values, as responsible technological development of artificial intelligence (AI) is difficult without insights into humans, society, and culture, presenting examples through AI joint research projects conducted with MIT.

As the first presenter in Part 2, Yong-hee Kim, Director of the Future Institute for National Strategic Technology and Policy (FINST&P) at KAIST, in ‘ROK-U.S. Cooperation for Truly Sustainable Next-Generation Nuclear Power,’ states that many countries or companies are pursuing nuclear power for carbon neutrality and energy security. He suggests that to achieve sustainable nuclear power, three major issues—safety, spent fuel, and uranium resources—need to be resolved, and the molten salt fast reactor (MSFR), an advanced reactor, can be an effective solution.*Molten Salt Fast Reactor (MSFR): A type of Generation IV nuclear reactor that uses molten salt as nuclear fuel and coolant in a fast neutron reactor.

Byung Hee Hong, Professor at Seoul National University's Department of Chemistry, predicts in ‘Innovation in Strategic Industries Led by Graphene Mass Production Technology’ that graphene is a ‘dream new material’ that will overcome the limitations of existing technologies. If South Korea succeeds in mass-producing graphene, it will bring tremendous innovation across key industries such as AI semiconductors and sensors, quantum computing, and biomedical.

Finally, Hoi-Jun Yoo, Distinguished Professor at the KAIST Graduate School of Artificial Intelligence Semiconductor, in ‘The Present and Future of AI Semiconductors,’ explains that with the full-scale utilization of large-scale AI like ChatGPT, semiconductor design is tending to reorganize from a computation-centric to a memory-centric approach. He then presents the direction and feasibility of mid-to-long-term strategies for the competitive development of Korean AI semiconductors.

KAIST President Kwang-Hyung Lee stated the purpose of the event, saying, "As national strategic technology is a core agenda directly linked to our nation's future growth, KAIST will continue to provide a platform for science and technology and policy to communicate, together with domestic and international industry-academia-research institutions."

This event is co-hosted with the U.S. think tank Information Technology and Innovation Foundation (ITIF), which has played a leading role in science and technology innovation policy, with the sponsorship of the Ministry of Science and ICT.

2025.05.16 View 328

2025 National Strategic Technology Innovation Forum Held - Seeking ROK-U.S. Cooperation

The Future Institute for National Strategic Technology and Policy (FINST&P) at KAIST will host the 'National Strategic Technology* Innovation Forum for 1st half of 2025' on Thursday, May 22, at the Chung Kunmo Conference Hall in the Academic and Culture Building (E9) at the KAIST Main Campus in Daejeon.

* National Strategic Technologies: Technologies recognized for their strategic importance in terms of diplomacy and security, with significant impact on the national economy and related industries, and serving as the foundation for future innovation, including the creation of new technologies and industries. Currently, 12 major technologies such as AI, advanced bio, quantum, and semiconductors, and 50 detailed key technologies are being selected and supported (「Special Act on Fostering National Strategic Technologies」).

This forum will examine the policy direction for fostering national strategic technologies in South Korea amidst rapidly changing international dynamics, such as escalating conflict between the United States and China and increasing global security uncertainties. Furthermore, it will discuss ways to strengthen technology innovation between South Korea and the United States to secure scientific and technological sovereignty and future growth engines.

The forum will feature: △An opening address by KAIST President Kwang-Hyung Lee △Congratulatory remarks by Minister Sang-im Yoo of the Ministry of Science and ICT △A keynote speech by Robert D. Atkinson, President of the Information Technology and Innovation Foundation (ITIF) of the U.S. Subsequently, △Part 1, ‘ROK-U.S. Science and Technology Cooperation,’ will share the latest global trends in national strategic technologies and discuss ROK-U.S. science and technology cooperation under the U.S.-China technology hegemony structure.

Following this, △Part 2, ‘ROK-U.S. Cooperation in Key Detailed Technology Fields,’ will analyze R&D trends and current issues focusing on major national strategic technologies, and derive action-oriented policy tasks that South Korea can pursue based on ROK-U.S. cooperation.

< National Strategic Technology Innovation Forum Poster >

Each session of Part 1 and Part 2 will consist of presentations by domestic and international experts, followed by a comprehensive discussion and Q&A with the audience, promising more in-depth discussions.

Robert D. Atkinson, President of the U.S. Information Technology and Innovation Foundation (ITIF), in his keynote speech ‘The Trump 2.0 Era: South Korea's New Growth Strategy,’ suggests that South Korea should shift from its existing export-oriented growth to a new growth strategy based on broad technological innovation, and promote technological innovation by improving "shadow regulations" imposed by social practices.

The first presenter in Part 1, Stephen Ezell, Vice President for Global Innovation Policy at ITIF, emphasizes in ‘U.S.-China Conflict: South Korea's Response and Global Implications’ that South Korea must overcome the crisis by improving overall national productivity and fostering a competitive service industry.

Following this, Kyungjin Song, Country Representative of The Asia Foundation Korea Office, suggests in ‘Strengthening ROK-U.S. Strategic Technology Partnership Cooperation’ that as global technological hegemony competition changes the diplomatic and security landscape, ROK-U.S. cooperation should advance towards an institutional and sustainable cooperation foundation through a multi-layered partnership structure involving both countries' parliaments, industries, academia, and civil society.

Jaemin Jung, Dean of the College of Humanities and Social Sciences at KAIST, in ‘The Value of Humanities, Social Sciences, and Arts in the Age of Artificial Intelligence,’ explains the role and importance of the KAIST College of Humanities and Social Sciences in connecting technological innovation with human-centered values, as responsible technological development of artificial intelligence (AI) is difficult without insights into humans, society, and culture, presenting examples through AI joint research projects conducted with MIT.

As the first presenter in Part 2, Yong-hee Kim, Director of the Future Institute for National Strategic Technology and Policy (FINST&P) at KAIST, in ‘ROK-U.S. Cooperation for Truly Sustainable Next-Generation Nuclear Power,’ states that many countries or companies are pursuing nuclear power for carbon neutrality and energy security. He suggests that to achieve sustainable nuclear power, three major issues—safety, spent fuel, and uranium resources—need to be resolved, and the molten salt fast reactor (MSFR), an advanced reactor, can be an effective solution.*Molten Salt Fast Reactor (MSFR): A type of Generation IV nuclear reactor that uses molten salt as nuclear fuel and coolant in a fast neutron reactor.

Byung Hee Hong, Professor at Seoul National University's Department of Chemistry, predicts in ‘Innovation in Strategic Industries Led by Graphene Mass Production Technology’ that graphene is a ‘dream new material’ that will overcome the limitations of existing technologies. If South Korea succeeds in mass-producing graphene, it will bring tremendous innovation across key industries such as AI semiconductors and sensors, quantum computing, and biomedical.

Finally, Hoi-Jun Yoo, Distinguished Professor at the KAIST Graduate School of Artificial Intelligence Semiconductor, in ‘The Present and Future of AI Semiconductors,’ explains that with the full-scale utilization of large-scale AI like ChatGPT, semiconductor design is tending to reorganize from a computation-centric to a memory-centric approach. He then presents the direction and feasibility of mid-to-long-term strategies for the competitive development of Korean AI semiconductors.

KAIST President Kwang-Hyung Lee stated the purpose of the event, saying, "As national strategic technology is a core agenda directly linked to our nation's future growth, KAIST will continue to provide a platform for science and technology and policy to communicate, together with domestic and international industry-academia-research institutions."

This event is co-hosted with the U.S. think tank Information Technology and Innovation Foundation (ITIF), which has played a leading role in science and technology innovation policy, with the sponsorship of the Ministry of Science and ICT.

2025.05.16 View 328 -

Decoding Fear: KAIST Identifies An Affective Brain Circuit Crucial for Fear Memory Formation by Non-nociceptive Threat Stimulus

Fear memories can form in the brain following exposure to threatening situations such as natural disasters, accidents, or violence. When these memories become excessive or distorted, they can lead to severe mental health disorders, including post-traumatic stress disorder (PTSD), anxiety disorders, and depression. However, the mechanisms underlying fear memory formation triggered by affective pain rather than direct physical pain have remained largely unexplored – until now.

A KAIST research team has identified, for the first time, a brain circuit specifically responsible for forming fear memories in the absence of physical pain, marking a significant advance in understanding how psychological distress is processed and drives fear memory formation in the brain. This discovery opens the door to the development of targeted treatments for trauma-related conditions by addressing the underlying neural pathways.

< Photo 1. (from left) Professor Jin-Hee Han, Dr. Junho Han and Ph.D. Candidate Boin Suh of the Department of Biological Sciences >

KAIST (President Kwang-Hyung Lee) announced on May 15th that the research team led by Professor Jin-Hee Han in the Department of Biological Sciences has identified the pIC-PBN circuit*, a key neural pathway involved in forming fear memories triggered by psychological threats in the absence of sensory pain. This groundbreaking work was conducted through experiments with mice.*pIC–PBN circuit: A newly identified descending neural pathway from the posterior insular cortex (pIC) to the parabrachial nucleus (PBN), specialized for transmitting psychological threat information.

Traditionally, the lateral parabrachial nucleus (PBN) has been recognized as a critical part of the ascending pain pathway, receiving pain signals from the spinal cord. However, this study reveals a previously unknown role for the PBN in processing fear induced by non-painful psychological stimuli, fundamentally changing our understanding of its function in the brain.

This work is considered the first experimental evidence that 'emotional distress' and 'physical pain' are processed through different neural circuits to form fear memories, making it a significant contribution to the field of neuroscience. It clearly demonstrates the existence of a dedicated pathway (pIC-PBN) for transmitting emotional distress.

The study's first author, Dr. Junho Han, shared the personal motivation behind this research: “Our dog, Lego, is afraid of motorcycles. He never actually crashed into one, but ever since having a traumatizing event of having a motorbike almost run into him, just hearing the sound now triggers a fearful response. Humans react similarly – even if you didn’t have a personal experience of being involved in an accident, a near-miss or exposure to alarming media can create lasting fear memories, which may eventually lead to PTSD.”

He continued, “Until now, fear memory research has mainly relied on experimental models involving physical pain. However, much of real-world human fears arise from psychological threats, rather than from direct physical harm. Despite this, little was known about the brain circuits responsible for processing these psychological threats that can drive fear memory formation.”

To investigate this, the research team developed a novel fear conditioning model that utilizes visual threat stimuli instead of electrical shocks. In this model, mice were exposed to a rapidly expanding visual disk on a ceiling screen, simulating the threat of an approaching predator. This approach allowed the team to demonstrate that fear memories can form in response to a non-nociceptive, psychological threat alone, without the need for physical pain.

< Figure 1. Artificial activation of the posterior insular cortex (pIC) to lateral parabrachial nucleus (PBN) neural circuit induces anxiety-like behaviors and fear memory formation in mice. >

Using advanced chemogenetic and optogenetic techniques, the team precisely controlled neuronal activity, revealing that the lateral parabrachial nucleus (PBN) is essential to form fear memories in response to visual threats. They further traced the origin of these signals to the posterior insular cortex (pIC), a region known to process negative emotions and pain, confirming a direct connection between the two areas.

The study also showed that inhibiting the pIC–PBN circuit significantly reduced fear memory formation in response to visual threats, without affecting innate fear responses or physical pain-based learning. Conversely, artificially activating this circuit alone was sufficient to drive fear memory formation, confirming its role as a key pathway for processing psychological threat information.

< Figure 2. Schematic diagram of brain neural circuits transmitting emotional & physical pain threat signals. Visual threat stimuli do not involve physical pain but can create an anxious state and form fear memory through the affective pain signaling pathway. >

Professor Jin-Hee Han commented, “This study lays an important foundation for understanding how emotional distress-based mental disorders, such as PTSD, panic disorder, and anxiety disorder, develop, and opens new possibilities for targeted treatment approaches.”

The findings, authored by Dr. Junho Han (first author), Ph.D. candidate Boin Suh (second author), and Dr. Jin-Hee Han (corresponding author) of the Department of Biological Sciences, were published online in the international journal Science Advances on May 9, 2025.※ Paper Title: A top-down insular cortex circuit crucial for non-nociceptive fear learning. Science Advances (https://doi.org/10.1101/2024.10.14.618356)※ Author Information: Junho Han (first author), Boin Suh (second author), and Jin-Hee Han (corresponding author)

This research was supported by grants from the National Research Foundation of Korea (NRF-2022M3E5E8081183 and NRF-2017M3C7A1031322).

2025.05.15 View 1274

Decoding Fear: KAIST Identifies An Affective Brain Circuit Crucial for Fear Memory Formation by Non-nociceptive Threat Stimulus