Nature+Research

-

Blue-enriched White Light to Wake You Up in the Morning

(from left: Professor Hyun Jung Chung, Professor Hyeon-Jeong Suk, Taesu Kim and Professor Kyungah Choi)

Here is a good news for those of who have difficulty with morning alertness. A KAIST research team proposed that a blue-enriched LED light can effectively help people overcome morning drowsiness. This study will provide the basis for major changes in future lighting strategies and thereby help create better indoor environments.

Considerable research has been devoted to unmasking circadian rhythms. The 2017 Nobel Prize in Physiology or Medicine went to Jeffrey C. Hall, Michael Rosbash, and Michael W. Young for unveiling the molecular mechanisms that control circadian rhythms. In particular, the relationship between light and its physiological effects has been investigated since the discovery of a novel, third type of photoreceptor in the human retina in the early 2000s. Rods and cones regulate visual effects, while the third type, photosensitive retinal ganglion cells, regulate a large variety of biological and behavioral processes including melatonin and cortisol secretion, alertness, and functional magnetic resonance imaging (fMRI).

Initial studies on light sources have shown that blue monochromatic, fully saturated lights are effective for stimulating physiological responses, but the relative effectiveness of commercially available white light sources is less well understood. Moreover, the research was more focused on the negative effects of blue light; for instance, when people are exposed to blue light at night, they have trouble achieving deep sleep because the light restrains melatonin secretion.

However, Professor Hyeon-Jeong Suk and Professor Kyungah Choi from the Department of Industrial Design and their team argue that the effects of blue-enriched morning light on physiological responses are time dependent, and that it has positive effects on melatonin levels and the subjective perception of alertness, mood, and visual comfort compared with warm white light.

The team conducted an experiment with 15 university students. They investigated whether an hour of morning light exposure with different chromaticity would affect their physiological and subjective responses differently. The decline of melatonin levels was significantly greater after the exposure to blue-enriched white light in comparison with warm white light.

Professor Suk said, “Light takes a huge part of our lives since we spend most of our time indoors. Light is one of the most powerful tools to affect changes in how we perceive and experience the environment around us.”

Professor Choi added, “When we investigate all of the psychological and physiological effects of light, we see there is much more to light than just efficient quantities. I believe that human-centric lighting strategies could be applied to a variety of environments, including residential areas, learning environments, and working spaces to improve our everyday lives.”

This research was collaborated with Professor Hyun Jung Chung from the Graduate School of Nanoscience and Technology and was published in Scientific Reports (10.1038/s41598-018-36791-5) on January 23, 2019.

Figure 1. Changes in melatonin secretion during day and night time

2019.03.06 View 13132

Blue-enriched White Light to Wake You Up in the Morning

(from left: Professor Hyun Jung Chung, Professor Hyeon-Jeong Suk, Taesu Kim and Professor Kyungah Choi)

Here is a good news for those of who have difficulty with morning alertness. A KAIST research team proposed that a blue-enriched LED light can effectively help people overcome morning drowsiness. This study will provide the basis for major changes in future lighting strategies and thereby help create better indoor environments.

Considerable research has been devoted to unmasking circadian rhythms. The 2017 Nobel Prize in Physiology or Medicine went to Jeffrey C. Hall, Michael Rosbash, and Michael W. Young for unveiling the molecular mechanisms that control circadian rhythms. In particular, the relationship between light and its physiological effects has been investigated since the discovery of a novel, third type of photoreceptor in the human retina in the early 2000s. Rods and cones regulate visual effects, while the third type, photosensitive retinal ganglion cells, regulate a large variety of biological and behavioral processes including melatonin and cortisol secretion, alertness, and functional magnetic resonance imaging (fMRI).

Initial studies on light sources have shown that blue monochromatic, fully saturated lights are effective for stimulating physiological responses, but the relative effectiveness of commercially available white light sources is less well understood. Moreover, the research was more focused on the negative effects of blue light; for instance, when people are exposed to blue light at night, they have trouble achieving deep sleep because the light restrains melatonin secretion.

However, Professor Hyeon-Jeong Suk and Professor Kyungah Choi from the Department of Industrial Design and their team argue that the effects of blue-enriched morning light on physiological responses are time dependent, and that it has positive effects on melatonin levels and the subjective perception of alertness, mood, and visual comfort compared with warm white light.

The team conducted an experiment with 15 university students. They investigated whether an hour of morning light exposure with different chromaticity would affect their physiological and subjective responses differently. The decline of melatonin levels was significantly greater after the exposure to blue-enriched white light in comparison with warm white light.

Professor Suk said, “Light takes a huge part of our lives since we spend most of our time indoors. Light is one of the most powerful tools to affect changes in how we perceive and experience the environment around us.”

Professor Choi added, “When we investigate all of the psychological and physiological effects of light, we see there is much more to light than just efficient quantities. I believe that human-centric lighting strategies could be applied to a variety of environments, including residential areas, learning environments, and working spaces to improve our everyday lives.”

This research was collaborated with Professor Hyun Jung Chung from the Graduate School of Nanoscience and Technology and was published in Scientific Reports (10.1038/s41598-018-36791-5) on January 23, 2019.

Figure 1. Changes in melatonin secretion during day and night time

2019.03.06 View 13132 -

Ultrathin Digital Camera Inspired by Xenos Peckii Eyes

(Professor Ki-Hun Jeong from the Department of Bio and Brain Engineering)

The visual system of Xenos peckii, an endoparasite of paper wasps, demonstrates distinct benefits for high sensitivity and high resolution, differing from the compound eyes of most insects. Taking their unique features, a KAIST team developed an ultrathin digital camera that emulates the unique eyes of Xenos peckii.

The ultrathin digital camera offers a wide field of view and high resolution in a slimmer body compared to existing imaging systems. It is expected to support various applications, such as monitoring equipment, medical imaging devices, and mobile imaging systems.

Professor Ki-Hun Jeong from the Department of Bio and Brain Engineering and his team are known for mimicking biological visual organs. The team’s past research includes an LED lens based on the abdominal segments of fireflies and biologically inspired anti-reflective structures.

Recently, the demand for ultrathin digital cameras has increased, due to the miniaturization of electronic and optical devices. However, most camera modules use multiple lenses along the optical axis to compensate for optical aberrations, resulting in a larger volume as well as a thicker total track length of digital cameras. Resolution and sensitivity would be compromised if these modules were to be simply reduced in size and thickness.

To address this issue, the team have developed micro-optical components, inspired from the visual system of Xenos peckii, and combined them with a CMOS (complementary metal oxide semiconductor) image sensor to achieve an ultrathin digital camera.

This new camera, measuring less than 2mm in thickness, emulates the eyes of Xenos peckii by using dozens of microprism arrays and microlens arrays. A microprism and microlens pair form a channel and the light-absorbing medium between the channels reduces optical crosstalk. Each channel captures the partial image at slightly different orientation, and the retrieved partial images are combined into a single image, thereby ensuring a wide field of view and high resolution.

Professor Jeong said, “We have proposed a novel method of fabricating an ultrathin camera. As the first insect-inspired, ultrathin camera that integrates a microcamera on a conventional CMOS image sensor array, our study will have a significant impact in optics and related fields.”

This research, led by PhD candidates Dongmin Keum and Kyung-Won Jang, was published in Light: Science & Applications on October 24, 2018.

Figure 1. Natural Xenos peckii eye and the biological inspiration for the ultrathin digital camera (Light: Science & Applications 2018)

Figure 2. Optical images captured by the bioinspired ultrathin digital camera (Light: Science & Applications 2018)

2018.12.31 View 10019

Ultrathin Digital Camera Inspired by Xenos Peckii Eyes

(Professor Ki-Hun Jeong from the Department of Bio and Brain Engineering)

The visual system of Xenos peckii, an endoparasite of paper wasps, demonstrates distinct benefits for high sensitivity and high resolution, differing from the compound eyes of most insects. Taking their unique features, a KAIST team developed an ultrathin digital camera that emulates the unique eyes of Xenos peckii.

The ultrathin digital camera offers a wide field of view and high resolution in a slimmer body compared to existing imaging systems. It is expected to support various applications, such as monitoring equipment, medical imaging devices, and mobile imaging systems.

Professor Ki-Hun Jeong from the Department of Bio and Brain Engineering and his team are known for mimicking biological visual organs. The team’s past research includes an LED lens based on the abdominal segments of fireflies and biologically inspired anti-reflective structures.

Recently, the demand for ultrathin digital cameras has increased, due to the miniaturization of electronic and optical devices. However, most camera modules use multiple lenses along the optical axis to compensate for optical aberrations, resulting in a larger volume as well as a thicker total track length of digital cameras. Resolution and sensitivity would be compromised if these modules were to be simply reduced in size and thickness.

To address this issue, the team have developed micro-optical components, inspired from the visual system of Xenos peckii, and combined them with a CMOS (complementary metal oxide semiconductor) image sensor to achieve an ultrathin digital camera.

This new camera, measuring less than 2mm in thickness, emulates the eyes of Xenos peckii by using dozens of microprism arrays and microlens arrays. A microprism and microlens pair form a channel and the light-absorbing medium between the channels reduces optical crosstalk. Each channel captures the partial image at slightly different orientation, and the retrieved partial images are combined into a single image, thereby ensuring a wide field of view and high resolution.

Professor Jeong said, “We have proposed a novel method of fabricating an ultrathin camera. As the first insect-inspired, ultrathin camera that integrates a microcamera on a conventional CMOS image sensor array, our study will have a significant impact in optics and related fields.”

This research, led by PhD candidates Dongmin Keum and Kyung-Won Jang, was published in Light: Science & Applications on October 24, 2018.

Figure 1. Natural Xenos peckii eye and the biological inspiration for the ultrathin digital camera (Light: Science & Applications 2018)

Figure 2. Optical images captured by the bioinspired ultrathin digital camera (Light: Science & Applications 2018)

2018.12.31 View 10019 -

Skin Hardness to Estimate Better Human Thermal Status

(Professor Young-Ho Cho and Researcher Sunghyun Yoon)

Under the same temperature and humidity, human thermal status may vary due to individual body constitution and climatic environment. A KAIST research team previously developed a wearable sweat rate sensor for human thermal comfort monitoring. Furthering the development, this time they proposed skin hardness as an additional, independent physiological sign to estimate human thermal status more accurately. This novel approach can be applied to developing systems incorporating human-machine interaction, which requires accurate information about human thermal status.

Professor Young-Ho Cho and his team from the Department of Bio and Brain Engineering had previously studied skin temperature and sweat rate to determine human thermal comfort, and developed a watch-type sweat rate sensor that accurately and steadily detects thermal comfort last February (title: Wearable Sweat Rate Sensors for Human Thermal Comfort Monitoring ).

However, skin temperature and sweat rate are still not enough to estimate exact human thermal comfort. Hence, an additional indicator is required for enhancing the accuracy and reliability of the estimation and the team selected skin hardness. When people feel hot or cold, arrector pili muscles connected to hair follicles contract and expand, and skin hardness comes from this contraction and relaxation of the muscles. Based on the phenomenon of changing skin hardness, the team proposed skin hardness as a new indicator for measuring human thermal sensation.

With this new estimation model using three physiological signs for estimating human thermal status, the team conducted human experiments and verified that skin hardness is effective and independent from the two conventional physiological signs. Adding skin hardness to the conventional model can reduce errors by 23.5%, which makes its estimation more reliable.

The team will develop a sensor that detects skin hardness and applies it to cognitive air-conditioning and heating systems that better interact with humans than existing systems.

Professor Cho said, “Introducing this new indicator, skin hardness, elevates the reliability of measuring human thermal comfort regardless of individual body constitution and climatic environment. Based on this method, we can develop a personalized air conditioning and heating system that will allow affective interaction between humans and machines by sharing both physical and mental health conditions and emotions.”

This research, led by researchers Sunghyun Yoon and Jai Kyoung Sim, was published in Scientific Reports, Vol.8, Article No.12027 on August 13, 2018. (pp.1-6)

Figure 1. Measuring human thermal status through skin hardness

Figure 2. The instrument used for measuring human thermal status through skin hardness

2018.10.17 View 7571

Skin Hardness to Estimate Better Human Thermal Status

(Professor Young-Ho Cho and Researcher Sunghyun Yoon)

Under the same temperature and humidity, human thermal status may vary due to individual body constitution and climatic environment. A KAIST research team previously developed a wearable sweat rate sensor for human thermal comfort monitoring. Furthering the development, this time they proposed skin hardness as an additional, independent physiological sign to estimate human thermal status more accurately. This novel approach can be applied to developing systems incorporating human-machine interaction, which requires accurate information about human thermal status.

Professor Young-Ho Cho and his team from the Department of Bio and Brain Engineering had previously studied skin temperature and sweat rate to determine human thermal comfort, and developed a watch-type sweat rate sensor that accurately and steadily detects thermal comfort last February (title: Wearable Sweat Rate Sensors for Human Thermal Comfort Monitoring ).

However, skin temperature and sweat rate are still not enough to estimate exact human thermal comfort. Hence, an additional indicator is required for enhancing the accuracy and reliability of the estimation and the team selected skin hardness. When people feel hot or cold, arrector pili muscles connected to hair follicles contract and expand, and skin hardness comes from this contraction and relaxation of the muscles. Based on the phenomenon of changing skin hardness, the team proposed skin hardness as a new indicator for measuring human thermal sensation.

With this new estimation model using three physiological signs for estimating human thermal status, the team conducted human experiments and verified that skin hardness is effective and independent from the two conventional physiological signs. Adding skin hardness to the conventional model can reduce errors by 23.5%, which makes its estimation more reliable.

The team will develop a sensor that detects skin hardness and applies it to cognitive air-conditioning and heating systems that better interact with humans than existing systems.

Professor Cho said, “Introducing this new indicator, skin hardness, elevates the reliability of measuring human thermal comfort regardless of individual body constitution and climatic environment. Based on this method, we can develop a personalized air conditioning and heating system that will allow affective interaction between humans and machines by sharing both physical and mental health conditions and emotions.”

This research, led by researchers Sunghyun Yoon and Jai Kyoung Sim, was published in Scientific Reports, Vol.8, Article No.12027 on August 13, 2018. (pp.1-6)

Figure 1. Measuring human thermal status through skin hardness

Figure 2. The instrument used for measuring human thermal status through skin hardness

2018.10.17 View 7571 -

Electron Heating in Weakly Ionized Collisional Plasmas

(from left: Professor Wonho Choe and Research Professor Sanghoo Park)

A KAIST research team successfully identified the underlying principles behind electron heating, which is one of the most important phenomena in plasmas. As the electric heating determines wide range of physical and chemical properties of plasmas, this outcome will allow relevant industries to extend and effectively customize a range of plasma characteristics for their specific needs.

Plasma, frequently called the fourth state of matter, can be mostly formed by artificially energizing gases in standard temperature (25°C) and pressure (1 atm) range. Among the many types of plasma, atmospheric-pressure plasmas have been gaining a great deal of attention due to their unique features and applicability in various scientific and industrial fields.

Because plasma characteristics strongly depends on gas pressure in the sub-atmospheric to atmospheric pressure range, characterizing the plasma at different pressures is a prerequisite for understanding the fundamental principles of plasmas and for their industrial applications.

In that sense, information on the spatio-temporal evolution in the electron density and temperature is very important because various physical and chemical reactions within a plasma arise from electrons. Hence, electron heating has been an interesting topic in the field of plasma.

Because collisions between free electrons and neutral gases are frequent under atmospheric-pressure conditions, there are physical limits to measuring the electron density and temperature in plasmas using conventional diagnostic tools, thus the principles behind free electron heating could not be experimentally revealed.

Moreover, lacking information on a key parameter of electron heating and its controlling methods is troublesome and limit improving the reactivity and applicability of such plasmas.

To address these issues, Professor Wonho Choe and his team from the Department of Nuclear and Quantum Engineering employed neutral bremsstrahlung-based electron diagnostics in order to accurately examine the electron density and temperature in target plasmas. In addition, a novel imaging diagnostics for two dimensional distribution of electron information was developed.

Using the diagnostic technique they developed, the team measured the nanosecond-resolved electron temperature in weakly ionized collisional plasmas, and they succeeded in revealing the spatiotemporal distribution and the fundamental principle involved in the electron heating process.

The team successfully revealed the fundamental principle of the electron heating process under atmospheric to sub-atmospheric pressure (0.25-1atm) conditions through conducting the experiment on the spatiotemporal evolution of electron temperature.

Their findings of the underlying research data on free electrons in weakly ionized collisional plasmas will contribute to enhancing the field of plasma science and their commercial applications.

Professor Choe said, “The results of this study provide a clear picture of electron heating in weakly ionized plasmas under conditions where collisions between free electrons and neutral particles are frequent. We hope this study will be informative and helpful in utilizing and commercializing atmospheric-pressure plasma sources in the near future.”

Articles related to this research, led by Research Professor Sanghoo Park, were published in Scientific Reports on May 14 and July 5.

Figure 1. Nanosecond-resolved visualization of the electron heating structure. Spatiotemporal evolution of 514.5-nm continuum radiation,Te, Ar I emission

Figure 2. Nanosecond-resolved visualization of electron heating. Spatiotemporal evolution of neutral bremsstrahlung at 514.5 nm

2018.09.10 View 7903

Electron Heating in Weakly Ionized Collisional Plasmas

(from left: Professor Wonho Choe and Research Professor Sanghoo Park)

A KAIST research team successfully identified the underlying principles behind electron heating, which is one of the most important phenomena in plasmas. As the electric heating determines wide range of physical and chemical properties of plasmas, this outcome will allow relevant industries to extend and effectively customize a range of plasma characteristics for their specific needs.

Plasma, frequently called the fourth state of matter, can be mostly formed by artificially energizing gases in standard temperature (25°C) and pressure (1 atm) range. Among the many types of plasma, atmospheric-pressure plasmas have been gaining a great deal of attention due to their unique features and applicability in various scientific and industrial fields.

Because plasma characteristics strongly depends on gas pressure in the sub-atmospheric to atmospheric pressure range, characterizing the plasma at different pressures is a prerequisite for understanding the fundamental principles of plasmas and for their industrial applications.

In that sense, information on the spatio-temporal evolution in the electron density and temperature is very important because various physical and chemical reactions within a plasma arise from electrons. Hence, electron heating has been an interesting topic in the field of plasma.

Because collisions between free electrons and neutral gases are frequent under atmospheric-pressure conditions, there are physical limits to measuring the electron density and temperature in plasmas using conventional diagnostic tools, thus the principles behind free electron heating could not be experimentally revealed.

Moreover, lacking information on a key parameter of electron heating and its controlling methods is troublesome and limit improving the reactivity and applicability of such plasmas.

To address these issues, Professor Wonho Choe and his team from the Department of Nuclear and Quantum Engineering employed neutral bremsstrahlung-based electron diagnostics in order to accurately examine the electron density and temperature in target plasmas. In addition, a novel imaging diagnostics for two dimensional distribution of electron information was developed.

Using the diagnostic technique they developed, the team measured the nanosecond-resolved electron temperature in weakly ionized collisional plasmas, and they succeeded in revealing the spatiotemporal distribution and the fundamental principle involved in the electron heating process.

The team successfully revealed the fundamental principle of the electron heating process under atmospheric to sub-atmospheric pressure (0.25-1atm) conditions through conducting the experiment on the spatiotemporal evolution of electron temperature.

Their findings of the underlying research data on free electrons in weakly ionized collisional plasmas will contribute to enhancing the field of plasma science and their commercial applications.

Professor Choe said, “The results of this study provide a clear picture of electron heating in weakly ionized plasmas under conditions where collisions between free electrons and neutral particles are frequent. We hope this study will be informative and helpful in utilizing and commercializing atmospheric-pressure plasma sources in the near future.”

Articles related to this research, led by Research Professor Sanghoo Park, were published in Scientific Reports on May 14 and July 5.

Figure 1. Nanosecond-resolved visualization of the electron heating structure. Spatiotemporal evolution of 514.5-nm continuum radiation,Te, Ar I emission

Figure 2. Nanosecond-resolved visualization of electron heating. Spatiotemporal evolution of neutral bremsstrahlung at 514.5 nm

2018.09.10 View 7903 -

Finding Human Thermal Comfort with a Watch-type Sweat Rate Sensor

(from left: Professor Young-Ho Cho and Researcher SungHyun Yoon)

KAIST developed a watch-type sweat rate sensor. This subminiature device can detect human thermal comfort accurately and steadily by measuring an individual’s sweat rate.

It is natural to sweat more in the summer and less in the winter; however, an individual’s sweat rate may vary in a given environment. Therefore, sweat can be an excellent proxy for sensing core body temperature.

Conventional sweat rate sensors using natural ventilation require bulky external devices, such as pumps and ice condensers. They are usually for physiological experiments, hence they need a manual ventilation process or high power, bulky thermos-pneumatic actuators to lift sweat rate detection chambers above skin for continuous measurement. There is also a small sweat rate sensor, but it needs a long recovery period.

To overcome these problems, Professor Young-Ho Cho and his team from the Department of Bio and Brain Engineering developed a lightweight, watch-type sweat sensor. The team integrated miniaturized thermos-pneumatic actuators for automatic natural ventilation, which allows sweat to be measured continuously.

This watch-type sensor measures sweat rate with the humidity rising rate when the chamber is closed during skin contact. Since the team integrated thermos-pneumatic actuators, the chamber no longer needs to be separated manually from skin after each measurement in order for the chamber to ventilate the collected humidity.

Moreover, this sensor is wind-resistant enough to be used for portable and wearable devices. The team identified that the sensor operates steadily with air velocity ranging up to 1.5m/s, equivalent to the average human walking speed.

Although this subminiature sensor (35mm x 25mm) only weighs 30 grams, it operates continuously for more than four hours using the conventional wrist watch batteries.

The team plans to utilize this technology for developing a new concept of cognitive air-conditioning systems recognizing Human thermal status directly; while the conventional air-conditioning systems measuring air temperature and humidity.

Professor Cho said, “Our sensor for human thermal comfort monitoring can be applied to customized or smart air conditioners. Furthermore, there will be more demands for both physical and mental healthcare, hence this technology will serve as a new platform for personalized emotional communion between humans and devices.”

This research, led by researchers Jai Kyoung Sim and SungHyun Yoon, was published in Scientific Reports on January 19, 2018.

Figure1. The fabricated watch-type sweat rate sensor for human thermal comfort monitoring

Figure 2. Views of the watch-type sweat rate sensor

Figure 3. Operation of the watch-type sweat rate sensor

2018.02.08 View 9825

Finding Human Thermal Comfort with a Watch-type Sweat Rate Sensor

(from left: Professor Young-Ho Cho and Researcher SungHyun Yoon)

KAIST developed a watch-type sweat rate sensor. This subminiature device can detect human thermal comfort accurately and steadily by measuring an individual’s sweat rate.

It is natural to sweat more in the summer and less in the winter; however, an individual’s sweat rate may vary in a given environment. Therefore, sweat can be an excellent proxy for sensing core body temperature.

Conventional sweat rate sensors using natural ventilation require bulky external devices, such as pumps and ice condensers. They are usually for physiological experiments, hence they need a manual ventilation process or high power, bulky thermos-pneumatic actuators to lift sweat rate detection chambers above skin for continuous measurement. There is also a small sweat rate sensor, but it needs a long recovery period.

To overcome these problems, Professor Young-Ho Cho and his team from the Department of Bio and Brain Engineering developed a lightweight, watch-type sweat sensor. The team integrated miniaturized thermos-pneumatic actuators for automatic natural ventilation, which allows sweat to be measured continuously.

This watch-type sensor measures sweat rate with the humidity rising rate when the chamber is closed during skin contact. Since the team integrated thermos-pneumatic actuators, the chamber no longer needs to be separated manually from skin after each measurement in order for the chamber to ventilate the collected humidity.

Moreover, this sensor is wind-resistant enough to be used for portable and wearable devices. The team identified that the sensor operates steadily with air velocity ranging up to 1.5m/s, equivalent to the average human walking speed.

Although this subminiature sensor (35mm x 25mm) only weighs 30 grams, it operates continuously for more than four hours using the conventional wrist watch batteries.

The team plans to utilize this technology for developing a new concept of cognitive air-conditioning systems recognizing Human thermal status directly; while the conventional air-conditioning systems measuring air temperature and humidity.

Professor Cho said, “Our sensor for human thermal comfort monitoring can be applied to customized or smart air conditioners. Furthermore, there will be more demands for both physical and mental healthcare, hence this technology will serve as a new platform for personalized emotional communion between humans and devices.”

This research, led by researchers Jai Kyoung Sim and SungHyun Yoon, was published in Scientific Reports on January 19, 2018.

Figure1. The fabricated watch-type sweat rate sensor for human thermal comfort monitoring

Figure 2. Views of the watch-type sweat rate sensor

Figure 3. Operation of the watch-type sweat rate sensor

2018.02.08 View 9825 -

The Medici Effect: Highly Flexible, Wearable Displays Born in KAIST

(Ph.D. candidate Seungyeop Choi)

How do you feel when technology you saw in a movie is made into reality? Collaboration between the electrical engineering and textile industries has made TVs or smartphone screens displaying on clothing a reality.

A research team led by Professor Kyung Cheol Choi at the School of Electrical Engineering presented wearable displays for various applications including fashion, IT, and healthcare. Integrating OLED (organic light-emitting diode) into fabrics, the team developed the most highly flexible and reliable technology for wearable displays in the world.

Recently, information displays have become increasingly important as they construct the external part of smart devices for the next generation. As world trends are focusing on the Internet of Things (IoTs) and wearable technology, the team drew a lot of attention by making great progress towards commercializing clothing-shaped ‘wearable displays’.

The research for realizing displays on clothing gained considerable attention from academia as well as industry when research on luminescence formed in fabrics was introduced in 2011; however, there was no technology for commercializing it due to its surface roughness and flexibility.

Because of this technical limitation, clothing-shaped wearable displays were thought to be unreachable technology. However, the KAIST team recently succeeded in developing the world’s most highly efficient, light-emitting clothes that can be commercialized.

The research team used two different approaches, fabric-type and fiber-type, in order to realize clothing-shaped wearable displays. In 2015, the team successfully laminated a thin planarization sheet thermally onto fabric to form a surface that is compatible with the OLEDs approximately 200 hundred nanometers thick. Also, the team reported their research outcomes on enhancing the reliability of operating fiber-based OLEDs. In 2016, the team introduced a dip-coating method, capable of uniformly depositing layers, to develop polymer light-emitting diodes, which show high luminance even on thin fabric.

Based on the research performance in 2015 and 2016, Ph.D. candidate Seungyeop Choi took the lead in the research team and succeeded in realizing fabric-based OLEDs, showing high luminance and efficiency while maintaining the flexibility of the fabric.

The long-term reliability of this wearable device that has the world’s best electrical and optical characteristics was verified through their self-developed, organic and inorganic encapsulation technology. According to the team, their wearable device facilitates the operation of OLEDs even at a bending radius of 2mm.

According to Choi, “Having wavy structures and empty spaces, fiber plays a significant role in lowering the mechanical stress on the OLEDs.”

“Screen displayed on our daily clothing is no longer a future technology,” said Professor Choi. “Light-emitting clothes will have considerable influence on not only the e-textile industry but also the automobile and healthcare industries.”

Moreover, the research team remarked, “It means a lot to realize clothing-shaped OLEDs that have the world’s best luminance and efficiency. It is the most flexible fabric-based light-emitting device among those reported. Moreover, noting that this research carried out an in-depth analysis of the mechanical characteristics of the clothing-spared, light-emitting device, the research performance will become a guideline for developing the fabric-based electronics industry.”

This research was funded by the Ministry of Trade, Industry and Energy and collaborated with KOLON Glotech, INC. The research performance was published in Scientific Reports in July.

(OLEDs operating in fabrics)

(Current-voltage-luminance and efficiency of the highly flexible, fabric-based OLEDs;Image of OLEDs after repetitive bending tests;Verification of flexibility through mechanical simulation)

2017.08.24 View 17358

The Medici Effect: Highly Flexible, Wearable Displays Born in KAIST

(Ph.D. candidate Seungyeop Choi)

How do you feel when technology you saw in a movie is made into reality? Collaboration between the electrical engineering and textile industries has made TVs or smartphone screens displaying on clothing a reality.

A research team led by Professor Kyung Cheol Choi at the School of Electrical Engineering presented wearable displays for various applications including fashion, IT, and healthcare. Integrating OLED (organic light-emitting diode) into fabrics, the team developed the most highly flexible and reliable technology for wearable displays in the world.

Recently, information displays have become increasingly important as they construct the external part of smart devices for the next generation. As world trends are focusing on the Internet of Things (IoTs) and wearable technology, the team drew a lot of attention by making great progress towards commercializing clothing-shaped ‘wearable displays’.

The research for realizing displays on clothing gained considerable attention from academia as well as industry when research on luminescence formed in fabrics was introduced in 2011; however, there was no technology for commercializing it due to its surface roughness and flexibility.

Because of this technical limitation, clothing-shaped wearable displays were thought to be unreachable technology. However, the KAIST team recently succeeded in developing the world’s most highly efficient, light-emitting clothes that can be commercialized.

The research team used two different approaches, fabric-type and fiber-type, in order to realize clothing-shaped wearable displays. In 2015, the team successfully laminated a thin planarization sheet thermally onto fabric to form a surface that is compatible with the OLEDs approximately 200 hundred nanometers thick. Also, the team reported their research outcomes on enhancing the reliability of operating fiber-based OLEDs. In 2016, the team introduced a dip-coating method, capable of uniformly depositing layers, to develop polymer light-emitting diodes, which show high luminance even on thin fabric.

Based on the research performance in 2015 and 2016, Ph.D. candidate Seungyeop Choi took the lead in the research team and succeeded in realizing fabric-based OLEDs, showing high luminance and efficiency while maintaining the flexibility of the fabric.

The long-term reliability of this wearable device that has the world’s best electrical and optical characteristics was verified through their self-developed, organic and inorganic encapsulation technology. According to the team, their wearable device facilitates the operation of OLEDs even at a bending radius of 2mm.

According to Choi, “Having wavy structures and empty spaces, fiber plays a significant role in lowering the mechanical stress on the OLEDs.”

“Screen displayed on our daily clothing is no longer a future technology,” said Professor Choi. “Light-emitting clothes will have considerable influence on not only the e-textile industry but also the automobile and healthcare industries.”

Moreover, the research team remarked, “It means a lot to realize clothing-shaped OLEDs that have the world’s best luminance and efficiency. It is the most flexible fabric-based light-emitting device among those reported. Moreover, noting that this research carried out an in-depth analysis of the mechanical characteristics of the clothing-spared, light-emitting device, the research performance will become a guideline for developing the fabric-based electronics industry.”

This research was funded by the Ministry of Trade, Industry and Energy and collaborated with KOLON Glotech, INC. The research performance was published in Scientific Reports in July.

(OLEDs operating in fabrics)

(Current-voltage-luminance and efficiency of the highly flexible, fabric-based OLEDs;Image of OLEDs after repetitive bending tests;Verification of flexibility through mechanical simulation)

2017.08.24 View 17358 -

Material-Independent Nanocoating Antimicrobial Spray Significantly Extends the Shelf Life of Produce

The edible coating on produce has drawn a great deal of attention in the food and agricultural industry. It could not only prolong postharvest shelf life of produce against external changes in the environment but also provide additional nutrients to be useful for human health. However, most versions of the coating have had intrinsic limitations in their practical application. First, highly specific interactions between coating materials and target surfaces are required for a stable and durable coating. Even further, the coating of bulk substrates, such as fruits, is time consuming or is not achievable in the conventional solution-based coating. In this respect, material-independent and rapid coating strategies are highly demanded.

The research team led by Professor Insung Choi of the Department of Chemistry developed a sprayable nanocoating technique using plant-derived polyphenol that can be applied to any surface. This new nanocoating process can be completed in seconds to form nanometer-thick films, allowing for the coating of commodity goods, such as shoe insoles and fruits, in a controlled fashion. For example, spray-coated mandarin oranges and strawberries show significantly-prolonged postharvest shelf life, suggesting the practical potential in edible coatings of perishable produce.

The technology has been patented and is currently being commercialized for widespread use as a means of preserving produce. The research results have recently been published in Scientific Reports on Aug 1.

Polyphenols, a metabolite of photosynthesis, possess several hydroxyl groups and are found in a large number of plants showing excellent antioxidant properties. They have been widely used as a nontoxic food additive and are known to exhibit antibacterial, as well as potential anti-carcinogenic capabilities. Polyphenols can also be used with iron ions, which are naturally found in the body, to form an adhesive complex, which has been used in leather tanning, ink, etc.

The research team combined these chemical properties of polyphenol-iron complexes with spray techniques to develop their nanocoating technology. Compared to conventional immersion coating methods, which dip substrates in specialized coating solutions, this spray technique can coat the select areas more quickly. The spray also prevents cross contamination, which is a big concern for immersion methods. The research team has showcased the spray’s ability to coat a variety of different materials, including metals, plastics, glass, as well as textile fabrics. The polyphenol complex has been used to form antifogging films on corrective lenses, as well as antifungal treatments for shoe soles, demonstrating the versatility of their technique.

Furthermore, the spray has been used to coat produce with a naturally antibacterial, edible film. The coatings significantly improved the shelf life of tangerines and strawberries, preserving freshness beyond 28 days and 58 hours, respectively. (Uncoated fruit decomposed and became moldy under the same conditions). See the image below.

a –I, II: Uncoated and coated tangerines incubated for 14 and 28 days in daily-life settings

b –I: Uncoated and coated strawberries incubated for 58 hours in daily-life settings

b –II: Statistical investigation of the resulting edibility.

Professor Choi said, “Nanocoating technologies are still in their infancy, but they have untapped potential for exciting applications. As we have shown, nanocoatings can be easily adapted for several different uses, and the creative combination of existing nanomaterials and coating methods can synergize to unlock this potential.”

2017.08.10 View 10558

Material-Independent Nanocoating Antimicrobial Spray Significantly Extends the Shelf Life of Produce

The edible coating on produce has drawn a great deal of attention in the food and agricultural industry. It could not only prolong postharvest shelf life of produce against external changes in the environment but also provide additional nutrients to be useful for human health. However, most versions of the coating have had intrinsic limitations in their practical application. First, highly specific interactions between coating materials and target surfaces are required for a stable and durable coating. Even further, the coating of bulk substrates, such as fruits, is time consuming or is not achievable in the conventional solution-based coating. In this respect, material-independent and rapid coating strategies are highly demanded.

The research team led by Professor Insung Choi of the Department of Chemistry developed a sprayable nanocoating technique using plant-derived polyphenol that can be applied to any surface. This new nanocoating process can be completed in seconds to form nanometer-thick films, allowing for the coating of commodity goods, such as shoe insoles and fruits, in a controlled fashion. For example, spray-coated mandarin oranges and strawberries show significantly-prolonged postharvest shelf life, suggesting the practical potential in edible coatings of perishable produce.

The technology has been patented and is currently being commercialized for widespread use as a means of preserving produce. The research results have recently been published in Scientific Reports on Aug 1.

Polyphenols, a metabolite of photosynthesis, possess several hydroxyl groups and are found in a large number of plants showing excellent antioxidant properties. They have been widely used as a nontoxic food additive and are known to exhibit antibacterial, as well as potential anti-carcinogenic capabilities. Polyphenols can also be used with iron ions, which are naturally found in the body, to form an adhesive complex, which has been used in leather tanning, ink, etc.

The research team combined these chemical properties of polyphenol-iron complexes with spray techniques to develop their nanocoating technology. Compared to conventional immersion coating methods, which dip substrates in specialized coating solutions, this spray technique can coat the select areas more quickly. The spray also prevents cross contamination, which is a big concern for immersion methods. The research team has showcased the spray’s ability to coat a variety of different materials, including metals, plastics, glass, as well as textile fabrics. The polyphenol complex has been used to form antifogging films on corrective lenses, as well as antifungal treatments for shoe soles, demonstrating the versatility of their technique.

Furthermore, the spray has been used to coat produce with a naturally antibacterial, edible film. The coatings significantly improved the shelf life of tangerines and strawberries, preserving freshness beyond 28 days and 58 hours, respectively. (Uncoated fruit decomposed and became moldy under the same conditions). See the image below.

a –I, II: Uncoated and coated tangerines incubated for 14 and 28 days in daily-life settings

b –I: Uncoated and coated strawberries incubated for 58 hours in daily-life settings

b –II: Statistical investigation of the resulting edibility.

Professor Choi said, “Nanocoating technologies are still in their infancy, but they have untapped potential for exciting applications. As we have shown, nanocoatings can be easily adapted for several different uses, and the creative combination of existing nanomaterials and coating methods can synergize to unlock this potential.”

2017.08.10 View 10558 -

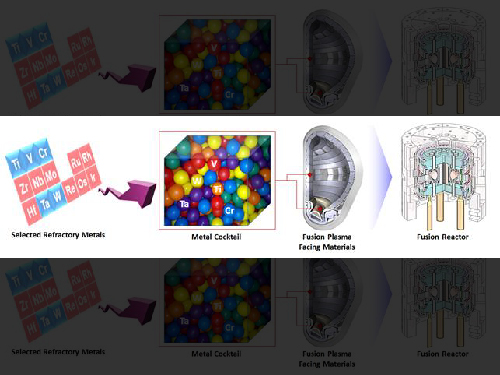

Extreme Materials for Fusion with Metal Cocktail

The research team under Professor Ryu Ho-jin of the Department of Nuclear and Quantum Engineering has developed a new material for facing fusion plasma environments using metal powder mixing technology. This technology is expected to extend the range of materials that can be designed for use in extreme environments such as in fusion power generators.

The durability of the tokamak vessel, which holds high-temperature plasma, is very important to create fusion power reactors, which are expected to be a future energy source. Currently, high-melting-point metals, such as tungsten, are considered plasma-facing materials to protect the tokamak vessel. However, high-energy thermal shocks, plasma ions, and neutrons are fatal to the plasma-facing material during high temperature fusion plasma operation. Therefore, it is necessary to develop new high-performance materials.

The ITER project, in which seven countries including the United States, the EU, and Korea participate jointly, is constructing a nuclear fusion experimental reactor in France with the goal of achieving the first plasma in 2025 and deuterium-tritium fusion operation in 2035. In Korea, the KSTAR tokamak at the National Fusion Research Institute has succeeded in maintaining high-performance plasma for 70 seconds.

Researchers in Europe, the United States, and China, who are leading the research on fusion plasma-facing materials, are studying the improvement of physical properties by adding a small amount of metal elements to tungsten. However, Professor Ryu’s team reported that by mixing various metals’ powders, including tungsten, they have succeeded in producing a new material that has twice the hardness and strength of tungsten. The difference in the atomic sizes of the well-mixed elements in the alloy is very significant because it makes it difficult to deform the alloy.

The team will continue its research to find alloying compositions that optimize mechanical properties as well as thermal conductivity, plasma interactions, neutron irradiation embrittlement, tritium absorption, and high-temperature oxidation properties.

Professor Ryu said, "Fusion plasma-facing materials are exposed to extreme environments and no metal is capable of withstanding thermal shock, plasma, and neutron damage simultaneously. As a result of this research, attempts to develop complex metallic materials for nuclear fusion and nuclear power are expected to become more active around the world. "

Ph.D. candidate Owais Ahmed Waseem is the first author of this project. The research is supported by the Ministry of Science, ICT and Future Planning, the Korea Research Foundation's Fusion Basic Research project, and the Engineering Research Center. The results were published in 'Scientific Report' on May 16.

Figure 1. Tungsten-based high strengh alloy sample

Figure 2. Fusion plasma facing material development by powder processing of refractory elements

2017.05.26 View 11173

Extreme Materials for Fusion with Metal Cocktail

The research team under Professor Ryu Ho-jin of the Department of Nuclear and Quantum Engineering has developed a new material for facing fusion plasma environments using metal powder mixing technology. This technology is expected to extend the range of materials that can be designed for use in extreme environments such as in fusion power generators.

The durability of the tokamak vessel, which holds high-temperature plasma, is very important to create fusion power reactors, which are expected to be a future energy source. Currently, high-melting-point metals, such as tungsten, are considered plasma-facing materials to protect the tokamak vessel. However, high-energy thermal shocks, plasma ions, and neutrons are fatal to the plasma-facing material during high temperature fusion plasma operation. Therefore, it is necessary to develop new high-performance materials.

The ITER project, in which seven countries including the United States, the EU, and Korea participate jointly, is constructing a nuclear fusion experimental reactor in France with the goal of achieving the first plasma in 2025 and deuterium-tritium fusion operation in 2035. In Korea, the KSTAR tokamak at the National Fusion Research Institute has succeeded in maintaining high-performance plasma for 70 seconds.

Researchers in Europe, the United States, and China, who are leading the research on fusion plasma-facing materials, are studying the improvement of physical properties by adding a small amount of metal elements to tungsten. However, Professor Ryu’s team reported that by mixing various metals’ powders, including tungsten, they have succeeded in producing a new material that has twice the hardness and strength of tungsten. The difference in the atomic sizes of the well-mixed elements in the alloy is very significant because it makes it difficult to deform the alloy.

The team will continue its research to find alloying compositions that optimize mechanical properties as well as thermal conductivity, plasma interactions, neutron irradiation embrittlement, tritium absorption, and high-temperature oxidation properties.

Professor Ryu said, "Fusion plasma-facing materials are exposed to extreme environments and no metal is capable of withstanding thermal shock, plasma, and neutron damage simultaneously. As a result of this research, attempts to develop complex metallic materials for nuclear fusion and nuclear power are expected to become more active around the world. "

Ph.D. candidate Owais Ahmed Waseem is the first author of this project. The research is supported by the Ministry of Science, ICT and Future Planning, the Korea Research Foundation's Fusion Basic Research project, and the Engineering Research Center. The results were published in 'Scientific Report' on May 16.

Figure 1. Tungsten-based high strengh alloy sample

Figure 2. Fusion plasma facing material development by powder processing of refractory elements

2017.05.26 View 11173 -

Tactile Sensor for Robot Skin Advanced by KAIST Team

The joint research team of Professors Jung Kim and Inkyu Park from the Department of Mechanical Engineering developed a tactile sensor that can act as skin for robots using silicon and carbon materials. This technology produced a sensor that can absorb shock and distinguish various forms of touch, and it is hoped to be used as robot skin in the future.

Skin serves an important role as the largest organ of the human body. As well as protecting major organs from external shock, skin also measures and distinguishes delicate tactile information and transfer it to the nervous system.

Current robotic sensory technology allows robots to have visual and auditory systems at nearly similar levels to human capacity, but there are limitations in tactile sensors that can detect changes in the environment throughout the body. To apply skin with similar functions as humans to robots, it is essential to develop skin sensor technology with high flexibility and high shock absorption. Another limitation for developing robot skin was connecting numerous sensors all over the body using electric wiring.

To overcome this problem, the research team combined silicon and carbon nanotubes (CNT) to produce a composite, which was then used in combination with a medical imaging technique called electrical impedance tomography (EIT). This led to technology that can distinguish various forms of force over a large area without electrical wiring.

The sensing material can distinguish the location and the size of various forms by touch, and thus can be applied to robot skin that can absorb shock as well as serves as a 3D computer interface and tactile sensor. It can withstand strong force such as a hammer strike, and can be re-used even after partial damage to the sensor by filling and hardening the damaged region with composite. Further, the sensor can be made by filling a 3D shape frame with silicon-nanotube composite. Using this technology, new forms of computer interaces can be developed with both curbed and flat surfaces.

This research was conducted through a collaboration between Professor Park, an expert in nanostructures and sensors, and Professor Kim, an expert in bio-robotics. Hence, the technology is likely to be applied in real products.

Professor Kim said, “Flexible tactile sensors can not only be directly adhered to the body, but they also provides information on modified states in multiple dimensions”. He continued, “This technology will contribute to the soft robot industry in the areas of robot skin and the field of wearable medical appliances.”

Professor Park said, “This technology implemented a next-generation user interface through the integration of functional nano-composite material and computer tomography.”

This research was published in Scientific Reports, a sister journal of Nature, online on January 25. This research was conducted as joint research by first author Hyo-Sang Lee, as well as Donguk Kwon and Ji-seung Cho, and was funded by the Ministry of Science, ICT and Future Planning.

(Fiigrue 1: Robotic hand responding to resistance via a connection with the developed tactile sensor)

(Figure 2: Manufacturing process for pressure-resistant composite using silicon rubber and carbon nanotubes)

(Figure 3: Computer interface using pressure-resistant composite)

2017.04.17 View 14214

Tactile Sensor for Robot Skin Advanced by KAIST Team

The joint research team of Professors Jung Kim and Inkyu Park from the Department of Mechanical Engineering developed a tactile sensor that can act as skin for robots using silicon and carbon materials. This technology produced a sensor that can absorb shock and distinguish various forms of touch, and it is hoped to be used as robot skin in the future.

Skin serves an important role as the largest organ of the human body. As well as protecting major organs from external shock, skin also measures and distinguishes delicate tactile information and transfer it to the nervous system.

Current robotic sensory technology allows robots to have visual and auditory systems at nearly similar levels to human capacity, but there are limitations in tactile sensors that can detect changes in the environment throughout the body. To apply skin with similar functions as humans to robots, it is essential to develop skin sensor technology with high flexibility and high shock absorption. Another limitation for developing robot skin was connecting numerous sensors all over the body using electric wiring.

To overcome this problem, the research team combined silicon and carbon nanotubes (CNT) to produce a composite, which was then used in combination with a medical imaging technique called electrical impedance tomography (EIT). This led to technology that can distinguish various forms of force over a large area without electrical wiring.

The sensing material can distinguish the location and the size of various forms by touch, and thus can be applied to robot skin that can absorb shock as well as serves as a 3D computer interface and tactile sensor. It can withstand strong force such as a hammer strike, and can be re-used even after partial damage to the sensor by filling and hardening the damaged region with composite. Further, the sensor can be made by filling a 3D shape frame with silicon-nanotube composite. Using this technology, new forms of computer interaces can be developed with both curbed and flat surfaces.

This research was conducted through a collaboration between Professor Park, an expert in nanostructures and sensors, and Professor Kim, an expert in bio-robotics. Hence, the technology is likely to be applied in real products.

Professor Kim said, “Flexible tactile sensors can not only be directly adhered to the body, but they also provides information on modified states in multiple dimensions”. He continued, “This technology will contribute to the soft robot industry in the areas of robot skin and the field of wearable medical appliances.”

Professor Park said, “This technology implemented a next-generation user interface through the integration of functional nano-composite material and computer tomography.”

This research was published in Scientific Reports, a sister journal of Nature, online on January 25. This research was conducted as joint research by first author Hyo-Sang Lee, as well as Donguk Kwon and Ji-seung Cho, and was funded by the Ministry of Science, ICT and Future Planning.

(Fiigrue 1: Robotic hand responding to resistance via a connection with the developed tactile sensor)

(Figure 2: Manufacturing process for pressure-resistant composite using silicon rubber and carbon nanotubes)

(Figure 3: Computer interface using pressure-resistant composite)

2017.04.17 View 14214 -

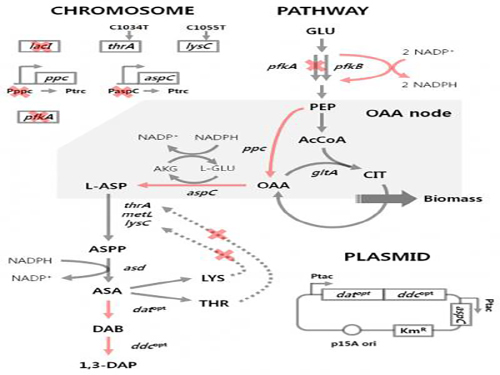

'Engineered Bacterium Produces 1,3-Diaminopropane'

A research team led by Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering at KAIST reported, for the first time, the production of 1,3-diaminopropane via fermentation of an engineered bacterium.

1,3-Diaminopropane is a three carbon diamine, which has a wide range of industrial applications including epoxy resin and cross-linking agents, as well as precursors for pharmaceuticals, agrochemicals, and organic chemicals. It can also be polymerized with dicarboxylic acids to make polyamides (nylons) for use as engineering plastics, medical materials, and adhesives.

Traditionally, 1,3-diaminopropane is derived from petroleum-based processes. In effort to address critical problems such as the depletion of petroleum and environmental issues inherent to the petroleum-based processes, the research team has developed an Escherichia coli (E. coli) strain capable of producing 1,3-diaminopropane. Using this technology, 1,3-diaminopropane can now be produced from renewable biomass instead of petroleum.

E. coli as found in nature is unable to produce 1,3-diaminopropane. Metabolic engineering, a technology to transform microorganisms into highly efficient microbial cell factories capable of producing chemical compounds of interest, was utilized to engineer the E. coli strain. First, naturally existing metabolic pathways for the biosynthesis of 1,3-diaminopropane were introduced into a virtual cell in silico to determine the most efficient metabolic pathway for the 1,3-diaminopropane production. The metabolic pathway selected was then introduced into an E. coli strain and successfully produced 1,3-diaminopropane for the first time in the world.

The research team applied metabolic engineering additionally, and the production titer of 1,3-diaminopropane increased about 21 fold. The Fed-batch fermentation of the engineered E. coli strain produced 13 grams per liter of 1,3-diaminoproapne. With this technology, 1,3-diaminopropane can be produced using renewable biomass, and it will be the starting point for replacing the current petroleum-based processes with bio-based processes.

Professor Lee said, “Our study suggested a possibility to produce 1,3-diaminopropane based on biorefinery. Further study will be done to increase the titer and productivity of 1,3-diaminopropane.”

This work was published online in Scientific Reports on August 11, 2015.

Reference: Chae, T.U. et al. "Metabolic engineering of Escherichia coli for the production of 1,3-diaminopropane, a three carbon diamine," Scientific Reports:

http://www.nature.com/articles/srep13040

This research was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from Ministry of Science, ICT and Future Planning (MSIP) through the National Research Foundation (NRF) of Korea.

Figure 1: Metabolic engineering strategies for 1,3-diaminopropane production using C4 pathway

Figure 2: Fed-batch fermentation profiles of two final engineered E. coli strains

2015.08.12 View 12541

'Engineered Bacterium Produces 1,3-Diaminopropane'

A research team led by Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering at KAIST reported, for the first time, the production of 1,3-diaminopropane via fermentation of an engineered bacterium.

1,3-Diaminopropane is a three carbon diamine, which has a wide range of industrial applications including epoxy resin and cross-linking agents, as well as precursors for pharmaceuticals, agrochemicals, and organic chemicals. It can also be polymerized with dicarboxylic acids to make polyamides (nylons) for use as engineering plastics, medical materials, and adhesives.

Traditionally, 1,3-diaminopropane is derived from petroleum-based processes. In effort to address critical problems such as the depletion of petroleum and environmental issues inherent to the petroleum-based processes, the research team has developed an Escherichia coli (E. coli) strain capable of producing 1,3-diaminopropane. Using this technology, 1,3-diaminopropane can now be produced from renewable biomass instead of petroleum.

E. coli as found in nature is unable to produce 1,3-diaminopropane. Metabolic engineering, a technology to transform microorganisms into highly efficient microbial cell factories capable of producing chemical compounds of interest, was utilized to engineer the E. coli strain. First, naturally existing metabolic pathways for the biosynthesis of 1,3-diaminopropane were introduced into a virtual cell in silico to determine the most efficient metabolic pathway for the 1,3-diaminopropane production. The metabolic pathway selected was then introduced into an E. coli strain and successfully produced 1,3-diaminopropane for the first time in the world.

The research team applied metabolic engineering additionally, and the production titer of 1,3-diaminopropane increased about 21 fold. The Fed-batch fermentation of the engineered E. coli strain produced 13 grams per liter of 1,3-diaminoproapne. With this technology, 1,3-diaminopropane can be produced using renewable biomass, and it will be the starting point for replacing the current petroleum-based processes with bio-based processes.

Professor Lee said, “Our study suggested a possibility to produce 1,3-diaminopropane based on biorefinery. Further study will be done to increase the titer and productivity of 1,3-diaminopropane.”

This work was published online in Scientific Reports on August 11, 2015.

Reference: Chae, T.U. et al. "Metabolic engineering of Escherichia coli for the production of 1,3-diaminopropane, a three carbon diamine," Scientific Reports:

http://www.nature.com/articles/srep13040

This research was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from Ministry of Science, ICT and Future Planning (MSIP) through the National Research Foundation (NRF) of Korea.

Figure 1: Metabolic engineering strategies for 1,3-diaminopropane production using C4 pathway

Figure 2: Fed-batch fermentation profiles of two final engineered E. coli strains

2015.08.12 View 12541 -

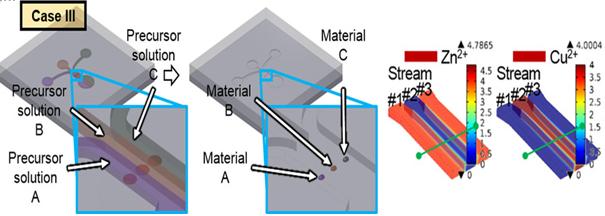

KAIST Develops Subminiature, Power-Efficient Air Pollution Sensing Probe

Professor Inkyu Park and his research team from the Department of Mechanical Engineering at KAIST have developed a subminiature, power-efficient air-pollution sensing probe that can be applied to mobile devices. Their research findings were published online in the January 30th issue of Scientific Reports.

As air pollution has increased, people have taken greater interest in health care. The developed technology could allow people to measure independently the air pollution level of their surrounding environments.

Previous instruments used to measure air pollution levels were bulky and consumed a lot of power. They also often produced inaccurate results when measuring air pollution in which different toxic gases were mixed. These problems could not be resolved with existing semiconductor manufacturing process.

Using local temperature field control technology, Professor Park’s team succeeded in integrating multiple heterogeneous nanomaterials and fitting them onto a small, low-power electronic chip. This microheating sensor can heat microscale regions through local hydrothermal synthesis. Because it requires a miniscale amount of nanomaterials to manufacture, the sensor is most suitable for mobile devices.

Professor Park said, “Our research will contribute to the development of convergence technology in such field as air pollution sensing probes, biosensors, electronic devices, and displays.”

The team's research was supported by the Ministry of Education and the Ministry of Science, ICT and Future Planning, Republic of Korea.

Figure 1 – The Concept of Multiple Nanomaterial Device and Numerical Simulation Results of Precursor Solutions

Figure 2 - Multiple Nanomaterial Manufactured in a Microscale Region

2015.02.27 View 12868

KAIST Develops Subminiature, Power-Efficient Air Pollution Sensing Probe

Professor Inkyu Park and his research team from the Department of Mechanical Engineering at KAIST have developed a subminiature, power-efficient air-pollution sensing probe that can be applied to mobile devices. Their research findings were published online in the January 30th issue of Scientific Reports.

As air pollution has increased, people have taken greater interest in health care. The developed technology could allow people to measure independently the air pollution level of their surrounding environments.

Previous instruments used to measure air pollution levels were bulky and consumed a lot of power. They also often produced inaccurate results when measuring air pollution in which different toxic gases were mixed. These problems could not be resolved with existing semiconductor manufacturing process.

Using local temperature field control technology, Professor Park’s team succeeded in integrating multiple heterogeneous nanomaterials and fitting them onto a small, low-power electronic chip. This microheating sensor can heat microscale regions through local hydrothermal synthesis. Because it requires a miniscale amount of nanomaterials to manufacture, the sensor is most suitable for mobile devices.

Professor Park said, “Our research will contribute to the development of convergence technology in such field as air pollution sensing probes, biosensors, electronic devices, and displays.”

The team's research was supported by the Ministry of Education and the Ministry of Science, ICT and Future Planning, Republic of Korea.

Figure 1 – The Concept of Multiple Nanomaterial Device and Numerical Simulation Results of Precursor Solutions

Figure 2 - Multiple Nanomaterial Manufactured in a Microscale Region

2015.02.27 View 12868