FiL

-

Ultralight advanced material developed by KAIST and U of Toronto

< (From left) Professor Seunghwa Ryu of KAIST Department of Mechanical Engineering, Professor Tobin Filleter of the University of Toronto, Dr. Jinwook Yeo of KAIST, and Dr. Peter Serles of the University of Toronto >

Recently, in advanced industries such as automobiles, aerospace, and mobility, there has been increasing demand for materials that achieve weight reduction while maintaining excellent mechanical properties. An international joint research team has developed an ultralight, high-strength material utilizing nanostructures, presenting the potential for various industrial applications through customized design in the future.

KAIST (represented by President Kwang Hyung Lee) announced on the 18th of February that a research team led by Professor Seunghwa Ryu from the Department of Mechanical Engineering, in collaboration with Professor Tobin Filleter from the University of Toronto, has developed a nano-lattice structure that maximizes lightweight properties while maintaining high stiffness and strength.

In this study, the research team optimized the beam shape of the lattice structure to maintain its lightweight characteristics while maximizing stiffness and strength.

Particularly, using a multi-objective Bayesian optimization algorithm*, the team conducted an optimal design process that simultaneously considers tensile and shear stiffness improvement and weight reduction. They demonstrated that the optimal lattice structure could be predicted and designed with significantly less data (about 400 data points) compared to conventional methods.

*Multi-objective Bayesian optimization algorithm: A method that finds the optimal solution while considering multiple objectives simultaneously. It efficiently collects data and predicts results even under conditions of uncertainty.

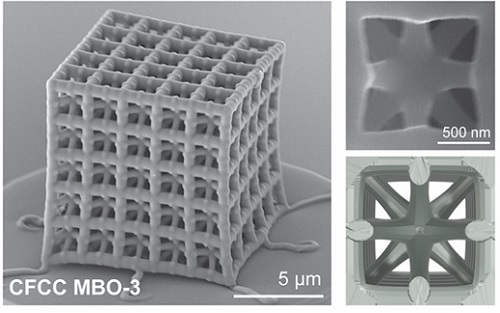

< Figure 1. Multi-objective Bayesian optimization for generative design of carbon nanolattices with high compressive stiffness and strength at low density. The upper is the illustration of process workflow. The lower part shows top four MBO CFCC geometries with their 2D Bézier curves. (The optimized structure is predicted and designed with much less data (approximately 400) than the conventional method >

Furthermore, to maximize the effect where mechanical properties improve as size decreases at the nanoscale, the research team utilized pyrolytic carbon* material to implement an ultralight, high-strength, high-stiffness nano-lattice structure.

*Pyrolytic carbon: A carbon material obtained by decomposing organic substances at high temperatures. It has excellent heat resistance and strength, making it widely used in industries such as semiconductor equipment coatings and artificial joint coatings, where it must withstand high temperatures without deformation.

For this, the team applied two-photon polymerization (2PP) technology* to precisely fabricate complex nano-lattice structures, and mechanical performance evaluations confirmed that the developed structure simultaneously possesses strength comparable to steel and the lightness of Styrofoam.

*Two-photon polymerization (2PP) technology: An advanced optical manufacturing technique based on the principle that polymerization occurs only when two photons of a specific wavelength are absorbed simultaneously.

Additionally, the research team demonstrated that multi-focus two-photon polymerization (multi-focus 2PP) technology enables the fabrication of millimeter-scale structures while maintaining nanoscale precision.

Professor Seunghwa Ryu explained, "This technology innovatively solves the stress concentration issue, which has been a limitation of conventional design methods, through three-dimensional nano-lattice structures, achieving both ultralight weight and high strength in material development."

< Figure 2. FESEM image of the fabricated nano-lattice structure and (bottom right) the macroscopic nanolattice resting on a bubble >

He further emphasized, "By integrating data-driven optimal design with precision 3D printing technology, this development not only meets the demand for lightweight materials in the aerospace and automotive industries but also opens possibilities for various industrial applications through customized design."

This study was led by Dr. Peter Serles of the Department of Mechanical & Industrial Engineering at University of Toronto and Dr. Jinwook Yeo from KAIST as co-first authors, with Professor Seunghwa Ryu and Professor Tobin Filleter as corresponding authors.

The research was published on January 23, 2025 in the international journal Advanced Materials (Paper title: “Ultrahigh Specific Strength by Bayesian Optimization of Lightweight Carbon Nanolattices”).

DOI: https://doi.org/10.1002/adma.202410651

This research was supported by the Multiphase Materials Innovation Manufacturing Research Center (an ERC program) funded by the Ministry of Science and ICT, the M3DT (Medical Device Digital Development Tool) project funded by the Ministry of Food and Drug Safety, and the KAIST International Collaboration Program.

2025.02.18 View 3160

Ultralight advanced material developed by KAIST and U of Toronto

< (From left) Professor Seunghwa Ryu of KAIST Department of Mechanical Engineering, Professor Tobin Filleter of the University of Toronto, Dr. Jinwook Yeo of KAIST, and Dr. Peter Serles of the University of Toronto >

Recently, in advanced industries such as automobiles, aerospace, and mobility, there has been increasing demand for materials that achieve weight reduction while maintaining excellent mechanical properties. An international joint research team has developed an ultralight, high-strength material utilizing nanostructures, presenting the potential for various industrial applications through customized design in the future.

KAIST (represented by President Kwang Hyung Lee) announced on the 18th of February that a research team led by Professor Seunghwa Ryu from the Department of Mechanical Engineering, in collaboration with Professor Tobin Filleter from the University of Toronto, has developed a nano-lattice structure that maximizes lightweight properties while maintaining high stiffness and strength.

In this study, the research team optimized the beam shape of the lattice structure to maintain its lightweight characteristics while maximizing stiffness and strength.

Particularly, using a multi-objective Bayesian optimization algorithm*, the team conducted an optimal design process that simultaneously considers tensile and shear stiffness improvement and weight reduction. They demonstrated that the optimal lattice structure could be predicted and designed with significantly less data (about 400 data points) compared to conventional methods.

*Multi-objective Bayesian optimization algorithm: A method that finds the optimal solution while considering multiple objectives simultaneously. It efficiently collects data and predicts results even under conditions of uncertainty.

< Figure 1. Multi-objective Bayesian optimization for generative design of carbon nanolattices with high compressive stiffness and strength at low density. The upper is the illustration of process workflow. The lower part shows top four MBO CFCC geometries with their 2D Bézier curves. (The optimized structure is predicted and designed with much less data (approximately 400) than the conventional method >

Furthermore, to maximize the effect where mechanical properties improve as size decreases at the nanoscale, the research team utilized pyrolytic carbon* material to implement an ultralight, high-strength, high-stiffness nano-lattice structure.

*Pyrolytic carbon: A carbon material obtained by decomposing organic substances at high temperatures. It has excellent heat resistance and strength, making it widely used in industries such as semiconductor equipment coatings and artificial joint coatings, where it must withstand high temperatures without deformation.

For this, the team applied two-photon polymerization (2PP) technology* to precisely fabricate complex nano-lattice structures, and mechanical performance evaluations confirmed that the developed structure simultaneously possesses strength comparable to steel and the lightness of Styrofoam.

*Two-photon polymerization (2PP) technology: An advanced optical manufacturing technique based on the principle that polymerization occurs only when two photons of a specific wavelength are absorbed simultaneously.

Additionally, the research team demonstrated that multi-focus two-photon polymerization (multi-focus 2PP) technology enables the fabrication of millimeter-scale structures while maintaining nanoscale precision.

Professor Seunghwa Ryu explained, "This technology innovatively solves the stress concentration issue, which has been a limitation of conventional design methods, through three-dimensional nano-lattice structures, achieving both ultralight weight and high strength in material development."

< Figure 2. FESEM image of the fabricated nano-lattice structure and (bottom right) the macroscopic nanolattice resting on a bubble >

He further emphasized, "By integrating data-driven optimal design with precision 3D printing technology, this development not only meets the demand for lightweight materials in the aerospace and automotive industries but also opens possibilities for various industrial applications through customized design."

This study was led by Dr. Peter Serles of the Department of Mechanical & Industrial Engineering at University of Toronto and Dr. Jinwook Yeo from KAIST as co-first authors, with Professor Seunghwa Ryu and Professor Tobin Filleter as corresponding authors.

The research was published on January 23, 2025 in the international journal Advanced Materials (Paper title: “Ultrahigh Specific Strength by Bayesian Optimization of Lightweight Carbon Nanolattices”).

DOI: https://doi.org/10.1002/adma.202410651

This research was supported by the Multiphase Materials Innovation Manufacturing Research Center (an ERC program) funded by the Ministry of Science and ICT, the M3DT (Medical Device Digital Development Tool) project funded by the Ministry of Food and Drug Safety, and the KAIST International Collaboration Program.

2025.02.18 View 3160 -

A Way for Smartwatches to Detect Depression Risks Devised by KAIST and U of Michigan Researchers

- A international joint research team of KAIST and the University of Michigan developed a digital biomarker for predicting symptoms of depression based on data collected by smartwatches

- It has the potential to be used as a medical technology to replace the economically burdensome fMRI measurement test

- It is expected to expand the scope of digital health data analysis

The CORONA virus pandemic also brought about a pandemic of mental illness. Approximately one billion people worldwide suffer from various psychiatric conditions. Korea is one of more serious cases, with approximately 1.8 million patients exhibiting depression and anxiety disorders, and the total number of patients with clinical mental diseases has increased by 37% in five years to approximately 4.65 million. A joint research team from Korea and the US has developed a technology that uses biometric data collected through wearable devices to predict tomorrow's mood and, further, to predict the possibility of developing symptoms of depression.

< Figure 1. Schematic diagram of the research results. Based on the biometric data collected by a smartwatch, a mathematical algorithm that solves the inverse problem to estimate the brain's circadian phase and sleep stages has been developed. This algorithm can estimate the degrees of circadian disruption, and these estimates can be used as the digital biomarkers to predict depression risks. >

KAIST (President Kwang Hyung Lee) announced on the 15th of January that the research team under Professor Dae Wook Kim from the Department of Brain and Cognitive Sciences and the team under Professor Daniel B. Forger from the Department of Mathematics at the University of Michigan in the United States have developed a technology to predict symptoms of depression such as sleep disorders, depression, loss of appetite, overeating, and decreased concentration in shift workers from the activity and heart rate data collected from smartwatches.

According to WHO, a promising new treatment direction for mental illness focuses on the sleep and circadian timekeeping system located in the hypothalamus of the brain, which directly affect impulsivity, emotional responses, decision-making, and overall mood.

However, in order to measure endogenous circadian rhythms and sleep states, blood or saliva must be drawn every 30 minutes throughout the night to measure changes in the concentration of the melatonin hormone in our bodies and polysomnography (PSG) must be performed. As such treatments requires hospitalization and most psychiatric patients only visit for outpatient treatment, there has been no significant progress in developing treatment methods that take these two factors into account. In addition, the cost of the PSG test, which is approximately $1000, leaves mental health treatment considering sleep and circadian rhythms out of reach for the socially disadvantaged.

The solution to overcome these problems is to employ wearable devices for the easier collection of biometric data such as heart rate, body temperature, and activity level in real time without spatial constraints. However, current wearable devices have the limitation of providing only indirect information on biomarkers required by medical staff, such as the phase of the circadian clock.

The joint research team developed a filtering technology that accurately estimates the phase of the circadian clock, which changes daily, such as heart rate and activity time series data collected from a smartwatch. This is an implementation of a digital twin that precisely describes the circadian rhythm in the brain, and it can be used to estimate circadian rhythm disruption.

< Figure 2. The suprachiasmatic nucleus located in the hypothalamus of the brain is the central biological clock that regulates the 24-hour physiological rhythm and plays a key role in maintaining the body’s circadian rhythm. If the phase of this biological clock is disrupted, it affects various parts of the brain, which can cause psychiatric conditions such as depression. >

The possibility of using the digital twin of this circadian clock to predict the symptoms of depression was verified through collaboration with the research team of Professor Srijan Sen of the Michigan Neuroscience Institute and Professor Amy Bohnert of the Department of Psychiatry of the University of Michigan.

The collaborative research team conducted a large-scale prospective cohort study involving approximately 800 shift workers and showed that the circadian rhythm disruption digital biomarker estimated through the technology can predict tomorrow's mood as well as six symptoms, including sleep problems, appetite changes, decreased concentration, and suicidal thoughts, which are representative symptoms of depression.

< Figure 3. The circadian rhythm of hormones such as melatonin regulates various physiological functions and behaviors such as heart rate and activity level. These physiological and behavioral signals can be measured in daily life through wearable devices. In order to estimate the body’s circadian rhythm inversely based on the measured biometric signals, a mathematical algorithm is needed. This algorithm plays a key role in accurately identifying the characteristics of circadian rhythms by extracting hidden physiological patterns from biosignals. >

Professor Dae Wook Kim said, "It is very meaningful to be able to conduct research that provides a clue for ways to apply wearable biometric data using mathematics that have not previously been utilized for actual disease management." He added, "We expect that this research will be able to present continuous and non-invasive mental health monitoring technology. This is expected to present a new paradigm for mental health care. By resolving some of the major problems socially disadvantaged people may face in current treatment practices, they may be able to take more active steps when experiencing symptoms of depression, such as seeking counsel before things get out of hand."

< Figure 4. A mathematical algorithm was devised to circumvent the problems of estimating the phase of the brain's biological clock and sleep stages inversely from the biodata collected by a smartwatch. This algorithm can estimate the degree of daily circadian rhythm disruption, and this estimate can be used as a digital biomarker to predict depression symptoms. >

The results of this study, in which Professor Dae Wook Kim of the Department of Brain and Cognitive Sciences at KAIST participated as the joint first author and corresponding author, were published in the online version of the international academic journal npj Digital Medicine on December 5, 2024. (Paper title: The real-world association between digital markers of circadian disruption and mental health risks) DOI: 10.1038/s41746-024-01348-6

This study was conducted with the support of the KAIST's Research Support Program for New Faculty Members, the US National Science Foundation, the US National Institutes of Health, and the US Army Research Institute MURI Program.

2025.01.20 View 5120

A Way for Smartwatches to Detect Depression Risks Devised by KAIST and U of Michigan Researchers

- A international joint research team of KAIST and the University of Michigan developed a digital biomarker for predicting symptoms of depression based on data collected by smartwatches

- It has the potential to be used as a medical technology to replace the economically burdensome fMRI measurement test

- It is expected to expand the scope of digital health data analysis

The CORONA virus pandemic also brought about a pandemic of mental illness. Approximately one billion people worldwide suffer from various psychiatric conditions. Korea is one of more serious cases, with approximately 1.8 million patients exhibiting depression and anxiety disorders, and the total number of patients with clinical mental diseases has increased by 37% in five years to approximately 4.65 million. A joint research team from Korea and the US has developed a technology that uses biometric data collected through wearable devices to predict tomorrow's mood and, further, to predict the possibility of developing symptoms of depression.

< Figure 1. Schematic diagram of the research results. Based on the biometric data collected by a smartwatch, a mathematical algorithm that solves the inverse problem to estimate the brain's circadian phase and sleep stages has been developed. This algorithm can estimate the degrees of circadian disruption, and these estimates can be used as the digital biomarkers to predict depression risks. >

KAIST (President Kwang Hyung Lee) announced on the 15th of January that the research team under Professor Dae Wook Kim from the Department of Brain and Cognitive Sciences and the team under Professor Daniel B. Forger from the Department of Mathematics at the University of Michigan in the United States have developed a technology to predict symptoms of depression such as sleep disorders, depression, loss of appetite, overeating, and decreased concentration in shift workers from the activity and heart rate data collected from smartwatches.

According to WHO, a promising new treatment direction for mental illness focuses on the sleep and circadian timekeeping system located in the hypothalamus of the brain, which directly affect impulsivity, emotional responses, decision-making, and overall mood.

However, in order to measure endogenous circadian rhythms and sleep states, blood or saliva must be drawn every 30 minutes throughout the night to measure changes in the concentration of the melatonin hormone in our bodies and polysomnography (PSG) must be performed. As such treatments requires hospitalization and most psychiatric patients only visit for outpatient treatment, there has been no significant progress in developing treatment methods that take these two factors into account. In addition, the cost of the PSG test, which is approximately $1000, leaves mental health treatment considering sleep and circadian rhythms out of reach for the socially disadvantaged.

The solution to overcome these problems is to employ wearable devices for the easier collection of biometric data such as heart rate, body temperature, and activity level in real time without spatial constraints. However, current wearable devices have the limitation of providing only indirect information on biomarkers required by medical staff, such as the phase of the circadian clock.

The joint research team developed a filtering technology that accurately estimates the phase of the circadian clock, which changes daily, such as heart rate and activity time series data collected from a smartwatch. This is an implementation of a digital twin that precisely describes the circadian rhythm in the brain, and it can be used to estimate circadian rhythm disruption.

< Figure 2. The suprachiasmatic nucleus located in the hypothalamus of the brain is the central biological clock that regulates the 24-hour physiological rhythm and plays a key role in maintaining the body’s circadian rhythm. If the phase of this biological clock is disrupted, it affects various parts of the brain, which can cause psychiatric conditions such as depression. >

The possibility of using the digital twin of this circadian clock to predict the symptoms of depression was verified through collaboration with the research team of Professor Srijan Sen of the Michigan Neuroscience Institute and Professor Amy Bohnert of the Department of Psychiatry of the University of Michigan.

The collaborative research team conducted a large-scale prospective cohort study involving approximately 800 shift workers and showed that the circadian rhythm disruption digital biomarker estimated through the technology can predict tomorrow's mood as well as six symptoms, including sleep problems, appetite changes, decreased concentration, and suicidal thoughts, which are representative symptoms of depression.

< Figure 3. The circadian rhythm of hormones such as melatonin regulates various physiological functions and behaviors such as heart rate and activity level. These physiological and behavioral signals can be measured in daily life through wearable devices. In order to estimate the body’s circadian rhythm inversely based on the measured biometric signals, a mathematical algorithm is needed. This algorithm plays a key role in accurately identifying the characteristics of circadian rhythms by extracting hidden physiological patterns from biosignals. >

Professor Dae Wook Kim said, "It is very meaningful to be able to conduct research that provides a clue for ways to apply wearable biometric data using mathematics that have not previously been utilized for actual disease management." He added, "We expect that this research will be able to present continuous and non-invasive mental health monitoring technology. This is expected to present a new paradigm for mental health care. By resolving some of the major problems socially disadvantaged people may face in current treatment practices, they may be able to take more active steps when experiencing symptoms of depression, such as seeking counsel before things get out of hand."

< Figure 4. A mathematical algorithm was devised to circumvent the problems of estimating the phase of the brain's biological clock and sleep stages inversely from the biodata collected by a smartwatch. This algorithm can estimate the degree of daily circadian rhythm disruption, and this estimate can be used as a digital biomarker to predict depression symptoms. >

The results of this study, in which Professor Dae Wook Kim of the Department of Brain and Cognitive Sciences at KAIST participated as the joint first author and corresponding author, were published in the online version of the international academic journal npj Digital Medicine on December 5, 2024. (Paper title: The real-world association between digital markers of circadian disruption and mental health risks) DOI: 10.1038/s41746-024-01348-6

This study was conducted with the support of the KAIST's Research Support Program for New Faculty Members, the US National Science Foundation, the US National Institutes of Health, and the US Army Research Institute MURI Program.

2025.01.20 View 5120 -

KAIST Secures Core Technology for Ultra-High-Resolution Image Sensors

A joint research team from Korea and the United States has developed next-generation, high-resolution image sensor technology with higher power efficiency and a smaller size compared to existing sensors. Notably, they have secured foundational technology for ultra-high-resolution shortwave infrared (SWIR) image sensors, an area currently dominated by Sony, paving the way for future market entry.

KAIST (represented by President Kwang Hyung Lee) announced on the 20th of November that a research team led by Professor SangHyeon Kim from the School of Electrical Engineering, in collaboration with Inha University and Yale University in the U.S., has developed an ultra-thin broadband photodiode (PD), marking a significant breakthrough in high-performance image sensor technology.

This research drastically improves the trade-off between the absorption layer thickness and quantum efficiency found in conventional photodiode technology. Specifically, it achieved high quantum efficiency of over 70% even in an absorption layer thinner than one micrometer (μm), reducing the thickness of the absorption layer by approximately 70% compared to existing technologies.

A thinner absorption layer simplifies pixel processing, allowing for higher resolution and smoother carrier diffusion, which is advantageous for light carrier acquisition while also reducing the cost. However, a fundamental issue with thinner absorption layers is the reduced absorption of long-wavelength light.

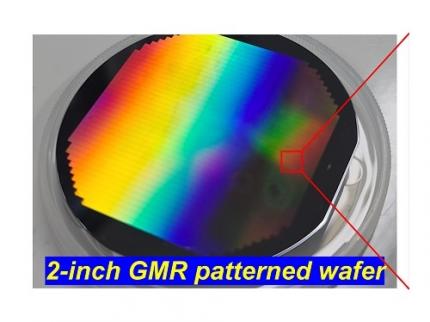

< Figure 1. Schematic diagram of the InGaAs photodiode image sensor integrated on the Guided-Mode Resonance (GMR) structure proposed in this study (left), a photograph of the fabricated wafer, and a scanning electron microscope (SEM) image of the periodic patterns (right) >

The research team introduced a guided-mode resonance (GMR) structure* that enables high-efficiency light absorption across a wide spectral range from 400 nanometers (nm) to 1,700 nanometers (nm). This wavelength range includes not only visible light but also light the SWIR region, making it valuable for various industrial applications.

*Guided-Mode Resonance (GMR) Structure: A concept used in electromagnetics, a phenomenon in which a specific (light) wave resonates (forming a strong electric/magnetic field) at a specific wavelength. Since energy is maximized under these conditions, it has been used to increase antenna or radar efficiency.

The improved performance in the SWIR region is expected to play a significant role in developing next-generation image sensors with increasingly high resolutions. The GMR structure, in particular, holds potential for further enhancing resolution and other performance metrics through hybrid integration and monolithic 3D integration with complementary metal-oxide-semiconductor (CMOS)-based readout integrated circuits (ROIC).

< Figure 2. Benchmark for state-of-the-art InGaAs-based SWIR pixels with simulated EQE lines as a function of TAL variation. Performance is maintained while reducing the absorption layer thickness from 2.1 micrometers or more to 1 micrometer or less while reducing it by 50% to 70% >

The research team has significantly enhanced international competitiveness in low-power devices and ultra-high-resolution imaging technology, opening up possibilities for applications in digital cameras, security systems, medical and industrial image sensors, as well as future ultra-high-resolution sensors for autonomous driving, aerospace, and satellite observation.

Professor Sang Hyun Kim, the lead researcher, commented, “This research demonstrates that significantly higher performance than existing technologies can be achieved even with ultra-thin absorption layers.”

< Figure 3. Top optical microscope image and cross-sectional scanning electron microscope image of the InGaAs photodiode image sensor fabricated on the GMR structure (left). Improved quantum efficiency performance of the ultra-thin image sensor (red) fabricated with the technology proposed in this study (right) >

The results of this research were published on 15th of November, in the prestigious international journal Light: Science & Applications (JCR 2.9%, IF=20.6), with Professor Dae-Myung Geum of Inha University (formerly a KAIST postdoctoral researcher) and Dr. Jinha Lim (currently a postdoctoral researcher at Yale University) as co-first authors. (Paper title: “Highly-efficient (>70%) and Wide-spectral (400 nm -1700 nm) sub-micron-thick InGaAs photodiodes for future high-resolution image sensors”)

This study was supported by the National Research Foundation of Korea.

2024.11.22 View 3914

KAIST Secures Core Technology for Ultra-High-Resolution Image Sensors

A joint research team from Korea and the United States has developed next-generation, high-resolution image sensor technology with higher power efficiency and a smaller size compared to existing sensors. Notably, they have secured foundational technology for ultra-high-resolution shortwave infrared (SWIR) image sensors, an area currently dominated by Sony, paving the way for future market entry.

KAIST (represented by President Kwang Hyung Lee) announced on the 20th of November that a research team led by Professor SangHyeon Kim from the School of Electrical Engineering, in collaboration with Inha University and Yale University in the U.S., has developed an ultra-thin broadband photodiode (PD), marking a significant breakthrough in high-performance image sensor technology.

This research drastically improves the trade-off between the absorption layer thickness and quantum efficiency found in conventional photodiode technology. Specifically, it achieved high quantum efficiency of over 70% even in an absorption layer thinner than one micrometer (μm), reducing the thickness of the absorption layer by approximately 70% compared to existing technologies.

A thinner absorption layer simplifies pixel processing, allowing for higher resolution and smoother carrier diffusion, which is advantageous for light carrier acquisition while also reducing the cost. However, a fundamental issue with thinner absorption layers is the reduced absorption of long-wavelength light.

< Figure 1. Schematic diagram of the InGaAs photodiode image sensor integrated on the Guided-Mode Resonance (GMR) structure proposed in this study (left), a photograph of the fabricated wafer, and a scanning electron microscope (SEM) image of the periodic patterns (right) >

The research team introduced a guided-mode resonance (GMR) structure* that enables high-efficiency light absorption across a wide spectral range from 400 nanometers (nm) to 1,700 nanometers (nm). This wavelength range includes not only visible light but also light the SWIR region, making it valuable for various industrial applications.

*Guided-Mode Resonance (GMR) Structure: A concept used in electromagnetics, a phenomenon in which a specific (light) wave resonates (forming a strong electric/magnetic field) at a specific wavelength. Since energy is maximized under these conditions, it has been used to increase antenna or radar efficiency.

The improved performance in the SWIR region is expected to play a significant role in developing next-generation image sensors with increasingly high resolutions. The GMR structure, in particular, holds potential for further enhancing resolution and other performance metrics through hybrid integration and monolithic 3D integration with complementary metal-oxide-semiconductor (CMOS)-based readout integrated circuits (ROIC).

< Figure 2. Benchmark for state-of-the-art InGaAs-based SWIR pixels with simulated EQE lines as a function of TAL variation. Performance is maintained while reducing the absorption layer thickness from 2.1 micrometers or more to 1 micrometer or less while reducing it by 50% to 70% >

The research team has significantly enhanced international competitiveness in low-power devices and ultra-high-resolution imaging technology, opening up possibilities for applications in digital cameras, security systems, medical and industrial image sensors, as well as future ultra-high-resolution sensors for autonomous driving, aerospace, and satellite observation.

Professor Sang Hyun Kim, the lead researcher, commented, “This research demonstrates that significantly higher performance than existing technologies can be achieved even with ultra-thin absorption layers.”

< Figure 3. Top optical microscope image and cross-sectional scanning electron microscope image of the InGaAs photodiode image sensor fabricated on the GMR structure (left). Improved quantum efficiency performance of the ultra-thin image sensor (red) fabricated with the technology proposed in this study (right) >

The results of this research were published on 15th of November, in the prestigious international journal Light: Science & Applications (JCR 2.9%, IF=20.6), with Professor Dae-Myung Geum of Inha University (formerly a KAIST postdoctoral researcher) and Dr. Jinha Lim (currently a postdoctoral researcher at Yale University) as co-first authors. (Paper title: “Highly-efficient (>70%) and Wide-spectral (400 nm -1700 nm) sub-micron-thick InGaAs photodiodes for future high-resolution image sensors”)

This study was supported by the National Research Foundation of Korea.

2024.11.22 View 3914 -

KAIST Research team develops anti-icing film that only requires sunlight

A KAIST research team has developed an anti-icing and de-icing film coating technology that can apply the photothermal effect of gold nanoparticles to industrial sites without the need for heating wires, periodic spray or oil coating of anti-freeze substances, and substrate design alterations.

The group led by Professor Hyoungsoo Kim from the Department of Mechanical Engineering (Fluid & Interface Laboratory) and Professor Dong Ki Yoon from the Department of Chemistry (Soft Material Assembly Group) revealed on January 3 to have together developed an original technique that can uniformly pattern gold nanorod (GNR) particles in quadrants through simple evaporation, and have used this to develop an anti-icing and de-icing surface.

Many scientists in recent years have tried to control substrate surfaces through various coating techniques, and those involving the patterning of functional nanomaterials have gained special attention. In particular, GNR is considered a promising candidate nanomaterial for its biocompatibility, chemical stability, relatively simple synthesis, and its stable and unique property of surface plasmon resonance. To maximize the performance of GNR, it is important to achieve a high uniformity during film deposition, and a high level of rod alignment. However, achieving both criteria has thus far been a difficult challenge.

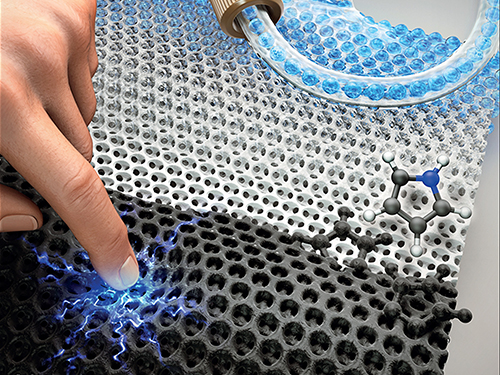

< Figure 1. Conceptual image to display Hydrodynamic mechanisms for the formation of a homogeneous quadrant cellulose nanocrystal(CNC) matrix. >

To solve this, the joint research team utilized cellulose nanocrystal (CNC), a next-generation functional nanomaterial that can easily be extracted from nature. By co-assembling GNR on CNC quadrant templates, the team could uniformly dry the film and successfully obtain a GNR film with a uniform alignment in a ring-shape. Compared to existing coffee-ring films, the highly uniform and aligned GNR film developed through this research showed enhanced plasmonic photothermal properties, and the team showed that it could carry out anti-icing and de-icing functions by simply irradiating light in the visible wavelength range.

< Figure 2. Optical and thermal performance evaluation results of gold nanorod film and demonstration of plasmonic heater for anti-icing and de-icing. >

Professor Hyoungsoo Kim said, “This technique can be applied to plastic, as well as flexible surfaces. By using it on exterior materials and films, it can generate its own heat energy, which would greatly save energy through voluntary thermal energy harvesting across various applications including cars, aircrafts, and windows in residential or commercial spaces, where frosting becomes a serious issue in the winter.” Professor Dong Ki Yoon added, “This research is significant in that we can now freely pattern the CNC-GNR composite, which was previously difficult to create into films, over a large area. We can utilize this as an anti-icing material, and if we were to take advantage of the plasmonic properties of gold, we can also use it like stained-glass to decorate glass surfaces.”

This research was conducted by Ph.D. candidate Jeongsu Pyeon from the Department of Mechanical Engineering, and his co-first author Dr. Soon Mo Park (a KAIST graduate, currently a post-doctoral associate at Cornell University), and was pushed in the online volume of Nature Communication on December 8, 2023 under the title “Plasmonic Metasurfaces of Cellulose Nanocrystal Matrices with Quadrants of Aligned Gold Nanorods for Photothermal Anti-Icing." Recognized for its achievement, the research was also selected as an editor’s highlight for the journals Materials Science and Chemistry, and Inorganic and Physical Chemistry.

This research was supported by the Individual Basic Mid-Sized Research Fund from the National Research Foundation of Korea and the Center for Multiscale Chiral Architectures.

2024.01.16 View 9630

KAIST Research team develops anti-icing film that only requires sunlight

A KAIST research team has developed an anti-icing and de-icing film coating technology that can apply the photothermal effect of gold nanoparticles to industrial sites without the need for heating wires, periodic spray or oil coating of anti-freeze substances, and substrate design alterations.

The group led by Professor Hyoungsoo Kim from the Department of Mechanical Engineering (Fluid & Interface Laboratory) and Professor Dong Ki Yoon from the Department of Chemistry (Soft Material Assembly Group) revealed on January 3 to have together developed an original technique that can uniformly pattern gold nanorod (GNR) particles in quadrants through simple evaporation, and have used this to develop an anti-icing and de-icing surface.

Many scientists in recent years have tried to control substrate surfaces through various coating techniques, and those involving the patterning of functional nanomaterials have gained special attention. In particular, GNR is considered a promising candidate nanomaterial for its biocompatibility, chemical stability, relatively simple synthesis, and its stable and unique property of surface plasmon resonance. To maximize the performance of GNR, it is important to achieve a high uniformity during film deposition, and a high level of rod alignment. However, achieving both criteria has thus far been a difficult challenge.

< Figure 1. Conceptual image to display Hydrodynamic mechanisms for the formation of a homogeneous quadrant cellulose nanocrystal(CNC) matrix. >

To solve this, the joint research team utilized cellulose nanocrystal (CNC), a next-generation functional nanomaterial that can easily be extracted from nature. By co-assembling GNR on CNC quadrant templates, the team could uniformly dry the film and successfully obtain a GNR film with a uniform alignment in a ring-shape. Compared to existing coffee-ring films, the highly uniform and aligned GNR film developed through this research showed enhanced plasmonic photothermal properties, and the team showed that it could carry out anti-icing and de-icing functions by simply irradiating light in the visible wavelength range.

< Figure 2. Optical and thermal performance evaluation results of gold nanorod film and demonstration of plasmonic heater for anti-icing and de-icing. >

Professor Hyoungsoo Kim said, “This technique can be applied to plastic, as well as flexible surfaces. By using it on exterior materials and films, it can generate its own heat energy, which would greatly save energy through voluntary thermal energy harvesting across various applications including cars, aircrafts, and windows in residential or commercial spaces, where frosting becomes a serious issue in the winter.” Professor Dong Ki Yoon added, “This research is significant in that we can now freely pattern the CNC-GNR composite, which was previously difficult to create into films, over a large area. We can utilize this as an anti-icing material, and if we were to take advantage of the plasmonic properties of gold, we can also use it like stained-glass to decorate glass surfaces.”

This research was conducted by Ph.D. candidate Jeongsu Pyeon from the Department of Mechanical Engineering, and his co-first author Dr. Soon Mo Park (a KAIST graduate, currently a post-doctoral associate at Cornell University), and was pushed in the online volume of Nature Communication on December 8, 2023 under the title “Plasmonic Metasurfaces of Cellulose Nanocrystal Matrices with Quadrants of Aligned Gold Nanorods for Photothermal Anti-Icing." Recognized for its achievement, the research was also selected as an editor’s highlight for the journals Materials Science and Chemistry, and Inorganic and Physical Chemistry.

This research was supported by the Individual Basic Mid-Sized Research Fund from the National Research Foundation of Korea and the Center for Multiscale Chiral Architectures.

2024.01.16 View 9630 -

Researchers finds a way to reduce the overheating of semiconductor devices

The demand to shrink the size of semiconductors coupled with the problem of the heat generated at the hot spots of the devices not being effectively dispersed has negatively affected the reliability and durability of modern devices. Existing thermal management technologies have not been up to the task. Thus, the discovery of a new way of dispersing heat by using surface waves generated on the thin metal films over the substrate is an important breakthrough.

KAIST (President Kwang Hyung Lee) announced that Professor Bong Jae Lee's research team in the Department of Mechanical Engineering succeeded in measuring a newly observed transference of heat induced by 'surface plasmon polariton' (SPP) in a thin metal film deposited on a substrate for the first time in the world.

☞ Surface plasmon polariton (SPP) refers to a surface wave formed on the surface of a metal as a result of strong interaction between the electromagnetic field at the interface between the dielectric and the metal and the free electrons on the metal surface and similar collectively vibrating particles.

The research team utilized surface plasmon polaritons (SPP), which are surface waves generated at the metal-dielectric interface, to improve thermal diffusion in nanoscale thin metal films. Since this new heat transfer mode occurs when a thin film of metal is deposited on a substrate, it is highly usable in the device manufacturing process and has the advantage of being able to be manufactured over a large area. The research team showed that the thermal conductivity increased by about 25% due to surface waves generated over a 100-nm-thick titanium (Ti) film with a radius of about 3 cm.

KAIST Professor Bong Jae Lee, who led the research, said, "The significance of this research is that a new heat transfer mode using surface waves over a thin metal film deposited on a substrate with low processing difficulty was identified for the first time in the world. It can be applied as a nanoscale heat spreader to efficiently dissipate heat near the hot spots for easily overheatable semiconductor devices.”

The result has great implications for the development of high-performance semiconductor devices in the future in that it can be applied to rapidly dissipate heat on a nanoscale thin film. In particular, this new heat transfer mode identified by the research team is expected to solve the fundamental problem of thermal management in semiconductor devices as it enables even more effective heat transfer at nanoscale thickness while the thermal conductivity of the thin film usually decreases due to the boundary scattering effect.

This study was published online on April 26 in 'Physical Review Letters' and was selected as an Editors' Suggestion. The research was carried out with support from the Basic Research Laboratory Support Program of the National Research Foundation of Korea.

< Figure. Schematic diagram of the principle of measuring the thermal conductivity of thin Titanium (TI) films and the thermal conductivity of surface plasmon polariton measured on the Ti film >

2023.06.01 View 7460

Researchers finds a way to reduce the overheating of semiconductor devices

The demand to shrink the size of semiconductors coupled with the problem of the heat generated at the hot spots of the devices not being effectively dispersed has negatively affected the reliability and durability of modern devices. Existing thermal management technologies have not been up to the task. Thus, the discovery of a new way of dispersing heat by using surface waves generated on the thin metal films over the substrate is an important breakthrough.

KAIST (President Kwang Hyung Lee) announced that Professor Bong Jae Lee's research team in the Department of Mechanical Engineering succeeded in measuring a newly observed transference of heat induced by 'surface plasmon polariton' (SPP) in a thin metal film deposited on a substrate for the first time in the world.

☞ Surface plasmon polariton (SPP) refers to a surface wave formed on the surface of a metal as a result of strong interaction between the electromagnetic field at the interface between the dielectric and the metal and the free electrons on the metal surface and similar collectively vibrating particles.

The research team utilized surface plasmon polaritons (SPP), which are surface waves generated at the metal-dielectric interface, to improve thermal diffusion in nanoscale thin metal films. Since this new heat transfer mode occurs when a thin film of metal is deposited on a substrate, it is highly usable in the device manufacturing process and has the advantage of being able to be manufactured over a large area. The research team showed that the thermal conductivity increased by about 25% due to surface waves generated over a 100-nm-thick titanium (Ti) film with a radius of about 3 cm.

KAIST Professor Bong Jae Lee, who led the research, said, "The significance of this research is that a new heat transfer mode using surface waves over a thin metal film deposited on a substrate with low processing difficulty was identified for the first time in the world. It can be applied as a nanoscale heat spreader to efficiently dissipate heat near the hot spots for easily overheatable semiconductor devices.”

The result has great implications for the development of high-performance semiconductor devices in the future in that it can be applied to rapidly dissipate heat on a nanoscale thin film. In particular, this new heat transfer mode identified by the research team is expected to solve the fundamental problem of thermal management in semiconductor devices as it enables even more effective heat transfer at nanoscale thickness while the thermal conductivity of the thin film usually decreases due to the boundary scattering effect.

This study was published online on April 26 in 'Physical Review Letters' and was selected as an Editors' Suggestion. The research was carried out with support from the Basic Research Laboratory Support Program of the National Research Foundation of Korea.

< Figure. Schematic diagram of the principle of measuring the thermal conductivity of thin Titanium (TI) films and the thermal conductivity of surface plasmon polariton measured on the Ti film >

2023.06.01 View 7460 -

Phage resistant Escherichia coli strains developed to reduce fermentation failure

A genome engineering-based systematic strategy for developing phage resistant Escherichia coli strains has been successfully developed through the collaborative efforts of a team led by Professor Sang Yup Lee, Professor Shi Chen, and Professor Lianrong Wang. This study by Xuan Zou et al. was published in Nature Communications in August 2022 and featured in Nature Communications Editors’ Highlights. The collaboration by the School of Pharmaceutical Sciences at Wuhan University, the First Affiliated Hospital of Shenzhen University, and the KAIST Department of Chemical and Biomolecular Engineering has made an important advance in the metabolic engineering and fermentation industry as it solves a big problem of phage infection causing fermentation failure.

Systems metabolic engineering is a highly interdisciplinary field that has made the development of microbial cell factories to produce various bioproducts including chemicals, fuels, and materials possible in a sustainable and environmentally friendly way, mitigating the impact of worldwide resource depletion and climate change. Escherichia coli is one of the most important chassis microbial strains, given its wide applications in the bio-based production of a diverse range of chemicals and materials. With the development of tools and strategies for systems metabolic engineering using E. coli, a highly optimized and well-characterized cell factory will play a crucial role in converting cheap and readily available raw materials into products of great economic and industrial value.

However, the consistent problem of phage contamination in fermentation imposes a devastating impact on host cells and threatens the productivity of bacterial bioprocesses in biotechnology facilities, which can lead to widespread fermentation failure and immeasurable economic loss. Host-controlled defense systems can be developed into effective genetic engineering solutions to address bacteriophage contamination in industrial-scale fermentation; however, most of the resistance mechanisms only narrowly restrict phages and their effect on phage contamination will be limited.

There have been attempts to develop diverse abilities/systems for environmental adaptation or antiviral defense. The team’s collaborative efforts developed a new type II single-stranded DNA phosphorothioation (Ssp) defense system derived from E. coli 3234/A, which can be used in multiple industrial E. coli strains (e.g., E. coli K-12, B and W) to provide broad protection against various types of dsDNA coliphages. Furthermore, they developed a systematic genome engineering strategy involving the simultaneous genomic integration of the Ssp defense module and mutations in components that are essential to the phage life cycle. This strategy can be used to transform E. coli hosts that are highly susceptible to phage attack into strains with powerful restriction effects on the tested bacteriophages. This endows hosts with strong resistance against a wide spectrum of phage infections without affecting bacterial growth and normal physiological function. More importantly, the resulting engineered phage-resistant strains maintained the capabilities of producing the desired chemicals and recombinant proteins even under high levels of phage cocktail challenge, which provides crucial protection against phage attacks.

This is a major step forward, as it provides a systematic solution for engineering phage-resistant bacterial strains, especially industrial bioproduction strains, to protect cells from a wide range of bacteriophages. Considering the functionality of this engineering strategy with diverse E. coli strains, the strategy reported in this study can be widely extended to other bacterial species and industrial applications, which will be of great interest to researchers in academia and industry alike.

Fig. A schematic model of the systematic strategy for engineering phage-sensitive industrial E. coli strains into strains with broad antiphage activities. Through the simultaneous genomic integration of a DNA phosphorothioation-based Ssp defense module and mutations of components essential for the phage life cycle, the engineered E. coli strains show strong resistance against diverse phages tested and maintain the capabilities of producing example recombinant proteins, even under high levels of phage cocktail challenge.

2022.08.23 View 13350

Phage resistant Escherichia coli strains developed to reduce fermentation failure

A genome engineering-based systematic strategy for developing phage resistant Escherichia coli strains has been successfully developed through the collaborative efforts of a team led by Professor Sang Yup Lee, Professor Shi Chen, and Professor Lianrong Wang. This study by Xuan Zou et al. was published in Nature Communications in August 2022 and featured in Nature Communications Editors’ Highlights. The collaboration by the School of Pharmaceutical Sciences at Wuhan University, the First Affiliated Hospital of Shenzhen University, and the KAIST Department of Chemical and Biomolecular Engineering has made an important advance in the metabolic engineering and fermentation industry as it solves a big problem of phage infection causing fermentation failure.

Systems metabolic engineering is a highly interdisciplinary field that has made the development of microbial cell factories to produce various bioproducts including chemicals, fuels, and materials possible in a sustainable and environmentally friendly way, mitigating the impact of worldwide resource depletion and climate change. Escherichia coli is one of the most important chassis microbial strains, given its wide applications in the bio-based production of a diverse range of chemicals and materials. With the development of tools and strategies for systems metabolic engineering using E. coli, a highly optimized and well-characterized cell factory will play a crucial role in converting cheap and readily available raw materials into products of great economic and industrial value.

However, the consistent problem of phage contamination in fermentation imposes a devastating impact on host cells and threatens the productivity of bacterial bioprocesses in biotechnology facilities, which can lead to widespread fermentation failure and immeasurable economic loss. Host-controlled defense systems can be developed into effective genetic engineering solutions to address bacteriophage contamination in industrial-scale fermentation; however, most of the resistance mechanisms only narrowly restrict phages and their effect on phage contamination will be limited.

There have been attempts to develop diverse abilities/systems for environmental adaptation or antiviral defense. The team’s collaborative efforts developed a new type II single-stranded DNA phosphorothioation (Ssp) defense system derived from E. coli 3234/A, which can be used in multiple industrial E. coli strains (e.g., E. coli K-12, B and W) to provide broad protection against various types of dsDNA coliphages. Furthermore, they developed a systematic genome engineering strategy involving the simultaneous genomic integration of the Ssp defense module and mutations in components that are essential to the phage life cycle. This strategy can be used to transform E. coli hosts that are highly susceptible to phage attack into strains with powerful restriction effects on the tested bacteriophages. This endows hosts with strong resistance against a wide spectrum of phage infections without affecting bacterial growth and normal physiological function. More importantly, the resulting engineered phage-resistant strains maintained the capabilities of producing the desired chemicals and recombinant proteins even under high levels of phage cocktail challenge, which provides crucial protection against phage attacks.

This is a major step forward, as it provides a systematic solution for engineering phage-resistant bacterial strains, especially industrial bioproduction strains, to protect cells from a wide range of bacteriophages. Considering the functionality of this engineering strategy with diverse E. coli strains, the strategy reported in this study can be widely extended to other bacterial species and industrial applications, which will be of great interest to researchers in academia and industry alike.

Fig. A schematic model of the systematic strategy for engineering phage-sensitive industrial E. coli strains into strains with broad antiphage activities. Through the simultaneous genomic integration of a DNA phosphorothioation-based Ssp defense module and mutations of components essential for the phage life cycle, the engineered E. coli strains show strong resistance against diverse phages tested and maintain the capabilities of producing example recombinant proteins, even under high levels of phage cocktail challenge.

2022.08.23 View 13350 -

Professor Il-Doo Kim Receives the Science Minister’s Award

Professor Il-Doo Kim from the Department of Materials Science and Engineering received the Science and ICT Minister’s Award in recognition of his commercialization and technology transfer achievements during the Day of IP celebration.

Professor Kim, who has made over 222 patents application and registration home and abroad, has advanced toxic gas detection and breath gas sensor technology by arraying nanosensor fibers. His technological advances in micro-electro-mechanical systems (MEMS) helped to advance the commercialization of the MEMS-related sensor and improve its overall competitiveness.

He founded the Il-Doo Kim Research Center in 2019 and focuses on the commercialization of nanofiber manufacturing through electrospinning and highly efficient nanofiber filters. For instance, he succeeded in manufacturing a nano-filter recyclable mask that maintains excellent filtering efficiency even after hand washing through the development of proprietary technology that aligns nanofibers with a diameter of 100~500 nanometers in orthogonal or unidirectional directions.

Professor Kim also serves as an associate editor at ACS Nano. He said, “The importance of IP goes without saying. I look forward to the registration and application of more KAIST patents leading to commercialization, paving the way for national technological competitiveness.”

2021.09.15 View 7372

Professor Il-Doo Kim Receives the Science Minister’s Award

Professor Il-Doo Kim from the Department of Materials Science and Engineering received the Science and ICT Minister’s Award in recognition of his commercialization and technology transfer achievements during the Day of IP celebration.

Professor Kim, who has made over 222 patents application and registration home and abroad, has advanced toxic gas detection and breath gas sensor technology by arraying nanosensor fibers. His technological advances in micro-electro-mechanical systems (MEMS) helped to advance the commercialization of the MEMS-related sensor and improve its overall competitiveness.

He founded the Il-Doo Kim Research Center in 2019 and focuses on the commercialization of nanofiber manufacturing through electrospinning and highly efficient nanofiber filters. For instance, he succeeded in manufacturing a nano-filter recyclable mask that maintains excellent filtering efficiency even after hand washing through the development of proprietary technology that aligns nanofibers with a diameter of 100~500 nanometers in orthogonal or unidirectional directions.

Professor Kim also serves as an associate editor at ACS Nano. He said, “The importance of IP goes without saying. I look forward to the registration and application of more KAIST patents leading to commercialization, paving the way for national technological competitiveness.”

2021.09.15 View 7372 -

Sulfur-Containing Polymer Generates High Refractive Index and Transparency

Transparent polymer thin film with refractive index exceeding 1.9 to serve as new platform materials for high-end optical device applications

Researchers reported a novel technology enhancing the high transparency of refractive polymer film via a one-step vapor deposition process. The sulfur-containing polymer (SCP) film produced by Professor Sung Gap Im’s research team at KAIST’s Department of Chemical and Biomolecular Engineering has exhibited excellent environmental stability and chemical resistance, which is highly desirable for its application in long-term optical device applications. The high refractive index exceeding 1.9 while being fully transparent in the entire visible range will help expand the applications of optoelectronic devices.

The refractive index is a ratio of the speed of light in a vacuum to the phase velocity of light in a material, used as a measure of how much the path of light is bent when passing through a material. With the miniaturization of various optical parts used in mobile devices and imaging, demand has been rapidly growing for high refractive index transparent materials that induce more light refraction with a thin film.

As polymers have outstanding physical properties and can be easily processed in various forms, they are widely used in a variety of applications such as plastic eyeglass lenses. However, there have been very few polymers developed so far with a refractive index exceeding 1.75, and existing high refractive index polymers require costly materials and complicated manufacturing processes.

Above all, core technologies for producing such materials have been dominated by Japanese companies, causing long-standing challenges for Korean manufacturers. Securing a stable supply of high-performance, high refractive index materials is crucial for the production of optical devices that are lighter, more affordable, and can be freely manipulated.

The research team successfully manufactured a whole new polymer thin film material with a refractive index exceeding 1.9 and excellent transparency, using just a one-step chemical reaction. The SCP film showed outstanding optical transparency across the entire visible light region, presumably due to the uniformly dispersed, short-segment polysulfide chains, which is a distinct feature unachievable in polymerizations with molten sulfur.

The team focused on the fact that elemental sulfur is easily sublimated to produce a high refractive index polymer by polymerizing the vaporized sulfur with a variety of substances. This method suppresses the formation of overly long S-S chains while achieving outstanding thermal stability in high sulfur concentrations and generating transparent non-crystalline polymers across the entire visible spectrum.

Due to the characteristics of the vapor phase process, the high refractive index thin film can be coated not just on silicon wafers or glass substrates, but on a wide range of textured surfaces as well. We believe this thin film polymer is the first to have achieved an ultrahigh refractive index exceeding 1.9.

Professor Im said, “This high-performance polymer film can be created in a simple one-step manner, which is highly advantageous in the synthesis of SCPs with a high refractive index. This will serve as a platform material for future high-end optical device applications.”

This study, in collaboration with research teams from Seoul National University and Kyung Hee University, was reported in Science Advances. (Title: One-Step Vapor-Phase Synthesis of Transparent High-Refractive Index Sulfur-Containing Polymers)

This research was supported by the Ministry of Science and ICT’s Global Frontier Project (Center for Advanced Soft-Electronics), Leading Research Center Support Program (Wearable Platform Materials Technology Center), and Basic Science Research Program (Advanced Research Project).

2020.08.04 View 9956

Sulfur-Containing Polymer Generates High Refractive Index and Transparency

Transparent polymer thin film with refractive index exceeding 1.9 to serve as new platform materials for high-end optical device applications

Researchers reported a novel technology enhancing the high transparency of refractive polymer film via a one-step vapor deposition process. The sulfur-containing polymer (SCP) film produced by Professor Sung Gap Im’s research team at KAIST’s Department of Chemical and Biomolecular Engineering has exhibited excellent environmental stability and chemical resistance, which is highly desirable for its application in long-term optical device applications. The high refractive index exceeding 1.9 while being fully transparent in the entire visible range will help expand the applications of optoelectronic devices.

The refractive index is a ratio of the speed of light in a vacuum to the phase velocity of light in a material, used as a measure of how much the path of light is bent when passing through a material. With the miniaturization of various optical parts used in mobile devices and imaging, demand has been rapidly growing for high refractive index transparent materials that induce more light refraction with a thin film.

As polymers have outstanding physical properties and can be easily processed in various forms, they are widely used in a variety of applications such as plastic eyeglass lenses. However, there have been very few polymers developed so far with a refractive index exceeding 1.75, and existing high refractive index polymers require costly materials and complicated manufacturing processes.

Above all, core technologies for producing such materials have been dominated by Japanese companies, causing long-standing challenges for Korean manufacturers. Securing a stable supply of high-performance, high refractive index materials is crucial for the production of optical devices that are lighter, more affordable, and can be freely manipulated.

The research team successfully manufactured a whole new polymer thin film material with a refractive index exceeding 1.9 and excellent transparency, using just a one-step chemical reaction. The SCP film showed outstanding optical transparency across the entire visible light region, presumably due to the uniformly dispersed, short-segment polysulfide chains, which is a distinct feature unachievable in polymerizations with molten sulfur.

The team focused on the fact that elemental sulfur is easily sublimated to produce a high refractive index polymer by polymerizing the vaporized sulfur with a variety of substances. This method suppresses the formation of overly long S-S chains while achieving outstanding thermal stability in high sulfur concentrations and generating transparent non-crystalline polymers across the entire visible spectrum.

Due to the characteristics of the vapor phase process, the high refractive index thin film can be coated not just on silicon wafers or glass substrates, but on a wide range of textured surfaces as well. We believe this thin film polymer is the first to have achieved an ultrahigh refractive index exceeding 1.9.

Professor Im said, “This high-performance polymer film can be created in a simple one-step manner, which is highly advantageous in the synthesis of SCPs with a high refractive index. This will serve as a platform material for future high-end optical device applications.”

This study, in collaboration with research teams from Seoul National University and Kyung Hee University, was reported in Science Advances. (Title: One-Step Vapor-Phase Synthesis of Transparent High-Refractive Index Sulfur-Containing Polymers)

This research was supported by the Ministry of Science and ICT’s Global Frontier Project (Center for Advanced Soft-Electronics), Leading Research Center Support Program (Wearable Platform Materials Technology Center), and Basic Science Research Program (Advanced Research Project).

2020.08.04 View 9956 -

From Dark to Light in a Flash: Smart Film Lets Windows Switch Autonomously

Researchers have developed a new easy-to-use smart optical film technology that allows smart window devices to autonomously switch between transparent and opaque states in response to the surrounding light conditions.

The proposed 3D hybrid nanocomposite film with a highly periodic network structure has empirically demonstrated its high speed and performance, enabling the smart window to quantify and self-regulate its high-contrast optical transmittance. As a proof of concept, a mobile-app-enabled smart window device for Internet of Things (IoT) applications has been realized using the proposed smart optical film with successful expansion to the 3-by-3-inch scale. This energy-efficient and cost-effective technology holds great promise for future use in various applications that require active optical transmission modulation.

Flexible optical transmission modulation technologies for smart applications including privacy-protection windows, zero-energy buildings, and beam projection screens have been in the spotlight in recent years. Conventional technologies that used external stimuli such as electricity, heat, or light to modulate optical transmission had only limited applications due to their slow response speeds, unnecessary color switching, and low durability, stability, and safety.

The optical transmission modulation contrast achieved by controlling the light scattering interfaces on non-periodic 2D surface structures that often have low optical density such as cracks, wrinkles, and pillars is also generally low. In addition, since the light scattering interfaces are exposed and not subject to any passivation, they can be vulnerable to external damage and may lose optical transmission modulation functions. Furthermore, in-plane scattering interfaces that randomly exist on the surface make large-area modulation with uniformity difficult.

Inspired by these limitations, a KAIST research team led by Professor Seokwoo Jeon from the Department of Materials Science and Engineering and Professor Jung-Wuk Hong of the Civil and Environmental Engineering Department used proximity-field nanopatterning (PnP) technology that effectively produces highly periodic 3D hybrid nanostructures, and an atomic layer deposition (ALD) technique that allows the precise control of oxide deposition and the high-quality fabrication of semiconductor devices.

The team then successfully produced a large-scale smart optical film with a size of 3 by 3 inches in which ultrathin alumina nanoshells are inserted between the elastomers in a periodic 3D nanonetwork.

This “mechano-responsive” 3D hybrid nanocomposite film with a highly periodic network structure is the largest smart optical transmission modulation film that exists. The film has been shown to have state-of-the-art optical transmission modulation of up to 74% at visible wavelengths from 90% initial transmission to 16% in the scattering state under strain. Its durability and stability were proved by more than 10,000 tests of harsh mechanical deformation including stretching, releasing, bending, and being placed under high temperatures of up to 70°C. When this film was used, the transmittance of the smart window device was adjusted promptly and automatically within one second in response to the surrounding light conditions. Through these experiments, the underlying physics of optical scattering phenomena occurring in the heterogeneous interfaces were identified. Their findings were reported in the online edition of Advanced Science on April 26. KAIST Professor Jong-Hwa Shin’s group and Professor Young-Seok Shim at Silla University also collaborated on this project.

Donghwi Cho, a PhD candidate in materials science and engineering at KAIST and co-lead author of the study, said, “Our smart optical film technology can better control high-contrast optical transmittance by relatively simple operating principles and with low energy consumption and costs.”

“When this technology is applied by simply attaching the film to a conventional smart window glass surface without replacing the existing window system, fast switching and uniform tinting are possible while also securing durability, stability, and safety. In addition, its wide range of applications for stretchable or rollable devices such as wall-type displays for a beam projection screen will also fulfill aesthetic needs,” he added.

This work was supported by the National Research Foundation of Korea (NRF), and the Korean Ministries of Science, ICT and Future Planning (MSIP), and Science and ICT (MSIT).

Publication:

Cho, D, et al. (2020) ‘High-Contrast Optical Modulation from Strain-Indicated Nanogaps at 3D Heterogeneous Interfaces’ Advanced Science, 1903708. Available online at https://doi.org/10.1002/advs.201903708

Profile: Seokwoo Jeon, PhD

Professor

jeon39@kaist.ac.kr

https://fdml.kaist.ac.kr/

Flexible Device and Metamaterials Lab (FDML)

Department of Materials Science and Engineering (MSE)

Korea Advanced Institute of Science and Technology (KAIST)

https://www.kaist.ac.krDaejeon 34141, Korea

Profile: Jung-Wuk Hong, PhD

Associate Professor

j.hong@kaist.ac.kr

http://aaml.kaist.ac.kr

Advanced Applied Mechanics Laboratory (AAML)

Department of Civil and Environmental Engineering

KAIST

Profile: Donghwi Cho

PhD Candidate

roy0202@kaist.ac.krFDML, MSE, KAIST

Profile: Young-Seok Shim, PhD

Assistant Professor

ysshim@silla.ac.kr

Division of Materials Science and Engineering Silla University

https://www.silla.ac.kr

Busan 46958, Korea

(END)

2020.06.02 View 13970

From Dark to Light in a Flash: Smart Film Lets Windows Switch Autonomously

Researchers have developed a new easy-to-use smart optical film technology that allows smart window devices to autonomously switch between transparent and opaque states in response to the surrounding light conditions.

The proposed 3D hybrid nanocomposite film with a highly periodic network structure has empirically demonstrated its high speed and performance, enabling the smart window to quantify and self-regulate its high-contrast optical transmittance. As a proof of concept, a mobile-app-enabled smart window device for Internet of Things (IoT) applications has been realized using the proposed smart optical film with successful expansion to the 3-by-3-inch scale. This energy-efficient and cost-effective technology holds great promise for future use in various applications that require active optical transmission modulation.

Flexible optical transmission modulation technologies for smart applications including privacy-protection windows, zero-energy buildings, and beam projection screens have been in the spotlight in recent years. Conventional technologies that used external stimuli such as electricity, heat, or light to modulate optical transmission had only limited applications due to their slow response speeds, unnecessary color switching, and low durability, stability, and safety.

The optical transmission modulation contrast achieved by controlling the light scattering interfaces on non-periodic 2D surface structures that often have low optical density such as cracks, wrinkles, and pillars is also generally low. In addition, since the light scattering interfaces are exposed and not subject to any passivation, they can be vulnerable to external damage and may lose optical transmission modulation functions. Furthermore, in-plane scattering interfaces that randomly exist on the surface make large-area modulation with uniformity difficult.

Inspired by these limitations, a KAIST research team led by Professor Seokwoo Jeon from the Department of Materials Science and Engineering and Professor Jung-Wuk Hong of the Civil and Environmental Engineering Department used proximity-field nanopatterning (PnP) technology that effectively produces highly periodic 3D hybrid nanostructures, and an atomic layer deposition (ALD) technique that allows the precise control of oxide deposition and the high-quality fabrication of semiconductor devices.

The team then successfully produced a large-scale smart optical film with a size of 3 by 3 inches in which ultrathin alumina nanoshells are inserted between the elastomers in a periodic 3D nanonetwork.

This “mechano-responsive” 3D hybrid nanocomposite film with a highly periodic network structure is the largest smart optical transmission modulation film that exists. The film has been shown to have state-of-the-art optical transmission modulation of up to 74% at visible wavelengths from 90% initial transmission to 16% in the scattering state under strain. Its durability and stability were proved by more than 10,000 tests of harsh mechanical deformation including stretching, releasing, bending, and being placed under high temperatures of up to 70°C. When this film was used, the transmittance of the smart window device was adjusted promptly and automatically within one second in response to the surrounding light conditions. Through these experiments, the underlying physics of optical scattering phenomena occurring in the heterogeneous interfaces were identified. Their findings were reported in the online edition of Advanced Science on April 26. KAIST Professor Jong-Hwa Shin’s group and Professor Young-Seok Shim at Silla University also collaborated on this project.

Donghwi Cho, a PhD candidate in materials science and engineering at KAIST and co-lead author of the study, said, “Our smart optical film technology can better control high-contrast optical transmittance by relatively simple operating principles and with low energy consumption and costs.”

“When this technology is applied by simply attaching the film to a conventional smart window glass surface without replacing the existing window system, fast switching and uniform tinting are possible while also securing durability, stability, and safety. In addition, its wide range of applications for stretchable or rollable devices such as wall-type displays for a beam projection screen will also fulfill aesthetic needs,” he added.

This work was supported by the National Research Foundation of Korea (NRF), and the Korean Ministries of Science, ICT and Future Planning (MSIP), and Science and ICT (MSIT).

Publication:

Cho, D, et al. (2020) ‘High-Contrast Optical Modulation from Strain-Indicated Nanogaps at 3D Heterogeneous Interfaces’ Advanced Science, 1903708. Available online at https://doi.org/10.1002/advs.201903708