l

-

Plasma, an Excellent Sterilizer to Remove Harmful Bacteria

(PhD candidate Joo Young Park, Professor Wonho Choe and PhD researcher Sanghoo Park)

KAIST researchers are using plasma to remove bacteria that are stuck to surfaces of plastic bottles and food. This novel technology will contribute to disinfection in medical settings as well as food and agricultural industries.

Professor Wonho Choe and his team from the Department of Physics developed a technology that removes biofilm, which is comprised of microorganisms, by using plasma as a non-thermal sterilization method.

Plasma contains multiple bactericidal agents, including reactive species. In particular, the chemicals formed in aqueous solution during plasma exposure have the potential for high antibacterial activity against various bacterial infections.

The team treated water with plasma to see how effectively bactericidal agents in the plasma water can remove biofilm comprised of harmful microorganism such as Escherichia coli, Salmonella, and Listeria.

The team identified that reactive species, including hydroxyl radical, hydrogen peroxide, ozone, nitrite, and superoxide produced during plasma treatment, showed considerable ability to remove the biofilm. Hydrogen peroxide showed the strongest effect removing the biofilm; however, the hydroxyl radical also played a significant role in removing biofilm. Despite having a concentration 100 to 10,000 times lower than other reactive species, the hydroxyl radical showed a high biofilm removal efficacy owing to its strong oxidative power.

These findings reveal that plasma can be used as a no-residual and safe sterilization process alternative to conventional methods. With these outcomes, the team is planning to develop and commercialize a technology that can produce hydroxyl radicals with plasma.

Professor Choe has registered a patent for flexible packaging materials that facilitate plasma and completed the technology transfer to the startup company, named ‘Plasmapp’, which focuses on commercializing bactericidal technology.

“This research outcome will be the foundation for understanding plasma control technology and physicochemical interactions between plasma and microorganisms. It will also become an accelerator for utilizing plasma technology in the medical, food, and agricultural fields,” said Professor Choe.

This research, led by PhD candidate Joo Young Park and PhD researcher Sanghoo Park in collaboration with Professor Cheorun Jo’s team from Seoul National University, was published in ACS Applied Materials and Interfaces on December 20, 2017.

Figure 1. Flexible packaging materials that facilitate plasma

Figure 2. Schematic diagram of biofilm treatment with plasma

Figure 3. Concept of plasma application and evaluation result of reactive species' efficacy

Figure 4. STERPACK, the product launched by Plasmapp

2018.01.25 View 10374

Plasma, an Excellent Sterilizer to Remove Harmful Bacteria

(PhD candidate Joo Young Park, Professor Wonho Choe and PhD researcher Sanghoo Park)

KAIST researchers are using plasma to remove bacteria that are stuck to surfaces of plastic bottles and food. This novel technology will contribute to disinfection in medical settings as well as food and agricultural industries.

Professor Wonho Choe and his team from the Department of Physics developed a technology that removes biofilm, which is comprised of microorganisms, by using plasma as a non-thermal sterilization method.

Plasma contains multiple bactericidal agents, including reactive species. In particular, the chemicals formed in aqueous solution during plasma exposure have the potential for high antibacterial activity against various bacterial infections.

The team treated water with plasma to see how effectively bactericidal agents in the plasma water can remove biofilm comprised of harmful microorganism such as Escherichia coli, Salmonella, and Listeria.

The team identified that reactive species, including hydroxyl radical, hydrogen peroxide, ozone, nitrite, and superoxide produced during plasma treatment, showed considerable ability to remove the biofilm. Hydrogen peroxide showed the strongest effect removing the biofilm; however, the hydroxyl radical also played a significant role in removing biofilm. Despite having a concentration 100 to 10,000 times lower than other reactive species, the hydroxyl radical showed a high biofilm removal efficacy owing to its strong oxidative power.

These findings reveal that plasma can be used as a no-residual and safe sterilization process alternative to conventional methods. With these outcomes, the team is planning to develop and commercialize a technology that can produce hydroxyl radicals with plasma.

Professor Choe has registered a patent for flexible packaging materials that facilitate plasma and completed the technology transfer to the startup company, named ‘Plasmapp’, which focuses on commercializing bactericidal technology.

“This research outcome will be the foundation for understanding plasma control technology and physicochemical interactions between plasma and microorganisms. It will also become an accelerator for utilizing plasma technology in the medical, food, and agricultural fields,” said Professor Choe.

This research, led by PhD candidate Joo Young Park and PhD researcher Sanghoo Park in collaboration with Professor Cheorun Jo’s team from Seoul National University, was published in ACS Applied Materials and Interfaces on December 20, 2017.

Figure 1. Flexible packaging materials that facilitate plasma

Figure 2. Schematic diagram of biofilm treatment with plasma

Figure 3. Concept of plasma application and evaluation result of reactive species' efficacy

Figure 4. STERPACK, the product launched by Plasmapp

2018.01.25 View 10374 -

Realizing Highly Efficient Quantum Dot LEDs with Metallic Nanostructures

(Professor Yong-Hoon Cho and PhD candidate Hyun Chul Park)

KAIST researchers have discovered a technology that enhances the efficiency of Quantum Dot LEDs.

Professor Yong-Hoon Cho from the Department of Physics and his team succeeded in improving the efficiency of Quantum Dot (QD) Light-Emitting Diodes (LEDs) by designing metallic nanostructure substrates.

QD LEDs possess very small semiconductor light sources and are considered to be the new rising technology for high performance full-color display. However, it is expensive to manufacture displays with QD LED only.

Existing QD-based displays use blue LEDs as a source of light, and they employ a method of color conversion through excitation of green and red QDs.

There are two inconveniences with the existing QD-based displays. As mentioned previously, QD LED is costly, hence the unit price of QD-based displays is higher. Also, the efficiency of a liquid type of QDs is drastically lowered after contact with air.

Professor Cho found the solution in a metallic nanostructure for lowering the production cost while improving the efficiency of QD LEDs.

The team exploited the phenomenon of so-called surface plasmonic resonances when nanoscale metallic structures are exposed to light. Depending on the metal, the size, and the shape, the properties of metallic structures vary.

The team used different metallic nanostructures for each QD LED – silver nanodisks for Red QDs and aluminum nanodisks for Green GDs – to make them more fluorescent.

With brighter QDs, it requires fewer QDs to manufacture QD LEDs, contributing to a lower unit price.

The team used silver and aluminum in this research, but metallic nanostructures can be redesigned according to the desired purposes.

Professor Cho said, “Implementing metallic nanostructures into QD LEDs in a proper manner can reduce the quantity of the QDs required for the system, leading to lower unit prices.”

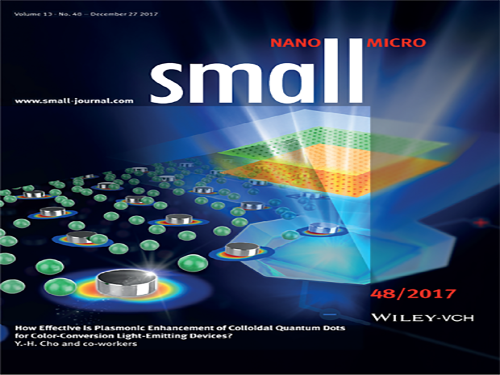

This research, led by PhD candidate Hyun Chul Park, was chosen as the cover of the international journal, Small, on December 27, 2017.

Figure 1. Cover of the journal

Figure 2. Spectrum showing different fluorescence with and without metallic nanostructure

2018.01.23 View 7458

Realizing Highly Efficient Quantum Dot LEDs with Metallic Nanostructures

(Professor Yong-Hoon Cho and PhD candidate Hyun Chul Park)

KAIST researchers have discovered a technology that enhances the efficiency of Quantum Dot LEDs.

Professor Yong-Hoon Cho from the Department of Physics and his team succeeded in improving the efficiency of Quantum Dot (QD) Light-Emitting Diodes (LEDs) by designing metallic nanostructure substrates.

QD LEDs possess very small semiconductor light sources and are considered to be the new rising technology for high performance full-color display. However, it is expensive to manufacture displays with QD LED only.

Existing QD-based displays use blue LEDs as a source of light, and they employ a method of color conversion through excitation of green and red QDs.

There are two inconveniences with the existing QD-based displays. As mentioned previously, QD LED is costly, hence the unit price of QD-based displays is higher. Also, the efficiency of a liquid type of QDs is drastically lowered after contact with air.

Professor Cho found the solution in a metallic nanostructure for lowering the production cost while improving the efficiency of QD LEDs.

The team exploited the phenomenon of so-called surface plasmonic resonances when nanoscale metallic structures are exposed to light. Depending on the metal, the size, and the shape, the properties of metallic structures vary.

The team used different metallic nanostructures for each QD LED – silver nanodisks for Red QDs and aluminum nanodisks for Green GDs – to make them more fluorescent.

With brighter QDs, it requires fewer QDs to manufacture QD LEDs, contributing to a lower unit price.

The team used silver and aluminum in this research, but metallic nanostructures can be redesigned according to the desired purposes.

Professor Cho said, “Implementing metallic nanostructures into QD LEDs in a proper manner can reduce the quantity of the QDs required for the system, leading to lower unit prices.”

This research, led by PhD candidate Hyun Chul Park, was chosen as the cover of the international journal, Small, on December 27, 2017.

Figure 1. Cover of the journal

Figure 2. Spectrum showing different fluorescence with and without metallic nanostructure

2018.01.23 View 7458 -

Cellular Mechanism for Severe Viral Hepatitis Identified

(Professor Shin(left) and Professor Jung)

KAIST medical scientists identified a cellular mechanism causing inflammatory changes in regulatory T cells that can lead to severe viral hepatitis. Research on this mechanism will help further understand the nature of various inflammatory diseases and lead to the development of relevant clinical treatments.

It is known that activated immune cells of patients with viral hepatitis destroy hepatocyte, but its regulatory mechanism has not yet been described.

Regulatory T cells inhibit activation of other immune cells and thus are important for homeostasis of the immune system. However, recent studies contradictorily show that immune inhibitory functions of regulatory T cells weaken in inflammatory conditions and the cells secrete inflammatory cytokines in response. Meanwhile, such a phenomenon was not observed in viral hepatitis including types A, B and C.

The team focused on changes in regulatory T cells in patients with viral hepatitis and discovered that regulatory T cells undergo inflammatory changes to secrete inflammatory cytokines (protein secreted by immune cells) called TNF. They also proved regulatory T cells that secrete TNF contribute to the progression of viral hepatitis.

The team confirmed that regulatory T cells of acute hepatitis A patients have reduced immune-inhibitory functions. Instead, their regulatory T cells secrete TNF. Through this research, the team identified a molecular mechanism for changes in regulatory T cells and identified the transcription factor regulating the process. Furthermore, the team found similar changes to be also present in hepatitis B and C patients.

A KAIST immunology research team led by Professors Eui-Cheol Shin and Min Kyung Jung at the Graduate School of Medical Science & Engineering conducted this translational research with teams from Chungnam National University and Yonsei University to identify the mechanism in humans, instead of using animal models. The research was described in Gastroenterology last December.

Professor Shin said, “This is the first research on regulatory T cells that contributes to hepatocyte damage in viral hepatitis.” He continued, “It is significant for identifying the cells and the molecules that can be used as effective treatment targets for viral hepatitis in the future. This research was funded by the Samsung Science and Technology Foundation.

(Figure1: Treg cells from acute hepatitis A (AHA) patients produce tumor necrosis factor (TNF) andhave reduced suppressive activity. These changes are due to a decrease in FoxP3 transcription factor and an increase in RORγt transcription factor. TNF-producing Treg cells are associated with severe liver injury in AHA patients.)

(Figure 2: A higher proportion of Treg cells from patients with acute hepatitis A, compared with healthy controls, produced TNF upon stimulation with anti-CD3 and anti-CD2. This study reports the presence and the significance of TNF-producing Treg cells for the first time in human patients.)

2018.01.18 View 9059

Cellular Mechanism for Severe Viral Hepatitis Identified

(Professor Shin(left) and Professor Jung)

KAIST medical scientists identified a cellular mechanism causing inflammatory changes in regulatory T cells that can lead to severe viral hepatitis. Research on this mechanism will help further understand the nature of various inflammatory diseases and lead to the development of relevant clinical treatments.

It is known that activated immune cells of patients with viral hepatitis destroy hepatocyte, but its regulatory mechanism has not yet been described.

Regulatory T cells inhibit activation of other immune cells and thus are important for homeostasis of the immune system. However, recent studies contradictorily show that immune inhibitory functions of regulatory T cells weaken in inflammatory conditions and the cells secrete inflammatory cytokines in response. Meanwhile, such a phenomenon was not observed in viral hepatitis including types A, B and C.

The team focused on changes in regulatory T cells in patients with viral hepatitis and discovered that regulatory T cells undergo inflammatory changes to secrete inflammatory cytokines (protein secreted by immune cells) called TNF. They also proved regulatory T cells that secrete TNF contribute to the progression of viral hepatitis.

The team confirmed that regulatory T cells of acute hepatitis A patients have reduced immune-inhibitory functions. Instead, their regulatory T cells secrete TNF. Through this research, the team identified a molecular mechanism for changes in regulatory T cells and identified the transcription factor regulating the process. Furthermore, the team found similar changes to be also present in hepatitis B and C patients.

A KAIST immunology research team led by Professors Eui-Cheol Shin and Min Kyung Jung at the Graduate School of Medical Science & Engineering conducted this translational research with teams from Chungnam National University and Yonsei University to identify the mechanism in humans, instead of using animal models. The research was described in Gastroenterology last December.

Professor Shin said, “This is the first research on regulatory T cells that contributes to hepatocyte damage in viral hepatitis.” He continued, “It is significant for identifying the cells and the molecules that can be used as effective treatment targets for viral hepatitis in the future. This research was funded by the Samsung Science and Technology Foundation.

(Figure1: Treg cells from acute hepatitis A (AHA) patients produce tumor necrosis factor (TNF) andhave reduced suppressive activity. These changes are due to a decrease in FoxP3 transcription factor and an increase in RORγt transcription factor. TNF-producing Treg cells are associated with severe liver injury in AHA patients.)

(Figure 2: A higher proportion of Treg cells from patients with acute hepatitis A, compared with healthy controls, produced TNF upon stimulation with anti-CD3 and anti-CD2. This study reports the presence and the significance of TNF-producing Treg cells for the first time in human patients.)

2018.01.18 View 9059 -

Easier Way to Produce High Performing, Flexible Micro-Supercapacitor

(Professor Minyang Yang and PhD Student Jae Hak Lee)

Professor Minyang Yang from the Department of Mechanical Engineering and his team developed a high-energy, flexible micro-supercapacitor in a simple and cost-effective way.

Compared to conventional micro-batteries, such as lithium-ion batteries, these new batteries, also called supercapacitors, are significantly faster to charge and semi-permanent.

Thin, flexible micro-supercapacitors can be a power source directly attached to wearable and flexible electronics.

However, fabrication of these micro-supercapacitors requires a complex patterning process, such as lithography techniques and vacuum evaporation. Hence, the process requires expensive instruments and toxic chemicals.

To simplify the fabrication of micro-supercapacitors in an eco-friendly manner, the team developed laser growth sintering technology. This technology manufactures superporous silver electrodes and applies them to the supercapacitors’ electrodes.

The team used a laser to form micro-patterns and generated nanoporous structures inside. This laser-induced growth sintering contributed to shortening the manufacturing process from ten steps to one.

Moreover, the team explored this unique laser growth sintering process –nucleation, growth, and sintering –by employing a particle-free, organometallic solution, which is not costly compared to typical laser-sintering methods for metallic nanoparticle solutions used in the printing of micro-electrodes.

Finally, unlike the typical supercapacitors comprised of a single substance, the team applied an asymmetric electrode configuration of nanoporous gold and manganese dioxide, which exhibits a highly-specific capacitance, to operate at a high voltage.

This method allows the team to develop energy storage with a high capacity. This developed micro-supercapacitor only requires four seconds to be charged and passed more than 5,000 durability tests.

Professor Yang said, “This research outcome can be used as energy storage installed in wearable and flexible electronic devices. Through this research, we are one step closer to realizing a complete version of flexible electronic devices by incorporating a power supply.”

This research, led by PhD candidate Jae Hak Lee, was selected as the cover of Journal of Materials Chemistry A on December 21, 2017.

Figure 1. Cover of the Journal Materials Chemistry A

Figure 2. Manufactured micro-supercapacitor and its performance

Figure 3. Laser growth sintering mechanism

Figure 4. Structural change of the silver conductor according to the irradiated laser energy

2018.01.18 View 8470

Easier Way to Produce High Performing, Flexible Micro-Supercapacitor

(Professor Minyang Yang and PhD Student Jae Hak Lee)

Professor Minyang Yang from the Department of Mechanical Engineering and his team developed a high-energy, flexible micro-supercapacitor in a simple and cost-effective way.

Compared to conventional micro-batteries, such as lithium-ion batteries, these new batteries, also called supercapacitors, are significantly faster to charge and semi-permanent.

Thin, flexible micro-supercapacitors can be a power source directly attached to wearable and flexible electronics.

However, fabrication of these micro-supercapacitors requires a complex patterning process, such as lithography techniques and vacuum evaporation. Hence, the process requires expensive instruments and toxic chemicals.

To simplify the fabrication of micro-supercapacitors in an eco-friendly manner, the team developed laser growth sintering technology. This technology manufactures superporous silver electrodes and applies them to the supercapacitors’ electrodes.

The team used a laser to form micro-patterns and generated nanoporous structures inside. This laser-induced growth sintering contributed to shortening the manufacturing process from ten steps to one.

Moreover, the team explored this unique laser growth sintering process –nucleation, growth, and sintering –by employing a particle-free, organometallic solution, which is not costly compared to typical laser-sintering methods for metallic nanoparticle solutions used in the printing of micro-electrodes.

Finally, unlike the typical supercapacitors comprised of a single substance, the team applied an asymmetric electrode configuration of nanoporous gold and manganese dioxide, which exhibits a highly-specific capacitance, to operate at a high voltage.

This method allows the team to develop energy storage with a high capacity. This developed micro-supercapacitor only requires four seconds to be charged and passed more than 5,000 durability tests.

Professor Yang said, “This research outcome can be used as energy storage installed in wearable and flexible electronic devices. Through this research, we are one step closer to realizing a complete version of flexible electronic devices by incorporating a power supply.”

This research, led by PhD candidate Jae Hak Lee, was selected as the cover of Journal of Materials Chemistry A on December 21, 2017.

Figure 1. Cover of the Journal Materials Chemistry A

Figure 2. Manufactured micro-supercapacitor and its performance

Figure 3. Laser growth sintering mechanism

Figure 4. Structural change of the silver conductor according to the irradiated laser energy

2018.01.18 View 8470 -

Lifespan of Fuel Cells Maximized Using Small Amount of Metals

(Professor Jung (far right) and his team)

Fuel cells are key future energy technology that is emerging as eco-friendly and renewable energy sources. In particular, solid oxide fuel cells composed of ceramic materials gain increasing attention for their ability to directly convert various forms of fuel such as biomass, LNG, and LPG to electric energy.

KAIST researchers described a new technique to improve chemical stability of electrode materials which can extend the lifespan by employing a very little amount of metals.

The core factor that determines the performance of solid oxide fuel cells is the cathode at which the reduction reaction of oxygen occurs. Conventionally, oxides with perovskite structure (ABO3) are used in cathodes. However, despite the high performance of perovskite oxides at initial operation, the performance decreases with time, limiting their long-term use. In particular, the condition of high temperature oxidation state required for cathode operation leads to surface segregation phenomenon, in which second phases such as strontium oxide (SrOx) accumulate on the surface of oxides, resulting in decrease in electrode performance. The detailed mechanism of this phenomenon and a way to effectively inhibit it has not been suggested.

Using computational chemistry and experimental data, Professor WooChul Jung’s team at the Department of Materials Science and Engineering observed that local compressive states around the Sr atoms in a perovskite electrode lattice weakened the Sr-O bond strength, which in turn promote strontium segregation. The team identified local changes in strain distribution in perovskite oxide as the main cause of segregation on strontium surface. Based on these findings, the team doped different sizes of metals in oxides to control the extent of lattice strain in cathode material and effectively inhibited strontium segregation.

Professor Jung said, “This technology can be implemented by adding a small amount of metal atoms during material synthesis, without any additional process.” He continued, “I hope this technology will be useful in developing high-durable perovskite oxide electrode in the future.”

The study co-led by Professor Jung and Professor Jeong Woo Han at Department of Chemical Engineering, University of Seoul was featured as the cover of Energy and Environmental Science in the first issue of 2018.

(Figure1.Correlation between the extent of lattice strain in electrode, strontium segregation, and electrode reaction.)

(Figure 2. Cathode surface of solid oxide fuel cell stabilized using the developed technology)

2018.01.18 View 8681

Lifespan of Fuel Cells Maximized Using Small Amount of Metals

(Professor Jung (far right) and his team)

Fuel cells are key future energy technology that is emerging as eco-friendly and renewable energy sources. In particular, solid oxide fuel cells composed of ceramic materials gain increasing attention for their ability to directly convert various forms of fuel such as biomass, LNG, and LPG to electric energy.

KAIST researchers described a new technique to improve chemical stability of electrode materials which can extend the lifespan by employing a very little amount of metals.

The core factor that determines the performance of solid oxide fuel cells is the cathode at which the reduction reaction of oxygen occurs. Conventionally, oxides with perovskite structure (ABO3) are used in cathodes. However, despite the high performance of perovskite oxides at initial operation, the performance decreases with time, limiting their long-term use. In particular, the condition of high temperature oxidation state required for cathode operation leads to surface segregation phenomenon, in which second phases such as strontium oxide (SrOx) accumulate on the surface of oxides, resulting in decrease in electrode performance. The detailed mechanism of this phenomenon and a way to effectively inhibit it has not been suggested.

Using computational chemistry and experimental data, Professor WooChul Jung’s team at the Department of Materials Science and Engineering observed that local compressive states around the Sr atoms in a perovskite electrode lattice weakened the Sr-O bond strength, which in turn promote strontium segregation. The team identified local changes in strain distribution in perovskite oxide as the main cause of segregation on strontium surface. Based on these findings, the team doped different sizes of metals in oxides to control the extent of lattice strain in cathode material and effectively inhibited strontium segregation.

Professor Jung said, “This technology can be implemented by adding a small amount of metal atoms during material synthesis, without any additional process.” He continued, “I hope this technology will be useful in developing high-durable perovskite oxide electrode in the future.”

The study co-led by Professor Jung and Professor Jeong Woo Han at Department of Chemical Engineering, University of Seoul was featured as the cover of Energy and Environmental Science in the first issue of 2018.

(Figure1.Correlation between the extent of lattice strain in electrode, strontium segregation, and electrode reaction.)

(Figure 2. Cathode surface of solid oxide fuel cell stabilized using the developed technology)

2018.01.18 View 8681 -

Three Professors Named KAST Fellows

(Professor Dan Keun Sung at the center)

(Professor Y.H. Cho at the center)

(Professor K.H. Cho at the center)

The Korean Academy of Science and Technology (KAST) inducted three KAIST professors as fellows at the New Year’s ceremony held at KAST on January 12. They were among the 24 newly elected fellows of the most distinguished academy in Korea. The new fellows are Professor Dan Keun Sung of the School of Electrical Engineering, Professor Kwang-Hyun Cho of the Department of Bio and Brain Engineering, and Professor Yong-Hoon Cho of the Department of Physics.

Professor Sung was recognized for his lifetime academic achievements in fields related with network protocols and energy ICT. He also played a crucial role in launching the Korean satellites KITSAT-1,2,3 and the establishment of the Satellite Technology Research Center at KAIST.

Professor Y.H.Cho has been a pioneer in the field of low-dimensional semiconductor-powered quantum photonics that enables quantum optical research in solid state. He has been recognized as a renowned scholar in this field internationally.

Professor K.H.Cho has conducted original research that combines IT and BT in systems biology and has applied novel technologies of electronic modeling and computer simulation analysis for investigating complex life sciences. Professor Cho, who is in his 40s, is the youngest fellow among the newly inducted fellows.

2018.01.16 View 15731

Three Professors Named KAST Fellows

(Professor Dan Keun Sung at the center)

(Professor Y.H. Cho at the center)

(Professor K.H. Cho at the center)

The Korean Academy of Science and Technology (KAST) inducted three KAIST professors as fellows at the New Year’s ceremony held at KAST on January 12. They were among the 24 newly elected fellows of the most distinguished academy in Korea. The new fellows are Professor Dan Keun Sung of the School of Electrical Engineering, Professor Kwang-Hyun Cho of the Department of Bio and Brain Engineering, and Professor Yong-Hoon Cho of the Department of Physics.

Professor Sung was recognized for his lifetime academic achievements in fields related with network protocols and energy ICT. He also played a crucial role in launching the Korean satellites KITSAT-1,2,3 and the establishment of the Satellite Technology Research Center at KAIST.

Professor Y.H.Cho has been a pioneer in the field of low-dimensional semiconductor-powered quantum photonics that enables quantum optical research in solid state. He has been recognized as a renowned scholar in this field internationally.

Professor K.H.Cho has conducted original research that combines IT and BT in systems biology and has applied novel technologies of electronic modeling and computer simulation analysis for investigating complex life sciences. Professor Cho, who is in his 40s, is the youngest fellow among the newly inducted fellows.

2018.01.16 View 15731 -

Harnessing the Strength of KAIST Alumni: New Head of KAA Inaugurated

KAIST alumni gathered in Seoul on January 13 to celebrate the New Year and the newly-elected leadership of the KAIST Alumni Association (KAA). More than 300 alumni, including President Sung-Chul Shin who is also an alumnus of KAIST, joined the gala event held at the Lotte Hotel.

Photo: Ki-Chul Cha(left) and Jung Sik Koh(right)

The KAA inaugurated its new president, Ki-Chul Cha, who was preceded by Jung Sik Koh, the former CEO at the Korea Resources Corporation. His term starts from January 2018 to December 2020.

Cha is the CEO of Inbody Co Ltd., a global company specializing in developing and selling medical instruments, such as a body composition analyzers, and medical solutions. He is also an adjunct professor in the Department of Mechanical Engineering at Yonsei University. Cha obtained a master’s degree in Mechanical Engineering at KAIST in 1980, and a Ph.D. in Bioengineering at the University of Utah, before finishing his post-doc fellowship at Harvard Medical School.

Cha plans to explore the idea that alumni engagement, saying, “KAIST stays as a home in the memories of 60,000 alumni. I will dedicate myself to stimulating the alumni association to make KAISTians proud.”

At the gala event, the KAA awarded the Alumni of the Year honor to six alumni who distinguished themselves in the areas of professional achievement, humanitarianism, and public service. They are the Director of Startup KAIST Professor Byoung Yoon Kim; President of LG Chem Ltd and Head of Battery Research and Development Myung Hwan Kim; Director of INNOX Advanced Materials Co., Ltd Kyung Ho Chang; Vice President of the Korea International Trade Association Jung-Kwan Kim; CEO of Samsung Electro-Mechanics Yun-Tae Lee; and CEO of ENF Technology Jinbae Jung.

Photo: President Shin(far right) poses with six awardees of the Distinguished Alumni Award and the former President of KAA, Koh(far left)

2018.01.16 View 11743

Harnessing the Strength of KAIST Alumni: New Head of KAA Inaugurated

KAIST alumni gathered in Seoul on January 13 to celebrate the New Year and the newly-elected leadership of the KAIST Alumni Association (KAA). More than 300 alumni, including President Sung-Chul Shin who is also an alumnus of KAIST, joined the gala event held at the Lotte Hotel.

Photo: Ki-Chul Cha(left) and Jung Sik Koh(right)

The KAA inaugurated its new president, Ki-Chul Cha, who was preceded by Jung Sik Koh, the former CEO at the Korea Resources Corporation. His term starts from January 2018 to December 2020.

Cha is the CEO of Inbody Co Ltd., a global company specializing in developing and selling medical instruments, such as a body composition analyzers, and medical solutions. He is also an adjunct professor in the Department of Mechanical Engineering at Yonsei University. Cha obtained a master’s degree in Mechanical Engineering at KAIST in 1980, and a Ph.D. in Bioengineering at the University of Utah, before finishing his post-doc fellowship at Harvard Medical School.

Cha plans to explore the idea that alumni engagement, saying, “KAIST stays as a home in the memories of 60,000 alumni. I will dedicate myself to stimulating the alumni association to make KAISTians proud.”

At the gala event, the KAA awarded the Alumni of the Year honor to six alumni who distinguished themselves in the areas of professional achievement, humanitarianism, and public service. They are the Director of Startup KAIST Professor Byoung Yoon Kim; President of LG Chem Ltd and Head of Battery Research and Development Myung Hwan Kim; Director of INNOX Advanced Materials Co., Ltd Kyung Ho Chang; Vice President of the Korea International Trade Association Jung-Kwan Kim; CEO of Samsung Electro-Mechanics Yun-Tae Lee; and CEO of ENF Technology Jinbae Jung.

Photo: President Shin(far right) poses with six awardees of the Distinguished Alumni Award and the former President of KAA, Koh(far left)

2018.01.16 View 11743 -

New Arylation Inducing Reaction Developed

(Professor Chang(left) and Professor Baik)

KAIST researchers have identified a reaction mechanism that selectively introduces aryl groups at the desired position of a molecule at room temperature. A team, co-led by Professor Sukbok Chang and Mu-Hyun Baik of the Department of Chemistry, used an iridium catalyst for the reaction. The team also proved that the reaction proceeds by an unusual mechanism by employing computer simulations that were substantiated with targeted experimental probes.

Hydrocarbon is an omnipresent material in nature. But its low reactivity makes it difficult to process to value-added products at the room temperature. Thus, designing catalysts that can accelerate the reaction remains an important challenge in chemistry.

In particular, since most chemicals used in medicine, pharmacy, or material chemistry contain aryl groups, an effective reaction to selectively introduce the aryl group has been an area of intensive research in organic chemistry.

In order to introduce an aryl group into stable carbon-hydrogen (C-H) bond, activation of the C-H bond with a halogen atom or organic metal is required prior to the introduction of the aryl group, or C-H functionalization directly on C-H bond is needed. Direct functionalization is more effective and economical, but most reactions require harsh reaction conditions such as high temperature or excess additives. And adding the aryl fragment selectively to only one among the many possible sites in the molecule is difficult. The new catalyst developed by these KAIST researchers is highly selective.

This work is the latest example of a successful teamwork between experimental and theoretical research groups: Computer simulations revealed that traditional approaches to arylation required high energies because the intermediates produced during the reaction are too low in energy. Based on this insight, the researchers thought of changing the character of the intermediate by oxidizing it, which was predicted to be a great way of increasing the reactivity of the catalyst. Subsequent experimental work showed that this design strategy is highly effective resulting in unprecedented chemical transformations.

Professor Chang said, “We have been able to carry out location-selective arylation at room temperature, as well as identifying a new reaction pathway, different from the conventionally suggested mechanism.” He continued, “This research is significant for identifying the reaction pathway and developing a novel selective reaction method that does not require high temperature or additives based on the mechanistic understanding. This work is a triumph of rational design, rather than fortuitous discovery.” The research findings were published online in Nature Chemistry on December 11, 2017.

(Figure 1: X-ray crystal structure transmetallation intermediate)

(Figure 2: Correlation between oxidation state of intermediate and energy barrier required for reductive elimination of intermediate as calculated using density function from computational chemistry )

(Figure 3: Arylation mechanism using iridium catalyst as suggested by the research team)

2018.01.11 View 6301

New Arylation Inducing Reaction Developed

(Professor Chang(left) and Professor Baik)

KAIST researchers have identified a reaction mechanism that selectively introduces aryl groups at the desired position of a molecule at room temperature. A team, co-led by Professor Sukbok Chang and Mu-Hyun Baik of the Department of Chemistry, used an iridium catalyst for the reaction. The team also proved that the reaction proceeds by an unusual mechanism by employing computer simulations that were substantiated with targeted experimental probes.

Hydrocarbon is an omnipresent material in nature. But its low reactivity makes it difficult to process to value-added products at the room temperature. Thus, designing catalysts that can accelerate the reaction remains an important challenge in chemistry.

In particular, since most chemicals used in medicine, pharmacy, or material chemistry contain aryl groups, an effective reaction to selectively introduce the aryl group has been an area of intensive research in organic chemistry.

In order to introduce an aryl group into stable carbon-hydrogen (C-H) bond, activation of the C-H bond with a halogen atom or organic metal is required prior to the introduction of the aryl group, or C-H functionalization directly on C-H bond is needed. Direct functionalization is more effective and economical, but most reactions require harsh reaction conditions such as high temperature or excess additives. And adding the aryl fragment selectively to only one among the many possible sites in the molecule is difficult. The new catalyst developed by these KAIST researchers is highly selective.

This work is the latest example of a successful teamwork between experimental and theoretical research groups: Computer simulations revealed that traditional approaches to arylation required high energies because the intermediates produced during the reaction are too low in energy. Based on this insight, the researchers thought of changing the character of the intermediate by oxidizing it, which was predicted to be a great way of increasing the reactivity of the catalyst. Subsequent experimental work showed that this design strategy is highly effective resulting in unprecedented chemical transformations.

Professor Chang said, “We have been able to carry out location-selective arylation at room temperature, as well as identifying a new reaction pathway, different from the conventionally suggested mechanism.” He continued, “This research is significant for identifying the reaction pathway and developing a novel selective reaction method that does not require high temperature or additives based on the mechanistic understanding. This work is a triumph of rational design, rather than fortuitous discovery.” The research findings were published online in Nature Chemistry on December 11, 2017.

(Figure 1: X-ray crystal structure transmetallation intermediate)

(Figure 2: Correlation between oxidation state of intermediate and energy barrier required for reductive elimination of intermediate as calculated using density function from computational chemistry )

(Figure 3: Arylation mechanism using iridium catalyst as suggested by the research team)

2018.01.11 View 6301 -

KAIST Students Invited to the BNL

Siheon Ryee and Taek Jung Kim, combined Masters and PhD students from the Department of Physics, have been invited to be visiting researchers at the Brookhaven National Laboratory (BNL).

The BNL, located in Long Island, New York, is one of the most esteemed institutes in the United States. Ryee and Kim received the invitation from the Center for Computational Design of Functional Strongly Correlated Materials and Theoretical Spectroscopy. This center was established by scholars who have been leading this field in the United States.

The two students will be participating in developing a methodology and code for calculating strongly correlated electronic materials, and a grant of 40,000 USD will be provided to each student. This amount of support is not often awarded to researchers outside of postdoctoral programs.

Moreover, they are guaranteed to continue their combined Masters and PhD program and write their dissertations under the supervision of their advisor, Professor Myung Joon Han from the Department of Physics.

Professor Han said, “I was impressed by how well-known scholars established the center in order to cooperate with each other to solve challenging problems. Also, I was surprised and happy that my students were invited to this outstanding institute.”

“I believe that doing research with leaders in their field will give valuable experience to the students. At the same time, my students will be a great help to the scholars of the institute,” he added.

2018.01.11 View 8989

KAIST Students Invited to the BNL

Siheon Ryee and Taek Jung Kim, combined Masters and PhD students from the Department of Physics, have been invited to be visiting researchers at the Brookhaven National Laboratory (BNL).

The BNL, located in Long Island, New York, is one of the most esteemed institutes in the United States. Ryee and Kim received the invitation from the Center for Computational Design of Functional Strongly Correlated Materials and Theoretical Spectroscopy. This center was established by scholars who have been leading this field in the United States.

The two students will be participating in developing a methodology and code for calculating strongly correlated electronic materials, and a grant of 40,000 USD will be provided to each student. This amount of support is not often awarded to researchers outside of postdoctoral programs.

Moreover, they are guaranteed to continue their combined Masters and PhD program and write their dissertations under the supervision of their advisor, Professor Myung Joon Han from the Department of Physics.

Professor Han said, “I was impressed by how well-known scholars established the center in order to cooperate with each other to solve challenging problems. Also, I was surprised and happy that my students were invited to this outstanding institute.”

“I believe that doing research with leaders in their field will give valuable experience to the students. At the same time, my students will be a great help to the scholars of the institute,” he added.

2018.01.11 View 8989 -

Professor Jung Awarded the Pople Medal by the APATCC

(Professor Yousung Jung)

Professor Yousung Jung of the Graduate School of EEWS won the Pople Medal from the Asia-Pacific Association of Theoretical & Computational Chemists (APATCC).

The Pople Medal has been awarded annually since 2007 to recognize young scholars in the fields of theoretical/computational chemistry in honor of Sir John Anthony Pople, who passed away in 2004. Dr. Pople was a British theoretical chemist and a Nobel laureate in 1998 for his development of computational methods in quantum chemistry.

The Pople Medal is awarded to scientists at or under the age of 45 in the Asia-Pacific region who have distinguished themselves through pioneering and important contributions.

Professor Jung was honored for his outstanding contributions to developing efficient electronic structure methods and their applications to energy materials discovery. He has published more than 120 papers in prestigious academic journals. He also has an h-index of 44, and has been cited more than 8,000 times.

2018.01.10 View 8144

Professor Jung Awarded the Pople Medal by the APATCC

(Professor Yousung Jung)

Professor Yousung Jung of the Graduate School of EEWS won the Pople Medal from the Asia-Pacific Association of Theoretical & Computational Chemists (APATCC).

The Pople Medal has been awarded annually since 2007 to recognize young scholars in the fields of theoretical/computational chemistry in honor of Sir John Anthony Pople, who passed away in 2004. Dr. Pople was a British theoretical chemist and a Nobel laureate in 1998 for his development of computational methods in quantum chemistry.

The Pople Medal is awarded to scientists at or under the age of 45 in the Asia-Pacific region who have distinguished themselves through pioneering and important contributions.

Professor Jung was honored for his outstanding contributions to developing efficient electronic structure methods and their applications to energy materials discovery. He has published more than 120 papers in prestigious academic journals. He also has an h-index of 44, and has been cited more than 8,000 times.

2018.01.10 View 8144 -

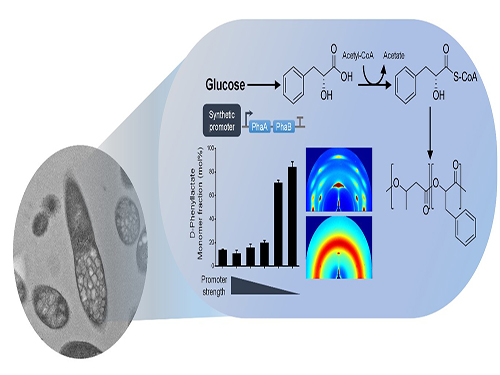

One-Step Production of Aromatic Polyesters by E. coli Strains

KAIST systems metabolic engineers defined a novel strategy for microbial aromatic polyesters production fused with synthetic biology from renewable biomass. The team of Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering produced aromatic polyesters from Escherichia coli (E. coli) strains by applying microbial fermentation, employing direct microbial fermentation from renewable feedstock carbohydrates.

This is the first report to determine a platform strain of engineered E. coli capable of producing environmentally friendly aromatic polyesters. This engineered E. coli strain, if desired, has the potential to be used as a platform strain capable of producing various high-valued aromatic polyesters from renewable biomass. This research was published in Nature Communications on January 8.

Conventionally, aromatic polyesters boast solid strength and heat stability so that there has been a great deal of interest in fermentative production of aromatic polyesters from renewable non-food biomass, but without success.

However, aromatic polyesters are only made by feeding the cells with corresponding aromatic monomers as substrates, and have not been produced by direct fermentation from renewable feedstock carbohydrates such as glucose.

To address this issue, the team prescribed the detailed procedure for aromatic polyester production through identifying CoA-transferase that activates phenylalkanoates into their corresponding CoA derivatives. In this process, researchers employed metabolic engineering of E. coli to produce phenylalkanoates from glucose based on genome-scale metabolic flux analysis. In particular, the KAIST team made a modulation of gene expression to produce various aromatic polyesters having different monomer fractions.

The research team successfully produced aromatic polyesters, a non-natural polymer using the strategy that combines systems metabolic engineering and synthetic biology. They succeeded in biosynthesis of various kinds of aromatic polyesters through the system, thus proving the technical excellence of the environmentally friendly biosynthetic system of this research. Furthermore, his team also proved the potential of expanding the range of aromatic polyesters from renewable resources, which is expected to play an important role in the bio-plastic industry.

Professor Lee said, “An eco-friendly and sustainable chemical industry is the key global agenda every nation faces. We are making a research focus to a biochemical industry free from petroleum dependence, and conducting diverse research activities to address the issue. This novel technology we are presenting will serve as an opportunity to advance the biochemical industry moving forward.”

This work was supported by the Intelligent Synthetic Biology Center through the Global Frontier Project (2011-0031963) and also by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries (NRF-2012M1A2A2026556 and NRF-2012M1A2A2026557) from the Ministry of Science and ICT through the National Research Foundation of Korea.

Figure: Biosynthesis of aromatic polyesters by metabolically engineered E. coli.This schematic diagram shows the overall conceptualization of how metabolically engineered E. coli produced aromatic polyesters from glucose.

2018.01.09 View 7903

One-Step Production of Aromatic Polyesters by E. coli Strains

KAIST systems metabolic engineers defined a novel strategy for microbial aromatic polyesters production fused with synthetic biology from renewable biomass. The team of Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering produced aromatic polyesters from Escherichia coli (E. coli) strains by applying microbial fermentation, employing direct microbial fermentation from renewable feedstock carbohydrates.

This is the first report to determine a platform strain of engineered E. coli capable of producing environmentally friendly aromatic polyesters. This engineered E. coli strain, if desired, has the potential to be used as a platform strain capable of producing various high-valued aromatic polyesters from renewable biomass. This research was published in Nature Communications on January 8.

Conventionally, aromatic polyesters boast solid strength and heat stability so that there has been a great deal of interest in fermentative production of aromatic polyesters from renewable non-food biomass, but without success.

However, aromatic polyesters are only made by feeding the cells with corresponding aromatic monomers as substrates, and have not been produced by direct fermentation from renewable feedstock carbohydrates such as glucose.

To address this issue, the team prescribed the detailed procedure for aromatic polyester production through identifying CoA-transferase that activates phenylalkanoates into their corresponding CoA derivatives. In this process, researchers employed metabolic engineering of E. coli to produce phenylalkanoates from glucose based on genome-scale metabolic flux analysis. In particular, the KAIST team made a modulation of gene expression to produce various aromatic polyesters having different monomer fractions.

The research team successfully produced aromatic polyesters, a non-natural polymer using the strategy that combines systems metabolic engineering and synthetic biology. They succeeded in biosynthesis of various kinds of aromatic polyesters through the system, thus proving the technical excellence of the environmentally friendly biosynthetic system of this research. Furthermore, his team also proved the potential of expanding the range of aromatic polyesters from renewable resources, which is expected to play an important role in the bio-plastic industry.

Professor Lee said, “An eco-friendly and sustainable chemical industry is the key global agenda every nation faces. We are making a research focus to a biochemical industry free from petroleum dependence, and conducting diverse research activities to address the issue. This novel technology we are presenting will serve as an opportunity to advance the biochemical industry moving forward.”

This work was supported by the Intelligent Synthetic Biology Center through the Global Frontier Project (2011-0031963) and also by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries (NRF-2012M1A2A2026556 and NRF-2012M1A2A2026557) from the Ministry of Science and ICT through the National Research Foundation of Korea.

Figure: Biosynthesis of aromatic polyesters by metabolically engineered E. coli.This schematic diagram shows the overall conceptualization of how metabolically engineered E. coli produced aromatic polyesters from glucose.

2018.01.09 View 7903 -

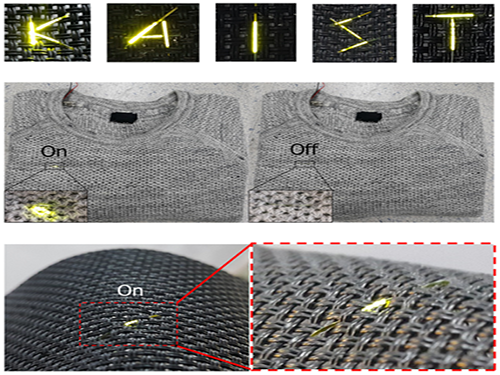

Fiber OLEDs, Thinner Than a Hair

(Seonil Kwon, PhD Candidate)

Professor Kyung Cheol Choi from the School of Electrical Engineering and his team succeeded in fabricating highly efficient Organic Light-Emitting Diodes (OLEDs) on an ultra-thin fiber.

The team expects the technology, which produces high-efficiency, long-lasting OLEDs, can be widely utilized in wearable displays.

Existing fiber-based wearable displays’ OLEDs show much lower performance compared to those fabricated on planar substrates. This low performance caused a limitation for applying it to actual wearable displays.

In order to solve this problem, the team designed a structure of OLEDs compatible to fiber and used a dip-coating method in a three-dimensional structure of fibers. Through this method, the team successfully developed efficient OLEDs that are designed to last a lifetime and are still equivalent to those on planar substrates.

The team identified that solution process planar OLEDs can be applied to fibers without any reduction in performance through the technology. This fiber OLEDs exhibited luminance and current efficiency values of over 10,000 cd/m^2(candela/square meter) and 11 cd/A (candela/ampere).

The team also verified that the fiber OLEDs withstood tensile strains of up to 4.3% while retaining more than 90% of their current efficiency. In addition, they could be woven into textiles and knitted clothes without causing any problems.

Moreover, the technology allows for fabricating OLEDs on fibers with diameters ranging from 300㎛ down to 90㎛, thinner than a human hair, which attests to the scalability of the proposed fabrication scheme.

Noting that every process is carried out at a low temperature (~105℃), fibers vulnerable to high temperatures can also employ this fabrication scheme.

Professor Choi said, “Existing fiber-based wearable displays had limitations for applicability due to their low performance. However, this technology can fabricate OLEDs with high performance on fibers. This simple, low-cost process opens a way to commercialize fiber-based wearable displays.”

This research led by a PhD candidate Seonil Kwon was published online in the international journal for nanoscience, Nano Letters, on December 6.

(Fiber-based OLEDs woven into knitted clothes)

This work was funded by the Engineering Research Center of Excellence Program (Grant No. NRF-2017R1A5A1014708) and Nano-Material Technology Development Program (Grant No. NRF-2016M3A7B4910635) by the National Research Foundation of Korea, the Ministry of Science and ICT of Korea.

2018.01.09 View 14391

Fiber OLEDs, Thinner Than a Hair

(Seonil Kwon, PhD Candidate)

Professor Kyung Cheol Choi from the School of Electrical Engineering and his team succeeded in fabricating highly efficient Organic Light-Emitting Diodes (OLEDs) on an ultra-thin fiber.

The team expects the technology, which produces high-efficiency, long-lasting OLEDs, can be widely utilized in wearable displays.

Existing fiber-based wearable displays’ OLEDs show much lower performance compared to those fabricated on planar substrates. This low performance caused a limitation for applying it to actual wearable displays.

In order to solve this problem, the team designed a structure of OLEDs compatible to fiber and used a dip-coating method in a three-dimensional structure of fibers. Through this method, the team successfully developed efficient OLEDs that are designed to last a lifetime and are still equivalent to those on planar substrates.

The team identified that solution process planar OLEDs can be applied to fibers without any reduction in performance through the technology. This fiber OLEDs exhibited luminance and current efficiency values of over 10,000 cd/m^2(candela/square meter) and 11 cd/A (candela/ampere).

The team also verified that the fiber OLEDs withstood tensile strains of up to 4.3% while retaining more than 90% of their current efficiency. In addition, they could be woven into textiles and knitted clothes without causing any problems.

Moreover, the technology allows for fabricating OLEDs on fibers with diameters ranging from 300㎛ down to 90㎛, thinner than a human hair, which attests to the scalability of the proposed fabrication scheme.

Noting that every process is carried out at a low temperature (~105℃), fibers vulnerable to high temperatures can also employ this fabrication scheme.

Professor Choi said, “Existing fiber-based wearable displays had limitations for applicability due to their low performance. However, this technology can fabricate OLEDs with high performance on fibers. This simple, low-cost process opens a way to commercialize fiber-based wearable displays.”

This research led by a PhD candidate Seonil Kwon was published online in the international journal for nanoscience, Nano Letters, on December 6.

(Fiber-based OLEDs woven into knitted clothes)

This work was funded by the Engineering Research Center of Excellence Program (Grant No. NRF-2017R1A5A1014708) and Nano-Material Technology Development Program (Grant No. NRF-2016M3A7B4910635) by the National Research Foundation of Korea, the Ministry of Science and ICT of Korea.

2018.01.09 View 14391