Engineering

-

A KAIST Student Team Wins the ACM UIST 2014 Student Innovation Contest

A KAIST team consisted of students from the Departments of Industrial Design and Computer Science participated in the ACM UIST 2014 Student Innovation Contest and received 1st Prize in the category of People’s Choice.

The Association for Computing Machinery (ACM) Symposium on User Interface Software and Technology (UIST) is an international forum to promote innovations in human-computer interfaces, which takes place annually and is sponsored by ACM Special Interest Groups on Computer-Human Interaction (SIGCHI) and Computer Graphics (SIGGRAPH). The ACM UIST conference brings together professionals in the fields of graphical and web-user interfaces, tangible and ubiquitous computing, virtual and augmented reality, multimedia, and input and output devices.

The Student Innovation Contest has been held during the UIST conference since 2009 to innovate new interactions on state-of-the-art hardware. The participating students were given with the hardware platform to build on—this year, it was Kinoma Create, a JavaScript-powered construction kit that allows makers, professional product designers, and web developers to create personal projects, consumer electronics, and "Internet of Things" prototypes. Contestants demonstrated their creations on household interfaces, and two winners in each of three categories -- Most Creative, Most Useful, and the People’s Choice -- were awarded.

Utilizing Kinoma Create, which came with a built-in touchscreen, WiFi, Bluetooth, a front-facing sensor connector, and a 50-pin rear sensor dock, the KAIST team developed a “smart mop,” transforming the irksome task of cleaning into a fun game. The smart mop identifies target dirt and shows its location on the display built in the rod of a mop. If the user turns on a game mode, then winning scores are gained wherever the target dirt is cleaned.

The People’s Choice award was decided by conference attendees, and they voted the smart mop as their most favorite project.

Professor Tek-Jin Nam of the Department of Industrial Design at KAIST, who advised the students, said, "A total of 24 teams from such prestigious universities as Carnegie Mellon University, Georgia Institute of Technology, and the University of Tokyo joined the contest, and we are pleased with the good results. Many people, in fact, praised the integration of creativity and technical excellence our have shown through the smart mop.”

Team KAIST: pictured from right to left, Sun-Jun Kim, Se-Jin Kim, and Han-Jong Kim

The Smart Mop can clean the floor and offer users a fun game.

2014.11.12 View 12301

A KAIST Student Team Wins the ACM UIST 2014 Student Innovation Contest

A KAIST team consisted of students from the Departments of Industrial Design and Computer Science participated in the ACM UIST 2014 Student Innovation Contest and received 1st Prize in the category of People’s Choice.

The Association for Computing Machinery (ACM) Symposium on User Interface Software and Technology (UIST) is an international forum to promote innovations in human-computer interfaces, which takes place annually and is sponsored by ACM Special Interest Groups on Computer-Human Interaction (SIGCHI) and Computer Graphics (SIGGRAPH). The ACM UIST conference brings together professionals in the fields of graphical and web-user interfaces, tangible and ubiquitous computing, virtual and augmented reality, multimedia, and input and output devices.

The Student Innovation Contest has been held during the UIST conference since 2009 to innovate new interactions on state-of-the-art hardware. The participating students were given with the hardware platform to build on—this year, it was Kinoma Create, a JavaScript-powered construction kit that allows makers, professional product designers, and web developers to create personal projects, consumer electronics, and "Internet of Things" prototypes. Contestants demonstrated their creations on household interfaces, and two winners in each of three categories -- Most Creative, Most Useful, and the People’s Choice -- were awarded.

Utilizing Kinoma Create, which came with a built-in touchscreen, WiFi, Bluetooth, a front-facing sensor connector, and a 50-pin rear sensor dock, the KAIST team developed a “smart mop,” transforming the irksome task of cleaning into a fun game. The smart mop identifies target dirt and shows its location on the display built in the rod of a mop. If the user turns on a game mode, then winning scores are gained wherever the target dirt is cleaned.

The People’s Choice award was decided by conference attendees, and they voted the smart mop as their most favorite project.

Professor Tek-Jin Nam of the Department of Industrial Design at KAIST, who advised the students, said, "A total of 24 teams from such prestigious universities as Carnegie Mellon University, Georgia Institute of Technology, and the University of Tokyo joined the contest, and we are pleased with the good results. Many people, in fact, praised the integration of creativity and technical excellence our have shown through the smart mop.”

Team KAIST: pictured from right to left, Sun-Jun Kim, Se-Jin Kim, and Han-Jong Kim

The Smart Mop can clean the floor and offer users a fun game.

2014.11.12 View 12301 -

Professor Sung-Yong Kim Receives the Young Scientist Award

Professor Sung-Yong Kim of the Department of Ocean Systems Engineering at KAIST received the Young Scientist Award for 2014 conferred by the Korean Society of Oceanography (KSO). The award was presented at the KSO’s fall conference that took place on November 6, 2014 at the campus of the Naval Academy of the Republic of Korea in Jinhae.

Professor Kim has been recognized for his outstanding research in coastal oceanography and environmental fluid mechanics. His research papers are frequently published in prestigious journals such as the Journal of Geophysical Research-Oceans by the American Geophysical Union.

2014.11.11 View 8392

Professor Sung-Yong Kim Receives the Young Scientist Award

Professor Sung-Yong Kim of the Department of Ocean Systems Engineering at KAIST received the Young Scientist Award for 2014 conferred by the Korean Society of Oceanography (KSO). The award was presented at the KSO’s fall conference that took place on November 6, 2014 at the campus of the Naval Academy of the Republic of Korea in Jinhae.

Professor Kim has been recognized for his outstanding research in coastal oceanography and environmental fluid mechanics. His research papers are frequently published in prestigious journals such as the Journal of Geophysical Research-Oceans by the American Geophysical Union.

2014.11.11 View 8392 -

Professor Joong-Keun Park Receives SeAH Heam Academic Award

Professor Joong-Keun Park of the Department of Materials Science and Engineering at KAIST received an award from SeAH Steel Corp. in recognition of his academic achievements in the field of metallic and materials engineering.

The award was presented at the 2014 Fall Conference of the Korean Institute of Metals and Materials which took place on October 22-24 at the Kangwon Land Convention Hotel.

The award, called “SeAH Heam Academic Award,” is given annually to a scholar who has contributed to the development of new metal and polymer composite materials and its related field in Korea. Following the award ceremony, Professor Park gave a keynote speech on ferrous metals for automotive materials.

2014.11.04 View 8690

Professor Joong-Keun Park Receives SeAH Heam Academic Award

Professor Joong-Keun Park of the Department of Materials Science and Engineering at KAIST received an award from SeAH Steel Corp. in recognition of his academic achievements in the field of metallic and materials engineering.

The award was presented at the 2014 Fall Conference of the Korean Institute of Metals and Materials which took place on October 22-24 at the Kangwon Land Convention Hotel.

The award, called “SeAH Heam Academic Award,” is given annually to a scholar who has contributed to the development of new metal and polymer composite materials and its related field in Korea. Following the award ceremony, Professor Park gave a keynote speech on ferrous metals for automotive materials.

2014.11.04 View 8690 -

The 2014 SoC Robot Competition Took Place

Professor Hoi-Jun Yoo of the Department of Electrical Engineering at KAIST and his research team hosted a competition for miniature robots with artificial intelligence at KINTEX in Ilsan, Korea, on October 23-26, 2014.

The competition, called the 2014 SoC Robot War, showed the latest developments of semiconductor and robot technology through the robots’ presentations of the Korean martial art, Taekwondo, and hurdles race. SoC is a system on ship, an integrated circuit that holds all components of a computer or other electronic systems in a single chip. SoC robots are equipped with an artificial intelligence system, and therefore, can recognize things on their own or respond automatically to environmental changes. SoC robots are developed with the integration of semiconductor technology and robotics engineering.

Marking the thirteenth competition this year since its inception, the Robot War featured two competitions between HURO and Taekwon Robots. Under the HURO competition, participating robots were required to run a hurdle race, pass through barricades, and cross a bridge. The winning team received an award from the president of the Republic of Korea. Robots participating in the Taekwon Robot competition performed some of the main movements of Taekwondo such as front and side kicks and fist techniques. The winning team received an award from the prime minster of the Republic of Korea.

A total of 105 teams with 530 students and researchers from different universities across the country participated in preliminaries, and 30 teams qualified for the final competition.

2014.10.27 View 9315

The 2014 SoC Robot Competition Took Place

Professor Hoi-Jun Yoo of the Department of Electrical Engineering at KAIST and his research team hosted a competition for miniature robots with artificial intelligence at KINTEX in Ilsan, Korea, on October 23-26, 2014.

The competition, called the 2014 SoC Robot War, showed the latest developments of semiconductor and robot technology through the robots’ presentations of the Korean martial art, Taekwondo, and hurdles race. SoC is a system on ship, an integrated circuit that holds all components of a computer or other electronic systems in a single chip. SoC robots are equipped with an artificial intelligence system, and therefore, can recognize things on their own or respond automatically to environmental changes. SoC robots are developed with the integration of semiconductor technology and robotics engineering.

Marking the thirteenth competition this year since its inception, the Robot War featured two competitions between HURO and Taekwon Robots. Under the HURO competition, participating robots were required to run a hurdle race, pass through barricades, and cross a bridge. The winning team received an award from the president of the Republic of Korea. Robots participating in the Taekwon Robot competition performed some of the main movements of Taekwondo such as front and side kicks and fist techniques. The winning team received an award from the prime minster of the Republic of Korea.

A total of 105 teams with 530 students and researchers from different universities across the country participated in preliminaries, and 30 teams qualified for the final competition.

2014.10.27 View 9315 -

Wuhan University, China, Appoints Distinguished Professor Sang Yup Lee as Honorary Professor

Sang Yup Lee, Distinguished Professor of the Department of Chemical and Biomolecular Engineering at KAIST, has been appointed an honorary professor at Wuhan University in Hubei Province, China. This is the third time that Professor Lee has received an honorary professorship from Chinese academic institutions. The Chinese Academy of Sciences appointed him an honorary professor in 2012, and Shanghai Jia Tong University asked him to serve as an advisory professor in 2013, respectively.

Professor Lee was recognized for his pioneering research in systems metabolic engineering of microorganisms necessary for the development of green chemical industries. He succeeded in producing succinic acid through bacterial fermentation and engineering plastic raw materials in the most effective and economical method for the first time in the world. Professor Lee also developed polylactic acid, a bio-based polymer that allows plastics to be produced through natural and renewable resources, as well as the microbial production of alkanes, an alternative to gasoline that can be produced from fatty acids.

Professor Lee has been actively working as a member of a group of global leaders supported by the World Economic Forum (WEF), serving the Chairman of the Future of Chemicals, Advanced Materials & Biotechnology, Global Agenda Councils, WEF.

Wuhan University is a comprehensive and key national university selected by the Chinese government as a major recipient of state funding for research. It is also known as one of the most beautiful campuses in China.

2014.10.20 View 10294

Wuhan University, China, Appoints Distinguished Professor Sang Yup Lee as Honorary Professor

Sang Yup Lee, Distinguished Professor of the Department of Chemical and Biomolecular Engineering at KAIST, has been appointed an honorary professor at Wuhan University in Hubei Province, China. This is the third time that Professor Lee has received an honorary professorship from Chinese academic institutions. The Chinese Academy of Sciences appointed him an honorary professor in 2012, and Shanghai Jia Tong University asked him to serve as an advisory professor in 2013, respectively.

Professor Lee was recognized for his pioneering research in systems metabolic engineering of microorganisms necessary for the development of green chemical industries. He succeeded in producing succinic acid through bacterial fermentation and engineering plastic raw materials in the most effective and economical method for the first time in the world. Professor Lee also developed polylactic acid, a bio-based polymer that allows plastics to be produced through natural and renewable resources, as well as the microbial production of alkanes, an alternative to gasoline that can be produced from fatty acids.

Professor Lee has been actively working as a member of a group of global leaders supported by the World Economic Forum (WEF), serving the Chairman of the Future of Chemicals, Advanced Materials & Biotechnology, Global Agenda Councils, WEF.

Wuhan University is a comprehensive and key national university selected by the Chinese government as a major recipient of state funding for research. It is also known as one of the most beautiful campuses in China.

2014.10.20 View 10294 -

An Artist and Scientist, the Dean of Northwestern University speaks at KAIST

How does an abstract artist look at the world of science? Can art enhance scientific inquiry?

The Department of Chemical and Biomolecular Engineering (CBE), KAIST, invited Professor Julio Mario Ottino to speak at its fourth Annual KAIST CBE Global Distinguished Lectureship from the 15th to 16th October. Professor Ottino is the Dean of the Robert R. McCormick School of Engineering and Applied Science at Northwestern University.

Professor Ottino is a famous artist as well as a scientist. He pursues his disciplines in engineering and art as ways by which an artistic value and scientific truth can coexist. By merging these disciplines, he is praised for adopting balanced engineering education that emphasizes analytical skills and creativity at Northwestern University.

The lecture took place over two days. The topic of the first day was “Creativity” and the next day, “Formalism in Science.”

On the first day, Professor Ottino spoke about “Creativity in Science, Art, and Technology -- How art is separated from science.” He argues that as creativity is essential in art, science, and technology, artistic creativity can help develop scientific and technological creativity.

The next lecture featured “Mixing of Fluids and Solids: Parallels, Divergences, and Lessons.”

He emphasized that the birth of mixing of fluids and researches on granular matter and segregation offered valuable insights and lessons. Although these two topics have developed in different ways, he laid down some examples on how scientific theories have progressed under formalism.

2014.10.16 View 9142

An Artist and Scientist, the Dean of Northwestern University speaks at KAIST

How does an abstract artist look at the world of science? Can art enhance scientific inquiry?

The Department of Chemical and Biomolecular Engineering (CBE), KAIST, invited Professor Julio Mario Ottino to speak at its fourth Annual KAIST CBE Global Distinguished Lectureship from the 15th to 16th October. Professor Ottino is the Dean of the Robert R. McCormick School of Engineering and Applied Science at Northwestern University.

Professor Ottino is a famous artist as well as a scientist. He pursues his disciplines in engineering and art as ways by which an artistic value and scientific truth can coexist. By merging these disciplines, he is praised for adopting balanced engineering education that emphasizes analytical skills and creativity at Northwestern University.

The lecture took place over two days. The topic of the first day was “Creativity” and the next day, “Formalism in Science.”

On the first day, Professor Ottino spoke about “Creativity in Science, Art, and Technology -- How art is separated from science.” He argues that as creativity is essential in art, science, and technology, artistic creativity can help develop scientific and technological creativity.

The next lecture featured “Mixing of Fluids and Solids: Parallels, Divergences, and Lessons.”

He emphasized that the birth of mixing of fluids and researches on granular matter and segregation offered valuable insights and lessons. Although these two topics have developed in different ways, he laid down some examples on how scientific theories have progressed under formalism.

2014.10.16 View 9142 -

KAIST Registers an Internationally Recognized Standard Patent

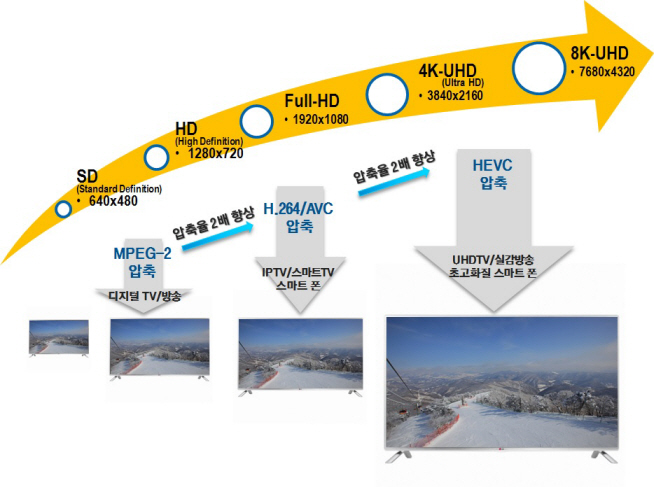

A video compression technology, jointly developed by Professor Mun-Chul Kim of the Department of Electrical Engineering at KAIST, the Electronics and Telecommunications Research Institute (ETRI), and the Korean Broadcasting System (KBS), is registered internationally as the standard patent in the next-generation High Efficiency Video Coding (HEVC).

HEVC (H.265) is an international technology standard that compresses large image data for Ultra High Definition (UHD) televisions and smartphones. It has the twice the compression efficiency as that of H.264/AVC which is most commonly used for processing full HD sources. This means that it is able to compress a video file to half the size while maintaining the same image quality.

Although the related market is at a nascent stage, HEVC technology has already been applied to the latest version of televisions and smartphones. Experts predict that the market will grow to USD 200 billion by 2016, and KAIST is expected to receive a royalty payment of USD 9.3 million from this patent.

The International Organization for Standardization (ISO/IEC) established the HEVC standard in January 2013. Also, an international patent pool licensing corporation, MPEG LA announced the HEVC standard patent pool on September 29, 2014.

Professor Joongmyeon Bae, Dean of the Office of University-Industry Cooperation (OUIC) of KAIST, said, “This is an unprecedented case for Korea whereby a core technology developed by a university became an international standard, which has a vast impact on the market.”

President of KAIST, Steve Kang commented, “With its advanced technology, KAIST joined the HEVC standard patent pool as one of the 23 founding members along with Apple, Siemens, and NEC. This is a remarkable achievement.”

Picture 1: Improvements in video compression technology

Picture 2: Comparison of different screen resolutions

2014.10.09 View 13788

KAIST Registers an Internationally Recognized Standard Patent

A video compression technology, jointly developed by Professor Mun-Chul Kim of the Department of Electrical Engineering at KAIST, the Electronics and Telecommunications Research Institute (ETRI), and the Korean Broadcasting System (KBS), is registered internationally as the standard patent in the next-generation High Efficiency Video Coding (HEVC).

HEVC (H.265) is an international technology standard that compresses large image data for Ultra High Definition (UHD) televisions and smartphones. It has the twice the compression efficiency as that of H.264/AVC which is most commonly used for processing full HD sources. This means that it is able to compress a video file to half the size while maintaining the same image quality.

Although the related market is at a nascent stage, HEVC technology has already been applied to the latest version of televisions and smartphones. Experts predict that the market will grow to USD 200 billion by 2016, and KAIST is expected to receive a royalty payment of USD 9.3 million from this patent.

The International Organization for Standardization (ISO/IEC) established the HEVC standard in January 2013. Also, an international patent pool licensing corporation, MPEG LA announced the HEVC standard patent pool on September 29, 2014.

Professor Joongmyeon Bae, Dean of the Office of University-Industry Cooperation (OUIC) of KAIST, said, “This is an unprecedented case for Korea whereby a core technology developed by a university became an international standard, which has a vast impact on the market.”

President of KAIST, Steve Kang commented, “With its advanced technology, KAIST joined the HEVC standard patent pool as one of the 23 founding members along with Apple, Siemens, and NEC. This is a remarkable achievement.”

Picture 1: Improvements in video compression technology

Picture 2: Comparison of different screen resolutions

2014.10.09 View 13788 -

KAIST Co-owns the HEVC Patent Portfolio License

MPEG LA, LLC, a firm based in Denver, Colorado, which licenses patent pools covering essential patents required for the use of video coding technology, such as MPEG-2, MPEG-4 Visual (Part 2), and HEVC/H.264, announced the availability of the High Efficiency Video Coding (HEVC) Patent Portfolio License on September 29, 2014.

The HEVC standard, also known as H.265 and MPEG-H Part 2, is necessary to improve video coding and transmission efficiency for the Internet, televisions, and mobile gadgets with increased speed and capacity.

Through the portfolio license, users can easily obtain patent rights required for the HEVC standard in a single transaction, instead of negotiating separate licenses from multiple patent holders.

A total of 23 enterprises currently own essential HEVC patents. KAIST is the only Korean university among the joint patent owners. Collaborating with the Korea Broadcasting System (KBS) and the Electronics and Telecommunications Research Institute (ETRI), Professor Mun-Chul Kim of the Electrical Engineering Department at KAIST developed one of the core patents.

For a link to a press release distributed by MPEG LA, LLC, please see:

MPEG LA, LLC, September 29, 2014

"MPEG LA, LLC Offers HEVC Patent Portfolio License"

http://www.mpegla.com/main/Pages/Media.aspx

2014.10.02 View 14224

KAIST Co-owns the HEVC Patent Portfolio License

MPEG LA, LLC, a firm based in Denver, Colorado, which licenses patent pools covering essential patents required for the use of video coding technology, such as MPEG-2, MPEG-4 Visual (Part 2), and HEVC/H.264, announced the availability of the High Efficiency Video Coding (HEVC) Patent Portfolio License on September 29, 2014.

The HEVC standard, also known as H.265 and MPEG-H Part 2, is necessary to improve video coding and transmission efficiency for the Internet, televisions, and mobile gadgets with increased speed and capacity.

Through the portfolio license, users can easily obtain patent rights required for the HEVC standard in a single transaction, instead of negotiating separate licenses from multiple patent holders.

A total of 23 enterprises currently own essential HEVC patents. KAIST is the only Korean university among the joint patent owners. Collaborating with the Korea Broadcasting System (KBS) and the Electronics and Telecommunications Research Institute (ETRI), Professor Mun-Chul Kim of the Electrical Engineering Department at KAIST developed one of the core patents.

For a link to a press release distributed by MPEG LA, LLC, please see:

MPEG LA, LLC, September 29, 2014

"MPEG LA, LLC Offers HEVC Patent Portfolio License"

http://www.mpegla.com/main/Pages/Media.aspx

2014.10.02 View 14224 -

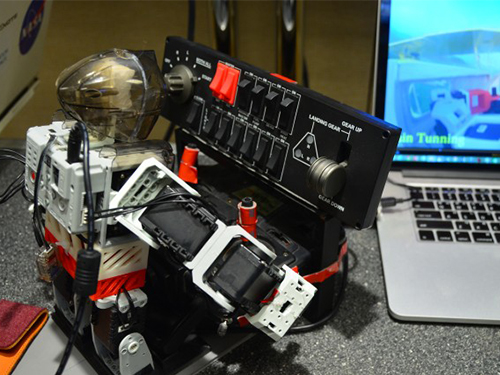

PIBOT, a small humanoid robot flies an aircraft

The 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2014) took place in Chicago, Illinois, on September 14-18, 2014.

Professor David Hyunchul Shim and his students from the Department of Aerospace Engineering, KAIST, presented a research paper entitled “A Robot-machine Interface for Full-functionality Automation Using a Humanoid” at the conference.

The robot called “PIBOT,” a pint-sized, tiny humanoid robot, uses a mixture of flight data and visuals to fly an airplane, capable of identifying and operating all of the buttons and switches in the cockpit of a normal light aircraft designed for humans.

For now, the robot is only flying a simulator, but Professor Shim expects that “PIBOT will help us have a fully automated flight experience, eventually replacing human pilots.”

The IEEE Spectrum magazine published an article on PIBOT posted online September 18, 2014. Please follow the link below for the article:

IEEE Spectrum, September 18, 2014

Tiny Humanoid Robot Learning to Fly Real Airplanes

http://spectrum.ieee.org/automaton/robotics/humanoids/tiny-humanoid-robot-learning-to-fly-real-airplanes

2014.09.23 View 14624

PIBOT, a small humanoid robot flies an aircraft

The 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2014) took place in Chicago, Illinois, on September 14-18, 2014.

Professor David Hyunchul Shim and his students from the Department of Aerospace Engineering, KAIST, presented a research paper entitled “A Robot-machine Interface for Full-functionality Automation Using a Humanoid” at the conference.

The robot called “PIBOT,” a pint-sized, tiny humanoid robot, uses a mixture of flight data and visuals to fly an airplane, capable of identifying and operating all of the buttons and switches in the cockpit of a normal light aircraft designed for humans.

For now, the robot is only flying a simulator, but Professor Shim expects that “PIBOT will help us have a fully automated flight experience, eventually replacing human pilots.”

The IEEE Spectrum magazine published an article on PIBOT posted online September 18, 2014. Please follow the link below for the article:

IEEE Spectrum, September 18, 2014

Tiny Humanoid Robot Learning to Fly Real Airplanes

http://spectrum.ieee.org/automaton/robotics/humanoids/tiny-humanoid-robot-learning-to-fly-real-airplanes

2014.09.23 View 14624 -

Distinguished Professor Sang Yup Lee Gives Special Lecture at Tianjin University, China

Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering at KAIST gave a special lecture at Tianjin University, China, on September 12, 2014.

The university has invited prestigious scholars and scientists including Nobel Prize laureates from all around the world to their program called the "BeiYang Lecture Series."

Professor Lee said:

"The lecture series has invited many eminent global leaders such as Dr. Steven Chu, who received the Nobel Prize in Physics in 1997 and also served the 12th United States Secretary of Energy. It is a great honor to participate in the program as a speaker. The university told me that in recognition of my research in the development of sustainable biochemical industry through systems metabolic engineering, I was invited to speak.”

Professor Lee presented his speech entitled “Production of Chemical Materials through Microorganism Metabolic Systems Engineering” and took questions from the audience.

Professor Lee developed the world’s most efficient microorganism and bioprocess such as succinate, butanol, and engineering plastic raw materials. In recent years, he has succeeded in producing a small quantity of gasoline through converting in-vivo generated fatty acids.

2014.09.16 View 10179

Distinguished Professor Sang Yup Lee Gives Special Lecture at Tianjin University, China

Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering at KAIST gave a special lecture at Tianjin University, China, on September 12, 2014.

The university has invited prestigious scholars and scientists including Nobel Prize laureates from all around the world to their program called the "BeiYang Lecture Series."

Professor Lee said:

"The lecture series has invited many eminent global leaders such as Dr. Steven Chu, who received the Nobel Prize in Physics in 1997 and also served the 12th United States Secretary of Energy. It is a great honor to participate in the program as a speaker. The university told me that in recognition of my research in the development of sustainable biochemical industry through systems metabolic engineering, I was invited to speak.”

Professor Lee presented his speech entitled “Production of Chemical Materials through Microorganism Metabolic Systems Engineering” and took questions from the audience.

Professor Lee developed the world’s most efficient microorganism and bioprocess such as succinate, butanol, and engineering plastic raw materials. In recent years, he has succeeded in producing a small quantity of gasoline through converting in-vivo generated fatty acids.

2014.09.16 View 10179 -

Distinguished Professor Sang Yup Lee Participates in the 2014 Summer Davos Forum

Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering, KAIST, was invited to lead four sessions at the Annual Meeting 2014, the World Economic Forum, also known as the Summer Davos Forum, which was held in Tianjin, China, from September 10th to 12th.

Two of the four sessions Professor Lee participated in were held on September 10th. At the first session entitled “Biotechnology Ecosystem,” he examined with other panelists the future of bioengineering in depth and discussed major policies and industry trends that will be necessary for the development of future biotechnologies.

Professor Lee later attended the “Strategic Shifts in Healthcare” session as a moderator. Issues related to transforming the health industry such as the next-generation genomics, mobile health and telemedicine, and wearable devices and predictive analytics were addressed.

On September 12, Professor Lee joined the “IdeasLab with KAIST” and gave a presentation on nanotechnology. There was a total of ten IdeasLab sessions held at the Summer Davos Forum, and KAIST was the only Korean university ever invited to host this session. In addition to Professor Lee’s presentation, three more presentations were made by KAIST professors on such topics as “Sustainable Energy and Materials” and “Next-generation Semiconductors.”

Lastly, Professor Lee participated in the “Global Promising Technology” session with the World Economic Forum’s Global Agenda Council members. At this session, he explained the selection of the “World’s Top 10 Most Promising Technologies” and “Bio Sector’s Top 10 Technologies” and led discussions about the “2015 Top 10 Technologies” with the council members.

The Davos Forum has been announcing the “World’s Top 10 Most Promising Technologies” since 2012, and Professor Lee has played a key role in the selection while working as the Chairman of Global Agenda Council. The selection results are presented at the Davos Forum every year and have attracted a lot of attention from around the world.

2014.09.15 View 13105

Distinguished Professor Sang Yup Lee Participates in the 2014 Summer Davos Forum

Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering, KAIST, was invited to lead four sessions at the Annual Meeting 2014, the World Economic Forum, also known as the Summer Davos Forum, which was held in Tianjin, China, from September 10th to 12th.

Two of the four sessions Professor Lee participated in were held on September 10th. At the first session entitled “Biotechnology Ecosystem,” he examined with other panelists the future of bioengineering in depth and discussed major policies and industry trends that will be necessary for the development of future biotechnologies.

Professor Lee later attended the “Strategic Shifts in Healthcare” session as a moderator. Issues related to transforming the health industry such as the next-generation genomics, mobile health and telemedicine, and wearable devices and predictive analytics were addressed.

On September 12, Professor Lee joined the “IdeasLab with KAIST” and gave a presentation on nanotechnology. There was a total of ten IdeasLab sessions held at the Summer Davos Forum, and KAIST was the only Korean university ever invited to host this session. In addition to Professor Lee’s presentation, three more presentations were made by KAIST professors on such topics as “Sustainable Energy and Materials” and “Next-generation Semiconductors.”

Lastly, Professor Lee participated in the “Global Promising Technology” session with the World Economic Forum’s Global Agenda Council members. At this session, he explained the selection of the “World’s Top 10 Most Promising Technologies” and “Bio Sector’s Top 10 Technologies” and led discussions about the “2015 Top 10 Technologies” with the council members.

The Davos Forum has been announcing the “World’s Top 10 Most Promising Technologies” since 2012, and Professor Lee has played a key role in the selection while working as the Chairman of Global Agenda Council. The selection results are presented at the Davos Forum every year and have attracted a lot of attention from around the world.

2014.09.15 View 13105 -

Kiseok Song, a Ph.D. candidate in the Electrical Engineering Department, receives the 2014 Marconi Society Young Scholar Award

Established

in 1974 to commemorate the eminent Italian inventor and electrical engineer,

Guglielmo Marconi, the Marconi Society has recognized significant contributions

in science and technology by awarding the Marconi Prize, with an annual USD

100,000 grant, to a living scientist who has made great advancements in

communications technology.

Along

with the Marconi Prize, the Society has been presenting the Young Scholars

Awards over the past six years to reward young and emerging scientists’ brilliant

academic and research achievements as well as their entrepreneurship. For this

year’s seventh Young Scholar Awards, a KAIST doctoral student was selected as

one of the two recipients.

Kiseok

Song, a Ph.D. candidate in the Department of Electrical Engineering, KAIST, has

been named as a 2014 Marconi Society Paul Baran Young Scholar. The Marconi Society said that Song was being recognized for "his

academic achievements and leadership in the field of communications and

information science,” according to a press release distributed by the Society on August 28, 2014.

Studying

under the advice of Professor Hoi-Jun Yoo of the Department of Electrical

Engineering at KAIST, Song has developed bio-medical System on a Chip (SoC)

such as smart wireless bio-medical systems combined with optimized SoCs,

compact bio-medical patch systems connected to smart phones, smart electro-acupuncture

and transdermal drug delivery, and multi-modal non-invasive glucose monitors.

The

press release quoted Professor Yoo’s comment on the meaning of Song’s research:

“All

of these bio-medical systems open a new healthcare paradigm to improve people’s

quality of life in combination with the current mobile smart phones.”

In

addition to Song, Himanshu Asnani, a Stanford Ph.D. candidate and system engineer

at Ericsson Silicon Valley, received the other award. The award

ceremony will be held at the Marconi Society’s annual award gala at the

National Academies of Science Building in Washington D.C., on October 2, 2014.

For

details, please read the following press release:

The

Marconi Society, Press Release, August 28, 2014

“Kiseok

Song Receives the 2014 Marconi Society Young Scholar Award”

http://www.marconisociety.org/press/2014Song.html

2014.09.08 View 9592

Kiseok Song, a Ph.D. candidate in the Electrical Engineering Department, receives the 2014 Marconi Society Young Scholar Award

Established

in 1974 to commemorate the eminent Italian inventor and electrical engineer,

Guglielmo Marconi, the Marconi Society has recognized significant contributions

in science and technology by awarding the Marconi Prize, with an annual USD

100,000 grant, to a living scientist who has made great advancements in

communications technology.

Along

with the Marconi Prize, the Society has been presenting the Young Scholars

Awards over the past six years to reward young and emerging scientists’ brilliant

academic and research achievements as well as their entrepreneurship. For this

year’s seventh Young Scholar Awards, a KAIST doctoral student was selected as

one of the two recipients.

Kiseok

Song, a Ph.D. candidate in the Department of Electrical Engineering, KAIST, has

been named as a 2014 Marconi Society Paul Baran Young Scholar. The Marconi Society said that Song was being recognized for "his

academic achievements and leadership in the field of communications and

information science,” according to a press release distributed by the Society on August 28, 2014.

Studying

under the advice of Professor Hoi-Jun Yoo of the Department of Electrical

Engineering at KAIST, Song has developed bio-medical System on a Chip (SoC)

such as smart wireless bio-medical systems combined with optimized SoCs,

compact bio-medical patch systems connected to smart phones, smart electro-acupuncture

and transdermal drug delivery, and multi-modal non-invasive glucose monitors.

The

press release quoted Professor Yoo’s comment on the meaning of Song’s research:

“All

of these bio-medical systems open a new healthcare paradigm to improve people’s

quality of life in combination with the current mobile smart phones.”

In

addition to Song, Himanshu Asnani, a Stanford Ph.D. candidate and system engineer

at Ericsson Silicon Valley, received the other award. The award

ceremony will be held at the Marconi Society’s annual award gala at the

National Academies of Science Building in Washington D.C., on October 2, 2014.

For

details, please read the following press release:

The

Marconi Society, Press Release, August 28, 2014

“Kiseok

Song Receives the 2014 Marconi Society Young Scholar Award”

http://www.marconisociety.org/press/2014Song.html

2014.09.08 View 9592