AR

-

Professor Kwangjo Kim Named as Fellow of IACR

Professor Kwangjo Kim of the Graduate School of Information Security has been selected as a fellow of the International Association for Cryptologic Research (IACR).

The IACR has honored outstanding scholars who have achieved academic excellence in cryptologic research since 2004. He is the first Korean scholar to receive an IACR fellowship.

The IACR, established in 1981, is responsible for organizing international cryptologic conferences every year including the three major cryptologic academic conferences Eurocrypt, Crypto, and Asiacript. The IACR also sponsors workshop series such as the Theory of Cryptography Conference (TCC), the Workshop on Fast Software Encryption (FSE), the Public Key Cryptography Workshop (PKC), and Cryptographic Hardware and Embedded Systems (CHES).

Professor Kim, an internationally acclaimed scholar in the fields of cryptology and information security theory and its applications, was recognized for his outstanding academic achievements and leadership. He has made significant contributions to cryptology in Korea by hosting Asiacript in 1996 and 2001 as well as CHES in 2014. During his 34 years of academic activities, he has published more than 80 SCI journal papers and garnered more than 20,000 citations.

Professor Kim served on the board of the directors of the IACR from 2000 to 2004 and was the chairperson of the Asiacript Steering Committee from 2005 to 2008. He is on the editorial board of the online journal Cryptography.

Professor Kim said, “I am so humbled and honored to be named as a fellow of such a prestigious academic association. I will continue to strive to assist highly educated information security personnel with further research in cryptology.”

2017.03.16 View 8372

Professor Kwangjo Kim Named as Fellow of IACR

Professor Kwangjo Kim of the Graduate School of Information Security has been selected as a fellow of the International Association for Cryptologic Research (IACR).

The IACR has honored outstanding scholars who have achieved academic excellence in cryptologic research since 2004. He is the first Korean scholar to receive an IACR fellowship.

The IACR, established in 1981, is responsible for organizing international cryptologic conferences every year including the three major cryptologic academic conferences Eurocrypt, Crypto, and Asiacript. The IACR also sponsors workshop series such as the Theory of Cryptography Conference (TCC), the Workshop on Fast Software Encryption (FSE), the Public Key Cryptography Workshop (PKC), and Cryptographic Hardware and Embedded Systems (CHES).

Professor Kim, an internationally acclaimed scholar in the fields of cryptology and information security theory and its applications, was recognized for his outstanding academic achievements and leadership. He has made significant contributions to cryptology in Korea by hosting Asiacript in 1996 and 2001 as well as CHES in 2014. During his 34 years of academic activities, he has published more than 80 SCI journal papers and garnered more than 20,000 citations.

Professor Kim served on the board of the directors of the IACR from 2000 to 2004 and was the chairperson of the Asiacript Steering Committee from 2005 to 2008. He is on the editorial board of the online journal Cryptography.

Professor Kim said, “I am so humbled and honored to be named as a fellow of such a prestigious academic association. I will continue to strive to assist highly educated information security personnel with further research in cryptology.”

2017.03.16 View 8372 -

Dr.Sung-Chul Shin Inaugurated as the 16th President of KAIST

(President Shin delivers his inaugural address at the inauguration ceremony on March 15.)

Professor Sung-Chul Shin was officially inaugurated as its 16th president of KAIST on March 15 in a ceremony at the KAIST Auditorium.

The celebration began with a procession by dignitaries including the KAIST Board of Trustees Chairman Jang-Moo Lee, the National Academy of Sciences of Korea President Sook-Il Kwun, Daejeon City Mayor Sun-Taik Kwon, National Assemblyman Sangmin Lee, KAIST Alumni Association President Jungsik Koh. Academic leaders, foreign envoys, faculty, students, and staff members of KAIST joined the ceremony.

In his inaugural speech, President Shin presented a new vision for KAIST to become a global value creator in the Fourth Industrial Revolution. He said that KAIST has played a pivotal role in the nation’s industrialization and information revolution over the past half century and, with the advent of the new industry paradigm, KAIST should be now responsible for being a new value creator, not only serving the nation but pursuing global betterment. “KAIST should be a global hub of new knowledge and technology creation,” he emphasized.

Envisioning a “Global Value-Creative World-Leading University,” President Shin aims for KAIST to be an institution which can create global value as an innovative global leading research university. To realize this vision, he pledged to continue innovation in five areas of education, research & development, technology commercialization, globalization of the campus, and future strategy for the university and the nation.

In the educational innovation, he emphasized multidisciplinary studies, team work, and leadership training for students. To this end, KAIST will expand the non-departmental courses toward entire 4-year course while concurrently operating the existing system of declaring a major in students’ second year. KAIST will offer mandatory courses in humanities, social sciences, and arts and most classes will be run by team-based learning and group research activities. “KAIST Global Leadership Center” will support students to develop the qualities required for collaboration and the global leaderships.

With respect to the research innovation, President Shin said KAIST will establish “Convergence Research Matrix” system to foster strategic research groups for interdisciplinary and convergence collaboration across a wide range of divisions and departments. “Based on the CRMS, we will identify 10 flagship future-oriented convergence research areas for KAIST to truly claim its reputation as a world-leading research university,” he said. He added he will also introduce the “Collaborative Research Lab” system to better retain the academic successes without interruption, and to improve the continuity of research. “We will strive to organize teams of professors in diverse age groups to work together in mutually complementary fields,” he added.

In terms of technological commercialization, he hopes that KAIST to be a role model. He said he will make every effort to establish a resilient R&DB environment with ideas, technologies, and entrepreneurship. KAIST will rev up a new university-industry cooperation, fully sponsoring the creation of “Technology in-Kind Investment Companies.”

KAIST will continue to take initiative for globalization. He said KAIST will create an ‘English-Only Zone’ at the campus, saying that his ultimate goal is to create Korean-English bilingual campus. He also asked the foreign community to make their effort to learn Korean and Korean culture while staying at KAIST, in an effort to embrace diversity at the campus. He plans to increase the ratio of foreign faculty from nine percent to 15 percent, while doubling the current foreign student enrollment ratio of five percent.

As for the future strategy for the university and the nation, he will soon finalize the long-term strategic plan of “Vision 2031” that will lay out a roadmap for KAIST future direction toward its 60th anniversary. KAIST will also play a fundamental role in shaping national policies and strategies for science and technology by operating think-tank groups that consist of KAIST beyond disciplines. These think-tanks will design detailed development plans for KAIST as well as for national strategies for the advancement of science and technology.

He said that such institutional innovation will not be completed without the support, dedication, and passion of all KAIST members, adding that he will strive to serve them with 3Cs (Change, Communication, and Care).

For the full text of President Shin’s inaugural address, please click.

2017.03.15 View 10915

Dr.Sung-Chul Shin Inaugurated as the 16th President of KAIST

(President Shin delivers his inaugural address at the inauguration ceremony on March 15.)

Professor Sung-Chul Shin was officially inaugurated as its 16th president of KAIST on March 15 in a ceremony at the KAIST Auditorium.

The celebration began with a procession by dignitaries including the KAIST Board of Trustees Chairman Jang-Moo Lee, the National Academy of Sciences of Korea President Sook-Il Kwun, Daejeon City Mayor Sun-Taik Kwon, National Assemblyman Sangmin Lee, KAIST Alumni Association President Jungsik Koh. Academic leaders, foreign envoys, faculty, students, and staff members of KAIST joined the ceremony.

In his inaugural speech, President Shin presented a new vision for KAIST to become a global value creator in the Fourth Industrial Revolution. He said that KAIST has played a pivotal role in the nation’s industrialization and information revolution over the past half century and, with the advent of the new industry paradigm, KAIST should be now responsible for being a new value creator, not only serving the nation but pursuing global betterment. “KAIST should be a global hub of new knowledge and technology creation,” he emphasized.

Envisioning a “Global Value-Creative World-Leading University,” President Shin aims for KAIST to be an institution which can create global value as an innovative global leading research university. To realize this vision, he pledged to continue innovation in five areas of education, research & development, technology commercialization, globalization of the campus, and future strategy for the university and the nation.

In the educational innovation, he emphasized multidisciplinary studies, team work, and leadership training for students. To this end, KAIST will expand the non-departmental courses toward entire 4-year course while concurrently operating the existing system of declaring a major in students’ second year. KAIST will offer mandatory courses in humanities, social sciences, and arts and most classes will be run by team-based learning and group research activities. “KAIST Global Leadership Center” will support students to develop the qualities required for collaboration and the global leaderships.

With respect to the research innovation, President Shin said KAIST will establish “Convergence Research Matrix” system to foster strategic research groups for interdisciplinary and convergence collaboration across a wide range of divisions and departments. “Based on the CRMS, we will identify 10 flagship future-oriented convergence research areas for KAIST to truly claim its reputation as a world-leading research university,” he said. He added he will also introduce the “Collaborative Research Lab” system to better retain the academic successes without interruption, and to improve the continuity of research. “We will strive to organize teams of professors in diverse age groups to work together in mutually complementary fields,” he added.

In terms of technological commercialization, he hopes that KAIST to be a role model. He said he will make every effort to establish a resilient R&DB environment with ideas, technologies, and entrepreneurship. KAIST will rev up a new university-industry cooperation, fully sponsoring the creation of “Technology in-Kind Investment Companies.”

KAIST will continue to take initiative for globalization. He said KAIST will create an ‘English-Only Zone’ at the campus, saying that his ultimate goal is to create Korean-English bilingual campus. He also asked the foreign community to make their effort to learn Korean and Korean culture while staying at KAIST, in an effort to embrace diversity at the campus. He plans to increase the ratio of foreign faculty from nine percent to 15 percent, while doubling the current foreign student enrollment ratio of five percent.

As for the future strategy for the university and the nation, he will soon finalize the long-term strategic plan of “Vision 2031” that will lay out a roadmap for KAIST future direction toward its 60th anniversary. KAIST will also play a fundamental role in shaping national policies and strategies for science and technology by operating think-tank groups that consist of KAIST beyond disciplines. These think-tanks will design detailed development plans for KAIST as well as for national strategies for the advancement of science and technology.

He said that such institutional innovation will not be completed without the support, dedication, and passion of all KAIST members, adding that he will strive to serve them with 3Cs (Change, Communication, and Care).

For the full text of President Shin’s inaugural address, please click.

2017.03.15 View 10915 -

13 KAIST Faculty Named as Inaugural Members of Y-KAST

The Korean Academy of Science and Technology (KAST) launched the Young Korean Academy of Science and Technology (Y-KAST) and selected 73 scientists as its inaugural members on February 24. Among them, 13 KAIST faculty were recognized as the inaugural members of Y-KAST.

Y-KAIST, made up of distinguished mid-career scientists under the age of 45, will take the leading role in international collaboration as well as innovative agenda-making in science and technology.

The inaugural members include Professor Hyotcherl Ihee of the Department of Chemistry and Dr. Sung-Jin Oh of the Center for Mathematical Challenges at the Korea Institute for Advanced Study (KIAS), affiliated with KAIST. Professor Ihee is gaining wide acclaim in the fields of physics and chemistry, and in 2016, Dr. Oh was the youngest ever awardee of the Presidential Award of Young Scientist.

The other Y-KAIST members are as follows: Professors Haeshin Lee of the Department of Chemistry; Mi Young Kim, Byung-Kwan Cho, and Ji-Joon Song of the Department of Biological Sciences; Song-Yong Kim of the Department of Mechanical Engineering; Sang-il Oum of the Department of Mathematical Sciences; Jung Kyoon Choi of the Department of Bio and Brain Engineering; Seokwoo Jeon, Sang Ouk Kim, and Il-Doo Kim of the Department of Materials Science and Engineering; Jang Wook Choi of the Graduate School of EEWS (Energy, Environment, Water and Sustainability); and Jeong Ho Lee of the Graduate School of Medical Science and Engineering.

The leading countries of the Academy of Science, which include Germany, Sweden, Belgium, Canada, and Japan, have established the Young Academy of Science since 2010 in order to encourage the research activities of their young scientists and to establish a global platform for collaborative research projects through their active networking at home and abroad.

President Myung-Chul Lee of KAST said, “We will spare no effort to connect these outstanding mid-career researchers for their future collaboration. Their networking will make significant impacts toward their own research activities as well as the global stature of Korea’s science and technology R&D.

(Photo caption: Members of Y-KAST pose at the inaugural ceremony of Y-KAST on February 24.)

2017.03.02 View 17780

13 KAIST Faculty Named as Inaugural Members of Y-KAST

The Korean Academy of Science and Technology (KAST) launched the Young Korean Academy of Science and Technology (Y-KAST) and selected 73 scientists as its inaugural members on February 24. Among them, 13 KAIST faculty were recognized as the inaugural members of Y-KAST.

Y-KAIST, made up of distinguished mid-career scientists under the age of 45, will take the leading role in international collaboration as well as innovative agenda-making in science and technology.

The inaugural members include Professor Hyotcherl Ihee of the Department of Chemistry and Dr. Sung-Jin Oh of the Center for Mathematical Challenges at the Korea Institute for Advanced Study (KIAS), affiliated with KAIST. Professor Ihee is gaining wide acclaim in the fields of physics and chemistry, and in 2016, Dr. Oh was the youngest ever awardee of the Presidential Award of Young Scientist.

The other Y-KAIST members are as follows: Professors Haeshin Lee of the Department of Chemistry; Mi Young Kim, Byung-Kwan Cho, and Ji-Joon Song of the Department of Biological Sciences; Song-Yong Kim of the Department of Mechanical Engineering; Sang-il Oum of the Department of Mathematical Sciences; Jung Kyoon Choi of the Department of Bio and Brain Engineering; Seokwoo Jeon, Sang Ouk Kim, and Il-Doo Kim of the Department of Materials Science and Engineering; Jang Wook Choi of the Graduate School of EEWS (Energy, Environment, Water and Sustainability); and Jeong Ho Lee of the Graduate School of Medical Science and Engineering.

The leading countries of the Academy of Science, which include Germany, Sweden, Belgium, Canada, and Japan, have established the Young Academy of Science since 2010 in order to encourage the research activities of their young scientists and to establish a global platform for collaborative research projects through their active networking at home and abroad.

President Myung-Chul Lee of KAST said, “We will spare no effort to connect these outstanding mid-career researchers for their future collaboration. Their networking will make significant impacts toward their own research activities as well as the global stature of Korea’s science and technology R&D.

(Photo caption: Members of Y-KAST pose at the inaugural ceremony of Y-KAST on February 24.)

2017.03.02 View 17780 -

Dr. Sung-Chul Shin Selected 16th President of KAIST

(President Sung-Chul Shin)

The KAIST Board of Trustees elected Professor Sung-Chul Shin of the Department of Physics the 16th president of KAIST on February 21. Professor Shin succeeds President Sung-Mo Kang whose four-year term will end on February 23. He is the first KAIST alumnus to serve as its president.

The Board of Trustees announced, “We believe that Professor Shin’s scientific achievement, outstanding leadership, and clear vision will serve KAIST faculty, students, and staff very well. He will be the best person to help KAIST leap forward in the four years ahead.”

The newly-elected president said, “I am humbled and honored to have been elected to lead such a prestigious institute of Korea. Aiming to be one of the top ten global universities, KAIST will continue to innovate its systems.” Previously, Dr. Shin led the Daegu Gyeongbuk Institute of Science and Technology (DGIST) for six years as president since 2011.

Professor Shin joined the KAIST faculty in 1989. He graduated from Seoul National University and then earned his MS degree in condensed matter physics at KAIST in 1977. After earning his Ph.D. in material physics at Northwestern University in 1984, he worked at Eastman Kodak Research Labs as a senior research scientist for five years.

Before heading to DGIST, President Shin held key administrative positions at KAIST from the early 1990s including dean of planning, dean of the international office, and vice-dean of student affairs. During President Robert Laughlin’s tenure, the first foreign president at KAIST, he served as vice-president for two years from 2004. He also served on the Presidential Advisory Council on Science and Technology of the Korean government as vice chairperson from 2015 to 2016.

A renowned scholar in the field of nanoscience, President Shin’s research focuses on the artificial synthesis and characterization of nonmagnetic materials, magnetic anisotropy, and magneto-optical phenomena. He leads the Laboratory for Nanospinics of Spintronic Materials at KAIST and has published in 290 journals while holding 37 patents.

A fellow in the American Physical Society (APS) since 2008, he was the president of the Korean Physical Society from 2011 to 2012. He has been on the editorial board of J. Magnetism and Magnetic Materials from 2009 and was the first Korean recipient of the Asian Union of Magnetics Societies (AUMS) Award, which recognizes outstanding scientists in the field of magnetics.

President Shin envisions making KAIST’s research and education more competitive through continuing innovation. His innovation efforts will extend to the five key areas of education, research, technology commercialization, globalization, and future planning.

Among his priorities, he emphasizes multidisciplinary studies and leadership training for students. He plans to focus on undeclared major courses for undergraduates to help them expand their experience and exposure to diverse disciplines. This approach will help create well-rounded engineers, scientists, and entrepreneurs by enabling them to develop skills while leveraging a strong connection to the arts, humanities, and social sciences.

To better respond to Industry 4.0, which calls for convergence studies and collaborative work, he proposed establishing a ‘Convergence Innovation System’ by strategically selecting 10 flagship convergence research groups. In order to accelerate the technology commercialization and ecosystem of start-ups, he will strengthen entrepreneurship education, making it a prerequisite requirement for students. President Shin said he will spare no effort to incubate and spin-off ventures in which KAIST technology is being transferred. For globalization efforts, he plans to increase the ratio of foreign faculty from 9 percent to 15 percent, while doubling the current foreign student enrollment ratio of 5 percent. For future strategic innovation, he will implement a long-term innovation strategic plan dubbed ‘Vision 2031.’

2017.02.22 View 11344

Dr. Sung-Chul Shin Selected 16th President of KAIST

(President Sung-Chul Shin)

The KAIST Board of Trustees elected Professor Sung-Chul Shin of the Department of Physics the 16th president of KAIST on February 21. Professor Shin succeeds President Sung-Mo Kang whose four-year term will end on February 23. He is the first KAIST alumnus to serve as its president.

The Board of Trustees announced, “We believe that Professor Shin’s scientific achievement, outstanding leadership, and clear vision will serve KAIST faculty, students, and staff very well. He will be the best person to help KAIST leap forward in the four years ahead.”

The newly-elected president said, “I am humbled and honored to have been elected to lead such a prestigious institute of Korea. Aiming to be one of the top ten global universities, KAIST will continue to innovate its systems.” Previously, Dr. Shin led the Daegu Gyeongbuk Institute of Science and Technology (DGIST) for six years as president since 2011.

Professor Shin joined the KAIST faculty in 1989. He graduated from Seoul National University and then earned his MS degree in condensed matter physics at KAIST in 1977. After earning his Ph.D. in material physics at Northwestern University in 1984, he worked at Eastman Kodak Research Labs as a senior research scientist for five years.

Before heading to DGIST, President Shin held key administrative positions at KAIST from the early 1990s including dean of planning, dean of the international office, and vice-dean of student affairs. During President Robert Laughlin’s tenure, the first foreign president at KAIST, he served as vice-president for two years from 2004. He also served on the Presidential Advisory Council on Science and Technology of the Korean government as vice chairperson from 2015 to 2016.

A renowned scholar in the field of nanoscience, President Shin’s research focuses on the artificial synthesis and characterization of nonmagnetic materials, magnetic anisotropy, and magneto-optical phenomena. He leads the Laboratory for Nanospinics of Spintronic Materials at KAIST and has published in 290 journals while holding 37 patents.

A fellow in the American Physical Society (APS) since 2008, he was the president of the Korean Physical Society from 2011 to 2012. He has been on the editorial board of J. Magnetism and Magnetic Materials from 2009 and was the first Korean recipient of the Asian Union of Magnetics Societies (AUMS) Award, which recognizes outstanding scientists in the field of magnetics.

President Shin envisions making KAIST’s research and education more competitive through continuing innovation. His innovation efforts will extend to the five key areas of education, research, technology commercialization, globalization, and future planning.

Among his priorities, he emphasizes multidisciplinary studies and leadership training for students. He plans to focus on undeclared major courses for undergraduates to help them expand their experience and exposure to diverse disciplines. This approach will help create well-rounded engineers, scientists, and entrepreneurs by enabling them to develop skills while leveraging a strong connection to the arts, humanities, and social sciences.

To better respond to Industry 4.0, which calls for convergence studies and collaborative work, he proposed establishing a ‘Convergence Innovation System’ by strategically selecting 10 flagship convergence research groups. In order to accelerate the technology commercialization and ecosystem of start-ups, he will strengthen entrepreneurship education, making it a prerequisite requirement for students. President Shin said he will spare no effort to incubate and spin-off ventures in which KAIST technology is being transferred. For globalization efforts, he plans to increase the ratio of foreign faculty from 9 percent to 15 percent, while doubling the current foreign student enrollment ratio of 5 percent. For future strategic innovation, he will implement a long-term innovation strategic plan dubbed ‘Vision 2031.’

2017.02.22 View 11344 -

KAIST Celebrates the 2017 Commencement

KAIST hosted its 2017 Commencement, awarding diplomas to 2,767 members of the Class of 2017 during a ceremony on February 17. President Sung-Mo Kang, Minister Yang-hee Choi of Science, ICT, and Future Planning, and Chairman of the KAIST Board of Trustees Jang-Moo Lee joined the ceremony along with the graduates and their family and friends at the Ryu Keun Chul Sports Complex.

The graduating class included 638 Ph.D. degrees, 1,335 Master’s degrees, and 794 Bachelor’s degrees being conferred. Among them, Young-Ki Song from the Department of Electric Engineering was honored to win the Minister’s Award, the highest award bestowed to an undergraduate. The KAIST Presidential Award went to Min-Jae Park of the Department of Mathematical Sciences and the KAIST Board of Trustee Chairman’s Award was presented to Jae-Hyung Cho from the Department of Mechanical Engineering.

Including this year’s graduating class, KAIST has turned out more than 59,000 highly educated science and technology talents including 11,731 Ph.D.s since its foundation in 1971. This year, 24-year-old Seo-Hee Oh earned her Ph.D. in chemistry as the youngest Ph.D. of the year after completing her Master’s and Ph.D. combined course in three years.

President Sung-Mo Kang praised the creativity of this graduating class and their excellent ability in his charge, saying, “As future leaders of our society, you are expected to develop a sense of compassion and outstanding professionalism to contribute to the advancement of not only Korea but also the whole world.’

For full text of President Kang’s charge to the graduates, please click.

2017.02.17 View 9082

KAIST Celebrates the 2017 Commencement

KAIST hosted its 2017 Commencement, awarding diplomas to 2,767 members of the Class of 2017 during a ceremony on February 17. President Sung-Mo Kang, Minister Yang-hee Choi of Science, ICT, and Future Planning, and Chairman of the KAIST Board of Trustees Jang-Moo Lee joined the ceremony along with the graduates and their family and friends at the Ryu Keun Chul Sports Complex.

The graduating class included 638 Ph.D. degrees, 1,335 Master’s degrees, and 794 Bachelor’s degrees being conferred. Among them, Young-Ki Song from the Department of Electric Engineering was honored to win the Minister’s Award, the highest award bestowed to an undergraduate. The KAIST Presidential Award went to Min-Jae Park of the Department of Mathematical Sciences and the KAIST Board of Trustee Chairman’s Award was presented to Jae-Hyung Cho from the Department of Mechanical Engineering.

Including this year’s graduating class, KAIST has turned out more than 59,000 highly educated science and technology talents including 11,731 Ph.D.s since its foundation in 1971. This year, 24-year-old Seo-Hee Oh earned her Ph.D. in chemistry as the youngest Ph.D. of the year after completing her Master’s and Ph.D. combined course in three years.

President Sung-Mo Kang praised the creativity of this graduating class and their excellent ability in his charge, saying, “As future leaders of our society, you are expected to develop a sense of compassion and outstanding professionalism to contribute to the advancement of not only Korea but also the whole world.’

For full text of President Kang’s charge to the graduates, please click.

2017.02.17 View 9082 -

An Improved Carbon Nanotube Semiconductor

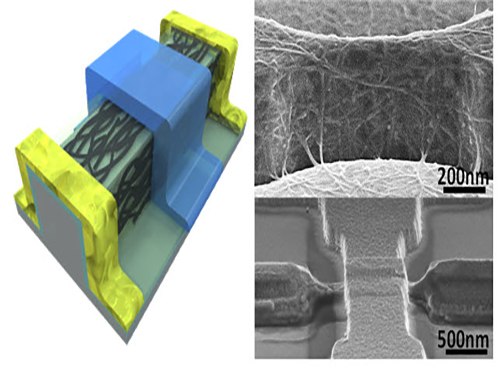

Professor Yang-Kyu Choi and his research team of the School of Electrical Engineering at KAIST collaborated with Professor Sung-Jin Choi of Kookmin University to develop a large-scale carbon nanotube semiconductor by using a 3-D fin-gate structure with carbon nanotubes on its top.

Dong Il Lee, a postdoctoral researcher at KAIST’s Electrical Engineering School, participated in this study as the first author. It was published in ACS Nano on November 10, 2016, and was entitled “Three-Dimensional Fin-Structured Semiconducting Carbon Nanotube Network Transistor.”

A semiconductor made with carbon nanotubes operates faster than a silicon semiconductor and requires less energy, yielding higher performance.

Most electronic equipment and devices, however, use silicon semiconductors because it is difficult to fabricate highly purified and densely packed semiconductors with carbon nanotubes (CNTs).

To date, the performance of CNTs was limited due to their low density. Their purity was also low, so it was impossible to make products that had a constant yield on a large-surface wafer or substrate. These characteristics made the mass production of semiconducting CNTs difficult.

To solve these difficulties, the research team used a 3-D fin-gate to vapor-deposit carbon nanotubes on its top. They developed a semiconductor that had a high current density with a width less than 50 nm.

The three-dimensional fin structure was able to vapor-deposit 600 carbon nanotubes per micrometer. This structure could have 20 times more nanotubes than the two dimensional structure, which could only vapor-deposit thirty in the same 1 micrometer width.

In addition, the research team used semi-conductive carbon nanotubes having a purity rating higher than 99.9% from a previous study to obtain a high yield semiconductor.

The semiconductor from the research group has a high current density even with a width less than 50 μm. The new semiconductor is expected to be five times faster than a silicon-based semiconductor and will require five times less electricity during operation.

Furthermore, the new semiconductor can be made by or will be compatible with the equipment for producing silicon-based semiconductors, so there will be no additional costs.

Researcher Lee said, “As a next generation semiconductor, the carbon nanotube semiconductor will have better performance, and its effectiveness will be higher.” He also added, “Hopefully, the new semiconductor will replace the silicon-based semiconductors in ten years.”

This study received support from the Center for Integrated Smart Sensors funded by the Ministry of Science, ICT & Future Planning of Korea as the Global Frontier Project, and from the CMOS (Complementary Metal-Oxide-Semiconductor) THz Technology Convergence Center of the Pioneer Research Center Program sponsored by the National Research Foundation of Korea.

Picture 1: 3D Diagram of the Carbon Nanotube Electronic Device and Its Scanning Electron Microscope (SEM) Image

Picture 2: 3D Transistor Device on an 8-inch Base and the SEM Image of Its Cross Section

2017.02.16 View 10993

An Improved Carbon Nanotube Semiconductor

Professor Yang-Kyu Choi and his research team of the School of Electrical Engineering at KAIST collaborated with Professor Sung-Jin Choi of Kookmin University to develop a large-scale carbon nanotube semiconductor by using a 3-D fin-gate structure with carbon nanotubes on its top.

Dong Il Lee, a postdoctoral researcher at KAIST’s Electrical Engineering School, participated in this study as the first author. It was published in ACS Nano on November 10, 2016, and was entitled “Three-Dimensional Fin-Structured Semiconducting Carbon Nanotube Network Transistor.”

A semiconductor made with carbon nanotubes operates faster than a silicon semiconductor and requires less energy, yielding higher performance.

Most electronic equipment and devices, however, use silicon semiconductors because it is difficult to fabricate highly purified and densely packed semiconductors with carbon nanotubes (CNTs).

To date, the performance of CNTs was limited due to their low density. Their purity was also low, so it was impossible to make products that had a constant yield on a large-surface wafer or substrate. These characteristics made the mass production of semiconducting CNTs difficult.

To solve these difficulties, the research team used a 3-D fin-gate to vapor-deposit carbon nanotubes on its top. They developed a semiconductor that had a high current density with a width less than 50 nm.

The three-dimensional fin structure was able to vapor-deposit 600 carbon nanotubes per micrometer. This structure could have 20 times more nanotubes than the two dimensional structure, which could only vapor-deposit thirty in the same 1 micrometer width.

In addition, the research team used semi-conductive carbon nanotubes having a purity rating higher than 99.9% from a previous study to obtain a high yield semiconductor.

The semiconductor from the research group has a high current density even with a width less than 50 μm. The new semiconductor is expected to be five times faster than a silicon-based semiconductor and will require five times less electricity during operation.

Furthermore, the new semiconductor can be made by or will be compatible with the equipment for producing silicon-based semiconductors, so there will be no additional costs.

Researcher Lee said, “As a next generation semiconductor, the carbon nanotube semiconductor will have better performance, and its effectiveness will be higher.” He also added, “Hopefully, the new semiconductor will replace the silicon-based semiconductors in ten years.”

This study received support from the Center for Integrated Smart Sensors funded by the Ministry of Science, ICT & Future Planning of Korea as the Global Frontier Project, and from the CMOS (Complementary Metal-Oxide-Semiconductor) THz Technology Convergence Center of the Pioneer Research Center Program sponsored by the National Research Foundation of Korea.

Picture 1: 3D Diagram of the Carbon Nanotube Electronic Device and Its Scanning Electron Microscope (SEM) Image

Picture 2: 3D Transistor Device on an 8-inch Base and the SEM Image of Its Cross Section

2017.02.16 View 10993 -

Dr.M Drives Smart Healthcare Industry in Partnership with Hancom

President Sung-Mo Kang signed an agreement on January 25 with Hancom Group Chairman Sang Chul Kim to establish a smart healthcare complex in Gapyeong, Kyonggido. With the Gapyeong complex launch, KAIST will come to commercialize Dr. M system along with other Dr.M consortium members as a new growth engine to drive the smart health industry.

Dr. M is a smart healthcare platform developed by the Health Science Research Institute at KAIST in 2014. Dr. M is capable of analyzing and predicting diseases, as well as prescribing, by incorporating ICT and medical technologies. Dr. M applies diverse technologies such as healthcare sensors, wearable devices, low-power communications technology, and cloud and big data collection platforms.

Hancom Group, a leading computer software company in Korea, has participated in the project since 2015 for advancing the smart healthcare market by developing mobile healthcare software program. Hancom joined the Dr.M consortium launched last November.

(President Kang (left) poses with Hancom Chairman Kim after signing.)

2017.02.03 View 6701

Dr.M Drives Smart Healthcare Industry in Partnership with Hancom

President Sung-Mo Kang signed an agreement on January 25 with Hancom Group Chairman Sang Chul Kim to establish a smart healthcare complex in Gapyeong, Kyonggido. With the Gapyeong complex launch, KAIST will come to commercialize Dr. M system along with other Dr.M consortium members as a new growth engine to drive the smart health industry.

Dr. M is a smart healthcare platform developed by the Health Science Research Institute at KAIST in 2014. Dr. M is capable of analyzing and predicting diseases, as well as prescribing, by incorporating ICT and medical technologies. Dr. M applies diverse technologies such as healthcare sensors, wearable devices, low-power communications technology, and cloud and big data collection platforms.

Hancom Group, a leading computer software company in Korea, has participated in the project since 2015 for advancing the smart healthcare market by developing mobile healthcare software program. Hancom joined the Dr.M consortium launched last November.

(President Kang (left) poses with Hancom Chairman Kim after signing.)

2017.02.03 View 6701 -

EWB-KAIST Wraps up Five-Year Project in Nepal

‘Engineers Without Borders-KAIST (EWB-KAIST)’ led by Professor Tae-ho Song from the Department of Mechanical Engineering returned to Korea on January 10 after a two-week project in Nangi, Nepal.

EWB-KAIST was established in 2012 by KAIST students and professors. Since then, the team visited Nangi, in the Annapurna region of Nepal, to engage in Appropriate Technology (AT) development projects. The projects included building passive houses and small hydroelectric power, and teaching science education. In particular, passive houses that use straw as an insulator received great a reception from the locals.

This was their last visit to Nepal, since the five-year project has now come to an end. Future projects in Mongolia will be led by Professor Buhm Soon Park from the Graduate School of Science and Technology Policy.

Professor Song commented, “I am glad that the Nepal project was successfully conducted over the last five years. To make sure the support does not end here, I will personally continue to visit the Himalayas to assist the villagers.”

EWB-KAIST is a non-profit organization that conducts activities with the aim of AT development and providing support for less-developed countries in need of the benefits of technology.

( Passive house made of straws by EWB-KAIST team in Nangi, Nepal.)

2017.02.01 View 7416

EWB-KAIST Wraps up Five-Year Project in Nepal

‘Engineers Without Borders-KAIST (EWB-KAIST)’ led by Professor Tae-ho Song from the Department of Mechanical Engineering returned to Korea on January 10 after a two-week project in Nangi, Nepal.

EWB-KAIST was established in 2012 by KAIST students and professors. Since then, the team visited Nangi, in the Annapurna region of Nepal, to engage in Appropriate Technology (AT) development projects. The projects included building passive houses and small hydroelectric power, and teaching science education. In particular, passive houses that use straw as an insulator received great a reception from the locals.

This was their last visit to Nepal, since the five-year project has now come to an end. Future projects in Mongolia will be led by Professor Buhm Soon Park from the Graduate School of Science and Technology Policy.

Professor Song commented, “I am glad that the Nepal project was successfully conducted over the last five years. To make sure the support does not end here, I will personally continue to visit the Himalayas to assist the villagers.”

EWB-KAIST is a non-profit organization that conducts activities with the aim of AT development and providing support for less-developed countries in need of the benefits of technology.

( Passive house made of straws by EWB-KAIST team in Nangi, Nepal.)

2017.02.01 View 7416 -

KAIST Intensive Science Camp for Middle-High School Students

The KAIST Global Institute of Talented Education (Director: Dong-Soo Kwon) invited around 90 middle and high school students for an advanced science intensive camp from January 22 to 24.

This camp targeted middle and high school students in community centers or child-care institutions. It aims to increase students’ interest in science and engineering, and assist them with their career paths through programs such as special lectures on science, advanced science projects, and career mentoring.

Participating students were divided into groups of seven or eight with a KAIST student as a mentor to conduct advanced science projects such as VR controller production and robot arm programming. The camp included exploring future career options and science and engineering college admission counselling.

Jiyoung Ryu, Research Professor for the KAIST Global Institute of Talented Education, said, “KAIST started the science and engineering career experience program in 2016 with the Ministry of Education and Korea Research Institute for Vocational Education and Training (KRIVET). So far, 6000 middle and high school students from around the country have participated. The camp is more meaningful since it educates students in social responsibility, in addition to the fields of science and engineering, both of which are missions and goals that KAIST strives for.” She continued to say, “We plan to continue to expand the program in the future.”

The KAIST Global Institute of Talented Education is actively conducting research and projects on national education for talented youth such as policy research concerning gifted education, science and engineering career education, advanced science camps, training for gifted education teachers, and cyber gifted education programs.

2017.02.01 View 8306

KAIST Intensive Science Camp for Middle-High School Students

The KAIST Global Institute of Talented Education (Director: Dong-Soo Kwon) invited around 90 middle and high school students for an advanced science intensive camp from January 22 to 24.

This camp targeted middle and high school students in community centers or child-care institutions. It aims to increase students’ interest in science and engineering, and assist them with their career paths through programs such as special lectures on science, advanced science projects, and career mentoring.

Participating students were divided into groups of seven or eight with a KAIST student as a mentor to conduct advanced science projects such as VR controller production and robot arm programming. The camp included exploring future career options and science and engineering college admission counselling.

Jiyoung Ryu, Research Professor for the KAIST Global Institute of Talented Education, said, “KAIST started the science and engineering career experience program in 2016 with the Ministry of Education and Korea Research Institute for Vocational Education and Training (KRIVET). So far, 6000 middle and high school students from around the country have participated. The camp is more meaningful since it educates students in social responsibility, in addition to the fields of science and engineering, both of which are missions and goals that KAIST strives for.” She continued to say, “We plan to continue to expand the program in the future.”

The KAIST Global Institute of Talented Education is actively conducting research and projects on national education for talented youth such as policy research concerning gifted education, science and engineering career education, advanced science camps, training for gifted education teachers, and cyber gifted education programs.

2017.02.01 View 8306 -

JETS Conference 2017

KAIST and four science and technology research universities in Korea co-hosted a technology start-up fair, the 2017 JETS (Job, Exhibition, Tech Forum, and Startup) Conference January 19 ~20 in the Ryu Geun-chul Sports Complex at KAIST.

Korea’s major science and technology research universities, Daegu Gyeongbuk Institute of Science and Technology (DGIST), Gwangju Institute of Science and Technology (GIST), Pohang University of Science and Technology (Postech), and Ulsan National Institute of Science and Technology (UNIST), held the event in a collaborative effort to educate, inspire, and connect young entrepreneurs, especially those who will launch technology start-ups.

The conference brought entrepreneurs and innovators together who seek ways of working with and supporting start-ups and for their sustainable growth. It also drew aspiring young students and researchers from universities and the government-funded research institutions who are in the process of commercializing their technology. Students from each university’s industry-academia cooperation program who incubated their technology and ideas were key contributors.

At the Tech Forum, entrepreneurship and technology consultation specialists including Joe Jasin, managing director at DNA Investment Partners in the US, the founder of Cyworld Dong-Hyung Lee, and Professor Hawoong Jeong, a complex bio-network specialist from the Department of Physics of KAIST lectured on the ecosystem of start-ups and its trends and development.

The Dean of University-Industry Cooperation at KAIST Joongmyeon Bae said, "We organized this event in collaboration with four major research universities to further encourage technology start-ups from young students and help their ideas and technology bear fruit. We will continue to strive to create an ecosystem of start-ups which works efficiently.”

(Above photo: Founder of the Cyworld, Dong-Hyung Lee gives a lecture at the Tech Forum. Below photo: Students visit exhibition booth of each participating institution.)

2017.01.20 View 11999

JETS Conference 2017

KAIST and four science and technology research universities in Korea co-hosted a technology start-up fair, the 2017 JETS (Job, Exhibition, Tech Forum, and Startup) Conference January 19 ~20 in the Ryu Geun-chul Sports Complex at KAIST.

Korea’s major science and technology research universities, Daegu Gyeongbuk Institute of Science and Technology (DGIST), Gwangju Institute of Science and Technology (GIST), Pohang University of Science and Technology (Postech), and Ulsan National Institute of Science and Technology (UNIST), held the event in a collaborative effort to educate, inspire, and connect young entrepreneurs, especially those who will launch technology start-ups.

The conference brought entrepreneurs and innovators together who seek ways of working with and supporting start-ups and for their sustainable growth. It also drew aspiring young students and researchers from universities and the government-funded research institutions who are in the process of commercializing their technology. Students from each university’s industry-academia cooperation program who incubated their technology and ideas were key contributors.

At the Tech Forum, entrepreneurship and technology consultation specialists including Joe Jasin, managing director at DNA Investment Partners in the US, the founder of Cyworld Dong-Hyung Lee, and Professor Hawoong Jeong, a complex bio-network specialist from the Department of Physics of KAIST lectured on the ecosystem of start-ups and its trends and development.

The Dean of University-Industry Cooperation at KAIST Joongmyeon Bae said, "We organized this event in collaboration with four major research universities to further encourage technology start-ups from young students and help their ideas and technology bear fruit. We will continue to strive to create an ecosystem of start-ups which works efficiently.”

(Above photo: Founder of the Cyworld, Dong-Hyung Lee gives a lecture at the Tech Forum. Below photo: Students visit exhibition booth of each participating institution.)

2017.01.20 View 11999 -

KAIST Joins IoF 2020 with 'Oliot'

KAIST will take part in the Internet of Food & Farm 2020 (IoF 2020) project with its international standard IoT open source platform ‘Oliot’ (Open Language for the Internet of Things, http://oliot.org), developed by a research team under Professor Daeyoung Kim from the School of Computing. Dr. Kim is also the director at the Auto-ID Labs at KAIST (http://autoidlabs.org).

IoF 2020 is a project to provide solutions and facilitate the large-scale uptake of IoT by addressing the organizational and technological challenges the European farming and food sectors face today. The project will develop innovative IoT solutions by fostering co-creation in interactive improvement cycles focusing on user acceptability and business models to boost technology and market-readiness levels.

Along with 71 partners from 16 countries, Professor Kim’s ‘Oliot’ will play a part in creating an ecosystem for providing safe and healthy agrifood, incorporating ICT(information and communications technologies) into the areas of smart farms and the agrifood service sector over the next four years. The project received €30 million in funding from Horizon 2020, the largest research and innovation program in the EU. KAIST is the only Korean institution to participate in this project.

For the project, Professor Kim’s team will initially establish smart farm and food service testbeds for the domestic agrifood industry with ‘Oliot’ prior to connecting to the European one. Professor Kim said he will leverage Artificial Intelligence (AI) and deep learning in order to analyze the data collected from the ecosystems in the EU. He aims to open an integrated IoT platform system incorporated with AI technologies to serve governments, institutions, corporations, and farmers.

It is expected that technologies developed for IoF 2020 will also benefit the domestic agrifood market and its supply chain infrastructure. Oliot will also be expected to further advance domestic smart industries including health care and connected vehicles.

George Beers, project manager at Wageningen University & Research and the IoF 2020 project coordinator said, “IoF 2020 has the potential to transform the paradigm of the supply chain of agrifood from the farm to consumers’ dining tables. We believe this project will contribute to enhance European competitiveness and excellence in the food commerce industry.”

Professor Kim said, “Technological applications of international standard IoT have already started in the domestic agrifood industry in collaboration with KAIST. We are working now with Asian and South American countries, as well as European nations, for the integration of a global agrifood business ecosystem.”

Auto-ID Labs are a global research consortium of seven academic institutions that research and develop new technologies for advancing global commerce, partnering with GS1 (Global Standard 1), a non-profit organization that established standards for global commerce such as introducing barcodes to the retail industry. The Auto-ID Labs include MIT, University of Cambridge, Keio University, Fudan University, and ETH Zurich/University of St. Gallen as well as KAIST.

2017.01.18 View 7685

KAIST Joins IoF 2020 with 'Oliot'

KAIST will take part in the Internet of Food & Farm 2020 (IoF 2020) project with its international standard IoT open source platform ‘Oliot’ (Open Language for the Internet of Things, http://oliot.org), developed by a research team under Professor Daeyoung Kim from the School of Computing. Dr. Kim is also the director at the Auto-ID Labs at KAIST (http://autoidlabs.org).

IoF 2020 is a project to provide solutions and facilitate the large-scale uptake of IoT by addressing the organizational and technological challenges the European farming and food sectors face today. The project will develop innovative IoT solutions by fostering co-creation in interactive improvement cycles focusing on user acceptability and business models to boost technology and market-readiness levels.

Along with 71 partners from 16 countries, Professor Kim’s ‘Oliot’ will play a part in creating an ecosystem for providing safe and healthy agrifood, incorporating ICT(information and communications technologies) into the areas of smart farms and the agrifood service sector over the next four years. The project received €30 million in funding from Horizon 2020, the largest research and innovation program in the EU. KAIST is the only Korean institution to participate in this project.

For the project, Professor Kim’s team will initially establish smart farm and food service testbeds for the domestic agrifood industry with ‘Oliot’ prior to connecting to the European one. Professor Kim said he will leverage Artificial Intelligence (AI) and deep learning in order to analyze the data collected from the ecosystems in the EU. He aims to open an integrated IoT platform system incorporated with AI technologies to serve governments, institutions, corporations, and farmers.

It is expected that technologies developed for IoF 2020 will also benefit the domestic agrifood market and its supply chain infrastructure. Oliot will also be expected to further advance domestic smart industries including health care and connected vehicles.

George Beers, project manager at Wageningen University & Research and the IoF 2020 project coordinator said, “IoF 2020 has the potential to transform the paradigm of the supply chain of agrifood from the farm to consumers’ dining tables. We believe this project will contribute to enhance European competitiveness and excellence in the food commerce industry.”

Professor Kim said, “Technological applications of international standard IoT have already started in the domestic agrifood industry in collaboration with KAIST. We are working now with Asian and South American countries, as well as European nations, for the integration of a global agrifood business ecosystem.”

Auto-ID Labs are a global research consortium of seven academic institutions that research and develop new technologies for advancing global commerce, partnering with GS1 (Global Standard 1), a non-profit organization that established standards for global commerce such as introducing barcodes to the retail industry. The Auto-ID Labs include MIT, University of Cambridge, Keio University, Fudan University, and ETH Zurich/University of St. Gallen as well as KAIST.

2017.01.18 View 7685 -

KAIST Alumni of the Year

(From left Chul-Hwan Kim, president and CEO of Orange Power, Hooshik Kim, president & CEO of Vieworks, Chilhee Chung, presient of Samsung Advanced Institute of Technology, KAIST President Sung-Mo Kang, KAIST Alumni Association President Jung-Sik Ko, Won-Pil Baek, senior vice president for R&D program at Korea Atomic Energy Research Insitute, Hyonho Jung, CEO of Medytox, Jaehwa Kim on behalf of Han-Oh Park, president & CEO of Bioneer Corporation)

The KAIST Alumni Association presented the Alumni of the Year award to six of its most accomplished alumni at the New Year dinner held at the Lotte Hotel in Seoul on January 14.

KAIST alumni community, which numbers over 500,000, has made a significant impact around the globe in science and technology, industry, education, and the public sector. Each year, the KAIST Alumni Association honors individuals who have made a significant contribution with outstanding leadership through the Alumni of the Year awards.

KAIST Alumni Association President Jung-Sik Ko awarded the recipients at the dinner. About 200 alumni, faculty, and students, including KAIST President Sung-Mo Kang, joined the celebration.

The 2016 awardees are Dr. Chilhee Chung, president of Samsung Advanced Institute of Technology(SAIT); Dr.Won-Pil Baek, senior vice president for R&D program at Korea Atomic Energy Research Institute(KAERI); Dr.Han-Oh Park, president & CEO of Bioneer Corporation; Dr.Hyonho Jung, CEO of Medytox; Hooshik Kim, president & CEO of Vieworks; and Dr.Chul-Hwan Kim, president & CEO of Orange Power.

Dr. Chung of SAIT (MS in physics ’79) played a leading role in developing top-notch system semiconductors and memory device technology while serving as president of the Samsung Electronic Semiconductor R&D Center. He has focused on the development of cutting-edge future technology, the Quantum Dot, by incorporating eco-friendly materials with the highest efficiency and color purity which is cadmium-free.

Working at KAERI since 2001, Dr. Baek (Ph.D. in nuclear and quantum engineering ’87) has made contributions to help Korea emerge as a nuclear technology powerhouse. He played a critical role in developing and facilitating a global nuclear safety verification facility dubbed ‘ATLAS.’ Such nuclear technological prowess led the Korean government to advance into the foreign markets, such as exporting nuclear power plants to United Arab Emirates.

The CEO of Bioneer, Dr. Park (Ph.D. in chemistry ’87) started a bio-venture in Korea. His company has developed hundreds of reagents, diagnostic kits, and advanced equipment for gene research over two decades. Bioneer has paved the way for establishing a world-class level of infrastructure in genomic technology. By developing the innovative technology "SAMiRNA ™ (Self-Assembled-Micelle-inhibitory-RNA)" that overcomes the problems in drug development, Bioneer presented a new solution for the treatment of incurable diseases. In collaboration with global pharmaceutical companies and research groups, Dr. Park has successfully led joint development in the licensing of new therapeutic medicine candidates for various incurable diseases.

Dr. Jung (Ph.D. in biological sciences ’88) founded the bio-pharmaceutical company Medytox in 2000. Medytox is the first company in Korea that commercialized botulinum toxin formulation. Medytox developed the non-animal liquid botulinum toxin formulation for the first time in the world. It successfully localized botulinum preparation that can treat various neurological diseases. Medytox’s new toxin formulation resulted in improving public health care as well as relieving the heavy dependence on importing bio-pharmaceutical products.

As the CEO of Vieworks, Kim (MS in physics ’95) succeeded in commercializing of digital X-ray. Especially, it is leading the design of optical and image systems that affect the quality of digital X-ray image. Kim’s company established related technology base, contributing to human health promotion and national industrial development.

President Kim of Orange Power (Ph.D. in chemical and biomolecular engineering ’93) is also the founder of the KITE Entrepreneurship Foundation. He launched Biogenix Co., Ltd. and Image and Materials Co. in 2005. In order to nurture an entrepreneurship and start-ups eco-system, he invested 10 billion KRW from the proceeds of the sale of one of his start-ups. In addition, he started Orange Power Co., Ltd. in 2012 to solve the secondary battery heat problem and established a global partnership with Hydro Quebec in Canada, Nexion in UK, Volkswagen of Germany, and Tesla of the US.

2017.01.16 View 12045

KAIST Alumni of the Year

(From left Chul-Hwan Kim, president and CEO of Orange Power, Hooshik Kim, president & CEO of Vieworks, Chilhee Chung, presient of Samsung Advanced Institute of Technology, KAIST President Sung-Mo Kang, KAIST Alumni Association President Jung-Sik Ko, Won-Pil Baek, senior vice president for R&D program at Korea Atomic Energy Research Insitute, Hyonho Jung, CEO of Medytox, Jaehwa Kim on behalf of Han-Oh Park, president & CEO of Bioneer Corporation)

The KAIST Alumni Association presented the Alumni of the Year award to six of its most accomplished alumni at the New Year dinner held at the Lotte Hotel in Seoul on January 14.

KAIST alumni community, which numbers over 500,000, has made a significant impact around the globe in science and technology, industry, education, and the public sector. Each year, the KAIST Alumni Association honors individuals who have made a significant contribution with outstanding leadership through the Alumni of the Year awards.

KAIST Alumni Association President Jung-Sik Ko awarded the recipients at the dinner. About 200 alumni, faculty, and students, including KAIST President Sung-Mo Kang, joined the celebration.

The 2016 awardees are Dr. Chilhee Chung, president of Samsung Advanced Institute of Technology(SAIT); Dr.Won-Pil Baek, senior vice president for R&D program at Korea Atomic Energy Research Institute(KAERI); Dr.Han-Oh Park, president & CEO of Bioneer Corporation; Dr.Hyonho Jung, CEO of Medytox; Hooshik Kim, president & CEO of Vieworks; and Dr.Chul-Hwan Kim, president & CEO of Orange Power.

Dr. Chung of SAIT (MS in physics ’79) played a leading role in developing top-notch system semiconductors and memory device technology while serving as president of the Samsung Electronic Semiconductor R&D Center. He has focused on the development of cutting-edge future technology, the Quantum Dot, by incorporating eco-friendly materials with the highest efficiency and color purity which is cadmium-free.

Working at KAERI since 2001, Dr. Baek (Ph.D. in nuclear and quantum engineering ’87) has made contributions to help Korea emerge as a nuclear technology powerhouse. He played a critical role in developing and facilitating a global nuclear safety verification facility dubbed ‘ATLAS.’ Such nuclear technological prowess led the Korean government to advance into the foreign markets, such as exporting nuclear power plants to United Arab Emirates.

The CEO of Bioneer, Dr. Park (Ph.D. in chemistry ’87) started a bio-venture in Korea. His company has developed hundreds of reagents, diagnostic kits, and advanced equipment for gene research over two decades. Bioneer has paved the way for establishing a world-class level of infrastructure in genomic technology. By developing the innovative technology "SAMiRNA ™ (Self-Assembled-Micelle-inhibitory-RNA)" that overcomes the problems in drug development, Bioneer presented a new solution for the treatment of incurable diseases. In collaboration with global pharmaceutical companies and research groups, Dr. Park has successfully led joint development in the licensing of new therapeutic medicine candidates for various incurable diseases.

Dr. Jung (Ph.D. in biological sciences ’88) founded the bio-pharmaceutical company Medytox in 2000. Medytox is the first company in Korea that commercialized botulinum toxin formulation. Medytox developed the non-animal liquid botulinum toxin formulation for the first time in the world. It successfully localized botulinum preparation that can treat various neurological diseases. Medytox’s new toxin formulation resulted in improving public health care as well as relieving the heavy dependence on importing bio-pharmaceutical products.

As the CEO of Vieworks, Kim (MS in physics ’95) succeeded in commercializing of digital X-ray. Especially, it is leading the design of optical and image systems that affect the quality of digital X-ray image. Kim’s company established related technology base, contributing to human health promotion and national industrial development.

President Kim of Orange Power (Ph.D. in chemical and biomolecular engineering ’93) is also the founder of the KITE Entrepreneurship Foundation. He launched Biogenix Co., Ltd. and Image and Materials Co. in 2005. In order to nurture an entrepreneurship and start-ups eco-system, he invested 10 billion KRW from the proceeds of the sale of one of his start-ups. In addition, he started Orange Power Co., Ltd. in 2012 to solve the secondary battery heat problem and established a global partnership with Hydro Quebec in Canada, Nexion in UK, Volkswagen of Germany, and Tesla of the US.

2017.01.16 View 12045