SMA

-

To Talk or Not to Talk: Smart Speaker Determines Optimal Timing to Talk

A KAIST research team has developed a new context-awareness technology that enables AI assistants to determine when to talk to their users based on user circumstances. This technology can contribute to developing advanced AI assistants that can offer pre-emptive services such as reminding users to take medication on time or modifying schedules based on the actual progress of planned tasks.

Unlike conventional AI assistants that used to act passively upon users’ commands, today’s AI assistants are evolving to provide more proactive services through self-reasoning of user circumstances. This opens up new opportunities for AI assistants to better support users in their daily lives. However, if AI assistants do not talk at the right time, they could rather interrupt their users instead of helping them.

The right time for talking is more difficult for AI assistants to determine than it appears. This is because the context can differ depending on the state of the user or the surrounding environment.

A group of researchers led by Professor Uichin Lee from the KAIST School of Computing identified key contextual factors in user circumstances that determine when the AI assistant should start, stop, or resume engaging in voice services in smart home environments. Their findings were published in the Proceedings of the ACM on Interactive, Mobile, Wearable and Ubiquitous Technologies (IMWUT) in September.

The group conducted this study in collaboration with Professor Jae-Gil Lee’s group in the KAIST School of Computing, Professor Sangsu Lee’s group in the KAIST Department of Industrial Design, and Professor Auk Kim’s group at Kangwon National University.

After developing smart speakers equipped with AI assistant function for experimental use, the researchers installed them in the rooms of 40 students who live in double-occupancy campus dormitories and collected a total of 3,500 in-situ user response data records over a period of a week.

The smart speakers repeatedly asked the students a question, “Is now a good time to talk?” at random intervals or whenever a student’s movement was detected. Students answered with either “yes” or “no” and then explained why, describing what they had been doing before being questioned by the smart speakers.

Data analysis revealed that 47% of user responses were “no” indicating they did not want to be interrupted. The research team then created 19 home activity categories to cross-analyze the key contextual factors that determine opportune moments for AI assistants to talk, and classified these factors into ‘personal,’ ‘movement,’ and ‘social’ factors respectively.

Personal factors, for instance, include:

1. the degree of concentration on or engagement in activities,

2. the degree urgency and busyness,

3. the state of user’s mental or physical condition, and

4. the state of being able to talk or listen while multitasking.

While users were busy concentrating on studying, tired, or drying hair, they found it difficult to engage in conversational interactions with the smart speakers.

Some representative movement factors include departure, entrance, and physical activity transitions. Interestingly, in movement scenarios, the team found that the communication range was an important factor. Departure is an outbound movement from the smart speaker, and entrance is an inbound movement. Users were much more available during inbound movement scenarios as opposed to outbound movement scenarios.

In general, smart speakers are located in a shared place at home, such as a living room, where multiple family members gather at the same time. In Professor Lee’s group’s experiment, almost half of the in-situ user responses were collected when both roommates were present. The group found social presence also influenced interruptibility. Roommates often wanted to minimize possible interpersonal conflicts, such as disturbing their roommates' sleep or work.

Narae Cha, the lead author of this study, explained, “By considering personal, movement, and social factors, we can envision a smart speaker that can intelligently manage the timing of conversations with users.”

She believes that this work lays the foundation for the future of AI assistants, adding, “Multi-modal sensory data can be used for context sensing, and this context information will help smart speakers proactively determine when it is a good time to start, stop, or resume conversations with their users.”

This work was supported by the National Research Foundation (NRF) of Korea.

Publication:

Cha, N, et al. (2020) “Hello There! Is Now a Good Time to Talk?”: Opportune Moments for Proactive Interactions with Smart Speakers. Proceedings of the ACM on Interactive, Mobile, Wearable and Ubiquitous Technologies (IMWUT), Vol. 4, No. 3, Article No. 74, pp. 1-28. Available online at https://doi.org/10.1145/3411810

Link to Introductory Video:

https://youtu.be/AA8CTi2hEf0

Profile:

Uichin Lee

Associate Professor

uclee@kaist.ac.kr

http://ic.kaist.ac.kr

Interactive Computing Lab.

School of Computing

https://www.kaist.ac.kr

Korea Advanced Institute of Science and Technology (KAIST) Daejeon, Republic of Korea

(END)

2020.11.05 View 13094

To Talk or Not to Talk: Smart Speaker Determines Optimal Timing to Talk

A KAIST research team has developed a new context-awareness technology that enables AI assistants to determine when to talk to their users based on user circumstances. This technology can contribute to developing advanced AI assistants that can offer pre-emptive services such as reminding users to take medication on time or modifying schedules based on the actual progress of planned tasks.

Unlike conventional AI assistants that used to act passively upon users’ commands, today’s AI assistants are evolving to provide more proactive services through self-reasoning of user circumstances. This opens up new opportunities for AI assistants to better support users in their daily lives. However, if AI assistants do not talk at the right time, they could rather interrupt their users instead of helping them.

The right time for talking is more difficult for AI assistants to determine than it appears. This is because the context can differ depending on the state of the user or the surrounding environment.

A group of researchers led by Professor Uichin Lee from the KAIST School of Computing identified key contextual factors in user circumstances that determine when the AI assistant should start, stop, or resume engaging in voice services in smart home environments. Their findings were published in the Proceedings of the ACM on Interactive, Mobile, Wearable and Ubiquitous Technologies (IMWUT) in September.

The group conducted this study in collaboration with Professor Jae-Gil Lee’s group in the KAIST School of Computing, Professor Sangsu Lee’s group in the KAIST Department of Industrial Design, and Professor Auk Kim’s group at Kangwon National University.

After developing smart speakers equipped with AI assistant function for experimental use, the researchers installed them in the rooms of 40 students who live in double-occupancy campus dormitories and collected a total of 3,500 in-situ user response data records over a period of a week.

The smart speakers repeatedly asked the students a question, “Is now a good time to talk?” at random intervals or whenever a student’s movement was detected. Students answered with either “yes” or “no” and then explained why, describing what they had been doing before being questioned by the smart speakers.

Data analysis revealed that 47% of user responses were “no” indicating they did not want to be interrupted. The research team then created 19 home activity categories to cross-analyze the key contextual factors that determine opportune moments for AI assistants to talk, and classified these factors into ‘personal,’ ‘movement,’ and ‘social’ factors respectively.

Personal factors, for instance, include:

1. the degree of concentration on or engagement in activities,

2. the degree urgency and busyness,

3. the state of user’s mental or physical condition, and

4. the state of being able to talk or listen while multitasking.

While users were busy concentrating on studying, tired, or drying hair, they found it difficult to engage in conversational interactions with the smart speakers.

Some representative movement factors include departure, entrance, and physical activity transitions. Interestingly, in movement scenarios, the team found that the communication range was an important factor. Departure is an outbound movement from the smart speaker, and entrance is an inbound movement. Users were much more available during inbound movement scenarios as opposed to outbound movement scenarios.

In general, smart speakers are located in a shared place at home, such as a living room, where multiple family members gather at the same time. In Professor Lee’s group’s experiment, almost half of the in-situ user responses were collected when both roommates were present. The group found social presence also influenced interruptibility. Roommates often wanted to minimize possible interpersonal conflicts, such as disturbing their roommates' sleep or work.

Narae Cha, the lead author of this study, explained, “By considering personal, movement, and social factors, we can envision a smart speaker that can intelligently manage the timing of conversations with users.”

She believes that this work lays the foundation for the future of AI assistants, adding, “Multi-modal sensory data can be used for context sensing, and this context information will help smart speakers proactively determine when it is a good time to start, stop, or resume conversations with their users.”

This work was supported by the National Research Foundation (NRF) of Korea.

Publication:

Cha, N, et al. (2020) “Hello There! Is Now a Good Time to Talk?”: Opportune Moments for Proactive Interactions with Smart Speakers. Proceedings of the ACM on Interactive, Mobile, Wearable and Ubiquitous Technologies (IMWUT), Vol. 4, No. 3, Article No. 74, pp. 1-28. Available online at https://doi.org/10.1145/3411810

Link to Introductory Video:

https://youtu.be/AA8CTi2hEf0

Profile:

Uichin Lee

Associate Professor

uclee@kaist.ac.kr

http://ic.kaist.ac.kr

Interactive Computing Lab.

School of Computing

https://www.kaist.ac.kr

Korea Advanced Institute of Science and Technology (KAIST) Daejeon, Republic of Korea

(END)

2020.11.05 View 13094 -

KAIST Showcases Healthcare Technologies at K-Hospital Fair 2020

KAIST Pavilion showcased its innovative medical and healthcare technologies and their advanced applications at the K-Hospital Fair 2020. Five KAIST research groups who teamed up for the Post-COVID-19 New Deal R&D Initiative Project participated in the fair held in Seoul last week.

The K-Hospital Fair is a yearly event organized by the Korean Hospital Association to present the latest research and practical innovations to help the medical industry better serve the patients. This year, 120 healthcare organizations participated in the fair and operated 320 booths.

At the fair, a research group led by Professor Il-Doo Kim from the Department of Materials Science and Engineering demonstrated the manufacturing process of orthogonal nanofibers used to develop their ‘recyclable nano-fiber filtered face mask’ introduced in March of this year. This mask has garnered immense international attention for maintaining its sturdy frame and filtering function even after being washed more than 20 times. Professor Kim is now extending his facilities for the mass production of this mask at his start-up company. While awaiting final approval from the Ministry of Food and Drug Safety to bring his product into the market, Professor Kim is developing other mask variations such as eco-friendly biodegradable masks and transparent masks to aid the hearing-impaired who rely on lip reading to communicate.

The team working under Professor Wonho Choe from the Department of Nuclear and Quantum Engineering presented two low-temperature plasma sterilizers for medical use, co-developed with Plasmapp, a start-up company founded by a KAIST alumnus. Their sterilizers are the first ones that can sterilize medical devices by diffusing hydrogen peroxide vapor into the pouch. They rapidly sterilize medical instruments and materials in just seven minutes without leaving toxic residue, while reducing sterilization time and costs by 90%.

Professor Hyung-Soon Park and his researchers from the Department of Mechanical Engineering introduced a smart protective suit ventilation system that features high cooling capacity and a slimmed-down design. For comfortable use, the suit is equipped with a technique that monitors its inner temperature and humidity and automatically controls its inner circulation accordingly. The group also presented a new system that helps a person in a contaminated suit undress without coming into contact with the contaminated outer part of the suit.

Professor Jong Chul Ye's group from the Department of Bio and Brain Engineering demonstrated AI software that can quickly diagnose an infectious disease based on chest X-ray imaging. The technique compares the differences in the severity of pneumonia in individual patients to distinguish whether their conditions fall under viral pneumonia including COVID-19, bacterial pneumonia, tuberculosis, other diseases, or normal conditions. The AI software visualizes the basis of its reasoning for each of the suspected diseases and provides them as information that can be utilized by medical personnel.

Finally, researchers of Professor Ki-Hun Jeong’s team from the Department of Bio and Brain Engineering demonstrated their ultra-high-speed sub-miniature molecular diagnostic system for the on-site diagnosis of diseases. The existing Polymerase Chain Reaction (PCR) diagnostic usually takes from 30 minutes to an hour to provide results, but their new technique using an LED light source can present results within just three minutes and it is expected to be used actively for on-site diagnosis.

Professor Choongsik Bae, the Director of the Post-COVID-19 New Deal R&D Initiative Project, said, “KAIST will build a healthy relationship amongst researchers, enterprises, and hospitals to contribute to the end of COVID-19 and build a new paradigm of Korean disease prevention and control.”

KAIST launched the Post-COVID-19 New Deal R&D Initiative in July with the support of the Ministry of Science and ICT of Korea. This unit was created to overcome the pandemic crisis by using science and technology, and to contribute to economic development by creating a new antiviral drug industry. The unit is comprised of 464 KAIST members including professors, researchers, and students as well as 503 professionals from enterprises, hospitals, and research centers.

(END)

2020.10.26 View 15999

KAIST Showcases Healthcare Technologies at K-Hospital Fair 2020

KAIST Pavilion showcased its innovative medical and healthcare technologies and their advanced applications at the K-Hospital Fair 2020. Five KAIST research groups who teamed up for the Post-COVID-19 New Deal R&D Initiative Project participated in the fair held in Seoul last week.

The K-Hospital Fair is a yearly event organized by the Korean Hospital Association to present the latest research and practical innovations to help the medical industry better serve the patients. This year, 120 healthcare organizations participated in the fair and operated 320 booths.

At the fair, a research group led by Professor Il-Doo Kim from the Department of Materials Science and Engineering demonstrated the manufacturing process of orthogonal nanofibers used to develop their ‘recyclable nano-fiber filtered face mask’ introduced in March of this year. This mask has garnered immense international attention for maintaining its sturdy frame and filtering function even after being washed more than 20 times. Professor Kim is now extending his facilities for the mass production of this mask at his start-up company. While awaiting final approval from the Ministry of Food and Drug Safety to bring his product into the market, Professor Kim is developing other mask variations such as eco-friendly biodegradable masks and transparent masks to aid the hearing-impaired who rely on lip reading to communicate.

The team working under Professor Wonho Choe from the Department of Nuclear and Quantum Engineering presented two low-temperature plasma sterilizers for medical use, co-developed with Plasmapp, a start-up company founded by a KAIST alumnus. Their sterilizers are the first ones that can sterilize medical devices by diffusing hydrogen peroxide vapor into the pouch. They rapidly sterilize medical instruments and materials in just seven minutes without leaving toxic residue, while reducing sterilization time and costs by 90%.

Professor Hyung-Soon Park and his researchers from the Department of Mechanical Engineering introduced a smart protective suit ventilation system that features high cooling capacity and a slimmed-down design. For comfortable use, the suit is equipped with a technique that monitors its inner temperature and humidity and automatically controls its inner circulation accordingly. The group also presented a new system that helps a person in a contaminated suit undress without coming into contact with the contaminated outer part of the suit.

Professor Jong Chul Ye's group from the Department of Bio and Brain Engineering demonstrated AI software that can quickly diagnose an infectious disease based on chest X-ray imaging. The technique compares the differences in the severity of pneumonia in individual patients to distinguish whether their conditions fall under viral pneumonia including COVID-19, bacterial pneumonia, tuberculosis, other diseases, or normal conditions. The AI software visualizes the basis of its reasoning for each of the suspected diseases and provides them as information that can be utilized by medical personnel.

Finally, researchers of Professor Ki-Hun Jeong’s team from the Department of Bio and Brain Engineering demonstrated their ultra-high-speed sub-miniature molecular diagnostic system for the on-site diagnosis of diseases. The existing Polymerase Chain Reaction (PCR) diagnostic usually takes from 30 minutes to an hour to provide results, but their new technique using an LED light source can present results within just three minutes and it is expected to be used actively for on-site diagnosis.

Professor Choongsik Bae, the Director of the Post-COVID-19 New Deal R&D Initiative Project, said, “KAIST will build a healthy relationship amongst researchers, enterprises, and hospitals to contribute to the end of COVID-19 and build a new paradigm of Korean disease prevention and control.”

KAIST launched the Post-COVID-19 New Deal R&D Initiative in July with the support of the Ministry of Science and ICT of Korea. This unit was created to overcome the pandemic crisis by using science and technology, and to contribute to economic development by creating a new antiviral drug industry. The unit is comprised of 464 KAIST members including professors, researchers, and students as well as 503 professionals from enterprises, hospitals, and research centers.

(END)

2020.10.26 View 15999 -

From Dark to Light in a Flash: Smart Film Lets Windows Switch Autonomously

Researchers have developed a new easy-to-use smart optical film technology that allows smart window devices to autonomously switch between transparent and opaque states in response to the surrounding light conditions.

The proposed 3D hybrid nanocomposite film with a highly periodic network structure has empirically demonstrated its high speed and performance, enabling the smart window to quantify and self-regulate its high-contrast optical transmittance. As a proof of concept, a mobile-app-enabled smart window device for Internet of Things (IoT) applications has been realized using the proposed smart optical film with successful expansion to the 3-by-3-inch scale. This energy-efficient and cost-effective technology holds great promise for future use in various applications that require active optical transmission modulation.

Flexible optical transmission modulation technologies for smart applications including privacy-protection windows, zero-energy buildings, and beam projection screens have been in the spotlight in recent years. Conventional technologies that used external stimuli such as electricity, heat, or light to modulate optical transmission had only limited applications due to their slow response speeds, unnecessary color switching, and low durability, stability, and safety.

The optical transmission modulation contrast achieved by controlling the light scattering interfaces on non-periodic 2D surface structures that often have low optical density such as cracks, wrinkles, and pillars is also generally low. In addition, since the light scattering interfaces are exposed and not subject to any passivation, they can be vulnerable to external damage and may lose optical transmission modulation functions. Furthermore, in-plane scattering interfaces that randomly exist on the surface make large-area modulation with uniformity difficult.

Inspired by these limitations, a KAIST research team led by Professor Seokwoo Jeon from the Department of Materials Science and Engineering and Professor Jung-Wuk Hong of the Civil and Environmental Engineering Department used proximity-field nanopatterning (PnP) technology that effectively produces highly periodic 3D hybrid nanostructures, and an atomic layer deposition (ALD) technique that allows the precise control of oxide deposition and the high-quality fabrication of semiconductor devices.

The team then successfully produced a large-scale smart optical film with a size of 3 by 3 inches in which ultrathin alumina nanoshells are inserted between the elastomers in a periodic 3D nanonetwork.

This “mechano-responsive” 3D hybrid nanocomposite film with a highly periodic network structure is the largest smart optical transmission modulation film that exists. The film has been shown to have state-of-the-art optical transmission modulation of up to 74% at visible wavelengths from 90% initial transmission to 16% in the scattering state under strain. Its durability and stability were proved by more than 10,000 tests of harsh mechanical deformation including stretching, releasing, bending, and being placed under high temperatures of up to 70°C. When this film was used, the transmittance of the smart window device was adjusted promptly and automatically within one second in response to the surrounding light conditions. Through these experiments, the underlying physics of optical scattering phenomena occurring in the heterogeneous interfaces were identified. Their findings were reported in the online edition of Advanced Science on April 26. KAIST Professor Jong-Hwa Shin’s group and Professor Young-Seok Shim at Silla University also collaborated on this project.

Donghwi Cho, a PhD candidate in materials science and engineering at KAIST and co-lead author of the study, said, “Our smart optical film technology can better control high-contrast optical transmittance by relatively simple operating principles and with low energy consumption and costs.”

“When this technology is applied by simply attaching the film to a conventional smart window glass surface without replacing the existing window system, fast switching and uniform tinting are possible while also securing durability, stability, and safety. In addition, its wide range of applications for stretchable or rollable devices such as wall-type displays for a beam projection screen will also fulfill aesthetic needs,” he added.

This work was supported by the National Research Foundation of Korea (NRF), and the Korean Ministries of Science, ICT and Future Planning (MSIP), and Science and ICT (MSIT).

Publication:

Cho, D, et al. (2020) ‘High-Contrast Optical Modulation from Strain-Indicated Nanogaps at 3D Heterogeneous Interfaces’ Advanced Science, 1903708. Available online at https://doi.org/10.1002/advs.201903708

Profile: Seokwoo Jeon, PhD

Professor

jeon39@kaist.ac.kr

https://fdml.kaist.ac.kr/

Flexible Device and Metamaterials Lab (FDML)

Department of Materials Science and Engineering (MSE)

Korea Advanced Institute of Science and Technology (KAIST)

https://www.kaist.ac.krDaejeon 34141, Korea

Profile: Jung-Wuk Hong, PhD

Associate Professor

j.hong@kaist.ac.kr

http://aaml.kaist.ac.kr

Advanced Applied Mechanics Laboratory (AAML)

Department of Civil and Environmental Engineering

KAIST

Profile: Donghwi Cho

PhD Candidate

roy0202@kaist.ac.krFDML, MSE, KAIST

Profile: Young-Seok Shim, PhD

Assistant Professor

ysshim@silla.ac.kr

Division of Materials Science and Engineering Silla University

https://www.silla.ac.kr

Busan 46958, Korea

(END)

2020.06.02 View 14769

From Dark to Light in a Flash: Smart Film Lets Windows Switch Autonomously

Researchers have developed a new easy-to-use smart optical film technology that allows smart window devices to autonomously switch between transparent and opaque states in response to the surrounding light conditions.

The proposed 3D hybrid nanocomposite film with a highly periodic network structure has empirically demonstrated its high speed and performance, enabling the smart window to quantify and self-regulate its high-contrast optical transmittance. As a proof of concept, a mobile-app-enabled smart window device for Internet of Things (IoT) applications has been realized using the proposed smart optical film with successful expansion to the 3-by-3-inch scale. This energy-efficient and cost-effective technology holds great promise for future use in various applications that require active optical transmission modulation.

Flexible optical transmission modulation technologies for smart applications including privacy-protection windows, zero-energy buildings, and beam projection screens have been in the spotlight in recent years. Conventional technologies that used external stimuli such as electricity, heat, or light to modulate optical transmission had only limited applications due to their slow response speeds, unnecessary color switching, and low durability, stability, and safety.

The optical transmission modulation contrast achieved by controlling the light scattering interfaces on non-periodic 2D surface structures that often have low optical density such as cracks, wrinkles, and pillars is also generally low. In addition, since the light scattering interfaces are exposed and not subject to any passivation, they can be vulnerable to external damage and may lose optical transmission modulation functions. Furthermore, in-plane scattering interfaces that randomly exist on the surface make large-area modulation with uniformity difficult.

Inspired by these limitations, a KAIST research team led by Professor Seokwoo Jeon from the Department of Materials Science and Engineering and Professor Jung-Wuk Hong of the Civil and Environmental Engineering Department used proximity-field nanopatterning (PnP) technology that effectively produces highly periodic 3D hybrid nanostructures, and an atomic layer deposition (ALD) technique that allows the precise control of oxide deposition and the high-quality fabrication of semiconductor devices.

The team then successfully produced a large-scale smart optical film with a size of 3 by 3 inches in which ultrathin alumina nanoshells are inserted between the elastomers in a periodic 3D nanonetwork.

This “mechano-responsive” 3D hybrid nanocomposite film with a highly periodic network structure is the largest smart optical transmission modulation film that exists. The film has been shown to have state-of-the-art optical transmission modulation of up to 74% at visible wavelengths from 90% initial transmission to 16% in the scattering state under strain. Its durability and stability were proved by more than 10,000 tests of harsh mechanical deformation including stretching, releasing, bending, and being placed under high temperatures of up to 70°C. When this film was used, the transmittance of the smart window device was adjusted promptly and automatically within one second in response to the surrounding light conditions. Through these experiments, the underlying physics of optical scattering phenomena occurring in the heterogeneous interfaces were identified. Their findings were reported in the online edition of Advanced Science on April 26. KAIST Professor Jong-Hwa Shin’s group and Professor Young-Seok Shim at Silla University also collaborated on this project.

Donghwi Cho, a PhD candidate in materials science and engineering at KAIST and co-lead author of the study, said, “Our smart optical film technology can better control high-contrast optical transmittance by relatively simple operating principles and with low energy consumption and costs.”

“When this technology is applied by simply attaching the film to a conventional smart window glass surface without replacing the existing window system, fast switching and uniform tinting are possible while also securing durability, stability, and safety. In addition, its wide range of applications for stretchable or rollable devices such as wall-type displays for a beam projection screen will also fulfill aesthetic needs,” he added.

This work was supported by the National Research Foundation of Korea (NRF), and the Korean Ministries of Science, ICT and Future Planning (MSIP), and Science and ICT (MSIT).

Publication:

Cho, D, et al. (2020) ‘High-Contrast Optical Modulation from Strain-Indicated Nanogaps at 3D Heterogeneous Interfaces’ Advanced Science, 1903708. Available online at https://doi.org/10.1002/advs.201903708

Profile: Seokwoo Jeon, PhD

Professor

jeon39@kaist.ac.kr

https://fdml.kaist.ac.kr/

Flexible Device and Metamaterials Lab (FDML)

Department of Materials Science and Engineering (MSE)

Korea Advanced Institute of Science and Technology (KAIST)

https://www.kaist.ac.krDaejeon 34141, Korea

Profile: Jung-Wuk Hong, PhD

Associate Professor

j.hong@kaist.ac.kr

http://aaml.kaist.ac.kr

Advanced Applied Mechanics Laboratory (AAML)

Department of Civil and Environmental Engineering

KAIST

Profile: Donghwi Cho

PhD Candidate

roy0202@kaist.ac.krFDML, MSE, KAIST

Profile: Young-Seok Shim, PhD

Assistant Professor

ysshim@silla.ac.kr

Division of Materials Science and Engineering Silla University

https://www.silla.ac.kr

Busan 46958, Korea

(END)

2020.06.02 View 14769 -

Professor Youngchul Kim Joins Presidential Commission on Architecture Policy

Professor Youngchul Kim from the Department of Civil and Environmental Engineering, who is also the Director of the Smart City Research Center at KAIST, was appointed as a commissioner of the 6th Presidential Commission on Architecture Policy on May 19. Professor Kim will contribute to coordinating and deliberating national architecture and urban development policies. He will serve a two-year term beginning this month.

The Presidential Commission on Architecture Policy is made up of 30 commissioners. Nineteen members, including Professor Kim, are experts from the private sector, and the rest include the Minister of Land, Infrastructure, and Transport, the Minister for Environment, and other government officials. The non-governmental commissioners represent a diverse mixture of genders, ages, and regions for the balanced development of the nation.

(END)

2020.05.21 View 8089

Professor Youngchul Kim Joins Presidential Commission on Architecture Policy

Professor Youngchul Kim from the Department of Civil and Environmental Engineering, who is also the Director of the Smart City Research Center at KAIST, was appointed as a commissioner of the 6th Presidential Commission on Architecture Policy on May 19. Professor Kim will contribute to coordinating and deliberating national architecture and urban development policies. He will serve a two-year term beginning this month.

The Presidential Commission on Architecture Policy is made up of 30 commissioners. Nineteen members, including Professor Kim, are experts from the private sector, and the rest include the Minister of Land, Infrastructure, and Transport, the Minister for Environment, and other government officials. The non-governmental commissioners represent a diverse mixture of genders, ages, and regions for the balanced development of the nation.

(END)

2020.05.21 View 8089 -

Antivirus Industry the Centerpiece of New Deal R&D Initiatives

- KAIST launches post-COVID-19 R&D initiatives for smart mobile medical systems. -

KAIST will make the antivirus industry the centerpiece of what it is touting as the KAIST New Deal R&D initiative, which will drive new growth engines for preparing for the post-coronavirus era.

According to the new initiative, KAIST will concentrate on creating antivirus technologies, infectious disease-related big data management, and non-contact services platforms as key future R&D projects.

President Sung-Chul Shin launched the COVID-19 R&D Initiative task force last month, composed of more than 50 professors from the Graduate School of Medical Science and Engineering, the Department of Biological Sciences, the College of Engineering, and the Department of Industrial Design. The task force came up with key research agendas that will promote smart mobile medical systems in the years ahead.

“We will devote all of our R&D capacities to pursue a smart healthcare society,” said President Shin. “Our competitiveness in the fields of AI, ICT, materials, and bio-technology holds significant potential for building a healthy society powered by smart medical systems in Korea,” he added.

The smart medical systems focus mainly on building an Epidemic Mitigating Mobile Module (EMMM). The EMMM will manage epidemics via the three phases of prevention, emergency response, and treatment, with the development of each phase’s technological modules. The EMMM will also build an AI big data platform to assist with clinical applications and epidemic management.

Technologies applicable for the prevention phase include developing recyclable antivirus masks, plasma virus sterilizers, and smart breathable protective gowns. KAIST researchers will also focus on developing diagnosis modules that will identify epidemics more quickly and accurately.

Most significantly, KAIST aims to develop technologies for anti-infection medical services such as the transformable negative pressure ambulance module and negative pressure room, which are specially developed for respiratory infections.

The new R&D initiatives will center on virus therapies and treatments, specifically pushing forward vaccine and robotics studies. As caring robots and delivery robots will become common as main caregivers via noncontact services, research focusing on robotics will be significantly enhanced.

Even before launching the new R&D initiatives, researchers have started to present new technologies to help address the pandemic. Professor Il-Doo Kim’s team in the Department of Materials Science and Engineering developed a washable nano-fiber filtered face mask that is preparing for commercialization.

GPS tracking of infections has expanded comprehensively to detect both indoor and outdoor activities of infected patients. Professor Dong-Soo Han from the School of Computing developed Wi-Fi positioning software built into mobile phones that can trace both activities and is now preparing to roll it out.

Virologist Ui-Cheol Shin from the Graduate School of Medical Science and Engineering is carrying out research on a universal T-cell vaccine that can block the Betacoronaviruses. It is reported that that new epidemics such as SARS, MERS, and COVID-19 carry Betacoronaviruses.

Research teams in the Graduate School of AI are conducting various research projects on building prediction models for outbreaks and spreads using big data.

(END)

2020.05.20 View 14063

Antivirus Industry the Centerpiece of New Deal R&D Initiatives

- KAIST launches post-COVID-19 R&D initiatives for smart mobile medical systems. -

KAIST will make the antivirus industry the centerpiece of what it is touting as the KAIST New Deal R&D initiative, which will drive new growth engines for preparing for the post-coronavirus era.

According to the new initiative, KAIST will concentrate on creating antivirus technologies, infectious disease-related big data management, and non-contact services platforms as key future R&D projects.

President Sung-Chul Shin launched the COVID-19 R&D Initiative task force last month, composed of more than 50 professors from the Graduate School of Medical Science and Engineering, the Department of Biological Sciences, the College of Engineering, and the Department of Industrial Design. The task force came up with key research agendas that will promote smart mobile medical systems in the years ahead.

“We will devote all of our R&D capacities to pursue a smart healthcare society,” said President Shin. “Our competitiveness in the fields of AI, ICT, materials, and bio-technology holds significant potential for building a healthy society powered by smart medical systems in Korea,” he added.

The smart medical systems focus mainly on building an Epidemic Mitigating Mobile Module (EMMM). The EMMM will manage epidemics via the three phases of prevention, emergency response, and treatment, with the development of each phase’s technological modules. The EMMM will also build an AI big data platform to assist with clinical applications and epidemic management.

Technologies applicable for the prevention phase include developing recyclable antivirus masks, plasma virus sterilizers, and smart breathable protective gowns. KAIST researchers will also focus on developing diagnosis modules that will identify epidemics more quickly and accurately.

Most significantly, KAIST aims to develop technologies for anti-infection medical services such as the transformable negative pressure ambulance module and negative pressure room, which are specially developed for respiratory infections.

The new R&D initiatives will center on virus therapies and treatments, specifically pushing forward vaccine and robotics studies. As caring robots and delivery robots will become common as main caregivers via noncontact services, research focusing on robotics will be significantly enhanced.

Even before launching the new R&D initiatives, researchers have started to present new technologies to help address the pandemic. Professor Il-Doo Kim’s team in the Department of Materials Science and Engineering developed a washable nano-fiber filtered face mask that is preparing for commercialization.

GPS tracking of infections has expanded comprehensively to detect both indoor and outdoor activities of infected patients. Professor Dong-Soo Han from the School of Computing developed Wi-Fi positioning software built into mobile phones that can trace both activities and is now preparing to roll it out.

Virologist Ui-Cheol Shin from the Graduate School of Medical Science and Engineering is carrying out research on a universal T-cell vaccine that can block the Betacoronaviruses. It is reported that that new epidemics such as SARS, MERS, and COVID-19 carry Betacoronaviruses.

Research teams in the Graduate School of AI are conducting various research projects on building prediction models for outbreaks and spreads using big data.

(END)

2020.05.20 View 14063 -

Blood-Based Multiplexed Diagnostic Sensor Helps to Accurately Detect Alzheimer’s Disease

A research team at KAIST reported clinically accurate multiplexed electrical biosensor for detecting Alzheimer’s disease by measuring its core biomarkers using densely aligned carbon nanotubes.

Alzheimer’s disease is the most prevalent neurodegenerative disorder, affecting one in ten aged over 65 years. Early diagnosis can reduce the risk of suffering the disease by one-third, according to recent reports. However, its early diagnosis remains challenging due to the low accuracy but high cost of diagnosis.

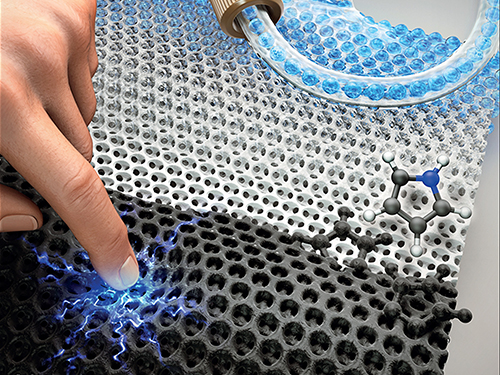

Research team led by Professors Chan Beum Park and Steve Park described an ultrasensitive detection of multiple Alzheimer's disease core biomarker in human plasma. The team have designed the sensor array by employing a densely aligned single-walled carbon nanotube thin films as a transducer.

The representative biomarkers of Alzheimer's disease are beta-amyloid42, beta-amyloid40, total tau protein, phosphorylated tau protein and the concentrations of these biomarkers in human plasma are directly correlated with the pathology of Alzheimer’s disease.

The research team developed a highly sensitive resistive biosensor based on densely aligned carbon nanotubes fabricated by Langmuir-Blodgett method with a low manufacturing cost.

Aligned carbon nanotubes with high density minimizes the tube-to-tube junction resistance compared with randomly distributed carbon nanotubes, which leads to the improvement of sensor sensitivity. To be more specific, this resistive sensor with densely aligned carbon nanotubes exhibits a sensitivity over 100 times higher than that of conventional carbon nanotube-based biosensors.

By measuring the concentrations of four Alzheimer’s disease biomarkers simultaneously Alzheimer patients can be discriminated from health controls with an average sensitivity of 90.0%, a selectivity of 90.0% and an average accuracy of 88.6%.

This work, titled “Clinically accurate diagnosis of Alzheimer’s disease via multiplexed sensing of core biomarkers in human plasma”, were published in Nature Communications on January 8th 2020. The authors include PhD candidate Kayoung Kim and MS candidate Min-Ji Kim.

Professor Steve Park said, “This study was conducted on patients who are already confirmed with Alzheimer’s Disease. For further use in practical setting, it is necessary to test the patients with mild cognitive impairment.” He also emphasized that, “It is essential to establish a nationwide infrastructure, such as mild cognitive impairment cohort study and a dementia cohort study. This would enable the establishment of world-wide research network, and will help various private and public institutions.”

This research was supported by the Ministry of Science and ICT, Human Resource Bank of Chungnam National University Hospital and Chungbuk National University Hospital.

< A schematic diagram of a high-density aligned carbon nanotube-based resistive sensor that distinguishes patients with Alzheimer’s Disease by measuring the concentration of four biomarkers in the blood. >

Profile:

Professor Steve Park

stevepark@kaist.ac.kr

Department of Materials Science and Engineering

http://steveparklab.kaist.ac.kr/

KAIST

Profile:

Professor Chan Beum Park

parkcb at kaist.ac.kr

Department of Materials Science and Engineering

http://biomaterials.kaist.ac.kr/

KAIST

2020.02.07 View 12258

Blood-Based Multiplexed Diagnostic Sensor Helps to Accurately Detect Alzheimer’s Disease

A research team at KAIST reported clinically accurate multiplexed electrical biosensor for detecting Alzheimer’s disease by measuring its core biomarkers using densely aligned carbon nanotubes.

Alzheimer’s disease is the most prevalent neurodegenerative disorder, affecting one in ten aged over 65 years. Early diagnosis can reduce the risk of suffering the disease by one-third, according to recent reports. However, its early diagnosis remains challenging due to the low accuracy but high cost of diagnosis.

Research team led by Professors Chan Beum Park and Steve Park described an ultrasensitive detection of multiple Alzheimer's disease core biomarker in human plasma. The team have designed the sensor array by employing a densely aligned single-walled carbon nanotube thin films as a transducer.

The representative biomarkers of Alzheimer's disease are beta-amyloid42, beta-amyloid40, total tau protein, phosphorylated tau protein and the concentrations of these biomarkers in human plasma are directly correlated with the pathology of Alzheimer’s disease.

The research team developed a highly sensitive resistive biosensor based on densely aligned carbon nanotubes fabricated by Langmuir-Blodgett method with a low manufacturing cost.

Aligned carbon nanotubes with high density minimizes the tube-to-tube junction resistance compared with randomly distributed carbon nanotubes, which leads to the improvement of sensor sensitivity. To be more specific, this resistive sensor with densely aligned carbon nanotubes exhibits a sensitivity over 100 times higher than that of conventional carbon nanotube-based biosensors.

By measuring the concentrations of four Alzheimer’s disease biomarkers simultaneously Alzheimer patients can be discriminated from health controls with an average sensitivity of 90.0%, a selectivity of 90.0% and an average accuracy of 88.6%.

This work, titled “Clinically accurate diagnosis of Alzheimer’s disease via multiplexed sensing of core biomarkers in human plasma”, were published in Nature Communications on January 8th 2020. The authors include PhD candidate Kayoung Kim and MS candidate Min-Ji Kim.

Professor Steve Park said, “This study was conducted on patients who are already confirmed with Alzheimer’s Disease. For further use in practical setting, it is necessary to test the patients with mild cognitive impairment.” He also emphasized that, “It is essential to establish a nationwide infrastructure, such as mild cognitive impairment cohort study and a dementia cohort study. This would enable the establishment of world-wide research network, and will help various private and public institutions.”

This research was supported by the Ministry of Science and ICT, Human Resource Bank of Chungnam National University Hospital and Chungbuk National University Hospital.

< A schematic diagram of a high-density aligned carbon nanotube-based resistive sensor that distinguishes patients with Alzheimer’s Disease by measuring the concentration of four biomarkers in the blood. >

Profile:

Professor Steve Park

stevepark@kaist.ac.kr

Department of Materials Science and Engineering

http://steveparklab.kaist.ac.kr/

KAIST

Profile:

Professor Chan Beum Park

parkcb at kaist.ac.kr

Department of Materials Science and Engineering

http://biomaterials.kaist.ac.kr/

KAIST

2020.02.07 View 12258 -

Object Identification and Interaction with a Smartphone Knock

(Professor Lee (far right) demonstrate 'Knocker' with his students.)

A KAIST team has featured a new technology, “Knocker”, which identifies objects and executes actions just by knocking on it with the smartphone. Software powered by machine learning of sounds, vibrations, and other reactions will perform the users’ directions.

What separates Knocker from existing technology is the sensor fusion of sound and motion. Previously, object identification used either computer vision technology with cameras or hardware such as RFID (Radio Frequency Identification) tags. These solutions all have their limitations. For computer vision technology, users need to take pictures of every item. Even worse, the technology will not work well in poor lighting situations. Using hardware leads to additional costs and labor burdens.

Knocker, on the other hand, can identify objects even in dark environments only with a smartphone, without requiring any specialized hardware or using a camera. Knocker utilizes the smartphone’s built-in sensors such as a microphone, an accelerometer, and a gyroscope to capture a unique set of responses generated when a smartphone is knocked against an object. Machine learning is used to analyze these responses and classify and identify objects.

The research team under Professor Sung-Ju Lee from the School of Computing confirmed the applicability of Knocker technology using 23 everyday objects such as books, laptop computers, water bottles, and bicycles. In noisy environments such as a busy café or on the side of a road, it achieved 83% identification accuracy. In a quiet indoor environment, the accuracy rose to 98%.

The team believes Knocker will open a new paradigm of object interaction. For instance, by knocking on an empty water bottle, a smartphone can automatically order new water bottles from a merchant app. When integrated with IoT devices, knocking on a bed’s headboard before going to sleep could turn off the lights and set an alarm. The team suggested and implemented 15 application cases in the paper, presented during the 2019 ACM International Joint Conference on Pervasive and Ubiquitous Computing (UbiComp 2019) held in London last month.

Professor Sung-Ju Lee said, “This new technology does not require any specialized sensor or hardware. It simply uses the built-in sensors on smartphones and takes advantage of the power of machine learning. It’s a software solution that everyday smartphone users could immediately benefit from.” He continued, “This technology enables users to conveniently interact with their favorite objects.”

The research was supported in part by the Next-Generation Information Computing Development Program through the National Research Foundation of Korea funded by the Ministry of Science and ICT and an Institute for Information & Communications Technology Promotion (IITP) grant funded by the Ministry of Science and ICT.

Figure: An example knock on a bottle. Knocker identifies the object by analyzing a unique set of responses from the knock, and automatically launches a proper application or service.

2019.10.02 View 29905

Object Identification and Interaction with a Smartphone Knock

(Professor Lee (far right) demonstrate 'Knocker' with his students.)

A KAIST team has featured a new technology, “Knocker”, which identifies objects and executes actions just by knocking on it with the smartphone. Software powered by machine learning of sounds, vibrations, and other reactions will perform the users’ directions.

What separates Knocker from existing technology is the sensor fusion of sound and motion. Previously, object identification used either computer vision technology with cameras or hardware such as RFID (Radio Frequency Identification) tags. These solutions all have their limitations. For computer vision technology, users need to take pictures of every item. Even worse, the technology will not work well in poor lighting situations. Using hardware leads to additional costs and labor burdens.

Knocker, on the other hand, can identify objects even in dark environments only with a smartphone, without requiring any specialized hardware or using a camera. Knocker utilizes the smartphone’s built-in sensors such as a microphone, an accelerometer, and a gyroscope to capture a unique set of responses generated when a smartphone is knocked against an object. Machine learning is used to analyze these responses and classify and identify objects.

The research team under Professor Sung-Ju Lee from the School of Computing confirmed the applicability of Knocker technology using 23 everyday objects such as books, laptop computers, water bottles, and bicycles. In noisy environments such as a busy café or on the side of a road, it achieved 83% identification accuracy. In a quiet indoor environment, the accuracy rose to 98%.

The team believes Knocker will open a new paradigm of object interaction. For instance, by knocking on an empty water bottle, a smartphone can automatically order new water bottles from a merchant app. When integrated with IoT devices, knocking on a bed’s headboard before going to sleep could turn off the lights and set an alarm. The team suggested and implemented 15 application cases in the paper, presented during the 2019 ACM International Joint Conference on Pervasive and Ubiquitous Computing (UbiComp 2019) held in London last month.

Professor Sung-Ju Lee said, “This new technology does not require any specialized sensor or hardware. It simply uses the built-in sensors on smartphones and takes advantage of the power of machine learning. It’s a software solution that everyday smartphone users could immediately benefit from.” He continued, “This technology enables users to conveniently interact with their favorite objects.”

The research was supported in part by the Next-Generation Information Computing Development Program through the National Research Foundation of Korea funded by the Ministry of Science and ICT and an Institute for Information & Communications Technology Promotion (IITP) grant funded by the Ministry of Science and ICT.

Figure: An example knock on a bottle. Knocker identifies the object by analyzing a unique set of responses from the knock, and automatically launches a proper application or service.

2019.10.02 View 29905 -

Highly Uniform and Low Hysteresis Pressure Sensor to Increase Practical Applicability

< Professor Steve Park (left) and the First Author Mr. Jinwon Oh (right) >

Researchers have designed a flexible pressure sensor that is expected to have a much wider applicability. A KAIST research team fabricated a piezoresistive pressure sensor of high uniformity with low hysteresis by chemically grafting a conductive polymer onto a porous elastomer template.

The team discovered that the uniformity of pore size and shape is directly related to the uniformity of the sensor. The team noted that by increasing pore size and shape variability, the variability of the sensor characteristics also increases.

Researchers led by Professor Steve Park from the Department of Materials Science and Engineering confirmed that compared to other sensors composed of randomly sized and shaped pores, which had a coefficient of variation in relative resistance change of 69.65%, their newly developed sensor exhibited much higher uniformity with a coefficient of variation of 2.43%. This study was reported in Small as the cover article on August 16.

Flexible pressure sensors have been actively researched and widely applied in electronic equipment such as touch screens, robots, wearable healthcare devices, electronic skin, and human-machine interfaces. In particular, piezoresistive pressure sensors based on elastomer‐conductive material composites hold significant potential due to their many advantages including a simple and low-cost fabrication process.

Various research results have been reported for ways to improve the performance of piezoresistive pressure sensors, most of which have been focused on increasing the sensitivity. Despite its significance, maximizing the sensitivity of composite-based piezoresistive pressure sensors is not necessary for many applications. On the other hand, sensor-to-sensor uniformity and hysteresis are two properties that are of critical importance to realize any application.

The importance of sensor-to-sensor uniformity is obvious. If the sensors manufactured under the same conditions have different properties, measurement reliability is compromised, and therefore the sensor cannot be used in a practical setting.

In addition, low hysteresis is also essential for improved measurement reliability. Hysteresis is a phenomenon in which the electrical readings differ depending on how fast or slow the sensor is being pressed, whether pressure is being released or applied, and how long and to what degree the sensor has been pressed. When a sensor has high hysteresis, the electrical readings will differ even under the same pressure, making the measurements unreliable.

Researchers said they observed a negligible hysteresis degree which was only 2%. This was attributed to the strong chemical bonding between the conductive polymer and the elastomer template, which prevents their relative sliding and displacement, and the porosity of the elastomer that enhances elastic behavior.

“This technology brings forth insight into how to address the two critical issues in pressure sensors: uniformity and hysteresis. We expect our technology to play an important role in increasing practical applications and the commercialization of pressure sensors in the near future,” said Professor Park.

This work was conducted as part of the KAIST‐funded Global Singularity Research Program for 2019, and also supported by the KUSTAR‐KAIST Institute.

Figure 1. Image of a porous elastomer template with uniform pore size and shape (left), Graph showing high uniformity in the sensors’ performance (right).

Figure 2. Hysteresis loops of the sensor at different pressure levels (left), and after a different number of cycles (right).

Figure 3. The cover page of Small Journal, Volume 15, Issue 33.

Publication:

Jinwon Oh, Jin‐Oh Kim, Yunjoo Kim, Han Byul Choi, Jun Chang Yang, Serin Lee, Mikhail Pyatykh, Jung Kim, Joo Yong Sim, and Steve Park. 2019. Highly Uniform and Low Hysteresis Piezoresistive Pressure Sensors Based on Chemical Grafting of Polypyrrole on Elastomer Template with Uniform Pore Size. Small. Wiley-VCH Verlag GmbH & Co. KgaA, Weinheim, Germany, Volume No. 15, Issue No. 33, Full Paper No. 201901744, 8 pages. https://doi.org/10.1002/smll.201901744

Profile: Prof. Steve Park, MS, PhD

stevepark@kaist.ac.kr

http://steveparklab.kaist.ac.kr/

Assistant Professor

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Mr. Jinwon Oh, MS

jwoh1701@gmail.com

http://steveparklab.kaist.ac.kr/

Researcher

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Prof. Jung Kim, MS, PhD

jungkim@kaist.ac.kr

http://medev.kaist.ac.kr/

Professor

Biorobotics Laboratory

Department of Mechanical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Joo Yong Sim, PhD

jsim@etri.re.kr

Researcher

Bio-Medical IT Convergence Research Department

Electronics and Telecommunications Research Institute (ETRI)

https://www.etri.re.krDaejeon 34129, Korea

(END)

2019.08.19 View 29436

Highly Uniform and Low Hysteresis Pressure Sensor to Increase Practical Applicability

< Professor Steve Park (left) and the First Author Mr. Jinwon Oh (right) >

Researchers have designed a flexible pressure sensor that is expected to have a much wider applicability. A KAIST research team fabricated a piezoresistive pressure sensor of high uniformity with low hysteresis by chemically grafting a conductive polymer onto a porous elastomer template.

The team discovered that the uniformity of pore size and shape is directly related to the uniformity of the sensor. The team noted that by increasing pore size and shape variability, the variability of the sensor characteristics also increases.

Researchers led by Professor Steve Park from the Department of Materials Science and Engineering confirmed that compared to other sensors composed of randomly sized and shaped pores, which had a coefficient of variation in relative resistance change of 69.65%, their newly developed sensor exhibited much higher uniformity with a coefficient of variation of 2.43%. This study was reported in Small as the cover article on August 16.

Flexible pressure sensors have been actively researched and widely applied in electronic equipment such as touch screens, robots, wearable healthcare devices, electronic skin, and human-machine interfaces. In particular, piezoresistive pressure sensors based on elastomer‐conductive material composites hold significant potential due to their many advantages including a simple and low-cost fabrication process.

Various research results have been reported for ways to improve the performance of piezoresistive pressure sensors, most of which have been focused on increasing the sensitivity. Despite its significance, maximizing the sensitivity of composite-based piezoresistive pressure sensors is not necessary for many applications. On the other hand, sensor-to-sensor uniformity and hysteresis are two properties that are of critical importance to realize any application.

The importance of sensor-to-sensor uniformity is obvious. If the sensors manufactured under the same conditions have different properties, measurement reliability is compromised, and therefore the sensor cannot be used in a practical setting.

In addition, low hysteresis is also essential for improved measurement reliability. Hysteresis is a phenomenon in which the electrical readings differ depending on how fast or slow the sensor is being pressed, whether pressure is being released or applied, and how long and to what degree the sensor has been pressed. When a sensor has high hysteresis, the electrical readings will differ even under the same pressure, making the measurements unreliable.

Researchers said they observed a negligible hysteresis degree which was only 2%. This was attributed to the strong chemical bonding between the conductive polymer and the elastomer template, which prevents their relative sliding and displacement, and the porosity of the elastomer that enhances elastic behavior.

“This technology brings forth insight into how to address the two critical issues in pressure sensors: uniformity and hysteresis. We expect our technology to play an important role in increasing practical applications and the commercialization of pressure sensors in the near future,” said Professor Park.

This work was conducted as part of the KAIST‐funded Global Singularity Research Program for 2019, and also supported by the KUSTAR‐KAIST Institute.

Figure 1. Image of a porous elastomer template with uniform pore size and shape (left), Graph showing high uniformity in the sensors’ performance (right).

Figure 2. Hysteresis loops of the sensor at different pressure levels (left), and after a different number of cycles (right).

Figure 3. The cover page of Small Journal, Volume 15, Issue 33.

Publication:

Jinwon Oh, Jin‐Oh Kim, Yunjoo Kim, Han Byul Choi, Jun Chang Yang, Serin Lee, Mikhail Pyatykh, Jung Kim, Joo Yong Sim, and Steve Park. 2019. Highly Uniform and Low Hysteresis Piezoresistive Pressure Sensors Based on Chemical Grafting of Polypyrrole on Elastomer Template with Uniform Pore Size. Small. Wiley-VCH Verlag GmbH & Co. KgaA, Weinheim, Germany, Volume No. 15, Issue No. 33, Full Paper No. 201901744, 8 pages. https://doi.org/10.1002/smll.201901744

Profile: Prof. Steve Park, MS, PhD

stevepark@kaist.ac.kr

http://steveparklab.kaist.ac.kr/

Assistant Professor

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Mr. Jinwon Oh, MS

jwoh1701@gmail.com

http://steveparklab.kaist.ac.kr/

Researcher

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Prof. Jung Kim, MS, PhD

jungkim@kaist.ac.kr

http://medev.kaist.ac.kr/

Professor

Biorobotics Laboratory

Department of Mechanical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Joo Yong Sim, PhD

jsim@etri.re.kr

Researcher

Bio-Medical IT Convergence Research Department

Electronics and Telecommunications Research Institute (ETRI)

https://www.etri.re.krDaejeon 34129, Korea

(END)

2019.08.19 View 29436 -

Micropatch Made of DNA

Researchers reported the fabrication of microstructure arrays of DNA materials using topographic control. This method provides a platform for forming multiscale hierarchical orientations of soft and biomaterials using a process of simple shearing and controlled evaporation on a patterned substrate. This approach enables the potential of patterning applications using DNA or other anisotropic biomaterials.

DNA is one of the most abundant biomaterials found in all living organisms in nature. It has unique characteristics of fine feature size and liquid crystalline phase, enabling to create various kinds of microstructure DNA arrays. Based on these characteristics, DNA has been used as a building block for “origami” and textile art at the nanometer scale.

A KAIST research team led by Professors Dong Ki Yoon and Hyungsoo Kim fabricated a DNA-based micropatch using the “coffee ring effect” and its multi-angle control technology, which was published online in Nature Communications on June 7.

The research team used cheap DNA material extracted from salmon to realize the micropatch structure with well-aligned knit or ice cream cone shapes. When the DNA material in an aqueous solution is rubbed between two solid substrates while water is evaporating, DNA chains are unidirectionally aligned to make a thin film such as in LCD display devices. The DNA chains can make more complex microstructures such as knit or a texture with ice cream cone shapes when the same procedure is carried out in topographical patterns like microposts (Figure 1). This can be applied to make metamaterials by mixing with functionalized gold nanorods to show plasmonic color.

Plasmon resonance is a phenomenon in which electrons vibrate uniformly on the surface of a substrate made of metal, reacting only to light that matches a specific energy to enhance the clarity and expression of colors. For this, the most important factor is the orientation in which the gold nanorods align. That is, when the rods are aligned side by side in one direction, the optical and electrical characteristics are maximized. The research team focused on this point and made the DNA micropatch as a frame to orient the gold nanorods in a unique shape and fabricated a plasmonic color film (Figure 2).

Professor Yoon said this study is meaningful in that it deals with the evaporation phenomenon, which has not been studied much in the field of polymers and biopolymers in terms of basic science. He explained, “This will also help maximize the efficiency of polymeric materials that can be orientated in coating, 2D, and 3D printing applications. Furthermore, DNA that exists infinitely in nature can be expected to have industrial application value as a new material since it can easily form complexes with other materials as described in this study.”

(Figure 1. The DNA micropatch using topographic control. (a) The experimental scheme.

(b) Enlarged image of (e). (c-e) Different micropatches made of DNA using different shearing directions.)

(Figure 2. The knit-like structures made of DNA-gold nanorod complex. (a,b) Optical

and polarized optical microscopy images. (c-f) Plasmonic colors reflected from aligned DNA-gold nanorod complex depending on the sample rotation.)

2019.07.01 View 35538

Micropatch Made of DNA

Researchers reported the fabrication of microstructure arrays of DNA materials using topographic control. This method provides a platform for forming multiscale hierarchical orientations of soft and biomaterials using a process of simple shearing and controlled evaporation on a patterned substrate. This approach enables the potential of patterning applications using DNA or other anisotropic biomaterials.

DNA is one of the most abundant biomaterials found in all living organisms in nature. It has unique characteristics of fine feature size and liquid crystalline phase, enabling to create various kinds of microstructure DNA arrays. Based on these characteristics, DNA has been used as a building block for “origami” and textile art at the nanometer scale.

A KAIST research team led by Professors Dong Ki Yoon and Hyungsoo Kim fabricated a DNA-based micropatch using the “coffee ring effect” and its multi-angle control technology, which was published online in Nature Communications on June 7.

The research team used cheap DNA material extracted from salmon to realize the micropatch structure with well-aligned knit or ice cream cone shapes. When the DNA material in an aqueous solution is rubbed between two solid substrates while water is evaporating, DNA chains are unidirectionally aligned to make a thin film such as in LCD display devices. The DNA chains can make more complex microstructures such as knit or a texture with ice cream cone shapes when the same procedure is carried out in topographical patterns like microposts (Figure 1). This can be applied to make metamaterials by mixing with functionalized gold nanorods to show plasmonic color.

Plasmon resonance is a phenomenon in which electrons vibrate uniformly on the surface of a substrate made of metal, reacting only to light that matches a specific energy to enhance the clarity and expression of colors. For this, the most important factor is the orientation in which the gold nanorods align. That is, when the rods are aligned side by side in one direction, the optical and electrical characteristics are maximized. The research team focused on this point and made the DNA micropatch as a frame to orient the gold nanorods in a unique shape and fabricated a plasmonic color film (Figure 2).

Professor Yoon said this study is meaningful in that it deals with the evaporation phenomenon, which has not been studied much in the field of polymers and biopolymers in terms of basic science. He explained, “This will also help maximize the efficiency of polymeric materials that can be orientated in coating, 2D, and 3D printing applications. Furthermore, DNA that exists infinitely in nature can be expected to have industrial application value as a new material since it can easily form complexes with other materials as described in this study.”

(Figure 1. The DNA micropatch using topographic control. (a) The experimental scheme.

(b) Enlarged image of (e). (c-e) Different micropatches made of DNA using different shearing directions.)

(Figure 2. The knit-like structures made of DNA-gold nanorod complex. (a,b) Optical

and polarized optical microscopy images. (c-f) Plasmonic colors reflected from aligned DNA-gold nanorod complex depending on the sample rotation.)

2019.07.01 View 35538 -

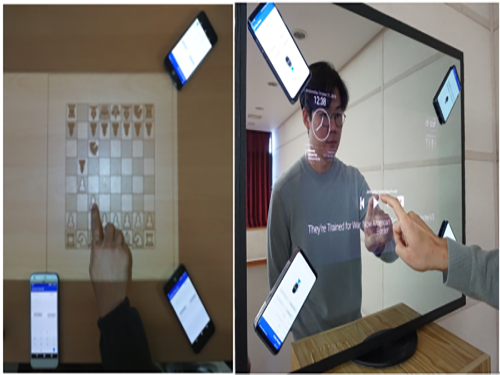

Sound-based Touch Input Technology for Smart Tables and Mirrors

(from left: MS candidate Anish Byanjankar, Research Assistant Professor Hyosu Kim and Professor Insik Shin)

Time passes so quickly, especially in the morning. Your hands are so busy brushing your teeth and checking the weather on your smartphone. You might wish that your mirror could turn into a touch screen and free up your hands. That wish can be achieved very soon. A KAIST team has developed a smartphone-based touch sound localization technology to facilitate ubiquitous interactions, turning objects like furniture and mirrors into touch input tools.

This technology analyzes touch sounds generated from a user’s touch on a surface and identifies the location of the touch input. For instance, users can turn surrounding tables or walls into virtual keyboards and write lengthy e-mails much more conveniently by using only the built-in microphone on their smartphones or tablets. Moreover, family members can enjoy a virtual chessboard or enjoy board games on their dining tables.

Additionally, traditional smart devices such as smart TVs or mirrors, which only provide simple screen display functions, can play a smarter role by adding touch input function support (see the image below).

Figure 1.Examples of using touch input technology: By using only smartphone, you can use surrounding objects as a touch screen anytime and anywhere.

The most important aspect of enabling the sound-based touch input method is to identify the location of touch inputs in a precise manner (within about 1cm error). However, it is challenging to meet these requirements, mainly because this technology can be used in diverse and dynamically changing environments. Users may use objects like desks, walls, or mirrors as touch input tools and the surrounding environments (e.g. location of nearby objects or ambient noise level) can be varied. These environmental changes can affect the characteristics of touch sounds.

To address this challenge, Professor Insik Shin from the School of Computing and his team focused on analyzing the fundamental properties of touch sounds, especially how they are transmitted through solid surfaces.

On solid surfaces, sound experiences a dispersion phenomenon that makes different frequency components travel at different speeds. Based on this phenomenon, the team observed that the arrival time difference (TDoA) between frequency components increases in proportion to the sound transmission distance, and this linear relationship is not affected by the variations of surround environments.

Based on these observations, Research Assistant Professor Hyosu Kim proposed a novel sound-based touch input technology that records touch sounds transmitted through solid surfaces, then conducts a simple calibration process to identify the relationship between TDoA and the sound transmission distance, finally achieving accurate touch input localization.

The accuracy of the proposed system was then measured. The average localization error was lower than about 0.4 cm on a 17-inch touch screen. Particularly, it provided a measurement error of less than 1cm, even with a variety of objects such as wooden desks, glass mirrors, and acrylic boards and when the position of nearby objects and noise levels changed dynamically. Experiments with practical users have also shown positive responses to all measurement factors, including user experience and accuracy.

Professor Shin said, “This is novel touch interface technology that allows a touch input system just by installing three to four microphones, so it can easily turn nearby objects into touch screens.”

The proposed system was presented at ACM SenSys, a top-tier conference in the field of mobile computing and sensing, and was selected as a best paper runner-up in November 2018.

(The demonstration video of the sound-based touch input technology)

2018.12.26 View 9846

Sound-based Touch Input Technology for Smart Tables and Mirrors

(from left: MS candidate Anish Byanjankar, Research Assistant Professor Hyosu Kim and Professor Insik Shin)

Time passes so quickly, especially in the morning. Your hands are so busy brushing your teeth and checking the weather on your smartphone. You might wish that your mirror could turn into a touch screen and free up your hands. That wish can be achieved very soon. A KAIST team has developed a smartphone-based touch sound localization technology to facilitate ubiquitous interactions, turning objects like furniture and mirrors into touch input tools.

This technology analyzes touch sounds generated from a user’s touch on a surface and identifies the location of the touch input. For instance, users can turn surrounding tables or walls into virtual keyboards and write lengthy e-mails much more conveniently by using only the built-in microphone on their smartphones or tablets. Moreover, family members can enjoy a virtual chessboard or enjoy board games on their dining tables.

Additionally, traditional smart devices such as smart TVs or mirrors, which only provide simple screen display functions, can play a smarter role by adding touch input function support (see the image below).

Figure 1.Examples of using touch input technology: By using only smartphone, you can use surrounding objects as a touch screen anytime and anywhere.

The most important aspect of enabling the sound-based touch input method is to identify the location of touch inputs in a precise manner (within about 1cm error). However, it is challenging to meet these requirements, mainly because this technology can be used in diverse and dynamically changing environments. Users may use objects like desks, walls, or mirrors as touch input tools and the surrounding environments (e.g. location of nearby objects or ambient noise level) can be varied. These environmental changes can affect the characteristics of touch sounds.

To address this challenge, Professor Insik Shin from the School of Computing and his team focused on analyzing the fundamental properties of touch sounds, especially how they are transmitted through solid surfaces.

On solid surfaces, sound experiences a dispersion phenomenon that makes different frequency components travel at different speeds. Based on this phenomenon, the team observed that the arrival time difference (TDoA) between frequency components increases in proportion to the sound transmission distance, and this linear relationship is not affected by the variations of surround environments.

Based on these observations, Research Assistant Professor Hyosu Kim proposed a novel sound-based touch input technology that records touch sounds transmitted through solid surfaces, then conducts a simple calibration process to identify the relationship between TDoA and the sound transmission distance, finally achieving accurate touch input localization.

The accuracy of the proposed system was then measured. The average localization error was lower than about 0.4 cm on a 17-inch touch screen. Particularly, it provided a measurement error of less than 1cm, even with a variety of objects such as wooden desks, glass mirrors, and acrylic boards and when the position of nearby objects and noise levels changed dynamically. Experiments with practical users have also shown positive responses to all measurement factors, including user experience and accuracy.

Professor Shin said, “This is novel touch interface technology that allows a touch input system just by installing three to four microphones, so it can easily turn nearby objects into touch screens.”