Department+of+mechanical+engineering

-

KAIST Research team develops anti-icing film that only requires sunlight

A KAIST research team has developed an anti-icing and de-icing film coating technology that can apply the photothermal effect of gold nanoparticles to industrial sites without the need for heating wires, periodic spray or oil coating of anti-freeze substances, and substrate design alterations.

The group led by Professor Hyoungsoo Kim from the Department of Mechanical Engineering (Fluid & Interface Laboratory) and Professor Dong Ki Yoon from the Department of Chemistry (Soft Material Assembly Group) revealed on January 3 to have together developed an original technique that can uniformly pattern gold nanorod (GNR) particles in quadrants through simple evaporation, and have used this to develop an anti-icing and de-icing surface.

Many scientists in recent years have tried to control substrate surfaces through various coating techniques, and those involving the patterning of functional nanomaterials have gained special attention. In particular, GNR is considered a promising candidate nanomaterial for its biocompatibility, chemical stability, relatively simple synthesis, and its stable and unique property of surface plasmon resonance. To maximize the performance of GNR, it is important to achieve a high uniformity during film deposition, and a high level of rod alignment. However, achieving both criteria has thus far been a difficult challenge.

< Figure 1. Conceptual image to display Hydrodynamic mechanisms for the formation of a homogeneous quadrant cellulose nanocrystal(CNC) matrix. >

To solve this, the joint research team utilized cellulose nanocrystal (CNC), a next-generation functional nanomaterial that can easily be extracted from nature. By co-assembling GNR on CNC quadrant templates, the team could uniformly dry the film and successfully obtain a GNR film with a uniform alignment in a ring-shape. Compared to existing coffee-ring films, the highly uniform and aligned GNR film developed through this research showed enhanced plasmonic photothermal properties, and the team showed that it could carry out anti-icing and de-icing functions by simply irradiating light in the visible wavelength range.

< Figure 2. Optical and thermal performance evaluation results of gold nanorod film and demonstration of plasmonic heater for anti-icing and de-icing. >

Professor Hyoungsoo Kim said, “This technique can be applied to plastic, as well as flexible surfaces. By using it on exterior materials and films, it can generate its own heat energy, which would greatly save energy through voluntary thermal energy harvesting across various applications including cars, aircrafts, and windows in residential or commercial spaces, where frosting becomes a serious issue in the winter.” Professor Dong Ki Yoon added, “This research is significant in that we can now freely pattern the CNC-GNR composite, which was previously difficult to create into films, over a large area. We can utilize this as an anti-icing material, and if we were to take advantage of the plasmonic properties of gold, we can also use it like stained-glass to decorate glass surfaces.”

This research was conducted by Ph.D. candidate Jeongsu Pyeon from the Department of Mechanical Engineering, and his co-first author Dr. Soon Mo Park (a KAIST graduate, currently a post-doctoral associate at Cornell University), and was pushed in the online volume of Nature Communication on December 8, 2023 under the title “Plasmonic Metasurfaces of Cellulose Nanocrystal Matrices with Quadrants of Aligned Gold Nanorods for Photothermal Anti-Icing." Recognized for its achievement, the research was also selected as an editor’s highlight for the journals Materials Science and Chemistry, and Inorganic and Physical Chemistry.

This research was supported by the Individual Basic Mid-Sized Research Fund from the National Research Foundation of Korea and the Center for Multiscale Chiral Architectures.

2024.01.16 View 12316

KAIST Research team develops anti-icing film that only requires sunlight

A KAIST research team has developed an anti-icing and de-icing film coating technology that can apply the photothermal effect of gold nanoparticles to industrial sites without the need for heating wires, periodic spray or oil coating of anti-freeze substances, and substrate design alterations.

The group led by Professor Hyoungsoo Kim from the Department of Mechanical Engineering (Fluid & Interface Laboratory) and Professor Dong Ki Yoon from the Department of Chemistry (Soft Material Assembly Group) revealed on January 3 to have together developed an original technique that can uniformly pattern gold nanorod (GNR) particles in quadrants through simple evaporation, and have used this to develop an anti-icing and de-icing surface.

Many scientists in recent years have tried to control substrate surfaces through various coating techniques, and those involving the patterning of functional nanomaterials have gained special attention. In particular, GNR is considered a promising candidate nanomaterial for its biocompatibility, chemical stability, relatively simple synthesis, and its stable and unique property of surface plasmon resonance. To maximize the performance of GNR, it is important to achieve a high uniformity during film deposition, and a high level of rod alignment. However, achieving both criteria has thus far been a difficult challenge.

< Figure 1. Conceptual image to display Hydrodynamic mechanisms for the formation of a homogeneous quadrant cellulose nanocrystal(CNC) matrix. >

To solve this, the joint research team utilized cellulose nanocrystal (CNC), a next-generation functional nanomaterial that can easily be extracted from nature. By co-assembling GNR on CNC quadrant templates, the team could uniformly dry the film and successfully obtain a GNR film with a uniform alignment in a ring-shape. Compared to existing coffee-ring films, the highly uniform and aligned GNR film developed through this research showed enhanced plasmonic photothermal properties, and the team showed that it could carry out anti-icing and de-icing functions by simply irradiating light in the visible wavelength range.

< Figure 2. Optical and thermal performance evaluation results of gold nanorod film and demonstration of plasmonic heater for anti-icing and de-icing. >

Professor Hyoungsoo Kim said, “This technique can be applied to plastic, as well as flexible surfaces. By using it on exterior materials and films, it can generate its own heat energy, which would greatly save energy through voluntary thermal energy harvesting across various applications including cars, aircrafts, and windows in residential or commercial spaces, where frosting becomes a serious issue in the winter.” Professor Dong Ki Yoon added, “This research is significant in that we can now freely pattern the CNC-GNR composite, which was previously difficult to create into films, over a large area. We can utilize this as an anti-icing material, and if we were to take advantage of the plasmonic properties of gold, we can also use it like stained-glass to decorate glass surfaces.”

This research was conducted by Ph.D. candidate Jeongsu Pyeon from the Department of Mechanical Engineering, and his co-first author Dr. Soon Mo Park (a KAIST graduate, currently a post-doctoral associate at Cornell University), and was pushed in the online volume of Nature Communication on December 8, 2023 under the title “Plasmonic Metasurfaces of Cellulose Nanocrystal Matrices with Quadrants of Aligned Gold Nanorods for Photothermal Anti-Icing." Recognized for its achievement, the research was also selected as an editor’s highlight for the journals Materials Science and Chemistry, and Inorganic and Physical Chemistry.

This research was supported by the Individual Basic Mid-Sized Research Fund from the National Research Foundation of Korea and the Center for Multiscale Chiral Architectures.

2024.01.16 View 12316 -

KAIST develops an artificial muscle device that produces force 34 times its weight

- Professor IlKwon Oh’s research team in KAIST’s Department of Mechanical Engineering developed a soft fluidic switch using an ionic polymer artificial muscle that runs with ultra-low power to lift objects 34 times greater than its weight.

- Its light weight and small size make it applicable to various industrial fields such as soft electronics, smart textiles, and biomedical devices by controlling fluid flow with high precision, even in narrow spaces.

Soft robots, medical devices, and wearable devices have permeated our daily lives. KAIST researchers have developed a fluid switch using ionic polymer artificial muscles that operates at ultra-low power and produces a force 34 times greater than its weight. Fluid switches control fluid flow, causing the fluid to flow in a specific direction to invoke various movements.

KAIST (President Kwang-Hyung Lee) announced on the 4th of January that a research team under Professor IlKwon Oh from the Department of Mechanical Engineering has developed a soft fluidic switch that operates at ultra-low voltage and can be used in narrow spaces.

Artificial muscles imitate human muscles and provide flexible and natural movements compared to traditional motors, making them one of the basic elements used in soft robots, medical devices, and wearable devices. These artificial muscles create movements in response to external stimuli such as electricity, air pressure, and temperature changes, and in order to utilize artificial muscles, it is important to control these movements precisely.

Switches based on existing motors were difficult to use within limited spaces due to their rigidity and large size. In order to address these issues, the research team developed an electro-ionic soft actuator that can control fluid flow while producing large amounts of force, even in a narrow pipe, and used it as a soft fluidic switch.

< Figure 1. The separation of fluid droplets using a soft fluid switch at ultra-low voltage. >

The ionic polymer artificial muscle developed by the research team is composed of metal electrodes and ionic polymers, and it generates force and movement in response to electricity. A polysulfonated covalent organic framework (pS-COF) made by combining organic molecules on the surface of the artificial muscle electrode was used to generate an impressive amount of force relative to its weight with ultra-low power (~0.01V).

As a result, the artificial muscle, which was manufactured to be as thin as a hair with a thickness of 180 µm, produced a force more than 34 times greater than its light weight of 10 mg to initiate smooth movement. Through this, the research team was able to precisely control the direction of fluid flow with low power.

< Figure 2. The synthesis and use of pS-COF as a common electrode-electrolyte host for electroactive soft fluid switches. A) The synthesis schematic of pS-COF. B) The schematic diagram of the operating principle of the electrochemical soft switch. C) The schematic diagram of using a pS-COF-based electrochemical soft switch to control fluid flow in dynamic operation. >

Professor IlKwon Oh, who led this research, said, “The electrochemical soft fluidic switch that operate at ultra-low power can open up many possibilities in the fields of soft robots, soft electronics, and microfluidics based on fluid control.” He added, “From smart fibers to biomedical devices, this technology has the potential to be immediately put to use in a variety of industrial settings as it can be easily applied to ultra-small electronic systems in our daily lives.”

The results of this study, in which Dr. Manmatha Mahato, a research professor in the Department of Mechanical Engineering at KAIST, participated as the first author, were published in the international academic journal Science Advances on December 13, 2023. (Paper title: Polysulfonated Covalent Organic Framework as Active Electrode Host for Mobile Cation Guests in Electrochemical Soft Actuator)

This research was conducted with support from the National Research Foundation of Korea's Leader Scientist Support Project (Creative Research Group) and Future Convergence Pioneer Project.

* Paper DOI: https://www.science.org/doi/abs/10.1126/sciadv.adk9752

2024.01.11 View 12069

KAIST develops an artificial muscle device that produces force 34 times its weight

- Professor IlKwon Oh’s research team in KAIST’s Department of Mechanical Engineering developed a soft fluidic switch using an ionic polymer artificial muscle that runs with ultra-low power to lift objects 34 times greater than its weight.

- Its light weight and small size make it applicable to various industrial fields such as soft electronics, smart textiles, and biomedical devices by controlling fluid flow with high precision, even in narrow spaces.

Soft robots, medical devices, and wearable devices have permeated our daily lives. KAIST researchers have developed a fluid switch using ionic polymer artificial muscles that operates at ultra-low power and produces a force 34 times greater than its weight. Fluid switches control fluid flow, causing the fluid to flow in a specific direction to invoke various movements.

KAIST (President Kwang-Hyung Lee) announced on the 4th of January that a research team under Professor IlKwon Oh from the Department of Mechanical Engineering has developed a soft fluidic switch that operates at ultra-low voltage and can be used in narrow spaces.

Artificial muscles imitate human muscles and provide flexible and natural movements compared to traditional motors, making them one of the basic elements used in soft robots, medical devices, and wearable devices. These artificial muscles create movements in response to external stimuli such as electricity, air pressure, and temperature changes, and in order to utilize artificial muscles, it is important to control these movements precisely.

Switches based on existing motors were difficult to use within limited spaces due to their rigidity and large size. In order to address these issues, the research team developed an electro-ionic soft actuator that can control fluid flow while producing large amounts of force, even in a narrow pipe, and used it as a soft fluidic switch.

< Figure 1. The separation of fluid droplets using a soft fluid switch at ultra-low voltage. >

The ionic polymer artificial muscle developed by the research team is composed of metal electrodes and ionic polymers, and it generates force and movement in response to electricity. A polysulfonated covalent organic framework (pS-COF) made by combining organic molecules on the surface of the artificial muscle electrode was used to generate an impressive amount of force relative to its weight with ultra-low power (~0.01V).

As a result, the artificial muscle, which was manufactured to be as thin as a hair with a thickness of 180 µm, produced a force more than 34 times greater than its light weight of 10 mg to initiate smooth movement. Through this, the research team was able to precisely control the direction of fluid flow with low power.

< Figure 2. The synthesis and use of pS-COF as a common electrode-electrolyte host for electroactive soft fluid switches. A) The synthesis schematic of pS-COF. B) The schematic diagram of the operating principle of the electrochemical soft switch. C) The schematic diagram of using a pS-COF-based electrochemical soft switch to control fluid flow in dynamic operation. >

Professor IlKwon Oh, who led this research, said, “The electrochemical soft fluidic switch that operate at ultra-low power can open up many possibilities in the fields of soft robots, soft electronics, and microfluidics based on fluid control.” He added, “From smart fibers to biomedical devices, this technology has the potential to be immediately put to use in a variety of industrial settings as it can be easily applied to ultra-small electronic systems in our daily lives.”

The results of this study, in which Dr. Manmatha Mahato, a research professor in the Department of Mechanical Engineering at KAIST, participated as the first author, were published in the international academic journal Science Advances on December 13, 2023. (Paper title: Polysulfonated Covalent Organic Framework as Active Electrode Host for Mobile Cation Guests in Electrochemical Soft Actuator)

This research was conducted with support from the National Research Foundation of Korea's Leader Scientist Support Project (Creative Research Group) and Future Convergence Pioneer Project.

* Paper DOI: https://www.science.org/doi/abs/10.1126/sciadv.adk9752

2024.01.11 View 12069 -

Researchers finds a way to reduce the overheating of semiconductor devices

The demand to shrink the size of semiconductors coupled with the problem of the heat generated at the hot spots of the devices not being effectively dispersed has negatively affected the reliability and durability of modern devices. Existing thermal management technologies have not been up to the task. Thus, the discovery of a new way of dispersing heat by using surface waves generated on the thin metal films over the substrate is an important breakthrough.

KAIST (President Kwang Hyung Lee) announced that Professor Bong Jae Lee's research team in the Department of Mechanical Engineering succeeded in measuring a newly observed transference of heat induced by 'surface plasmon polariton' (SPP) in a thin metal film deposited on a substrate for the first time in the world.

☞ Surface plasmon polariton (SPP) refers to a surface wave formed on the surface of a metal as a result of strong interaction between the electromagnetic field at the interface between the dielectric and the metal and the free electrons on the metal surface and similar collectively vibrating particles.

The research team utilized surface plasmon polaritons (SPP), which are surface waves generated at the metal-dielectric interface, to improve thermal diffusion in nanoscale thin metal films. Since this new heat transfer mode occurs when a thin film of metal is deposited on a substrate, it is highly usable in the device manufacturing process and has the advantage of being able to be manufactured over a large area. The research team showed that the thermal conductivity increased by about 25% due to surface waves generated over a 100-nm-thick titanium (Ti) film with a radius of about 3 cm.

KAIST Professor Bong Jae Lee, who led the research, said, "The significance of this research is that a new heat transfer mode using surface waves over a thin metal film deposited on a substrate with low processing difficulty was identified for the first time in the world. It can be applied as a nanoscale heat spreader to efficiently dissipate heat near the hot spots for easily overheatable semiconductor devices.”

The result has great implications for the development of high-performance semiconductor devices in the future in that it can be applied to rapidly dissipate heat on a nanoscale thin film. In particular, this new heat transfer mode identified by the research team is expected to solve the fundamental problem of thermal management in semiconductor devices as it enables even more effective heat transfer at nanoscale thickness while the thermal conductivity of the thin film usually decreases due to the boundary scattering effect.

This study was published online on April 26 in 'Physical Review Letters' and was selected as an Editors' Suggestion. The research was carried out with support from the Basic Research Laboratory Support Program of the National Research Foundation of Korea.

< Figure. Schematic diagram of the principle of measuring the thermal conductivity of thin Titanium (TI) films and the thermal conductivity of surface plasmon polariton measured on the Ti film >

2023.06.01 View 9629

Researchers finds a way to reduce the overheating of semiconductor devices

The demand to shrink the size of semiconductors coupled with the problem of the heat generated at the hot spots of the devices not being effectively dispersed has negatively affected the reliability and durability of modern devices. Existing thermal management technologies have not been up to the task. Thus, the discovery of a new way of dispersing heat by using surface waves generated on the thin metal films over the substrate is an important breakthrough.

KAIST (President Kwang Hyung Lee) announced that Professor Bong Jae Lee's research team in the Department of Mechanical Engineering succeeded in measuring a newly observed transference of heat induced by 'surface plasmon polariton' (SPP) in a thin metal film deposited on a substrate for the first time in the world.

☞ Surface plasmon polariton (SPP) refers to a surface wave formed on the surface of a metal as a result of strong interaction between the electromagnetic field at the interface between the dielectric and the metal and the free electrons on the metal surface and similar collectively vibrating particles.

The research team utilized surface plasmon polaritons (SPP), which are surface waves generated at the metal-dielectric interface, to improve thermal diffusion in nanoscale thin metal films. Since this new heat transfer mode occurs when a thin film of metal is deposited on a substrate, it is highly usable in the device manufacturing process and has the advantage of being able to be manufactured over a large area. The research team showed that the thermal conductivity increased by about 25% due to surface waves generated over a 100-nm-thick titanium (Ti) film with a radius of about 3 cm.

KAIST Professor Bong Jae Lee, who led the research, said, "The significance of this research is that a new heat transfer mode using surface waves over a thin metal film deposited on a substrate with low processing difficulty was identified for the first time in the world. It can be applied as a nanoscale heat spreader to efficiently dissipate heat near the hot spots for easily overheatable semiconductor devices.”

The result has great implications for the development of high-performance semiconductor devices in the future in that it can be applied to rapidly dissipate heat on a nanoscale thin film. In particular, this new heat transfer mode identified by the research team is expected to solve the fundamental problem of thermal management in semiconductor devices as it enables even more effective heat transfer at nanoscale thickness while the thermal conductivity of the thin film usually decreases due to the boundary scattering effect.

This study was published online on April 26 in 'Physical Review Letters' and was selected as an Editors' Suggestion. The research was carried out with support from the Basic Research Laboratory Support Program of the National Research Foundation of Korea.

< Figure. Schematic diagram of the principle of measuring the thermal conductivity of thin Titanium (TI) films and the thermal conductivity of surface plasmon polariton measured on the Ti film >

2023.06.01 View 9629 -

KAIST’s Robo-Dog “RaiBo” runs through the sandy beach

KAIST (President Kwang Hyung Lee) announced on the 25th that a research team led by Professor Jemin Hwangbo of the Department of Mechanical Engineering developed a quadrupedal robot control technology that can walk robustly with agility even in deformable terrain such as sandy beach.

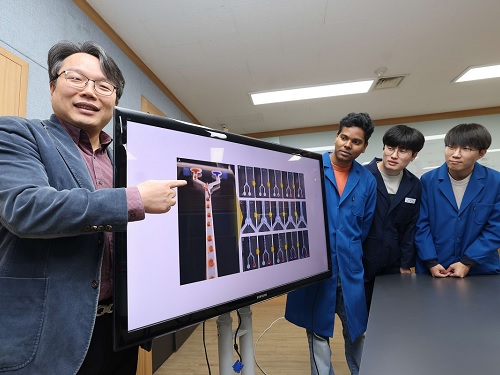

< Photo. RAI Lab Team with Professor Hwangbo in the middle of the back row. >

Professor Hwangbo's research team developed a technology to model the force received by a walking robot on the ground made of granular materials such as sand and simulate it via a quadrupedal robot. Also, the team worked on an artificial neural network structure which is suitable in making real-time decisions needed in adapting to various types of ground without prior information while walking at the same time and applied it on to reinforcement learning. The trained neural network controller is expected to expand the scope of application of quadrupedal walking robots by proving its robustness in changing terrain, such as the ability to move in high-speed even on a sandy beach and walk and turn on soft grounds like an air mattress without losing balance.

This research, with Ph.D. Student Soo-Young Choi of KAIST Department of Mechanical Engineering as the first author, was published in January in the “Science Robotics”. (Paper title: Learning quadrupedal locomotion on deformable terrain).

Reinforcement learning is an AI learning method used to create a machine that collects data on the results of various actions in an arbitrary situation and utilizes that set of data to perform a task. Because the amount of data required for reinforcement learning is so vast, a method of collecting data through simulations that approximates physical phenomena in the real environment is widely used.

In particular, learning-based controllers in the field of walking robots have been applied to real environments after learning through data collected in simulations to successfully perform walking controls in various terrains.

However, since the performance of the learning-based controller rapidly decreases when the actual environment has any discrepancy from the learned simulation environment, it is important to implement an environment similar to the real one in the data collection stage. Therefore, in order to create a learning-based controller that can maintain balance in a deforming terrain, the simulator must provide a similar contact experience.

The research team defined a contact model that predicted the force generated upon contact from the motion dynamics of a walking body based on a ground reaction force model that considered the additional mass effect of granular media defined in previous studies.

Furthermore, by calculating the force generated from one or several contacts at each time step, the deforming terrain was efficiently simulated.

The research team also introduced an artificial neural network structure that implicitly predicts ground characteristics by using a recurrent neural network that analyzes time-series data from the robot's sensors.

The learned controller was mounted on the robot 'RaiBo', which was built hands-on by the research team to show high-speed walking of up to 3.03 m/s on a sandy beach where the robot's feet were completely submerged in the sand. Even when applied to harder grounds, such as grassy fields, and a running track, it was able to run stably by adapting to the characteristics of the ground without any additional programming or revision to the controlling algorithm.

In addition, it rotated with stability at 1.54 rad/s (approximately 90° per second) on an air mattress and demonstrated its quick adaptability even in the situation in which the terrain suddenly turned soft.

The research team demonstrated the importance of providing a suitable contact experience during the learning process by comparison with a controller that assumed the ground to be rigid, and proved that the proposed recurrent neural network modifies the controller's walking method according to the ground properties.

The simulation and learning methodology developed by the research team is expected to contribute to robots performing practical tasks as it expands the range of terrains that various walking robots can operate on.

The first author, Suyoung Choi, said, “It has been shown that providing a learning-based controller with a close contact experience with real deforming ground is essential for application to deforming terrain.” He went on to add that “The proposed controller can be used without prior information on the terrain, so it can be applied to various robot walking studies.”

This research was carried out with the support of the Samsung Research Funding & Incubation Center of Samsung Electronics.

< Figure 1. Adaptability of the proposed controller to various ground environments. The controller learned from a wide range of randomized granular media simulations showed adaptability to various natural and artificial terrains, and demonstrated high-speed walking ability and energy efficiency. >

< Figure 2. Contact model definition for simulation of granular substrates. The research team used a model that considered the additional mass effect for the vertical force and a Coulomb friction model for the horizontal direction while approximating the contact with the granular medium as occurring at a point. Furthermore, a model that simulates the ground resistance that can occur on the side of the foot was introduced and used for simulation. >

2023.01.26 View 18496

KAIST’s Robo-Dog “RaiBo” runs through the sandy beach

KAIST (President Kwang Hyung Lee) announced on the 25th that a research team led by Professor Jemin Hwangbo of the Department of Mechanical Engineering developed a quadrupedal robot control technology that can walk robustly with agility even in deformable terrain such as sandy beach.

< Photo. RAI Lab Team with Professor Hwangbo in the middle of the back row. >

Professor Hwangbo's research team developed a technology to model the force received by a walking robot on the ground made of granular materials such as sand and simulate it via a quadrupedal robot. Also, the team worked on an artificial neural network structure which is suitable in making real-time decisions needed in adapting to various types of ground without prior information while walking at the same time and applied it on to reinforcement learning. The trained neural network controller is expected to expand the scope of application of quadrupedal walking robots by proving its robustness in changing terrain, such as the ability to move in high-speed even on a sandy beach and walk and turn on soft grounds like an air mattress without losing balance.

This research, with Ph.D. Student Soo-Young Choi of KAIST Department of Mechanical Engineering as the first author, was published in January in the “Science Robotics”. (Paper title: Learning quadrupedal locomotion on deformable terrain).

Reinforcement learning is an AI learning method used to create a machine that collects data on the results of various actions in an arbitrary situation and utilizes that set of data to perform a task. Because the amount of data required for reinforcement learning is so vast, a method of collecting data through simulations that approximates physical phenomena in the real environment is widely used.

In particular, learning-based controllers in the field of walking robots have been applied to real environments after learning through data collected in simulations to successfully perform walking controls in various terrains.

However, since the performance of the learning-based controller rapidly decreases when the actual environment has any discrepancy from the learned simulation environment, it is important to implement an environment similar to the real one in the data collection stage. Therefore, in order to create a learning-based controller that can maintain balance in a deforming terrain, the simulator must provide a similar contact experience.

The research team defined a contact model that predicted the force generated upon contact from the motion dynamics of a walking body based on a ground reaction force model that considered the additional mass effect of granular media defined in previous studies.

Furthermore, by calculating the force generated from one or several contacts at each time step, the deforming terrain was efficiently simulated.

The research team also introduced an artificial neural network structure that implicitly predicts ground characteristics by using a recurrent neural network that analyzes time-series data from the robot's sensors.

The learned controller was mounted on the robot 'RaiBo', which was built hands-on by the research team to show high-speed walking of up to 3.03 m/s on a sandy beach where the robot's feet were completely submerged in the sand. Even when applied to harder grounds, such as grassy fields, and a running track, it was able to run stably by adapting to the characteristics of the ground without any additional programming or revision to the controlling algorithm.

In addition, it rotated with stability at 1.54 rad/s (approximately 90° per second) on an air mattress and demonstrated its quick adaptability even in the situation in which the terrain suddenly turned soft.

The research team demonstrated the importance of providing a suitable contact experience during the learning process by comparison with a controller that assumed the ground to be rigid, and proved that the proposed recurrent neural network modifies the controller's walking method according to the ground properties.

The simulation and learning methodology developed by the research team is expected to contribute to robots performing practical tasks as it expands the range of terrains that various walking robots can operate on.

The first author, Suyoung Choi, said, “It has been shown that providing a learning-based controller with a close contact experience with real deforming ground is essential for application to deforming terrain.” He went on to add that “The proposed controller can be used without prior information on the terrain, so it can be applied to various robot walking studies.”

This research was carried out with the support of the Samsung Research Funding & Incubation Center of Samsung Electronics.

< Figure 1. Adaptability of the proposed controller to various ground environments. The controller learned from a wide range of randomized granular media simulations showed adaptability to various natural and artificial terrains, and demonstrated high-speed walking ability and energy efficiency. >

< Figure 2. Contact model definition for simulation of granular substrates. The research team used a model that considered the additional mass effect for the vertical force and a Coulomb friction model for the horizontal direction while approximating the contact with the granular medium as occurring at a point. Furthermore, a model that simulates the ground resistance that can occur on the side of the foot was introduced and used for simulation. >

2023.01.26 View 18496 -

A Quick but Clingy Creepy-Crawler that will MARVEL You

Engineered by KAIST Mechanics, a quadrupedal robot climbs steel walls and crawls across metal ceilings at the fastest speed that the world has ever seen.

< Photo 1. (From left) KAIST ME Prof. Hae-Won Park, Ph.D. Student Yong Um, Ph.D. Student Seungwoo Hong >

- Professor Hae-Won Park's team at the Department of Mechanical Engineering developed a quadrupedal robot that can move at a high speed on ferrous walls and ceilings.

- It is expected to make a wide variety of contributions as it is to be used to conduct inspections and repairs of large steel structures such as ships, bridges, and transmission towers, offering an alternative to dangerous or risky activities required in hazardous environments while maintaining productivity and efficiency through automation and unmanning of such operations.

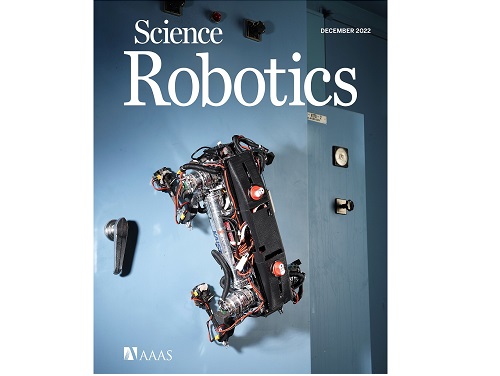

- The study was published as the cover paper of the December issue of Science Robotics.

KAIST (President Kwang Hyung Lee) announced on the 26th that a research team led by Professor Hae-Won Park of the Department of Mechanical Engineering developed a quadrupedal walking robot that can move at high speed on steel walls and ceilings named M.A.R.V.E.L. - rightly so as it is a Magnetically Adhesive Robot for Versatile and Expeditious Locomotion as described in their paper, “Agile and Versatile Climbing on Ferromagnetic Surfaces with a Quadrupedal Robot.” (DOI: 10.1126/scirobotics.add1017)

To make this happen, Professor Park's research team developed a foot pad that can quickly turn the magnetic adhesive force on and off while retaining high adhesive force even on an uneven surface through the use of the Electro-Permanent Magnet (EPM), a device that can magnetize and demagnetize an electromagnet with little power, and the Magneto-Rheological Elastomer (MRE), an elastic material made by mixing a magnetic response factor, such as iron powder, with an elastic material, such as rubber, which they mounted on a small quadrupedal robot they made in-house, at their own laboratory. These walking robots are expected to be put into a wide variety of usage, including being programmed to perform inspections, repairs, and maintenance tasks on large structures made of steel, such as ships, bridges, transmission towers, large storage areas, and construction sites.

This study, in which Seungwoo Hong and Yong Um of the Department of Mechanical Engineering participated as co-first authors, was published as the cover paper in the December issue of Science Robotics.

< Image on the Cover of 2022 December issue of Science Robotics >

Existing wall-climbing robots use wheels or endless tracks, so their mobility is limited on surfaces with steps or irregularities. On the other hand, walking robots for climbing can expect improved mobility in obstacle terrain, but have disadvantages in that they have significantly slower moving speeds or cannot perform various movements.

In order to enable fast movement of the walking robot, the sole of the foot must have strong adhesion force and be able to control the adhesion to quickly switch from sticking to the surface or to be off of it. In addition, it is necessary to maintain the adhesion force even on a rough or uneven surface.

To solve this problem, the research team used the EPM and MRE for the first time in designing the soles of walking robots. An EPM is a magnet that can turn on and off the electromagnetic force with a short current pulse. Unlike general electromagnets, it has the advantage that it does not require energy to maintain the magnetic force. The research team proposed a new EPM with a rectangular structure arrangement, enabling faster switching while significantly lowering the voltage required for switching compared to existing electromagnets.

In addition, the research team was able to increase the frictional force without significantly reducing the magnetic force of the sole by covering the sole with an MRE. The proposed sole weighs only 169 g, but provides a vertical gripping force of about *535 Newtons (N) and a frictional force of 445 N, which is sufficient gripping force for a quadrupedal robot weighing 8 kg.

* 535 N converted to kg is 54.5 kg, and 445 N is 45.4 kg. In other words, even if an external force of up to 54.5 kg in the vertical direction and up to 45.4 kg in the horizontal direction is applied (or even if a corresponding weight is hung), the sole of the foot does not come off the steel plate.

MARVEL climbed up a vertical wall at high speed at a speed of 70 cm per second, and was able to walk while hanging upside down from the ceiling at a maximum speed of 50 cm per second. This is the world's fastest speed for a walking climbing robot. In addition, the research team demonstrated that the robot can climb at a speed of up to 35 cm even on a surface that is painted, dirty with dust and the rust-tainted surfaces of water tanks, proving the robot's performance in a real environment. It was experimentally demonstrated that the robot not only exhibited high speed, but also can switch from floor to wall and from wall to ceiling, and overcome 5-cm high obstacles protruding from walls without difficulty.

The new climbing quadrupedal robot is expected to be widely used for inspection, repair, and maintenance of large steel structures such as ships, bridges, transmission towers, oil pipelines, large storage areas, and construction sites. As the works required in these places involves risks such as falls, suffocation and other accidents that may result in serious injuries or casualties, the need for automation is of utmost urgency.

One of the first co-authors of the paper, a Ph.D. student, Yong Um of KAIST’s Department of Mechanical Engineering, said, "By the use of the magnetic soles made up of the EPM and MRE and the non-linear model predictive controller suitable for climbing, the robot can speedily move through a variety of ferromagnetic surfaces including walls and ceilings, not just level grounds. We believe this would become a cornerstone that will expand the mobility and the places of pedal-mobile robots can venture into." He added, “These robots can be put into good use in executing dangerous and difficult tasks on steel structures in places like the shipbuilding yards.”

This research was carried out with support from the National Research Foundation of Korea's Basic Research in Science & Engineering Program for Mid-Career Researchers and Korea Shipbuilding & Offshore Engineering Co., Ltd..

< Figure 1. The quadrupedal robot (MARVEL) walking over various ferrous surfaces. (A) vertical wall (B) ceiling. (C) over obstacles on a vertical wall (D) making floor-to-wall and wall-to-ceiling transitions (E) moving over a storage tank (F) walking on a wall with a 2-kg weight and over a ceiling with a 3-kg load. >

< Figure 2. Description of the magnetic foot (A) Components of the magnet sole: ankle, Square Eletro-Permanent Magnet(S-EPM), MRE footpad. (B) Components of the S-EPM and MRE footpad. (C) Working principle of the S-EPM. When the magnetization direction is aligned as shown in the left figure, magnetic flux comes out of the keeper and circulates through the steel plate, generating holding force (ON state). Conversely, if the magnetization direction is aligned as shown in the figure on the right, the magnetic flux circulates inside the S-EPM and the holding force disappears (OFF state). >

Video Introduction: Agile and versatile climbing on ferromagnetic surfaces with a quadrupedal robot - YouTube

2022.12.30 View 20133

A Quick but Clingy Creepy-Crawler that will MARVEL You

Engineered by KAIST Mechanics, a quadrupedal robot climbs steel walls and crawls across metal ceilings at the fastest speed that the world has ever seen.

< Photo 1. (From left) KAIST ME Prof. Hae-Won Park, Ph.D. Student Yong Um, Ph.D. Student Seungwoo Hong >

- Professor Hae-Won Park's team at the Department of Mechanical Engineering developed a quadrupedal robot that can move at a high speed on ferrous walls and ceilings.

- It is expected to make a wide variety of contributions as it is to be used to conduct inspections and repairs of large steel structures such as ships, bridges, and transmission towers, offering an alternative to dangerous or risky activities required in hazardous environments while maintaining productivity and efficiency through automation and unmanning of such operations.

- The study was published as the cover paper of the December issue of Science Robotics.

KAIST (President Kwang Hyung Lee) announced on the 26th that a research team led by Professor Hae-Won Park of the Department of Mechanical Engineering developed a quadrupedal walking robot that can move at high speed on steel walls and ceilings named M.A.R.V.E.L. - rightly so as it is a Magnetically Adhesive Robot for Versatile and Expeditious Locomotion as described in their paper, “Agile and Versatile Climbing on Ferromagnetic Surfaces with a Quadrupedal Robot.” (DOI: 10.1126/scirobotics.add1017)

To make this happen, Professor Park's research team developed a foot pad that can quickly turn the magnetic adhesive force on and off while retaining high adhesive force even on an uneven surface through the use of the Electro-Permanent Magnet (EPM), a device that can magnetize and demagnetize an electromagnet with little power, and the Magneto-Rheological Elastomer (MRE), an elastic material made by mixing a magnetic response factor, such as iron powder, with an elastic material, such as rubber, which they mounted on a small quadrupedal robot they made in-house, at their own laboratory. These walking robots are expected to be put into a wide variety of usage, including being programmed to perform inspections, repairs, and maintenance tasks on large structures made of steel, such as ships, bridges, transmission towers, large storage areas, and construction sites.

This study, in which Seungwoo Hong and Yong Um of the Department of Mechanical Engineering participated as co-first authors, was published as the cover paper in the December issue of Science Robotics.

< Image on the Cover of 2022 December issue of Science Robotics >

Existing wall-climbing robots use wheels or endless tracks, so their mobility is limited on surfaces with steps or irregularities. On the other hand, walking robots for climbing can expect improved mobility in obstacle terrain, but have disadvantages in that they have significantly slower moving speeds or cannot perform various movements.

In order to enable fast movement of the walking robot, the sole of the foot must have strong adhesion force and be able to control the adhesion to quickly switch from sticking to the surface or to be off of it. In addition, it is necessary to maintain the adhesion force even on a rough or uneven surface.

To solve this problem, the research team used the EPM and MRE for the first time in designing the soles of walking robots. An EPM is a magnet that can turn on and off the electromagnetic force with a short current pulse. Unlike general electromagnets, it has the advantage that it does not require energy to maintain the magnetic force. The research team proposed a new EPM with a rectangular structure arrangement, enabling faster switching while significantly lowering the voltage required for switching compared to existing electromagnets.

In addition, the research team was able to increase the frictional force without significantly reducing the magnetic force of the sole by covering the sole with an MRE. The proposed sole weighs only 169 g, but provides a vertical gripping force of about *535 Newtons (N) and a frictional force of 445 N, which is sufficient gripping force for a quadrupedal robot weighing 8 kg.

* 535 N converted to kg is 54.5 kg, and 445 N is 45.4 kg. In other words, even if an external force of up to 54.5 kg in the vertical direction and up to 45.4 kg in the horizontal direction is applied (or even if a corresponding weight is hung), the sole of the foot does not come off the steel plate.

MARVEL climbed up a vertical wall at high speed at a speed of 70 cm per second, and was able to walk while hanging upside down from the ceiling at a maximum speed of 50 cm per second. This is the world's fastest speed for a walking climbing robot. In addition, the research team demonstrated that the robot can climb at a speed of up to 35 cm even on a surface that is painted, dirty with dust and the rust-tainted surfaces of water tanks, proving the robot's performance in a real environment. It was experimentally demonstrated that the robot not only exhibited high speed, but also can switch from floor to wall and from wall to ceiling, and overcome 5-cm high obstacles protruding from walls without difficulty.

The new climbing quadrupedal robot is expected to be widely used for inspection, repair, and maintenance of large steel structures such as ships, bridges, transmission towers, oil pipelines, large storage areas, and construction sites. As the works required in these places involves risks such as falls, suffocation and other accidents that may result in serious injuries or casualties, the need for automation is of utmost urgency.

One of the first co-authors of the paper, a Ph.D. student, Yong Um of KAIST’s Department of Mechanical Engineering, said, "By the use of the magnetic soles made up of the EPM and MRE and the non-linear model predictive controller suitable for climbing, the robot can speedily move through a variety of ferromagnetic surfaces including walls and ceilings, not just level grounds. We believe this would become a cornerstone that will expand the mobility and the places of pedal-mobile robots can venture into." He added, “These robots can be put into good use in executing dangerous and difficult tasks on steel structures in places like the shipbuilding yards.”

This research was carried out with support from the National Research Foundation of Korea's Basic Research in Science & Engineering Program for Mid-Career Researchers and Korea Shipbuilding & Offshore Engineering Co., Ltd..

< Figure 1. The quadrupedal robot (MARVEL) walking over various ferrous surfaces. (A) vertical wall (B) ceiling. (C) over obstacles on a vertical wall (D) making floor-to-wall and wall-to-ceiling transitions (E) moving over a storage tank (F) walking on a wall with a 2-kg weight and over a ceiling with a 3-kg load. >

< Figure 2. Description of the magnetic foot (A) Components of the magnet sole: ankle, Square Eletro-Permanent Magnet(S-EPM), MRE footpad. (B) Components of the S-EPM and MRE footpad. (C) Working principle of the S-EPM. When the magnetization direction is aligned as shown in the left figure, magnetic flux comes out of the keeper and circulates through the steel plate, generating holding force (ON state). Conversely, if the magnetization direction is aligned as shown in the figure on the right, the magnetic flux circulates inside the S-EPM and the holding force disappears (OFF state). >

Video Introduction: Agile and versatile climbing on ferromagnetic surfaces with a quadrupedal robot - YouTube

2022.12.30 View 20133 -

A KAIST Research Team Develops Diesel Reforming Catalyst Enabling Hydrogen Production for Future Mobile Fuel Cells

This catalyst capability allowing stable hydrogen production from commercial diesel is expected to be applied in mobile fuel cell systems in the future hydrogen economy

On August 16, a joint research team led by Professors Joongmyeon Bae and Kang Taek Lee of KAIST’s Department of Mechanical Engineering and Dr. Chan-Woo Lee of Korea Institute of Energy Research (KIER) announced the successful development of a highly active and durable reforming catalyst allowing hydrogen production from commercial diesel.

Fuel reforming is a hydrogen production technique that extracts hydrogen from hydrocarbons through catalytic reactions. Diesel, being a liquid fuel, has a high storage density for hydrogen and is easy to transport and store. There have therefore been continuous research efforts to apply hydrogel supply systems using diesel reformation in mobile fuel cells, such as for auxiliary power in heavy trucks or air-independent propulsion (AIP) systems in submarines.

However, diesel is a mixture of high hydrocarbons including long-chained paraffin, double-bonded olefin, and aromatic hydrocarbons with benzene groups, and it requires a highly active catalyst to effectively break them down. In addition, the catalyst must be extremely durable against caulking and sintering, as they are often the main causes of catalyst degradation. Such challenges have limited the use of diesel reformation technologies to date.

The joint research team successfully developed a highly active and durable diesel reforming catalyst through elution (a heat treatment method used to uniformly grow active metals retained in an oxide support as ions in the form of metal nanoparticles), forming alloy nanoparticles. The design was based on the fact that eluted nanoparticles strongly interact with the support, allowing a high degree of dispersion at high temperatures, and that producing an alloy from dissimilar metals can increase the performance of catalysts through a synergistic effect.

The research team introduced a solution combustion synthesis method to produce a multi-component catalyst with a trace amount of platinum (Pt) and ruthenium (Ru) penetrated into a ceria (CeO2) lattice, which is a structure commonly used as a support for catalysts in redox reactions. When exposed to a diesel reforming reaction environment, the catalyst induces Pt-Ru alloy nanoparticle formation upon Pt and Ru elution onto the support surface.

In addition to the catalyst analysis, the research team also succeeded in characterizing the behaviour of active metal elution and alloy formation from an energetic perspective using a density functional theory-based calculation. In a performance comparison test between the Pt-Ru alloy catalyst against existing single-metal catalysts, the reforming activity was shown to have improved, as it showed a 100% fuel conversion rate even at a low temperature (600oC, compared to the original 800oC). In a long-term durability test (800oC, 200 hours), the catalyst showed commercial stability by successfully producing hydrogen from commercial diesel without performance degradation.

The study was conducted by Ph.D. candidate Jaemyung Lee of KAIST’s Department of Mechanical Engineering as the first author. Ph.D. candidate Changho Yeon of KIER, Dr. Jiwoo Oh of KAIST’s Department of Mechanical Engineering, Dr. Gwangwoo Han of KIER, Ph.D. candidate Jeong Do Yoo of KAIST’s Department of Mechanical Engineering, and Dr. Hyung Joong Yun of the Korea Basic Science Institute contributed as co-authors. Dr. Chan-Woo Lee of KIER and Professors Kang Taek Lee and Joongmyeon Bae of KAIST’s Department of Mechanical Engineering contributed as corresponding authors. The research was published in the online version of Applied Catalysis B: Environmental (IF 24.319, JCR 0.93%) on June 17, under the title “Highly Active and Stable Catalyst with Exsolved PtRu Alloy Nanoparticles for Hydrogen Production via Commercial Diesel Reforming”.

Professor Joongmyeon Bae said, “The fact that hydrogen can be stably produced from commercial diesel makes this a very meaningful achievement, and we look forward to this technology contributing to the active introduction of mobile fuel cell systems in the early hydrogen economy.” He added, “Our approach to catalyst design may be applied not only to reforming reactions, but also in various other fields.”

This research was supported by the National Research Foundation of Korea through funding from the Ministry of Science, ICT and Future Planning.

Figure. Schematic diagram of high-performance diesel reforming catalyst with eluted platinum-ruthenium alloy nanoparticles and long-term durability verification experiment results for commercial diesel reforming reaction

2022.09.07 View 16750

A KAIST Research Team Develops Diesel Reforming Catalyst Enabling Hydrogen Production for Future Mobile Fuel Cells

This catalyst capability allowing stable hydrogen production from commercial diesel is expected to be applied in mobile fuel cell systems in the future hydrogen economy

On August 16, a joint research team led by Professors Joongmyeon Bae and Kang Taek Lee of KAIST’s Department of Mechanical Engineering and Dr. Chan-Woo Lee of Korea Institute of Energy Research (KIER) announced the successful development of a highly active and durable reforming catalyst allowing hydrogen production from commercial diesel.

Fuel reforming is a hydrogen production technique that extracts hydrogen from hydrocarbons through catalytic reactions. Diesel, being a liquid fuel, has a high storage density for hydrogen and is easy to transport and store. There have therefore been continuous research efforts to apply hydrogel supply systems using diesel reformation in mobile fuel cells, such as for auxiliary power in heavy trucks or air-independent propulsion (AIP) systems in submarines.

However, diesel is a mixture of high hydrocarbons including long-chained paraffin, double-bonded olefin, and aromatic hydrocarbons with benzene groups, and it requires a highly active catalyst to effectively break them down. In addition, the catalyst must be extremely durable against caulking and sintering, as they are often the main causes of catalyst degradation. Such challenges have limited the use of diesel reformation technologies to date.

The joint research team successfully developed a highly active and durable diesel reforming catalyst through elution (a heat treatment method used to uniformly grow active metals retained in an oxide support as ions in the form of metal nanoparticles), forming alloy nanoparticles. The design was based on the fact that eluted nanoparticles strongly interact with the support, allowing a high degree of dispersion at high temperatures, and that producing an alloy from dissimilar metals can increase the performance of catalysts through a synergistic effect.

The research team introduced a solution combustion synthesis method to produce a multi-component catalyst with a trace amount of platinum (Pt) and ruthenium (Ru) penetrated into a ceria (CeO2) lattice, which is a structure commonly used as a support for catalysts in redox reactions. When exposed to a diesel reforming reaction environment, the catalyst induces Pt-Ru alloy nanoparticle formation upon Pt and Ru elution onto the support surface.

In addition to the catalyst analysis, the research team also succeeded in characterizing the behaviour of active metal elution and alloy formation from an energetic perspective using a density functional theory-based calculation. In a performance comparison test between the Pt-Ru alloy catalyst against existing single-metal catalysts, the reforming activity was shown to have improved, as it showed a 100% fuel conversion rate even at a low temperature (600oC, compared to the original 800oC). In a long-term durability test (800oC, 200 hours), the catalyst showed commercial stability by successfully producing hydrogen from commercial diesel without performance degradation.

The study was conducted by Ph.D. candidate Jaemyung Lee of KAIST’s Department of Mechanical Engineering as the first author. Ph.D. candidate Changho Yeon of KIER, Dr. Jiwoo Oh of KAIST’s Department of Mechanical Engineering, Dr. Gwangwoo Han of KIER, Ph.D. candidate Jeong Do Yoo of KAIST’s Department of Mechanical Engineering, and Dr. Hyung Joong Yun of the Korea Basic Science Institute contributed as co-authors. Dr. Chan-Woo Lee of KIER and Professors Kang Taek Lee and Joongmyeon Bae of KAIST’s Department of Mechanical Engineering contributed as corresponding authors. The research was published in the online version of Applied Catalysis B: Environmental (IF 24.319, JCR 0.93%) on June 17, under the title “Highly Active and Stable Catalyst with Exsolved PtRu Alloy Nanoparticles for Hydrogen Production via Commercial Diesel Reforming”.

Professor Joongmyeon Bae said, “The fact that hydrogen can be stably produced from commercial diesel makes this a very meaningful achievement, and we look forward to this technology contributing to the active introduction of mobile fuel cell systems in the early hydrogen economy.” He added, “Our approach to catalyst design may be applied not only to reforming reactions, but also in various other fields.”

This research was supported by the National Research Foundation of Korea through funding from the Ministry of Science, ICT and Future Planning.

Figure. Schematic diagram of high-performance diesel reforming catalyst with eluted platinum-ruthenium alloy nanoparticles and long-term durability verification experiment results for commercial diesel reforming reaction

2022.09.07 View 16750 -

Now You Can See Floral Scents!

Optical interferometry visualizes how often lilies emit volatile organic compounds

Have you ever thought about when flowers emit their scents?

KAIST mechanical engineers and biological scientists directly visualized how often a lily releases a floral scent using a laser interferometry method. These measurement results can provide new insights for understanding and further exploring the biosynthesis and emission mechanisms of floral volatiles.

Why is it important to know this? It is well known that the fragrance of flowers affects their interactions with pollinators, microorganisms, and florivores. For instance, many flowering plants can tune their scent emission rates when pollinators are active for pollination. Petunias and the wild tobacco Nicotiana attenuata emit floral scents at night to attract night-active pollinators. Thus, visualizing scent emissions can help us understand the ecological evolution of plant-pollinator interactions.

Many groups have been trying to develop methods for scent analysis. Mass spectrometry has been one widely used method for investigating the fragrance of flowers. Although mass spectrometry reveals the quality and quantity of floral scents, it is impossible to directly measure the releasing frequency. A laser-based gas detection system and a smartphone-based detection system using chemo-responsive dyes have also been used to measure volatile organic compounds (VOCs) in real-time, but it is still hard to measure the time-dependent emission rate of floral scents.

However, the KAIST research team co-led by Professor Hyoungsoo Kim from the Department of Mechanical Engineering and Professor Sang-Gyu Kim from the Department of Biological Sciences measured a refractive index difference between the vapor of the VOCs of lilies and the air to measure the emission frequency. The floral scent vapor was detected and the refractive index of air was 1.0 while that of the major floral scent of a linalool lily was 1.46.

Professor Hyoungsoo Kim said, “We expect this technology to be further applicable to various industrial sectors such as developing it to detect hazardous substances in a space.” The research team also plans to identify the DNA mechanism that controls floral scent secretion.

The current work entitled “Real-time visualization of scent accumulation reveals the frequency of floral scent emissions” was published in ‘Frontiers in Plant Science’ on April 18, 2022. (https://doi.org/10.3389/fpls.2022.835305).

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF-2021R1A2C2007835), the Rural Development Administration (PJ016403), and the KAIST-funded Global Singularity Research PREP-Program.

-Publication:H. Kim, G. Lee, J. Song, and S.-G. Kim, "Real-time visualization of scent accumulation reveals the frequency of floral scent emissions," Frontiers in Plant Science 18, 835305 (2022) (https://doi.org/10.3389/fpls.2022.835305)

-Profile:Professor Hyoungsoo Kimhttp://fil.kaist.ac.kr

@MadeInH on TwitterDepartment of Mechanical EngineeringKAIST

Professor Sang-Gyu Kimhttps://sites.google.com/view/kimlab/home Department of Biological SciencesKAIST

2022.05.25 View 11784

Now You Can See Floral Scents!

Optical interferometry visualizes how often lilies emit volatile organic compounds

Have you ever thought about when flowers emit their scents?

KAIST mechanical engineers and biological scientists directly visualized how often a lily releases a floral scent using a laser interferometry method. These measurement results can provide new insights for understanding and further exploring the biosynthesis and emission mechanisms of floral volatiles.

Why is it important to know this? It is well known that the fragrance of flowers affects their interactions with pollinators, microorganisms, and florivores. For instance, many flowering plants can tune their scent emission rates when pollinators are active for pollination. Petunias and the wild tobacco Nicotiana attenuata emit floral scents at night to attract night-active pollinators. Thus, visualizing scent emissions can help us understand the ecological evolution of plant-pollinator interactions.

Many groups have been trying to develop methods for scent analysis. Mass spectrometry has been one widely used method for investigating the fragrance of flowers. Although mass spectrometry reveals the quality and quantity of floral scents, it is impossible to directly measure the releasing frequency. A laser-based gas detection system and a smartphone-based detection system using chemo-responsive dyes have also been used to measure volatile organic compounds (VOCs) in real-time, but it is still hard to measure the time-dependent emission rate of floral scents.

However, the KAIST research team co-led by Professor Hyoungsoo Kim from the Department of Mechanical Engineering and Professor Sang-Gyu Kim from the Department of Biological Sciences measured a refractive index difference between the vapor of the VOCs of lilies and the air to measure the emission frequency. The floral scent vapor was detected and the refractive index of air was 1.0 while that of the major floral scent of a linalool lily was 1.46.

Professor Hyoungsoo Kim said, “We expect this technology to be further applicable to various industrial sectors such as developing it to detect hazardous substances in a space.” The research team also plans to identify the DNA mechanism that controls floral scent secretion.

The current work entitled “Real-time visualization of scent accumulation reveals the frequency of floral scent emissions” was published in ‘Frontiers in Plant Science’ on April 18, 2022. (https://doi.org/10.3389/fpls.2022.835305).

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF-2021R1A2C2007835), the Rural Development Administration (PJ016403), and the KAIST-funded Global Singularity Research PREP-Program.

-Publication:H. Kim, G. Lee, J. Song, and S.-G. Kim, "Real-time visualization of scent accumulation reveals the frequency of floral scent emissions," Frontiers in Plant Science 18, 835305 (2022) (https://doi.org/10.3389/fpls.2022.835305)

-Profile:Professor Hyoungsoo Kimhttp://fil.kaist.ac.kr

@MadeInH on TwitterDepartment of Mechanical EngineeringKAIST

Professor Sang-Gyu Kimhttps://sites.google.com/view/kimlab/home Department of Biological SciencesKAIST

2022.05.25 View 11784 -

Thermal Superconductor Lab Becomes the 7th Cross-Generation Collaborative Lab

The Thermal Superconductor Lab led by Senior Professor Sung Jin Kim from the Department of Mechanical Engineering will team up with Junior Professor Youngsuk Nam to develop next-generation superconductors. The two professor team was selected as the 7th Cross-Generation Collaborative Lab last week and will sustain the academic legacy of Professor Kim’s three decades of research on superconductors. The team will continue to develop thin, next-generation superconductors that carry super thermal conductivity using phase transition control technology and thin film packaging.

Thin-filmed, next-generation superconductors can be used in various high-temperature flexible electronic devices. The superconductors built inside of the semiconductor device packages will also be used for managing the low-powered but high-performance temperatures of semiconductor and electronic equipment.

Professor Kim said, “I am very pleased that my research, know-how, and knowledge from over 30 years of work will continue through the Cross-Generation Collaborative Lab system with Professor Nam. We will spare no effort to advance superconductor technology and play a part in KAIST leading global technology fields.” Junior Professor Nam also stressed that the team is excited to continue its research on crucial technology for managing the temperatures of semiconductors and other electronic equipment.

KAIST started this innovative research system in 2018, and in 2021 it established the steering committee to select new labs based on: originality, differentiation, and excellence; academic, social, economic impact; the urgency of cross-generation research; the senior professor’s academic excellence and international reputation; and the senior professor’s research vision. Selected labs receive 500 million KRW in research funding over five years.

2022.01.27 View 7854

Thermal Superconductor Lab Becomes the 7th Cross-Generation Collaborative Lab

The Thermal Superconductor Lab led by Senior Professor Sung Jin Kim from the Department of Mechanical Engineering will team up with Junior Professor Youngsuk Nam to develop next-generation superconductors. The two professor team was selected as the 7th Cross-Generation Collaborative Lab last week and will sustain the academic legacy of Professor Kim’s three decades of research on superconductors. The team will continue to develop thin, next-generation superconductors that carry super thermal conductivity using phase transition control technology and thin film packaging.

Thin-filmed, next-generation superconductors can be used in various high-temperature flexible electronic devices. The superconductors built inside of the semiconductor device packages will also be used for managing the low-powered but high-performance temperatures of semiconductor and electronic equipment.

Professor Kim said, “I am very pleased that my research, know-how, and knowledge from over 30 years of work will continue through the Cross-Generation Collaborative Lab system with Professor Nam. We will spare no effort to advance superconductor technology and play a part in KAIST leading global technology fields.” Junior Professor Nam also stressed that the team is excited to continue its research on crucial technology for managing the temperatures of semiconductors and other electronic equipment.

KAIST started this innovative research system in 2018, and in 2021 it established the steering committee to select new labs based on: originality, differentiation, and excellence; academic, social, economic impact; the urgency of cross-generation research; the senior professor’s academic excellence and international reputation; and the senior professor’s research vision. Selected labs receive 500 million KRW in research funding over five years.

2022.01.27 View 7854 -

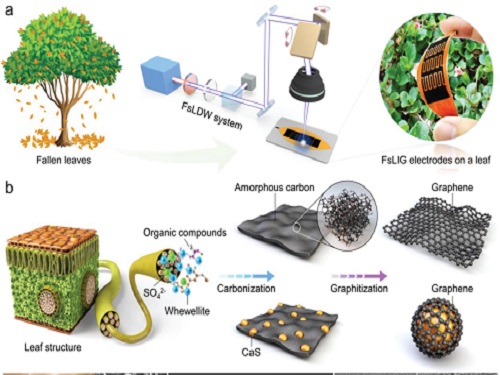

Eco-Friendly Micro-Supercapacitors Using Fallen Leaves

Green micro-supercapacitors on a single leaf could easily be applied in wearable electronics, smart houses, and IoTs

A KAIST research team has developed graphene-inorganic-hybrid micro-supercapacitors made of fallen leaves using femtosecond laser direct writing. The rapid development of wearable electronics requires breakthrough innovations in flexible energy storage devices in which micro-supercapacitors have drawn a great deal of interest due to their high power density, long lifetimes, and short charging times. Recently, there has been an enormous increase in waste batteries owing to the growing demand and the shortened replacement cycle in consumer electronics. The safety and environmental issues involved in the collection, recycling, and processing of such waste batteries are creating a number of challenges.

Forests cover about 30 percent of the Earth’s surface and produce a huge amount of fallen leaves. This naturally occurring biomass comes in large quantities and is completely biodegradable, which makes it an attractive sustainable resource. Nevertheless, if the fallen leaves are left neglected instead of being used efficiently, they can contribute to fire hazards, air pollution, and global warming.

To solve both problems at once, a research team led by Professor Young-Jin Kim from the Department of Mechanical Engineering and Dr. Hana Yoon from the Korea Institute of Energy Research developed a novel technology that can create 3D porous graphene microelectrodes with high electrical conductivity by irradiating femtosecond laser pulses on the leaves in ambient air. This one-step fabrication does not require any additional materials or pre-treatment.

They showed that this technique could quickly and easily produce porous graphene electrodes at a low price, and demonstrated potential applications by fabricating graphene micro-supercapacitors to power an LED and an electronic watch. These results open up a new possibility for the mass production of flexible and green graphene-based electronic devices.

Professor Young-Jin Kim said, “Leaves create forest biomass that comes in unmanageable quantities, so using them for next-generation energy storage devices makes it possible for us to reuse waste resources, thereby establishing a virtuous cycle.”

This research was published in Advanced Functional Materials last month and was sponsored by the Ministry of Agriculture Food and Rural Affairs, the Korea Forest Service, and the Korea Institute of Energy Research.

-Publication

Truong-Son Dinh Le, Yeong A. Lee, Han Ku Nam, Kyu Yeon Jang, Dongwook Yang, Byunggi Kim, Kanghoon Yim, Seung Woo Kim, Hana Yoon, and Young-jin Kim, “Green Flexible Graphene-Inorganic-Hybrid Micro-Supercapacitors Made of Fallen Leaves Enabled by Ultrafast Laser Pulses," December 05, 2021, Advanced Functional Materials (doi.org/10.1002/adfm.202107768)

-ProfileProfessor Young-Jin KimUltra-Precision Metrology and Manufacturing (UPM2) LaboratoryDepartment of Mechanical EngineeringKAIST

2022.01.27 View 14675

Eco-Friendly Micro-Supercapacitors Using Fallen Leaves

Green micro-supercapacitors on a single leaf could easily be applied in wearable electronics, smart houses, and IoTs

A KAIST research team has developed graphene-inorganic-hybrid micro-supercapacitors made of fallen leaves using femtosecond laser direct writing. The rapid development of wearable electronics requires breakthrough innovations in flexible energy storage devices in which micro-supercapacitors have drawn a great deal of interest due to their high power density, long lifetimes, and short charging times. Recently, there has been an enormous increase in waste batteries owing to the growing demand and the shortened replacement cycle in consumer electronics. The safety and environmental issues involved in the collection, recycling, and processing of such waste batteries are creating a number of challenges.

Forests cover about 30 percent of the Earth’s surface and produce a huge amount of fallen leaves. This naturally occurring biomass comes in large quantities and is completely biodegradable, which makes it an attractive sustainable resource. Nevertheless, if the fallen leaves are left neglected instead of being used efficiently, they can contribute to fire hazards, air pollution, and global warming.

To solve both problems at once, a research team led by Professor Young-Jin Kim from the Department of Mechanical Engineering and Dr. Hana Yoon from the Korea Institute of Energy Research developed a novel technology that can create 3D porous graphene microelectrodes with high electrical conductivity by irradiating femtosecond laser pulses on the leaves in ambient air. This one-step fabrication does not require any additional materials or pre-treatment.

They showed that this technique could quickly and easily produce porous graphene electrodes at a low price, and demonstrated potential applications by fabricating graphene micro-supercapacitors to power an LED and an electronic watch. These results open up a new possibility for the mass production of flexible and green graphene-based electronic devices.

Professor Young-Jin Kim said, “Leaves create forest biomass that comes in unmanageable quantities, so using them for next-generation energy storage devices makes it possible for us to reuse waste resources, thereby establishing a virtuous cycle.”

This research was published in Advanced Functional Materials last month and was sponsored by the Ministry of Agriculture Food and Rural Affairs, the Korea Forest Service, and the Korea Institute of Energy Research.

-Publication

Truong-Son Dinh Le, Yeong A. Lee, Han Ku Nam, Kyu Yeon Jang, Dongwook Yang, Byunggi Kim, Kanghoon Yim, Seung Woo Kim, Hana Yoon, and Young-jin Kim, “Green Flexible Graphene-Inorganic-Hybrid Micro-Supercapacitors Made of Fallen Leaves Enabled by Ultrafast Laser Pulses," December 05, 2021, Advanced Functional Materials (doi.org/10.1002/adfm.202107768)

-ProfileProfessor Young-Jin KimUltra-Precision Metrology and Manufacturing (UPM2) LaboratoryDepartment of Mechanical EngineeringKAIST

2022.01.27 View 14675 -

Nanoscale Self-Assembling Salt-Crystal ‘Origami’ Balls Envelop Liquids

Mechanical engineers have devised a ‘crystal capillary origami’ technique where salt crystals spontaneously encapsulate liquid droplets

Researchers have developed a technique whereby they can spontaneously encapsulate microscopic droplets of water and oil emulsion in a tiny sphere made of salt crystals—sort of like a minute, self-constructing origami soccer ball filled with liquid. The process, which they are calling ‘crystal capillary origami,’ could be used in a range of fields from more precise drug delivery to nanoscale medical devices.The technique is described in a paper appearing in the journal Nanoscale on September 21.

Capillary action, or ‘capillarity,’ will be familiar to most people as the way that water or other liquids can move up narrow tubes or other porous materials seemingly in defiance of gravity (for example within the vascular systems of plants, or even more simply, the drawing up of paint between the hairs of a paintbrush). This effect is due to the forces of cohesion (the tendency of a liquid’s molecules to stick together), which results in surface tension, and adhesion (their tendency to stick to the surface of other substances). The strength of the capillarity depends on the chemistry of the liquid, the chemistry of the porous material, and on the other forces acting on them both. For example, a liquid with lower surface tension than water would not be able to hold up a water strider insect.

Less well known is a related phenomenon, elasto-capillarity, that takes advantage of the relationship between capillarity and the elasticity of a very tiny flat sheet of a solid material. In certain circumstances, the capillary forces can overcome the elastic bending resistance of the sheet.

This relationship can be exploited to create ‘capillary origami,’ or three-dimensional structures. When a liquid droplet is placed on the flat sheet, the latter can spontaneously encapsulate the former due to surface tension. Capillary origami can take on other forms including wrinkling, buckling, or self-folding into other shapes. The specific geometrical shape that the 3D capillary origami structure ends up taking is determined by both the chemistry of the flat sheet and that of the liquid, and by carefully designing the shape and size of the sheet.

There is one big problem with these small devices, however. “These conventional self-assembled origami structures cannot be completely spherical and will always have discontinuous boundaries, or what you might call ‘edges,’ as a result of the original two-dimensional shape of the sheet,” said Kwangseok Park, a lead researcher on the project. He added, “These edges could turn out to be future defects with the potential for failure in the face of increased stress.” Non-spherical particles are also known to be more disadvantageous than spherical particles in terms of cellular uptake.