Department+of+Mechanical+Engineering

-

Solutal Marangoni Flows of Miscible Liquid Drive Transport without Surface Contamination

(Professor Hyoungsoo Kim, Department of Mechanical Engineering, KAIST)

A research team led by Hyoungsoo Kim, a professor of Mechanical Engineering at KAIST, succeeded in quantifying the phenomenon called, the Marangoni effect, which occurs at the interface between alcohol and water. It is expected that this finding will be a valuable resource used for effectively removing impurities from a surface fluid without any contamination, and developing materials that can replace surfactants.

This research, co-conducted with a research team led by Professor Howard A. Stone at Princeton University, was published online in Nature Physics on July 31.

The Marangoni effect, also known as tears of wine, is generated when two fluids having a different surface tension meet, causing finite mixing, spreading time and length scale. Typically, people believe that infinitely miscible liquids immediately mix together; however, it is not always true according to this paper.

The typical surface tension of alcohol is three times lower than that of water, and this different surface tension generates the Marangoni-driven convection flow at the interface of the two liquids. In addition, there is a certain amount of time required for them to mix.

This phenomenon has been discussed many times since it was discovered in early the 20th century, yet there was a limit to quantifying and explaining it.

Professor Kim, considering the mixing and spreading mechanism, used various flow visualization techniques and equipment for capturing high speed images in his experiment.

Through the flow visualization methods, the team succeeded in quantifying and explaining the complex, physicochemical phenomenon generated between water and alcohol. Moreover, they developed a theoretical model to predict the physicochemical hydrodynamic phenomena.

The theoretical model can predict the speed of Marangoni-driven convection flow, the area of a drop of alcohol and the time required to develop the flow field. Hence, this model can map out types of materials (e.g., alcohol) and the volume of a drop of liquid as applicable to target a specific situation.

Moreover, the research team believes that the interfacial flow enables the driving of bulk flows and that it can be a source of technology for effectively delivering drugs and removing impurities from a surface of substance without causing secondary contamination.

Above all, the results show a possibility for replacing surfactant with alcohol as a material used for delivering drugs. In the case of the drug delivery, some drugs are encapsulated with a surfactant in order to be effectively transported in vivo; however, the surfactant accumulates in the body, which can cause various side effects, such as heart disease. Therefore, using new materials like alcohol for drug delivery will contribute to preventing the side effects caused by the surfactant.

“The surfactant is used for delivering drugs, but it is difficult to be expelled from the body. This will cause various side effects, such as heart diseases in asthmatic patients,” said Professor Kim. “I hope that using new materials, like alcohol, will free people from these side effects.”

(Marangoni-driven convection flow generated at the interface between water and alcohol, and the flow visualization results)

- A drop of alcohol on a water surface

- Comparison of mixing structures on the surface

- Marangoni mixing flow under the free surface

2017.08.18 View 9659

Solutal Marangoni Flows of Miscible Liquid Drive Transport without Surface Contamination

(Professor Hyoungsoo Kim, Department of Mechanical Engineering, KAIST)

A research team led by Hyoungsoo Kim, a professor of Mechanical Engineering at KAIST, succeeded in quantifying the phenomenon called, the Marangoni effect, which occurs at the interface between alcohol and water. It is expected that this finding will be a valuable resource used for effectively removing impurities from a surface fluid without any contamination, and developing materials that can replace surfactants.

This research, co-conducted with a research team led by Professor Howard A. Stone at Princeton University, was published online in Nature Physics on July 31.

The Marangoni effect, also known as tears of wine, is generated when two fluids having a different surface tension meet, causing finite mixing, spreading time and length scale. Typically, people believe that infinitely miscible liquids immediately mix together; however, it is not always true according to this paper.

The typical surface tension of alcohol is three times lower than that of water, and this different surface tension generates the Marangoni-driven convection flow at the interface of the two liquids. In addition, there is a certain amount of time required for them to mix.

This phenomenon has been discussed many times since it was discovered in early the 20th century, yet there was a limit to quantifying and explaining it.

Professor Kim, considering the mixing and spreading mechanism, used various flow visualization techniques and equipment for capturing high speed images in his experiment.

Through the flow visualization methods, the team succeeded in quantifying and explaining the complex, physicochemical phenomenon generated between water and alcohol. Moreover, they developed a theoretical model to predict the physicochemical hydrodynamic phenomena.

The theoretical model can predict the speed of Marangoni-driven convection flow, the area of a drop of alcohol and the time required to develop the flow field. Hence, this model can map out types of materials (e.g., alcohol) and the volume of a drop of liquid as applicable to target a specific situation.

Moreover, the research team believes that the interfacial flow enables the driving of bulk flows and that it can be a source of technology for effectively delivering drugs and removing impurities from a surface of substance without causing secondary contamination.

Above all, the results show a possibility for replacing surfactant with alcohol as a material used for delivering drugs. In the case of the drug delivery, some drugs are encapsulated with a surfactant in order to be effectively transported in vivo; however, the surfactant accumulates in the body, which can cause various side effects, such as heart disease. Therefore, using new materials like alcohol for drug delivery will contribute to preventing the side effects caused by the surfactant.

“The surfactant is used for delivering drugs, but it is difficult to be expelled from the body. This will cause various side effects, such as heart diseases in asthmatic patients,” said Professor Kim. “I hope that using new materials, like alcohol, will free people from these side effects.”

(Marangoni-driven convection flow generated at the interface between water and alcohol, and the flow visualization results)

- A drop of alcohol on a water surface

- Comparison of mixing structures on the surface

- Marangoni mixing flow under the free surface

2017.08.18 View 9659 -

Parasitic Robot System for Turtle's Waypoint Navigation

A KAIST research team presented a hybrid animal-robot interaction called “the parasitic robot system,” that imitates the nature relationship between parasites and host.

The research team led by Professor Phil-Seung Lee of the Department of Mechanical Engineering took an animal’s locomotive abilities to apply the theory of using a robot as a parasite. The robot is attached to its host animal in a way similar to an actual parasite, and it interacts with the host through particular devices and algorithms.

Even with remarkable technology advancements, robots that operate in complex and harsh environments still have some serious limitations in moving and recharging. However, millions of years of evolution have led to there being many real animals capable of excellent locomotion and survive in actual natural environment.

Certain kinds of real parasites can manipulate the behavior of the host to increase the probability of its own reproduction. Similarly, in the proposed concept of a “parasitic robot,” a specific behavior is induced by the parasitic robot in its host to benefit the robot.

The team chose a turtle as their first host animal and designed a parasitic robot that can perform “stimulus-response training.” The parasitic robot, which is attached to the turtle, can induce the turtle’s object-tracking behavior through repeated training sessions.

The robot then simply guides it using LEDs and feeds it snacks as a reward for going in the right direction through a programmed algorithm. After training sessions lasting five weeks, the parasitic robot can successfully control the direction of movement of the host turtles in the waypoint navigation task in a water tank.

This hybrid animal–robot interaction system could provide an alternative solution of the limitations of conventional mobile robot systems in various fields. Ph.D. candidate Dae-Gun Kim, the first author of this research said that there are a wide variety of animals including mice, birds, and fish that could perform equally as well at such tasks. He said that in the future, this system will be applied to various exploration and reconnaissance missions that humans and robots find it difficult to do on their own.

Kim said, “This hybrid animal-robot interaction system could provide an alternative solution to the limitations of conventional mobile robot systems in various fields, and could also act as a useful interaction system for the behavioral sciences.”

The research was published in the Journal of Bionic Engineering April issue.

2017.05.19 View 10908

Parasitic Robot System for Turtle's Waypoint Navigation

A KAIST research team presented a hybrid animal-robot interaction called “the parasitic robot system,” that imitates the nature relationship between parasites and host.

The research team led by Professor Phil-Seung Lee of the Department of Mechanical Engineering took an animal’s locomotive abilities to apply the theory of using a robot as a parasite. The robot is attached to its host animal in a way similar to an actual parasite, and it interacts with the host through particular devices and algorithms.

Even with remarkable technology advancements, robots that operate in complex and harsh environments still have some serious limitations in moving and recharging. However, millions of years of evolution have led to there being many real animals capable of excellent locomotion and survive in actual natural environment.

Certain kinds of real parasites can manipulate the behavior of the host to increase the probability of its own reproduction. Similarly, in the proposed concept of a “parasitic robot,” a specific behavior is induced by the parasitic robot in its host to benefit the robot.

The team chose a turtle as their first host animal and designed a parasitic robot that can perform “stimulus-response training.” The parasitic robot, which is attached to the turtle, can induce the turtle’s object-tracking behavior through repeated training sessions.

The robot then simply guides it using LEDs and feeds it snacks as a reward for going in the right direction through a programmed algorithm. After training sessions lasting five weeks, the parasitic robot can successfully control the direction of movement of the host turtles in the waypoint navigation task in a water tank.

This hybrid animal–robot interaction system could provide an alternative solution of the limitations of conventional mobile robot systems in various fields. Ph.D. candidate Dae-Gun Kim, the first author of this research said that there are a wide variety of animals including mice, birds, and fish that could perform equally as well at such tasks. He said that in the future, this system will be applied to various exploration and reconnaissance missions that humans and robots find it difficult to do on their own.

Kim said, “This hybrid animal-robot interaction system could provide an alternative solution to the limitations of conventional mobile robot systems in various fields, and could also act as a useful interaction system for the behavioral sciences.”

The research was published in the Journal of Bionic Engineering April issue.

2017.05.19 View 10908 -

Tactile Sensor for Robot Skin Advanced by KAIST Team

The joint research team of Professors Jung Kim and Inkyu Park from the Department of Mechanical Engineering developed a tactile sensor that can act as skin for robots using silicon and carbon materials. This technology produced a sensor that can absorb shock and distinguish various forms of touch, and it is hoped to be used as robot skin in the future.

Skin serves an important role as the largest organ of the human body. As well as protecting major organs from external shock, skin also measures and distinguishes delicate tactile information and transfer it to the nervous system.

Current robotic sensory technology allows robots to have visual and auditory systems at nearly similar levels to human capacity, but there are limitations in tactile sensors that can detect changes in the environment throughout the body. To apply skin with similar functions as humans to robots, it is essential to develop skin sensor technology with high flexibility and high shock absorption. Another limitation for developing robot skin was connecting numerous sensors all over the body using electric wiring.

To overcome this problem, the research team combined silicon and carbon nanotubes (CNT) to produce a composite, which was then used in combination with a medical imaging technique called electrical impedance tomography (EIT). This led to technology that can distinguish various forms of force over a large area without electrical wiring.

The sensing material can distinguish the location and the size of various forms by touch, and thus can be applied to robot skin that can absorb shock as well as serves as a 3D computer interface and tactile sensor. It can withstand strong force such as a hammer strike, and can be re-used even after partial damage to the sensor by filling and hardening the damaged region with composite. Further, the sensor can be made by filling a 3D shape frame with silicon-nanotube composite. Using this technology, new forms of computer interaces can be developed with both curbed and flat surfaces.

This research was conducted through a collaboration between Professor Park, an expert in nanostructures and sensors, and Professor Kim, an expert in bio-robotics. Hence, the technology is likely to be applied in real products.

Professor Kim said, “Flexible tactile sensors can not only be directly adhered to the body, but they also provides information on modified states in multiple dimensions”. He continued, “This technology will contribute to the soft robot industry in the areas of robot skin and the field of wearable medical appliances.”

Professor Park said, “This technology implemented a next-generation user interface through the integration of functional nano-composite material and computer tomography.”

This research was published in Scientific Reports, a sister journal of Nature, online on January 25. This research was conducted as joint research by first author Hyo-Sang Lee, as well as Donguk Kwon and Ji-seung Cho, and was funded by the Ministry of Science, ICT and Future Planning.

(Fiigrue 1: Robotic hand responding to resistance via a connection with the developed tactile sensor)

(Figure 2: Manufacturing process for pressure-resistant composite using silicon rubber and carbon nanotubes)

(Figure 3: Computer interface using pressure-resistant composite)

2017.04.17 View 14203

Tactile Sensor for Robot Skin Advanced by KAIST Team

The joint research team of Professors Jung Kim and Inkyu Park from the Department of Mechanical Engineering developed a tactile sensor that can act as skin for robots using silicon and carbon materials. This technology produced a sensor that can absorb shock and distinguish various forms of touch, and it is hoped to be used as robot skin in the future.

Skin serves an important role as the largest organ of the human body. As well as protecting major organs from external shock, skin also measures and distinguishes delicate tactile information and transfer it to the nervous system.

Current robotic sensory technology allows robots to have visual and auditory systems at nearly similar levels to human capacity, but there are limitations in tactile sensors that can detect changes in the environment throughout the body. To apply skin with similar functions as humans to robots, it is essential to develop skin sensor technology with high flexibility and high shock absorption. Another limitation for developing robot skin was connecting numerous sensors all over the body using electric wiring.

To overcome this problem, the research team combined silicon and carbon nanotubes (CNT) to produce a composite, which was then used in combination with a medical imaging technique called electrical impedance tomography (EIT). This led to technology that can distinguish various forms of force over a large area without electrical wiring.

The sensing material can distinguish the location and the size of various forms by touch, and thus can be applied to robot skin that can absorb shock as well as serves as a 3D computer interface and tactile sensor. It can withstand strong force such as a hammer strike, and can be re-used even after partial damage to the sensor by filling and hardening the damaged region with composite. Further, the sensor can be made by filling a 3D shape frame with silicon-nanotube composite. Using this technology, new forms of computer interaces can be developed with both curbed and flat surfaces.

This research was conducted through a collaboration between Professor Park, an expert in nanostructures and sensors, and Professor Kim, an expert in bio-robotics. Hence, the technology is likely to be applied in real products.

Professor Kim said, “Flexible tactile sensors can not only be directly adhered to the body, but they also provides information on modified states in multiple dimensions”. He continued, “This technology will contribute to the soft robot industry in the areas of robot skin and the field of wearable medical appliances.”

Professor Park said, “This technology implemented a next-generation user interface through the integration of functional nano-composite material and computer tomography.”

This research was published in Scientific Reports, a sister journal of Nature, online on January 25. This research was conducted as joint research by first author Hyo-Sang Lee, as well as Donguk Kwon and Ji-seung Cho, and was funded by the Ministry of Science, ICT and Future Planning.

(Fiigrue 1: Robotic hand responding to resistance via a connection with the developed tactile sensor)

(Figure 2: Manufacturing process for pressure-resistant composite using silicon rubber and carbon nanotubes)

(Figure 3: Computer interface using pressure-resistant composite)

2017.04.17 View 14203 -

Controlling Turtle Motion with Human Thought

KAIST researchers have developed a technology that can remotely control an animal’s movement with human thought.

In the 2009 blockbuster “Avatar,” a human remotely controls the body of an alien. It does so by injecting human intelligence into a remotely located, biological body. Although still in the realm of science fiction, researchers are nevertheless developing so-called ‘brain-computer interfaces’ (BCIs) following recent advances in electronics and computing. These technologies can ‘read’ and use human thought to control machines, for example, humanoid robots.

New research has demonstrated the possibility of combining a BCI with a device that transmits information from a computer to a brain, or known as a ‘computer-to-brain interface’ (CBI). The combination of these devices could be used to establish a functional link between the brains of different species. Now, researchers from the Korea Advanced Institute of Science and Technology (KAIST) have developed a human-turtle interaction system in which a signal originating from a human brain can affect where a turtle moves.

Unlike previous research that has tried to control animal movement by applying invasive methods, most notably in insects, Professors Phill-Seung Lee of the Mechanical Engineering Department and Sungho Jo of the Computing School propose a conceptual system that can guide an animal’s moving path by controlling its instinctive escape behavior. They chose a turtle because of its cognitive abilities as well as its ability to distinguish different wavelengths of light. Specifically, turtles can recognize a white light source as an open space and so move toward it. They also show specific avoidance behavior to things that might obstruct their view. Turtles also move toward and away from obstacles in their environment in a predictable manner. It was this instinctive, predictable behavior that the researchers induced using the BCI.

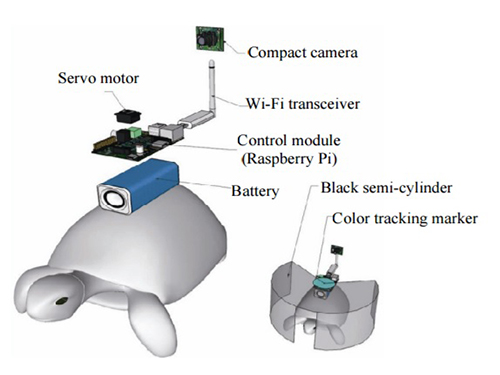

The entire human-turtle setup is as follows: A head-mounted display (HMD) is combined with a BCI to immerse the human user in the turtle’s environment. The human operator wears the BCI-HMD system, while the turtle has a 'cyborg system'—consisting of a camera, Wi-Fi transceiver, computer control module, and battery—all mounted on the turtle’s upper shell. Also included on the turtle’s shell is a black semi-cylinder with a slit, which forms the ‘stimulation device.’ This can be turned ±36 degrees via the BCI.

The entire process works like this: the human operator receives images from the camera mounted on the turtle. These real-time video images allow the human operator to decide where the turtle should move. The human provides thought commands that are recognized by the wearable BCI system as electroencephalography (EEG) signals. The BCI can distinguish between three mental states: left, right, and idle. The left and right commands activate the turtle’s stimulation device via Wi-Fi, turning it so that it obstructs the turtle’s view. This invokes its natural instinct to move toward light and change its direction. Finally, the human acquires updated visual feedback from the camera mounted on the shell and in this way continues to remotely navigate the turtle’s trajectory.

The research demonstrates that the animal guiding scheme via BCI can be used in a variety of environments with turtles moving indoors and outdoors on many different surfaces, like gravel and grass, and tackling a range of obstacles, such as shallow water and trees. This technology could be developed to integrate positioning systems and improved augmented and virtual reality techniques, enabling various applications, including devices for military reconnaissance and surveillance.

***

Reference: “Remote Navigation of Turtle by Controlling Instinct Behavior via Human Brain-computer Interface,” Journal of Bionic Engineering, July 2016 (DOI: 10.1016/S1672-6529(16)60322-0)

Depiction of Cyborg System

A human controller influences the turtle’s escape behavior by sending left and right signals via Wi-Fi to a control system on the back of the turtle.

2017.02.21 View 17015

Controlling Turtle Motion with Human Thought

KAIST researchers have developed a technology that can remotely control an animal’s movement with human thought.

In the 2009 blockbuster “Avatar,” a human remotely controls the body of an alien. It does so by injecting human intelligence into a remotely located, biological body. Although still in the realm of science fiction, researchers are nevertheless developing so-called ‘brain-computer interfaces’ (BCIs) following recent advances in electronics and computing. These technologies can ‘read’ and use human thought to control machines, for example, humanoid robots.

New research has demonstrated the possibility of combining a BCI with a device that transmits information from a computer to a brain, or known as a ‘computer-to-brain interface’ (CBI). The combination of these devices could be used to establish a functional link between the brains of different species. Now, researchers from the Korea Advanced Institute of Science and Technology (KAIST) have developed a human-turtle interaction system in which a signal originating from a human brain can affect where a turtle moves.

Unlike previous research that has tried to control animal movement by applying invasive methods, most notably in insects, Professors Phill-Seung Lee of the Mechanical Engineering Department and Sungho Jo of the Computing School propose a conceptual system that can guide an animal’s moving path by controlling its instinctive escape behavior. They chose a turtle because of its cognitive abilities as well as its ability to distinguish different wavelengths of light. Specifically, turtles can recognize a white light source as an open space and so move toward it. They also show specific avoidance behavior to things that might obstruct their view. Turtles also move toward and away from obstacles in their environment in a predictable manner. It was this instinctive, predictable behavior that the researchers induced using the BCI.

The entire human-turtle setup is as follows: A head-mounted display (HMD) is combined with a BCI to immerse the human user in the turtle’s environment. The human operator wears the BCI-HMD system, while the turtle has a 'cyborg system'—consisting of a camera, Wi-Fi transceiver, computer control module, and battery—all mounted on the turtle’s upper shell. Also included on the turtle’s shell is a black semi-cylinder with a slit, which forms the ‘stimulation device.’ This can be turned ±36 degrees via the BCI.

The entire process works like this: the human operator receives images from the camera mounted on the turtle. These real-time video images allow the human operator to decide where the turtle should move. The human provides thought commands that are recognized by the wearable BCI system as electroencephalography (EEG) signals. The BCI can distinguish between three mental states: left, right, and idle. The left and right commands activate the turtle’s stimulation device via Wi-Fi, turning it so that it obstructs the turtle’s view. This invokes its natural instinct to move toward light and change its direction. Finally, the human acquires updated visual feedback from the camera mounted on the shell and in this way continues to remotely navigate the turtle’s trajectory.

The research demonstrates that the animal guiding scheme via BCI can be used in a variety of environments with turtles moving indoors and outdoors on many different surfaces, like gravel and grass, and tackling a range of obstacles, such as shallow water and trees. This technology could be developed to integrate positioning systems and improved augmented and virtual reality techniques, enabling various applications, including devices for military reconnaissance and surveillance.

***

Reference: “Remote Navigation of Turtle by Controlling Instinct Behavior via Human Brain-computer Interface,” Journal of Bionic Engineering, July 2016 (DOI: 10.1016/S1672-6529(16)60322-0)

Depiction of Cyborg System

A human controller influences the turtle’s escape behavior by sending left and right signals via Wi-Fi to a control system on the back of the turtle.

2017.02.21 View 17015 -

EWB-KAIST Wraps up Five-Year Project in Nepal

‘Engineers Without Borders-KAIST (EWB-KAIST)’ led by Professor Tae-ho Song from the Department of Mechanical Engineering returned to Korea on January 10 after a two-week project in Nangi, Nepal.

EWB-KAIST was established in 2012 by KAIST students and professors. Since then, the team visited Nangi, in the Annapurna region of Nepal, to engage in Appropriate Technology (AT) development projects. The projects included building passive houses and small hydroelectric power, and teaching science education. In particular, passive houses that use straw as an insulator received great a reception from the locals.

This was their last visit to Nepal, since the five-year project has now come to an end. Future projects in Mongolia will be led by Professor Buhm Soon Park from the Graduate School of Science and Technology Policy.

Professor Song commented, “I am glad that the Nepal project was successfully conducted over the last five years. To make sure the support does not end here, I will personally continue to visit the Himalayas to assist the villagers.”

EWB-KAIST is a non-profit organization that conducts activities with the aim of AT development and providing support for less-developed countries in need of the benefits of technology.

( Passive house made of straws by EWB-KAIST team in Nangi, Nepal.)

2017.02.01 View 9342

EWB-KAIST Wraps up Five-Year Project in Nepal

‘Engineers Without Borders-KAIST (EWB-KAIST)’ led by Professor Tae-ho Song from the Department of Mechanical Engineering returned to Korea on January 10 after a two-week project in Nangi, Nepal.

EWB-KAIST was established in 2012 by KAIST students and professors. Since then, the team visited Nangi, in the Annapurna region of Nepal, to engage in Appropriate Technology (AT) development projects. The projects included building passive houses and small hydroelectric power, and teaching science education. In particular, passive houses that use straw as an insulator received great a reception from the locals.

This was their last visit to Nepal, since the five-year project has now come to an end. Future projects in Mongolia will be led by Professor Buhm Soon Park from the Graduate School of Science and Technology Policy.

Professor Song commented, “I am glad that the Nepal project was successfully conducted over the last five years. To make sure the support does not end here, I will personally continue to visit the Himalayas to assist the villagers.”

EWB-KAIST is a non-profit organization that conducts activities with the aim of AT development and providing support for less-developed countries in need of the benefits of technology.

( Passive house made of straws by EWB-KAIST team in Nangi, Nepal.)

2017.02.01 View 9342 -

Mechanical Engineering Building on Campus Refurbished

KAIST’s Mechanical Engineering Department has finished the project to remodel its buildings and hosted an opening ceremony on December 12, 2016, which was attended by the university’s senior management and guests including President Steve Kang and Choong-Hwan Ahn, Architecture Policy Officer at the Ministry of Land, Infrastructure and Transport of Korea (MLIT).

With an investment of approximately USD 10 million, the old buildings (each consisting of seven floors and one basement) were transformed into smart, green buildings. Among the upgrades were the establishment of LED lighting systems, the replacement of the exterior walls with insulated materials, and the installation of double-glazed windows, all resulting in the improvement of the buildings’ energy efficiency. Previously, offices and lecture halls in the buildings had individual cooling and heating systems, which consumed a great deal of energy, but they were replaced with a centralized smart energy control system that monitors the operation status as well as energy consumption in real time.

With these new improvements, the Department was able to slash its energy consumption by 32%, for which it received Green Building Conversion Certification from MLIT. The ministry issues the certification to buildings that reduce their energy consumption by over 20% as a result of infrastructure upgrades. Beginning with the Mechanical Engineering buildings, KAIST will work on obtaining this certification for all of its buildings that are either under renovation or construction.

President Kang said, “We are pleased to offer our students a comfortable environment for study and research and will continue improving outdated facilities and infrastructure to make the campus safer and nicer.”

Picture 1: Ribbon-cutting ceremony for the refurbished Mechanical Engineering buildings on campus

Picture 2: Mechanical engineering buildings

2016.12.09 View 9045

Mechanical Engineering Building on Campus Refurbished

KAIST’s Mechanical Engineering Department has finished the project to remodel its buildings and hosted an opening ceremony on December 12, 2016, which was attended by the university’s senior management and guests including President Steve Kang and Choong-Hwan Ahn, Architecture Policy Officer at the Ministry of Land, Infrastructure and Transport of Korea (MLIT).

With an investment of approximately USD 10 million, the old buildings (each consisting of seven floors and one basement) were transformed into smart, green buildings. Among the upgrades were the establishment of LED lighting systems, the replacement of the exterior walls with insulated materials, and the installation of double-glazed windows, all resulting in the improvement of the buildings’ energy efficiency. Previously, offices and lecture halls in the buildings had individual cooling and heating systems, which consumed a great deal of energy, but they were replaced with a centralized smart energy control system that monitors the operation status as well as energy consumption in real time.

With these new improvements, the Department was able to slash its energy consumption by 32%, for which it received Green Building Conversion Certification from MLIT. The ministry issues the certification to buildings that reduce their energy consumption by over 20% as a result of infrastructure upgrades. Beginning with the Mechanical Engineering buildings, KAIST will work on obtaining this certification for all of its buildings that are either under renovation or construction.

President Kang said, “We are pleased to offer our students a comfortable environment for study and research and will continue improving outdated facilities and infrastructure to make the campus safer and nicer.”

Picture 1: Ribbon-cutting ceremony for the refurbished Mechanical Engineering buildings on campus

Picture 2: Mechanical engineering buildings

2016.12.09 View 9045 -

KAIST Startups Annually Engage 33,000 People, and Their Sales Total Nearly 10 Billion Dollars

According to a recent study, KAIST startups annually engage 33,000 people, and their sales total nearly 10 billion US dollars. Also amongst 1,245 companies, 50 were listed in stock markets including KOSDAQ and KONEX. President Kang of KAIST commissioned an evaluation of KAIST startups last year. The report consisted of six chapters: current status of entrepreneurs and companies, cross analysis based on individuals’ background and academic degree, annual performance analysis, and current status of startup assistance.

The report categorized the startups with respect to the founders’ background. Of 1,245 companies, KAIST alumni founded 929 (74.6%) of the companies under study: 191 (15.3%) were located within the KAIST campuses, 91 (7.3%) were founded by enrolled students, and 74 (2.7%) by professors. The startup founders had different levels of education: 515 (41.4%) founders had master’s degree, 443 (35.6%) Ph.D. degree, and only 213 (17.1%) had only bachelor’s degree as the highest level of education attained. The reason behind the majority of founders having a master’s degree or higher degree is that many people established a startup after obtaining specialized knowledge and skills.

Focusing on the founders’ college majors, 719 (70.6%) founders were from the engineering department, 111 (10.9%) from the business administration department, 103 (10.1%) from the natural science department, and 86 (8.4%) from other departments. Looking at the companies' locations, 462 (37.5%) were placed in Seoul, 355 (28.8%) in Daejeon, and 273 (22.2%) in Gyeonggi.

By the end of 2013, the total asset of 1,069 companies came to 12 billion and 444 million dollars. Their total sales figure was 10 billion and 13 million dollars, and annual employments summed up to 33,000 people. The companies generated a significant portion of gross regional domestic product (GRDP) in each region. They formed 0.49% of GRDP of Seoul, took up 1.67% GRDP of Gyeonggi, and 5.53% of that of Daejeon.

Along with the performance analysis, the report also took a survey of suggestions on future startup assistance and opinions on current startup assistance policies. To a question asking what constituted the most difficult part of startup, 31.7% of respondents answered “attraction of investment,” 22.8% chose “a lack of human resources,” and 16.8% said “consulting” amongst 214 respondents. The study showed that major and medium enterprises face difficulty in finding human resources whereas small businesses experience obstacles attracting investment. Some startups had help from KAIST: 44 startups were provided with the office space, 21 had educational supports, and 18 were supported in research and development.

The report demonstrates that startups established by KAIST alumni and members play a key role in the South Korean economy despite KAIST’s short startup history, which began only since the end of 1990s. Based on this report, KAIST plans to listen continuously to the needs of alumni founders, and use those responses as a guide to entrepreneurship education for current students.

The Dean of the Office of University and Industry Cooperation, Joongmyeon Bae, who oversaw the publication of this report, said, "As this report is the first in Korea to study the status of alumni startups, it will be incredibly valuable in modifying the startup assistance policies.”

To spread an entrepreneurial spirit and start-up cultures in the campus and enhance the startup supporting system, KAIST has founded various startup centers on and off the campus.

2015.07.14 View 10143

KAIST Startups Annually Engage 33,000 People, and Their Sales Total Nearly 10 Billion Dollars

According to a recent study, KAIST startups annually engage 33,000 people, and their sales total nearly 10 billion US dollars. Also amongst 1,245 companies, 50 were listed in stock markets including KOSDAQ and KONEX. President Kang of KAIST commissioned an evaluation of KAIST startups last year. The report consisted of six chapters: current status of entrepreneurs and companies, cross analysis based on individuals’ background and academic degree, annual performance analysis, and current status of startup assistance.

The report categorized the startups with respect to the founders’ background. Of 1,245 companies, KAIST alumni founded 929 (74.6%) of the companies under study: 191 (15.3%) were located within the KAIST campuses, 91 (7.3%) were founded by enrolled students, and 74 (2.7%) by professors. The startup founders had different levels of education: 515 (41.4%) founders had master’s degree, 443 (35.6%) Ph.D. degree, and only 213 (17.1%) had only bachelor’s degree as the highest level of education attained. The reason behind the majority of founders having a master’s degree or higher degree is that many people established a startup after obtaining specialized knowledge and skills.

Focusing on the founders’ college majors, 719 (70.6%) founders were from the engineering department, 111 (10.9%) from the business administration department, 103 (10.1%) from the natural science department, and 86 (8.4%) from other departments. Looking at the companies' locations, 462 (37.5%) were placed in Seoul, 355 (28.8%) in Daejeon, and 273 (22.2%) in Gyeonggi.

By the end of 2013, the total asset of 1,069 companies came to 12 billion and 444 million dollars. Their total sales figure was 10 billion and 13 million dollars, and annual employments summed up to 33,000 people. The companies generated a significant portion of gross regional domestic product (GRDP) in each region. They formed 0.49% of GRDP of Seoul, took up 1.67% GRDP of Gyeonggi, and 5.53% of that of Daejeon.

Along with the performance analysis, the report also took a survey of suggestions on future startup assistance and opinions on current startup assistance policies. To a question asking what constituted the most difficult part of startup, 31.7% of respondents answered “attraction of investment,” 22.8% chose “a lack of human resources,” and 16.8% said “consulting” amongst 214 respondents. The study showed that major and medium enterprises face difficulty in finding human resources whereas small businesses experience obstacles attracting investment. Some startups had help from KAIST: 44 startups were provided with the office space, 21 had educational supports, and 18 were supported in research and development.

The report demonstrates that startups established by KAIST alumni and members play a key role in the South Korean economy despite KAIST’s short startup history, which began only since the end of 1990s. Based on this report, KAIST plans to listen continuously to the needs of alumni founders, and use those responses as a guide to entrepreneurship education for current students.

The Dean of the Office of University and Industry Cooperation, Joongmyeon Bae, who oversaw the publication of this report, said, "As this report is the first in Korea to study the status of alumni startups, it will be incredibly valuable in modifying the startup assistance policies.”

To spread an entrepreneurial spirit and start-up cultures in the campus and enhance the startup supporting system, KAIST has founded various startup centers on and off the campus.

2015.07.14 View 10143 -

KAIST Develops Subminiature, Power-Efficient Air Pollution Sensing Probe

Professor Inkyu Park and his research team from the Department of Mechanical Engineering at KAIST have developed a subminiature, power-efficient air-pollution sensing probe that can be applied to mobile devices. Their research findings were published online in the January 30th issue of Scientific Reports.

As air pollution has increased, people have taken greater interest in health care. The developed technology could allow people to measure independently the air pollution level of their surrounding environments.

Previous instruments used to measure air pollution levels were bulky and consumed a lot of power. They also often produced inaccurate results when measuring air pollution in which different toxic gases were mixed. These problems could not be resolved with existing semiconductor manufacturing process.

Using local temperature field control technology, Professor Park’s team succeeded in integrating multiple heterogeneous nanomaterials and fitting them onto a small, low-power electronic chip. This microheating sensor can heat microscale regions through local hydrothermal synthesis. Because it requires a miniscale amount of nanomaterials to manufacture, the sensor is most suitable for mobile devices.

Professor Park said, “Our research will contribute to the development of convergence technology in such field as air pollution sensing probes, biosensors, electronic devices, and displays.”

The team's research was supported by the Ministry of Education and the Ministry of Science, ICT and Future Planning, Republic of Korea.

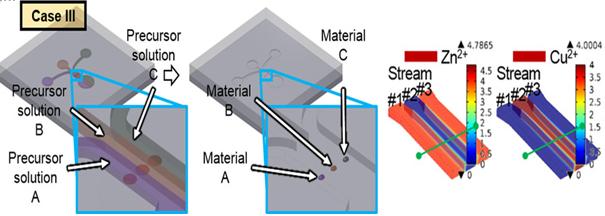

Figure 1 – The Concept of Multiple Nanomaterial Device and Numerical Simulation Results of Precursor Solutions

Figure 2 - Multiple Nanomaterial Manufactured in a Microscale Region

2015.02.27 View 12845

KAIST Develops Subminiature, Power-Efficient Air Pollution Sensing Probe

Professor Inkyu Park and his research team from the Department of Mechanical Engineering at KAIST have developed a subminiature, power-efficient air-pollution sensing probe that can be applied to mobile devices. Their research findings were published online in the January 30th issue of Scientific Reports.

As air pollution has increased, people have taken greater interest in health care. The developed technology could allow people to measure independently the air pollution level of their surrounding environments.

Previous instruments used to measure air pollution levels were bulky and consumed a lot of power. They also often produced inaccurate results when measuring air pollution in which different toxic gases were mixed. These problems could not be resolved with existing semiconductor manufacturing process.

Using local temperature field control technology, Professor Park’s team succeeded in integrating multiple heterogeneous nanomaterials and fitting them onto a small, low-power electronic chip. This microheating sensor can heat microscale regions through local hydrothermal synthesis. Because it requires a miniscale amount of nanomaterials to manufacture, the sensor is most suitable for mobile devices.

Professor Park said, “Our research will contribute to the development of convergence technology in such field as air pollution sensing probes, biosensors, electronic devices, and displays.”

The team's research was supported by the Ministry of Education and the Ministry of Science, ICT and Future Planning, Republic of Korea.

Figure 1 – The Concept of Multiple Nanomaterial Device and Numerical Simulation Results of Precursor Solutions

Figure 2 - Multiple Nanomaterial Manufactured in a Microscale Region

2015.02.27 View 12845 -

Broadband and Ultrathin Polarization Manipulators Developed

Professor Bumki Min from the Department of Mechanical Engineering at KAIST has developed a technology that can manipulate a polarized light in broadband operation with the use of a metamaterial.

It is expected that this technology will lead to the development of broadband optical devices that can be applied to broadband communication and display.

When an object or its structure is analyzed by using a polarized light such as a laser, the results are generally affected by the polarized state of the light. Therefore, in an optics laboratory, the light is polarized by various methods.

In such cases, researchers employ wave plates or photoactive materials. However, the performance of these devices depend vastly on wavelength, and so they are not suitable to be used as a polarizer, especially in broadband.

There were many attempts to make artificial materials that are very photoactive by using metamaterials which have a strong resonance. Nonetheless, because the materials had an unavoidable dispersion in the resonance frequency, they were not adequate for broadband operation.

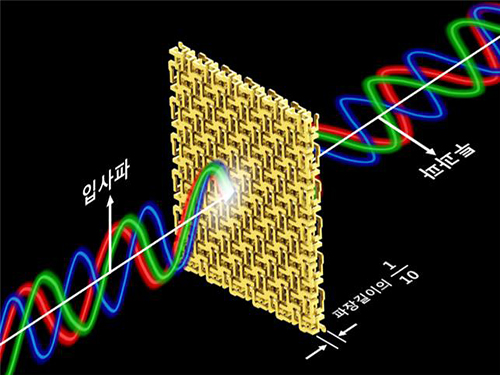

Professor Min’s research team arranged and connected helical metamaterials that are smaller than the wavelength of light. They verified theoretically and experimentally that polarized light can be constantly rotated regardless of the wavelength by super-thin materials that have thickness less than one-tenth of the wavelength of the light. The experiment which confirmed the theory was conducted in the microwave band.

Broadband polarized rotational 3D metamaterials were found to rotate the polarized microwave within the range of 0.1 GHz to 40 GHz by 45 degrees regardless of its frequency. This nondispersive property is quite unnatural because it is difficult to find a material that does not change in a wide band.

In addition, the research team materialized the broadband nondispersive polarized rotational property by designing the metamaterial in a way that it has chirality, which determines the number of rotations proportional to the wavelength.

Professor Min said, “As the technology is able to manipulate ultrathin polarization of light in broadband, it will lead to the creation of ultra-shallow broadband optical devices.”

Sponsored by the Ministry of Science, ICT and Future Planning of the Republic of Korea and the National Research Foundation of Korea, this research was led by a PhD candidate, Hyun-Sung Park, under the guidance of Professor Min. The research findings were published online in the November 17th issue of Nature Communications.

Figure 1 – Broadband and Ultrathin Polarization Manipulators Produced by 3D Printer

Figure 2 – Concept of Broadband and Ultrathin Polarization Manipulators

2014.12.03 View 13785

Broadband and Ultrathin Polarization Manipulators Developed

Professor Bumki Min from the Department of Mechanical Engineering at KAIST has developed a technology that can manipulate a polarized light in broadband operation with the use of a metamaterial.

It is expected that this technology will lead to the development of broadband optical devices that can be applied to broadband communication and display.

When an object or its structure is analyzed by using a polarized light such as a laser, the results are generally affected by the polarized state of the light. Therefore, in an optics laboratory, the light is polarized by various methods.

In such cases, researchers employ wave plates or photoactive materials. However, the performance of these devices depend vastly on wavelength, and so they are not suitable to be used as a polarizer, especially in broadband.

There were many attempts to make artificial materials that are very photoactive by using metamaterials which have a strong resonance. Nonetheless, because the materials had an unavoidable dispersion in the resonance frequency, they were not adequate for broadband operation.

Professor Min’s research team arranged and connected helical metamaterials that are smaller than the wavelength of light. They verified theoretically and experimentally that polarized light can be constantly rotated regardless of the wavelength by super-thin materials that have thickness less than one-tenth of the wavelength of the light. The experiment which confirmed the theory was conducted in the microwave band.

Broadband polarized rotational 3D metamaterials were found to rotate the polarized microwave within the range of 0.1 GHz to 40 GHz by 45 degrees regardless of its frequency. This nondispersive property is quite unnatural because it is difficult to find a material that does not change in a wide band.

In addition, the research team materialized the broadband nondispersive polarized rotational property by designing the metamaterial in a way that it has chirality, which determines the number of rotations proportional to the wavelength.

Professor Min said, “As the technology is able to manipulate ultrathin polarization of light in broadband, it will lead to the creation of ultra-shallow broadband optical devices.”

Sponsored by the Ministry of Science, ICT and Future Planning of the Republic of Korea and the National Research Foundation of Korea, this research was led by a PhD candidate, Hyun-Sung Park, under the guidance of Professor Min. The research findings were published online in the November 17th issue of Nature Communications.

Figure 1 – Broadband and Ultrathin Polarization Manipulators Produced by 3D Printer

Figure 2 – Concept of Broadband and Ultrathin Polarization Manipulators

2014.12.03 View 13785 -

3D Printer Developed by KAIST Undergraduate Students

More than 100 Pre-orders Prior to Product Launch Made

KAIST undergraduate students received more than 100 pre-orders before the launch for 3D printers they developed and became a hot topic of interest.

KAIST Research Institute for Social Technology and Innovations (Head Hong-Kyu Lee) had a launch party at Daejeon Riviera Hotel on 17 November 2014 for “Commercial Delta 3D Printer” developed by KAIST undergraduate students inviting around 50 businesses, buyers and representatives of 3D Printing Industry Association.

“3D Printer” uses blueprints of products such as toys, mug cups and chairs to make 3D objects and is thought to be revolutionary technology in manufacturing industry. The interest has grown as recent printers could print even fruits and cosmetics.

The printing structure of 3D printer can be divided roughly into horizontal Mendel method and Delta method. KAIST students focused on the Delta method to give a differentiated product from 90% of commercial products that use Mendel method.

First, the students focused on lowering the cost of unit price by using self-developed components. The carriage (transport machine) of the product is replaced by self-developed components instead of bearing to reduce the noise and the linking method was changed to beads from loop guide to increase the completeness of the printed product. Also, an auto-levelling is loaded to ensure the nozzle and the bed is parallel and hence increasing convenience for the users. Further, the printer, designed by a product designer in Germany, is linked to a smartphone application for blueprints.

A student in the development team, Seokhyeon Seo (Department of Computer Science, 3rd Year Undergraduate) said, “The biggest merits of the product are lowering the price to a 1/3 by using self-developed components and reducing the noise.” He continued, “By using a smartphone application, anyone can easily design the product. So it is applicable to use for education or at home”

In the exhibit, “3D Printing Korea 2014,” in Coex, Seoul the printer had a preview demonstration, and received more than 100 pre-orders from educational and business training institutions. Further, buyers from Canada and the US requested opening agencies in their countries.

KAIST Research Institute for Social Technology and Innovations Head Hong-Kyu Lee said, “3D printing is an innovative technology that could bring the 3rd industrial revolution.” He continued, “It is still early days but the demand will increase exponentially.”

This project was a research project of KAIST Research Institute for Social Technology and Innovations led by a development team consisting of 4 undergraduate students of KAIST, one student from University of Oxford and one German product designer.

Students in the picture below are Won-Hoi Kim (Department of Mechanical Engineering), Sung-Hyun Cho (Department of Mechanical Engineering), and Suk-Hyun Seo (Department of Computer Science) from left to right.

2014.11.19 View 12784

3D Printer Developed by KAIST Undergraduate Students

More than 100 Pre-orders Prior to Product Launch Made

KAIST undergraduate students received more than 100 pre-orders before the launch for 3D printers they developed and became a hot topic of interest.

KAIST Research Institute for Social Technology and Innovations (Head Hong-Kyu Lee) had a launch party at Daejeon Riviera Hotel on 17 November 2014 for “Commercial Delta 3D Printer” developed by KAIST undergraduate students inviting around 50 businesses, buyers and representatives of 3D Printing Industry Association.

“3D Printer” uses blueprints of products such as toys, mug cups and chairs to make 3D objects and is thought to be revolutionary technology in manufacturing industry. The interest has grown as recent printers could print even fruits and cosmetics.

The printing structure of 3D printer can be divided roughly into horizontal Mendel method and Delta method. KAIST students focused on the Delta method to give a differentiated product from 90% of commercial products that use Mendel method.

First, the students focused on lowering the cost of unit price by using self-developed components. The carriage (transport machine) of the product is replaced by self-developed components instead of bearing to reduce the noise and the linking method was changed to beads from loop guide to increase the completeness of the printed product. Also, an auto-levelling is loaded to ensure the nozzle and the bed is parallel and hence increasing convenience for the users. Further, the printer, designed by a product designer in Germany, is linked to a smartphone application for blueprints.

A student in the development team, Seokhyeon Seo (Department of Computer Science, 3rd Year Undergraduate) said, “The biggest merits of the product are lowering the price to a 1/3 by using self-developed components and reducing the noise.” He continued, “By using a smartphone application, anyone can easily design the product. So it is applicable to use for education or at home”

In the exhibit, “3D Printing Korea 2014,” in Coex, Seoul the printer had a preview demonstration, and received more than 100 pre-orders from educational and business training institutions. Further, buyers from Canada and the US requested opening agencies in their countries.

KAIST Research Institute for Social Technology and Innovations Head Hong-Kyu Lee said, “3D printing is an innovative technology that could bring the 3rd industrial revolution.” He continued, “It is still early days but the demand will increase exponentially.”

This project was a research project of KAIST Research Institute for Social Technology and Innovations led by a development team consisting of 4 undergraduate students of KAIST, one student from University of Oxford and one German product designer.

Students in the picture below are Won-Hoi Kim (Department of Mechanical Engineering), Sung-Hyun Cho (Department of Mechanical Engineering), and Suk-Hyun Seo (Department of Computer Science) from left to right.

2014.11.19 View 12784 -

KAIST Offers Massive Open Online Courses (MOOCs) to Global Learners

Global learners can now take premier engineering courses offered by the Korea Advanced Institute of Science and Technology (KAIST) through one of the leading online education providers, Coursera.

KAIST has begun offering three massive open online courses (MOOCs) to reach millions of students on the Internet. Collaborating with Coursera to provide a MOOC platform, KAIST will extend its excellence in science and engineering to a broader global audience while using technology to enhance the classroom experience for its students on campus.

Three courses are offered in the following areas: sound engineering (as of May 12th); an interdisciplinary approach of physics, life science, and industrial design (to be launched in late May); and business management (to be launched in June).

Professor Yang-Hann Kim of Mechanical Engineering, an instructor who will teach the “Introduction to Acoustics” course, explained his decision to participate in MOOCs:

“I have been teaching acoustics engineering at KAIST over the past 30 years. I wanted to share my knowledge and expertise with researchers and students who are otherwise unable to receive a quality education in a traditional education setting. This is a great opportunity to offer my talent to the global community.”

The Center for Excellence in Learning & Teaching at KAIST has worked with professors to design online courses, record video lectures, and create student assignments. Students will learn in 10- to 15-minute lesson segments over a ten-week period, with an anticipated workload of 4-6 hours per week, on average.

KAIST made a partnership agreement with Coursera in October 2013 to provide free online courses for Korean and global learners. Beginning with three courses, the university plans to increase the number of classes incrementally.

To get more information about KAIST’s MOOC offerings, please visit https://www.coursera.org/kaist.

Founded by two computer science professors at Stanford University in 2012, Coursera offers free online education to anyone interested in learning and equipped with the Internet, including students, professionals, and life-long learners, to empower them with knowledge and skills. As of April 2014, Coursera has 7.1 million users in 641 courses from 108 institutions.

2014.05.14 View 11212

KAIST Offers Massive Open Online Courses (MOOCs) to Global Learners

Global learners can now take premier engineering courses offered by the Korea Advanced Institute of Science and Technology (KAIST) through one of the leading online education providers, Coursera.

KAIST has begun offering three massive open online courses (MOOCs) to reach millions of students on the Internet. Collaborating with Coursera to provide a MOOC platform, KAIST will extend its excellence in science and engineering to a broader global audience while using technology to enhance the classroom experience for its students on campus.

Three courses are offered in the following areas: sound engineering (as of May 12th); an interdisciplinary approach of physics, life science, and industrial design (to be launched in late May); and business management (to be launched in June).

Professor Yang-Hann Kim of Mechanical Engineering, an instructor who will teach the “Introduction to Acoustics” course, explained his decision to participate in MOOCs:

“I have been teaching acoustics engineering at KAIST over the past 30 years. I wanted to share my knowledge and expertise with researchers and students who are otherwise unable to receive a quality education in a traditional education setting. This is a great opportunity to offer my talent to the global community.”

The Center for Excellence in Learning & Teaching at KAIST has worked with professors to design online courses, record video lectures, and create student assignments. Students will learn in 10- to 15-minute lesson segments over a ten-week period, with an anticipated workload of 4-6 hours per week, on average.

KAIST made a partnership agreement with Coursera in October 2013 to provide free online courses for Korean and global learners. Beginning with three courses, the university plans to increase the number of classes incrementally.

To get more information about KAIST’s MOOC offerings, please visit https://www.coursera.org/kaist.

Founded by two computer science professors at Stanford University in 2012, Coursera offers free online education to anyone interested in learning and equipped with the Internet, including students, professionals, and life-long learners, to empower them with knowledge and skills. As of April 2014, Coursera has 7.1 million users in 641 courses from 108 institutions.

2014.05.14 View 11212 -

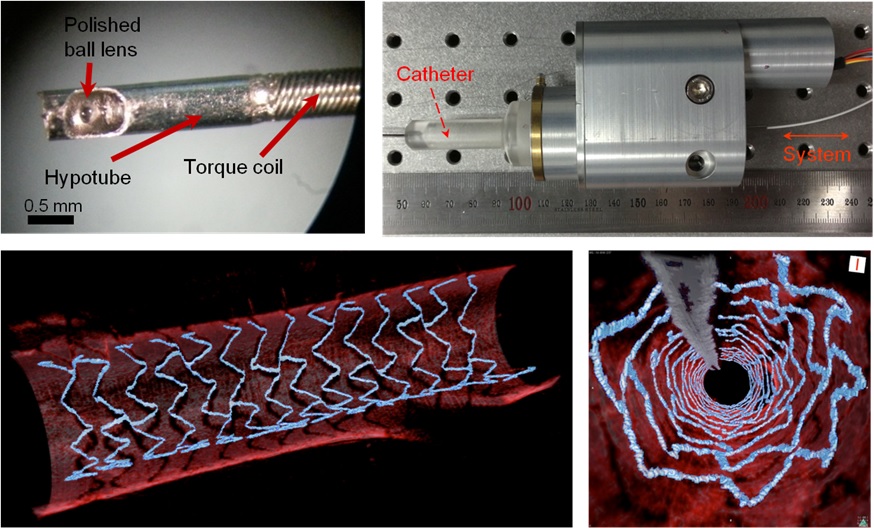

High Resolution 3D Blood Vessel Endoscope System Developed

Professor Wangyeol Oh of KAIST’s Mechanical Engineering Department has succeeded in developing an optical imaging endoscope system that employs an imaging velocity, which is up to 3.5 times faster than the previous systems. Furthermore, he has utilized this endoscope to acquire the world’s first high-resolution 3D images of the insides of in vivo blood vessel.

Professor Oh’s work is Korea’s first development of blood vessel endoscope system, possessing an imaging speed, resolution, imaging quality, and image-capture area. The system can also simultaneously perform a functional imaging, such as polarized imaging, which is advantageous for identifying the vulnerability of the blood vessel walls.

The Endoscopic Optical Coherence Tomography (OCT) System provides the highest resolution that is used to diagnose cardiovascular diseases, represented mainly by myocardial infarction.

However, the previous system was not fast enough to take images inside of the vessels, and therefore it was often impossible to accurately identify and analyze the vessel condition. To achieve an in vivo blood vessel optical imaging in clinical trials, the endoscope needed to be inserted, after which a clear liquid flows instantly, and pictures can be taken in only a few seconds.

The KAIST research team proposed a solution for such problem by developing a high-speed, high-resolution optical tomographic imaging system, a flexible endoscope with a diameter of 0.8 mm, as well as a device that can scan the imaging light within the blood vessels at high speed. Then, these devices were combined to visualize the internal structure of the vessel wall.

Using the developed system, the researchers were able to obtain high-resolution images of about 7 cm blood vessels of a rabbit’s aorta, which is similar size to human’s coronary arteries. The tomography scan took only 5.8 seconds, at a speed of 350 scans per second in all three directions with a resolution of 10~35㎛.

If the images are taken every 200 ㎛, like the currently available commercial vascular imaging endoscopes, a 7cm length vessel can be imaged in only one second.

Professor Wangyeol Oh said, “Our newly developed blood vessel endoscope system was tested by imaging a live animal’s blood vessels, which is similar to human blood vessels. The result was very successful.”

“Collaborating closely with hospitals, we are preparing to produce the imaging of an animal’s coronary arteries, which is similar in size to the human heart,” commented Professor Oh on the future clinical application and commercialization of the endoscope system. He added, “After such procedures, the technique can be applied in clinical patients within a few years.”

Professor Oh’s research was supported by the National Research Foundation of Korea and the Global Frontier Project by the Korean government. The research results were published in the 2014 January’s edition of Biomedical Optics Express.

Figure 1: End portion of optical endoscope (upper left)

Figure 2: High-speed optical scanning unit of the endoscope (top right)

Figure 3: High-resolution images of the inside of in vivo animal blood vessels (in the direction of vascular circumference and length)

Figure 4: High-resolution images of the inside of in vivo animal blood vessels (in the direction of the vein depth)

2014.03.25 View 14146

High Resolution 3D Blood Vessel Endoscope System Developed

Professor Wangyeol Oh of KAIST’s Mechanical Engineering Department has succeeded in developing an optical imaging endoscope system that employs an imaging velocity, which is up to 3.5 times faster than the previous systems. Furthermore, he has utilized this endoscope to acquire the world’s first high-resolution 3D images of the insides of in vivo blood vessel.

Professor Oh’s work is Korea’s first development of blood vessel endoscope system, possessing an imaging speed, resolution, imaging quality, and image-capture area. The system can also simultaneously perform a functional imaging, such as polarized imaging, which is advantageous for identifying the vulnerability of the blood vessel walls.

The Endoscopic Optical Coherence Tomography (OCT) System provides the highest resolution that is used to diagnose cardiovascular diseases, represented mainly by myocardial infarction.

However, the previous system was not fast enough to take images inside of the vessels, and therefore it was often impossible to accurately identify and analyze the vessel condition. To achieve an in vivo blood vessel optical imaging in clinical trials, the endoscope needed to be inserted, after which a clear liquid flows instantly, and pictures can be taken in only a few seconds.

The KAIST research team proposed a solution for such problem by developing a high-speed, high-resolution optical tomographic imaging system, a flexible endoscope with a diameter of 0.8 mm, as well as a device that can scan the imaging light within the blood vessels at high speed. Then, these devices were combined to visualize the internal structure of the vessel wall.

Using the developed system, the researchers were able to obtain high-resolution images of about 7 cm blood vessels of a rabbit’s aorta, which is similar size to human’s coronary arteries. The tomography scan took only 5.8 seconds, at a speed of 350 scans per second in all three directions with a resolution of 10~35㎛.

If the images are taken every 200 ㎛, like the currently available commercial vascular imaging endoscopes, a 7cm length vessel can be imaged in only one second.

Professor Wangyeol Oh said, “Our newly developed blood vessel endoscope system was tested by imaging a live animal’s blood vessels, which is similar to human blood vessels. The result was very successful.”

“Collaborating closely with hospitals, we are preparing to produce the imaging of an animal’s coronary arteries, which is similar in size to the human heart,” commented Professor Oh on the future clinical application and commercialization of the endoscope system. He added, “After such procedures, the technique can be applied in clinical patients within a few years.”

Professor Oh’s research was supported by the National Research Foundation of Korea and the Global Frontier Project by the Korean government. The research results were published in the 2014 January’s edition of Biomedical Optics Express.

Figure 1: End portion of optical endoscope (upper left)

Figure 2: High-speed optical scanning unit of the endoscope (top right)

Figure 3: High-resolution images of the inside of in vivo animal blood vessels (in the direction of vascular circumference and length)

Figure 4: High-resolution images of the inside of in vivo animal blood vessels (in the direction of the vein depth)

2014.03.25 View 14146