rescue

-

Team KAIST placed among top two at MBZIRC Maritime Grand Challenge

Representing Korean Robotics at Sea: KAIST’s 26-month strife rewarded

Team KAIST placed among top two at MBZIRC Maritime Grand Challenge

- Team KAIST, composed of students from the labs of Professor Jinwhan Kim of the Department of Mechanical Engineering and Professor Hyunchul Shim of the School of Electrical and Engineering, came through the challenge as the first runner-up winning the prize money totaling up to $650,000 (KRW 860 million).

- Successfully led the autonomous collaboration of unmanned aerial and maritime vehicles using cutting-edge robotics and AI technology through to the final round of the competition held in Abu Dhabi from January 10 to February 6, 2024.

KAIST (President Kwang-Hyung Lee), reported on the 8th that Team KAIST, led by students from the labs of Professor Jinwhan Kim of the Department of Mechanical Engineering and Professor Hyunchul Shim of the School of Electrical Engineering, with Pablo Aviation as a partner, won a total prize money of $650,000 (KRW 860 million) at the Maritime Grand Challenge by the Mohamed Bin Zayed International Robotics Challenge (MBZIRC), finishing first runner-up.

This competition, which is the largest ever robotics competition held over water, is sponsored by the government of the United Arab Emirates and organized by ASPIRE, an organization under the Abu Dhabi Ministry of Science, with a total prize money of $3 million.

In the competition, which started at the end of 2021, 52 teams from around the world participated and five teams were selected to go on to the finals in February 2023 after going through the first and second stages of screening. The final round was held from January 10 to February 6, 2024, using actual unmanned ships and drones in a secluded sea area of 10 km2 off the coast of Abu Dhabi, the capital of the United Arab Emirates. A total of 18 KAIST students and Professor Jinwhan Kim and Professor Hyunchul Shim took part in this competition at the location at Abu Dhabi.

Team KAIST will receive $500,000 in prize money for taking second place in the final, and the team’s prize money totals up to $650,000 including $150,000 that was as special midterm award for finalists.

The final mission scenario is to find the target vessel on the run carrying illegal cargoes among many ships moving within the GPS-disabled marine surface, and inspect the deck for two different types of stolen cargo to recover them using the aerial vehicle to bring the small cargo and the robot manipulator topped on an unmanned ship to retrieve the larger one. The true aim of the mission is to complete it through autonomous collaboration of the unmanned ship and the aerial vehicle without human intervention throughout the entire mission process. In particular, since GPS cannot be used in this competition due to regulations, Professor Jinwhan Kim's research team developed autonomous operation techniques for unmanned ships, including searching and navigating methods using maritime radar, and Professor Hyunchul Shim's research team developed video-based navigation and a technology to combine a small autonomous robot with a drone.

The final mission is to retrieve cargo on board a ship fleeing at sea through autonomous collaboration between unmanned ships and unmanned aerial vehicles without human intervention. The overall mission consists the first stage of conducting the inspection to find the target ship among several ships moving at sea and the second stage of conducting the intervention mission to retrieve the cargoes on the deck of the ship. Each team was given a total of three opportunities, and the team that completed the highest-level mission in the shortest time during the three attempts received the highest score.

In the first attempt, KAIST was the only team to succeed in the first stage search mission, but the competition began in earnest as the Croatian team also completed the first stage mission in the second attempt. As the competition schedule was delayed due to strong winds and high waves that continued for several days, the organizers decided to hold the finals with the three teams, including the Team KAIST and the team from Croatia’s the University of Zagreb, which completed the first stage of the mission, and Team Fly-Eagle, a team of researcher from China and UAE that partially completed the first stage. The three teams were given the chance to proceed to the finals and try for the third attempt, and in the final competition, the Croatian team won, KAIST took the second place, and the combined team of UAE-China combined team took the third place. The final prize to be given for the winning team is set at $2 million with $500,000 for the runner-up team, and $250,000 for the third-place.

Professor Jinwhan Kim of the Department of Mechanical Engineering, who served as the advisor for Team KAIST, said, “I would like to express my gratitude and congratulations to the students who put in a huge academic and physical efforts in preparing for the competition over the past two years. I feel rewarded because, regardless of the results, every bit of efforts put into this up to this point will become the base of their confidence and a valuable asset in their growth into a great researcher.” Sol Han, a doctoral student in mechanical engineering who served as the team leader, said, “I am disappointed of how narrowly we missed out on winning at the end, but I am satisfied with the significance of the output we’ve got and I am grateful to the team members who worked hard together for that.”

HD Hyundai, Rainbow Robotics, Avikus, and FIMS also participated as sponsors for Team KAIST's campaign.

2024.02.09 View 11237

Team KAIST placed among top two at MBZIRC Maritime Grand Challenge

Representing Korean Robotics at Sea: KAIST’s 26-month strife rewarded

Team KAIST placed among top two at MBZIRC Maritime Grand Challenge

- Team KAIST, composed of students from the labs of Professor Jinwhan Kim of the Department of Mechanical Engineering and Professor Hyunchul Shim of the School of Electrical and Engineering, came through the challenge as the first runner-up winning the prize money totaling up to $650,000 (KRW 860 million).

- Successfully led the autonomous collaboration of unmanned aerial and maritime vehicles using cutting-edge robotics and AI technology through to the final round of the competition held in Abu Dhabi from January 10 to February 6, 2024.

KAIST (President Kwang-Hyung Lee), reported on the 8th that Team KAIST, led by students from the labs of Professor Jinwhan Kim of the Department of Mechanical Engineering and Professor Hyunchul Shim of the School of Electrical Engineering, with Pablo Aviation as a partner, won a total prize money of $650,000 (KRW 860 million) at the Maritime Grand Challenge by the Mohamed Bin Zayed International Robotics Challenge (MBZIRC), finishing first runner-up.

This competition, which is the largest ever robotics competition held over water, is sponsored by the government of the United Arab Emirates and organized by ASPIRE, an organization under the Abu Dhabi Ministry of Science, with a total prize money of $3 million.

In the competition, which started at the end of 2021, 52 teams from around the world participated and five teams were selected to go on to the finals in February 2023 after going through the first and second stages of screening. The final round was held from January 10 to February 6, 2024, using actual unmanned ships and drones in a secluded sea area of 10 km2 off the coast of Abu Dhabi, the capital of the United Arab Emirates. A total of 18 KAIST students and Professor Jinwhan Kim and Professor Hyunchul Shim took part in this competition at the location at Abu Dhabi.

Team KAIST will receive $500,000 in prize money for taking second place in the final, and the team’s prize money totals up to $650,000 including $150,000 that was as special midterm award for finalists.

The final mission scenario is to find the target vessel on the run carrying illegal cargoes among many ships moving within the GPS-disabled marine surface, and inspect the deck for two different types of stolen cargo to recover them using the aerial vehicle to bring the small cargo and the robot manipulator topped on an unmanned ship to retrieve the larger one. The true aim of the mission is to complete it through autonomous collaboration of the unmanned ship and the aerial vehicle without human intervention throughout the entire mission process. In particular, since GPS cannot be used in this competition due to regulations, Professor Jinwhan Kim's research team developed autonomous operation techniques for unmanned ships, including searching and navigating methods using maritime radar, and Professor Hyunchul Shim's research team developed video-based navigation and a technology to combine a small autonomous robot with a drone.

The final mission is to retrieve cargo on board a ship fleeing at sea through autonomous collaboration between unmanned ships and unmanned aerial vehicles without human intervention. The overall mission consists the first stage of conducting the inspection to find the target ship among several ships moving at sea and the second stage of conducting the intervention mission to retrieve the cargoes on the deck of the ship. Each team was given a total of three opportunities, and the team that completed the highest-level mission in the shortest time during the three attempts received the highest score.

In the first attempt, KAIST was the only team to succeed in the first stage search mission, but the competition began in earnest as the Croatian team also completed the first stage mission in the second attempt. As the competition schedule was delayed due to strong winds and high waves that continued for several days, the organizers decided to hold the finals with the three teams, including the Team KAIST and the team from Croatia’s the University of Zagreb, which completed the first stage of the mission, and Team Fly-Eagle, a team of researcher from China and UAE that partially completed the first stage. The three teams were given the chance to proceed to the finals and try for the third attempt, and in the final competition, the Croatian team won, KAIST took the second place, and the combined team of UAE-China combined team took the third place. The final prize to be given for the winning team is set at $2 million with $500,000 for the runner-up team, and $250,000 for the third-place.

Professor Jinwhan Kim of the Department of Mechanical Engineering, who served as the advisor for Team KAIST, said, “I would like to express my gratitude and congratulations to the students who put in a huge academic and physical efforts in preparing for the competition over the past two years. I feel rewarded because, regardless of the results, every bit of efforts put into this up to this point will become the base of their confidence and a valuable asset in their growth into a great researcher.” Sol Han, a doctoral student in mechanical engineering who served as the team leader, said, “I am disappointed of how narrowly we missed out on winning at the end, but I am satisfied with the significance of the output we’ve got and I am grateful to the team members who worked hard together for that.”

HD Hyundai, Rainbow Robotics, Avikus, and FIMS also participated as sponsors for Team KAIST's campaign.

2024.02.09 View 11237 -

A Quick but Clingy Creepy-Crawler that will MARVEL You

Engineered by KAIST Mechanics, a quadrupedal robot climbs steel walls and crawls across metal ceilings at the fastest speed that the world has ever seen.

< Photo 1. (From left) KAIST ME Prof. Hae-Won Park, Ph.D. Student Yong Um, Ph.D. Student Seungwoo Hong >

- Professor Hae-Won Park's team at the Department of Mechanical Engineering developed a quadrupedal robot that can move at a high speed on ferrous walls and ceilings.

- It is expected to make a wide variety of contributions as it is to be used to conduct inspections and repairs of large steel structures such as ships, bridges, and transmission towers, offering an alternative to dangerous or risky activities required in hazardous environments while maintaining productivity and efficiency through automation and unmanning of such operations.

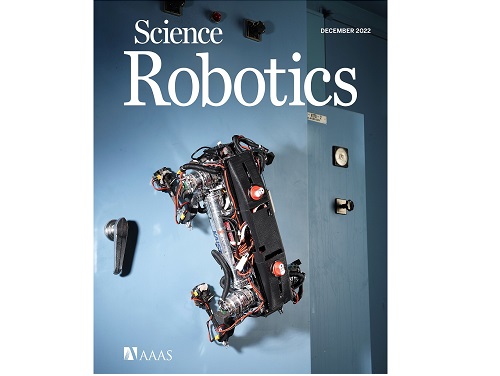

- The study was published as the cover paper of the December issue of Science Robotics.

KAIST (President Kwang Hyung Lee) announced on the 26th that a research team led by Professor Hae-Won Park of the Department of Mechanical Engineering developed a quadrupedal walking robot that can move at high speed on steel walls and ceilings named M.A.R.V.E.L. - rightly so as it is a Magnetically Adhesive Robot for Versatile and Expeditious Locomotion as described in their paper, “Agile and Versatile Climbing on Ferromagnetic Surfaces with a Quadrupedal Robot.” (DOI: 10.1126/scirobotics.add1017)

To make this happen, Professor Park's research team developed a foot pad that can quickly turn the magnetic adhesive force on and off while retaining high adhesive force even on an uneven surface through the use of the Electro-Permanent Magnet (EPM), a device that can magnetize and demagnetize an electromagnet with little power, and the Magneto-Rheological Elastomer (MRE), an elastic material made by mixing a magnetic response factor, such as iron powder, with an elastic material, such as rubber, which they mounted on a small quadrupedal robot they made in-house, at their own laboratory. These walking robots are expected to be put into a wide variety of usage, including being programmed to perform inspections, repairs, and maintenance tasks on large structures made of steel, such as ships, bridges, transmission towers, large storage areas, and construction sites.

This study, in which Seungwoo Hong and Yong Um of the Department of Mechanical Engineering participated as co-first authors, was published as the cover paper in the December issue of Science Robotics.

< Image on the Cover of 2022 December issue of Science Robotics >

Existing wall-climbing robots use wheels or endless tracks, so their mobility is limited on surfaces with steps or irregularities. On the other hand, walking robots for climbing can expect improved mobility in obstacle terrain, but have disadvantages in that they have significantly slower moving speeds or cannot perform various movements.

In order to enable fast movement of the walking robot, the sole of the foot must have strong adhesion force and be able to control the adhesion to quickly switch from sticking to the surface or to be off of it. In addition, it is necessary to maintain the adhesion force even on a rough or uneven surface.

To solve this problem, the research team used the EPM and MRE for the first time in designing the soles of walking robots. An EPM is a magnet that can turn on and off the electromagnetic force with a short current pulse. Unlike general electromagnets, it has the advantage that it does not require energy to maintain the magnetic force. The research team proposed a new EPM with a rectangular structure arrangement, enabling faster switching while significantly lowering the voltage required for switching compared to existing electromagnets.

In addition, the research team was able to increase the frictional force without significantly reducing the magnetic force of the sole by covering the sole with an MRE. The proposed sole weighs only 169 g, but provides a vertical gripping force of about *535 Newtons (N) and a frictional force of 445 N, which is sufficient gripping force for a quadrupedal robot weighing 8 kg.

* 535 N converted to kg is 54.5 kg, and 445 N is 45.4 kg. In other words, even if an external force of up to 54.5 kg in the vertical direction and up to 45.4 kg in the horizontal direction is applied (or even if a corresponding weight is hung), the sole of the foot does not come off the steel plate.

MARVEL climbed up a vertical wall at high speed at a speed of 70 cm per second, and was able to walk while hanging upside down from the ceiling at a maximum speed of 50 cm per second. This is the world's fastest speed for a walking climbing robot. In addition, the research team demonstrated that the robot can climb at a speed of up to 35 cm even on a surface that is painted, dirty with dust and the rust-tainted surfaces of water tanks, proving the robot's performance in a real environment. It was experimentally demonstrated that the robot not only exhibited high speed, but also can switch from floor to wall and from wall to ceiling, and overcome 5-cm high obstacles protruding from walls without difficulty.

The new climbing quadrupedal robot is expected to be widely used for inspection, repair, and maintenance of large steel structures such as ships, bridges, transmission towers, oil pipelines, large storage areas, and construction sites. As the works required in these places involves risks such as falls, suffocation and other accidents that may result in serious injuries or casualties, the need for automation is of utmost urgency.

One of the first co-authors of the paper, a Ph.D. student, Yong Um of KAIST’s Department of Mechanical Engineering, said, "By the use of the magnetic soles made up of the EPM and MRE and the non-linear model predictive controller suitable for climbing, the robot can speedily move through a variety of ferromagnetic surfaces including walls and ceilings, not just level grounds. We believe this would become a cornerstone that will expand the mobility and the places of pedal-mobile robots can venture into." He added, “These robots can be put into good use in executing dangerous and difficult tasks on steel structures in places like the shipbuilding yards.”

This research was carried out with support from the National Research Foundation of Korea's Basic Research in Science & Engineering Program for Mid-Career Researchers and Korea Shipbuilding & Offshore Engineering Co., Ltd..

< Figure 1. The quadrupedal robot (MARVEL) walking over various ferrous surfaces. (A) vertical wall (B) ceiling. (C) over obstacles on a vertical wall (D) making floor-to-wall and wall-to-ceiling transitions (E) moving over a storage tank (F) walking on a wall with a 2-kg weight and over a ceiling with a 3-kg load. >

< Figure 2. Description of the magnetic foot (A) Components of the magnet sole: ankle, Square Eletro-Permanent Magnet(S-EPM), MRE footpad. (B) Components of the S-EPM and MRE footpad. (C) Working principle of the S-EPM. When the magnetization direction is aligned as shown in the left figure, magnetic flux comes out of the keeper and circulates through the steel plate, generating holding force (ON state). Conversely, if the magnetization direction is aligned as shown in the figure on the right, the magnetic flux circulates inside the S-EPM and the holding force disappears (OFF state). >

Video Introduction: Agile and versatile climbing on ferromagnetic surfaces with a quadrupedal robot - YouTube

2022.12.30 View 16995

A Quick but Clingy Creepy-Crawler that will MARVEL You

Engineered by KAIST Mechanics, a quadrupedal robot climbs steel walls and crawls across metal ceilings at the fastest speed that the world has ever seen.

< Photo 1. (From left) KAIST ME Prof. Hae-Won Park, Ph.D. Student Yong Um, Ph.D. Student Seungwoo Hong >

- Professor Hae-Won Park's team at the Department of Mechanical Engineering developed a quadrupedal robot that can move at a high speed on ferrous walls and ceilings.

- It is expected to make a wide variety of contributions as it is to be used to conduct inspections and repairs of large steel structures such as ships, bridges, and transmission towers, offering an alternative to dangerous or risky activities required in hazardous environments while maintaining productivity and efficiency through automation and unmanning of such operations.

- The study was published as the cover paper of the December issue of Science Robotics.

KAIST (President Kwang Hyung Lee) announced on the 26th that a research team led by Professor Hae-Won Park of the Department of Mechanical Engineering developed a quadrupedal walking robot that can move at high speed on steel walls and ceilings named M.A.R.V.E.L. - rightly so as it is a Magnetically Adhesive Robot for Versatile and Expeditious Locomotion as described in their paper, “Agile and Versatile Climbing on Ferromagnetic Surfaces with a Quadrupedal Robot.” (DOI: 10.1126/scirobotics.add1017)

To make this happen, Professor Park's research team developed a foot pad that can quickly turn the magnetic adhesive force on and off while retaining high adhesive force even on an uneven surface through the use of the Electro-Permanent Magnet (EPM), a device that can magnetize and demagnetize an electromagnet with little power, and the Magneto-Rheological Elastomer (MRE), an elastic material made by mixing a magnetic response factor, such as iron powder, with an elastic material, such as rubber, which they mounted on a small quadrupedal robot they made in-house, at their own laboratory. These walking robots are expected to be put into a wide variety of usage, including being programmed to perform inspections, repairs, and maintenance tasks on large structures made of steel, such as ships, bridges, transmission towers, large storage areas, and construction sites.

This study, in which Seungwoo Hong and Yong Um of the Department of Mechanical Engineering participated as co-first authors, was published as the cover paper in the December issue of Science Robotics.

< Image on the Cover of 2022 December issue of Science Robotics >

Existing wall-climbing robots use wheels or endless tracks, so their mobility is limited on surfaces with steps or irregularities. On the other hand, walking robots for climbing can expect improved mobility in obstacle terrain, but have disadvantages in that they have significantly slower moving speeds or cannot perform various movements.

In order to enable fast movement of the walking robot, the sole of the foot must have strong adhesion force and be able to control the adhesion to quickly switch from sticking to the surface or to be off of it. In addition, it is necessary to maintain the adhesion force even on a rough or uneven surface.

To solve this problem, the research team used the EPM and MRE for the first time in designing the soles of walking robots. An EPM is a magnet that can turn on and off the electromagnetic force with a short current pulse. Unlike general electromagnets, it has the advantage that it does not require energy to maintain the magnetic force. The research team proposed a new EPM with a rectangular structure arrangement, enabling faster switching while significantly lowering the voltage required for switching compared to existing electromagnets.

In addition, the research team was able to increase the frictional force without significantly reducing the magnetic force of the sole by covering the sole with an MRE. The proposed sole weighs only 169 g, but provides a vertical gripping force of about *535 Newtons (N) and a frictional force of 445 N, which is sufficient gripping force for a quadrupedal robot weighing 8 kg.

* 535 N converted to kg is 54.5 kg, and 445 N is 45.4 kg. In other words, even if an external force of up to 54.5 kg in the vertical direction and up to 45.4 kg in the horizontal direction is applied (or even if a corresponding weight is hung), the sole of the foot does not come off the steel plate.

MARVEL climbed up a vertical wall at high speed at a speed of 70 cm per second, and was able to walk while hanging upside down from the ceiling at a maximum speed of 50 cm per second. This is the world's fastest speed for a walking climbing robot. In addition, the research team demonstrated that the robot can climb at a speed of up to 35 cm even on a surface that is painted, dirty with dust and the rust-tainted surfaces of water tanks, proving the robot's performance in a real environment. It was experimentally demonstrated that the robot not only exhibited high speed, but also can switch from floor to wall and from wall to ceiling, and overcome 5-cm high obstacles protruding from walls without difficulty.

The new climbing quadrupedal robot is expected to be widely used for inspection, repair, and maintenance of large steel structures such as ships, bridges, transmission towers, oil pipelines, large storage areas, and construction sites. As the works required in these places involves risks such as falls, suffocation and other accidents that may result in serious injuries or casualties, the need for automation is of utmost urgency.

One of the first co-authors of the paper, a Ph.D. student, Yong Um of KAIST’s Department of Mechanical Engineering, said, "By the use of the magnetic soles made up of the EPM and MRE and the non-linear model predictive controller suitable for climbing, the robot can speedily move through a variety of ferromagnetic surfaces including walls and ceilings, not just level grounds. We believe this would become a cornerstone that will expand the mobility and the places of pedal-mobile robots can venture into." He added, “These robots can be put into good use in executing dangerous and difficult tasks on steel structures in places like the shipbuilding yards.”

This research was carried out with support from the National Research Foundation of Korea's Basic Research in Science & Engineering Program for Mid-Career Researchers and Korea Shipbuilding & Offshore Engineering Co., Ltd..

< Figure 1. The quadrupedal robot (MARVEL) walking over various ferrous surfaces. (A) vertical wall (B) ceiling. (C) over obstacles on a vertical wall (D) making floor-to-wall and wall-to-ceiling transitions (E) moving over a storage tank (F) walking on a wall with a 2-kg weight and over a ceiling with a 3-kg load. >

< Figure 2. Description of the magnetic foot (A) Components of the magnet sole: ankle, Square Eletro-Permanent Magnet(S-EPM), MRE footpad. (B) Components of the S-EPM and MRE footpad. (C) Working principle of the S-EPM. When the magnetization direction is aligned as shown in the left figure, magnetic flux comes out of the keeper and circulates through the steel plate, generating holding force (ON state). Conversely, if the magnetization direction is aligned as shown in the figure on the right, the magnetic flux circulates inside the S-EPM and the holding force disappears (OFF state). >

Video Introduction: Agile and versatile climbing on ferromagnetic surfaces with a quadrupedal robot - YouTube

2022.12.30 View 16995 -

Industrial Design Senior Wins Top Award at International Forum Design

Sung-Joon Kim, a senior at the Department of Industrial Design, KAIST, has won the highest award at the International Forum Design held in Hanover, Germany, university sources said on Monday (April 13).

At the design exhibition held in February under the theme of "life, live, work," Kim presented "Rescue Stick," a portable life saving equipment and "Recovery Arm Sling," a medical treatment device, in cooperation with three students from other Korean universities. Both entries were included among the 15 works selected as the top designs.

The design competition has been organized by iF International Forum Design, known as one of the world"s three leading design exhibitions.

Kim, leader of the team, received the prize at the awarding ceremony held in Nuremberg on March 24. The award-winning designs were on display at the design fair of the Altenpflege + Propflege, a nursing care exhibition, in the same city on March 24-26.

2009.04.15 View 13156

Industrial Design Senior Wins Top Award at International Forum Design

Sung-Joon Kim, a senior at the Department of Industrial Design, KAIST, has won the highest award at the International Forum Design held in Hanover, Germany, university sources said on Monday (April 13).

At the design exhibition held in February under the theme of "life, live, work," Kim presented "Rescue Stick," a portable life saving equipment and "Recovery Arm Sling," a medical treatment device, in cooperation with three students from other Korean universities. Both entries were included among the 15 works selected as the top designs.

The design competition has been organized by iF International Forum Design, known as one of the world"s three leading design exhibitions.

Kim, leader of the team, received the prize at the awarding ceremony held in Nuremberg on March 24. The award-winning designs were on display at the design fair of the Altenpflege + Propflege, a nursing care exhibition, in the same city on March 24-26.

2009.04.15 View 13156