optical+transmittance

-

From Dark to Light in a Flash: Smart Film Lets Windows Switch Autonomously

Researchers have developed a new easy-to-use smart optical film technology that allows smart window devices to autonomously switch between transparent and opaque states in response to the surrounding light conditions.

The proposed 3D hybrid nanocomposite film with a highly periodic network structure has empirically demonstrated its high speed and performance, enabling the smart window to quantify and self-regulate its high-contrast optical transmittance. As a proof of concept, a mobile-app-enabled smart window device for Internet of Things (IoT) applications has been realized using the proposed smart optical film with successful expansion to the 3-by-3-inch scale. This energy-efficient and cost-effective technology holds great promise for future use in various applications that require active optical transmission modulation.

Flexible optical transmission modulation technologies for smart applications including privacy-protection windows, zero-energy buildings, and beam projection screens have been in the spotlight in recent years. Conventional technologies that used external stimuli such as electricity, heat, or light to modulate optical transmission had only limited applications due to their slow response speeds, unnecessary color switching, and low durability, stability, and safety.

The optical transmission modulation contrast achieved by controlling the light scattering interfaces on non-periodic 2D surface structures that often have low optical density such as cracks, wrinkles, and pillars is also generally low. In addition, since the light scattering interfaces are exposed and not subject to any passivation, they can be vulnerable to external damage and may lose optical transmission modulation functions. Furthermore, in-plane scattering interfaces that randomly exist on the surface make large-area modulation with uniformity difficult.

Inspired by these limitations, a KAIST research team led by Professor Seokwoo Jeon from the Department of Materials Science and Engineering and Professor Jung-Wuk Hong of the Civil and Environmental Engineering Department used proximity-field nanopatterning (PnP) technology that effectively produces highly periodic 3D hybrid nanostructures, and an atomic layer deposition (ALD) technique that allows the precise control of oxide deposition and the high-quality fabrication of semiconductor devices.

The team then successfully produced a large-scale smart optical film with a size of 3 by 3 inches in which ultrathin alumina nanoshells are inserted between the elastomers in a periodic 3D nanonetwork.

This “mechano-responsive” 3D hybrid nanocomposite film with a highly periodic network structure is the largest smart optical transmission modulation film that exists. The film has been shown to have state-of-the-art optical transmission modulation of up to 74% at visible wavelengths from 90% initial transmission to 16% in the scattering state under strain. Its durability and stability were proved by more than 10,000 tests of harsh mechanical deformation including stretching, releasing, bending, and being placed under high temperatures of up to 70°C. When this film was used, the transmittance of the smart window device was adjusted promptly and automatically within one second in response to the surrounding light conditions. Through these experiments, the underlying physics of optical scattering phenomena occurring in the heterogeneous interfaces were identified. Their findings were reported in the online edition of Advanced Science on April 26. KAIST Professor Jong-Hwa Shin’s group and Professor Young-Seok Shim at Silla University also collaborated on this project.

Donghwi Cho, a PhD candidate in materials science and engineering at KAIST and co-lead author of the study, said, “Our smart optical film technology can better control high-contrast optical transmittance by relatively simple operating principles and with low energy consumption and costs.”

“When this technology is applied by simply attaching the film to a conventional smart window glass surface without replacing the existing window system, fast switching and uniform tinting are possible while also securing durability, stability, and safety. In addition, its wide range of applications for stretchable or rollable devices such as wall-type displays for a beam projection screen will also fulfill aesthetic needs,” he added.

This work was supported by the National Research Foundation of Korea (NRF), and the Korean Ministries of Science, ICT and Future Planning (MSIP), and Science and ICT (MSIT).

Publication:

Cho, D, et al. (2020) ‘High-Contrast Optical Modulation from Strain-Indicated Nanogaps at 3D Heterogeneous Interfaces’ Advanced Science, 1903708. Available online at https://doi.org/10.1002/advs.201903708

Profile: Seokwoo Jeon, PhD

Professor

jeon39@kaist.ac.kr

https://fdml.kaist.ac.kr/

Flexible Device and Metamaterials Lab (FDML)

Department of Materials Science and Engineering (MSE)

Korea Advanced Institute of Science and Technology (KAIST)

https://www.kaist.ac.krDaejeon 34141, Korea

Profile: Jung-Wuk Hong, PhD

Associate Professor

j.hong@kaist.ac.kr

http://aaml.kaist.ac.kr

Advanced Applied Mechanics Laboratory (AAML)

Department of Civil and Environmental Engineering

KAIST

Profile: Donghwi Cho

PhD Candidate

roy0202@kaist.ac.krFDML, MSE, KAIST

Profile: Young-Seok Shim, PhD

Assistant Professor

ysshim@silla.ac.kr

Division of Materials Science and Engineering Silla University

https://www.silla.ac.kr

Busan 46958, Korea

(END)

2020.06.02 View 15933

From Dark to Light in a Flash: Smart Film Lets Windows Switch Autonomously

Researchers have developed a new easy-to-use smart optical film technology that allows smart window devices to autonomously switch between transparent and opaque states in response to the surrounding light conditions.

The proposed 3D hybrid nanocomposite film with a highly periodic network structure has empirically demonstrated its high speed and performance, enabling the smart window to quantify and self-regulate its high-contrast optical transmittance. As a proof of concept, a mobile-app-enabled smart window device for Internet of Things (IoT) applications has been realized using the proposed smart optical film with successful expansion to the 3-by-3-inch scale. This energy-efficient and cost-effective technology holds great promise for future use in various applications that require active optical transmission modulation.

Flexible optical transmission modulation technologies for smart applications including privacy-protection windows, zero-energy buildings, and beam projection screens have been in the spotlight in recent years. Conventional technologies that used external stimuli such as electricity, heat, or light to modulate optical transmission had only limited applications due to their slow response speeds, unnecessary color switching, and low durability, stability, and safety.

The optical transmission modulation contrast achieved by controlling the light scattering interfaces on non-periodic 2D surface structures that often have low optical density such as cracks, wrinkles, and pillars is also generally low. In addition, since the light scattering interfaces are exposed and not subject to any passivation, they can be vulnerable to external damage and may lose optical transmission modulation functions. Furthermore, in-plane scattering interfaces that randomly exist on the surface make large-area modulation with uniformity difficult.

Inspired by these limitations, a KAIST research team led by Professor Seokwoo Jeon from the Department of Materials Science and Engineering and Professor Jung-Wuk Hong of the Civil and Environmental Engineering Department used proximity-field nanopatterning (PnP) technology that effectively produces highly periodic 3D hybrid nanostructures, and an atomic layer deposition (ALD) technique that allows the precise control of oxide deposition and the high-quality fabrication of semiconductor devices.

The team then successfully produced a large-scale smart optical film with a size of 3 by 3 inches in which ultrathin alumina nanoshells are inserted between the elastomers in a periodic 3D nanonetwork.

This “mechano-responsive” 3D hybrid nanocomposite film with a highly periodic network structure is the largest smart optical transmission modulation film that exists. The film has been shown to have state-of-the-art optical transmission modulation of up to 74% at visible wavelengths from 90% initial transmission to 16% in the scattering state under strain. Its durability and stability were proved by more than 10,000 tests of harsh mechanical deformation including stretching, releasing, bending, and being placed under high temperatures of up to 70°C. When this film was used, the transmittance of the smart window device was adjusted promptly and automatically within one second in response to the surrounding light conditions. Through these experiments, the underlying physics of optical scattering phenomena occurring in the heterogeneous interfaces were identified. Their findings were reported in the online edition of Advanced Science on April 26. KAIST Professor Jong-Hwa Shin’s group and Professor Young-Seok Shim at Silla University also collaborated on this project.

Donghwi Cho, a PhD candidate in materials science and engineering at KAIST and co-lead author of the study, said, “Our smart optical film technology can better control high-contrast optical transmittance by relatively simple operating principles and with low energy consumption and costs.”

“When this technology is applied by simply attaching the film to a conventional smart window glass surface without replacing the existing window system, fast switching and uniform tinting are possible while also securing durability, stability, and safety. In addition, its wide range of applications for stretchable or rollable devices such as wall-type displays for a beam projection screen will also fulfill aesthetic needs,” he added.

This work was supported by the National Research Foundation of Korea (NRF), and the Korean Ministries of Science, ICT and Future Planning (MSIP), and Science and ICT (MSIT).

Publication:

Cho, D, et al. (2020) ‘High-Contrast Optical Modulation from Strain-Indicated Nanogaps at 3D Heterogeneous Interfaces’ Advanced Science, 1903708. Available online at https://doi.org/10.1002/advs.201903708

Profile: Seokwoo Jeon, PhD

Professor

jeon39@kaist.ac.kr

https://fdml.kaist.ac.kr/

Flexible Device and Metamaterials Lab (FDML)

Department of Materials Science and Engineering (MSE)

Korea Advanced Institute of Science and Technology (KAIST)

https://www.kaist.ac.krDaejeon 34141, Korea

Profile: Jung-Wuk Hong, PhD

Associate Professor

j.hong@kaist.ac.kr

http://aaml.kaist.ac.kr

Advanced Applied Mechanics Laboratory (AAML)

Department of Civil and Environmental Engineering

KAIST

Profile: Donghwi Cho

PhD Candidate

roy0202@kaist.ac.krFDML, MSE, KAIST

Profile: Young-Seok Shim, PhD

Assistant Professor

ysshim@silla.ac.kr

Division of Materials Science and Engineering Silla University

https://www.silla.ac.kr

Busan 46958, Korea

(END)

2020.06.02 View 15933 -

Wearable Strain Sensor Using Light Transmittance Helps Measure Physical Signals Better

KAIST researchers have developed a novel wearable strain sensor based on the modulation of optical transmittance of a carbon nanotube (CNT)-embedded elastomer. The sensor is capable of sensitive, stable, and continuous measurement of physical signals. This technology, featured in the March 4th issue of ACS Applied Materials & Interfaces as a front cover article, shows great potential for the detection of subtle human motions and the real-time monitoring of body postures for healthcare applications.

A wearable strain sensor must have high sensitivity, flexibility, and stretchability, as well as low cost. Those used especially for health monitoring should also be tied to long-term solid performance, and be environmentally stable. Various stretchable strain sensors based on piezo-resistive and capacitive principles have been developed to meet all these requirements.

Conventional piezo-resistive strain sensors using functional nanomaterials, including CNTs as the most common example, have shown high sensitivity and great sensing performance. However, they suffer from poor long-term stability and linearity, as well as considerable signal hysteresis. As an alternative, piezo-capacitive strain sensors with better stability, lower hysteresis, and higher stretchability have been suggested. But due to the fact that piezo-capacitive strain sensors exhibit limited sensitivity and strong electromagnetic interference caused by the conductive objects in the surrounding environment, these conventional stretchable strain sensors are still facing limitations that are yet to be resolved.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering suggested that an optical-type stretchable strain sensor can be a good alternative to resolve the limitations of conventional piezo-resistive and piezo-capacitive strain sensors, because they have high stability and are less affected by environmental disturbances. The team then introduced an optical wearable strain sensor based on the light transmittance changes of a CNT-embedded elastomer, which further addresses the low sensitivity problem of conventional optical stretchable strain sensors.

In order to achieve a large dynamic range for the sensor, Professor Park and his researchers chose Ecoflex as an elastomeric substrate with good mechanical durability, flexibility, and attachability on human skin, and the new optical wearable strain sensor developed by the research group actually shows a wide dynamic range of 0 to 400%.

In addition, the researchers propagated the microcracks under tensile strain within the film of multi-walled CNTs embedded in the Ecoflex substrate, changing the optical transmittance of the film. By doing so, it was possible for them to develop a wearable strain sensor having a sensitivity 10 times higher than conventional optical stretchable strain sensors.

The proposed sensor has also passed the durability test with excellent results. The sensor’s response after 13,000 sets of cyclic loading was stable without any noticeable drift. This suggests that the sensor response can be used without degradation, even if the sensor is repeatedly used for a long time and in various environmental conditions.

Using the developed sensor, the research team could measure the finger bending motion and used it for robot control. They also developed a three-axes sensor array for body posture monitoring. The sensor was able to monitor human motions with small strains such as a pulse near the carotid artery and muscle movement around the mouth during pronunciation.

Professor Park said, “In this study, our group developed a new wearable strain sensor platform that overcomes many limitations of previously developed resistive, capacitive, and optical-type stretchable strain sensors. Our sensor could be widely used in a variety of fields including soft robotics, wearable electronics, electronic skin, healthcare, and even entertainment.”

This work was supported by the National Research Foundation (NRF) of Korea.

Publication:

Jimin Gu, Donguk Kwon, Junseong Ahn, and Inkyu Park. (2020) “Wearable Strain sensors Using Light Transmittance Change of Carbon Nanotube-Embedded Elastomers with Microcracks” ACS Applied Materials & Interfaces. Volume 12. Issue 9. Available online at https://doi.org/10.1021/acsami.9b18069

Profile:

Inkyu Park

Professor

inkyu@kaist.ac.kr

http://mintlab1.kaist.ac.kr

Micro/Nano Transducers Laboratory (MINT Lab)

Department of Mechanical Engineering (ME)Korea Advanced Institute of Science and Technology (KAIST)

Profile:

Jimin Gu

Ph.D. Candidate

mint9411@kaist.ac.kr

http://mintlab1.kaist.ac.kr

MINT Lab

KAIST ME

(END)

2020.03.20 View 23499

Wearable Strain Sensor Using Light Transmittance Helps Measure Physical Signals Better

KAIST researchers have developed a novel wearable strain sensor based on the modulation of optical transmittance of a carbon nanotube (CNT)-embedded elastomer. The sensor is capable of sensitive, stable, and continuous measurement of physical signals. This technology, featured in the March 4th issue of ACS Applied Materials & Interfaces as a front cover article, shows great potential for the detection of subtle human motions and the real-time monitoring of body postures for healthcare applications.

A wearable strain sensor must have high sensitivity, flexibility, and stretchability, as well as low cost. Those used especially for health monitoring should also be tied to long-term solid performance, and be environmentally stable. Various stretchable strain sensors based on piezo-resistive and capacitive principles have been developed to meet all these requirements.

Conventional piezo-resistive strain sensors using functional nanomaterials, including CNTs as the most common example, have shown high sensitivity and great sensing performance. However, they suffer from poor long-term stability and linearity, as well as considerable signal hysteresis. As an alternative, piezo-capacitive strain sensors with better stability, lower hysteresis, and higher stretchability have been suggested. But due to the fact that piezo-capacitive strain sensors exhibit limited sensitivity and strong electromagnetic interference caused by the conductive objects in the surrounding environment, these conventional stretchable strain sensors are still facing limitations that are yet to be resolved.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering suggested that an optical-type stretchable strain sensor can be a good alternative to resolve the limitations of conventional piezo-resistive and piezo-capacitive strain sensors, because they have high stability and are less affected by environmental disturbances. The team then introduced an optical wearable strain sensor based on the light transmittance changes of a CNT-embedded elastomer, which further addresses the low sensitivity problem of conventional optical stretchable strain sensors.

In order to achieve a large dynamic range for the sensor, Professor Park and his researchers chose Ecoflex as an elastomeric substrate with good mechanical durability, flexibility, and attachability on human skin, and the new optical wearable strain sensor developed by the research group actually shows a wide dynamic range of 0 to 400%.

In addition, the researchers propagated the microcracks under tensile strain within the film of multi-walled CNTs embedded in the Ecoflex substrate, changing the optical transmittance of the film. By doing so, it was possible for them to develop a wearable strain sensor having a sensitivity 10 times higher than conventional optical stretchable strain sensors.

The proposed sensor has also passed the durability test with excellent results. The sensor’s response after 13,000 sets of cyclic loading was stable without any noticeable drift. This suggests that the sensor response can be used without degradation, even if the sensor is repeatedly used for a long time and in various environmental conditions.

Using the developed sensor, the research team could measure the finger bending motion and used it for robot control. They also developed a three-axes sensor array for body posture monitoring. The sensor was able to monitor human motions with small strains such as a pulse near the carotid artery and muscle movement around the mouth during pronunciation.

Professor Park said, “In this study, our group developed a new wearable strain sensor platform that overcomes many limitations of previously developed resistive, capacitive, and optical-type stretchable strain sensors. Our sensor could be widely used in a variety of fields including soft robotics, wearable electronics, electronic skin, healthcare, and even entertainment.”

This work was supported by the National Research Foundation (NRF) of Korea.

Publication:

Jimin Gu, Donguk Kwon, Junseong Ahn, and Inkyu Park. (2020) “Wearable Strain sensors Using Light Transmittance Change of Carbon Nanotube-Embedded Elastomers with Microcracks” ACS Applied Materials & Interfaces. Volume 12. Issue 9. Available online at https://doi.org/10.1021/acsami.9b18069

Profile:

Inkyu Park

Professor

inkyu@kaist.ac.kr

http://mintlab1.kaist.ac.kr

Micro/Nano Transducers Laboratory (MINT Lab)

Department of Mechanical Engineering (ME)Korea Advanced Institute of Science and Technology (KAIST)

Profile:

Jimin Gu

Ph.D. Candidate

mint9411@kaist.ac.kr

http://mintlab1.kaist.ac.kr

MINT Lab

KAIST ME

(END)

2020.03.20 View 23499 -

The control of light at the nano-level

Professor Min Bumki

Professor Min Bumki’s research team from the Department of Mechanical Engineering at KAIST have successfully gained control of the transmittance of light in optical devices using graphene* and artificial 2-dimensional metamaterials**.

* Graphene : a thin membrane composed of pure carbon, with atoms arranged in a regular hexagonal pattern

** Metamaterials : artificial materials engineered to have properties that may not be found in nature

The research results were published in the recent online edition (September 30th) of Nature Materials, a sister journal of the world renowned Nature journal, under the title ‘Terahertz waves with gate-controlled active graphene metamaterials’

Since the discovery of graphene in 2004 by Professors Novoselov and Geim from the University of Manchester (2010 Nobel Prize winners in Physics), it has been dubbed “the dream material” because of its outstanding physical properties.

Graphene has been especially praised for its ability to absorb approximately 2.3% of near infrared and visible rays due to its characteristic electron structure. This property allows graphene to be used as a transparent electrode, which is a vital electrical component used in touch screens and solar batteries. However, graphene’s optical transmittance was largely ignored by researchers due to its limited control using electrical methods and its small optical modulation in data transfer.

Professor Min’s team combined 0.34 nanometer-thick graphene with metamaterials to allow a more effective control of light transmittance and greater optical modulation. This graphene metamaterial can be integrated in to a thin and flexible macromolecule substrate which allows the control of transmittance using electric signals.

This research experimentally showed that graphene metamaterials can not only effective control optical transmittance, but can also be used in graphene optical memory devices using electrical hysteresis.

Professor Min said that “this research allows the effective control of light at the nanometer level” and that “this research will help in the development of microscopic optical modulators or memory disks”.

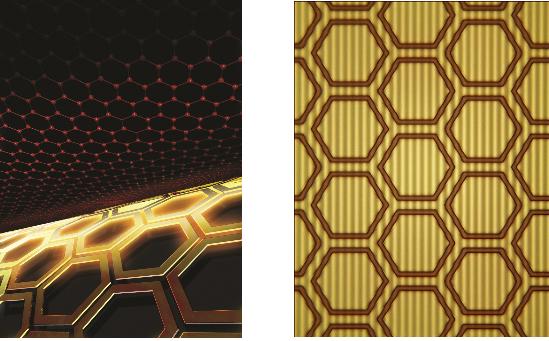

figure 1. The working drawing of graphene metamaterials

figure 2. Conceptual diagram (Left) and microscopic photo (right) of graphene metamaterials

2012.11.23 View 12395

The control of light at the nano-level

Professor Min Bumki

Professor Min Bumki’s research team from the Department of Mechanical Engineering at KAIST have successfully gained control of the transmittance of light in optical devices using graphene* and artificial 2-dimensional metamaterials**.

* Graphene : a thin membrane composed of pure carbon, with atoms arranged in a regular hexagonal pattern

** Metamaterials : artificial materials engineered to have properties that may not be found in nature

The research results were published in the recent online edition (September 30th) of Nature Materials, a sister journal of the world renowned Nature journal, under the title ‘Terahertz waves with gate-controlled active graphene metamaterials’

Since the discovery of graphene in 2004 by Professors Novoselov and Geim from the University of Manchester (2010 Nobel Prize winners in Physics), it has been dubbed “the dream material” because of its outstanding physical properties.

Graphene has been especially praised for its ability to absorb approximately 2.3% of near infrared and visible rays due to its characteristic electron structure. This property allows graphene to be used as a transparent electrode, which is a vital electrical component used in touch screens and solar batteries. However, graphene’s optical transmittance was largely ignored by researchers due to its limited control using electrical methods and its small optical modulation in data transfer.

Professor Min’s team combined 0.34 nanometer-thick graphene with metamaterials to allow a more effective control of light transmittance and greater optical modulation. This graphene metamaterial can be integrated in to a thin and flexible macromolecule substrate which allows the control of transmittance using electric signals.

This research experimentally showed that graphene metamaterials can not only effective control optical transmittance, but can also be used in graphene optical memory devices using electrical hysteresis.

Professor Min said that “this research allows the effective control of light at the nanometer level” and that “this research will help in the development of microscopic optical modulators or memory disks”.

figure 1. The working drawing of graphene metamaterials

figure 2. Conceptual diagram (Left) and microscopic photo (right) of graphene metamaterials

2012.11.23 View 12395