Advanced+Materials

-

KAIST perfectly reproduces Joseon-era Irworobongdo without pigments

Typically, chemical pigments that absorb specific wavelengths of light within the visible spectrum are required to produce colors. However, KAIST researchers have successfully reproduced the Joseon-era Irworobongdo [일월오봉도] painting using ultra-precise color graphics without any chemical pigments, allowing for the permanent and eco-friendly preservation of color graphics without fading or discoloration.

< (From left) Chaerim Son, a graduate of the Department of Biochemical Engineering (lead author), Seong Kyeong Nam, a graduate of the PhD program, Jiwoo Lee, a PhD student, and Professor Shin-Hyun Kim >

KAIST (represented by President Kwang Hyung Lee) announced on the 26th of February that a research team led by Professor Shinhyun Kim from the Department of Biological and Chemical Engineering had developed a technology that enables high-resolution color graphics without using any chemical pigments by employing hemisphere-shaped microstructures.

Morpho butterflies that are brilliant blue in color or Panther chameleons that change skin color exhibit coloration without chemical pigments, as ordered nanostructures within a material reflect visible light through optical interference. Since structural colors arise from physical structures rather than chemical substances, a single material can produce a wide range of colors.

However, the artificial implementation of structural coloration is highly challenging due to the complexity of creating ordered nanostructures. Additionally, it is difficult to produce a variety of colors and to pattern them precisely into complex designs.

< Figure 1. Principle of structural color expression using micro-hemispheres (left) and method of forming micro-hemisphere patterns based on photolithography (right) >

Professor Kim’s team overcame these challenges by using smooth-surfaced hemispherical microstructures instead of ordered nanostructures, enabling the high-precision patterning of diverse structural colors.

When light enters the inverted hemispherical microstructures, the portion of light entering from the sides undergoes total internal reflection along the curved surface, creating retroreflection. When the hemisphere diameter is approximately 10 micrometers (about one-tenth the thickness of a human hair), light traveling along different reflection paths interferes within the visible spectrum, producing structural coloration.

< Figure 2. “Irworobongdo”, the Painting of the Sun, Moon, and the Five Peaks, reproduced in fingernail size without pigment using approximately 200,000 micro-hemispheres >

The structural color can be tuned by adjusting the size of the hemispheres. By arranging hemispheres of varying sizes, much like mixing paints on a palette, an infinite range of colors can be generated.

To precisely pattern microscale hemispheres of different sizes, the research team employed photolithography* using positive photoresists** commonly used in semiconductor processing. They first patterned photoresists into micropillar structures, then induced reflow*** by heating the material, forming hemispherical microstructures.

*Photolithography: A technique used in semiconductor fabrication to pattern microscale structures.

**Positive photoresist: A photosensitive polymer that dissolves more easily in a developer solution after exposure to ultraviolet light.

***Reflow: A process in which a polymer material softens and reshapes into a curved structure when heated.

This method enables the formation of hemisphere-shaped microstructures with the desired sizes and colors in a single-step fabrication process. It also allows for the reproduction of arbitrary color graphics using a single material without any pigments.

The ultra-precise color graphics created with this technique can exhibit color variations depending on the angle of incident light or the viewing perspective. The pattern appears colored from one direction while remaining transparent from the opposite side, exhibiting a Janus effect. These structural color graphics achieve resolution comparable to cutting-edge LED displays, allowing complex color images to be captured within a fingernail-sized area and projected onto large screens.

< Figure 3. “Irworobongdo” that displays different shades depending on the angle of light and viewing direction >

Professor Shinhyun Kim, who led the research, stated, “Our newly developed pigment-free color graphics technology can serve as an innovative method for artistic expression, merging art with advanced materials. Additionally, it holds broad application potential in optical devices and sensors, anti-counterfeiting materials, aesthetic photocard printing, and many other fields.”

This research, with KAIST researcher Chaerim Son as the first author, was published in the prestigious materials science journal Advanced Materials on February 5.

(Paper title: “Retroreflective Multichrome Microdome Arrays Created by Single-Step Reflow”, DOI: 10.1002/adma.202413143 )

< Figure 4. Famous paintings reproduced without pigment: “Impression, Sunrise” (left), “Girl with a Pearl Earring” (right) >

The study was supported by the National Research Foundation of Korea through the Pioneer Converging Technology R&D Program and the Mid-Career Researcher Program.

2025.02.26 View 5956

KAIST perfectly reproduces Joseon-era Irworobongdo without pigments

Typically, chemical pigments that absorb specific wavelengths of light within the visible spectrum are required to produce colors. However, KAIST researchers have successfully reproduced the Joseon-era Irworobongdo [일월오봉도] painting using ultra-precise color graphics without any chemical pigments, allowing for the permanent and eco-friendly preservation of color graphics without fading or discoloration.

< (From left) Chaerim Son, a graduate of the Department of Biochemical Engineering (lead author), Seong Kyeong Nam, a graduate of the PhD program, Jiwoo Lee, a PhD student, and Professor Shin-Hyun Kim >

KAIST (represented by President Kwang Hyung Lee) announced on the 26th of February that a research team led by Professor Shinhyun Kim from the Department of Biological and Chemical Engineering had developed a technology that enables high-resolution color graphics without using any chemical pigments by employing hemisphere-shaped microstructures.

Morpho butterflies that are brilliant blue in color or Panther chameleons that change skin color exhibit coloration without chemical pigments, as ordered nanostructures within a material reflect visible light through optical interference. Since structural colors arise from physical structures rather than chemical substances, a single material can produce a wide range of colors.

However, the artificial implementation of structural coloration is highly challenging due to the complexity of creating ordered nanostructures. Additionally, it is difficult to produce a variety of colors and to pattern them precisely into complex designs.

< Figure 1. Principle of structural color expression using micro-hemispheres (left) and method of forming micro-hemisphere patterns based on photolithography (right) >

Professor Kim’s team overcame these challenges by using smooth-surfaced hemispherical microstructures instead of ordered nanostructures, enabling the high-precision patterning of diverse structural colors.

When light enters the inverted hemispherical microstructures, the portion of light entering from the sides undergoes total internal reflection along the curved surface, creating retroreflection. When the hemisphere diameter is approximately 10 micrometers (about one-tenth the thickness of a human hair), light traveling along different reflection paths interferes within the visible spectrum, producing structural coloration.

< Figure 2. “Irworobongdo”, the Painting of the Sun, Moon, and the Five Peaks, reproduced in fingernail size without pigment using approximately 200,000 micro-hemispheres >

The structural color can be tuned by adjusting the size of the hemispheres. By arranging hemispheres of varying sizes, much like mixing paints on a palette, an infinite range of colors can be generated.

To precisely pattern microscale hemispheres of different sizes, the research team employed photolithography* using positive photoresists** commonly used in semiconductor processing. They first patterned photoresists into micropillar structures, then induced reflow*** by heating the material, forming hemispherical microstructures.

*Photolithography: A technique used in semiconductor fabrication to pattern microscale structures.

**Positive photoresist: A photosensitive polymer that dissolves more easily in a developer solution after exposure to ultraviolet light.

***Reflow: A process in which a polymer material softens and reshapes into a curved structure when heated.

This method enables the formation of hemisphere-shaped microstructures with the desired sizes and colors in a single-step fabrication process. It also allows for the reproduction of arbitrary color graphics using a single material without any pigments.

The ultra-precise color graphics created with this technique can exhibit color variations depending on the angle of incident light or the viewing perspective. The pattern appears colored from one direction while remaining transparent from the opposite side, exhibiting a Janus effect. These structural color graphics achieve resolution comparable to cutting-edge LED displays, allowing complex color images to be captured within a fingernail-sized area and projected onto large screens.

< Figure 3. “Irworobongdo” that displays different shades depending on the angle of light and viewing direction >

Professor Shinhyun Kim, who led the research, stated, “Our newly developed pigment-free color graphics technology can serve as an innovative method for artistic expression, merging art with advanced materials. Additionally, it holds broad application potential in optical devices and sensors, anti-counterfeiting materials, aesthetic photocard printing, and many other fields.”

This research, with KAIST researcher Chaerim Son as the first author, was published in the prestigious materials science journal Advanced Materials on February 5.

(Paper title: “Retroreflective Multichrome Microdome Arrays Created by Single-Step Reflow”, DOI: 10.1002/adma.202413143 )

< Figure 4. Famous paintings reproduced without pigment: “Impression, Sunrise” (left), “Girl with a Pearl Earring” (right) >

The study was supported by the National Research Foundation of Korea through the Pioneer Converging Technology R&D Program and the Mid-Career Researcher Program.

2025.02.26 View 5956 -

Ultralight advanced material developed by KAIST and U of Toronto

< (From left) Professor Seunghwa Ryu of KAIST Department of Mechanical Engineering, Professor Tobin Filleter of the University of Toronto, Dr. Jinwook Yeo of KAIST, and Dr. Peter Serles of the University of Toronto >

Recently, in advanced industries such as automobiles, aerospace, and mobility, there has been increasing demand for materials that achieve weight reduction while maintaining excellent mechanical properties. An international joint research team has developed an ultralight, high-strength material utilizing nanostructures, presenting the potential for various industrial applications through customized design in the future.

KAIST (represented by President Kwang Hyung Lee) announced on the 18th of February that a research team led by Professor Seunghwa Ryu from the Department of Mechanical Engineering, in collaboration with Professor Tobin Filleter from the University of Toronto, has developed a nano-lattice structure that maximizes lightweight properties while maintaining high stiffness and strength.

In this study, the research team optimized the beam shape of the lattice structure to maintain its lightweight characteristics while maximizing stiffness and strength.

Particularly, using a multi-objective Bayesian optimization algorithm*, the team conducted an optimal design process that simultaneously considers tensile and shear stiffness improvement and weight reduction. They demonstrated that the optimal lattice structure could be predicted and designed with significantly less data (about 400 data points) compared to conventional methods.

*Multi-objective Bayesian optimization algorithm: A method that finds the optimal solution while considering multiple objectives simultaneously. It efficiently collects data and predicts results even under conditions of uncertainty.

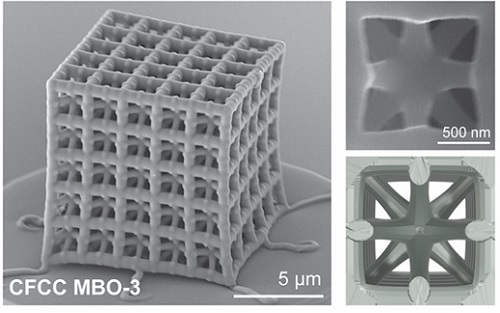

< Figure 1. Multi-objective Bayesian optimization for generative design of carbon nanolattices with high compressive stiffness and strength at low density. The upper is the illustration of process workflow. The lower part shows top four MBO CFCC geometries with their 2D Bézier curves. (The optimized structure is predicted and designed with much less data (approximately 400) than the conventional method >

Furthermore, to maximize the effect where mechanical properties improve as size decreases at the nanoscale, the research team utilized pyrolytic carbon* material to implement an ultralight, high-strength, high-stiffness nano-lattice structure.

*Pyrolytic carbon: A carbon material obtained by decomposing organic substances at high temperatures. It has excellent heat resistance and strength, making it widely used in industries such as semiconductor equipment coatings and artificial joint coatings, where it must withstand high temperatures without deformation.

For this, the team applied two-photon polymerization (2PP) technology* to precisely fabricate complex nano-lattice structures, and mechanical performance evaluations confirmed that the developed structure simultaneously possesses strength comparable to steel and the lightness of Styrofoam.

*Two-photon polymerization (2PP) technology: An advanced optical manufacturing technique based on the principle that polymerization occurs only when two photons of a specific wavelength are absorbed simultaneously.

Additionally, the research team demonstrated that multi-focus two-photon polymerization (multi-focus 2PP) technology enables the fabrication of millimeter-scale structures while maintaining nanoscale precision.

Professor Seunghwa Ryu explained, "This technology innovatively solves the stress concentration issue, which has been a limitation of conventional design methods, through three-dimensional nano-lattice structures, achieving both ultralight weight and high strength in material development."

< Figure 2. FESEM image of the fabricated nano-lattice structure and (bottom right) the macroscopic nanolattice resting on a bubble >

He further emphasized, "By integrating data-driven optimal design with precision 3D printing technology, this development not only meets the demand for lightweight materials in the aerospace and automotive industries but also opens possibilities for various industrial applications through customized design."

This study was led by Dr. Peter Serles of the Department of Mechanical & Industrial Engineering at University of Toronto and Dr. Jinwook Yeo from KAIST as co-first authors, with Professor Seunghwa Ryu and Professor Tobin Filleter as corresponding authors.

The research was published on January 23, 2025 in the international journal Advanced Materials (Paper title: “Ultrahigh Specific Strength by Bayesian Optimization of Lightweight Carbon Nanolattices”).

DOI: https://doi.org/10.1002/adma.202410651

This research was supported by the Multiphase Materials Innovation Manufacturing Research Center (an ERC program) funded by the Ministry of Science and ICT, the M3DT (Medical Device Digital Development Tool) project funded by the Ministry of Food and Drug Safety, and the KAIST International Collaboration Program.

2025.02.18 View 6852

Ultralight advanced material developed by KAIST and U of Toronto

< (From left) Professor Seunghwa Ryu of KAIST Department of Mechanical Engineering, Professor Tobin Filleter of the University of Toronto, Dr. Jinwook Yeo of KAIST, and Dr. Peter Serles of the University of Toronto >

Recently, in advanced industries such as automobiles, aerospace, and mobility, there has been increasing demand for materials that achieve weight reduction while maintaining excellent mechanical properties. An international joint research team has developed an ultralight, high-strength material utilizing nanostructures, presenting the potential for various industrial applications through customized design in the future.

KAIST (represented by President Kwang Hyung Lee) announced on the 18th of February that a research team led by Professor Seunghwa Ryu from the Department of Mechanical Engineering, in collaboration with Professor Tobin Filleter from the University of Toronto, has developed a nano-lattice structure that maximizes lightweight properties while maintaining high stiffness and strength.

In this study, the research team optimized the beam shape of the lattice structure to maintain its lightweight characteristics while maximizing stiffness and strength.

Particularly, using a multi-objective Bayesian optimization algorithm*, the team conducted an optimal design process that simultaneously considers tensile and shear stiffness improvement and weight reduction. They demonstrated that the optimal lattice structure could be predicted and designed with significantly less data (about 400 data points) compared to conventional methods.

*Multi-objective Bayesian optimization algorithm: A method that finds the optimal solution while considering multiple objectives simultaneously. It efficiently collects data and predicts results even under conditions of uncertainty.

< Figure 1. Multi-objective Bayesian optimization for generative design of carbon nanolattices with high compressive stiffness and strength at low density. The upper is the illustration of process workflow. The lower part shows top four MBO CFCC geometries with their 2D Bézier curves. (The optimized structure is predicted and designed with much less data (approximately 400) than the conventional method >

Furthermore, to maximize the effect where mechanical properties improve as size decreases at the nanoscale, the research team utilized pyrolytic carbon* material to implement an ultralight, high-strength, high-stiffness nano-lattice structure.

*Pyrolytic carbon: A carbon material obtained by decomposing organic substances at high temperatures. It has excellent heat resistance and strength, making it widely used in industries such as semiconductor equipment coatings and artificial joint coatings, where it must withstand high temperatures without deformation.

For this, the team applied two-photon polymerization (2PP) technology* to precisely fabricate complex nano-lattice structures, and mechanical performance evaluations confirmed that the developed structure simultaneously possesses strength comparable to steel and the lightness of Styrofoam.

*Two-photon polymerization (2PP) technology: An advanced optical manufacturing technique based on the principle that polymerization occurs only when two photons of a specific wavelength are absorbed simultaneously.

Additionally, the research team demonstrated that multi-focus two-photon polymerization (multi-focus 2PP) technology enables the fabrication of millimeter-scale structures while maintaining nanoscale precision.

Professor Seunghwa Ryu explained, "This technology innovatively solves the stress concentration issue, which has been a limitation of conventional design methods, through three-dimensional nano-lattice structures, achieving both ultralight weight and high strength in material development."

< Figure 2. FESEM image of the fabricated nano-lattice structure and (bottom right) the macroscopic nanolattice resting on a bubble >

He further emphasized, "By integrating data-driven optimal design with precision 3D printing technology, this development not only meets the demand for lightweight materials in the aerospace and automotive industries but also opens possibilities for various industrial applications through customized design."

This study was led by Dr. Peter Serles of the Department of Mechanical & Industrial Engineering at University of Toronto and Dr. Jinwook Yeo from KAIST as co-first authors, with Professor Seunghwa Ryu and Professor Tobin Filleter as corresponding authors.

The research was published on January 23, 2025 in the international journal Advanced Materials (Paper title: “Ultrahigh Specific Strength by Bayesian Optimization of Lightweight Carbon Nanolattices”).

DOI: https://doi.org/10.1002/adma.202410651

This research was supported by the Multiphase Materials Innovation Manufacturing Research Center (an ERC program) funded by the Ministry of Science and ICT, the M3DT (Medical Device Digital Development Tool) project funded by the Ministry of Food and Drug Safety, and the KAIST International Collaboration Program.

2025.02.18 View 6852 -

KAIST Proves Possibility of Preventing Hair Loss with Polyphenol Coating Technology

- KAIST's Professor Haeshin Lee's research team of the Department of Chemistry developed tannic scid-based hair coating technology

- Hair protein (hair and hair follicle) targeting delivery technology using polyphenol confirms a hair loss reduction effect of up to 90% to manifest within 7 Days

- This technology, first applied to 'Grabity' shampoo, proves effect of reducing hair loss chemically and physically

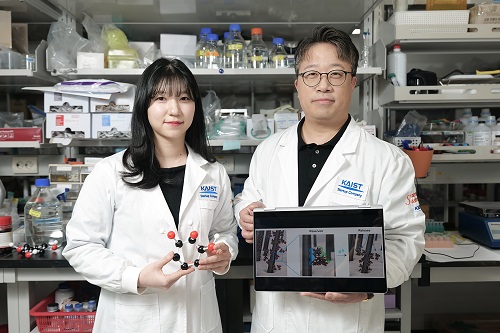

< Photo. (From left) KAIST Chemistry Department Ph.D. candidate Eunu Kim, Professor Haeshin Lee >

Hair loss is a problem that hundreds of millions of people around the world are experiencing, and has a significant psychological and social impact. KAIST researchers focused on the possibility that tannic acid, a type of natural polyphenol, could contribute to preventing hair loss, and through research, discovered that tannic acid is not a simple coating agent, but rather acts as an 'adhesion mediator' that alleviates hair loss.

KAIST (President Kwang-Hyung Lee) announced on the 6th that the Chemistry Department Professor Haeshin Lee's research team developed a new hair loss prevention technology that slowly releases hair loss-alleviating functional ingredients using tannic acid-based coating technology.

Hair loss includes androgenetic alopecia (AGA) and telogen effluvium (TE), and genetic, hormonal, and environmental factors work together, and there is currently a lack of effective treatments with few side effects.

Representative hair loss treatments, minoxidil and finasteride, show some effects, but require long-term use, and not only do their effects vary depending on the body type, but some users also experience side effects.

Professor Haeshin Lee's research team proved that tannic acid can strongly bind to keratin, the main protein in hair, and can be continuously attached to the hair surface, and confirmed that this can be used to release specific functional ingredients in a controlled manner.

In particular, the research team developed a combination that included functional ingredients for hair loss relief, such as salicylic acid (SCA), niacinamide (N), and dexpanthenol (DAL), and named it 'SCANDAL.' The research results showed that the Scandal complex combined with tannic acid is gradually released when it comes into contact with water and is delivered to the hair follicles along the hair surface.

< Figure 1. Schematic diagram of the hair loss relief mechanism by the tannic acid/SCANDAL complex. Tannic acid is a polyphenol compound containing a galol group that has a 360-degree adhesive function, and it binds to the hair surface on one side and binds to the hair loss relief functional ingredient SCANDAL on the other side to store it on the hair surface. Afterwards, when it comes into contact with moisture, SCANDAL is gradually released and delivered to the scalp and hair follicles to show the hair loss relief effect. >

The research team of Goodmona Clinic (Director: Geon Min Lee) applied the shampoo containing tannic acid/Scandal complex to 12 hair loss patients for 7 days, and observed a significant hair loss reduction effect in all clinicians. The results of the experiment showed a reduction in average hair loss of 56.2%, and there were cases where hair loss was reduced by up to 90.2%.

This suggests that tannic acid can be effective in alleviating hair loss by stably maintaining the Scandal component on the hair surface and gradually releasing it and delivering it to the hair follicles.

< Figure 2. When a tannic acid coating is applied to untreated bleached hair, a coating is formed as if the cuticles are tightly attached to each other. This was confirmed through X-ray photoelectron spectroscopy (XPS) analysis, and a decrease in signal intensity was observed in the surface analysis of nitrogen of amino acids contained in keratin protein after tannic acid coating. This proves that tannic acid successfully binds to the hair surface and covers the existing amino acids. To verify this more clearly, the oxidation-reduction reaction was induced through gold ion treatment, and as a result, the entire hair turned black, and it was confirmed that tannic acid reacted with gold ions on the hair surface to form a tannic acid-gold complex. >

Professor Haeshin Lee said, “We have successfully proven that tannic acid, a type of natural polyphenol, has a strong antioxidant effect and has the property of strongly binding to proteins, so it can act as a bio-adhesive.”

Professor Lee continued, “Although there have been cases of using it as a skin and protein coating material in previous studies, this study is the first case of combining with hair and delivering hair loss relief ingredients, and it was applied to ‘Grabity’ shampoo commercialized through Polyphenol Factory, a startup company. We are working to commercialize more diverse research results, such as shampoos that dramatically increase the strength of thin hair that breaks and products that straighten curly hair.”

< Figure 3. Tannic acid and the hair loss relief functional ingredient (SCANDAL) formed a stable complex through hydrogen bonding, and it was confirmed that tannic acid bound to the hair could effectively store SCANDAL. In addition, the results of transmission electron microscopy analysis of salicylic acid (SCA), niacinamide (N), and dexpanthenol (DAL) showed that all of them formed tannic acid-SCANDAL nanocomplexes. >

The results of this study, in which a Ph.D. candidate KAIST Department of Chemistry, Eunu Kim, was the first author and Professor Haeshin Lee was the corresponding author, were published in the online edition of the international academic journal ‘Advanced Materials Interfaces’ on January 6. (Paper title: Leveraging Multifaceted Polyphenol Interactions: An Approach for Hair Loss Mitigation) DOI: 10.1002/admi.202400851

< Figure 4. The hair loss relief functional ingredient (SCANDAL) stored on the hair surface with tannic acid was slowly released upon contact with moisture and delivered to the hair follicle along the hair surface. Salicylic acid (SCA) and niacinamide (N) were each released by more than 25% within 10 minutes. When shampoo containing tannic acid/SCANDAL complex was applied to the hair of 12 participants, hair loss was reduced by about 56.2% on average, and the reduction rate ranged from a minimum of 26.6% to a maximum of 90.2%. These results suggest that tannic acid stably binds SCANDAL to the hair surface, which allows for its gradual release into the hair follicle, resulting in a hair loss alleviation effect. >

This study was conducted with the support of Polyphenol Factory, a KAIST faculty startup company.

2025.02.06 View 6224

KAIST Proves Possibility of Preventing Hair Loss with Polyphenol Coating Technology

- KAIST's Professor Haeshin Lee's research team of the Department of Chemistry developed tannic scid-based hair coating technology

- Hair protein (hair and hair follicle) targeting delivery technology using polyphenol confirms a hair loss reduction effect of up to 90% to manifest within 7 Days

- This technology, first applied to 'Grabity' shampoo, proves effect of reducing hair loss chemically and physically

< Photo. (From left) KAIST Chemistry Department Ph.D. candidate Eunu Kim, Professor Haeshin Lee >

Hair loss is a problem that hundreds of millions of people around the world are experiencing, and has a significant psychological and social impact. KAIST researchers focused on the possibility that tannic acid, a type of natural polyphenol, could contribute to preventing hair loss, and through research, discovered that tannic acid is not a simple coating agent, but rather acts as an 'adhesion mediator' that alleviates hair loss.

KAIST (President Kwang-Hyung Lee) announced on the 6th that the Chemistry Department Professor Haeshin Lee's research team developed a new hair loss prevention technology that slowly releases hair loss-alleviating functional ingredients using tannic acid-based coating technology.

Hair loss includes androgenetic alopecia (AGA) and telogen effluvium (TE), and genetic, hormonal, and environmental factors work together, and there is currently a lack of effective treatments with few side effects.

Representative hair loss treatments, minoxidil and finasteride, show some effects, but require long-term use, and not only do their effects vary depending on the body type, but some users also experience side effects.

Professor Haeshin Lee's research team proved that tannic acid can strongly bind to keratin, the main protein in hair, and can be continuously attached to the hair surface, and confirmed that this can be used to release specific functional ingredients in a controlled manner.

In particular, the research team developed a combination that included functional ingredients for hair loss relief, such as salicylic acid (SCA), niacinamide (N), and dexpanthenol (DAL), and named it 'SCANDAL.' The research results showed that the Scandal complex combined with tannic acid is gradually released when it comes into contact with water and is delivered to the hair follicles along the hair surface.

< Figure 1. Schematic diagram of the hair loss relief mechanism by the tannic acid/SCANDAL complex. Tannic acid is a polyphenol compound containing a galol group that has a 360-degree adhesive function, and it binds to the hair surface on one side and binds to the hair loss relief functional ingredient SCANDAL on the other side to store it on the hair surface. Afterwards, when it comes into contact with moisture, SCANDAL is gradually released and delivered to the scalp and hair follicles to show the hair loss relief effect. >

The research team of Goodmona Clinic (Director: Geon Min Lee) applied the shampoo containing tannic acid/Scandal complex to 12 hair loss patients for 7 days, and observed a significant hair loss reduction effect in all clinicians. The results of the experiment showed a reduction in average hair loss of 56.2%, and there were cases where hair loss was reduced by up to 90.2%.

This suggests that tannic acid can be effective in alleviating hair loss by stably maintaining the Scandal component on the hair surface and gradually releasing it and delivering it to the hair follicles.

< Figure 2. When a tannic acid coating is applied to untreated bleached hair, a coating is formed as if the cuticles are tightly attached to each other. This was confirmed through X-ray photoelectron spectroscopy (XPS) analysis, and a decrease in signal intensity was observed in the surface analysis of nitrogen of amino acids contained in keratin protein after tannic acid coating. This proves that tannic acid successfully binds to the hair surface and covers the existing amino acids. To verify this more clearly, the oxidation-reduction reaction was induced through gold ion treatment, and as a result, the entire hair turned black, and it was confirmed that tannic acid reacted with gold ions on the hair surface to form a tannic acid-gold complex. >

Professor Haeshin Lee said, “We have successfully proven that tannic acid, a type of natural polyphenol, has a strong antioxidant effect and has the property of strongly binding to proteins, so it can act as a bio-adhesive.”

Professor Lee continued, “Although there have been cases of using it as a skin and protein coating material in previous studies, this study is the first case of combining with hair and delivering hair loss relief ingredients, and it was applied to ‘Grabity’ shampoo commercialized through Polyphenol Factory, a startup company. We are working to commercialize more diverse research results, such as shampoos that dramatically increase the strength of thin hair that breaks and products that straighten curly hair.”

< Figure 3. Tannic acid and the hair loss relief functional ingredient (SCANDAL) formed a stable complex through hydrogen bonding, and it was confirmed that tannic acid bound to the hair could effectively store SCANDAL. In addition, the results of transmission electron microscopy analysis of salicylic acid (SCA), niacinamide (N), and dexpanthenol (DAL) showed that all of them formed tannic acid-SCANDAL nanocomplexes. >

The results of this study, in which a Ph.D. candidate KAIST Department of Chemistry, Eunu Kim, was the first author and Professor Haeshin Lee was the corresponding author, were published in the online edition of the international academic journal ‘Advanced Materials Interfaces’ on January 6. (Paper title: Leveraging Multifaceted Polyphenol Interactions: An Approach for Hair Loss Mitigation) DOI: 10.1002/admi.202400851

< Figure 4. The hair loss relief functional ingredient (SCANDAL) stored on the hair surface with tannic acid was slowly released upon contact with moisture and delivered to the hair follicle along the hair surface. Salicylic acid (SCA) and niacinamide (N) were each released by more than 25% within 10 minutes. When shampoo containing tannic acid/SCANDAL complex was applied to the hair of 12 participants, hair loss was reduced by about 56.2% on average, and the reduction rate ranged from a minimum of 26.6% to a maximum of 90.2%. These results suggest that tannic acid stably binds SCANDAL to the hair surface, which allows for its gradual release into the hair follicle, resulting in a hair loss alleviation effect. >

This study was conducted with the support of Polyphenol Factory, a KAIST faculty startup company.

2025.02.06 View 6224 -

KAIST Develops CamBio - a New Biotemplating Method

- Professor Jae-Byum Chang and Professor Yeon Sik Jung’s joint research team of the Department of Materials Science and Engineering developed a highly tunable bio-templating method “CamBio” that makes use of intracellular protein structures

- Substrate performance improvement of up to 230% demonstrated via surface-enhanced Raman spectroscopy (SERS)

- Expected to have price competitiveness over bio-templating method as it expands the range of biological samples

- Expected to expand the range of application of nanostructure synthesis technology by utilizing various biological structures

< Photo 1. (From left) Professor Yeon Sik Jung, Ph.D. candidate Dae-Hyeon Song, Professor Jae-Byum Chang, and (from top right) Dr. Chang Woo Song and Dr. Seunghee H. Cho of the Department of Materials Science and Engineering >

Biological structures have complex characteristics that are difficult to replicate artificially, but biotemplating methods* that directly utilize these biological structures have been used in various fields of application. The KAIST research team succeeded in utilizing previously unusable biological structures and expanding the areas in which biotemplate methods can be applied.

*Biotemplating: A method of using biotemplates as a mold to create functional structural materials, utilizing the functions of these biological structures, from viruses to the tissues and organs that make up our bodies

KAIST (President Kwang Hyung Lee) announced on the 10th that a joint research team of Professors Jae-Byum Chang and Professor Yeon Sik Jung of the Department of Materials Science and Engineering developed a biotemplating method that utilizes specific intracellular proteins in biological samples and has high tunability.

Existing biotemplate methods mainly utilize only the external surface of biological samples or have limitations in utilizing the structure-function correlation of various biological structures due to limited dimensions and sample sizes, making it difficult to create functional nanostructures.

To solve this problem, the research team studied a way to utilize various biological structures within the cells while retaining high tunability.

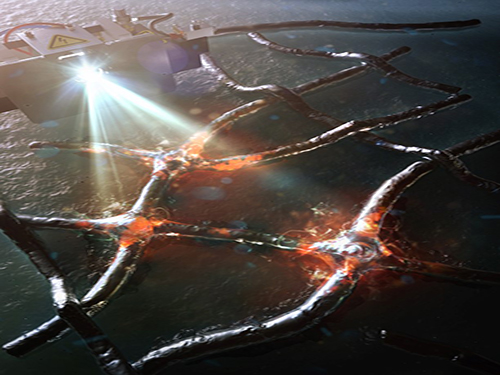

< Figure 1. CamBio utilizing microtubules, a intracellular protein structure. The silver nanoparticle chains synthesized along the microtubules that span the entire cell interior can be observed through an electron microscope, and it is shown that this can be used as a successful SERS substrate. >

As a result of the research, the team developed the “Conversion to advanced materials via labeled Biostructure”, shortened as “CamBio”, which enables the selective synthesis of nanostructures with various characteristics and sizes from specific protein structures composed of diverse proteins within biological specimens.

The CamBio method secures high tunability of functional nanostructures that can be manufactured from biological samples by merging various manufacturing and biological technologies.

Through the technology of repeatedly attaching antibodies, arranging cells in a certain shape, and thinly slicing tissue, the functional nanostructures made with CamBio showed improved performance on the surface-enhanced Raman spectroscopy (SERS)* substrate used for material detection.

*Surface-enhanced Raman spectroscopy (SERS): A technology that can detect very small amounts of substances using light, based on the principle that specific substances react to light and amplifies signals on surfaces of metals such as gold or silver.

The research team found that the nanoparticle chains made using the intracellular protein structures through the process of repeated labeling with antibodies allowed easier control, and improved SERS performance by up to 230%.

In addition, the research team expanded from utilizing the structures inside cells to obtaining samples of muscle tissues inside meat using a cryostat and successfully producing a substrate with periodic bands made of metal particles by performing the CamBio process. This method of producing a substrate not only allows large-scale production using biological samples, but also shows that it is a cost-effective method.

< Figure 2. A method for securing tunability using CamBio at the cell level. Examples of controlling characteristics by integrating iterative labeling and cell pattering techniques with CamBio are shown. >

The CamBio developed by the research team is expected to be used as a way to solve problems faced by various research fields as it is to expand the range of bio-samples that can be produced for various usage.

The first author, Dae-Hyeon Song, a Ph.D. candidate of KAIST Department of Materials Science and Engineering said, “Through CamBio, we have comprehensively accumulated biotemplating methods that can utilize more diverse protein structures,” and “If combined with the state-of-the-art biological technologies such as gene editing and 3D bioprinting and new material synthesis technologies, biostructures can be utilized in various fields of application.”

< Figure 3. A method for securing tunability using CamBio at the tissue level. In order to utilize proteins inside muscle tissue, the frozen tissue sectioning technology is combined, and through this, a substrate with a periodic nanoparticle band pattern is successfully produced, and it is shown that large-area acquisition of samples and price competitiveness can be achieved. >

This study, in which the Ph.D. candidate Dae-Hyeon Song along with Dr. Chang Woo Song, and Dr. Seunghee H. Cho of the same department participated as the first authors, was published online in the international academic journal, Advanced Science, on November 13th, 2024.

(Paper title: Highly Tunable, Nanomaterial-Functionalized Structural Templating of Intracellular Protein Structures Within Biological Species) https://doi.org/10.1002/advs.202406492

This study was conducted with a combination of support from various programs including the National Convergence Research of Scientific Challenges (National Research Foundation of Korea (NRF) 2024), Engineering Reseach Center (ERC) (Wearable Platform Materials Technology Center, NRF 2023), ERC (Global Bio-integrated Materials Center, NRF 2024), and the National Advanced Program for Biological Research Resources (Bioimaging Data Curation Center, NRF 2024) funded by Ministry of Science and ICT.

2025.01.10 View 6730

KAIST Develops CamBio - a New Biotemplating Method

- Professor Jae-Byum Chang and Professor Yeon Sik Jung’s joint research team of the Department of Materials Science and Engineering developed a highly tunable bio-templating method “CamBio” that makes use of intracellular protein structures

- Substrate performance improvement of up to 230% demonstrated via surface-enhanced Raman spectroscopy (SERS)

- Expected to have price competitiveness over bio-templating method as it expands the range of biological samples

- Expected to expand the range of application of nanostructure synthesis technology by utilizing various biological structures

< Photo 1. (From left) Professor Yeon Sik Jung, Ph.D. candidate Dae-Hyeon Song, Professor Jae-Byum Chang, and (from top right) Dr. Chang Woo Song and Dr. Seunghee H. Cho of the Department of Materials Science and Engineering >

Biological structures have complex characteristics that are difficult to replicate artificially, but biotemplating methods* that directly utilize these biological structures have been used in various fields of application. The KAIST research team succeeded in utilizing previously unusable biological structures and expanding the areas in which biotemplate methods can be applied.

*Biotemplating: A method of using biotemplates as a mold to create functional structural materials, utilizing the functions of these biological structures, from viruses to the tissues and organs that make up our bodies

KAIST (President Kwang Hyung Lee) announced on the 10th that a joint research team of Professors Jae-Byum Chang and Professor Yeon Sik Jung of the Department of Materials Science and Engineering developed a biotemplating method that utilizes specific intracellular proteins in biological samples and has high tunability.

Existing biotemplate methods mainly utilize only the external surface of biological samples or have limitations in utilizing the structure-function correlation of various biological structures due to limited dimensions and sample sizes, making it difficult to create functional nanostructures.

To solve this problem, the research team studied a way to utilize various biological structures within the cells while retaining high tunability.

< Figure 1. CamBio utilizing microtubules, a intracellular protein structure. The silver nanoparticle chains synthesized along the microtubules that span the entire cell interior can be observed through an electron microscope, and it is shown that this can be used as a successful SERS substrate. >

As a result of the research, the team developed the “Conversion to advanced materials via labeled Biostructure”, shortened as “CamBio”, which enables the selective synthesis of nanostructures with various characteristics and sizes from specific protein structures composed of diverse proteins within biological specimens.

The CamBio method secures high tunability of functional nanostructures that can be manufactured from biological samples by merging various manufacturing and biological technologies.

Through the technology of repeatedly attaching antibodies, arranging cells in a certain shape, and thinly slicing tissue, the functional nanostructures made with CamBio showed improved performance on the surface-enhanced Raman spectroscopy (SERS)* substrate used for material detection.

*Surface-enhanced Raman spectroscopy (SERS): A technology that can detect very small amounts of substances using light, based on the principle that specific substances react to light and amplifies signals on surfaces of metals such as gold or silver.

The research team found that the nanoparticle chains made using the intracellular protein structures through the process of repeated labeling with antibodies allowed easier control, and improved SERS performance by up to 230%.

In addition, the research team expanded from utilizing the structures inside cells to obtaining samples of muscle tissues inside meat using a cryostat and successfully producing a substrate with periodic bands made of metal particles by performing the CamBio process. This method of producing a substrate not only allows large-scale production using biological samples, but also shows that it is a cost-effective method.

< Figure 2. A method for securing tunability using CamBio at the cell level. Examples of controlling characteristics by integrating iterative labeling and cell pattering techniques with CamBio are shown. >

The CamBio developed by the research team is expected to be used as a way to solve problems faced by various research fields as it is to expand the range of bio-samples that can be produced for various usage.

The first author, Dae-Hyeon Song, a Ph.D. candidate of KAIST Department of Materials Science and Engineering said, “Through CamBio, we have comprehensively accumulated biotemplating methods that can utilize more diverse protein structures,” and “If combined with the state-of-the-art biological technologies such as gene editing and 3D bioprinting and new material synthesis technologies, biostructures can be utilized in various fields of application.”

< Figure 3. A method for securing tunability using CamBio at the tissue level. In order to utilize proteins inside muscle tissue, the frozen tissue sectioning technology is combined, and through this, a substrate with a periodic nanoparticle band pattern is successfully produced, and it is shown that large-area acquisition of samples and price competitiveness can be achieved. >

This study, in which the Ph.D. candidate Dae-Hyeon Song along with Dr. Chang Woo Song, and Dr. Seunghee H. Cho of the same department participated as the first authors, was published online in the international academic journal, Advanced Science, on November 13th, 2024.

(Paper title: Highly Tunable, Nanomaterial-Functionalized Structural Templating of Intracellular Protein Structures Within Biological Species) https://doi.org/10.1002/advs.202406492

This study was conducted with a combination of support from various programs including the National Convergence Research of Scientific Challenges (National Research Foundation of Korea (NRF) 2024), Engineering Reseach Center (ERC) (Wearable Platform Materials Technology Center, NRF 2023), ERC (Global Bio-integrated Materials Center, NRF 2024), and the National Advanced Program for Biological Research Resources (Bioimaging Data Curation Center, NRF 2024) funded by Ministry of Science and ICT.

2025.01.10 View 6730 -

KAIST Extends Lithium Metal Battery Lifespan by 750% Using Water

Lithium metal, a next-generation anode material, has been highlighted for overcoming the performance limitations of commercial batteries. However, issues inherent to lithium metal have caused shortened battery lifespans and increased fire risks. KAIST researchers have achieved a world-class breakthrough by extending the lifespan of lithium metal anodes by approximately 750% only using water.

KAIST (represented by President Kwang Hyung Lee) announced on the 2nd of December that Professor Il-Doo Kim from the Department of Materials Science and Engineering, in collaboration with Professor Jiyoung Lee from Ajou University, successfully stabilized lithium growth and significantly enhanced the lifespan of next-generation lithium metal batteries using eco-friendly hollow nanofibers as protective layers.

Conventional protective layer technologies, which involve applying a surface coating onto lithium metal in order to create an artificial interface with the electrolyte, have relied on toxic processes and expensive materials, with limited improvements in the lifespan of lithium metal anodes.

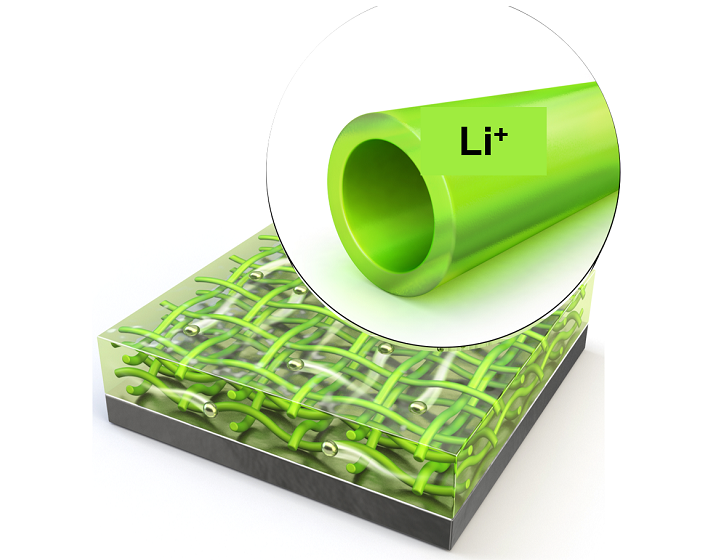

< Figure 1. Schematic illustration of the fabrication process of the newly developed protective membrane by eco-friendly electrospinning process using water >

To address these limitations, Professor Kim’s team proposed a hollow nanofiber protective layer capable of controlling lithium-ion growth through both physical and chemical means. This protective layer was manufactured through an environmentally friendly electrospinning process* using guar gum** extracted from plants as the primary material and utilizing water as the sole solvent.

*Electrospinning process: A method where polymer solutions are subjected to an electric field, producing continuous fibers with diameters ranging from tens of nanometers to several micrometers.

**Guar gum: A natural polymer extracted from guar beans, composed mainly of monosaccharides. Its oxidized functional groups regulate interactions with lithium ions.

< Figure 2. Physical and chemical control of Lithium dendrite by the newly developed protective membrane >

The nanofiber protective layer effectively controlled reversible chemical reactions between the electrolyte and lithium ions. The hollow spaces within the fibers suppressed the random accumulation of lithium ions on the metal surface, stabilizing the interface between the lithium metal surface and the electrolyte.

< Figure 3. Performance of Lithium metal battery full cells with the newly developed protective membrane >

As a result, the lithium metal anodes with this protective layer demonstrated approximately a 750% increase in lifespan compared to conventional lithium metal anodes. The battery retained 93.3% of its capacity even after 300 charge-discharge cycles, achieving world-class performance.

The researchers also verified that this natural protective layer decomposes entirely within about a month in soil, proving its eco-friendly nature throughout the manufacturing and disposal process.

< Figure 4. Excellent decomposition rate of the newly developed protective membrane >

Professor Il-Doo Kim explained, “By leveraging both physical and chemical protective functions, we were able to guide reversible reactions between lithium metal and the electrolyte more effectively and suppress dendrite growth, resulting in lithium metal anodes with unprecedented lifespan characteristics.”

He added, “As the environmental burden caused by battery production and disposal becomes a pressing issue due to surging battery demand, this water-based manufacturing method with biodegradable properties will significantly contribute to the commercialization of next-generation eco-friendly batteries.”

This study was led by Dr. Jiyoung Lee (now a professor in the Department of Chemical Engineering at Ajou University) and Dr. Hyunsub Song (currently at Samsung Electronics), both graduates of KAIST’s Department of Materials Science and Engineering. The findings were published as a front cover article in Advanced Materials, Volume 36, Issue 47, on November 21.

(Paper title: “Overcoming Chemical and Mechanical Instabilities in Lithium Metal Anodes with Sustainable and Eco-Friendly Artificial SEI Layer”)

The research was supported by the KAIST-LG Energy Solution Frontier Research Lab (FRL), the Alchemist Project funded by the Ministry of Trade, Industry and Energy, and the Top-Tier Research Support Program from the Ministry of Science and ICT.

2024.12.12 View 8192

KAIST Extends Lithium Metal Battery Lifespan by 750% Using Water

Lithium metal, a next-generation anode material, has been highlighted for overcoming the performance limitations of commercial batteries. However, issues inherent to lithium metal have caused shortened battery lifespans and increased fire risks. KAIST researchers have achieved a world-class breakthrough by extending the lifespan of lithium metal anodes by approximately 750% only using water.

KAIST (represented by President Kwang Hyung Lee) announced on the 2nd of December that Professor Il-Doo Kim from the Department of Materials Science and Engineering, in collaboration with Professor Jiyoung Lee from Ajou University, successfully stabilized lithium growth and significantly enhanced the lifespan of next-generation lithium metal batteries using eco-friendly hollow nanofibers as protective layers.

Conventional protective layer technologies, which involve applying a surface coating onto lithium metal in order to create an artificial interface with the electrolyte, have relied on toxic processes and expensive materials, with limited improvements in the lifespan of lithium metal anodes.

< Figure 1. Schematic illustration of the fabrication process of the newly developed protective membrane by eco-friendly electrospinning process using water >

To address these limitations, Professor Kim’s team proposed a hollow nanofiber protective layer capable of controlling lithium-ion growth through both physical and chemical means. This protective layer was manufactured through an environmentally friendly electrospinning process* using guar gum** extracted from plants as the primary material and utilizing water as the sole solvent.

*Electrospinning process: A method where polymer solutions are subjected to an electric field, producing continuous fibers with diameters ranging from tens of nanometers to several micrometers.

**Guar gum: A natural polymer extracted from guar beans, composed mainly of monosaccharides. Its oxidized functional groups regulate interactions with lithium ions.

< Figure 2. Physical and chemical control of Lithium dendrite by the newly developed protective membrane >

The nanofiber protective layer effectively controlled reversible chemical reactions between the electrolyte and lithium ions. The hollow spaces within the fibers suppressed the random accumulation of lithium ions on the metal surface, stabilizing the interface between the lithium metal surface and the electrolyte.

< Figure 3. Performance of Lithium metal battery full cells with the newly developed protective membrane >

As a result, the lithium metal anodes with this protective layer demonstrated approximately a 750% increase in lifespan compared to conventional lithium metal anodes. The battery retained 93.3% of its capacity even after 300 charge-discharge cycles, achieving world-class performance.

The researchers also verified that this natural protective layer decomposes entirely within about a month in soil, proving its eco-friendly nature throughout the manufacturing and disposal process.

< Figure 4. Excellent decomposition rate of the newly developed protective membrane >

Professor Il-Doo Kim explained, “By leveraging both physical and chemical protective functions, we were able to guide reversible reactions between lithium metal and the electrolyte more effectively and suppress dendrite growth, resulting in lithium metal anodes with unprecedented lifespan characteristics.”

He added, “As the environmental burden caused by battery production and disposal becomes a pressing issue due to surging battery demand, this water-based manufacturing method with biodegradable properties will significantly contribute to the commercialization of next-generation eco-friendly batteries.”

This study was led by Dr. Jiyoung Lee (now a professor in the Department of Chemical Engineering at Ajou University) and Dr. Hyunsub Song (currently at Samsung Electronics), both graduates of KAIST’s Department of Materials Science and Engineering. The findings were published as a front cover article in Advanced Materials, Volume 36, Issue 47, on November 21.

(Paper title: “Overcoming Chemical and Mechanical Instabilities in Lithium Metal Anodes with Sustainable and Eco-Friendly Artificial SEI Layer”)

The research was supported by the KAIST-LG Energy Solution Frontier Research Lab (FRL), the Alchemist Project funded by the Ministry of Trade, Industry and Energy, and the Top-Tier Research Support Program from the Ministry of Science and ICT.

2024.12.12 View 8192 -

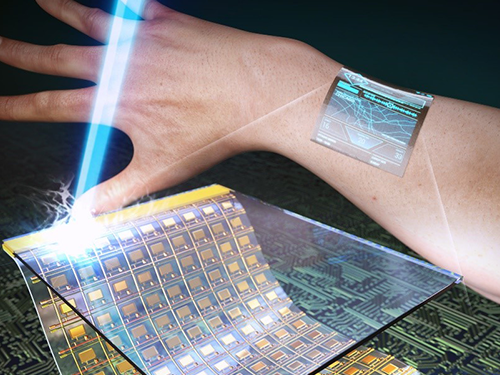

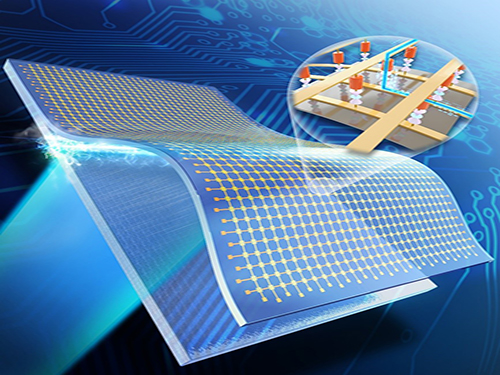

KAIST Team Develops an Insect-Mimicking Semiconductor to Detect Motion

The recent development of an “intelligent sensor” semiconductor that mimics the optic nerve of insects while operating at ultra-high speeds and low power offers extensive expandability into various innovative technologies. This technology is expected to be applied to various fields including transportation, safety, and security systems, contributing to both industry and society.

On February 19, a KAIST research team led by Professor Kyung Min Kim from the Department of Materials Science and Engineering (DMSE) announced the successful developed an intelligent motion detector by merging various memristor* devices to mimic the visual intelligence** of the optic nerve of insects.

*Memristor: a “memory resistor” whose state of resistance changes depending on the input signal

**Visual intelligence: the ability to interpret visual information and perform calculations within the optic nerve

With the recent advances in AI technology, vision systems are being improved by utilizing AI in various tasks such as image recognition, object detection, and motion analysis. However, existing vision systems typically recognize objects and their behaviour from the received image signals using complex algorithms. This method requires a significant amount of data traffic and higher power consumption, making it difficult to apply in mobile or IoT devices.

Meanwhile, insects are known to be able to effectively process visual information through an optic nerve circuit called the elementary motion detector, allowing them to detect objects and recognize their motion at an advanced level. However, mimicking this pathway using conventional silicon integrated circuit (CMOS) technology requires complex circuits, and its implementation into actual devices has thus been limited.

< Figure 1. Working principle of a biological elementary motion detection system. >

Professor Kyung Min Kim’s research team developed an intelligent motion detecting sensor that operates at a high level of efficiency and ultra-high speeds. The device has a simple structure consisting of only two types of memristors and a resistor developed by the team. The two different memristors each carry out a signal delay function and a signal integration and ignition function, respectively. Through them, the team could directly mimic the optic nerve of insects to analyze object movement.

< Figure 2. (Left) Optical image of the M-EMD device in the left panel (scale bar 200 μm) and SEM image of the device in the right panel (scale bar: 20 μm). (Middle) Responses of the M-EMD in positive direction. (Right) Responses of the M-EMD in negative direction. >

To demonstrate its potential for practical applications, the research team used the newly developed motion detector to design a neuromorphic computing system that can predict the path of a vehicle. The results showed that the device used 92.9% less energy compared to existing technology and predicted motion with more accuracy.

< Figure 3. Neuromorphic computing system configuration based on motion recognition devices >

Professor Kim said, “Insects make use of their very simple visual intelligence systems to detect the motion of objects at a surprising high speed. This research is significant in that we could mimic the functions of a nerve using a memristor device.” He added, “Edge AI devices, such as AI-topped mobile phones, are becoming increasingly important. This research can contribute to the integration of efficient vision systems for motion recognition, so we expect it to be applied to various fields such as autonomous vehicles, vehicle transportation systems, robotics, and machine vision.”

This research, conducted by co-first authors Hanchan Song and Min Gu Lee, both Ph.D. candidates at KAIST DMSE, was published in the online issue of Advanced Materials on January 29.

This research was supported by the Mid-Sized Research Project by the National Research Foundation of Korea, the Next-Generation Intelligent Semiconductor Technology Development Project, the PIM Artificial Intelligence Semiconductor Core Technology Development Project, the National Nano Fab Center, and the Leap Research Project by KAIST.

2024.02.29 View 9437

KAIST Team Develops an Insect-Mimicking Semiconductor to Detect Motion

The recent development of an “intelligent sensor” semiconductor that mimics the optic nerve of insects while operating at ultra-high speeds and low power offers extensive expandability into various innovative technologies. This technology is expected to be applied to various fields including transportation, safety, and security systems, contributing to both industry and society.

On February 19, a KAIST research team led by Professor Kyung Min Kim from the Department of Materials Science and Engineering (DMSE) announced the successful developed an intelligent motion detector by merging various memristor* devices to mimic the visual intelligence** of the optic nerve of insects.

*Memristor: a “memory resistor” whose state of resistance changes depending on the input signal

**Visual intelligence: the ability to interpret visual information and perform calculations within the optic nerve

With the recent advances in AI technology, vision systems are being improved by utilizing AI in various tasks such as image recognition, object detection, and motion analysis. However, existing vision systems typically recognize objects and their behaviour from the received image signals using complex algorithms. This method requires a significant amount of data traffic and higher power consumption, making it difficult to apply in mobile or IoT devices.

Meanwhile, insects are known to be able to effectively process visual information through an optic nerve circuit called the elementary motion detector, allowing them to detect objects and recognize their motion at an advanced level. However, mimicking this pathway using conventional silicon integrated circuit (CMOS) technology requires complex circuits, and its implementation into actual devices has thus been limited.

< Figure 1. Working principle of a biological elementary motion detection system. >

Professor Kyung Min Kim’s research team developed an intelligent motion detecting sensor that operates at a high level of efficiency and ultra-high speeds. The device has a simple structure consisting of only two types of memristors and a resistor developed by the team. The two different memristors each carry out a signal delay function and a signal integration and ignition function, respectively. Through them, the team could directly mimic the optic nerve of insects to analyze object movement.

< Figure 2. (Left) Optical image of the M-EMD device in the left panel (scale bar 200 μm) and SEM image of the device in the right panel (scale bar: 20 μm). (Middle) Responses of the M-EMD in positive direction. (Right) Responses of the M-EMD in negative direction. >

To demonstrate its potential for practical applications, the research team used the newly developed motion detector to design a neuromorphic computing system that can predict the path of a vehicle. The results showed that the device used 92.9% less energy compared to existing technology and predicted motion with more accuracy.

< Figure 3. Neuromorphic computing system configuration based on motion recognition devices >

Professor Kim said, “Insects make use of their very simple visual intelligence systems to detect the motion of objects at a surprising high speed. This research is significant in that we could mimic the functions of a nerve using a memristor device.” He added, “Edge AI devices, such as AI-topped mobile phones, are becoming increasingly important. This research can contribute to the integration of efficient vision systems for motion recognition, so we expect it to be applied to various fields such as autonomous vehicles, vehicle transportation systems, robotics, and machine vision.”

This research, conducted by co-first authors Hanchan Song and Min Gu Lee, both Ph.D. candidates at KAIST DMSE, was published in the online issue of Advanced Materials on January 29.

This research was supported by the Mid-Sized Research Project by the National Research Foundation of Korea, the Next-Generation Intelligent Semiconductor Technology Development Project, the PIM Artificial Intelligence Semiconductor Core Technology Development Project, the National Nano Fab Center, and the Leap Research Project by KAIST.

2024.02.29 View 9437 -

Success in Real-Time Observation of the Formation Process of Topological Solitons, a Core Technology for Next-Generation Information Transfer

< From left) Geonhyeong Park (Ph.D. Candidate), Yun-Seok Choi (Ph.D.), Professor Dong Ki Yoon, and Changjae Lee (Ph.D. Candidate) of the Department of Chemistry >

Professor Dong Ki Yoon's research team in the Department of Chemistry at KAIST announced on the 11th that they have succeeded in controlling the formation of topological solitons in a regular, large-area manner through the self-assembly of chiral liquid crystal materials and observing their formation process in real-time.

A soliton refers to a phenomenon where a specific wave persists without dissipating through interaction with its surroundings. In particular, even when a wave is transmitted over long distances, it retains its unique information until it reaches the desired destination. Therefore, in today's digital society, which is susceptible to hacking, solitons are highly anticipated to be the core of future communication due to their inherent high stability. Furthermore, topological solitons created using organic liquid crystal molecules are expected to be utilized as next-generation anti-counterfeiting devices and memory elements due to their unique spin directionality.

Professor Yoon's team specifically revealed the formation process of topological solitons in this study, which had not been observable in real-time under mild conditions such as room temperature until now. This was made possible by using self-assembling chiral liquid crystal materials in a confined space created by air pillars.

This research, in which Geonhyeong Park (Ph.D. Candidate, Department of Chemistry) and Dr. Ahram Suh participated as co-first authors, and Dr. Yun-Seok Choi and Changjae Lee (Ph.D. Candidate) from the same group also participated, was published online in the international journal 'Advanced Materials' on June 5th and is scheduled to be featured as the back cover of the July issue. (Paper title: "Fabrication of Arrays of Topological Solitons in Patterned Chiral Liquid Crystals for Real-Time Observation of Morphogenesis")

< Figure 1. Schematic diagram of the research>

< Figure 2. Real-time observation of topological soliton formation using liquid crystals>

In this study, Professor Yoon's team implemented topological soliton structures at approximately 30 degrees Celsius, similar to room temperature, using chiral (asymmetric) liquid crystal materials instead of the conventional liquid crystal molecules widely used as core materials in liquid crystal displays (LCDs). Generally, complex equipment is required to control the formation of topological solitons, and their formation time is very short, which has hindered research into their formation process until now.

To achieve regular formation and control of topological solitons formed by chiral liquid crystal molecules, Professor Yoon's team precisely controlled a combination of vertical alignment layers, which can orient molecules vertically, and air pillars. Specifically, they prepared concave patterns based on circular silicon material, several micrometers (one-millionth of a meter) in size, coated with a vertical alignment layer, and a glass substrate. By adjusting the gap to several micrometers and injecting chiral liquid crystal material, air pillars were spontaneously formed on the concave patterns. Subsequently, the liquid crystal molecules were vertically aligned on all substrates, inevitably causing regular distortions between the substrates, and between the substrate and the air pillars, thus developing a system where chiral molecular structures, i.e., topological solitons, could be formed.

The key to the formation and control of topological solitons lies in controlling the thermal phase transition to occur regularly as desired when cooling from the isotropic phase temperature (approximately 40 degrees Celsius) to the liquid crystal phase temperature (approximately 30 degrees Celsius), where the liquid crystal material near the air pillars is cooler than the liquid crystal material between the glass substrate and the silicon patterned parts. This is consistent with the everyday wisdom of eating steamed eggs from a 'Ttukbaegi' (earthen pot) by starting from the relatively cooler part exposed to the air (near the air pillars) rather than the hot pot part (silicon or glass substrate part).

Through real-time analysis, the research team elucidated that topological defects are formed by the naturally formed air pillars through controlled thermal phase transition, and topological solitons are formed only at the locations of these defects. This analysis technique has the potential for application in various fields, including the interpretation of topological soliton formation found in other physical phenomena such as skyrmion particles in electromagnetism.

< Figure 3. Snapshots during the formation process of regularly arranged topological solitons>

Professor Dong Ki Yoon stated, "General topological solitons are known to be highly stable, capable only of generation or annihilation. Through the results of this research, we can understand the formation process of solitons in more detail, and they can be used as spintronics application technology, considered a next-generation semiconductor device for storing and recording information."

This research was conducted in collaboration with Professor Ivan Smalyukh's laboratory at the University of Colorado, Department of Physics, and was supported by the Multiscale Chiral Structures Research Center and strategic projects of the National Research Foundation of Korea under the Ministry of Science and ICT.

2022.07.11 View 1620

Success in Real-Time Observation of the Formation Process of Topological Solitons, a Core Technology for Next-Generation Information Transfer

< From left) Geonhyeong Park (Ph.D. Candidate), Yun-Seok Choi (Ph.D.), Professor Dong Ki Yoon, and Changjae Lee (Ph.D. Candidate) of the Department of Chemistry >

Professor Dong Ki Yoon's research team in the Department of Chemistry at KAIST announced on the 11th that they have succeeded in controlling the formation of topological solitons in a regular, large-area manner through the self-assembly of chiral liquid crystal materials and observing their formation process in real-time.

A soliton refers to a phenomenon where a specific wave persists without dissipating through interaction with its surroundings. In particular, even when a wave is transmitted over long distances, it retains its unique information until it reaches the desired destination. Therefore, in today's digital society, which is susceptible to hacking, solitons are highly anticipated to be the core of future communication due to their inherent high stability. Furthermore, topological solitons created using organic liquid crystal molecules are expected to be utilized as next-generation anti-counterfeiting devices and memory elements due to their unique spin directionality.

Professor Yoon's team specifically revealed the formation process of topological solitons in this study, which had not been observable in real-time under mild conditions such as room temperature until now. This was made possible by using self-assembling chiral liquid crystal materials in a confined space created by air pillars.

This research, in which Geonhyeong Park (Ph.D. Candidate, Department of Chemistry) and Dr. Ahram Suh participated as co-first authors, and Dr. Yun-Seok Choi and Changjae Lee (Ph.D. Candidate) from the same group also participated, was published online in the international journal 'Advanced Materials' on June 5th and is scheduled to be featured as the back cover of the July issue. (Paper title: "Fabrication of Arrays of Topological Solitons in Patterned Chiral Liquid Crystals for Real-Time Observation of Morphogenesis")

< Figure 1. Schematic diagram of the research>

< Figure 2. Real-time observation of topological soliton formation using liquid crystals>

In this study, Professor Yoon's team implemented topological soliton structures at approximately 30 degrees Celsius, similar to room temperature, using chiral (asymmetric) liquid crystal materials instead of the conventional liquid crystal molecules widely used as core materials in liquid crystal displays (LCDs). Generally, complex equipment is required to control the formation of topological solitons, and their formation time is very short, which has hindered research into their formation process until now.

To achieve regular formation and control of topological solitons formed by chiral liquid crystal molecules, Professor Yoon's team precisely controlled a combination of vertical alignment layers, which can orient molecules vertically, and air pillars. Specifically, they prepared concave patterns based on circular silicon material, several micrometers (one-millionth of a meter) in size, coated with a vertical alignment layer, and a glass substrate. By adjusting the gap to several micrometers and injecting chiral liquid crystal material, air pillars were spontaneously formed on the concave patterns. Subsequently, the liquid crystal molecules were vertically aligned on all substrates, inevitably causing regular distortions between the substrates, and between the substrate and the air pillars, thus developing a system where chiral molecular structures, i.e., topological solitons, could be formed.

The key to the formation and control of topological solitons lies in controlling the thermal phase transition to occur regularly as desired when cooling from the isotropic phase temperature (approximately 40 degrees Celsius) to the liquid crystal phase temperature (approximately 30 degrees Celsius), where the liquid crystal material near the air pillars is cooler than the liquid crystal material between the glass substrate and the silicon patterned parts. This is consistent with the everyday wisdom of eating steamed eggs from a 'Ttukbaegi' (earthen pot) by starting from the relatively cooler part exposed to the air (near the air pillars) rather than the hot pot part (silicon or glass substrate part).

Through real-time analysis, the research team elucidated that topological defects are formed by the naturally formed air pillars through controlled thermal phase transition, and topological solitons are formed only at the locations of these defects. This analysis technique has the potential for application in various fields, including the interpretation of topological soliton formation found in other physical phenomena such as skyrmion particles in electromagnetism.

< Figure 3. Snapshots during the formation process of regularly arranged topological solitons>

Professor Dong Ki Yoon stated, "General topological solitons are known to be highly stable, capable only of generation or annihilation. Through the results of this research, we can understand the formation process of solitons in more detail, and they can be used as spintronics application technology, considered a next-generation semiconductor device for storing and recording information."

This research was conducted in collaboration with Professor Ivan Smalyukh's laboratory at the University of Colorado, Department of Physics, and was supported by the Multiscale Chiral Structures Research Center and strategic projects of the National Research Foundation of Korea under the Ministry of Science and ICT.

2022.07.11 View 1620 -

Lead-free, Efficient Perovskite for Photovoltaic Cells

(Clockwise from left: Post-doc Researcher Lamjed Debbichi, Master’s Candidate Songju Lee, Professor Min Seok Jang and Professor Hyungjun Kim)

A KAIST research team has proposed a perovskite material, Cs2Au2I6 that serves as a potential active material for highly efficient lead-free thin-film photovoltaic devices. This material is expected to lay the foundation to overcome previously known limitations of perovskite including its stability and toxicity issues.

As strong candidates for next-generation high-efficiency photovoltaic cells, perovskite photovoltaic cells have a maximum photoconversion efficiency of 22%, comparable to high-performance crystalline silicon photovoltaic cells. In addition, perovskite-based cells can be fabricated at low temperatures, thereby bringing about dramatic cost reductions.

However, it has been noted that conventional organic-inorganic hybrid perovskite materials exhibit low stability, eventually degrading their performance and making them unfit for continued use. Moreover, their inclusion of lead has undermined their environmental friendliness.