polymer

-

Ultralight advanced material developed by KAIST and U of Toronto

< (From left) Professor Seunghwa Ryu of KAIST Department of Mechanical Engineering, Professor Tobin Filleter of the University of Toronto, Dr. Jinwook Yeo of KAIST, and Dr. Peter Serles of the University of Toronto >

Recently, in advanced industries such as automobiles, aerospace, and mobility, there has been increasing demand for materials that achieve weight reduction while maintaining excellent mechanical properties. An international joint research team has developed an ultralight, high-strength material utilizing nanostructures, presenting the potential for various industrial applications through customized design in the future.

KAIST (represented by President Kwang Hyung Lee) announced on the 18th of February that a research team led by Professor Seunghwa Ryu from the Department of Mechanical Engineering, in collaboration with Professor Tobin Filleter from the University of Toronto, has developed a nano-lattice structure that maximizes lightweight properties while maintaining high stiffness and strength.

In this study, the research team optimized the beam shape of the lattice structure to maintain its lightweight characteristics while maximizing stiffness and strength.

Particularly, using a multi-objective Bayesian optimization algorithm*, the team conducted an optimal design process that simultaneously considers tensile and shear stiffness improvement and weight reduction. They demonstrated that the optimal lattice structure could be predicted and designed with significantly less data (about 400 data points) compared to conventional methods.

*Multi-objective Bayesian optimization algorithm: A method that finds the optimal solution while considering multiple objectives simultaneously. It efficiently collects data and predicts results even under conditions of uncertainty.

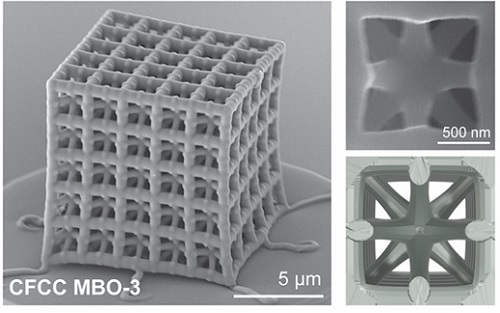

< Figure 1. Multi-objective Bayesian optimization for generative design of carbon nanolattices with high compressive stiffness and strength at low density. The upper is the illustration of process workflow. The lower part shows top four MBO CFCC geometries with their 2D Bézier curves. (The optimized structure is predicted and designed with much less data (approximately 400) than the conventional method >

Furthermore, to maximize the effect where mechanical properties improve as size decreases at the nanoscale, the research team utilized pyrolytic carbon* material to implement an ultralight, high-strength, high-stiffness nano-lattice structure.

*Pyrolytic carbon: A carbon material obtained by decomposing organic substances at high temperatures. It has excellent heat resistance and strength, making it widely used in industries such as semiconductor equipment coatings and artificial joint coatings, where it must withstand high temperatures without deformation.

For this, the team applied two-photon polymerization (2PP) technology* to precisely fabricate complex nano-lattice structures, and mechanical performance evaluations confirmed that the developed structure simultaneously possesses strength comparable to steel and the lightness of Styrofoam.

*Two-photon polymerization (2PP) technology: An advanced optical manufacturing technique based on the principle that polymerization occurs only when two photons of a specific wavelength are absorbed simultaneously.

Additionally, the research team demonstrated that multi-focus two-photon polymerization (multi-focus 2PP) technology enables the fabrication of millimeter-scale structures while maintaining nanoscale precision.

Professor Seunghwa Ryu explained, "This technology innovatively solves the stress concentration issue, which has been a limitation of conventional design methods, through three-dimensional nano-lattice structures, achieving both ultralight weight and high strength in material development."

< Figure 2. FESEM image of the fabricated nano-lattice structure and (bottom right) the macroscopic nanolattice resting on a bubble >

He further emphasized, "By integrating data-driven optimal design with precision 3D printing technology, this development not only meets the demand for lightweight materials in the aerospace and automotive industries but also opens possibilities for various industrial applications through customized design."

This study was led by Dr. Peter Serles of the Department of Mechanical & Industrial Engineering at University of Toronto and Dr. Jinwook Yeo from KAIST as co-first authors, with Professor Seunghwa Ryu and Professor Tobin Filleter as corresponding authors.

The research was published on January 23, 2025 in the international journal Advanced Materials (Paper title: “Ultrahigh Specific Strength by Bayesian Optimization of Lightweight Carbon Nanolattices”).

DOI: https://doi.org/10.1002/adma.202410651

This research was supported by the Multiphase Materials Innovation Manufacturing Research Center (an ERC program) funded by the Ministry of Science and ICT, the M3DT (Medical Device Digital Development Tool) project funded by the Ministry of Food and Drug Safety, and the KAIST International Collaboration Program.

2025.02.18 View 3299

Ultralight advanced material developed by KAIST and U of Toronto

< (From left) Professor Seunghwa Ryu of KAIST Department of Mechanical Engineering, Professor Tobin Filleter of the University of Toronto, Dr. Jinwook Yeo of KAIST, and Dr. Peter Serles of the University of Toronto >

Recently, in advanced industries such as automobiles, aerospace, and mobility, there has been increasing demand for materials that achieve weight reduction while maintaining excellent mechanical properties. An international joint research team has developed an ultralight, high-strength material utilizing nanostructures, presenting the potential for various industrial applications through customized design in the future.

KAIST (represented by President Kwang Hyung Lee) announced on the 18th of February that a research team led by Professor Seunghwa Ryu from the Department of Mechanical Engineering, in collaboration with Professor Tobin Filleter from the University of Toronto, has developed a nano-lattice structure that maximizes lightweight properties while maintaining high stiffness and strength.

In this study, the research team optimized the beam shape of the lattice structure to maintain its lightweight characteristics while maximizing stiffness and strength.

Particularly, using a multi-objective Bayesian optimization algorithm*, the team conducted an optimal design process that simultaneously considers tensile and shear stiffness improvement and weight reduction. They demonstrated that the optimal lattice structure could be predicted and designed with significantly less data (about 400 data points) compared to conventional methods.

*Multi-objective Bayesian optimization algorithm: A method that finds the optimal solution while considering multiple objectives simultaneously. It efficiently collects data and predicts results even under conditions of uncertainty.

< Figure 1. Multi-objective Bayesian optimization for generative design of carbon nanolattices with high compressive stiffness and strength at low density. The upper is the illustration of process workflow. The lower part shows top four MBO CFCC geometries with their 2D Bézier curves. (The optimized structure is predicted and designed with much less data (approximately 400) than the conventional method >

Furthermore, to maximize the effect where mechanical properties improve as size decreases at the nanoscale, the research team utilized pyrolytic carbon* material to implement an ultralight, high-strength, high-stiffness nano-lattice structure.

*Pyrolytic carbon: A carbon material obtained by decomposing organic substances at high temperatures. It has excellent heat resistance and strength, making it widely used in industries such as semiconductor equipment coatings and artificial joint coatings, where it must withstand high temperatures without deformation.

For this, the team applied two-photon polymerization (2PP) technology* to precisely fabricate complex nano-lattice structures, and mechanical performance evaluations confirmed that the developed structure simultaneously possesses strength comparable to steel and the lightness of Styrofoam.

*Two-photon polymerization (2PP) technology: An advanced optical manufacturing technique based on the principle that polymerization occurs only when two photons of a specific wavelength are absorbed simultaneously.

Additionally, the research team demonstrated that multi-focus two-photon polymerization (multi-focus 2PP) technology enables the fabrication of millimeter-scale structures while maintaining nanoscale precision.

Professor Seunghwa Ryu explained, "This technology innovatively solves the stress concentration issue, which has been a limitation of conventional design methods, through three-dimensional nano-lattice structures, achieving both ultralight weight and high strength in material development."

< Figure 2. FESEM image of the fabricated nano-lattice structure and (bottom right) the macroscopic nanolattice resting on a bubble >

He further emphasized, "By integrating data-driven optimal design with precision 3D printing technology, this development not only meets the demand for lightweight materials in the aerospace and automotive industries but also opens possibilities for various industrial applications through customized design."

This study was led by Dr. Peter Serles of the Department of Mechanical & Industrial Engineering at University of Toronto and Dr. Jinwook Yeo from KAIST as co-first authors, with Professor Seunghwa Ryu and Professor Tobin Filleter as corresponding authors.

The research was published on January 23, 2025 in the international journal Advanced Materials (Paper title: “Ultrahigh Specific Strength by Bayesian Optimization of Lightweight Carbon Nanolattices”).

DOI: https://doi.org/10.1002/adma.202410651

This research was supported by the Multiphase Materials Innovation Manufacturing Research Center (an ERC program) funded by the Ministry of Science and ICT, the M3DT (Medical Device Digital Development Tool) project funded by the Ministry of Food and Drug Safety, and the KAIST International Collaboration Program.

2025.02.18 View 3299 -

KAIST Develops a Multifunctional Structural Battery Capable of Energy Storage and Load Support

Structural batteries are used in industries such as eco-friendly, energy-based automobiles, mobility, and aerospace, and they must simultaneously meet the requirements of high energy density for energy storage and high load-bearing capacity. Conventional structural battery technology has struggled to enhance both functions concurrently. However, KAIST researchers have succeeded in developing foundational technology to address this issue.

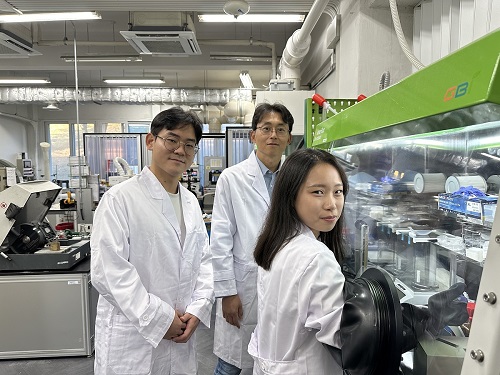

< Photo 1. (From left) Professor Seong Su Kim, PhD candidates Sangyoon Bae and Su Hyun Lim of the Department of Mechanical Engineering >

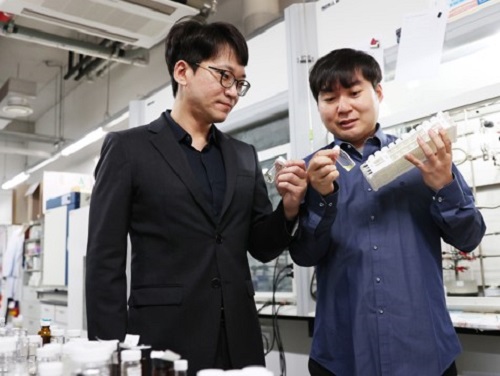

< Photo 2. (From left) Professor Seong Su Kim and Master's Graduate Mohamad A. Raja of KAIST Department of Mechanical Engineering >

KAIST (represented by President Kwang Hyung Lee) announced on the 19th of November that Professor Seong Su Kim's team from the Department of Mechanical Engineering has developed a thin, uniform, high-density, multifunctional structural carbon fiber composite battery* capable of supporting loads, and that is free from fire risks while offering high energy density.

*Multifunctional structural batteries: Refers to the ability of each material in the composite to simultaneously serve as a load-bearing structure and an energy storage element.

Early structural batteries involved embedding commercial lithium-ion batteries into layered composite materials. These batteries suffered from low integration of their mechanical and electrochemical properties, leading to challenges in material processing, assembly, and design optimization, making commercialization difficult.

To overcome these challenges, Professor Kim's team explored the concept of "energy-storing composite materials," focusing on interface and curing properties, which are critical in traditional composite design. This led to the development of high-density multifunctional structural carbon fiber composite batteries that maximize multifunctionality.

The team analyzed the curing mechanisms of epoxy resin, known for its strong mechanical properties, combined with ionic liquid and carbonate electrolyte-based solid polymer electrolytes. By controlling temperature and pressure, they were able to optimize the curing process.

The newly developed structural battery was manufactured through vacuum compression molding, increasing the volume fraction of carbon fibers—serving as both electrodes and current collectors—by over 160% compared to previous carbon-fiber-based batteries.

This greatly increased the contact area between electrodes and electrolytes, resulting in a high-density structural battery with improved electrochemical performance. Furthermore, the team effectively controlled air bubbles within the structural battery during the curing process, simultaneously enhancing the battery's mechanical properties.

Professor Seong Su Kim, the lead researcher, explained, “We proposed a framework for designing solid polymer electrolytes, a core material for high-stiffness, ultra-thin structural batteries, from both material and structural perspectives. These material-based structural batteries can serve as internal components in cars, drones, airplanes, and robots, significantly extending their operating time with a single charge. This represents a foundational technology for next-generation multifunctional energy storage applications.”

< Figure 2. Supplementary cover of ACS Applied Materials & Interfaces >

Mohamad A. Raja, a master’s graduate of KAIST’s Department of Mechanical Engineering, participated as the first author of this research, which was published in the prestigious journal ACS Applied Materials & Interfaces on September 10. The paper was recognized for its excellence and selected as a supplementary cover article. (Paper title: “Thin, Uniform, and Highly Packed Multifunctional Structural Carbon Fiber Composite Battery Lamina Informed by Solid Polymer Electrolyte Cure Kinetics.” https://doi.org/10.1021/acsami.4c08698)

This research was supported by the National Research Foundation of Korea’s Mid-Career Researcher Program and the National Semiconductor Research Laboratory Development Program.

2024.11.27 View 4335

KAIST Develops a Multifunctional Structural Battery Capable of Energy Storage and Load Support

Structural batteries are used in industries such as eco-friendly, energy-based automobiles, mobility, and aerospace, and they must simultaneously meet the requirements of high energy density for energy storage and high load-bearing capacity. Conventional structural battery technology has struggled to enhance both functions concurrently. However, KAIST researchers have succeeded in developing foundational technology to address this issue.

< Photo 1. (From left) Professor Seong Su Kim, PhD candidates Sangyoon Bae and Su Hyun Lim of the Department of Mechanical Engineering >

< Photo 2. (From left) Professor Seong Su Kim and Master's Graduate Mohamad A. Raja of KAIST Department of Mechanical Engineering >

KAIST (represented by President Kwang Hyung Lee) announced on the 19th of November that Professor Seong Su Kim's team from the Department of Mechanical Engineering has developed a thin, uniform, high-density, multifunctional structural carbon fiber composite battery* capable of supporting loads, and that is free from fire risks while offering high energy density.

*Multifunctional structural batteries: Refers to the ability of each material in the composite to simultaneously serve as a load-bearing structure and an energy storage element.

Early structural batteries involved embedding commercial lithium-ion batteries into layered composite materials. These batteries suffered from low integration of their mechanical and electrochemical properties, leading to challenges in material processing, assembly, and design optimization, making commercialization difficult.

To overcome these challenges, Professor Kim's team explored the concept of "energy-storing composite materials," focusing on interface and curing properties, which are critical in traditional composite design. This led to the development of high-density multifunctional structural carbon fiber composite batteries that maximize multifunctionality.

The team analyzed the curing mechanisms of epoxy resin, known for its strong mechanical properties, combined with ionic liquid and carbonate electrolyte-based solid polymer electrolytes. By controlling temperature and pressure, they were able to optimize the curing process.

The newly developed structural battery was manufactured through vacuum compression molding, increasing the volume fraction of carbon fibers—serving as both electrodes and current collectors—by over 160% compared to previous carbon-fiber-based batteries.

This greatly increased the contact area between electrodes and electrolytes, resulting in a high-density structural battery with improved electrochemical performance. Furthermore, the team effectively controlled air bubbles within the structural battery during the curing process, simultaneously enhancing the battery's mechanical properties.

Professor Seong Su Kim, the lead researcher, explained, “We proposed a framework for designing solid polymer electrolytes, a core material for high-stiffness, ultra-thin structural batteries, from both material and structural perspectives. These material-based structural batteries can serve as internal components in cars, drones, airplanes, and robots, significantly extending their operating time with a single charge. This represents a foundational technology for next-generation multifunctional energy storage applications.”

< Figure 2. Supplementary cover of ACS Applied Materials & Interfaces >

Mohamad A. Raja, a master’s graduate of KAIST’s Department of Mechanical Engineering, participated as the first author of this research, which was published in the prestigious journal ACS Applied Materials & Interfaces on September 10. The paper was recognized for its excellence and selected as a supplementary cover article. (Paper title: “Thin, Uniform, and Highly Packed Multifunctional Structural Carbon Fiber Composite Battery Lamina Informed by Solid Polymer Electrolyte Cure Kinetics.” https://doi.org/10.1021/acsami.4c08698)

This research was supported by the National Research Foundation of Korea’s Mid-Career Researcher Program and the National Semiconductor Research Laboratory Development Program.

2024.11.27 View 4335 -

A KAIST Research Team Develops High-Performance Stretchable Solar Cells

With the market for wearable electric devices growing rapidly, stretchable solar cells that can function under strain have received considerable attention as an energy source. To build such solar cells, it is necessary that their photoactive layer, which converts light into electricity, shows high electrical performance while possessing mechanical elasticity. However, satisfying both of these two requirements is challenging, making stretchable solar cells difficult to develop.

On December 26, a KAIST research team from the Department of Chemical and Biomolecular Engineering (CBE) led by Professor Bumjoon Kim announced the development of a new conductive polymer material that achieved both high electrical performance and elasticity while introducing the world’s highest-performing stretchable organic solar cell.

Organic solar cells are devices whose photoactive layer, which is responsible for the conversion of light into electricity, is composed of organic materials. Compared to existing non-organic material-based solar cells, they are lighter and flexible, making them highly applicable for wearable electrical devices. Solar cells as an energy source are particularly important for building electrical devices, but high-efficiency solar cells often lack flexibility, and their application in wearable devices have therefore been limited to this point.

The team led by Professor Kim conjugated a highly stretchable polymer to an electrically conductive polymer with excellent electrical properties through chemical bonding, and developed a new conductive polymer with both electrical conductivity and mechanical stretchability. This polymer meets the highest reported level of photovoltaic conversion efficiency (19%) using organic solar cells, while also showing 10 times the stretchability of existing devices. The team thereby built the world’s highest performing stretchable solar cell that can be stretched up to 40% during operation, and demonstrated its applicability for wearable devices.

< Figure 1. Chemical structure of the newly developed conductive polymer and performance of stretchable organic solar cells using the material. >

Professor Kim said, “Through this research, we not only developed the world’s best performing stretchable organic solar cell, but it is also significant that we developed a new polymer that can be applicable as a base material for various electronic devices that needs to be malleable and/or elastic.”

< Figure 2. Photovoltaic efficiency and mechanical stretchability of newly developed polymers compared to existing polymers. >

This research, conducted by KAIST researchers Jin-Woo Lee and Heung-Goo Lee as first co-authors in cooperation with teams led by Professor Taek-Soo Kim from the Department of Mechanical Engineering and Professor Sheng Li from the Department of CBE, was published in Joule on December 1 (Paper Title: Rigid and Soft Block-Copolymerized Conjugated Polymers Enable High-Performance Intrinsically-Stretchable Organic Solar Cells).

This research was supported by the National Research Foundation of Korea.

2024.01.04 View 8114

A KAIST Research Team Develops High-Performance Stretchable Solar Cells

With the market for wearable electric devices growing rapidly, stretchable solar cells that can function under strain have received considerable attention as an energy source. To build such solar cells, it is necessary that their photoactive layer, which converts light into electricity, shows high electrical performance while possessing mechanical elasticity. However, satisfying both of these two requirements is challenging, making stretchable solar cells difficult to develop.

On December 26, a KAIST research team from the Department of Chemical and Biomolecular Engineering (CBE) led by Professor Bumjoon Kim announced the development of a new conductive polymer material that achieved both high electrical performance and elasticity while introducing the world’s highest-performing stretchable organic solar cell.

Organic solar cells are devices whose photoactive layer, which is responsible for the conversion of light into electricity, is composed of organic materials. Compared to existing non-organic material-based solar cells, they are lighter and flexible, making them highly applicable for wearable electrical devices. Solar cells as an energy source are particularly important for building electrical devices, but high-efficiency solar cells often lack flexibility, and their application in wearable devices have therefore been limited to this point.

The team led by Professor Kim conjugated a highly stretchable polymer to an electrically conductive polymer with excellent electrical properties through chemical bonding, and developed a new conductive polymer with both electrical conductivity and mechanical stretchability. This polymer meets the highest reported level of photovoltaic conversion efficiency (19%) using organic solar cells, while also showing 10 times the stretchability of existing devices. The team thereby built the world’s highest performing stretchable solar cell that can be stretched up to 40% during operation, and demonstrated its applicability for wearable devices.

< Figure 1. Chemical structure of the newly developed conductive polymer and performance of stretchable organic solar cells using the material. >

Professor Kim said, “Through this research, we not only developed the world’s best performing stretchable organic solar cell, but it is also significant that we developed a new polymer that can be applicable as a base material for various electronic devices that needs to be malleable and/or elastic.”

< Figure 2. Photovoltaic efficiency and mechanical stretchability of newly developed polymers compared to existing polymers. >

This research, conducted by KAIST researchers Jin-Woo Lee and Heung-Goo Lee as first co-authors in cooperation with teams led by Professor Taek-Soo Kim from the Department of Mechanical Engineering and Professor Sheng Li from the Department of CBE, was published in Joule on December 1 (Paper Title: Rigid and Soft Block-Copolymerized Conjugated Polymers Enable High-Performance Intrinsically-Stretchable Organic Solar Cells).

This research was supported by the National Research Foundation of Korea.

2024.01.04 View 8114 -

KAIST develops biocompatible adhesive applicable to hair transplants

Aside from being used as a new medical adhesive, the new material can be applied to developing a new method of hair transplants, which cannot be repeated multiple times using current method of implanting the wholly intact follicles into the skin.

Medical adhesives are materials that can be applied to various uses such as wound healing, hemostasis, vascular anastomosis, and tissue engineering, and is expected to contribute greatly to the development of minimally invasive surgery and organ transplants. However, adhesives with high adhesion, low toxicity, and capable of decomposing in the body are rare. Adhesives based on natural proteins, such as fibrin and collagen, have high biocompatibility but insufficient adhesive strength. Synthetic polymer adhesives based on urethane or acrylic have greater adhesion but do not decompose well and may cause an inflammatory reaction in the body.

A joint research team led by Professor Myungeun Seo and Professor Haeshin Lee from the KAIST Department of Chemistry developed a bio-friendly adhesive from biocompatible polymers using tannic acid, the source of astringency in wine.

The research team focused on tannic acid, a natural polyphenolic product. Tannic acid is a polyphenol present in large amounts in fruit peels, nuts, and cacao. It has a high affinity and coating ability on other substances, and we sense the astringent taste in wine when tannic acid sticks to the surface of our tongue. When tannic acid is mixed with hydrophilic polymers, they form coacervates, or small droplets of jelly-like fluids that sink. If the polymers used are biocompatible, the mixture can be applied as a medical adhesive with low toxicity. However, coacervates are fundamentally fluid-like and cannot withstand large forces, which limits their adhesive capabilities. Thus, while research to utilize it as an adhesive has been actively discussed, a biodegradable material exhibiting strong adhesion due to its high shear strength has not yet been developed.

The research team figured out a way to enhance adhesion by mixing two biocompatible FDA-approved polymers, polyethylene glycol (PEG) and polylactic acid (PLA). While PEG, which is used widely in eyedrops and cream, is hydrophilic, PLA, a well-known bioplastic derived from lactic acid, is insoluble in water. The team combined the two into a block copolymer, which forms hydrophilic PLA aggregates in water with PEG blocks surrounding them. A coacervate created by mixing the micelles and tannic acid would behave like a solid due to the hard PLA components, and show an elastic modulus improved by a thousand times compared to PEG, enabling it to withstand much greater force as an adhesive.

Figure 1. (Above) Principle of biodegradable adhesive made by mixing poly(ethylene glycol)-poly(lactic acid) diblock copolymer and tannic acid in water. Yellow coacervate is precipitated through hydrogen bonding between the block copolymer micelles and tannic acid, and exhibits adhesion. After heat treatment, hydrogen bonds are rearranged to further improve adhesion. (Bottom) Adhesion comparison. Compared to using poly(ethylene glycol) polymer (d), it can support 10 times more weight when using block copolymer (e) and 60 times more weight after heat treatment (f). The indicated G' values represent the elastic modulus of the material.

Furthermore, the research team observed that the material’s mechanical properties can be improved by over a hundred times through a heating and cooling process that is used to heat-treat metals. They also discovered that this is due to the enforced interactions between micelle and tannic acid arrays.

The research team used the fact that the material shows minimal irritation to the skin and decomposes well in the body to demonstrate its possible application as an adhesive for hair transplantation through an animal experiment. Professor Haeshin Lee, who has pioneered various application fields including medical adhesives, hemostatic agents, and browning shampoo, focused on the adhesive capacities and low toxicity of polyphenols like tannic acid, and now looks forward to it improving the limitations of current hair transplant methods, which still involve follicle transfer and are difficult to be repeated multiple times.

Figure 2. (a) Overview of a hair transplantation method using a biodegradable adhesive (right) compared to a conventional hair transplantation method (left) that transplants hair containing hair follicles. After applying an adhesive to the tip of the hair, it is fixed to the skin by implanting it through a subcutaneous injection, and repeated treatment is possible. (b) Initial animal test results. One day after 15 hair transplantation, 12 strands of hair remain. If you pull the 3 strands of hair, you can see that the whole body is pulled up, indicating that it is firmly implanted into the skin. All strands of hair applied without the new adhesive material fell off, and in the case of adhesive without heat treatment, the efficiency was 1/7.

This research was conducted by first co-authors Dr. Jongmin Park (currently a senior researcher at the Korea Research Institute of Chemical Technology) from Professor Myeongeun Seo’s team and Dr. Eunsook Park from Professor Haeshin Lee’s team in the KAIST Department of Chemistry, and through joint research with the teams led by Professor Hyungjun Kim from the KAIST Department of Chemistry and Professor Siyoung Choi from the Department of Chemical and Biomolecular Engineering. The research was published online on August 22 in the international journal Au (JACS Au) under the title Biodegradable Block Copolymer-Tannic Acid Glue.

This study was funded by the Support Research Under Protection Project of the National Research Foundation (NRF), Leading Research Center Support Project (Research Center for Multiscale Chiral Structure), Biodegradable Plastics Commercialization and Demonstration Project by the Ministry of Trade and Industry, and institutional funding from the Korea Research Institute of Chemical Technology.

2022.10.07 View 11317

KAIST develops biocompatible adhesive applicable to hair transplants

Aside from being used as a new medical adhesive, the new material can be applied to developing a new method of hair transplants, which cannot be repeated multiple times using current method of implanting the wholly intact follicles into the skin.

Medical adhesives are materials that can be applied to various uses such as wound healing, hemostasis, vascular anastomosis, and tissue engineering, and is expected to contribute greatly to the development of minimally invasive surgery and organ transplants. However, adhesives with high adhesion, low toxicity, and capable of decomposing in the body are rare. Adhesives based on natural proteins, such as fibrin and collagen, have high biocompatibility but insufficient adhesive strength. Synthetic polymer adhesives based on urethane or acrylic have greater adhesion but do not decompose well and may cause an inflammatory reaction in the body.

A joint research team led by Professor Myungeun Seo and Professor Haeshin Lee from the KAIST Department of Chemistry developed a bio-friendly adhesive from biocompatible polymers using tannic acid, the source of astringency in wine.

The research team focused on tannic acid, a natural polyphenolic product. Tannic acid is a polyphenol present in large amounts in fruit peels, nuts, and cacao. It has a high affinity and coating ability on other substances, and we sense the astringent taste in wine when tannic acid sticks to the surface of our tongue. When tannic acid is mixed with hydrophilic polymers, they form coacervates, or small droplets of jelly-like fluids that sink. If the polymers used are biocompatible, the mixture can be applied as a medical adhesive with low toxicity. However, coacervates are fundamentally fluid-like and cannot withstand large forces, which limits their adhesive capabilities. Thus, while research to utilize it as an adhesive has been actively discussed, a biodegradable material exhibiting strong adhesion due to its high shear strength has not yet been developed.

The research team figured out a way to enhance adhesion by mixing two biocompatible FDA-approved polymers, polyethylene glycol (PEG) and polylactic acid (PLA). While PEG, which is used widely in eyedrops and cream, is hydrophilic, PLA, a well-known bioplastic derived from lactic acid, is insoluble in water. The team combined the two into a block copolymer, which forms hydrophilic PLA aggregates in water with PEG blocks surrounding them. A coacervate created by mixing the micelles and tannic acid would behave like a solid due to the hard PLA components, and show an elastic modulus improved by a thousand times compared to PEG, enabling it to withstand much greater force as an adhesive.

Figure 1. (Above) Principle of biodegradable adhesive made by mixing poly(ethylene glycol)-poly(lactic acid) diblock copolymer and tannic acid in water. Yellow coacervate is precipitated through hydrogen bonding between the block copolymer micelles and tannic acid, and exhibits adhesion. After heat treatment, hydrogen bonds are rearranged to further improve adhesion. (Bottom) Adhesion comparison. Compared to using poly(ethylene glycol) polymer (d), it can support 10 times more weight when using block copolymer (e) and 60 times more weight after heat treatment (f). The indicated G' values represent the elastic modulus of the material.

Furthermore, the research team observed that the material’s mechanical properties can be improved by over a hundred times through a heating and cooling process that is used to heat-treat metals. They also discovered that this is due to the enforced interactions between micelle and tannic acid arrays.

The research team used the fact that the material shows minimal irritation to the skin and decomposes well in the body to demonstrate its possible application as an adhesive for hair transplantation through an animal experiment. Professor Haeshin Lee, who has pioneered various application fields including medical adhesives, hemostatic agents, and browning shampoo, focused on the adhesive capacities and low toxicity of polyphenols like tannic acid, and now looks forward to it improving the limitations of current hair transplant methods, which still involve follicle transfer and are difficult to be repeated multiple times.

Figure 2. (a) Overview of a hair transplantation method using a biodegradable adhesive (right) compared to a conventional hair transplantation method (left) that transplants hair containing hair follicles. After applying an adhesive to the tip of the hair, it is fixed to the skin by implanting it through a subcutaneous injection, and repeated treatment is possible. (b) Initial animal test results. One day after 15 hair transplantation, 12 strands of hair remain. If you pull the 3 strands of hair, you can see that the whole body is pulled up, indicating that it is firmly implanted into the skin. All strands of hair applied without the new adhesive material fell off, and in the case of adhesive without heat treatment, the efficiency was 1/7.

This research was conducted by first co-authors Dr. Jongmin Park (currently a senior researcher at the Korea Research Institute of Chemical Technology) from Professor Myeongeun Seo’s team and Dr. Eunsook Park from Professor Haeshin Lee’s team in the KAIST Department of Chemistry, and through joint research with the teams led by Professor Hyungjun Kim from the KAIST Department of Chemistry and Professor Siyoung Choi from the Department of Chemical and Biomolecular Engineering. The research was published online on August 22 in the international journal Au (JACS Au) under the title Biodegradable Block Copolymer-Tannic Acid Glue.

This study was funded by the Support Research Under Protection Project of the National Research Foundation (NRF), Leading Research Center Support Project (Research Center for Multiscale Chiral Structure), Biodegradable Plastics Commercialization and Demonstration Project by the Ministry of Trade and Industry, and institutional funding from the Korea Research Institute of Chemical Technology.

2022.10.07 View 11317 -

New Polymer Mesophase Structure Discovered

Bilayer-folded lamellar mesophase induced by random polymer sequence

Polymers, large molecules made up of repeating smaller molecules called monomers, are found in nearly everything we use in our day-to-day lives. Polymers can be natural or created synthetically. Natural polymers, also called biopolymers, include DNA, proteins, and materials like silk, gelatin, and collagen. Synthetic polymers make up many different kinds of materials, including plastic, that are used in constructing everything from toys to industrial fiber cables to brake pads.

As polymers are formed through a process called polymerization, the monomers are connected through a chain. As the chain develops, the structure of the polymer determines its unique physical and chemical properties. Researchers are continually studying polymers, how they form, how they are structured, and how they develop these unique properties. By understanding this information, scientists can develop new uses for polymers and create new materials that can be used in a wide variety of industries.

In a paper published in Nature Communications on May 4, researchers describe a new structure found in an aqueous solution of an amphiphilic copolymer, called a bilayer-folded lamellar mesophase, that has been discovered through a random copolymer sequence.

“A new mesophase is an important discovery as it shows a new way for molecules to self-organize,” said Professor Myungeun Seo at the Department of Chemistry at KAIST. “We were particularly thrilled to identify this bilayer-folded lamellar phase because pure bilayer membranes are difficult to fold thermodynamically.”

Researchers think that this mesophase structure comes from the sequence of the monomers within the copolymer. The way the different monomers arrange themselves in the chain that makes up a copolymer is important and can have implications for what the copolymer can do. Many copolymers are random, which means that their structure relies on how the monomers interact with each other. In this case, the interaction between the hydrophobic monomers associates the copolymer chains to conceal the hydrophobic domain from water. As the structure gets more complex, researchers have found that a visible order develops so that monomers can be matched up with the right pair.

“While we tend to think random means disorder, here we showed that a periodic order can spontaneously arise from the random copolymer sequence based on their collective behavior,” said Professor Seo. “We believe this comes from the sequence matching problem: finding a perfectly complementary pair for a long sequence is nearly impossible.”

This is what creates the unique structure of this newly discovered mesophase. The copolymer spontaneously folds and creates a multilamellar structure that is separated by water. A multilamellar structure refers to plate-like folds and the folded layers stack on top of each other. The resulting mesophase is birefringent, meaning light refracts through it, it is similar to liquid crystalline, and viscoelastic, which means that it is both viscous and elastic at the same time.

Looking ahead, researchers hope to learn more about this new mesophase and figure out how to control the outcome. Once more is understood about the mesophase and how it is formed, it’s possible that new mesophases could be discovered as more sequences are researched. “One of the obvious questions for us is how to control the folding frequency and adjust the folded height, which we are currently working to address. Ultimately, we want to understand how different multinary sequences can associate with another to create order and apply the knowledge to develop new materials,” said Professor Seo. The National Research Foundation, the Ministry of Education, and the Ministry of Science and ICT of Korea funded this research.

-PublicationMinjoong Shin, Hayeon Kim, Geonhyeong Park, Jongmin Park, Hyungju Ahn, Dong Ki Yoon, Eunji Lee, Myungeun Seo, “Bilayer-folded lamellar mesophase induced by random polymersequence,” May 4, 2022, Nature Communications (https://doi.org/10.1038/s41467-022-30122-z)

-ProfileProfessor Myungeun SeoMacromolecular Materials Chemistry Lab (https://nanopsg.kaist.ac.kr/)Department of ChemistryCollege of Natural SciencesKAIST

2022.06.17 View 8934

New Polymer Mesophase Structure Discovered

Bilayer-folded lamellar mesophase induced by random polymer sequence

Polymers, large molecules made up of repeating smaller molecules called monomers, are found in nearly everything we use in our day-to-day lives. Polymers can be natural or created synthetically. Natural polymers, also called biopolymers, include DNA, proteins, and materials like silk, gelatin, and collagen. Synthetic polymers make up many different kinds of materials, including plastic, that are used in constructing everything from toys to industrial fiber cables to brake pads.

As polymers are formed through a process called polymerization, the monomers are connected through a chain. As the chain develops, the structure of the polymer determines its unique physical and chemical properties. Researchers are continually studying polymers, how they form, how they are structured, and how they develop these unique properties. By understanding this information, scientists can develop new uses for polymers and create new materials that can be used in a wide variety of industries.

In a paper published in Nature Communications on May 4, researchers describe a new structure found in an aqueous solution of an amphiphilic copolymer, called a bilayer-folded lamellar mesophase, that has been discovered through a random copolymer sequence.

“A new mesophase is an important discovery as it shows a new way for molecules to self-organize,” said Professor Myungeun Seo at the Department of Chemistry at KAIST. “We were particularly thrilled to identify this bilayer-folded lamellar phase because pure bilayer membranes are difficult to fold thermodynamically.”

Researchers think that this mesophase structure comes from the sequence of the monomers within the copolymer. The way the different monomers arrange themselves in the chain that makes up a copolymer is important and can have implications for what the copolymer can do. Many copolymers are random, which means that their structure relies on how the monomers interact with each other. In this case, the interaction between the hydrophobic monomers associates the copolymer chains to conceal the hydrophobic domain from water. As the structure gets more complex, researchers have found that a visible order develops so that monomers can be matched up with the right pair.

“While we tend to think random means disorder, here we showed that a periodic order can spontaneously arise from the random copolymer sequence based on their collective behavior,” said Professor Seo. “We believe this comes from the sequence matching problem: finding a perfectly complementary pair for a long sequence is nearly impossible.”

This is what creates the unique structure of this newly discovered mesophase. The copolymer spontaneously folds and creates a multilamellar structure that is separated by water. A multilamellar structure refers to plate-like folds and the folded layers stack on top of each other. The resulting mesophase is birefringent, meaning light refracts through it, it is similar to liquid crystalline, and viscoelastic, which means that it is both viscous and elastic at the same time.

Looking ahead, researchers hope to learn more about this new mesophase and figure out how to control the outcome. Once more is understood about the mesophase and how it is formed, it’s possible that new mesophases could be discovered as more sequences are researched. “One of the obvious questions for us is how to control the folding frequency and adjust the folded height, which we are currently working to address. Ultimately, we want to understand how different multinary sequences can associate with another to create order and apply the knowledge to develop new materials,” said Professor Seo. The National Research Foundation, the Ministry of Education, and the Ministry of Science and ICT of Korea funded this research.

-PublicationMinjoong Shin, Hayeon Kim, Geonhyeong Park, Jongmin Park, Hyungju Ahn, Dong Ki Yoon, Eunji Lee, Myungeun Seo, “Bilayer-folded lamellar mesophase induced by random polymersequence,” May 4, 2022, Nature Communications (https://doi.org/10.1038/s41467-022-30122-z)

-ProfileProfessor Myungeun SeoMacromolecular Materials Chemistry Lab (https://nanopsg.kaist.ac.kr/)Department of ChemistryCollege of Natural SciencesKAIST

2022.06.17 View 8934 -

Flexible Sensor-Integrated RFA Needle Leads to Smarter Medical Treatment

Clinical trial of flexible sensor-integrated radiofrequency ablation (RFA) needle tip monitors physical changes and steam pop

Researchers have designed a thin polymeric sensor platform on a radiofrequency ablation needle to monitor temperature and pressure in real time. The sensors integrated onto 1.5 mm diameter needle tip have proven their efficacy during clinical tests and expect to provide a new opportunity for safer and more effective medical practices. The research was reported in Advanced Science as the frontispiece on August 5.

Radiofrequency ablation (RFA) is a minimally invasive surgery technique for removing tumors and treating cardiovascular disease. During a procedure, an unintended audible explosion called ‘steam pop’ can occur due to the increased internal steam pressure in the ablation region. This phenomenon has been cited as a cause of various negative thermal and mechanical effects on neighboring tissue. Even more, the relationship between steam pop and cancer recurrence is still being investigated.

Professor Inkyu Park said that his team’s integrated sensors reliably detected the occurrence of steam pop. The sensors also monitor rapidly spreading hot steam in tissue. It is expected that the diverse properties of tissue undergoing RFA could be checked by utilizing the physical sensors integrated on the needle.

“We believe that the integrated sensors can provide useful information about a variety of medical procedures and accompanying environmental changes in the human body, and help develop more effective and safer surgical procedures,” said Professor Park.

Professor Park’s team built a thin film type pressure and temperature sensor stack with a thickness of less than 10 μm using a microfabrication process. For the pressure sensor, the team used contact resistance changes between metal electrodes and a carbon nanotube coated polymeric membrane. The entire sensor array was thoroughly insulated with medical tubes to minimize any exposure of the sensor materials to external tissue and maximize its biocompatibility.

During the clinical trial, the research team found that the accumulated hot steam is suddenly released during steam pops and this hot air spreads to neighboring tissue, which accelerates the ablation process. Furthermore, using in-situ ultrasound imaging and computational simulations, the research team could confirm the non-uniform temperature distribution around the RFA needle can be one of the primary reasons for the steam popping.

Professor Park explained that various physical and chemical sensors for different targets can be added to create other medical devices and industrial tools.

“This result will expand the usability and applicability of current flexible sensor technologies. We are also trying to integrate this sensor onto a 0.3mm diameter needle for in-vivo diagnosis applications and expect that this approach can be applied to other medical treatments as well as the industrial field,” added Professor Park. This study was supported by the National Research Foundation of Korea.

-PublicationJaeho Park, Jinwoo Lee, Hyo Keun Lim, Inkyu Park et al. “Real-Time Internal Steam Pop Detection during Radiofrequency Ablation with a Radiofrequency Ablation Needle Integrated with a Temperature and Pressure Sensor: Preclinical and clinical pilot tests," Advanced Science (https://doi/org/10.1002/advs.202100725) on August 5, 2021

-ProfileProfessor Inkyu ParkMicro & Nano Tranducers Laboratory http://mintlab1.kaist.ac.kr/

Department of Mechanical EngineeringCollege of EngineeringKAIST

2021.10.20 View 9091

Flexible Sensor-Integrated RFA Needle Leads to Smarter Medical Treatment

Clinical trial of flexible sensor-integrated radiofrequency ablation (RFA) needle tip monitors physical changes and steam pop

Researchers have designed a thin polymeric sensor platform on a radiofrequency ablation needle to monitor temperature and pressure in real time. The sensors integrated onto 1.5 mm diameter needle tip have proven their efficacy during clinical tests and expect to provide a new opportunity for safer and more effective medical practices. The research was reported in Advanced Science as the frontispiece on August 5.

Radiofrequency ablation (RFA) is a minimally invasive surgery technique for removing tumors and treating cardiovascular disease. During a procedure, an unintended audible explosion called ‘steam pop’ can occur due to the increased internal steam pressure in the ablation region. This phenomenon has been cited as a cause of various negative thermal and mechanical effects on neighboring tissue. Even more, the relationship between steam pop and cancer recurrence is still being investigated.

Professor Inkyu Park said that his team’s integrated sensors reliably detected the occurrence of steam pop. The sensors also monitor rapidly spreading hot steam in tissue. It is expected that the diverse properties of tissue undergoing RFA could be checked by utilizing the physical sensors integrated on the needle.

“We believe that the integrated sensors can provide useful information about a variety of medical procedures and accompanying environmental changes in the human body, and help develop more effective and safer surgical procedures,” said Professor Park.

Professor Park’s team built a thin film type pressure and temperature sensor stack with a thickness of less than 10 μm using a microfabrication process. For the pressure sensor, the team used contact resistance changes between metal electrodes and a carbon nanotube coated polymeric membrane. The entire sensor array was thoroughly insulated with medical tubes to minimize any exposure of the sensor materials to external tissue and maximize its biocompatibility.

During the clinical trial, the research team found that the accumulated hot steam is suddenly released during steam pops and this hot air spreads to neighboring tissue, which accelerates the ablation process. Furthermore, using in-situ ultrasound imaging and computational simulations, the research team could confirm the non-uniform temperature distribution around the RFA needle can be one of the primary reasons for the steam popping.

Professor Park explained that various physical and chemical sensors for different targets can be added to create other medical devices and industrial tools.

“This result will expand the usability and applicability of current flexible sensor technologies. We are also trying to integrate this sensor onto a 0.3mm diameter needle for in-vivo diagnosis applications and expect that this approach can be applied to other medical treatments as well as the industrial field,” added Professor Park. This study was supported by the National Research Foundation of Korea.

-PublicationJaeho Park, Jinwoo Lee, Hyo Keun Lim, Inkyu Park et al. “Real-Time Internal Steam Pop Detection during Radiofrequency Ablation with a Radiofrequency Ablation Needle Integrated with a Temperature and Pressure Sensor: Preclinical and clinical pilot tests," Advanced Science (https://doi/org/10.1002/advs.202100725) on August 5, 2021

-ProfileProfessor Inkyu ParkMicro & Nano Tranducers Laboratory http://mintlab1.kaist.ac.kr/

Department of Mechanical EngineeringCollege of EngineeringKAIST

2021.10.20 View 9091 -

Ultrafast, on-Chip PCR Could Speed Up Diagnoses during Pandemics

A rapid point-of-care diagnostic plasmofluidic chip can deliver result in only 8 minutes

Reverse transcription-polymerase chain reaction (RT-PCR) has been the gold standard for diagnosis during the COVID-19 pandemic. However, the PCR portion of the test requires bulky, expensive machines and takes about an hour to complete, making it difficult to quickly diagnose someone at a testing site. Now, researchers at KAIST have developed a plasmofluidic chip that can perform PCR in only about 8 minutes, which could speed up diagnoses during current and future pandemics.

The rapid diagnosis of COVID-19 and other highly contagious viral diseases is important for timely medical care, quarantining and contact tracing. Currently, RT-PCR uses enzymes to reverse transcribe tiny amounts of viral RNA to DNA, and then amplifies the DNA so that it can be detected by a fluorescent probe. It is the most sensitive and reliable diagnostic method.

But because the PCR portion of the test requires 30-40 cycles of heating and cooling in special machines, it takes about an hour to perform, and samples must typically be sent away to a lab, meaning that a patient usually has to wait a day or two to receive their diagnosis.

Professor Ki-Hun Jeong at the Department of Bio and Brain Engineering and his colleagues wanted to develop a plasmofluidic PCR chip that could quickly heat and cool miniscule volumes of liquids, allowing accurate point-of-care diagnoses in a fraction of the time. The research was reported in ACS Nano on May 19.

The researchers devised a postage stamp-sized polydimethylsiloxane chip with a microchamber array for the PCR reactions. When a drop of a sample is added to the chip, a vacuum pulls the liquid into the microchambers, which are positioned above glass nanopillars with gold nanoislands. Any microbubbles, which could interfere with the PCR reaction, diffuse out through an air-permeable wall. When a white LED is turned on beneath the chip, the gold nanoislands on the nanopillars quickly convert light to heat, and then rapidly cool when the light is switched off.

The researchers tested the device on a piece of DNA containing a SARS-CoV-2 gene, accomplishing 40 heating and cooling cycles and fluorescence detection in only 5 minutes, with an additional 3 minutes for sample loading. The amplification efficiency was 91%, whereas a comparable conventional PCR process has an efficiency of 98%. With the reverse transcriptase step added prior to sample loading, the entire testing time with the new method could take 10-13 minutes, as opposed to about an hour for typical RT-PCR testing. The new device could provide many opportunities for rapid point-of-care diagnostics during a pandemic, the researchers say.

-Publication

Ultrafast and Real-Time Nanoplasmonic On-Chip Polymerase Chain Reaction for Rapid and Quantitative Molecular Diagnostics

ACS Nano (https://doi.org/10.1021/acsnano.1c02154)

-Professor

Ki-Hun Jeong

Biophotonics Laboratory

https://biophotonics.kaist.ac.kr/

Department of Bio and Brain Engineeinrg

KAIST

2021.06.08 View 11584

Ultrafast, on-Chip PCR Could Speed Up Diagnoses during Pandemics

A rapid point-of-care diagnostic plasmofluidic chip can deliver result in only 8 minutes

Reverse transcription-polymerase chain reaction (RT-PCR) has been the gold standard for diagnosis during the COVID-19 pandemic. However, the PCR portion of the test requires bulky, expensive machines and takes about an hour to complete, making it difficult to quickly diagnose someone at a testing site. Now, researchers at KAIST have developed a plasmofluidic chip that can perform PCR in only about 8 minutes, which could speed up diagnoses during current and future pandemics.

The rapid diagnosis of COVID-19 and other highly contagious viral diseases is important for timely medical care, quarantining and contact tracing. Currently, RT-PCR uses enzymes to reverse transcribe tiny amounts of viral RNA to DNA, and then amplifies the DNA so that it can be detected by a fluorescent probe. It is the most sensitive and reliable diagnostic method.

But because the PCR portion of the test requires 30-40 cycles of heating and cooling in special machines, it takes about an hour to perform, and samples must typically be sent away to a lab, meaning that a patient usually has to wait a day or two to receive their diagnosis.

Professor Ki-Hun Jeong at the Department of Bio and Brain Engineering and his colleagues wanted to develop a plasmofluidic PCR chip that could quickly heat and cool miniscule volumes of liquids, allowing accurate point-of-care diagnoses in a fraction of the time. The research was reported in ACS Nano on May 19.

The researchers devised a postage stamp-sized polydimethylsiloxane chip with a microchamber array for the PCR reactions. When a drop of a sample is added to the chip, a vacuum pulls the liquid into the microchambers, which are positioned above glass nanopillars with gold nanoislands. Any microbubbles, which could interfere with the PCR reaction, diffuse out through an air-permeable wall. When a white LED is turned on beneath the chip, the gold nanoislands on the nanopillars quickly convert light to heat, and then rapidly cool when the light is switched off.

The researchers tested the device on a piece of DNA containing a SARS-CoV-2 gene, accomplishing 40 heating and cooling cycles and fluorescence detection in only 5 minutes, with an additional 3 minutes for sample loading. The amplification efficiency was 91%, whereas a comparable conventional PCR process has an efficiency of 98%. With the reverse transcriptase step added prior to sample loading, the entire testing time with the new method could take 10-13 minutes, as opposed to about an hour for typical RT-PCR testing. The new device could provide many opportunities for rapid point-of-care diagnostics during a pandemic, the researchers say.

-Publication

Ultrafast and Real-Time Nanoplasmonic On-Chip Polymerase Chain Reaction for Rapid and Quantitative Molecular Diagnostics

ACS Nano (https://doi.org/10.1021/acsnano.1c02154)

-Professor

Ki-Hun Jeong

Biophotonics Laboratory

https://biophotonics.kaist.ac.kr/

Department of Bio and Brain Engineeinrg

KAIST

2021.06.08 View 11584 -

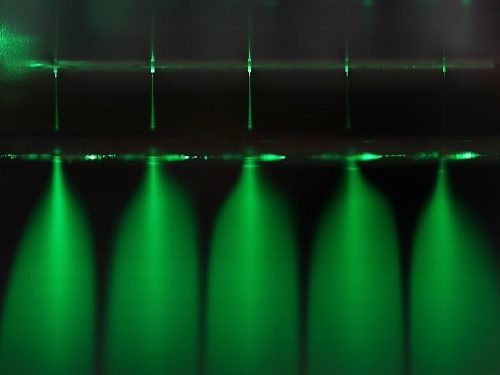

Electrosprayed Micro Droplets Help Kill Bacteria and Viruses

With COVID-19 raging around the globe, researchers are doubling down on methods for developing diverse antimicrobial technologies that could be effective in killing a virus, but harmless to humans and the environment.

A recent study by a KAIST research team will be one of the responses to such efforts. Professor Seung Seob Lee and Dr. Ji-hun Jeong from the Department of Mechanical Engineering developed a harmless air sterilization prototype featuring electrosprayed water from a polymer micro-nozzle array. This study is one of the projects being supported by the KAIST New Deal R&D Initiative in response to COVID-19. Their study was reported in Polymer.

The electrosprayed microdroplets encapsulate reactive oxygen species such as hydroxyl radicals, superoxides that are known to have an antimicrobial function. The encapsulation prolongs the life of reactive oxygen species, which enable the droplets to perform their antimicrobial function effectively. Prior research has already proven the antimicrobial and encapsulation effects of electrosprayed droplets.

Despite its potential for antimicrobial applications, electrosprayed water generally operates under an electrical discharge condition, which can generate ozone. The inhalation of ozone is known to cause damage to the respiratory system of humans. Another technical barrier for electrospraying is the low flow rate problem. Since electrospraying exhibits the dependence of droplet size on the flow rate, there is a limit for the amount of water microdroplets a single nozzle can produce.

With this in mind, the research team developed a dielectric polymer micro-nozzle array to perform the multiplexed electrospraying of water without electrical discharge. The polymer micro-nozzle array was fabricated using the MEMS (Micro Electro-Mechanical System) process. According to the research team, the nozzle can carry five to 19 micro-nozzles depending on the required application.

The high aspect ratio of the micro-nozzle and an in-plane extractor were proposed to concentrate the electric field at the tip of the micro-nozzle, which prevents the electrical discharge caused by the high surface tension of water. A micro-pillar array with a hydrophobic coating around the micro-nozzle was also proposed to prevent the wetting of the micro-nozzle array.

The polymer micro-nozzle array performed in steady cone jet mode without electrical discharge as confirmed by high-speed imaging and nanosecond pulsed imaging. The water microdroplets were measured to be in the range of six to 10 μm and displayed an antimicrobial effect on Escherichia coli and Staphylococcus aureus.

Professor Lee said, “We believe that this research can be applied to air conditioning products in areas that require antimicrobial and humidifying functions.”

Publication:

Jeong, J. H., et al. (2020) Polymer micro-atomizer for water electrospray in the cone jet mode. Polymer. Vol. No. 194, 122405. Available online at https://doi.org/10.1016/j.polymer.2020.122405

Profile: Seung Seob Lee, Ph.D.

sslee97@kaist.ac.kr

http://mmst.kaist.ac.kr/

Professor

Department of Mechanical Engineering (ME)

Korea Advanced Institute of Science and Technology (KAIST)

https://www.kaist.ac.kr

Daejeon 34141, Korea

Profile: Ji-hun Jeong, Ph.D.

jiuni6022@kaist.ac.kr

Postdoctoral researcher

Department of Mechanical Engineering (ME)

Korea Advanced Institute of Science and Technology (KAIST)

https://www.kaist.ac.kr

Daejeon 34141, Korea

(END)

2020.12.21 View 14243

Electrosprayed Micro Droplets Help Kill Bacteria and Viruses

With COVID-19 raging around the globe, researchers are doubling down on methods for developing diverse antimicrobial technologies that could be effective in killing a virus, but harmless to humans and the environment.

A recent study by a KAIST research team will be one of the responses to such efforts. Professor Seung Seob Lee and Dr. Ji-hun Jeong from the Department of Mechanical Engineering developed a harmless air sterilization prototype featuring electrosprayed water from a polymer micro-nozzle array. This study is one of the projects being supported by the KAIST New Deal R&D Initiative in response to COVID-19. Their study was reported in Polymer.

The electrosprayed microdroplets encapsulate reactive oxygen species such as hydroxyl radicals, superoxides that are known to have an antimicrobial function. The encapsulation prolongs the life of reactive oxygen species, which enable the droplets to perform their antimicrobial function effectively. Prior research has already proven the antimicrobial and encapsulation effects of electrosprayed droplets.

Despite its potential for antimicrobial applications, electrosprayed water generally operates under an electrical discharge condition, which can generate ozone. The inhalation of ozone is known to cause damage to the respiratory system of humans. Another technical barrier for electrospraying is the low flow rate problem. Since electrospraying exhibits the dependence of droplet size on the flow rate, there is a limit for the amount of water microdroplets a single nozzle can produce.

With this in mind, the research team developed a dielectric polymer micro-nozzle array to perform the multiplexed electrospraying of water without electrical discharge. The polymer micro-nozzle array was fabricated using the MEMS (Micro Electro-Mechanical System) process. According to the research team, the nozzle can carry five to 19 micro-nozzles depending on the required application.

The high aspect ratio of the micro-nozzle and an in-plane extractor were proposed to concentrate the electric field at the tip of the micro-nozzle, which prevents the electrical discharge caused by the high surface tension of water. A micro-pillar array with a hydrophobic coating around the micro-nozzle was also proposed to prevent the wetting of the micro-nozzle array.

The polymer micro-nozzle array performed in steady cone jet mode without electrical discharge as confirmed by high-speed imaging and nanosecond pulsed imaging. The water microdroplets were measured to be in the range of six to 10 μm and displayed an antimicrobial effect on Escherichia coli and Staphylococcus aureus.

Professor Lee said, “We believe that this research can be applied to air conditioning products in areas that require antimicrobial and humidifying functions.”

Publication:

Jeong, J. H., et al. (2020) Polymer micro-atomizer for water electrospray in the cone jet mode. Polymer. Vol. No. 194, 122405. Available online at https://doi.org/10.1016/j.polymer.2020.122405

Profile: Seung Seob Lee, Ph.D.

sslee97@kaist.ac.kr

http://mmst.kaist.ac.kr/

Professor

Department of Mechanical Engineering (ME)

Korea Advanced Institute of Science and Technology (KAIST)

https://www.kaist.ac.kr

Daejeon 34141, Korea

Profile: Ji-hun Jeong, Ph.D.

jiuni6022@kaist.ac.kr

Postdoctoral researcher

Department of Mechanical Engineering (ME)

Korea Advanced Institute of Science and Technology (KAIST)

https://www.kaist.ac.kr

Daejeon 34141, Korea

(END)

2020.12.21 View 14243 -

Sulfur-Containing Polymer Generates High Refractive Index and Transparency

Transparent polymer thin film with refractive index exceeding 1.9 to serve as new platform materials for high-end optical device applications

Researchers reported a novel technology enhancing the high transparency of refractive polymer film via a one-step vapor deposition process. The sulfur-containing polymer (SCP) film produced by Professor Sung Gap Im’s research team at KAIST’s Department of Chemical and Biomolecular Engineering has exhibited excellent environmental stability and chemical resistance, which is highly desirable for its application in long-term optical device applications. The high refractive index exceeding 1.9 while being fully transparent in the entire visible range will help expand the applications of optoelectronic devices.

The refractive index is a ratio of the speed of light in a vacuum to the phase velocity of light in a material, used as a measure of how much the path of light is bent when passing through a material. With the miniaturization of various optical parts used in mobile devices and imaging, demand has been rapidly growing for high refractive index transparent materials that induce more light refraction with a thin film.

As polymers have outstanding physical properties and can be easily processed in various forms, they are widely used in a variety of applications such as plastic eyeglass lenses. However, there have been very few polymers developed so far with a refractive index exceeding 1.75, and existing high refractive index polymers require costly materials and complicated manufacturing processes.

Above all, core technologies for producing such materials have been dominated by Japanese companies, causing long-standing challenges for Korean manufacturers. Securing a stable supply of high-performance, high refractive index materials is crucial for the production of optical devices that are lighter, more affordable, and can be freely manipulated.

The research team successfully manufactured a whole new polymer thin film material with a refractive index exceeding 1.9 and excellent transparency, using just a one-step chemical reaction. The SCP film showed outstanding optical transparency across the entire visible light region, presumably due to the uniformly dispersed, short-segment polysulfide chains, which is a distinct feature unachievable in polymerizations with molten sulfur.

The team focused on the fact that elemental sulfur is easily sublimated to produce a high refractive index polymer by polymerizing the vaporized sulfur with a variety of substances. This method suppresses the formation of overly long S-S chains while achieving outstanding thermal stability in high sulfur concentrations and generating transparent non-crystalline polymers across the entire visible spectrum.

Due to the characteristics of the vapor phase process, the high refractive index thin film can be coated not just on silicon wafers or glass substrates, but on a wide range of textured surfaces as well. We believe this thin film polymer is the first to have achieved an ultrahigh refractive index exceeding 1.9.

Professor Im said, “This high-performance polymer film can be created in a simple one-step manner, which is highly advantageous in the synthesis of SCPs with a high refractive index. This will serve as a platform material for future high-end optical device applications.”

This study, in collaboration with research teams from Seoul National University and Kyung Hee University, was reported in Science Advances. (Title: One-Step Vapor-Phase Synthesis of Transparent High-Refractive Index Sulfur-Containing Polymers)

This research was supported by the Ministry of Science and ICT’s Global Frontier Project (Center for Advanced Soft-Electronics), Leading Research Center Support Program (Wearable Platform Materials Technology Center), and Basic Science Research Program (Advanced Research Project).

2020.08.04 View 10018

Sulfur-Containing Polymer Generates High Refractive Index and Transparency

Transparent polymer thin film with refractive index exceeding 1.9 to serve as new platform materials for high-end optical device applications

Researchers reported a novel technology enhancing the high transparency of refractive polymer film via a one-step vapor deposition process. The sulfur-containing polymer (SCP) film produced by Professor Sung Gap Im’s research team at KAIST’s Department of Chemical and Biomolecular Engineering has exhibited excellent environmental stability and chemical resistance, which is highly desirable for its application in long-term optical device applications. The high refractive index exceeding 1.9 while being fully transparent in the entire visible range will help expand the applications of optoelectronic devices.

The refractive index is a ratio of the speed of light in a vacuum to the phase velocity of light in a material, used as a measure of how much the path of light is bent when passing through a material. With the miniaturization of various optical parts used in mobile devices and imaging, demand has been rapidly growing for high refractive index transparent materials that induce more light refraction with a thin film.

As polymers have outstanding physical properties and can be easily processed in various forms, they are widely used in a variety of applications such as plastic eyeglass lenses. However, there have been very few polymers developed so far with a refractive index exceeding 1.75, and existing high refractive index polymers require costly materials and complicated manufacturing processes.

Above all, core technologies for producing such materials have been dominated by Japanese companies, causing long-standing challenges for Korean manufacturers. Securing a stable supply of high-performance, high refractive index materials is crucial for the production of optical devices that are lighter, more affordable, and can be freely manipulated.

The research team successfully manufactured a whole new polymer thin film material with a refractive index exceeding 1.9 and excellent transparency, using just a one-step chemical reaction. The SCP film showed outstanding optical transparency across the entire visible light region, presumably due to the uniformly dispersed, short-segment polysulfide chains, which is a distinct feature unachievable in polymerizations with molten sulfur.

The team focused on the fact that elemental sulfur is easily sublimated to produce a high refractive index polymer by polymerizing the vaporized sulfur with a variety of substances. This method suppresses the formation of overly long S-S chains while achieving outstanding thermal stability in high sulfur concentrations and generating transparent non-crystalline polymers across the entire visible spectrum.

Due to the characteristics of the vapor phase process, the high refractive index thin film can be coated not just on silicon wafers or glass substrates, but on a wide range of textured surfaces as well. We believe this thin film polymer is the first to have achieved an ultrahigh refractive index exceeding 1.9.

Professor Im said, “This high-performance polymer film can be created in a simple one-step manner, which is highly advantageous in the synthesis of SCPs with a high refractive index. This will serve as a platform material for future high-end optical device applications.”

This study, in collaboration with research teams from Seoul National University and Kyung Hee University, was reported in Science Advances. (Title: One-Step Vapor-Phase Synthesis of Transparent High-Refractive Index Sulfur-Containing Polymers)

This research was supported by the Ministry of Science and ICT’s Global Frontier Project (Center for Advanced Soft-Electronics), Leading Research Center Support Program (Wearable Platform Materials Technology Center), and Basic Science Research Program (Advanced Research Project).

2020.08.04 View 10018 -

Universal Virus Detection Platform to Expedite Viral Diagnosis

Reactive polymer-based tester pre-screens dsRNAs of a wide range of viruses without their genome sequences

The prompt, precise, and massive detection of a virus is the key to combat infectious diseases such as Covid-19. A new viral diagnostic strategy using reactive polymer-grafted, double-stranded RNAs will serve as a pre-screening tester for a wide range of viruses with enhanced sensitivity.

Currently, the most widely using viral detection methodology is polymerase chain reaction (PCR) diagnosis, which amplifies and detects a piece of the viral genome. Prior knowledge of the relevant primer nucleic acids of the virus is quintessential for this test.

The detection platform developed by KAIST researchers identifies viral activities without amplifying specific nucleic acid targets. The research team, co-led by Professor Sheng Li and Professor Yoosik Kim from the Department of Chemical and Biomolecular Engineering, constructed a universal virus detection platform by utilizing the distinct features of the PPFPA-grafted surface and double-stranded RNAs.

The key principle of this platform is utilizing the distinct feature of reactive polymer-grafted surfaces, which serve as a versatile platform for the immobilization of functional molecules. These activated surfaces can be used in a wide range of applications including separation, delivery, and detection. As long double-stranded RNAs are common byproducts of viral transcription and replication, these PPFPA-grafted surfaces can detect the presence of different kinds of viruses without prior knowledge of their genomic sequences.

“We employed the PPFPA-grafted silicon surface to develop a universal virus detection platform by immobilizing antibodies that recognize double-stranded RNAs,” said Professor Kim.

To increase detection sensitivity, the research team devised two-step detection process analogues to sandwich enzyme-linked immunosorbent assay where the bound double-stranded RNAs are then visualized using fluorophore-tagged antibodies that also recognize the RNAs’ double-stranded secondary structure.

By utilizing the developed platform, long double-stranded RNAs can be detected and visualized from an RNA mixture as well as from total cell lysates, which contain a mixture of various abundant contaminants such as DNAs and proteins.

The research team successfully detected elevated levels of hepatitis C and A viruses with this tool.

“This new technology allows us to take on virus detection from a new perspective. By targeting a common biomarker, viral double-stranded RNAs, we can develop a pre-screening platform that can quickly differentiate infected populations from non-infected ones,” said Professor Li.

“This detection platform provides new perspectives for diagnosing infectious diseases. This will provide fast and accurate diagnoses for an infected population and prevent the influx of massive outbreaks,” said Professor Kim.

This work is featured in Biomacromolecules. This work was supported by the Agency for Defense Development (Grant UD170039ID), the Ministry of Science and ICT (NRF-2017R1D1A1B03034660, NRF-2019R1C1C1006672), and the KAIST Future Systems Healthcare Project from the Ministry of Science and ICT (KAISTHEALTHCARE42).

Profile:-Professor Yoosik KimDepartment of Chemical and Biomolecular Engineeringhttps://qcbio.kaist.ac.kr

KAIST-Professor Sheng LiDepartment of Chemical and Biomolecular Engineeringhttps://bcpolymer.kaist.ac.kr

KAIST