WCU

-

KAIST researchers verify and control the mechanical properties of graphene

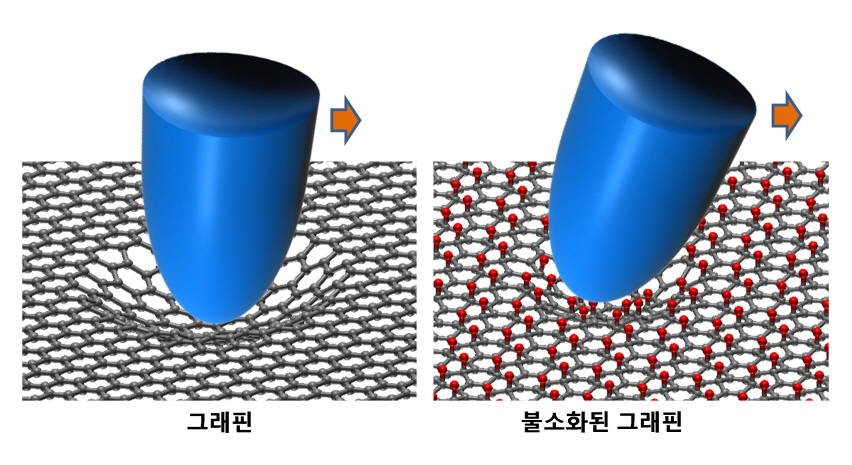

KAIST researchers have successfully verified and controlled the mechanical properties of graphene, a next-generation material. Professor Park Jung Yong from the EEWS Graduate School and Professor Kim Yong Hyun from the Graduate School of Nanoscience and Technology have succeeded in fluorinating a single atomic-layered graphene sample and controlling its frictional and adhesive properties. This is the first time the frictional properties of graphene have been examined at the atomic level, and the technology is expected to be applied to nano-sized robots and microscopic joints.

Graphene is often dubbed “the dream material” because of its ability to conduct high amounts of electricity even when bent, making it the next-generation substitute for silicon semiconductors, paving the way for flexible display and wearable computer technologies. Graphene also has high potential applications in mechanical engineering because of its great material strength, but its mechanical properties remained elusive until now.

Professor Park’s research team successfully produced individual graphene samples with fluorine-deficiency at the atomic level by placing the samples in Fluoro-xenon (XeF2) gas and applying heat. The surface of the graphene was scanned using a micro probe and a high vacuum atomic microscope to measure its dynamic properties.

The research team found that the fluorinated graphene sample had 6 times more friction and 0.7 times more adhesiveness than the original graphene. Electrical measurements confirmed the fluorination process, and the analysis of the findings helped setup the theory of frictional changes in graphene.

Professor Park stated that “graphene can be used for the lubrication of joints in nano-sized devices” and that this research has numerous applications such as the coating of graphene-based microdynamic devices.

This research was published in the online June edition of Nano Letters and was supported by the Ministry of Science, Technology, and Education and the National Research Foundation as part of the World Class University (WCU) program.

2012.07.24 View 18073

KAIST researchers verify and control the mechanical properties of graphene

KAIST researchers have successfully verified and controlled the mechanical properties of graphene, a next-generation material. Professor Park Jung Yong from the EEWS Graduate School and Professor Kim Yong Hyun from the Graduate School of Nanoscience and Technology have succeeded in fluorinating a single atomic-layered graphene sample and controlling its frictional and adhesive properties. This is the first time the frictional properties of graphene have been examined at the atomic level, and the technology is expected to be applied to nano-sized robots and microscopic joints.

Graphene is often dubbed “the dream material” because of its ability to conduct high amounts of electricity even when bent, making it the next-generation substitute for silicon semiconductors, paving the way for flexible display and wearable computer technologies. Graphene also has high potential applications in mechanical engineering because of its great material strength, but its mechanical properties remained elusive until now.

Professor Park’s research team successfully produced individual graphene samples with fluorine-deficiency at the atomic level by placing the samples in Fluoro-xenon (XeF2) gas and applying heat. The surface of the graphene was scanned using a micro probe and a high vacuum atomic microscope to measure its dynamic properties.

The research team found that the fluorinated graphene sample had 6 times more friction and 0.7 times more adhesiveness than the original graphene. Electrical measurements confirmed the fluorination process, and the analysis of the findings helped setup the theory of frictional changes in graphene.

Professor Park stated that “graphene can be used for the lubrication of joints in nano-sized devices” and that this research has numerous applications such as the coating of graphene-based microdynamic devices.

This research was published in the online June edition of Nano Letters and was supported by the Ministry of Science, Technology, and Education and the National Research Foundation as part of the World Class University (WCU) program.

2012.07.24 View 18073 -

Biomimetic reflective display technology developed

Professor Shin Jung Hoon

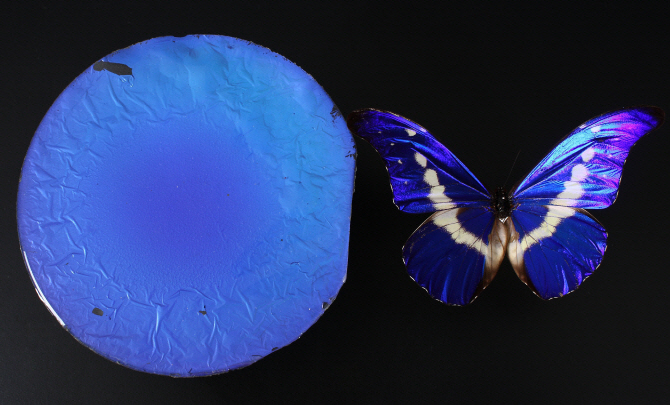

The bright colors of a rainbow or a peacock are produced by the reflection and interference of light in transparent periodic structures, producing what is called a structural color. These colors are very bright and change according to the viewing angle. On the other hand, the wings of a morpho-butterfly also have structural colors but are predominantly blue over a wide range of angles. This is because the unique structure of the morpho-butterfly’s wings contains both order and chaos.

Professor Shin Jung Hoon’s team from the Department of Physics and the Graduate School of Nanoscience and Technology at KAIST produced a display that mimics the structure of the morpho-butterfly’s wings using glass beads.

This research successfully produced a reflective display (one that reflects external light to project images), which could be used to make very bright displays with low energy consumption. This technology can also be used to make anti-counterfeit bills, as well as coating materials for mobile phones and wallets.

The structure of the morpho-butterfly’s wings seems to be in periodic order at the 1-micrometer level, but contains disorder at the 100-nanometer level. So far, no one had succeeded in reproducing a structure with both order and disorder at the nanometer level.

Professor Shin’s team randomly aligned differently sized glass beads of a few hundred nanometers to create chaos and placed a thin periodic film on top of it using the semiconductor deposition method, thereby creating the morpho-butterfly-like structure over a large area.

This new development produced better color and brightness than the morpho-butterfly wing and even exhibited less color change according to angle. The team sealed the film in thin plastic, which helped to maintain the superior properties whilst making it more firm and paper-like.

Professor Shin emphasized that the results were an exemplary success in the field of biomimetics and that structural colors could have other applications in sensors and fashion, for example.

The results were first introduced on May 3rd in Nature as one of the Research Highlights and will be published in the online version of the material science magazine, Advanced Materials.

This research was jointly conducted by Professor Shin Jung Hoon (Department of Physics / Graduate School of Nanoscience and Technology at KAIST), Professor Park NamKyoo (Department of Electrical and Computer Engineering at Seoul National University), and Samsung Advanced Institute of Technology. The funding was provided by the National Research Foundation of Korea and the Ministry of Education, Science and Technology as part of the World Class University (WCU) project.

Figure 2. The biomimetic film can express many different colors

Figure 3. The biomimetic diplay and a morpho-butterfly

2012.05.07 View 16743

Biomimetic reflective display technology developed

Professor Shin Jung Hoon

The bright colors of a rainbow or a peacock are produced by the reflection and interference of light in transparent periodic structures, producing what is called a structural color. These colors are very bright and change according to the viewing angle. On the other hand, the wings of a morpho-butterfly also have structural colors but are predominantly blue over a wide range of angles. This is because the unique structure of the morpho-butterfly’s wings contains both order and chaos.

Professor Shin Jung Hoon’s team from the Department of Physics and the Graduate School of Nanoscience and Technology at KAIST produced a display that mimics the structure of the morpho-butterfly’s wings using glass beads.

This research successfully produced a reflective display (one that reflects external light to project images), which could be used to make very bright displays with low energy consumption. This technology can also be used to make anti-counterfeit bills, as well as coating materials for mobile phones and wallets.

The structure of the morpho-butterfly’s wings seems to be in periodic order at the 1-micrometer level, but contains disorder at the 100-nanometer level. So far, no one had succeeded in reproducing a structure with both order and disorder at the nanometer level.

Professor Shin’s team randomly aligned differently sized glass beads of a few hundred nanometers to create chaos and placed a thin periodic film on top of it using the semiconductor deposition method, thereby creating the morpho-butterfly-like structure over a large area.

This new development produced better color and brightness than the morpho-butterfly wing and even exhibited less color change according to angle. The team sealed the film in thin plastic, which helped to maintain the superior properties whilst making it more firm and paper-like.

Professor Shin emphasized that the results were an exemplary success in the field of biomimetics and that structural colors could have other applications in sensors and fashion, for example.

The results were first introduced on May 3rd in Nature as one of the Research Highlights and will be published in the online version of the material science magazine, Advanced Materials.

This research was jointly conducted by Professor Shin Jung Hoon (Department of Physics / Graduate School of Nanoscience and Technology at KAIST), Professor Park NamKyoo (Department of Electrical and Computer Engineering at Seoul National University), and Samsung Advanced Institute of Technology. The funding was provided by the National Research Foundation of Korea and the Ministry of Education, Science and Technology as part of the World Class University (WCU) project.

Figure 2. The biomimetic film can express many different colors

Figure 3. The biomimetic diplay and a morpho-butterfly

2012.05.07 View 16743 -

Paving the Way to Next Generation Display

A new type of LCD that does not require polymer orientation films has been developed by researchers within the country. This technology will enable the creation of thiner and higher definition display.

Prof. Hee Tae Jung form KAIST’s biochemical engineering department led the research and Hyun Soo Jung, Hwan Jin Jeon doctoral students (1st co-authors), Doctor Yun Ho Kim from Korea Chemistry Research Center, and Prof. Shin Woong Kang from Jeon Buk University ( co-author) have participated in this research. This research has been funded by the WCU program and middle-grade researcher support program. The results of the research has been published as the online update of ‘‘Nature Asia Materials(NPG Asia Materials)” which is a sister magazine of the world renowned academic magazine ‘Nature’.

The flat display industry is the core industry leading the 21st century’s IT industry. The LCD is the main area of research. Korea is the leader of this industry, holding more than 50% of the world market. Many technologies are combined to make the electro-optic devices of the LCD function. The most important technology, which determines the indicating element’s quality and function is the technology to align the liquid crystals in one direction.

Currently, all LCD products are created by mechanically cutting into the surface of the polymer film and orienting the liquid crystal material along these cuts. However, the creation of polymer orientation films cost much time and money, and the high temperature processes necessary to stabilize the polymers does not allow for the free selection of circuit boards, and thus does not allow for the use in flexible display.

Prof. Hee Tae Jung devised a method to orient liquid display without the use of a polymer film using ITOs. Prof. Jung’s base technology has been tested on ITOs to maintain the necessary transparency and conductivity after forming a pattern with high decomposition rates and slenderness ratios.

The technology developed by the research team can horizontally or vertically align the transparent conductors without the use of polymer orientation films. Thus, the manufacturing processes have become much shortened and the LCDs can be made in much thinner from a few micrometers to a few centimeters. Also, it has a lower functioning voltage and faster response speed, showing the prospects of a high definition ultra-fast screen display development. Furthermore, this technology can be used for any type of board, and can be adjusted to a nanometer scale. This enables for its use in LCD based flexible or multi-domain modes.

Also, the transparent conductor patterning technology devised by the research team can be used not only for displays, but also for touch panels with highly increased sensitivity.

Prof. Jung said, “It was a long desire of the industry and academia to find a way to replace the polymer orientation film. This new technology does not need any polymer orientation films, and we can still use the original boards used for LCDs. This mean a lot to the industry. Also, this technology will increase the sensitivity of the touch panels for tablet PCs and smart phones. It can be used in many areas of future electronics base technology.”

2012.04.04 View 11949

Paving the Way to Next Generation Display

A new type of LCD that does not require polymer orientation films has been developed by researchers within the country. This technology will enable the creation of thiner and higher definition display.

Prof. Hee Tae Jung form KAIST’s biochemical engineering department led the research and Hyun Soo Jung, Hwan Jin Jeon doctoral students (1st co-authors), Doctor Yun Ho Kim from Korea Chemistry Research Center, and Prof. Shin Woong Kang from Jeon Buk University ( co-author) have participated in this research. This research has been funded by the WCU program and middle-grade researcher support program. The results of the research has been published as the online update of ‘‘Nature Asia Materials(NPG Asia Materials)” which is a sister magazine of the world renowned academic magazine ‘Nature’.

The flat display industry is the core industry leading the 21st century’s IT industry. The LCD is the main area of research. Korea is the leader of this industry, holding more than 50% of the world market. Many technologies are combined to make the electro-optic devices of the LCD function. The most important technology, which determines the indicating element’s quality and function is the technology to align the liquid crystals in one direction.

Currently, all LCD products are created by mechanically cutting into the surface of the polymer film and orienting the liquid crystal material along these cuts. However, the creation of polymer orientation films cost much time and money, and the high temperature processes necessary to stabilize the polymers does not allow for the free selection of circuit boards, and thus does not allow for the use in flexible display.

Prof. Hee Tae Jung devised a method to orient liquid display without the use of a polymer film using ITOs. Prof. Jung’s base technology has been tested on ITOs to maintain the necessary transparency and conductivity after forming a pattern with high decomposition rates and slenderness ratios.

The technology developed by the research team can horizontally or vertically align the transparent conductors without the use of polymer orientation films. Thus, the manufacturing processes have become much shortened and the LCDs can be made in much thinner from a few micrometers to a few centimeters. Also, it has a lower functioning voltage and faster response speed, showing the prospects of a high definition ultra-fast screen display development. Furthermore, this technology can be used for any type of board, and can be adjusted to a nanometer scale. This enables for its use in LCD based flexible or multi-domain modes.

Also, the transparent conductor patterning technology devised by the research team can be used not only for displays, but also for touch panels with highly increased sensitivity.

Prof. Jung said, “It was a long desire of the industry and academia to find a way to replace the polymer orientation film. This new technology does not need any polymer orientation films, and we can still use the original boards used for LCDs. This mean a lot to the industry. Also, this technology will increase the sensitivity of the touch panels for tablet PCs and smart phones. It can be used in many areas of future electronics base technology.”

2012.04.04 View 11949 -

Closer to the Dream: Graphene

A technique that allows easy and larger observation area of graphene’s crystal face was developed by Korean Research Team.

The research team, led by Professor Jeong Hui Tae (KAIST), consists of Doctorate candidate Kim Dae Woo, Dr. Kim Yoon Ho (primary author), Doctorate candidate Jeong Hyun Soo. The research is supported by WCU (World Class Research University) Development Plan, Mid-Aged Researcher Support Business and was published in the online edition of Nature Nanotechnology.

(Dissertation: Direct visualization of large0area graphene domains and boundaries by optical birefringency)

Professor Jeong’s team used the optical property of the liquid display used in LCD to visualize the size and shape of the single crystals along a flat surface. The visualization of the single crystal allowed the measurement of a near theoretical value of electrical conductivity of graphene.

Graphene has great electrical conductivity, transparent, mechanically stable, flexible, and is therefore regarded as the next generation electrical material. However the polycrystalinity of graphene meant that the actual electrical, mechanical properties were lower than the theoretical values. The reason was thought to be because of the size of the crystal faces and boundary structures.

Therefore, in order to create graphene that has good properties, observing the domain and boundary of graphene crystal faces is essential.

The new technique developed by the research team is another step towards commercializing transparent electrodes, flexible display, and electric materials like solar cells.

2012.01.31 View 12100

Closer to the Dream: Graphene

A technique that allows easy and larger observation area of graphene’s crystal face was developed by Korean Research Team.

The research team, led by Professor Jeong Hui Tae (KAIST), consists of Doctorate candidate Kim Dae Woo, Dr. Kim Yoon Ho (primary author), Doctorate candidate Jeong Hyun Soo. The research is supported by WCU (World Class Research University) Development Plan, Mid-Aged Researcher Support Business and was published in the online edition of Nature Nanotechnology.

(Dissertation: Direct visualization of large0area graphene domains and boundaries by optical birefringency)

Professor Jeong’s team used the optical property of the liquid display used in LCD to visualize the size and shape of the single crystals along a flat surface. The visualization of the single crystal allowed the measurement of a near theoretical value of electrical conductivity of graphene.

Graphene has great electrical conductivity, transparent, mechanically stable, flexible, and is therefore regarded as the next generation electrical material. However the polycrystalinity of graphene meant that the actual electrical, mechanical properties were lower than the theoretical values. The reason was thought to be because of the size of the crystal faces and boundary structures.

Therefore, in order to create graphene that has good properties, observing the domain and boundary of graphene crystal faces is essential.

The new technique developed by the research team is another step towards commercializing transparent electrodes, flexible display, and electric materials like solar cells.

2012.01.31 View 12100 -

Quantum Mechanical Calculation Theory Developed

An Electron Density Functional Calculation Theory, based on the widely used quantum mechanical principles and yet accurate and with shortened calculation period, was developed by Korean research team.

*Electron Density Functional Calculation Theory: Theory that proves that it is possible to calculate energy and properties with only simple wave equations and electron densities.

The research was conducted by Professor Jeong Yoo Sung (Graduate School of EEWS) and Professor William Goddard with support from WCU Foster Project initiated by Ministry of Education, Science and Technology and Korea Research Foundation. The result was published in the Proceedings of the National Academy of Sciences Journal.

The research team corrected the error when performing quantum calculations that arises from the length of calculation time and incorrect assumptions and developed a theory and algorithm that is more accurate and faster. The use of wave equations in quantum mechanical calculations results in high accuracy but there is a rapid increase in calculation time and is therefore difficult to implement in large molecules with hundreds, or thousands of atoms. By implementing a low electron density variable with relatively less calculation work, the size of calculable molecule increases but the accuracy decreases.

The team focused on the interaction between electrons with different spins to improve upon the speed of calculation in the conventional accurate calculation. The team used the fact that the interaction between electrons with different spins increases as it comes closer together in accordance with the Pauli’s Exclusion Principle.

In addition the interaction between electrons are local and therefore can ignore the interactions between far away electrons and still get the total energy value. The team also took advantage of this fact and developed the algorithm that decreased calculation time hundredth fold.

Professor Jeong commented that, “So far most of the domestic achievements were made by focusing on integrative researches by calculation science and material design communities but these involved short time frames. In areas that required lengthy time frames like fundamentals and software development, there was no competitive advantage. However this research is significant in that a superior solution was developed domestically”.

2012.01.31 View 12961

Quantum Mechanical Calculation Theory Developed

An Electron Density Functional Calculation Theory, based on the widely used quantum mechanical principles and yet accurate and with shortened calculation period, was developed by Korean research team.

*Electron Density Functional Calculation Theory: Theory that proves that it is possible to calculate energy and properties with only simple wave equations and electron densities.

The research was conducted by Professor Jeong Yoo Sung (Graduate School of EEWS) and Professor William Goddard with support from WCU Foster Project initiated by Ministry of Education, Science and Technology and Korea Research Foundation. The result was published in the Proceedings of the National Academy of Sciences Journal.

The research team corrected the error when performing quantum calculations that arises from the length of calculation time and incorrect assumptions and developed a theory and algorithm that is more accurate and faster. The use of wave equations in quantum mechanical calculations results in high accuracy but there is a rapid increase in calculation time and is therefore difficult to implement in large molecules with hundreds, or thousands of atoms. By implementing a low electron density variable with relatively less calculation work, the size of calculable molecule increases but the accuracy decreases.

The team focused on the interaction between electrons with different spins to improve upon the speed of calculation in the conventional accurate calculation. The team used the fact that the interaction between electrons with different spins increases as it comes closer together in accordance with the Pauli’s Exclusion Principle.

In addition the interaction between electrons are local and therefore can ignore the interactions between far away electrons and still get the total energy value. The team also took advantage of this fact and developed the algorithm that decreased calculation time hundredth fold.

Professor Jeong commented that, “So far most of the domestic achievements were made by focusing on integrative researches by calculation science and material design communities but these involved short time frames. In areas that required lengthy time frames like fundamentals and software development, there was no competitive advantage. However this research is significant in that a superior solution was developed domestically”.

2012.01.31 View 12961