LED

-

KAIST Research Team Develops Electronic Ink for Room-Temperature Printing of High-Resolution, Variable-Stiffness Electronics

A team of researchers from KAIST and Seoul National University has developed a groundbreaking electronic ink that enables room-temperature printing of variable-stiffness circuits capable of switching between rigid and soft modes. This advancement marks a significant leap toward next-generation wearable, implantable, and robotic devices.

< Photo 1. (From left) Professor Jae-Woong Jeong and PhD candidate Simok Lee of the School of Electrical Engineering, (in separate bubbles, from left) Professor Gun-Hee Lee of Pusan National University, Professor Seongjun Park of Seoul National University, Professor Steve Park of the Department of Materials Science and Engineering>

Variable-stiffness electronics are at the forefront of adaptive technology, offering the ability for a single device to transition between rigid and soft modes depending on its use case. Gallium, a metal known for its high rigidity contrast between solid and liquid states, is a promising candidate for such applications. However, its use has been hindered by challenges including high surface tension, low viscosity, and undesirable phase transitions during manufacturing.

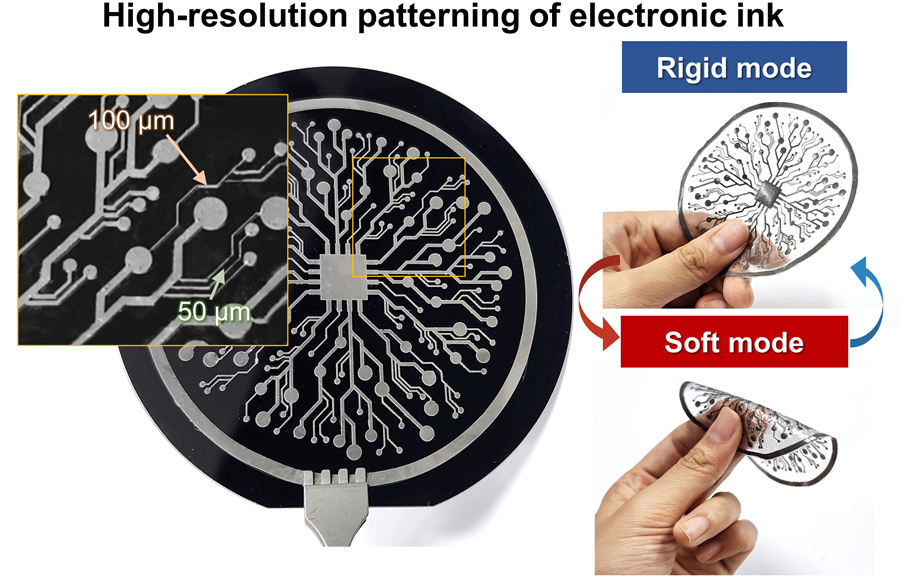

On June 4th, a research team led by Professor Jae-Woong Jeong from the School of Electrical Engineering at KAIST, Professor Seongjun Park from the Digital Healthcare Major at Seoul National University, and Professor Steve Park from the Department of Materials Science and Engineering at KAIST introduced a novel liquid metal electronic ink. This ink allows for micro-scale circuit printing – thinner than a human hair – at room temperature, with the ability to reversibly switch between rigid and soft modes depending on temperature.

The new ink combines printable viscosity with excellent electrical conductivity, enabling the creation of complex, high-resolution multilayer circuits comparable to commercial printed circuit boards (PCBs). These circuits can dynamically change stiffness in response to temperature, presenting new opportunities for multifunctional electronics, medical technologies, and robotics.

Conventional electronics typically have fixed form factors – either rigid for durability or soft for wearability. Rigid devices like smartphones and laptops offer robust performance but are uncomfortable when worn, while soft electronics are more comfortable but lack precise handling. As demand grows for devices that can adapt their stiffness to context, variable-stiffness electronics are becoming increasingly important.

< Figure 1. Fabrication process of stable, high-viscosity electronic ink by dispersing micro-sized gallium particles in a polymer matrix (left). High-resolution large-area circuit printing process through pH-controlled chemical sintering (right). >

To address this challenge, the researchers focused on gallium, which melts just below body temperature. Solid gallium is quite stiff, while its liquid form is fluid and soft. Despite its potential, gallium’s use in electronic printing has been limited by its high surface tension and instability when melted.

To overcome these issues, the team developed a pH-controlled liquid metal ink printing process. By dispersing micro-sized gallium particles into a hydrophilic polyurethane matrix using a neutral solvent (dimethyl sulfoxide, or DMSO), they created a stable, high-viscosity ink suitable for precision printing. During post-print heating, the DMSO decomposes to form an acidic environment, which removes the oxide layer on the gallium particles. This triggers the particles to coalesce into electrically conductive networks with tunable mechanical properties.

The resulting printed circuits exhibit fine feature sizes (~50 μm), high conductivity (2.27 × 10⁶ S/m), and a stiffness modulation ratio of up to 1,465 – allowing the material to shift from plastic-like rigidity to rubber-like softness. Furthermore, the ink is compatible with conventional printing techniques such as screen printing and dip coating, supporting large-area and 3D device fabrication.

< Figure 2. Key features of the electronic ink. (i) High-resolution printing and multilayer integration capability. (ii) Batch fabrication capability through large-area screen printing. (iii) Complex three-dimensional structure printing capability through dip coating. (iv) Excellent electrical conductivity and stiffness control capability.>

The team demonstrated this technology by developing a multi-functional device that operates as a rigid portable electronic under normal conditions but transforms into a soft wearable healthcare device when attached to the body. They also created a neural probe that remains stiff during surgical insertion for accurate positioning but softens once inside brain tissue to reduce inflammation – highlighting its potential for biomedical implants.

< Figure 3. Variable stiffness wearable electronics with high-resolution circuits and multilayer structure comparable to commercial printed circuit boards (PCBs). Functions as a rigid portable electronic device at room temperature, then transforms into a wearable healthcare device by softening at body temperature upon skin contact.>

“The core achievement of this research lies in overcoming the longstanding challenges of liquid metal printing through our innovative technology,” said Professor Jeong. “By controlling the ink’s acidity, we were able to electrically and mechanically connect printed gallium particles, enabling the room-temperature fabrication of high-resolution, large-area circuits with tunable stiffness. This opens up new possibilities for future personal electronics, medical devices, and robotics.”

< Figure 4. Body-temperature softening neural probe implemented by coating electronic ink on an optical waveguide structure. (Left) Remains rigid during surgery for precise manipulation and brain insertion, then softens after implantation to minimize mechanical stress on the brain and greatly enhance biocompatibility. (Right) >

This research was published in Science Advances under the title, “Phase-Change Metal Ink with pH-Controlled Chemical Sintering for Versatile and Scalable Fabrication of Variable Stiffness Electronics.” The work was supported by the National Research Foundation of Korea, the Boston-Korea Project, and the BK21 FOUR Program.

2025.06.04 View 2221

KAIST Research Team Develops Electronic Ink for Room-Temperature Printing of High-Resolution, Variable-Stiffness Electronics

A team of researchers from KAIST and Seoul National University has developed a groundbreaking electronic ink that enables room-temperature printing of variable-stiffness circuits capable of switching between rigid and soft modes. This advancement marks a significant leap toward next-generation wearable, implantable, and robotic devices.

< Photo 1. (From left) Professor Jae-Woong Jeong and PhD candidate Simok Lee of the School of Electrical Engineering, (in separate bubbles, from left) Professor Gun-Hee Lee of Pusan National University, Professor Seongjun Park of Seoul National University, Professor Steve Park of the Department of Materials Science and Engineering>

Variable-stiffness electronics are at the forefront of adaptive technology, offering the ability for a single device to transition between rigid and soft modes depending on its use case. Gallium, a metal known for its high rigidity contrast between solid and liquid states, is a promising candidate for such applications. However, its use has been hindered by challenges including high surface tension, low viscosity, and undesirable phase transitions during manufacturing.

On June 4th, a research team led by Professor Jae-Woong Jeong from the School of Electrical Engineering at KAIST, Professor Seongjun Park from the Digital Healthcare Major at Seoul National University, and Professor Steve Park from the Department of Materials Science and Engineering at KAIST introduced a novel liquid metal electronic ink. This ink allows for micro-scale circuit printing – thinner than a human hair – at room temperature, with the ability to reversibly switch between rigid and soft modes depending on temperature.

The new ink combines printable viscosity with excellent electrical conductivity, enabling the creation of complex, high-resolution multilayer circuits comparable to commercial printed circuit boards (PCBs). These circuits can dynamically change stiffness in response to temperature, presenting new opportunities for multifunctional electronics, medical technologies, and robotics.

Conventional electronics typically have fixed form factors – either rigid for durability or soft for wearability. Rigid devices like smartphones and laptops offer robust performance but are uncomfortable when worn, while soft electronics are more comfortable but lack precise handling. As demand grows for devices that can adapt their stiffness to context, variable-stiffness electronics are becoming increasingly important.

< Figure 1. Fabrication process of stable, high-viscosity electronic ink by dispersing micro-sized gallium particles in a polymer matrix (left). High-resolution large-area circuit printing process through pH-controlled chemical sintering (right). >

To address this challenge, the researchers focused on gallium, which melts just below body temperature. Solid gallium is quite stiff, while its liquid form is fluid and soft. Despite its potential, gallium’s use in electronic printing has been limited by its high surface tension and instability when melted.

To overcome these issues, the team developed a pH-controlled liquid metal ink printing process. By dispersing micro-sized gallium particles into a hydrophilic polyurethane matrix using a neutral solvent (dimethyl sulfoxide, or DMSO), they created a stable, high-viscosity ink suitable for precision printing. During post-print heating, the DMSO decomposes to form an acidic environment, which removes the oxide layer on the gallium particles. This triggers the particles to coalesce into electrically conductive networks with tunable mechanical properties.

The resulting printed circuits exhibit fine feature sizes (~50 μm), high conductivity (2.27 × 10⁶ S/m), and a stiffness modulation ratio of up to 1,465 – allowing the material to shift from plastic-like rigidity to rubber-like softness. Furthermore, the ink is compatible with conventional printing techniques such as screen printing and dip coating, supporting large-area and 3D device fabrication.

< Figure 2. Key features of the electronic ink. (i) High-resolution printing and multilayer integration capability. (ii) Batch fabrication capability through large-area screen printing. (iii) Complex three-dimensional structure printing capability through dip coating. (iv) Excellent electrical conductivity and stiffness control capability.>

The team demonstrated this technology by developing a multi-functional device that operates as a rigid portable electronic under normal conditions but transforms into a soft wearable healthcare device when attached to the body. They also created a neural probe that remains stiff during surgical insertion for accurate positioning but softens once inside brain tissue to reduce inflammation – highlighting its potential for biomedical implants.

< Figure 3. Variable stiffness wearable electronics with high-resolution circuits and multilayer structure comparable to commercial printed circuit boards (PCBs). Functions as a rigid portable electronic device at room temperature, then transforms into a wearable healthcare device by softening at body temperature upon skin contact.>

“The core achievement of this research lies in overcoming the longstanding challenges of liquid metal printing through our innovative technology,” said Professor Jeong. “By controlling the ink’s acidity, we were able to electrically and mechanically connect printed gallium particles, enabling the room-temperature fabrication of high-resolution, large-area circuits with tunable stiffness. This opens up new possibilities for future personal electronics, medical devices, and robotics.”

< Figure 4. Body-temperature softening neural probe implemented by coating electronic ink on an optical waveguide structure. (Left) Remains rigid during surgery for precise manipulation and brain insertion, then softens after implantation to minimize mechanical stress on the brain and greatly enhance biocompatibility. (Right) >

This research was published in Science Advances under the title, “Phase-Change Metal Ink with pH-Controlled Chemical Sintering for Versatile and Scalable Fabrication of Variable Stiffness Electronics.” The work was supported by the National Research Foundation of Korea, the Boston-Korea Project, and the BK21 FOUR Program.

2025.06.04 View 2221 -

KAIST to Develop a Korean-style ChatGPT Platform Specifically Geared Toward Medical Diagnosis and Drug Discovery

On May 23rd, KAIST (President Kwang-Hyung Lee) announced that its Digital Bio-Health AI Research Center (Director: Professor JongChul Ye of KAIST Kim Jaechul Graduate School of AI) has been selected for the Ministry of Science and ICT's 'AI Top-Tier Young Researcher Support Program (AI Star Fellowship Project).' With a total investment of ₩11.5 billion from May 2025 to December 2030, the center will embark on the full-scale development of AI technology and a platform capable of independently inferring and determining the kinds of diseases, and discovering new drugs.

< Photo. On May 20th, a kick-off meeting for the AI Star Fellowship Project was held at KAIST Kim Jaechul Graduate School of AI’s Yangjae Research Center with the KAIST research team and participating organizations of Samsung Medical Center, NAVER Cloud, and HITS. [From left to right in the front row] Professor Jaegul Joo (KAIST), Professor Yoonjae Choi (KAIST), Professor Woo Youn Kim (KAIST/HITS), Professor JongChul Ye (KAIST), Professor Sungsoo Ahn (KAIST), Dr. Haanju Yoo (NAVER Cloud), Yoonho Lee (KAIST), HyeYoon Moon (Samsung Medical Center), Dr. Su Min Kim (Samsung Medical Center) >

This project aims to foster an innovative AI research ecosystem centered on young researchers and develop an inferential AI agent that can utilize and automatically expand specialized knowledge systems in the bio and medical fields.

Professor JongChul Ye of the Kim Jaechul Graduate School of AI will serve as the lead researcher, with young researchers from KAIST including Professors Yoonjae Choi, Kimin Lee, Sungsoo Ahn, and Chanyoung Park, along with mid-career researchers like Professors Jaegul Joo and Woo Youn Kim, jointly undertaking the project. They will collaborate with various laboratories within KAIST to conduct comprehensive research covering the entire cycle from the theoretical foundations of AI inference to its practical application.

Specifically, the main goals include: - Building high-performance inference models that integrate diverse medical knowledge systems to enhance the precision and reliability of diagnosis and treatment. - Developing a convergence inference platform that efficiently combines symbol-based inference with neural network models. - Securing AI technology for new drug development and biomarker discovery based on 'cell ontology.'

Furthermore, through close collaboration with industry and medical institutions such as Samsung Medical Center, NAVER Cloud, and HITS Co., Ltd., the project aims to achieve: - Clinical diagnostic AI utilizing medical knowledge systems. - AI-based molecular target exploration for new drug development. - Commercialization of an extendible AI inference platform.

Professor JongChul Ye, Director of KAIST's Digital Bio-Health AI Research Center, stated, "At a time when competition in AI inference model development is intensifying, it is a great honor for KAIST to lead the development of AI technology specialized in the bio and medical fields with world-class young researchers." He added, "We will do our best to ensure that the participating young researchers reach a world-leading level in terms of research achievements after the completion of this seven-year project starting in 2025."

The AI Star Fellowship is a newly established program where post-doctoral researchers and faculty members within seven years of appointment participate as project leaders (PLs) to independently lead research. Multiple laboratories within a university and demand-side companies form a consortium to operate the program.

Through this initiative, KAIST plans to nurture bio-medical convergence AI talent and simultaneously promote the commercialization of core technologies in collaboration with Samsung Medical Center, NAVER Cloud, and HITS.

2025.05.26 View 3378

KAIST to Develop a Korean-style ChatGPT Platform Specifically Geared Toward Medical Diagnosis and Drug Discovery

On May 23rd, KAIST (President Kwang-Hyung Lee) announced that its Digital Bio-Health AI Research Center (Director: Professor JongChul Ye of KAIST Kim Jaechul Graduate School of AI) has been selected for the Ministry of Science and ICT's 'AI Top-Tier Young Researcher Support Program (AI Star Fellowship Project).' With a total investment of ₩11.5 billion from May 2025 to December 2030, the center will embark on the full-scale development of AI technology and a platform capable of independently inferring and determining the kinds of diseases, and discovering new drugs.

< Photo. On May 20th, a kick-off meeting for the AI Star Fellowship Project was held at KAIST Kim Jaechul Graduate School of AI’s Yangjae Research Center with the KAIST research team and participating organizations of Samsung Medical Center, NAVER Cloud, and HITS. [From left to right in the front row] Professor Jaegul Joo (KAIST), Professor Yoonjae Choi (KAIST), Professor Woo Youn Kim (KAIST/HITS), Professor JongChul Ye (KAIST), Professor Sungsoo Ahn (KAIST), Dr. Haanju Yoo (NAVER Cloud), Yoonho Lee (KAIST), HyeYoon Moon (Samsung Medical Center), Dr. Su Min Kim (Samsung Medical Center) >

This project aims to foster an innovative AI research ecosystem centered on young researchers and develop an inferential AI agent that can utilize and automatically expand specialized knowledge systems in the bio and medical fields.

Professor JongChul Ye of the Kim Jaechul Graduate School of AI will serve as the lead researcher, with young researchers from KAIST including Professors Yoonjae Choi, Kimin Lee, Sungsoo Ahn, and Chanyoung Park, along with mid-career researchers like Professors Jaegul Joo and Woo Youn Kim, jointly undertaking the project. They will collaborate with various laboratories within KAIST to conduct comprehensive research covering the entire cycle from the theoretical foundations of AI inference to its practical application.

Specifically, the main goals include: - Building high-performance inference models that integrate diverse medical knowledge systems to enhance the precision and reliability of diagnosis and treatment. - Developing a convergence inference platform that efficiently combines symbol-based inference with neural network models. - Securing AI technology for new drug development and biomarker discovery based on 'cell ontology.'

Furthermore, through close collaboration with industry and medical institutions such as Samsung Medical Center, NAVER Cloud, and HITS Co., Ltd., the project aims to achieve: - Clinical diagnostic AI utilizing medical knowledge systems. - AI-based molecular target exploration for new drug development. - Commercialization of an extendible AI inference platform.

Professor JongChul Ye, Director of KAIST's Digital Bio-Health AI Research Center, stated, "At a time when competition in AI inference model development is intensifying, it is a great honor for KAIST to lead the development of AI technology specialized in the bio and medical fields with world-class young researchers." He added, "We will do our best to ensure that the participating young researchers reach a world-leading level in terms of research achievements after the completion of this seven-year project starting in 2025."

The AI Star Fellowship is a newly established program where post-doctoral researchers and faculty members within seven years of appointment participate as project leaders (PLs) to independently lead research. Multiple laboratories within a university and demand-side companies form a consortium to operate the program.

Through this initiative, KAIST plans to nurture bio-medical convergence AI talent and simultaneously promote the commercialization of core technologies in collaboration with Samsung Medical Center, NAVER Cloud, and HITS.

2025.05.26 View 3378 -

KAIST Holds 2025 Commencement Ceremony

KAIST (President Kwang-Hyung Lee) held its 2025 Commencement Ceremony at the Lyu Keun-Chul Sports Complex on the Daejeon Main Campus at 2 p.m. on the 14th of February.

< A scene from KAIST Commencement 2025 - Guests of Honor and Administrative Professors Entering the Stage headed by the color guards of the ELKA (Encouraging Leaders of KAIST) >

At this ceremony, a total of 3,144 degrees were conferred, including 785 doctorates, 1,643 masters, and 716 bachelors. With this, KAIST has produced a total of 81,156 advanced science and technology personnel, including 17,313 doctorates, 41,566 masters, and 22,277 bachelors since its establishment in 1971.

Changyu Lee from the School of Computing received the Minister of Science and ICT Award, and the Chairman of the KAIST Board of Trustees Award went to Lance Khizner Dabu Gragasin, an international student from the Philippines of the Department of Chemical and Biological Engineering. The President’s Award was given to Seoyeong Yang of the Department of Biological Sciences, and the Alumni Association President’s Award and the Development Foundation Chairman’s Award was given to Gahyeon Bae of the Department of Industrial Design and Buyeon Kim of the Department of Mechanical Engineering, respectively.

Minister of Science and ICT Sang-Im Yoo joined the ceremony to deliver a congratulatory speech and to present the awards to outstanding graduates.

< Minister Sang-Im Yoo of the Ministry of Science, Technology and ICT giving his congratulatory message at KAIST Commencement 2025 >

The valedictorian speeches were given by Minjae Kim of the School of Computing, who has practiced the value of sharing that learning is not competition but cooperation, and Mohammed Haruna Hamza of the Department of Aerospace Engineering, a Nigerian international student. Mr. Hamza is the first foreign student to represent the graduating class as valedictorian since the founding of KAIST.

Hamza lost his home and school in his home country due to a terrorist group’s bombing and moved south, but despite the adversity, he continued his studies while pursuing his dream of becoming an aerospace engineer. As a result of his efforts, Hamza was invited by the Korean government to study at KAIST. He expressed his determination to pursue his dream by saying, “I am grateful for the people and experiences that helped me overcome my adversity. The future is the result of the decisions we make today.”

A Pakistani international student was chosen as one of this year's "Most Talked about Graduates of the Year". It is Ali Syed Sheraz who wore his doctoral cap at this year’s commencement ceremony. Ali, a single father who left his one-year-old son behind in his home country, working as a university lecturer. He joined the Ph.D. program in mechanical engineering in 2019 with a passion for mechanical energy.

Ali’s academic journey was full of challenges and growth. Due to COVID-19, his research was suspended for six months, and he had difficulty continuing his studies undergoing three surgeries after a bicycle accident, including a surgery for a fractured elbow, a nose surgery, and removal of kidney stones.

However, he accepted these failure and hardship as a process of growth and participated in the ‘Failed Project Showcase’ and ‘Failure Essay Contest’ held by the KAIST Failure Society, sharing his experiences and growing into a more solid researcher.

< Most Talked about Graduate Graduate of the Year - Syed Sheraz Ali >

Despite experiencing various hardships, he found lessons to learn from them and changed his perspective, which made him unafraid of taking on new challenges. He showed through his own example that failure is not just stumbling blocks but can be a stepping stone to success by looking at his studies and personal life positively.

Furthermore, after becoming the president of the Muslim Student Association, Ali introduced halal menus to the cafeteria on campus so that more Muslim students could eat comfortably. Thanks to this change, his time at KAIST has become an opportunity to understand and experience various cultures more.

Ali is researching artificial muscles (soft actuators) with the world's highest bending strain using MXene, an artificial muscle nanomaterial that can move smoothly, in Professor Il-kwon Oh's lab.

Ali said, "After completing my Ph.D., I plan to develop soft robots, healthcare electronics, and next-generation tactile technology based on MXene, a next-generation 2D material. It is important for my juniors not to be afraid of failure and to have a challenging attitude."

Another 'Most Talked about Graduate of the Year', Mr. Sung-Hyun Jung, who graduated with a master's degree from the Graduate School of Bio Innvation Management, is the CEO of Promedius, a medical AI startup, and has commercialized an osteoporosis diagnosis software based on chest X-rays using AI, and grown it into a leading company in the bone health field.

CEO Jung's challenge shows that KAIST's management education is not just theoretical but practical enough to be applied immediately in the field. CEO Jung, who is also the father of three daughters, experienced business failure in China during the period when the conflict between Korea and China was intensifying.

He moved to Silicon Valley in the United States to revive his business and tried to acquire even small businesses, but the reality was not easy. He worked hard, standing 14 hours a day in a kimchi factory and a restaurant kitchen to make a living. After finishing his life in the United States, CEO Jung returned to Korea and had the opportunity to join Lunit, a global medical AI leader founded by KAIST graduates. CEO Jung experienced the growth of the global medical AI market firsthand with unit Chairman Seungwook Paek.

When he entered the Master's Program at the Graduate School of Bio Innvation Management in 2023 to acquire more specialized knowledge, CEO Jung had just transferred to Promedius and was in a crisis situation with only about 6 months left before the company's funds were exhausted.

While considering a change in business direction because he judged that it would be difficult to survive with existing business items, he learned keywords and investment review perspectives that venture capital (VC) pays attention to in Professor Hoonje Cho’s ‘Bio-innovation Business Startup Strategy and Practice’ class. He attracted 11.4 billion won in investment by applying the investment proposal he wrote based on what he learned from the class to actual practice.

< Most Talked about Graduate of the Year - Sung-Hyun Jung >

In addition, he applied the innovation strategy in the medical field he learned in Professor Kihwan Park’s ‘Innovation and Marketing in Bio and Pharmaceutics’ to the field of osteoporosis, and achieved the result of being selected as the first Asian company to be a corporate advisory committee member of the International Osteoporosis Foundation (IOF). Through this, he established the company as a representative global entity in the osteoporosis field in just one year.

CEO Jung, who applied what he learned from KAIST to actual management and achieved results in the global market in a short period of time, said, “I want to prove that KAIST education is not limited to theory, but is very practical.” He said, “I want to let people know that my life, once full of hardship, got on the track toward success after encountering KAIST,” and expressed his ambition, saying, “My long-term goal is to create a world-class company that is recognized globally.”

In addition, an honorary doctorate was awarded to Chairman Joong Keun Lee of Booyoung Group at the commencement ceremony.

Chairman Joong Keun Lee, who is an entrepreneur that led Booyoung Group, a leading general construction company, received the honorary doctorate in business administration, for leading the development of domestic housing welfare, education, and culture.

KAIST Provost Gyunmin Lee said, “Chairman Joong Keun Lee spared no effort in providing dedicated support for the development of domestic science and technology and the cultivation of future talents. He is awarded the honorary doctorate in recognition of his social responsibility in various fields, including scholarships and support for educational facilities, as well as domestic and international education, culture, veterans affairs, and overseas support.”

Since founding Booyoung Group in 1983, Chairman Lee has boldly entered the rental housing business, a field that large construction companies had avoided, and has played a significant role in improving the quality of life of ordinary citizens by supplying 230,000 households out of 383 complexes and approximately 300,000 households nationwide as rental housing, thereby contributing greatly to the stability of national housing.

< Chairman Joong Keun Lee giving his acceptance speech for his honorary Doctorate >

Chairman Joong Keun Lee, who has been offering hope for a sustainable future, said, “I am honored to receive an honorary doctorate from KAIST, and I hope that KAIST students will nurture their dreams and talents and grow into global talents who will contribute to national development.”

President Kwang-Hyung Lee said, “Chairman Joong Keun Lee has been carrying out various social contribution activities, and in particular, through supporting academic infrastructure, which is the core of national competitiveness, we can see his deep interest in and sense of responsibility for the development of science and technology in our country.” He added, “I am truly delighted to have him as a member of the KAIST family, and I congratulate him on behalf of all members, including our students.”

President Kwang-Hyung Lee also delivered a message of encouragement at the ceremony to charge the graduates to, “Find and keep a dream of your own, be on the lookout for opportunities, don’t be afraid of making mistakes, and do not shy away from taking on challenging tasks.” He added, “Even if you fail, don’t give up. Keep on trying so that you will get to that stage of radiate your own light on the stages where anything is possible.” (End)

2025.02.14 View 6159

KAIST Holds 2025 Commencement Ceremony

KAIST (President Kwang-Hyung Lee) held its 2025 Commencement Ceremony at the Lyu Keun-Chul Sports Complex on the Daejeon Main Campus at 2 p.m. on the 14th of February.

< A scene from KAIST Commencement 2025 - Guests of Honor and Administrative Professors Entering the Stage headed by the color guards of the ELKA (Encouraging Leaders of KAIST) >

At this ceremony, a total of 3,144 degrees were conferred, including 785 doctorates, 1,643 masters, and 716 bachelors. With this, KAIST has produced a total of 81,156 advanced science and technology personnel, including 17,313 doctorates, 41,566 masters, and 22,277 bachelors since its establishment in 1971.

Changyu Lee from the School of Computing received the Minister of Science and ICT Award, and the Chairman of the KAIST Board of Trustees Award went to Lance Khizner Dabu Gragasin, an international student from the Philippines of the Department of Chemical and Biological Engineering. The President’s Award was given to Seoyeong Yang of the Department of Biological Sciences, and the Alumni Association President’s Award and the Development Foundation Chairman’s Award was given to Gahyeon Bae of the Department of Industrial Design and Buyeon Kim of the Department of Mechanical Engineering, respectively.

Minister of Science and ICT Sang-Im Yoo joined the ceremony to deliver a congratulatory speech and to present the awards to outstanding graduates.

< Minister Sang-Im Yoo of the Ministry of Science, Technology and ICT giving his congratulatory message at KAIST Commencement 2025 >

The valedictorian speeches were given by Minjae Kim of the School of Computing, who has practiced the value of sharing that learning is not competition but cooperation, and Mohammed Haruna Hamza of the Department of Aerospace Engineering, a Nigerian international student. Mr. Hamza is the first foreign student to represent the graduating class as valedictorian since the founding of KAIST.

Hamza lost his home and school in his home country due to a terrorist group’s bombing and moved south, but despite the adversity, he continued his studies while pursuing his dream of becoming an aerospace engineer. As a result of his efforts, Hamza was invited by the Korean government to study at KAIST. He expressed his determination to pursue his dream by saying, “I am grateful for the people and experiences that helped me overcome my adversity. The future is the result of the decisions we make today.”

A Pakistani international student was chosen as one of this year's "Most Talked about Graduates of the Year". It is Ali Syed Sheraz who wore his doctoral cap at this year’s commencement ceremony. Ali, a single father who left his one-year-old son behind in his home country, working as a university lecturer. He joined the Ph.D. program in mechanical engineering in 2019 with a passion for mechanical energy.

Ali’s academic journey was full of challenges and growth. Due to COVID-19, his research was suspended for six months, and he had difficulty continuing his studies undergoing three surgeries after a bicycle accident, including a surgery for a fractured elbow, a nose surgery, and removal of kidney stones.

However, he accepted these failure and hardship as a process of growth and participated in the ‘Failed Project Showcase’ and ‘Failure Essay Contest’ held by the KAIST Failure Society, sharing his experiences and growing into a more solid researcher.

< Most Talked about Graduate Graduate of the Year - Syed Sheraz Ali >

Despite experiencing various hardships, he found lessons to learn from them and changed his perspective, which made him unafraid of taking on new challenges. He showed through his own example that failure is not just stumbling blocks but can be a stepping stone to success by looking at his studies and personal life positively.

Furthermore, after becoming the president of the Muslim Student Association, Ali introduced halal menus to the cafeteria on campus so that more Muslim students could eat comfortably. Thanks to this change, his time at KAIST has become an opportunity to understand and experience various cultures more.

Ali is researching artificial muscles (soft actuators) with the world's highest bending strain using MXene, an artificial muscle nanomaterial that can move smoothly, in Professor Il-kwon Oh's lab.

Ali said, "After completing my Ph.D., I plan to develop soft robots, healthcare electronics, and next-generation tactile technology based on MXene, a next-generation 2D material. It is important for my juniors not to be afraid of failure and to have a challenging attitude."

Another 'Most Talked about Graduate of the Year', Mr. Sung-Hyun Jung, who graduated with a master's degree from the Graduate School of Bio Innvation Management, is the CEO of Promedius, a medical AI startup, and has commercialized an osteoporosis diagnosis software based on chest X-rays using AI, and grown it into a leading company in the bone health field.

CEO Jung's challenge shows that KAIST's management education is not just theoretical but practical enough to be applied immediately in the field. CEO Jung, who is also the father of three daughters, experienced business failure in China during the period when the conflict between Korea and China was intensifying.

He moved to Silicon Valley in the United States to revive his business and tried to acquire even small businesses, but the reality was not easy. He worked hard, standing 14 hours a day in a kimchi factory and a restaurant kitchen to make a living. After finishing his life in the United States, CEO Jung returned to Korea and had the opportunity to join Lunit, a global medical AI leader founded by KAIST graduates. CEO Jung experienced the growth of the global medical AI market firsthand with unit Chairman Seungwook Paek.

When he entered the Master's Program at the Graduate School of Bio Innvation Management in 2023 to acquire more specialized knowledge, CEO Jung had just transferred to Promedius and was in a crisis situation with only about 6 months left before the company's funds were exhausted.

While considering a change in business direction because he judged that it would be difficult to survive with existing business items, he learned keywords and investment review perspectives that venture capital (VC) pays attention to in Professor Hoonje Cho’s ‘Bio-innovation Business Startup Strategy and Practice’ class. He attracted 11.4 billion won in investment by applying the investment proposal he wrote based on what he learned from the class to actual practice.

< Most Talked about Graduate of the Year - Sung-Hyun Jung >

In addition, he applied the innovation strategy in the medical field he learned in Professor Kihwan Park’s ‘Innovation and Marketing in Bio and Pharmaceutics’ to the field of osteoporosis, and achieved the result of being selected as the first Asian company to be a corporate advisory committee member of the International Osteoporosis Foundation (IOF). Through this, he established the company as a representative global entity in the osteoporosis field in just one year.

CEO Jung, who applied what he learned from KAIST to actual management and achieved results in the global market in a short period of time, said, “I want to prove that KAIST education is not limited to theory, but is very practical.” He said, “I want to let people know that my life, once full of hardship, got on the track toward success after encountering KAIST,” and expressed his ambition, saying, “My long-term goal is to create a world-class company that is recognized globally.”

In addition, an honorary doctorate was awarded to Chairman Joong Keun Lee of Booyoung Group at the commencement ceremony.

Chairman Joong Keun Lee, who is an entrepreneur that led Booyoung Group, a leading general construction company, received the honorary doctorate in business administration, for leading the development of domestic housing welfare, education, and culture.

KAIST Provost Gyunmin Lee said, “Chairman Joong Keun Lee spared no effort in providing dedicated support for the development of domestic science and technology and the cultivation of future talents. He is awarded the honorary doctorate in recognition of his social responsibility in various fields, including scholarships and support for educational facilities, as well as domestic and international education, culture, veterans affairs, and overseas support.”

Since founding Booyoung Group in 1983, Chairman Lee has boldly entered the rental housing business, a field that large construction companies had avoided, and has played a significant role in improving the quality of life of ordinary citizens by supplying 230,000 households out of 383 complexes and approximately 300,000 households nationwide as rental housing, thereby contributing greatly to the stability of national housing.

< Chairman Joong Keun Lee giving his acceptance speech for his honorary Doctorate >

Chairman Joong Keun Lee, who has been offering hope for a sustainable future, said, “I am honored to receive an honorary doctorate from KAIST, and I hope that KAIST students will nurture their dreams and talents and grow into global talents who will contribute to national development.”

President Kwang-Hyung Lee said, “Chairman Joong Keun Lee has been carrying out various social contribution activities, and in particular, through supporting academic infrastructure, which is the core of national competitiveness, we can see his deep interest in and sense of responsibility for the development of science and technology in our country.” He added, “I am truly delighted to have him as a member of the KAIST family, and I congratulate him on behalf of all members, including our students.”

President Kwang-Hyung Lee also delivered a message of encouragement at the ceremony to charge the graduates to, “Find and keep a dream of your own, be on the lookout for opportunities, don’t be afraid of making mistakes, and do not shy away from taking on challenging tasks.” He added, “Even if you fail, don’t give up. Keep on trying so that you will get to that stage of radiate your own light on the stages where anything is possible.” (End)

2025.02.14 View 6159 -

KAIST Develops CamBio - a New Biotemplating Method

- Professor Jae-Byum Chang and Professor Yeon Sik Jung’s joint research team of the Department of Materials Science and Engineering developed a highly tunable bio-templating method “CamBio” that makes use of intracellular protein structures

- Substrate performance improvement of up to 230% demonstrated via surface-enhanced Raman spectroscopy (SERS)

- Expected to have price competitiveness over bio-templating method as it expands the range of biological samples

- Expected to expand the range of application of nanostructure synthesis technology by utilizing various biological structures

< Photo 1. (From left) Professor Yeon Sik Jung, Ph.D. candidate Dae-Hyeon Song, Professor Jae-Byum Chang, and (from top right) Dr. Chang Woo Song and Dr. Seunghee H. Cho of the Department of Materials Science and Engineering >

Biological structures have complex characteristics that are difficult to replicate artificially, but biotemplating methods* that directly utilize these biological structures have been used in various fields of application. The KAIST research team succeeded in utilizing previously unusable biological structures and expanding the areas in which biotemplate methods can be applied.

*Biotemplating: A method of using biotemplates as a mold to create functional structural materials, utilizing the functions of these biological structures, from viruses to the tissues and organs that make up our bodies

KAIST (President Kwang Hyung Lee) announced on the 10th that a joint research team of Professors Jae-Byum Chang and Professor Yeon Sik Jung of the Department of Materials Science and Engineering developed a biotemplating method that utilizes specific intracellular proteins in biological samples and has high tunability.

Existing biotemplate methods mainly utilize only the external surface of biological samples or have limitations in utilizing the structure-function correlation of various biological structures due to limited dimensions and sample sizes, making it difficult to create functional nanostructures.

To solve this problem, the research team studied a way to utilize various biological structures within the cells while retaining high tunability.

< Figure 1. CamBio utilizing microtubules, a intracellular protein structure. The silver nanoparticle chains synthesized along the microtubules that span the entire cell interior can be observed through an electron microscope, and it is shown that this can be used as a successful SERS substrate. >

As a result of the research, the team developed the “Conversion to advanced materials via labeled Biostructure”, shortened as “CamBio”, which enables the selective synthesis of nanostructures with various characteristics and sizes from specific protein structures composed of diverse proteins within biological specimens.

The CamBio method secures high tunability of functional nanostructures that can be manufactured from biological samples by merging various manufacturing and biological technologies.

Through the technology of repeatedly attaching antibodies, arranging cells in a certain shape, and thinly slicing tissue, the functional nanostructures made with CamBio showed improved performance on the surface-enhanced Raman spectroscopy (SERS)* substrate used for material detection.

*Surface-enhanced Raman spectroscopy (SERS): A technology that can detect very small amounts of substances using light, based on the principle that specific substances react to light and amplifies signals on surfaces of metals such as gold or silver.

The research team found that the nanoparticle chains made using the intracellular protein structures through the process of repeated labeling with antibodies allowed easier control, and improved SERS performance by up to 230%.

In addition, the research team expanded from utilizing the structures inside cells to obtaining samples of muscle tissues inside meat using a cryostat and successfully producing a substrate with periodic bands made of metal particles by performing the CamBio process. This method of producing a substrate not only allows large-scale production using biological samples, but also shows that it is a cost-effective method.

< Figure 2. A method for securing tunability using CamBio at the cell level. Examples of controlling characteristics by integrating iterative labeling and cell pattering techniques with CamBio are shown. >

The CamBio developed by the research team is expected to be used as a way to solve problems faced by various research fields as it is to expand the range of bio-samples that can be produced for various usage.

The first author, Dae-Hyeon Song, a Ph.D. candidate of KAIST Department of Materials Science and Engineering said, “Through CamBio, we have comprehensively accumulated biotemplating methods that can utilize more diverse protein structures,” and “If combined with the state-of-the-art biological technologies such as gene editing and 3D bioprinting and new material synthesis technologies, biostructures can be utilized in various fields of application.”

< Figure 3. A method for securing tunability using CamBio at the tissue level. In order to utilize proteins inside muscle tissue, the frozen tissue sectioning technology is combined, and through this, a substrate with a periodic nanoparticle band pattern is successfully produced, and it is shown that large-area acquisition of samples and price competitiveness can be achieved. >

This study, in which the Ph.D. candidate Dae-Hyeon Song along with Dr. Chang Woo Song, and Dr. Seunghee H. Cho of the same department participated as the first authors, was published online in the international academic journal, Advanced Science, on November 13th, 2024.

(Paper title: Highly Tunable, Nanomaterial-Functionalized Structural Templating of Intracellular Protein Structures Within Biological Species) https://doi.org/10.1002/advs.202406492

This study was conducted with a combination of support from various programs including the National Convergence Research of Scientific Challenges (National Research Foundation of Korea (NRF) 2024), Engineering Reseach Center (ERC) (Wearable Platform Materials Technology Center, NRF 2023), ERC (Global Bio-integrated Materials Center, NRF 2024), and the National Advanced Program for Biological Research Resources (Bioimaging Data Curation Center, NRF 2024) funded by Ministry of Science and ICT.

2025.01.10 View 5106

KAIST Develops CamBio - a New Biotemplating Method

- Professor Jae-Byum Chang and Professor Yeon Sik Jung’s joint research team of the Department of Materials Science and Engineering developed a highly tunable bio-templating method “CamBio” that makes use of intracellular protein structures

- Substrate performance improvement of up to 230% demonstrated via surface-enhanced Raman spectroscopy (SERS)

- Expected to have price competitiveness over bio-templating method as it expands the range of biological samples

- Expected to expand the range of application of nanostructure synthesis technology by utilizing various biological structures

< Photo 1. (From left) Professor Yeon Sik Jung, Ph.D. candidate Dae-Hyeon Song, Professor Jae-Byum Chang, and (from top right) Dr. Chang Woo Song and Dr. Seunghee H. Cho of the Department of Materials Science and Engineering >

Biological structures have complex characteristics that are difficult to replicate artificially, but biotemplating methods* that directly utilize these biological structures have been used in various fields of application. The KAIST research team succeeded in utilizing previously unusable biological structures and expanding the areas in which biotemplate methods can be applied.

*Biotemplating: A method of using biotemplates as a mold to create functional structural materials, utilizing the functions of these biological structures, from viruses to the tissues and organs that make up our bodies

KAIST (President Kwang Hyung Lee) announced on the 10th that a joint research team of Professors Jae-Byum Chang and Professor Yeon Sik Jung of the Department of Materials Science and Engineering developed a biotemplating method that utilizes specific intracellular proteins in biological samples and has high tunability.

Existing biotemplate methods mainly utilize only the external surface of biological samples or have limitations in utilizing the structure-function correlation of various biological structures due to limited dimensions and sample sizes, making it difficult to create functional nanostructures.

To solve this problem, the research team studied a way to utilize various biological structures within the cells while retaining high tunability.

< Figure 1. CamBio utilizing microtubules, a intracellular protein structure. The silver nanoparticle chains synthesized along the microtubules that span the entire cell interior can be observed through an electron microscope, and it is shown that this can be used as a successful SERS substrate. >

As a result of the research, the team developed the “Conversion to advanced materials via labeled Biostructure”, shortened as “CamBio”, which enables the selective synthesis of nanostructures with various characteristics and sizes from specific protein structures composed of diverse proteins within biological specimens.

The CamBio method secures high tunability of functional nanostructures that can be manufactured from biological samples by merging various manufacturing and biological technologies.

Through the technology of repeatedly attaching antibodies, arranging cells in a certain shape, and thinly slicing tissue, the functional nanostructures made with CamBio showed improved performance on the surface-enhanced Raman spectroscopy (SERS)* substrate used for material detection.

*Surface-enhanced Raman spectroscopy (SERS): A technology that can detect very small amounts of substances using light, based on the principle that specific substances react to light and amplifies signals on surfaces of metals such as gold or silver.

The research team found that the nanoparticle chains made using the intracellular protein structures through the process of repeated labeling with antibodies allowed easier control, and improved SERS performance by up to 230%.

In addition, the research team expanded from utilizing the structures inside cells to obtaining samples of muscle tissues inside meat using a cryostat and successfully producing a substrate with periodic bands made of metal particles by performing the CamBio process. This method of producing a substrate not only allows large-scale production using biological samples, but also shows that it is a cost-effective method.

< Figure 2. A method for securing tunability using CamBio at the cell level. Examples of controlling characteristics by integrating iterative labeling and cell pattering techniques with CamBio are shown. >

The CamBio developed by the research team is expected to be used as a way to solve problems faced by various research fields as it is to expand the range of bio-samples that can be produced for various usage.

The first author, Dae-Hyeon Song, a Ph.D. candidate of KAIST Department of Materials Science and Engineering said, “Through CamBio, we have comprehensively accumulated biotemplating methods that can utilize more diverse protein structures,” and “If combined with the state-of-the-art biological technologies such as gene editing and 3D bioprinting and new material synthesis technologies, biostructures can be utilized in various fields of application.”

< Figure 3. A method for securing tunability using CamBio at the tissue level. In order to utilize proteins inside muscle tissue, the frozen tissue sectioning technology is combined, and through this, a substrate with a periodic nanoparticle band pattern is successfully produced, and it is shown that large-area acquisition of samples and price competitiveness can be achieved. >

This study, in which the Ph.D. candidate Dae-Hyeon Song along with Dr. Chang Woo Song, and Dr. Seunghee H. Cho of the same department participated as the first authors, was published online in the international academic journal, Advanced Science, on November 13th, 2024.

(Paper title: Highly Tunable, Nanomaterial-Functionalized Structural Templating of Intracellular Protein Structures Within Biological Species) https://doi.org/10.1002/advs.202406492

This study was conducted with a combination of support from various programs including the National Convergence Research of Scientific Challenges (National Research Foundation of Korea (NRF) 2024), Engineering Reseach Center (ERC) (Wearable Platform Materials Technology Center, NRF 2023), ERC (Global Bio-integrated Materials Center, NRF 2024), and the National Advanced Program for Biological Research Resources (Bioimaging Data Curation Center, NRF 2024) funded by Ministry of Science and ICT.

2025.01.10 View 5106 -

A KAIST Team Develops Face-Conforming LED Mask Showing 340% Improved Efficacy in Deep Skin Elasticity

- A KAIST research team led by Professor Keon Jae Lee has developed a deep skin-stimulating LED mask which has been verified in clinical trials to improve dermis elasticity by 340%.

< Figure 1. Overall concept of face-fit surface-lighting micro-LEDs (FSLED) mask. a. Optical image of the FSLED mask showing uniform surface-lighting. schematic illustration of the FSLED mask. The 2D to 3D transformation procedure b. Difference in cosmetic effect on deep skin elasticity, wrinkles, and sagging between FSLED mask and CLED mask. (improvement percentage in eight weeks) >

Conventional LED masks, with their rigid design, fail to conform closely to the skin's contours. This limitation causes substantial light reflection, with up to 90% reflected over a distance of 2 cm, reducing light penetration and limiting stimulation of the deep skin layers essential for effective skin rejuvenation.

To address these challenges, Professor Lee's team developed a face-conforming surface lighting micro-LED (FSLED) mask, which can provide uniform photostimulation to the dermis. The key technology lies in the mask's ability to deliver uniform light to deep skin tissues while maintaining a conformal skin attachment. This is achieved through a 3D origami structure, integrated with 3,770 micro-LEDs and flexible surface light-diffusion layer, minimizing the gaps between the light source and the skin.

In clinical trials involving 33 participants, the FSLED mask demonstrated a 340% improvement in deep skin elasticity compared to conventional LED masks, proving its efficacy in significantly reducing skin wrinkles, sagging and aging.

Professor Keon Jae Lee said, “The FSLED mask provides cosmetic benefits to the entire facial dermis without the side effects of low-temperature burns, making home-care anti-aging treatment that enhances the quality of human life possible. The product is being manufactured by Fronics, KAIST startup company, and will be distributed globally through Amorepacific's network, with sales starting in November.”

This result titled “Clinical Validation of Face-fit Surface-lighting Micro Light-emitting Diode Mask for Skin Anti-aging Treatment”, in which Min Seo Kim, a student of the Master-Doctorate integrated program, and Jaehun An, a Ph.D. candidate, in the Department of Materials Science and Engineering of KAIST, took part as co-first authors, was published in Advanced Materials on October 22nd, 2024 (DOI: 10.1002/adma.202411651).

Introductory Video: Face-conforming surface LED mask for skin anti-aging ( https://www.youtube.com/watch?v=kSccLwx8N_w )

2024.10.29 View 7587

A KAIST Team Develops Face-Conforming LED Mask Showing 340% Improved Efficacy in Deep Skin Elasticity

- A KAIST research team led by Professor Keon Jae Lee has developed a deep skin-stimulating LED mask which has been verified in clinical trials to improve dermis elasticity by 340%.

< Figure 1. Overall concept of face-fit surface-lighting micro-LEDs (FSLED) mask. a. Optical image of the FSLED mask showing uniform surface-lighting. schematic illustration of the FSLED mask. The 2D to 3D transformation procedure b. Difference in cosmetic effect on deep skin elasticity, wrinkles, and sagging between FSLED mask and CLED mask. (improvement percentage in eight weeks) >

Conventional LED masks, with their rigid design, fail to conform closely to the skin's contours. This limitation causes substantial light reflection, with up to 90% reflected over a distance of 2 cm, reducing light penetration and limiting stimulation of the deep skin layers essential for effective skin rejuvenation.

To address these challenges, Professor Lee's team developed a face-conforming surface lighting micro-LED (FSLED) mask, which can provide uniform photostimulation to the dermis. The key technology lies in the mask's ability to deliver uniform light to deep skin tissues while maintaining a conformal skin attachment. This is achieved through a 3D origami structure, integrated with 3,770 micro-LEDs and flexible surface light-diffusion layer, minimizing the gaps between the light source and the skin.

In clinical trials involving 33 participants, the FSLED mask demonstrated a 340% improvement in deep skin elasticity compared to conventional LED masks, proving its efficacy in significantly reducing skin wrinkles, sagging and aging.

Professor Keon Jae Lee said, “The FSLED mask provides cosmetic benefits to the entire facial dermis without the side effects of low-temperature burns, making home-care anti-aging treatment that enhances the quality of human life possible. The product is being manufactured by Fronics, KAIST startup company, and will be distributed globally through Amorepacific's network, with sales starting in November.”

This result titled “Clinical Validation of Face-fit Surface-lighting Micro Light-emitting Diode Mask for Skin Anti-aging Treatment”, in which Min Seo Kim, a student of the Master-Doctorate integrated program, and Jaehun An, a Ph.D. candidate, in the Department of Materials Science and Engineering of KAIST, took part as co-first authors, was published in Advanced Materials on October 22nd, 2024 (DOI: 10.1002/adma.202411651).

Introductory Video: Face-conforming surface LED mask for skin anti-aging ( https://www.youtube.com/watch?v=kSccLwx8N_w )

2024.10.29 View 7587 -

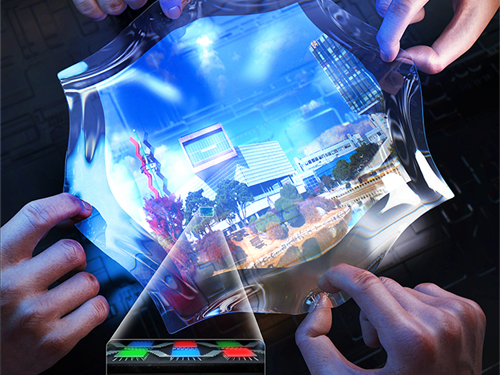

A KAIST research team develops a washable, transparent, and flexible OLED with MXene nanotechnology

Transparent and flexible displays, which have received a lot of attention in various fields including automobile displays, bio-healthcare, military, and fashion, are in fact known to break easily when experiencing small deformations. To solve this problem, active research is being conducted on many transparent and flexible conductive materials such as carbon nanotubes, graphene, silver nanowires, and conductive polymers.

On June 13, a joint research team led by Professor Kyung Cheol Choi from the KAIST School of Electrical Engineering and Dr. Yonghee Lee from the National Nano Fab Center (NNFC) announced the successful development of a water-resistant, transparent, and flexible OLED using MXene nanotechnology. The material can emit and transmit light even when exposed to water.

MXene is a 2D material with high electrical conductivity and optical transmittance, and it can be produced on a large scale through solution processes. However, despite these attractive properties, MXene’s applications were limited as a long-term electrical device due to its electrical properties being degraded easily by atmospheric moisture and water. The material was therefore unable to be systemized into the form of a matrix that can display information.

Professor Choi’s research team used an encapsulation tactic that can protect materials from oxidation caused by moisture and oxygen to develop a MXene-based OLED with a long lifespan and high stability against external environmental factors. The research team first focused on analyzing the degradation mechanism of MXene’s electrical conductivity, and then concentrated on designing an encapsulation membrane. The team blocked moisture and provided flexibility through residual stress offset, ultimately producing a double-layered encapsulation membrane. In addition, a thin plastic film with a thickness of a few micrometers was attached to the top layer to allow washing in water without degradation.

< Figure 1. (a) Transparent passive-matrix display made of MXene-based OLED, (b) Cross-sectional image of MXene-based OLED observed by transmission electron microscope (TEM), (c) Electro-optical characteristic graph of red, green, and blue MXene-based OLED >

Through this study, the research team developed a MXene-based red(R)/green(G)/blue(B) OLED that emits a brightness of over 1,000 cd/m2 that is detectable by the naked eye even under sunlight, thereby meeting the conditions for outdoor displays. As for the red MXene-based OLED, the researchers confirmed a standby storage life of 2,000 hours (under 70% luminescence), a standby operation life of 1,500 hours (under 60% luminescence), and a flexibility withstanding 1,000 cycles under a low curvature of under 1.5mm. In addition, they showed that its performance was maintained even after six hours of immersion under water (under 80% luminescence). Furthermore, a patterning technique was used to produce the MXene-based OLED in the form of a passive matrix, and the team demonstrated its use as a transparent display by displaying letters and shapes.

Ph.D. candidate So Yeong Jeong, who led this study, said, “To improve the reliability of MXene OLED, we focused on producing an adequate encapsulation structure and a suitable process design.” She added, “By producing a matrix-type MXene OLED and displaying simple letters and shapes, we have laid the foundations for MXene’s application in the field of transparent displays.”

< Image 1. Cover of ACS Nano Front Cover (Conceptual diagram of MXene-based OLED display) >

Professor Choi said, “This research will become the guideline for applying MXene in electrical devices, but we expect for it to also be applied in other fields that require flexible and transparent displays like automobiles, fashion, and functional clothing. And to widen the gap with China’s OLED technology, these new OLED convergence technologies must continue to be developed.”

This research was supported by the National Research Foundation of Korea and funded by the Ministry of Science and ICT, Korea. It was published as a front cover story of ACS Nano under the title, “Highly Air-Stable, Flexible, and Water-Resistive 2D Titanium Carbide MXene-Based RGB Organic Light-Emitting Diode Displays for Transparent Free-Form Electronics” on June 13.

2023.07.10 View 7857

A KAIST research team develops a washable, transparent, and flexible OLED with MXene nanotechnology

Transparent and flexible displays, which have received a lot of attention in various fields including automobile displays, bio-healthcare, military, and fashion, are in fact known to break easily when experiencing small deformations. To solve this problem, active research is being conducted on many transparent and flexible conductive materials such as carbon nanotubes, graphene, silver nanowires, and conductive polymers.

On June 13, a joint research team led by Professor Kyung Cheol Choi from the KAIST School of Electrical Engineering and Dr. Yonghee Lee from the National Nano Fab Center (NNFC) announced the successful development of a water-resistant, transparent, and flexible OLED using MXene nanotechnology. The material can emit and transmit light even when exposed to water.

MXene is a 2D material with high electrical conductivity and optical transmittance, and it can be produced on a large scale through solution processes. However, despite these attractive properties, MXene’s applications were limited as a long-term electrical device due to its electrical properties being degraded easily by atmospheric moisture and water. The material was therefore unable to be systemized into the form of a matrix that can display information.

Professor Choi’s research team used an encapsulation tactic that can protect materials from oxidation caused by moisture and oxygen to develop a MXene-based OLED with a long lifespan and high stability against external environmental factors. The research team first focused on analyzing the degradation mechanism of MXene’s electrical conductivity, and then concentrated on designing an encapsulation membrane. The team blocked moisture and provided flexibility through residual stress offset, ultimately producing a double-layered encapsulation membrane. In addition, a thin plastic film with a thickness of a few micrometers was attached to the top layer to allow washing in water without degradation.

< Figure 1. (a) Transparent passive-matrix display made of MXene-based OLED, (b) Cross-sectional image of MXene-based OLED observed by transmission electron microscope (TEM), (c) Electro-optical characteristic graph of red, green, and blue MXene-based OLED >

Through this study, the research team developed a MXene-based red(R)/green(G)/blue(B) OLED that emits a brightness of over 1,000 cd/m2 that is detectable by the naked eye even under sunlight, thereby meeting the conditions for outdoor displays. As for the red MXene-based OLED, the researchers confirmed a standby storage life of 2,000 hours (under 70% luminescence), a standby operation life of 1,500 hours (under 60% luminescence), and a flexibility withstanding 1,000 cycles under a low curvature of under 1.5mm. In addition, they showed that its performance was maintained even after six hours of immersion under water (under 80% luminescence). Furthermore, a patterning technique was used to produce the MXene-based OLED in the form of a passive matrix, and the team demonstrated its use as a transparent display by displaying letters and shapes.

Ph.D. candidate So Yeong Jeong, who led this study, said, “To improve the reliability of MXene OLED, we focused on producing an adequate encapsulation structure and a suitable process design.” She added, “By producing a matrix-type MXene OLED and displaying simple letters and shapes, we have laid the foundations for MXene’s application in the field of transparent displays.”

< Image 1. Cover of ACS Nano Front Cover (Conceptual diagram of MXene-based OLED display) >

Professor Choi said, “This research will become the guideline for applying MXene in electrical devices, but we expect for it to also be applied in other fields that require flexible and transparent displays like automobiles, fashion, and functional clothing. And to widen the gap with China’s OLED technology, these new OLED convergence technologies must continue to be developed.”

This research was supported by the National Research Foundation of Korea and funded by the Ministry of Science and ICT, Korea. It was published as a front cover story of ACS Nano under the title, “Highly Air-Stable, Flexible, and Water-Resistive 2D Titanium Carbide MXene-Based RGB Organic Light-Emitting Diode Displays for Transparent Free-Form Electronics” on June 13.

2023.07.10 View 7857 -

KAIST researchers devises a technology to utilize ultrahigh-resolution micro-LED with 40% reduced self-generated heat

In the digitized modern life, various forms of future displays, such as wearable and rollable displays are required. More and more people are wanting to connect to the virtual world whenever and wherever with the use of their smartglasses or smartwatches. Even further, we’ve been hearing about medical diagnosis kit on a shirt and a theatre-hat. However, it is not quite here in our hands yet due to technical limitations of being unable to fit as many pixels as a limited surface area of a glasses while keeping the power consumption at the a level that a hand held battery can supply, all the while the resolution of 4K+ is needed in order to perfectly immerse the users into the augmented or virtual reality through a wireless smartglasses or whatever the device.

KAIST (President Kwang Hyung Lee) announced on the 22nd that Professor Sang Hyeon Kim's research team of the Department of Electrical and Electronic Engineering re-examined the phenomenon of efficiency degradation of micro-LEDs with pixels in a size of micrometers (μm, one millionth of a meter) and found that it was possible to fundamentally resolve the problem by the use of epitaxial structure engineering.

Epitaxy refers to the process of stacking gallium nitride crystals that are used as a light emitting body on top of an ultrapure silicon or sapphire substrate used for μLEDs as a medium.

μLED is being actively studied because it has the advantages of superior brightness, contrast ratio, and lifespan compared to OLED. In 2018, Samsung Electronics commercialized a product equipped with μLED called 'The Wall'. And there is a prospect that Apple may be launching a μLED-mounted product in 2025.

In order to manufacture μLEDs, pixels are formed by cutting the epitaxial structure grown on a wafer into a cylinder or cuboid shape through an etching process, and this etching process is accompanied by a plasma-based process. However, these plasmas generate defects on the side of the pixel during the pixel formation process.

Therefore, as the pixel size becomes smaller and the resolution increases, the ratio of the surface area to the volume of the pixel increases, and defects on the side of the device that occur during processing further reduce the device efficiency of the μLED. Accordingly, a considerable amount of research has been conducted on mitigating or removing sidewall defects, but this method has a limit to the degree of improvement as it must be done at the post-processing stage after the grown of the epitaxial structure is finished.

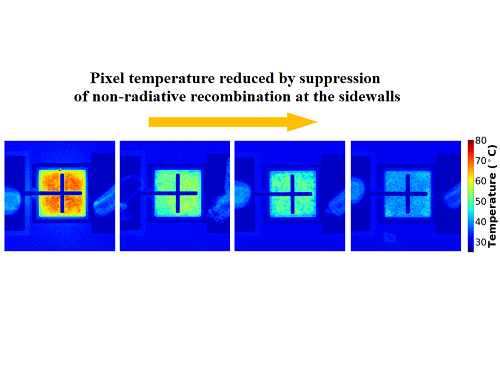

The research team identified that there is a difference in the current moving to the sidewall of the μLED depending on the epitaxial structure during μLED device operation, and based on the findings, the team built a structure that is not sensitive to sidewall defects to solve the problem of reduced efficiency due to miniaturization of μLED devices. In addition, the proposed structure reduced the self-generated heat while the device was running by about 40% compared to the existing structure, which is also of great significance in commercialization of ultrahigh-resolution μLED displays.

This study, which was led by Woo Jin Baek of Professor Sang Hyeon Kim's research team at the KAIST School of Electrical and Electronic Engineering as the first author with guidance by Professor Sang Hyeon Kim and Professor Dae-Myeong Geum of the Chungbuk National University (who was with the team as a postdoctoral researcher at the time) as corresponding authors, was published in the international journal, 'Nature Communications' on March 17th. (Title of the paper: Ultra-low-current driven InGaN blue micro light-emitting diodes for electrically efficient and self-heating relaxed microdisplay).

Professor Sang Hyeon Kim said, "This technological development has great meaning in identifying the cause of the drop in efficiency, which was an obstacle to miniaturization of μLED, and solving it with the design of the epitaxial structure.“ He added, ”We are looking forward to it being used in manufacturing of ultrahigh-resolution displays in the future."

This research was carried out with the support of the Samsung Future Technology Incubation Center.

Figure 1. Image of electroluminescence distribution of μLEDs fabricated from epitaxial structures with quantum barriers of different thicknesses while the current is running

Figure 2. Thermal distribution images of devices fabricated with different epitaxial structures under the same amount of light.

Figure 3. Normalized external quantum efficiency of the device fabricated with the optimized epitaxial structure by sizes.

2023.03.23 View 8286

KAIST researchers devises a technology to utilize ultrahigh-resolution micro-LED with 40% reduced self-generated heat

In the digitized modern life, various forms of future displays, such as wearable and rollable displays are required. More and more people are wanting to connect to the virtual world whenever and wherever with the use of their smartglasses or smartwatches. Even further, we’ve been hearing about medical diagnosis kit on a shirt and a theatre-hat. However, it is not quite here in our hands yet due to technical limitations of being unable to fit as many pixels as a limited surface area of a glasses while keeping the power consumption at the a level that a hand held battery can supply, all the while the resolution of 4K+ is needed in order to perfectly immerse the users into the augmented or virtual reality through a wireless smartglasses or whatever the device.

KAIST (President Kwang Hyung Lee) announced on the 22nd that Professor Sang Hyeon Kim's research team of the Department of Electrical and Electronic Engineering re-examined the phenomenon of efficiency degradation of micro-LEDs with pixels in a size of micrometers (μm, one millionth of a meter) and found that it was possible to fundamentally resolve the problem by the use of epitaxial structure engineering.

Epitaxy refers to the process of stacking gallium nitride crystals that are used as a light emitting body on top of an ultrapure silicon or sapphire substrate used for μLEDs as a medium.

μLED is being actively studied because it has the advantages of superior brightness, contrast ratio, and lifespan compared to OLED. In 2018, Samsung Electronics commercialized a product equipped with μLED called 'The Wall'. And there is a prospect that Apple may be launching a μLED-mounted product in 2025.

In order to manufacture μLEDs, pixels are formed by cutting the epitaxial structure grown on a wafer into a cylinder or cuboid shape through an etching process, and this etching process is accompanied by a plasma-based process. However, these plasmas generate defects on the side of the pixel during the pixel formation process.

Therefore, as the pixel size becomes smaller and the resolution increases, the ratio of the surface area to the volume of the pixel increases, and defects on the side of the device that occur during processing further reduce the device efficiency of the μLED. Accordingly, a considerable amount of research has been conducted on mitigating or removing sidewall defects, but this method has a limit to the degree of improvement as it must be done at the post-processing stage after the grown of the epitaxial structure is finished.

The research team identified that there is a difference in the current moving to the sidewall of the μLED depending on the epitaxial structure during μLED device operation, and based on the findings, the team built a structure that is not sensitive to sidewall defects to solve the problem of reduced efficiency due to miniaturization of μLED devices. In addition, the proposed structure reduced the self-generated heat while the device was running by about 40% compared to the existing structure, which is also of great significance in commercialization of ultrahigh-resolution μLED displays.

This study, which was led by Woo Jin Baek of Professor Sang Hyeon Kim's research team at the KAIST School of Electrical and Electronic Engineering as the first author with guidance by Professor Sang Hyeon Kim and Professor Dae-Myeong Geum of the Chungbuk National University (who was with the team as a postdoctoral researcher at the time) as corresponding authors, was published in the international journal, 'Nature Communications' on March 17th. (Title of the paper: Ultra-low-current driven InGaN blue micro light-emitting diodes for electrically efficient and self-heating relaxed microdisplay).

Professor Sang Hyeon Kim said, "This technological development has great meaning in identifying the cause of the drop in efficiency, which was an obstacle to miniaturization of μLED, and solving it with the design of the epitaxial structure.“ He added, ”We are looking forward to it being used in manufacturing of ultrahigh-resolution displays in the future."

This research was carried out with the support of the Samsung Future Technology Incubation Center.

Figure 1. Image of electroluminescence distribution of μLEDs fabricated from epitaxial structures with quantum barriers of different thicknesses while the current is running

Figure 2. Thermal distribution images of devices fabricated with different epitaxial structures under the same amount of light.

Figure 3. Normalized external quantum efficiency of the device fabricated with the optimized epitaxial structure by sizes.

2023.03.23 View 8286 -

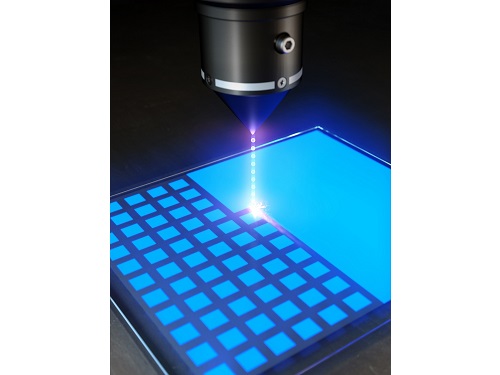

KAIST researchers develops a tech to enable production of ultrahigh-resolution LED with sub-micrometer scale pixels

Ultrahigh-resolution displays are an essential element for developing next-generation electronic products such as virtual reality (VR), augmented reality (AR), and smart watches, and can be applied not only to head-mounted displays, but also to smart glasses and smart lenses. The technology developed through this research is expected to be used to make such next-generation ultrahigh-resolution displays and other various sub-micro optoelectronic devices.