research

Professor Minyang Yang from the Department of Mechanical Engineering and his team developed a high-energy, flexible micro-supercapacitor in a simple and cost-effective way.

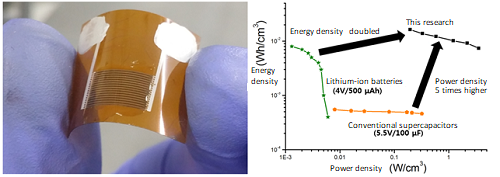

Compared to conventional micro-batteries, such as lithium-ion batteries, these new batteries, also called supercapacitors, are significantly faster to charge and semi-permanent.

Thin, flexible micro-supercapacitors can be a power source directly attached to wearable and flexible electronics.

However, fabrication of these micro-supercapacitors requires a complex patterning process, such as lithography techniques and vacuum evaporation. Hence, the process requires expensive instruments and toxic chemicals.

To simplify the fabrication of micro-supercapacitors in an eco-friendly manner, the team developed laser growth sintering technology. This technology manufactures superporous silver electrodes and applies them to the supercapacitors’ electrodes.

The team used a laser to form micro-patterns and generated nanoporous structures inside. This laser-induced growth sintering contributed to shortening the manufacturing process from ten steps to one.

Moreover, the team explored this unique laser growth sintering process –nucleation, growth, and sintering –by employing a particle-free, organometallic solution, which is not costly compared to typical laser-sintering methods for metallic nanoparticle solutions used in the printing of micro-electrodes.

Finally, unlike the typical supercapacitors comprised of a single substance, the team applied an asymmetric electrode configuration of nanoporous gold and manganese dioxide, which exhibits a highly-specific capacitance, to operate at a high voltage.

This method allows the team to develop energy storage with a high capacity. This developed micro-supercapacitor only requires four seconds to be charged and passed more than 5,000 durability tests.

Professor Yang said, “This research outcome can be used as energy storage installed in wearable and flexible electronic devices. Through this research, we are one step closer to realizing a complete version of flexible electronic devices by incorporating a power supply.”

This research, led by PhD candidate Jae Hak Lee, was selected as the cover of Journal of Materials Chemistry A on December 21, 2017.

Figure 4. Structural change of the silver conductor according to the irradiated laser energy

-

research On-chip Drug Screening for Identifying Antibiotic Interactions in Eight Hours

(from left: Seunggyu Kimand Professor Jessie Sungyun Jeon) A KAIST research team developed a microfluidic-based drug screening chip that identifies synergistic interactions between two antibiotics in eight hours. This chip can be a cell-based drug screening platform for exploring critical pharmacological patterns of antibiotic interactions, along with potential applications in screening other cell-type agents and guidance for clinical therapies. Antibiotic susceptibility te

2019-04-18 -

research True-meaning Wearable Displays: Self-powered, Washable and Wearable

(Video: The washing process of wearing display module) When we think about clothes, they are usually formed with textiles and have to be both wearable and washable for daily use; however, smart clothing has had a problem with its power sources and moisture permeability, which causes the devices to malfunction. This problem has now been overcome by a KAIST research team, who developed a textile-based wearable display module technology that is washable and does not require an external power s

2019-03-21 -

research Washing and Enrichment of Micro-Particles Encapsulated in Droplets

Researchers developed microfluidic technology for the washing and enrichment of in-droplet micro-particles. They presented the technology using a microfluidic chip based on surface acoustic wave (SAW)-driven acoustic radiation force (ARF). The team demonstrated the first instance of acoustic in-droplet micro-particle washing with a particle recovery rate of approximately 90 percent. They further extended the applicability of the proposed method to in-droplet particle enrichment with the unpr

2018-10-19 -

people Undergrad's Paper Chosen as the Cover Article in Soft Matter

(from left: Research Professor KyuHan Kim and Undergrad Student Subeen Kim) A KAIST undergraduate student, Subeen Kim, had his paper chosen as the cover article in an international journal during his senior year. There have been an increasing number of undergraduate students who were published as the first author because the KAIST Undergraduate Research Participation program allows more active research participation by undergraduate students. Through URP, Kim successfull

2018-05-03 -

research Lifespan of Fuel Cells Maximized Using Small Amount of Metals

(Professor Jung (far right) and his team) Fuel cells are key future energy technology that is emerging as eco-friendly and renewable energy sources. In particular, solid oxide fuel cells composed of ceramic materials gain increasing attention for their ability to directly convert various forms of fuel such as biomass, LNG, and LPG to electric energy. KAIST researchers described a new technique to improve chemical stability of electrode materials which can extend the lifespan by employing

2018-01-18