research

(Research team of Professor Park, Professor Jung, and research fellow Gao Min)

A KAIST research team reported a high-performance and cost effective hydrogen sensor using novel fabrication process based on the combination of polystyrene nanosphere lithography and semiconductor microfabrication processes.

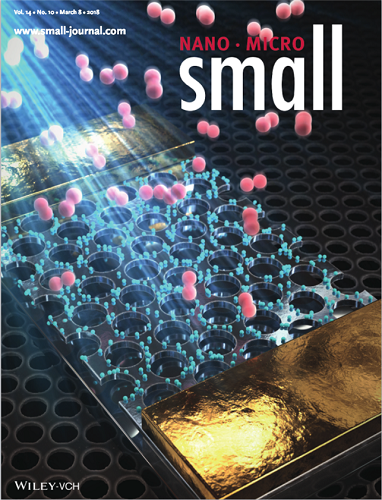

The research team, led by Professor Inkyu Park in the Department of Mechanical Engineering and Professor Yeon Sik Jung in the Department of Materials Science and Engineering, fabricated a nanostructured high-performance hydrogen gas sensor based on a palladium-decorated silicon nanomesh structure made using a polystyrene nanosphere self-assembly method. Their study was featured as the front cover article of journal “Small” (Publisher: Wiley-VCH) on March 8, 2018.

The nanosphere lithography method utilizes the self-assembly of a nanosphere monolayer. This could be an alternative choice for achieving uniform and well-ordered nanopatterns with minimum sub-10 nanometer dimensions. The research team said that the small dimensions of the silicon enhanced the palladium-gating effect and thus dramatically improved the sensitivity.

Hydrogen gas is widely considered to be one of the most promising next-generation energy resources. Also, it is a very important material for various industrial applications such as hydrogen-cooled systems, petroleum refinement, and metallurgical processes. However, hydrogen, which is highly flammable, is colorless and odorless and thus difficult to detect with human senses. Therefore, developing hydrogen gas sensors with high sensitivity, fast response, high selectivity, and good stability is of significant importance for the rising hydrogen economy.

Silicon nanowire-based devices have been employed as efficient components in high-performance sensors for detecting gases and other chemical and biological components. Since the nanowires have a high surface-to-volume ratio, they respond more sensitively to the surrounding environment.

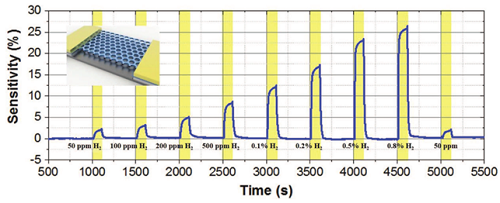

The research team’s gas sensor shows dramatically improved hydrogen gas sensitivity compared with a silicon thin film sensor without nanopatterns. Furthermore, a buffered oxide etchant (BOE) treatment of the silicon nanomesh structure results in an additional performance improvement through suspension of nanomesh strutures from the substrate and surface roughening. The sensor device shows a fast hydrogen response (response time < 5 seconds) and 10 times higher selectivity to hydrogen gas among other gases. Their sensing performance is stable and shows repeatable responses in both dry and high-humidity ambient environments.

Professor Park said that his approach will be very useful for the fabrication of low-cost, high-performance sensors for chemical and biological detection with applications to mobile and wearable devices in the coming era of internet of things (IoTs).

(Figure 1: The front cover image of Small dated on March 8.)

(Figure 2: Gas sensor responses upon the exposure to H2 at various concentrations.)

-

research KAIST’s Next-Generation Small Satellite-2 Completes a Two-Year Mission – the Successful Observation of Arctic and Forest Changes

KAIST (President Kwang-Hyung Lee) announced on the 25th of May that the Next-Generation Small Satellite-2 developed by the Satellite Technology Research Center (SaTReC, Director Jaeheung Han) and launched aboard the third Nuri rocket from the Naro Space Center at 18:24 on May 25, 2023, has successfully completed its two-year core mission of verifying homegrown Synthetic Aperture Radar (SAR) technology and conducting all-weather Earth observations. The SAR system onboard the satellite was design

2025-05-25 -

research Highly Uniform and Low Hysteresis Pressure Sensor to Increase Practical Applicability

< Professor Steve Park (left) and the First Author Mr. Jinwon Oh (right) > Researchers have designed a flexible pressure sensor that is expected to have a much wider applicability. A KAIST research team fabricated a piezoresistive pressure sensor of high uniformity with low hysteresis by chemically grafting a conductive polymer onto a porous elastomer template. The team discovered that the uniformity of pore size and shape is directly related to the uniformity of the sensor. The

2019-08-19 -

research Novel Material Properties of Hybrid Perovskite Nanostructures for Next-generation Non-linear Electronic Devices

(from left: Juho Lee, Dr. Muhammad Ejaz Khan and Professor Yong-Hoon Kim) A KAIST research team reported a novel non-linear device with the founding property coming from perovskite nanowires. They showed that hybrid perovskite-derived, inorganic-framework nanowires can acquire semi-metallicity, and proposed negative differential resistance (NDR) devices with excellent NDR characteristics that resulted from a novel quantum-hybridization NDR mechanism, implying the potential of perovskite nano

2019-02-22 -

research Hierarchical Porous Titanium Nitride Synthesized by Multiscale Phase Separation for LSBs

(from left: Professor Jinwoo Lee and PhD candidate Won-Gwang Lim) A KAIST research team developed ultra-stable, high-rate lithium-sulfur batteries (LSBs) by using hierarchical porous titanium nitride as a sulfur host, and achieved superior cycle stability and high rate performance for LSBs. The control of large amounts of energy is required for use in an electric vehicle or smart grid system. In this sense, the development of next-generation secondary batteries is in high

2019-01-28 -

research Highly Scalable Process to Obtain Stable 2D Nanosheet Dispersion

(Professor Do Hyun Kim and his team) A KAIST team developed technology that allows the mass production of two-dimensional (2D) nanomaterial dispersion by utilizing the characteristic shearing force of hydraulic power. The 2D nanosheet dispersion can be directly applied to solution-based processes to manufacture devices for electronics as well as energy storage and conversion. It is expected to be used in these devices with improved performance. There have been numero

2018-12-19