research

Scientists at KAIST have developed a new way of making fuel cell membranes using nanoscale fasteners, paving the way for lower-cost, higher-efficiency and more easily manufactured fuel cells.

The internal workings of fuel cells vary, but basically all types mix hydrogen and oxygen to produce a chemical reaction that delivers usable electricity and exhausts ordinary water as a by-product. One of the most efficient types is the proton exchange membrane (PEM) fuel cell, which operates at low enough temperatures to be used in homes and vehicles.

To generate electricity, PEM fuel cells rely on two chemical compartments separated by a permeable catalyst membrane. This membrane acts as an electrolyte; a negative electrode is bonded to one side of the membrane and a positive electrode is bonded to the other. The electrolyte membrane is often based on a polymer of perfluorosulfonic acid. Due to its high cost, however, a less expensive hydrocarbon-based electrolyte membrane has attracted interest in this technology sector.

Until now, the challenge in adopting such a hydrocarbon membrane has been that the interface between the electrode and hydrocarbon membrane is weak. This causes the membrane to delaminate relatively easily, falling apart and losing efficiency with use.

Professor Hee-Tak Kim of the Department of Chemical and Biomolecular Engineering at the Korea Advanced Institute of Science and Technology (KAIST) and his research team have developed a new fastening system that bonds the two materials mechanically rather than chemically. This opens the way to the development of fuel cell membranes that are less expensive, easier to manufacture, stronger and more efficient.

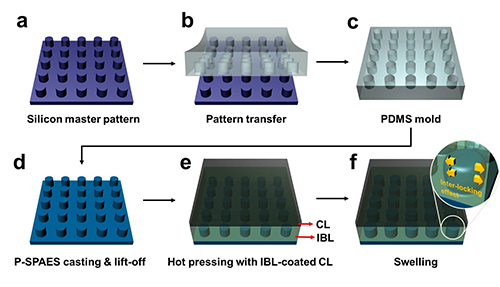

The researchers achieved this by moulding a pattern of tiny cylindrical pillars on the face of the hydrocarbon membrane. The pillars protrude into a softened skin of the electrode with heat. The mechanical bond sets and strengthens as the material cools and absorbs water. The pillar-patterned hydrocarbon membrane is cast using silicone moulds.

Professor Kim said, “This physically fastened bond is almost five times stronger and harder to separate than current bonds between the same layers.”

The new interlocking method also appears to offer a way to bond many types of hydrocarbon membranes that, until now, have been rejected because they couldn’t be fastened robustly. This would make hydrocarbon membranes practical for a number of applications beyond fuel cells such as rechargeable “redox flow” batteries.

The research team is now developing a stronger and more scalable interlocking interface for their nanoscale fasteners.

Picture: Schematic Diagram of the Fabrication of the Pillar P-SPAES Membrane and Its Working Principle of Interlocking Effects

-

research KAIST Develops AI That Automatically Designs Optimal Drug Candidates for Cancer-Targeting Mutations

< (From left) Ph.D candidate Wonho Zhung, Ph.D cadidate Joongwon Lee , Prof. Woo Young Kim , Ph.D candidate Jisu Seo > Traditional drug development methods involve identifying a target protin (e.g., a cancer cell receptor) that causes disease, and then searching through countless molecular candidates (potential drugs) that could bind to that protein and block its function. This process is costly, time-consuming, and has a low success rate. KAIST researchers have developed an AI model th

2025-08-12 -

event 2025 APEC Youth STEM Science Exchange Program Successfully Completed

<Photo1. Group photo at the end of the program> KAIST (President Kwang Hyung Lee) announced on the 11thof August that it successfully hosted the 'APEC Youth STEM Conference KAIST Academic Program,' a global science exchange program for 28 youth researchers from 10 countries and over 30 experts who participated in the '2025 APEC Youth STEM* Collaborative Research and Competition.' The event was held at the main campus in Daejeon on Saturday, August 9. STEM (Science, Technology, Eng

2025-08-11 -

event 'Team Atlanta', in which KAIST Professor Insu Yun research team participated, won the DARPA AI Cyber Challenge in the US, with a prize of 5.5 billion KRW

<Photo1. Group Photo of Team Atlanta> Team Atlanta, led by Professor Insu Yun of the Department of Electrical and Electronic Engineering at KAIST and Tae-soo Kim, an executive from Samsung Research, along with researchers from POSTECH and Georgia Tech, won the final championship at the AI Cyber Challenge (AIxCC) hosted by the Defense Advanced Research Projects Agency (DARPA). The final was held at the world's largest hacking conference, DEF CON 33, in Las Vegas on August 8 (local time)

2025-08-10 -

event Prof. Seungbum Koo’s Team Receives Clinical Biomechanics Award at the 30th International Society of Biomechanics Conference

<(From Left) Ph.D candidate Jeongseok Oh from KAIST, Dr. Seungwoo Yoon from KAIST, Prof.Joon-Ho Wang from Samsung Medical Center, Prof.Seungbum Koo from KAIST> Professor Seungbum Koo’s research team received the Clinical Biomechanics Award at the 30th International Society of Biomechanics (ISB) Conference, held in July 2025 in Stockholm, Sweden. The Plenary Lecture was delivered by first author and Ph.D. candidate Jeongseok Oh. This research was conducted in collaboration with P

2025-08-10 -

event KAIST’s Wearable Robot Design Wins ‘2025 Red Dot Award Best of the Best’

<Professor Hyunjoon Park, M.S candidate Eun-ju Kang, Prospective M.S candidate Jae-seong Kim, undergraduate student Min-su Kim> A team led by Professor Hyunjoon Park from the Department of Industrial Design won the ‘Best of the Best’ award at the 2025 Red Dot Design Awards, one of the world's top three design awards, for their 'Angel Robotics WSF1 VISION Concept.' The design for the next-generation wearable robot for people with paraplegia successfully implements functional

2025-08-09