Platform

-

Hydrogen-Natural Gas Hydrates Harvested by Natural Gas

A hydrogen-natural gas blend (HNGB) can be a game changer only if it can be stored safely and used as a sustainable clean energy resource. A recent study has suggested a new strategy for stably storing hydrogen, using natural gas as a stabilizer. The research proposed a practical gas phase modulator based synthesis of HNGB without generating chemical waste after dissociation for the immediate service.

The research team of Professor Jae Woo Lee from the Department of Chemical and Biomolecular Engineering in collaboration with the Gwangju Institute of Science and Technology (GIST) demonstrated that the natural gas modulator based synthesis leads to significantly reduced synthesis pressure simultaneously with the formation of hydrogen clusters in the confined nanoporous cages of clathrate hydrates. This approach minimizes the environmental impact and reduces operation costs since clathrate hydrates do not generate any chemical waste in both the synthesis and decomposition processes.

For the efficient storage and transportation of hydrogen, numerous materials have been investigated. Among others, clathrate hydrates offer distinct benefits. Clathrate hydrates are nanoporous inclusion compounds composed of a 3D network of polyhedral cages made of hydrogen-bonded ‘host’ water molecules and captured ‘guest’ gas or liquid molecules.

In this study, the research team used two gases, methane and ethane, which have lower equilibrium conditions compared to hydrogen as thermodynamic stabilizers. As a result, they succeeded in stably storing the hydrogen-natural gas compound in hydrates. According to the composition ratio of methane and ethane, structure I or II hydrates can be formed, both of which can stably store hydrogen-natural gas in low-pressure conditions.

The research team found that two hydrogen molecules are stored in small cages in tuned structure I hydrates, while up to three hydrogen molecules can be stored in both small and large cages in tuned structure II hydrates. Hydrates can store gas up to about 170-times its volume and the natural gas used as thermodynamic stabilizers in this study can also be used as an energy source.

The research team developed technology to produce hydrates from ice, produced hydrogen-natural gas hydrates by substitution, and successfully observed that the tuning phenomenon only occurs when hydrogen is involved in hydrate formation from the start for both structures of hydrates.

They expect that the findings can be applied to not only an energy-efficient gas storage material, but also a smart platform to utilize hydrogen natural gas blends, which can serve as a new alternative energy source with targeted hydrogen contents by designing synthetic pathways of mixed gas hydrates.

The research was published online in Energy Storage Materials on June 6, with the title ‘One-step formation of hydrogen clusters in clathrate hydrates stabilized via natural gas blending’.

Professor Lee said, “HNGB will utilize the existing natural gas infrastructure for transportation, so it is very likely that we can commercialize this hydrate system. We are investigating the kinetic performance through a follow-up strategy to increase the volume of gas storage.

This study was funded by the National Research Foundation of Korea and BK21 plus program.

(Figure1. Schematics showing the storage method for hydrogen in a natural gas hydrate using a substitution method and storage method directly from ice to a hydrogen-natural gas hydrate.)

(Figure 2. Artificially synthesized and dissociated hydrogen-natural gas hydrates. The Raman spectra of tuned sI and sII hydrate showing the hydrogen clusters in each cage.)

2019.06.21 View 42374

Hydrogen-Natural Gas Hydrates Harvested by Natural Gas

A hydrogen-natural gas blend (HNGB) can be a game changer only if it can be stored safely and used as a sustainable clean energy resource. A recent study has suggested a new strategy for stably storing hydrogen, using natural gas as a stabilizer. The research proposed a practical gas phase modulator based synthesis of HNGB without generating chemical waste after dissociation for the immediate service.

The research team of Professor Jae Woo Lee from the Department of Chemical and Biomolecular Engineering in collaboration with the Gwangju Institute of Science and Technology (GIST) demonstrated that the natural gas modulator based synthesis leads to significantly reduced synthesis pressure simultaneously with the formation of hydrogen clusters in the confined nanoporous cages of clathrate hydrates. This approach minimizes the environmental impact and reduces operation costs since clathrate hydrates do not generate any chemical waste in both the synthesis and decomposition processes.

For the efficient storage and transportation of hydrogen, numerous materials have been investigated. Among others, clathrate hydrates offer distinct benefits. Clathrate hydrates are nanoporous inclusion compounds composed of a 3D network of polyhedral cages made of hydrogen-bonded ‘host’ water molecules and captured ‘guest’ gas or liquid molecules.

In this study, the research team used two gases, methane and ethane, which have lower equilibrium conditions compared to hydrogen as thermodynamic stabilizers. As a result, they succeeded in stably storing the hydrogen-natural gas compound in hydrates. According to the composition ratio of methane and ethane, structure I or II hydrates can be formed, both of which can stably store hydrogen-natural gas in low-pressure conditions.

The research team found that two hydrogen molecules are stored in small cages in tuned structure I hydrates, while up to three hydrogen molecules can be stored in both small and large cages in tuned structure II hydrates. Hydrates can store gas up to about 170-times its volume and the natural gas used as thermodynamic stabilizers in this study can also be used as an energy source.

The research team developed technology to produce hydrates from ice, produced hydrogen-natural gas hydrates by substitution, and successfully observed that the tuning phenomenon only occurs when hydrogen is involved in hydrate formation from the start for both structures of hydrates.

They expect that the findings can be applied to not only an energy-efficient gas storage material, but also a smart platform to utilize hydrogen natural gas blends, which can serve as a new alternative energy source with targeted hydrogen contents by designing synthetic pathways of mixed gas hydrates.

The research was published online in Energy Storage Materials on June 6, with the title ‘One-step formation of hydrogen clusters in clathrate hydrates stabilized via natural gas blending’.

Professor Lee said, “HNGB will utilize the existing natural gas infrastructure for transportation, so it is very likely that we can commercialize this hydrate system. We are investigating the kinetic performance through a follow-up strategy to increase the volume of gas storage.

This study was funded by the National Research Foundation of Korea and BK21 plus program.

(Figure1. Schematics showing the storage method for hydrogen in a natural gas hydrate using a substitution method and storage method directly from ice to a hydrogen-natural gas hydrate.)

(Figure 2. Artificially synthesized and dissociated hydrogen-natural gas hydrates. The Raman spectra of tuned sI and sII hydrate showing the hydrogen clusters in each cage.)

2019.06.21 View 42374 -

Efficiently Producing Fatty Acids and Biofuels from Glucose

Researchers have presented a new strategy for efficiently producing fatty acids and biofuels that can transform glucose and oleaginous microorganisms into microbial diesel fuel, with one-step direct fermentative production.

The newly developed strain, created by Distinguished Professor Sang Yup Lee and his team, showed the highest efficiency in producing fatty acids and biodiesels ever reported. It will be expected to serve as a new platform to sustainably produce a wide array of fatty acid-based products from glucose and other carbon substrates.

Fossil fuels, which have long been energy resources for our daily lives, are now facing serious challenges: depletion of their reserves and their role in global warming. The production of sustainable bio-based renewable energy has emerged as an essential alternative and many studies to replace fossil fuels are underway. One of the representative examples is biodiesel. Currently, it is mainly being produced through the transesterification of vegetable oils or animal fats.

The research team engineered oleaginous microorganisms, Rhodococcus opacus, to produce fatty acids and their derivatives that can be used as biodiesel from glucose, one of the most abundant and cheap sugars derived from non-edible biomass.

Professor Lee’s team has already engineered Escherichia coli to produce short-chain hydrocarbons, which can be used as gasoline (published in Nature as the cover paper in 2013). However, the production efficiency of the short-chain hydrocarbons using E. coli (0.58 g/L) fell short of the levels required for commercialization.

To overcome these issues, the team employed oil-accumulating Rhodococcus opacus as a host strain in this study. First, the team optimized the cultivation conditions of Rhodococcus opacus to maximize the accumulation of oil (triacylglycerol), which serves as a precursor for the biosynthesis of fatty acids and their derivatives. Then, they systematically analyzed the metabolism of the strain and redesigned it to enable higher levels of fatty acids and two kinds of fatty acid-derived biodiesels (fatty acid ethyl esters and long-chain hydrocarbons) to be produced.

They found that the resulting strains produced 50.2, 21.3, and 5.2 g/L of fatty acids, fatty acid ethyl esters, and long-chain hydrocarbons, respectively. These are all the highest concentrations ever reported by microbial fermentations. It is expected that these strains can contribute to the future industrialization of microbial-based biodiesel production.

“This technology creates fatty acids and biodiesel with high efficiency by utilizing lignocellulose, one of the most abundant resources on the Earth, without depending on fossil fuels and vegetable or animal oils. This will provide new opportunities for oil and petroleum industries, which have long relied on fossil fuels, to turn to sustainable and eco-friendly biotechnologies,” said Professor Lee.

This paper titled “Engineering of an oleaginous bacterium for the production of fatty acids and fuels” was published in Nature Chemical Biology on June 17.

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT through the National Research Foundation (NRF) of Korea (NRF-2012M1A2A2026556 and NRF-2012M1A2A2026557).

(Figure: Metabolic engineering for the production of free fatty acids (FFAs), fatty acid ethyl esters (FAEEs), and long-chain hydrocarbons (LCHCs) in Rhodococcus opacus PD630. Researchers have presented a new strategy for efficiently producing fatty acids and biofuels that can transform glucose and oleaginous microorganisms into microbial diesel fuel, with one-step direct fermentative production.)

# # #

Source:

Hye Mi Kim, Tong Un Chae, So Young Choi, Won Jun Kim and Sang Yup Lee. Engineering of an oleaginous bacterium for the production of fatty acids and fuels. Nature Chemical Biology ( https://www.nature.com/nchembio/ ) DOI: 10.1038/s41589-019-0295-5

Profile

Dr. Sang Yup Lee

leesy@kaist.ac.kr

Distinguished Professor at the Department of Chemical and Biomolecular Engineering

KAIST

2019.06.19 View 50765

Efficiently Producing Fatty Acids and Biofuels from Glucose

Researchers have presented a new strategy for efficiently producing fatty acids and biofuels that can transform glucose and oleaginous microorganisms into microbial diesel fuel, with one-step direct fermentative production.

The newly developed strain, created by Distinguished Professor Sang Yup Lee and his team, showed the highest efficiency in producing fatty acids and biodiesels ever reported. It will be expected to serve as a new platform to sustainably produce a wide array of fatty acid-based products from glucose and other carbon substrates.

Fossil fuels, which have long been energy resources for our daily lives, are now facing serious challenges: depletion of their reserves and their role in global warming. The production of sustainable bio-based renewable energy has emerged as an essential alternative and many studies to replace fossil fuels are underway. One of the representative examples is biodiesel. Currently, it is mainly being produced through the transesterification of vegetable oils or animal fats.

The research team engineered oleaginous microorganisms, Rhodococcus opacus, to produce fatty acids and their derivatives that can be used as biodiesel from glucose, one of the most abundant and cheap sugars derived from non-edible biomass.

Professor Lee’s team has already engineered Escherichia coli to produce short-chain hydrocarbons, which can be used as gasoline (published in Nature as the cover paper in 2013). However, the production efficiency of the short-chain hydrocarbons using E. coli (0.58 g/L) fell short of the levels required for commercialization.

To overcome these issues, the team employed oil-accumulating Rhodococcus opacus as a host strain in this study. First, the team optimized the cultivation conditions of Rhodococcus opacus to maximize the accumulation of oil (triacylglycerol), which serves as a precursor for the biosynthesis of fatty acids and their derivatives. Then, they systematically analyzed the metabolism of the strain and redesigned it to enable higher levels of fatty acids and two kinds of fatty acid-derived biodiesels (fatty acid ethyl esters and long-chain hydrocarbons) to be produced.

They found that the resulting strains produced 50.2, 21.3, and 5.2 g/L of fatty acids, fatty acid ethyl esters, and long-chain hydrocarbons, respectively. These are all the highest concentrations ever reported by microbial fermentations. It is expected that these strains can contribute to the future industrialization of microbial-based biodiesel production.

“This technology creates fatty acids and biodiesel with high efficiency by utilizing lignocellulose, one of the most abundant resources on the Earth, without depending on fossil fuels and vegetable or animal oils. This will provide new opportunities for oil and petroleum industries, which have long relied on fossil fuels, to turn to sustainable and eco-friendly biotechnologies,” said Professor Lee.

This paper titled “Engineering of an oleaginous bacterium for the production of fatty acids and fuels” was published in Nature Chemical Biology on June 17.

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT through the National Research Foundation (NRF) of Korea (NRF-2012M1A2A2026556 and NRF-2012M1A2A2026557).

(Figure: Metabolic engineering for the production of free fatty acids (FFAs), fatty acid ethyl esters (FAEEs), and long-chain hydrocarbons (LCHCs) in Rhodococcus opacus PD630. Researchers have presented a new strategy for efficiently producing fatty acids and biofuels that can transform glucose and oleaginous microorganisms into microbial diesel fuel, with one-step direct fermentative production.)

# # #

Source:

Hye Mi Kim, Tong Un Chae, So Young Choi, Won Jun Kim and Sang Yup Lee. Engineering of an oleaginous bacterium for the production of fatty acids and fuels. Nature Chemical Biology ( https://www.nature.com/nchembio/ ) DOI: 10.1038/s41589-019-0295-5

Profile

Dr. Sang Yup Lee

leesy@kaist.ac.kr

Distinguished Professor at the Department of Chemical and Biomolecular Engineering

KAIST

2019.06.19 View 50765 -

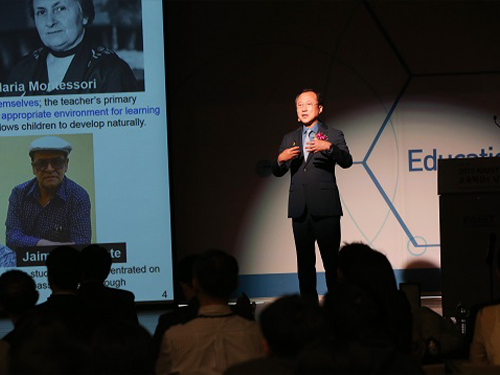

Education Innovation Day Reaffirms Rewarding of Excellence

Professors Tae-Eog Lee and Il-Chul Moon from the Department of Industrial & Systems Engineering received the Linkgenesis Best Teacher Award and the Soo-Young Lee Teaching Innovation Award on May 10. They were each awarded with 10 million KRW in prize money during the Education Innovation Day ceremony held at the Chung Kun-mo conference hall.

The award was endowed by KAIST Alumni Scholarship Chairman Hyung-Kyu Lim and KAIST Foundation Chairman Soo-Young Lee to support the innovation initiative and acknowledge faculty members who made significant contributions to educational innovation and benefited the general public though their innovations.

“KAIST’s vision for excellence and commitment to innovation is a game changer. Educational innovation is one of five pillars of Vision 2031, and it is our priority to foster critical and creative thinking students,” said President Sung-Chul Shin at the ceremony. All the awardees made presentation on their innovative projects and shared their ideas on better pedagogical methodology for next generation.

Professor Lee, dean of the KAIST Academy and the head of the Center for Excellence in Learning & Teaching was recognized for his contribution to enhancing educational quality through innovative learning and teaching methodology development. He has set up an Education 3.0 Initiative, an online education platform for flipped learning at KAIST.

Professor Moon also upgraded the online education platform to the 4.0 version and extended KAIST’s massive online courses through KOOC framework. This open platform offers more than 62 courses, with more than 170 thousand users registered since 2014.

Professor Song-Hong Park from the Department of Bio and Brain Engineering and Professor Jae-Woo Lee from the Department of Chemical and Biomolecular Engineering also won the Excellence Award.

2019.05.10 View 9766

Education Innovation Day Reaffirms Rewarding of Excellence

Professors Tae-Eog Lee and Il-Chul Moon from the Department of Industrial & Systems Engineering received the Linkgenesis Best Teacher Award and the Soo-Young Lee Teaching Innovation Award on May 10. They were each awarded with 10 million KRW in prize money during the Education Innovation Day ceremony held at the Chung Kun-mo conference hall.

The award was endowed by KAIST Alumni Scholarship Chairman Hyung-Kyu Lim and KAIST Foundation Chairman Soo-Young Lee to support the innovation initiative and acknowledge faculty members who made significant contributions to educational innovation and benefited the general public though their innovations.

“KAIST’s vision for excellence and commitment to innovation is a game changer. Educational innovation is one of five pillars of Vision 2031, and it is our priority to foster critical and creative thinking students,” said President Sung-Chul Shin at the ceremony. All the awardees made presentation on their innovative projects and shared their ideas on better pedagogical methodology for next generation.

Professor Lee, dean of the KAIST Academy and the head of the Center for Excellence in Learning & Teaching was recognized for his contribution to enhancing educational quality through innovative learning and teaching methodology development. He has set up an Education 3.0 Initiative, an online education platform for flipped learning at KAIST.

Professor Moon also upgraded the online education platform to the 4.0 version and extended KAIST’s massive online courses through KOOC framework. This open platform offers more than 62 courses, with more than 170 thousand users registered since 2014.

Professor Song-Hong Park from the Department of Bio and Brain Engineering and Professor Jae-Woo Lee from the Department of Chemical and Biomolecular Engineering also won the Excellence Award.

2019.05.10 View 9766 -

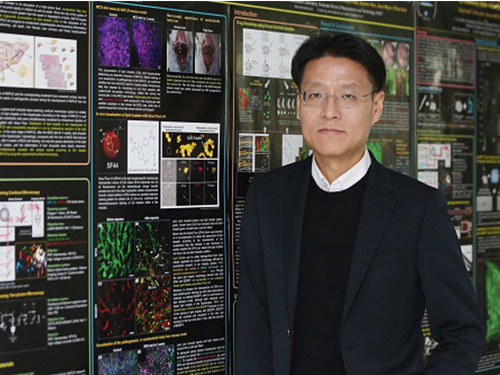

KAIST Identifies the Cause of Sepsis-induced Lung Injury

(Professor Pilhan Kim from the Graduate School of Medical Science and Engineering)

A KAIST research team succeeded in visualizing pulmonary microcirculation and circulating cells in vivo with a custom-built 3D intravital lung microscopic imaging system. They found a type of leukocyte called neutrophils aggregate inside the capillaries during sepsis-induced acute lung injury (ALI), leading to disturbances and dead space in blood microcirculation.

According to the researchers, this phenomenon is responsible for tissue hypoxia causing lung damage in the sepsis model, and mitigating neutrophils improves microcirculation as well as hypoxia.

The lungs are responsible for exchanging oxygen with carbon dioxide gases during the breathing process, providing an essential function for sustaining life. This gas exchange occurs in the alveoli, each surrounded by many capillaries containing the circulating red blood cells.

Researchers have been making efforts to observe microcirculation in alveoli, but it has been technically challenging to capture high-resolution images of capillaries and red blood cells inside the lungs that are in constant breathing motion.

Professor Pilhan Kim from the Graduate School of Medical Science and Engineering and his team developed an ultra-fast laser scanning confocal microscope and an imaging chamber that could minimize the movement of a lung while preserving its respiratory state. They used this technology to successfully capture red blood cell circulation inside the capillaries of animal models with sepsis.

During the process, they found that hypoxia was induced by the increase of dead space inside the lungs of a sepsis model, a space where red blood cells do not circulate. This phenomenon is due to the neutrophils aggregating and trapping inside the capillaries and the arterioles. It was also shown that trapped neutrophils damage the lung tissue in the sepsis model by inhibiting microcirculation as well as releasing reactive oxygen species.

Further studies showed that the aggregated neutrophils inside pulmonary vessels exhibit a higher expression of the Mac-1 receptor (CD11b/CD18), which is a receptor involved in intercellular adhesion, compared to the neutrophils that normally circulate. Additionally, they confirmed that Mac-1 inhibitors can improve inhibited microcirculation, ameliorate hypoxia, while reducing pulmonary edema in the sepsis model.

Their high-resolution 3D intravital microscope technology allows the real-time imaging of living cells inside the lungs. This work is expected to be used in research on various lung diseases, including sepsis.

The research team’s pulmonary circulation imaging and precise analytical techniques will be used as the base technology for developing new diagnostic technologies, evaluating new therapeutic agents for various diseases related to microcirculation.

Professor Kim said, “In the ALI model, the inhibition of pulmonary microcirculation occurs due to neutrophils. By controlling this effect and improving microcirculation, it is possible to eliminate hypoxia and pulmonary edema – a new, effective strategy for treating patients with sepsis.”

Their 3D intravital microscope technology was commercialized through IVIM Technology, Inc., which is a faculty startup at KAIST. They released an all-in-one intravital microscope model called ‘IVM-CM’ and ‘IVM-C’. This next-generation imaging equipment for basic biomedical research on the complex pathophysiology of various human diseases will play a crucial role in the future global bio-health market.

This research, led by Dr. Inwon Park from the Department of Emergency Medicine at Seoul National University Bundang Hospital and formally the Graduate School of Medical Science and Engineering at KAIST, was published in the European Respiratory Journal (2019, 53:1800736) on March 28, 2019.

Figure 1. Custom-built high-speed real-time intravital microscope platform

Figure 2. Illustrative schematic and photo of a 3D intravital lung microscopic imaging system

Figure 3. Aggregation of neutrophils and consequent flow disturbance in pulmonary arteriole in sepsis-induced lung injury

2019.05.07 View 45003

KAIST Identifies the Cause of Sepsis-induced Lung Injury

(Professor Pilhan Kim from the Graduate School of Medical Science and Engineering)

A KAIST research team succeeded in visualizing pulmonary microcirculation and circulating cells in vivo with a custom-built 3D intravital lung microscopic imaging system. They found a type of leukocyte called neutrophils aggregate inside the capillaries during sepsis-induced acute lung injury (ALI), leading to disturbances and dead space in blood microcirculation.

According to the researchers, this phenomenon is responsible for tissue hypoxia causing lung damage in the sepsis model, and mitigating neutrophils improves microcirculation as well as hypoxia.

The lungs are responsible for exchanging oxygen with carbon dioxide gases during the breathing process, providing an essential function for sustaining life. This gas exchange occurs in the alveoli, each surrounded by many capillaries containing the circulating red blood cells.

Researchers have been making efforts to observe microcirculation in alveoli, but it has been technically challenging to capture high-resolution images of capillaries and red blood cells inside the lungs that are in constant breathing motion.

Professor Pilhan Kim from the Graduate School of Medical Science and Engineering and his team developed an ultra-fast laser scanning confocal microscope and an imaging chamber that could minimize the movement of a lung while preserving its respiratory state. They used this technology to successfully capture red blood cell circulation inside the capillaries of animal models with sepsis.

During the process, they found that hypoxia was induced by the increase of dead space inside the lungs of a sepsis model, a space where red blood cells do not circulate. This phenomenon is due to the neutrophils aggregating and trapping inside the capillaries and the arterioles. It was also shown that trapped neutrophils damage the lung tissue in the sepsis model by inhibiting microcirculation as well as releasing reactive oxygen species.

Further studies showed that the aggregated neutrophils inside pulmonary vessels exhibit a higher expression of the Mac-1 receptor (CD11b/CD18), which is a receptor involved in intercellular adhesion, compared to the neutrophils that normally circulate. Additionally, they confirmed that Mac-1 inhibitors can improve inhibited microcirculation, ameliorate hypoxia, while reducing pulmonary edema in the sepsis model.

Their high-resolution 3D intravital microscope technology allows the real-time imaging of living cells inside the lungs. This work is expected to be used in research on various lung diseases, including sepsis.

The research team’s pulmonary circulation imaging and precise analytical techniques will be used as the base technology for developing new diagnostic technologies, evaluating new therapeutic agents for various diseases related to microcirculation.

Professor Kim said, “In the ALI model, the inhibition of pulmonary microcirculation occurs due to neutrophils. By controlling this effect and improving microcirculation, it is possible to eliminate hypoxia and pulmonary edema – a new, effective strategy for treating patients with sepsis.”

Their 3D intravital microscope technology was commercialized through IVIM Technology, Inc., which is a faculty startup at KAIST. They released an all-in-one intravital microscope model called ‘IVM-CM’ and ‘IVM-C’. This next-generation imaging equipment for basic biomedical research on the complex pathophysiology of various human diseases will play a crucial role in the future global bio-health market.

This research, led by Dr. Inwon Park from the Department of Emergency Medicine at Seoul National University Bundang Hospital and formally the Graduate School of Medical Science and Engineering at KAIST, was published in the European Respiratory Journal (2019, 53:1800736) on March 28, 2019.

Figure 1. Custom-built high-speed real-time intravital microscope platform

Figure 2. Illustrative schematic and photo of a 3D intravital lung microscopic imaging system

Figure 3. Aggregation of neutrophils and consequent flow disturbance in pulmonary arteriole in sepsis-induced lung injury

2019.05.07 View 45003 -

On-chip Drug Screening for Identifying Antibiotic Interactions in Eight Hours

(from left: Seunggyu Kimand Professor Jessie Sungyun Jeon)

A KAIST research team developed a microfluidic-based drug screening chip that identifies synergistic interactions between two antibiotics in eight hours. This chip can be a cell-based drug screening platform for exploring critical pharmacological patterns of antibiotic interactions, along with potential applications in screening other cell-type agents and guidance for clinical therapies.

Antibiotic susceptibility testing, which determines types and doses of antibiotics that can effectively inhibit bacterial growth, has become more critical in recent years with the emergence of antibiotic-resistant pathogenic bacteria strains.

To overcome the antibiotic-resistant bacteria, combinatory therapy using two or more kinds of antibiotics has been gaining considerable attention. However, the major problem is that this therapy is not always effective; occasionally, unfavorable antibiotic pairs may worsen results, leading to suppressed antimicrobial effects. Therefore, combinatory testing is a crucial preliminary process to find suitable antibiotic pairs and their concentration range against unknown pathogens, but the conventional testing methods are inconvenient for concentration dilution and sample preparation, and they take more than 24 hours to produce the results.

To reduce time and enhance the efficiency of combinatory testing, Professor Jessie Sungyun Jeon from the Department of Mechanical Engineering, in collaboration with Professor Hyun Jung Chung from the Department of Biological Sciences, developed a high-throughput drug screening chip that generates 121 pairwise concentrations between two antibiotics.

The team utilized a microfluidic chip with a sample volume of a few tens of microliters. This chip enabled 121 pairwise concentrations of two antibiotics to be automatically formed in only 35 minutes.

They loaded a mixture of bacterial samples and agarose into the microchannel and injected reagents with or without antibiotics into the surrounding microchannel. The diffusion of antibiotic molecules from the channel with antibiotics to the one without antibiotics resulted in the formation of two orthogonal concentration gradients of the two antibiotics on the bacteria-trapping agarose gel.

The team observed the inhibition of bacterial growth by the antibiotic orthogonal gradients over six hours with a microscope, and confirmed different patterns of antibiotic pairs, classifying the interaction types into either synergy or antagonism.

Professor Jeon said, “The feasibility of microfluidic-based drug screening chips is promising, and we expect our microfluidic chip to be commercialized and utilized in near future.”

This study, led by Seunggyu Kim, was published in Lab on a Chip (10.1039/c8lc01406j) on March 21, 2019.

Figure 1. Back cover image for the “Lab on a Chip”.

Figure 2. Examples of testing results using the microfluidic chips developed in this research.

2019.04.18 View 31687

On-chip Drug Screening for Identifying Antibiotic Interactions in Eight Hours

(from left: Seunggyu Kimand Professor Jessie Sungyun Jeon)

A KAIST research team developed a microfluidic-based drug screening chip that identifies synergistic interactions between two antibiotics in eight hours. This chip can be a cell-based drug screening platform for exploring critical pharmacological patterns of antibiotic interactions, along with potential applications in screening other cell-type agents and guidance for clinical therapies.

Antibiotic susceptibility testing, which determines types and doses of antibiotics that can effectively inhibit bacterial growth, has become more critical in recent years with the emergence of antibiotic-resistant pathogenic bacteria strains.

To overcome the antibiotic-resistant bacteria, combinatory therapy using two or more kinds of antibiotics has been gaining considerable attention. However, the major problem is that this therapy is not always effective; occasionally, unfavorable antibiotic pairs may worsen results, leading to suppressed antimicrobial effects. Therefore, combinatory testing is a crucial preliminary process to find suitable antibiotic pairs and their concentration range against unknown pathogens, but the conventional testing methods are inconvenient for concentration dilution and sample preparation, and they take more than 24 hours to produce the results.

To reduce time and enhance the efficiency of combinatory testing, Professor Jessie Sungyun Jeon from the Department of Mechanical Engineering, in collaboration with Professor Hyun Jung Chung from the Department of Biological Sciences, developed a high-throughput drug screening chip that generates 121 pairwise concentrations between two antibiotics.

The team utilized a microfluidic chip with a sample volume of a few tens of microliters. This chip enabled 121 pairwise concentrations of two antibiotics to be automatically formed in only 35 minutes.

They loaded a mixture of bacterial samples and agarose into the microchannel and injected reagents with or without antibiotics into the surrounding microchannel. The diffusion of antibiotic molecules from the channel with antibiotics to the one without antibiotics resulted in the formation of two orthogonal concentration gradients of the two antibiotics on the bacteria-trapping agarose gel.

The team observed the inhibition of bacterial growth by the antibiotic orthogonal gradients over six hours with a microscope, and confirmed different patterns of antibiotic pairs, classifying the interaction types into either synergy or antagonism.

Professor Jeon said, “The feasibility of microfluidic-based drug screening chips is promising, and we expect our microfluidic chip to be commercialized and utilized in near future.”

This study, led by Seunggyu Kim, was published in Lab on a Chip (10.1039/c8lc01406j) on March 21, 2019.

Figure 1. Back cover image for the “Lab on a Chip”.

Figure 2. Examples of testing results using the microfluidic chips developed in this research.

2019.04.18 View 31687 -

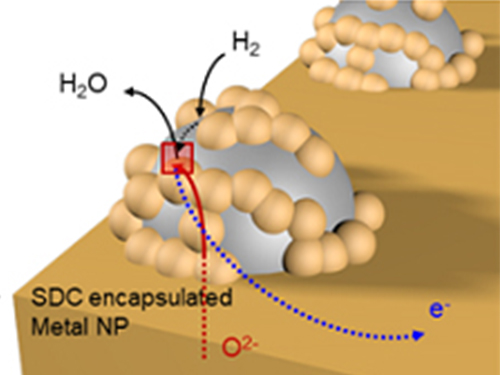

Unravelling Inherent Electrocatalysis to Improve the Performance of Hydrogen Fuel Cells

(Figure 1. Electrode structure for the precise evaluation of the metal nanoparticles’ electrochemical catalytic characteristics at a high temperature.)

A KAIST team presented an ideal electrode design to enhance the performance of high-temperature fuel cells. The new analytical platform with advanced nanoscale patterning method quantitatively revealed the electrochemical value of metal nanoparticles dispersed on the oxide electrode, thus leading to electrode design directions that can be used in a variety of eco-friendly energy technologies.

The team, working under Professor WooChul Jung and Professor Sang Ouk Kim at the Department of Materials Science and Engineering, described an accurate analysis of the reactivity of oxide electrodes boosted by metal nanoparticles, where all particles participate in the reaction. They identified how the metal catalysts activate hydrogen electro-oxidation on the ceria-based electrode surface and quantify how rapidly the reaction rate increases with the proper choice of metals.

Metal nanoparticles with diameters of 10 nanometers or less have become a key component in high-performance heterogeneous catalysts, primarily serving as a catalytic activator. Recent experimental and theoretical findings suggest that the optimization of the chemical nature at the metal and support interfaces is essential for performance improvement.

However, the high cost associated with cell fabrication and operation as well as poorer stability of metal nanoparticles at high temperatures have been a long-standing challenge. To solve this problem, the team utilized a globally recognized metal nano patterning technology that uses block copolymer self-assembled nano templates and succeeded in uniformly synthesizing metal particles 10 nanometers in size on the surface of oxide fuel cell electrodes. They also developed a technology to accurately analyze the catalyst characteristics of single particles at high temperatures and maximize the performance of a fuel cell with minimal catalyst use.

The research team confirmed that platinum, which is a commonly used metal catalyst, could boost fuel cell performance by as much as 21 times even at an amount of 300 nanograms, which only costs about 0.015 KRW.

The team quantitatively identified and compared the characteristics of widely used metal catalysts other than platinum, such as palladium, gold, and cobalt, and also elucidated the precise principle of catalyst performance through theoretical analysis.

(Figure 2. Comparison of the electrochemical catalytic characteristics for various 10nm metal nanoparticles (platinum, palladium, cobalt, gold) at a high temperature.)

Professor Jung said, "We have broken the conventional methods of increasing the amount of catalyst which have deemed inefficient and expensive. Our results suggest a clear idea for high performance fuel cells using very small amounts of nanoparticles. This technology can be applied to many different industrial fields, advancing the commercialization of eco-friendly energy technologies such as fuel cells that generate electricity and electrolytic cells that produce hydrogen from water.”

The research has been published as the cover article of Nature Nanotechnology in the March issue. This research was carried out with support from the Nano-Material Technology Development Program through the National Research Foundation of Korea.

2019.03.28 View 30965

Unravelling Inherent Electrocatalysis to Improve the Performance of Hydrogen Fuel Cells

(Figure 1. Electrode structure for the precise evaluation of the metal nanoparticles’ electrochemical catalytic characteristics at a high temperature.)

A KAIST team presented an ideal electrode design to enhance the performance of high-temperature fuel cells. The new analytical platform with advanced nanoscale patterning method quantitatively revealed the electrochemical value of metal nanoparticles dispersed on the oxide electrode, thus leading to electrode design directions that can be used in a variety of eco-friendly energy technologies.

The team, working under Professor WooChul Jung and Professor Sang Ouk Kim at the Department of Materials Science and Engineering, described an accurate analysis of the reactivity of oxide electrodes boosted by metal nanoparticles, where all particles participate in the reaction. They identified how the metal catalysts activate hydrogen electro-oxidation on the ceria-based electrode surface and quantify how rapidly the reaction rate increases with the proper choice of metals.

Metal nanoparticles with diameters of 10 nanometers or less have become a key component in high-performance heterogeneous catalysts, primarily serving as a catalytic activator. Recent experimental and theoretical findings suggest that the optimization of the chemical nature at the metal and support interfaces is essential for performance improvement.

However, the high cost associated with cell fabrication and operation as well as poorer stability of metal nanoparticles at high temperatures have been a long-standing challenge. To solve this problem, the team utilized a globally recognized metal nano patterning technology that uses block copolymer self-assembled nano templates and succeeded in uniformly synthesizing metal particles 10 nanometers in size on the surface of oxide fuel cell electrodes. They also developed a technology to accurately analyze the catalyst characteristics of single particles at high temperatures and maximize the performance of a fuel cell with minimal catalyst use.

The research team confirmed that platinum, which is a commonly used metal catalyst, could boost fuel cell performance by as much as 21 times even at an amount of 300 nanograms, which only costs about 0.015 KRW.

The team quantitatively identified and compared the characteristics of widely used metal catalysts other than platinum, such as palladium, gold, and cobalt, and also elucidated the precise principle of catalyst performance through theoretical analysis.

(Figure 2. Comparison of the electrochemical catalytic characteristics for various 10nm metal nanoparticles (platinum, palladium, cobalt, gold) at a high temperature.)

Professor Jung said, "We have broken the conventional methods of increasing the amount of catalyst which have deemed inefficient and expensive. Our results suggest a clear idea for high performance fuel cells using very small amounts of nanoparticles. This technology can be applied to many different industrial fields, advancing the commercialization of eco-friendly energy technologies such as fuel cells that generate electricity and electrolytic cells that produce hydrogen from water.”

The research has been published as the cover article of Nature Nanotechnology in the March issue. This research was carried out with support from the Nano-Material Technology Development Program through the National Research Foundation of Korea.

2019.03.28 View 30965 -

The Future Mobility of the Year 2019

KAIST announced the Future Mobility of the Year (FMOTY) 2019. The winners are Volvo 360C, Toyota e-Palette, and Toyota Concept-i WALK.

FMOTY are the first awards that recognizes concept cars that exhibit innovative services and practical transportation technology in three categories: private mobility, public and commercial mobility, and personal mobility.

Figure 1. The winner in the private mobility division, the Volvo 360C

In the private mobility division, the award went to the Volvo 360C. With targeted routes of roughly 186 miles, this vehicle has an ambitious service goal to replace airplanes by traveling these routes with great comfort. Goro Okazaki, a journalist with Car and Driver Japan, said, “The Volvo 360C clearly shows how highly personalized autonomous driving can change the future.”

Figure 2. The winner in the public mobility division, the Toyota e-Palette

The Toyota e-Palette was the winning car in commercial mobility division. This vehicle provides the best solution as a mobile service platform by transforming itself into mobile hospitals, hotels, stores and food trucks. Carlo Calderón, a journalist for Autopista Spain, said, “It has a great strength in remodeling its indoor and outdoor spaces according to various commercial uses.”

Figure 3. The winner in the personal mobility division, the Toyota Concept-i WALK

In the personal mobility division, the award went to the Toyota Concept-i WALK. It was recognized for having an exquisite user environment and artificial intelligent agent, along with an excellent completion. Jun Miao, a journalist with MJ CarShow China, said, “It is aesthetically pleasing. Beyond the upright control of conventional personal mobility, it allows agile control with a joystick.”

FMOTY conducted a screening process for 45 concept cars over three months and 16 renowned automotive experts from 11 countries participated as judges for this award, including Editor in Chief of BBC Top Gear Magazine Charlie Turner and European Bureau Chief of Automobile Magazine Georg Kacher. The judges said that FMOTY was born to propose a new aspect of future mobility, and in terms of evaluating technical and social values of concept cars, FMOTY carries great significance.

Kyung-soo Kim, Dean of the Cho Chun Shik Graduate School of Green Transportation said, “Globally renowned experts in the automotive field participated as judges to elevate the prestige and fairness of the awards. KAIST members were excluded from the entire judging process. I believe that the FMOTY Awards will expand public attention from the present to the future.”

Details can be found on the official website of FMOTY ( www.fmoty.org ).

2019.03.11 View 7835

The Future Mobility of the Year 2019

KAIST announced the Future Mobility of the Year (FMOTY) 2019. The winners are Volvo 360C, Toyota e-Palette, and Toyota Concept-i WALK.

FMOTY are the first awards that recognizes concept cars that exhibit innovative services and practical transportation technology in three categories: private mobility, public and commercial mobility, and personal mobility.

Figure 1. The winner in the private mobility division, the Volvo 360C

In the private mobility division, the award went to the Volvo 360C. With targeted routes of roughly 186 miles, this vehicle has an ambitious service goal to replace airplanes by traveling these routes with great comfort. Goro Okazaki, a journalist with Car and Driver Japan, said, “The Volvo 360C clearly shows how highly personalized autonomous driving can change the future.”

Figure 2. The winner in the public mobility division, the Toyota e-Palette

The Toyota e-Palette was the winning car in commercial mobility division. This vehicle provides the best solution as a mobile service platform by transforming itself into mobile hospitals, hotels, stores and food trucks. Carlo Calderón, a journalist for Autopista Spain, said, “It has a great strength in remodeling its indoor and outdoor spaces according to various commercial uses.”

Figure 3. The winner in the personal mobility division, the Toyota Concept-i WALK

In the personal mobility division, the award went to the Toyota Concept-i WALK. It was recognized for having an exquisite user environment and artificial intelligent agent, along with an excellent completion. Jun Miao, a journalist with MJ CarShow China, said, “It is aesthetically pleasing. Beyond the upright control of conventional personal mobility, it allows agile control with a joystick.”

FMOTY conducted a screening process for 45 concept cars over three months and 16 renowned automotive experts from 11 countries participated as judges for this award, including Editor in Chief of BBC Top Gear Magazine Charlie Turner and European Bureau Chief of Automobile Magazine Georg Kacher. The judges said that FMOTY was born to propose a new aspect of future mobility, and in terms of evaluating technical and social values of concept cars, FMOTY carries great significance.

Kyung-soo Kim, Dean of the Cho Chun Shik Graduate School of Green Transportation said, “Globally renowned experts in the automotive field participated as judges to elevate the prestige and fairness of the awards. KAIST members were excluded from the entire judging process. I believe that the FMOTY Awards will expand public attention from the present to the future.”

Details can be found on the official website of FMOTY ( www.fmoty.org ).

2019.03.11 View 7835 -

Brain-inspired Artificial Intelligence in Robots

(from left: PhD candidate Su Jin An, Dr. Jee Hang Lee and Professor Sang Wan Lee)

Research groups in KAIST, the University of Cambridge, Japan’s National Institute for Information and Communications Technology, and Google DeepMind argue that our understanding of how humans make intelligent decisions has now reached a critical point in which robot intelligence can be significantly enhanced by mimicking strategies that the human brain uses when we make decisions in our everyday lives.

In our rapidly changing world, both humans and autonomous robots constantly need to learn and adapt to new environments. But the difference is that humans are capable of making decisions according to the unique situations, whereas robots still rely on predetermined data to make decisions.

Despite the rapid progress being made in strengthening the physical capability of robots, their central control systems, which govern how robots decide what to do at any one time, are still inferior to those of humans. In particular, they often rely on pre-programmed instructions to direct their behavior, and lack the hallmark of human behavior, that is, the flexibility and capacity to quickly learn and adapt.

Applying neuroscience in robotics, Professor Sang Wan Lee from the Department of Bio and Brain Engineering, KAIST and Professor Ben Seymour from the University of Cambridge and Japan’s National Institute for Information and Communications Technology proposed a case in which robots should be designed based on the principles of the human brain. They argue that robot intelligence can be significantly enhanced by mimicking strategies that the human brain uses during decision-making processes in everyday life.

The problem with importing human-like intelligence into robots has always been a difficult task without knowing the computational principles for how the human brain makes decisions –in other words, how to translate brain activity into computer code for the robots’ ‘brains’.

However, researchers now argue that, following a series of recent discoveries in the field of computational neuroscience, there is enough of this code to effectively write it into robots. One of the examples discovered is the human brain’s ‘meta-controller’, a mechanism by which the brain decides how to switch between different subsystems to carry out complex tasks. Another example is the human pain system, which allows them to protect themselves in potentially hazardous environments. “Copying the brain’s code for these could greatly enhance the flexibility, efficiency, and safety of robots,” Professor Lee said.

The team argued that this inter-disciplinary approach will provide just as many benefits to neuroscience as to robotics. The recent explosion of interest in what lies behind psychiatric disorders such as anxiety, depression, and addiction has given rise to a set of sophisticated theories that are complex and difficult to test without some sort of advanced situation platform.

Professor Seymour explained, “We need a way of modelling the human brain to find how it interacts with the world in real-life to test whether and how different abnormalities in these models give rise to certain disorders. For instance, if we could reproduce anxiety behavior or obsessive-compulsive disorder in a robot, we could then predict what we need to do to treat it in humans.”

The team expects that producing robot models of different psychiatric disorders, in a similar way to how researchers use animal models now, will become a key future technology in clinical research.

The team also stated that there may also be other benefits to humans and intelligent robots learning, acting, and behaving in the same way. In future societies in which humans and robots live and work amongst each other, the ability to cooperate and empathize with robots might be much greater if we feel they think like us.

Professor Seymour said, “We might think that having robots with the human traits of being a bit impulsive or overcautious would be a detriment, but these traits are an unavoidable by-product of human-like intelligence. And it turns out that this is helping us to understand human behavior as human.”

The framework for achieving this brain-inspired artificial intelligence was published in two journals, Science Robotics (10.1126/scirobotics.aav2975) on January 16 and Current Opinion in Behavioral Sciences (10.1016/j.cobeha.2018.12.012) on February 6, 2019.

Figure 1. Overview of neuroscience - robotics approach for decision-making. The figure details key areas for interdisciplinary study (Current Opinion in Behavioral Sciences)

Figure 2. Brain-inspired solutions to robot learning. Neuroscientific views on various aspects of learning and cognition converge and create a new idea called prefrontal metacontrol, which can inspire researchers to design learning agents that can address various key challenges in robotics such as performance-efficiency-speed, cooperation-competition, and exploration-exploitation trade-offs (Science Robotics)

2019.02.20 View 6427

Brain-inspired Artificial Intelligence in Robots

(from left: PhD candidate Su Jin An, Dr. Jee Hang Lee and Professor Sang Wan Lee)

Research groups in KAIST, the University of Cambridge, Japan’s National Institute for Information and Communications Technology, and Google DeepMind argue that our understanding of how humans make intelligent decisions has now reached a critical point in which robot intelligence can be significantly enhanced by mimicking strategies that the human brain uses when we make decisions in our everyday lives.

In our rapidly changing world, both humans and autonomous robots constantly need to learn and adapt to new environments. But the difference is that humans are capable of making decisions according to the unique situations, whereas robots still rely on predetermined data to make decisions.

Despite the rapid progress being made in strengthening the physical capability of robots, their central control systems, which govern how robots decide what to do at any one time, are still inferior to those of humans. In particular, they often rely on pre-programmed instructions to direct their behavior, and lack the hallmark of human behavior, that is, the flexibility and capacity to quickly learn and adapt.

Applying neuroscience in robotics, Professor Sang Wan Lee from the Department of Bio and Brain Engineering, KAIST and Professor Ben Seymour from the University of Cambridge and Japan’s National Institute for Information and Communications Technology proposed a case in which robots should be designed based on the principles of the human brain. They argue that robot intelligence can be significantly enhanced by mimicking strategies that the human brain uses during decision-making processes in everyday life.

The problem with importing human-like intelligence into robots has always been a difficult task without knowing the computational principles for how the human brain makes decisions –in other words, how to translate brain activity into computer code for the robots’ ‘brains’.

However, researchers now argue that, following a series of recent discoveries in the field of computational neuroscience, there is enough of this code to effectively write it into robots. One of the examples discovered is the human brain’s ‘meta-controller’, a mechanism by which the brain decides how to switch between different subsystems to carry out complex tasks. Another example is the human pain system, which allows them to protect themselves in potentially hazardous environments. “Copying the brain’s code for these could greatly enhance the flexibility, efficiency, and safety of robots,” Professor Lee said.

The team argued that this inter-disciplinary approach will provide just as many benefits to neuroscience as to robotics. The recent explosion of interest in what lies behind psychiatric disorders such as anxiety, depression, and addiction has given rise to a set of sophisticated theories that are complex and difficult to test without some sort of advanced situation platform.

Professor Seymour explained, “We need a way of modelling the human brain to find how it interacts with the world in real-life to test whether and how different abnormalities in these models give rise to certain disorders. For instance, if we could reproduce anxiety behavior or obsessive-compulsive disorder in a robot, we could then predict what we need to do to treat it in humans.”

The team expects that producing robot models of different psychiatric disorders, in a similar way to how researchers use animal models now, will become a key future technology in clinical research.

The team also stated that there may also be other benefits to humans and intelligent robots learning, acting, and behaving in the same way. In future societies in which humans and robots live and work amongst each other, the ability to cooperate and empathize with robots might be much greater if we feel they think like us.

Professor Seymour said, “We might think that having robots with the human traits of being a bit impulsive or overcautious would be a detriment, but these traits are an unavoidable by-product of human-like intelligence. And it turns out that this is helping us to understand human behavior as human.”

The framework for achieving this brain-inspired artificial intelligence was published in two journals, Science Robotics (10.1126/scirobotics.aav2975) on January 16 and Current Opinion in Behavioral Sciences (10.1016/j.cobeha.2018.12.012) on February 6, 2019.

Figure 1. Overview of neuroscience - robotics approach for decision-making. The figure details key areas for interdisciplinary study (Current Opinion in Behavioral Sciences)

Figure 2. Brain-inspired solutions to robot learning. Neuroscientific views on various aspects of learning and cognition converge and create a new idea called prefrontal metacontrol, which can inspire researchers to design learning agents that can address various key challenges in robotics such as performance-efficiency-speed, cooperation-competition, and exploration-exploitation trade-offs (Science Robotics)

2019.02.20 View 6427 -

KAIST Develops Core Technology for Ultra-small 3D Image Sensor

(from left: Dr. Jong-Bum Yo, PhD candidate Seong-Hwan Kimand Professor Hyo-Hoon Park)

A KAIST research team developed a silicon optical phased array (OPA) chip, which can be a core component for three-dimensional image sensors. This research was co-led by PhD candidate Seong-Hwan Kim and Dr. Jong-Bum You from the National Nanofab Center (NNFC).

A 3D image sensor adds distance information to a two-dimensional image, such as a photo, to recognize it as a 3D image. It plays a vital role in various electronics including autonomous vehicles, drones, robots, and facial recognition systems, which require accurate measurement of the distance from objects.

Many automobile and drone companies are focusing on developing 3D image sensor systems, based on mechanical light detection and ranging (LiDAR) systems. However, it can only get as small as the size of a fist and has a high possibility of malfunctioning because it employs a mechanical method for laser beam-steering.

OPAs have gained a great attention as a key component to implement solid-state LiDAR because it can control the light direction electronically without moving parts. Silicon-based OPAs are small, durable, and can be mass-produced through conventional Si-CMOS processes.

However, in the development of OPAs, a big issue has been raised about how to achieve wide beam-steering in transversal and longitudinal directions. In the transversal direction, a wide beam-steering has been implemented, relatively easily, through a thermo-optic or electro-optic control of the phase shifters integrated with a 1D array. But the longitudinal beam-steering has been remaining as a technical challenge since only a narrow steering was possible with the same 1D array by changing the wavelengths of light, which is hard to implement in semiconductor processes.

If a light wavelength is changed, characteristics of element devices consisting the OPA can vary, which makes it difficult to control the light direction with reliability as well as to integrate a wavelength-tunable laser on a silicon-based chip. Therefore, it is essential to devise a new structure that can easily adjust the radiated light in both transversal and longitudinal directions.

By integrating tunable radiator, instead of tunable laser in a conventional OPA, Professor Hyo-Hoon Park from the School of Electrical Engineering and his team developed an ultra-small, low-power OPA chip that facilitates a wide 2D beam-steering with a monochromatic light source.

This OPA structure allows the minimizing of the 3D image sensors, as small as a dragonfly’s eye.

According to the team, the OPA can function as a 3D image sensor and also as a wireless transmitter sending the image data to a desired direction, enabling high-quality image data to be freely communicated between electronic devices.

Kim said, “It’s not an easy task to integrate a tunable light source in the OPA structures of previous works. We hope our research proposing a tunable radiator makes a big step towards commercializing OPAs.”

Dr. You added, “We will be able to support application researches of 3D image sensors, especially for facial recognition with smartphones and augmented reality services. We will try to prepare a processing platform in NNFC that provides core technologies of the 3D image sensor fabrication.”

This research was published in Optics Letters on January 15.

Figure 1.The manufactured OPA chip

Figure 2. Schematic feature showing an application of the OPA to a 3D image sensor

2019.02.08 View 7516

KAIST Develops Core Technology for Ultra-small 3D Image Sensor

(from left: Dr. Jong-Bum Yo, PhD candidate Seong-Hwan Kimand Professor Hyo-Hoon Park)

A KAIST research team developed a silicon optical phased array (OPA) chip, which can be a core component for three-dimensional image sensors. This research was co-led by PhD candidate Seong-Hwan Kim and Dr. Jong-Bum You from the National Nanofab Center (NNFC).

A 3D image sensor adds distance information to a two-dimensional image, such as a photo, to recognize it as a 3D image. It plays a vital role in various electronics including autonomous vehicles, drones, robots, and facial recognition systems, which require accurate measurement of the distance from objects.

Many automobile and drone companies are focusing on developing 3D image sensor systems, based on mechanical light detection and ranging (LiDAR) systems. However, it can only get as small as the size of a fist and has a high possibility of malfunctioning because it employs a mechanical method for laser beam-steering.

OPAs have gained a great attention as a key component to implement solid-state LiDAR because it can control the light direction electronically without moving parts. Silicon-based OPAs are small, durable, and can be mass-produced through conventional Si-CMOS processes.

However, in the development of OPAs, a big issue has been raised about how to achieve wide beam-steering in transversal and longitudinal directions. In the transversal direction, a wide beam-steering has been implemented, relatively easily, through a thermo-optic or electro-optic control of the phase shifters integrated with a 1D array. But the longitudinal beam-steering has been remaining as a technical challenge since only a narrow steering was possible with the same 1D array by changing the wavelengths of light, which is hard to implement in semiconductor processes.

If a light wavelength is changed, characteristics of element devices consisting the OPA can vary, which makes it difficult to control the light direction with reliability as well as to integrate a wavelength-tunable laser on a silicon-based chip. Therefore, it is essential to devise a new structure that can easily adjust the radiated light in both transversal and longitudinal directions.

By integrating tunable radiator, instead of tunable laser in a conventional OPA, Professor Hyo-Hoon Park from the School of Electrical Engineering and his team developed an ultra-small, low-power OPA chip that facilitates a wide 2D beam-steering with a monochromatic light source.

This OPA structure allows the minimizing of the 3D image sensors, as small as a dragonfly’s eye.

According to the team, the OPA can function as a 3D image sensor and also as a wireless transmitter sending the image data to a desired direction, enabling high-quality image data to be freely communicated between electronic devices.

Kim said, “It’s not an easy task to integrate a tunable light source in the OPA structures of previous works. We hope our research proposing a tunable radiator makes a big step towards commercializing OPAs.”

Dr. You added, “We will be able to support application researches of 3D image sensors, especially for facial recognition with smartphones and augmented reality services. We will try to prepare a processing platform in NNFC that provides core technologies of the 3D image sensor fabrication.”

This research was published in Optics Letters on January 15.

Figure 1.The manufactured OPA chip

Figure 2. Schematic feature showing an application of the OPA to a 3D image sensor

2019.02.08 View 7516 -

President Shin Speaks on Closing the Skills Gap at the WEF

(President Shin poses (far right) with the National University of Singapore President Tan Eng Chye (center) along with Distinguished Professor Sang Yup Lee in Davos last week.)

President Sung-Chul Shin shared his ideas on how reskilling is a critical element of growth, dynamism, and competitiveness for countries during a session titled “Closing the Skills Gap: Creating a Reskilling Revolution” at the World Economic Forum on January 24 in Davos.

While discussing a reskilling imperative alongside French Labor Minister Muriel Penicaud, he presented how the Korean government and KAIST are responding to the socio-economic transformation of workforces in the Fourth Industrial Revolution. After their presentation, Minister of Economy and Enterprise of Spain Nadia Calvirno Santamaria, Minister of Commerce and Industry of Oman Ali bin Masoud bin Ali Al Sunaidy, and Minister of Petroleum and Natural Gas, Skill Development, and Entrepreneurship of India Dharmendra Pradhan shared their views on the course of decision making regarding the proactive practices and policies they have applied for closing the gaps from their countries’ perspectives.

President Shin presented how to upskill and reskill SMEs and startups, the real players who will jumpstart the economy in the Fourth Industrial Revolution. He explained that the government is striving to change the existing structure of the economy, which is dominated by a few giant conglomerates. He added that the Korean government is trying to support SMEs and startups in terms of both funding and technology reskilling in order to rejuvenate the economy.

To better align itself with the government’s efforts, KAIST has introduced SME 4.0. SME 4.0 proposes to innovate the production process through the creation of a partnered platform between KAIST and SMEs across the country. With this platform, KAIST assists local SMEs for standardizing and systemizing all their processes of production, delivery, and management with enterprise resources planning (ERP) and manufacturing execution systems (MES). In addition, SME 4.0 offers retraining and re-tooling programs by linking the data generated through this platform in real time to better facilitate SMEs’ smart business.

(President Shin shakes hands with H.E.Mohammed Al-Tuwairi, Minister of Economy and Planning of Saudi Arabia before holding a bilaterla meeting in Davos.)

President Shin also explained about upskilling the leading corporations’ technological competitiveness, partnering with major leading corporations for upskilling their advanced technologies.

He also held a series of bilateral meetings with dignitaries attending the WEF annual meeting to discuss partnerships and collaborations. He also attended the Global University Leaders Forum (GULF), a community composed of 28 presidents from the world’s top universities on January 23. President Shin, who is on the advisory board of the Center for Fourth Industrial Revolution (C4IR), also participated in the board meeting and discussed the upcoming launching of the Korea C4IR, which will open at KAIST in March.

2019.01.28 View 7681

President Shin Speaks on Closing the Skills Gap at the WEF

(President Shin poses (far right) with the National University of Singapore President Tan Eng Chye (center) along with Distinguished Professor Sang Yup Lee in Davos last week.)

President Sung-Chul Shin shared his ideas on how reskilling is a critical element of growth, dynamism, and competitiveness for countries during a session titled “Closing the Skills Gap: Creating a Reskilling Revolution” at the World Economic Forum on January 24 in Davos.

While discussing a reskilling imperative alongside French Labor Minister Muriel Penicaud, he presented how the Korean government and KAIST are responding to the socio-economic transformation of workforces in the Fourth Industrial Revolution. After their presentation, Minister of Economy and Enterprise of Spain Nadia Calvirno Santamaria, Minister of Commerce and Industry of Oman Ali bin Masoud bin Ali Al Sunaidy, and Minister of Petroleum and Natural Gas, Skill Development, and Entrepreneurship of India Dharmendra Pradhan shared their views on the course of decision making regarding the proactive practices and policies they have applied for closing the gaps from their countries’ perspectives.

President Shin presented how to upskill and reskill SMEs and startups, the real players who will jumpstart the economy in the Fourth Industrial Revolution. He explained that the government is striving to change the existing structure of the economy, which is dominated by a few giant conglomerates. He added that the Korean government is trying to support SMEs and startups in terms of both funding and technology reskilling in order to rejuvenate the economy.

To better align itself with the government’s efforts, KAIST has introduced SME 4.0. SME 4.0 proposes to innovate the production process through the creation of a partnered platform between KAIST and SMEs across the country. With this platform, KAIST assists local SMEs for standardizing and systemizing all their processes of production, delivery, and management with enterprise resources planning (ERP) and manufacturing execution systems (MES). In addition, SME 4.0 offers retraining and re-tooling programs by linking the data generated through this platform in real time to better facilitate SMEs’ smart business.

(President Shin shakes hands with H.E.Mohammed Al-Tuwairi, Minister of Economy and Planning of Saudi Arabia before holding a bilaterla meeting in Davos.)

President Shin also explained about upskilling the leading corporations’ technological competitiveness, partnering with major leading corporations for upskilling their advanced technologies.

He also held a series of bilateral meetings with dignitaries attending the WEF annual meeting to discuss partnerships and collaborations. He also attended the Global University Leaders Forum (GULF), a community composed of 28 presidents from the world’s top universities on January 23. President Shin, who is on the advisory board of the Center for Fourth Industrial Revolution (C4IR), also participated in the board meeting and discussed the upcoming launching of the Korea C4IR, which will open at KAIST in March.

2019.01.28 View 7681 -

A Comprehensive Metabolic Map for Bio-Based Chemicals Production

A KAIST research team completed a metabolic map that charts all available strategies and pathways of chemical reactions that lead to the production of various industrial bio-based chemicals.

The team was led by Distinguished Professor Sang Yup Lee, who has produced high-quality metabolic engineering and systems engineering research for decades, and made the hallmark chemicals map after seven years of studies.

The team presented a very detailed analysis on metabolic engineering for the production of a wide range of industrial chemicals, fuels, and materials. Surveying the current trends in the bio-based production of chemicals in industrial biotechnology, the team thoroughly examined the current status of industrial chemicals produced using biological and/or chemical reactions.

This comprehensive map is expected to serve as a blueprint for the visual and intuitive inspection of biological and/or chemical reactions for the production of interest from renewable resources. The team also compiled an accompanying poster to visually present the synthetic pathways of chemicals in the context of their microbial metabolism.

As metabolic engineering has become increasing powerful in addressing limited fossil resources, climate change, and other environmental issues, the number of microbially produced chemicals using biomass as a carbon source has increased substantially. The sustainable production of industrial chemicals and materials has been explored with micro-organisms as cell factories and renewable nonfood biomass as raw materials for alternative petroleum. The engineering of these micro-organism has increasingly become more efficient and effective with the help of metabolic engineering – a practice of engineering using the metabolism of living organisms to produce a desired metabolite.

With the establishment of systems metabolic engineering – the integration of metabolic engineering with tools and strategies from systems biology, synthetic biology and evolutionary engineering – the speed at which micro-organisms are being engineered has reached an unparalleled pace.

In order to evaluate the current state at which metabolically engineered micro-organisms can produce a large portfolio of industrial chemicals, the team conducted an extensive review of the literature and mapped them out on a poster. This resulting poster, termed the bio-based chemicals map, presents synthetic pathways for industrial chemicals, which consist of biological and/or chemical reactions.

Industrial chemicals and their production routes are presented in the context of central carbon metabolic pathways as these key metabolites serve as precursors for the chemicals to be produced. The resulting biochemical map allows the detection and analysis of optimal synthetic pathways for a given industrial chemical. In addition to the poster, the authors have compiled a list of chemicals that have successfully been produced using micro-organisms and a list of the corresponding companies producing them commercially. This thorough review of the literature and the accompanying analytical summary will be an important resource for researchers interested in the production of chemicals from renewable biomass sources.

Metabolically engineered micro-organisms have already made a huge contribution toward the sustainable production of chemicals using renewable resources. Professor Lee said he wanted a detailed survey of the current state and capacity of bio-based chemicals production.

“We are so excited that this review and poster will expand further discussion on the production of important chemicals through engineered micro-organisms and also combined biological and chemical means in a more sustainable manner,” he explained.

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biofineries from the Ministry of Science and ICT through the National Research Foundation of Korea.

For further information, Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering at KAIST ( leesy@kaist.ac.kr , Tel: +82-42-350-3930)

Figure: Bio-based chemicals production through biological and chemical routes. This metabolic map describes representative chemicals that can be produced either by biological and/or chemical means. Red arrows represent chemical routes and blue arrows represent biological routes. Intermediate metabolites in the metabolism of a living organism can serve as a platform toward the production of industrially relevant chemicals. A more comprehensive map presented by the team can be found as a poster in the review.

2019.01.15 View 7794

A Comprehensive Metabolic Map for Bio-Based Chemicals Production

A KAIST research team completed a metabolic map that charts all available strategies and pathways of chemical reactions that lead to the production of various industrial bio-based chemicals.

The team was led by Distinguished Professor Sang Yup Lee, who has produced high-quality metabolic engineering and systems engineering research for decades, and made the hallmark chemicals map after seven years of studies.

The team presented a very detailed analysis on metabolic engineering for the production of a wide range of industrial chemicals, fuels, and materials. Surveying the current trends in the bio-based production of chemicals in industrial biotechnology, the team thoroughly examined the current status of industrial chemicals produced using biological and/or chemical reactions.

This comprehensive map is expected to serve as a blueprint for the visual and intuitive inspection of biological and/or chemical reactions for the production of interest from renewable resources. The team also compiled an accompanying poster to visually present the synthetic pathways of chemicals in the context of their microbial metabolism.

As metabolic engineering has become increasing powerful in addressing limited fossil resources, climate change, and other environmental issues, the number of microbially produced chemicals using biomass as a carbon source has increased substantially. The sustainable production of industrial chemicals and materials has been explored with micro-organisms as cell factories and renewable nonfood biomass as raw materials for alternative petroleum. The engineering of these micro-organism has increasingly become more efficient and effective with the help of metabolic engineering – a practice of engineering using the metabolism of living organisms to produce a desired metabolite.

With the establishment of systems metabolic engineering – the integration of metabolic engineering with tools and strategies from systems biology, synthetic biology and evolutionary engineering – the speed at which micro-organisms are being engineered has reached an unparalleled pace.

In order to evaluate the current state at which metabolically engineered micro-organisms can produce a large portfolio of industrial chemicals, the team conducted an extensive review of the literature and mapped them out on a poster. This resulting poster, termed the bio-based chemicals map, presents synthetic pathways for industrial chemicals, which consist of biological and/or chemical reactions.