Nano

-

Ultra Elastic Electrode Material Developed

KAIST research team succeeded in developing the next generation flexible and elastic electrode material crucial in the development of flexible displays, wearable computers, and etc.

Professor Jeon Seok Woo’s team of the department of Materials Science and Engineering succeeded in the development of a super elastic material.

The result of the experiment was introduced as the research highlight in Nature Communications and is especially significant as the main driving force behind the achievement were domestic researchers.

Professor Jeons team developed a structured three dimensional nano-porous structure over a 1inch by 1inch area that is 10micrometers in thickness. The structure is fabricated using world’s largest area three dimensional nano patterning technique.

The nano-porous structure was injected with elastomeric material and was subsequently removed to yield an inverse three dimensional elastic nano material. The pores were infiltrated with liquid conductive material which yielded a super elastic flexible electrode.

The fabricated electrode showed amazing elasticity levels and was able to light LED lamps in a 200% stretched state without decrease in electrical conductivity.

Conventional methods included folding and expanding a material like an accordion or creating a mesh-like structure by making holes in the material. However these methods yielded materials with limited elasticity and even 100% stretching resulted in the drastic decrease in electrical conductivity.

Professor Jeon expects the domestically developed technology to obtain the upper hand in the market and make great contributions in both science and society.

2012.07.26 View 10275

Ultra Elastic Electrode Material Developed

KAIST research team succeeded in developing the next generation flexible and elastic electrode material crucial in the development of flexible displays, wearable computers, and etc.

Professor Jeon Seok Woo’s team of the department of Materials Science and Engineering succeeded in the development of a super elastic material.

The result of the experiment was introduced as the research highlight in Nature Communications and is especially significant as the main driving force behind the achievement were domestic researchers.

Professor Jeons team developed a structured three dimensional nano-porous structure over a 1inch by 1inch area that is 10micrometers in thickness. The structure is fabricated using world’s largest area three dimensional nano patterning technique.

The nano-porous structure was injected with elastomeric material and was subsequently removed to yield an inverse three dimensional elastic nano material. The pores were infiltrated with liquid conductive material which yielded a super elastic flexible electrode.

The fabricated electrode showed amazing elasticity levels and was able to light LED lamps in a 200% stretched state without decrease in electrical conductivity.

Conventional methods included folding and expanding a material like an accordion or creating a mesh-like structure by making holes in the material. However these methods yielded materials with limited elasticity and even 100% stretching resulted in the drastic decrease in electrical conductivity.

Professor Jeon expects the domestically developed technology to obtain the upper hand in the market and make great contributions in both science and society.

2012.07.26 View 10275 -

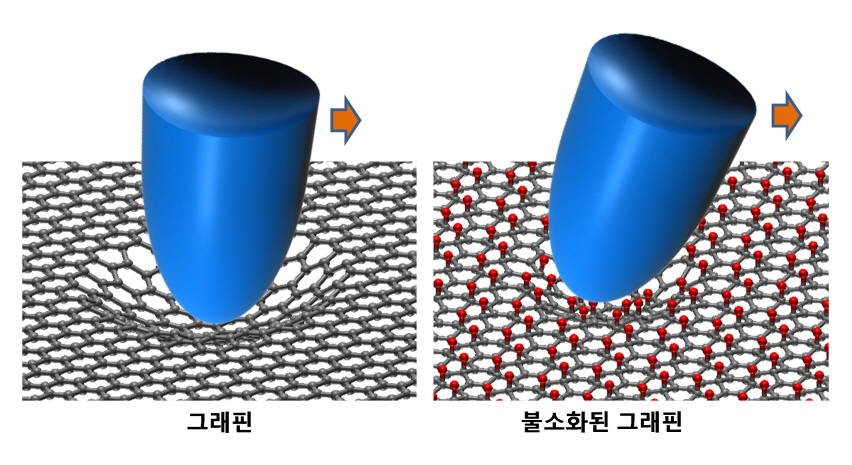

KAIST researchers verify and control the mechanical properties of graphene

KAIST researchers have successfully verified and controlled the mechanical properties of graphene, a next-generation material. Professor Park Jung Yong from the EEWS Graduate School and Professor Kim Yong Hyun from the Graduate School of Nanoscience and Technology have succeeded in fluorinating a single atomic-layered graphene sample and controlling its frictional and adhesive properties. This is the first time the frictional properties of graphene have been examined at the atomic level, and the technology is expected to be applied to nano-sized robots and microscopic joints.

Graphene is often dubbed “the dream material” because of its ability to conduct high amounts of electricity even when bent, making it the next-generation substitute for silicon semiconductors, paving the way for flexible display and wearable computer technologies. Graphene also has high potential applications in mechanical engineering because of its great material strength, but its mechanical properties remained elusive until now.

Professor Park’s research team successfully produced individual graphene samples with fluorine-deficiency at the atomic level by placing the samples in Fluoro-xenon (XeF2) gas and applying heat. The surface of the graphene was scanned using a micro probe and a high vacuum atomic microscope to measure its dynamic properties.

The research team found that the fluorinated graphene sample had 6 times more friction and 0.7 times more adhesiveness than the original graphene. Electrical measurements confirmed the fluorination process, and the analysis of the findings helped setup the theory of frictional changes in graphene.

Professor Park stated that “graphene can be used for the lubrication of joints in nano-sized devices” and that this research has numerous applications such as the coating of graphene-based microdynamic devices.

This research was published in the online June edition of Nano Letters and was supported by the Ministry of Science, Technology, and Education and the National Research Foundation as part of the World Class University (WCU) program.

2012.07.24 View 18102

KAIST researchers verify and control the mechanical properties of graphene

KAIST researchers have successfully verified and controlled the mechanical properties of graphene, a next-generation material. Professor Park Jung Yong from the EEWS Graduate School and Professor Kim Yong Hyun from the Graduate School of Nanoscience and Technology have succeeded in fluorinating a single atomic-layered graphene sample and controlling its frictional and adhesive properties. This is the first time the frictional properties of graphene have been examined at the atomic level, and the technology is expected to be applied to nano-sized robots and microscopic joints.

Graphene is often dubbed “the dream material” because of its ability to conduct high amounts of electricity even when bent, making it the next-generation substitute for silicon semiconductors, paving the way for flexible display and wearable computer technologies. Graphene also has high potential applications in mechanical engineering because of its great material strength, but its mechanical properties remained elusive until now.

Professor Park’s research team successfully produced individual graphene samples with fluorine-deficiency at the atomic level by placing the samples in Fluoro-xenon (XeF2) gas and applying heat. The surface of the graphene was scanned using a micro probe and a high vacuum atomic microscope to measure its dynamic properties.

The research team found that the fluorinated graphene sample had 6 times more friction and 0.7 times more adhesiveness than the original graphene. Electrical measurements confirmed the fluorination process, and the analysis of the findings helped setup the theory of frictional changes in graphene.

Professor Park stated that “graphene can be used for the lubrication of joints in nano-sized devices” and that this research has numerous applications such as the coating of graphene-based microdynamic devices.

This research was published in the online June edition of Nano Letters and was supported by the Ministry of Science, Technology, and Education and the National Research Foundation as part of the World Class University (WCU) program.

2012.07.24 View 18102 -

Professor Kyung Wook Baek Wins the Best Thesis Award at the 2012 Pan-Pacific Microelectronic Symposium

Prof. Kyung Wook Baek from KAIST"s material science department has won the Best Thesis Award at the 2012 Pan-Pacific Microelectronic Symposium.

The title of this thesis was "Recent Advances in Anisotropic Conductive Adhesives Technology : Materials and Processes". Prof Baek had the honor of having his thesis be appointed the best thesis of the symposium.

This thesis includes his 15 years of research on ACAs which are a key element of display and semiconductor packaging technology.

Prof. Baek"s research results has been recognized as incredibly innovative in the field of ACAs and ultrasonic connection devices. This thesis has been recognized as setting the foundation for commercialization by professionals from all over the world at the symposium.

Prof. Baek has announced two innovative technologies on ACAs at the symposium.

One is a technology that merges the nanofiber technology with the ATAs. This technology was highly applauded for overcoming the problem of electric connection in micro-pitch display semiconductors, and successfully applying this to electronic packaging materials.

Currently, commercialization process based on the patent is ongoing. It is expected that we will be able to take hold of the entire market once the commercialization succeeds.

The other technology was to improve the liability and overcome the limits of the current flow in ACAs through the use of solder molecules. This is also undergoing commercialization process for use in mobile electronic devices.

Together with this, Prof.Baek has reported an innovative case where the original heat compression process was replaced with a new ultrasonic process. This discovery is deemed to be extremely great due to its implications in replacing all heat compression systems. This too will soon be commercialized

Prof.Baek has played a crucial role in the development of electronic packaging material and processing technology. He has written the largest number of theses in this area, and has proven himself to be the world"s best through winning this award.

2012.05.10 View 11202

Professor Kyung Wook Baek Wins the Best Thesis Award at the 2012 Pan-Pacific Microelectronic Symposium

Prof. Kyung Wook Baek from KAIST"s material science department has won the Best Thesis Award at the 2012 Pan-Pacific Microelectronic Symposium.

The title of this thesis was "Recent Advances in Anisotropic Conductive Adhesives Technology : Materials and Processes". Prof Baek had the honor of having his thesis be appointed the best thesis of the symposium.

This thesis includes his 15 years of research on ACAs which are a key element of display and semiconductor packaging technology.

Prof. Baek"s research results has been recognized as incredibly innovative in the field of ACAs and ultrasonic connection devices. This thesis has been recognized as setting the foundation for commercialization by professionals from all over the world at the symposium.

Prof. Baek has announced two innovative technologies on ACAs at the symposium.

One is a technology that merges the nanofiber technology with the ATAs. This technology was highly applauded for overcoming the problem of electric connection in micro-pitch display semiconductors, and successfully applying this to electronic packaging materials.

Currently, commercialization process based on the patent is ongoing. It is expected that we will be able to take hold of the entire market once the commercialization succeeds.

The other technology was to improve the liability and overcome the limits of the current flow in ACAs through the use of solder molecules. This is also undergoing commercialization process for use in mobile electronic devices.

Together with this, Prof.Baek has reported an innovative case where the original heat compression process was replaced with a new ultrasonic process. This discovery is deemed to be extremely great due to its implications in replacing all heat compression systems. This too will soon be commercialized

Prof.Baek has played a crucial role in the development of electronic packaging material and processing technology. He has written the largest number of theses in this area, and has proven himself to be the world"s best through winning this award.

2012.05.10 View 11202 -

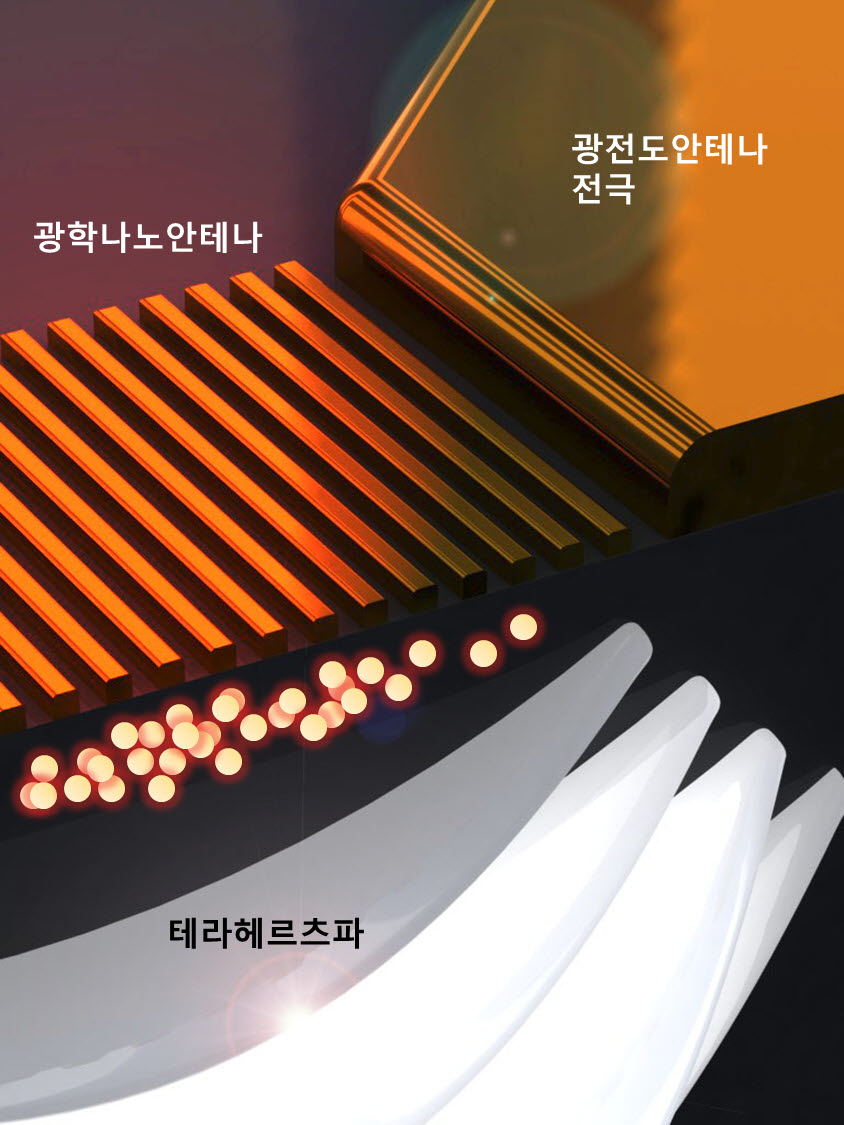

The output of terahertz waves enhanced by KAIST team

KAIST researchers have greatly improved the output of terahertz waves, the blue ocean of the optics world. This technology is expected to be applied to portable X-ray cameras, small bio-diagnostic systems, and in many other devices.

Professor Ki-Hun Jeong"s research team from the Department of Bio and Brain Engineering used optical nano-antenna technology to increase the output of terahertz waves by three times.

Terahertz waves are electromagnetic waves with frequencies between 100GHz to 30THz. They are produced when a femtosecond (10^-15 s) pulse laser is shone on a semiconductor substrate with photoconduction antennas, causing a photocurrent pulse of one picosecond (10^-12 s). Their long wavelengths, in comparison to visible light and infrared rays, give terahertz waves a high penetration power with less energy than X-rays, making them less harmful to humans.

These qualities allow us to see through objects, just as X-rays do, but because terahertz waves absorb certain frequencies, we can detect hidden explosives or drugs, which was not possible with X-rays. We can even identify fake drugs. Furthermore, using the spectral information, we can analyze a material"s innate qualities without chemical processing, making it possible to identify skin diseases without harming the body. However, the output was not sufficient to be used in biosensors and other applications.

Prof. Jeong"s team added optical nano-antennas, made from gold nano-rods, in between the photoconduction antennas and optimized the structure. This resulted in nanoplasmonic resonance in the photoconduction substrate, increasing the degree of integration of the photocurrent pulse and resulting in a three times larger output.

Hence, it is not only possible to see through objects more clearly, but it is also possible to analyze components without a biopsy.

Professor Jeong explained, "This technology, coupled with the miniaturization of terahertz devices, can be applied to endoscopes to detect early epithelial cancer" and that he will focus on creating and commercializing these biosensor systems.

This research was published in the March issue of the international nanotechnology journal ACS Nano and was funded by the Korea Evaluation Institute of Industrial Technology and the National Research Foundation of Korea.

Figure: Mimetic diagram of a THz generator with nano-antennas

2012.04.29 View 14206

The output of terahertz waves enhanced by KAIST team

KAIST researchers have greatly improved the output of terahertz waves, the blue ocean of the optics world. This technology is expected to be applied to portable X-ray cameras, small bio-diagnostic systems, and in many other devices.

Professor Ki-Hun Jeong"s research team from the Department of Bio and Brain Engineering used optical nano-antenna technology to increase the output of terahertz waves by three times.

Terahertz waves are electromagnetic waves with frequencies between 100GHz to 30THz. They are produced when a femtosecond (10^-15 s) pulse laser is shone on a semiconductor substrate with photoconduction antennas, causing a photocurrent pulse of one picosecond (10^-12 s). Their long wavelengths, in comparison to visible light and infrared rays, give terahertz waves a high penetration power with less energy than X-rays, making them less harmful to humans.

These qualities allow us to see through objects, just as X-rays do, but because terahertz waves absorb certain frequencies, we can detect hidden explosives or drugs, which was not possible with X-rays. We can even identify fake drugs. Furthermore, using the spectral information, we can analyze a material"s innate qualities without chemical processing, making it possible to identify skin diseases without harming the body. However, the output was not sufficient to be used in biosensors and other applications.

Prof. Jeong"s team added optical nano-antennas, made from gold nano-rods, in between the photoconduction antennas and optimized the structure. This resulted in nanoplasmonic resonance in the photoconduction substrate, increasing the degree of integration of the photocurrent pulse and resulting in a three times larger output.

Hence, it is not only possible to see through objects more clearly, but it is also possible to analyze components without a biopsy.

Professor Jeong explained, "This technology, coupled with the miniaturization of terahertz devices, can be applied to endoscopes to detect early epithelial cancer" and that he will focus on creating and commercializing these biosensor systems.

This research was published in the March issue of the international nanotechnology journal ACS Nano and was funded by the Korea Evaluation Institute of Industrial Technology and the National Research Foundation of Korea.

Figure: Mimetic diagram of a THz generator with nano-antennas

2012.04.29 View 14206 -

Inexpensive Separation Method of Graphene Developed

The problem with commercializing graphene that is synthesized onto metals over a wide area is that it can not be separated from the metal. However, a groundbreaking separation technology which is both cheap and environment friendly has been developed.

Prof. Taek soo Kim and Prof. Byung Jin Cho"s research teams have conducted this research under the support of the Global Frontier program and Researcher Support Program initiated by The Ministry of Education and Science and Korea Research Foundation. The research results have been posted on the online news flash of Nano Letters on februrary 29th. (Thesis title: Direct Measurement of Adhesion Energy of Monolayer Graphene As-Grown on Copper and Its Application to Renewable Transfer Process)

The research has generated exact results on the interfacial adhesive energy of graphene and its surface material for the first time. Through this, the catalyst metal are no longer to be used just once, but will be used for an infinite number of times, thereby being ecofriendly and efficient.

Wide area graphine synthesized onto the catalyst meatal are used in various ways such as for display and for solar cells. There has been much research going on in this field. However, in order to use this wide area graphene, the graphene must be removed from the catalyst metal without damage.

Until now, the metal had been melted away through the use of chemical substances in order to separate the graphene. However, this method has been very problematic. The metal can not be reused, the costs are very high, much harmful wastes were created in the process of melting the metals, and the process was very complicated.

The research teams of Professors Taek Su Kim and Byung Jin Cho measured the interfacial adhesive energy of the synthesized graphene and learned that it could be easily removed.

Also, the mechanically removed graphene was successfully used in creating molecular electronic devices directly. This has thus innovatively shortened the graphene manufacturing process. Also, it has been confirmed that the metalic board can be reused multiple times after the graphene is removed. A new, ecofriendly and cost friendly method of graphene manufacturing has been paved.

Through this discovery, it is expected that graphene will become easier to manufacture and that the period til the commercialization date of graphene will therefore be greatly reduced

Prof. Cho stated " This reserach has much academical meaning significance in that it has successfully defined the surfacial adhesive energy between the graphene and its catalyst material and it should receive much attention in that it solved the largest technical problem involved in the production of graphene.

2012.04.04 View 16097

Inexpensive Separation Method of Graphene Developed

The problem with commercializing graphene that is synthesized onto metals over a wide area is that it can not be separated from the metal. However, a groundbreaking separation technology which is both cheap and environment friendly has been developed.

Prof. Taek soo Kim and Prof. Byung Jin Cho"s research teams have conducted this research under the support of the Global Frontier program and Researcher Support Program initiated by The Ministry of Education and Science and Korea Research Foundation. The research results have been posted on the online news flash of Nano Letters on februrary 29th. (Thesis title: Direct Measurement of Adhesion Energy of Monolayer Graphene As-Grown on Copper and Its Application to Renewable Transfer Process)

The research has generated exact results on the interfacial adhesive energy of graphene and its surface material for the first time. Through this, the catalyst metal are no longer to be used just once, but will be used for an infinite number of times, thereby being ecofriendly and efficient.

Wide area graphine synthesized onto the catalyst meatal are used in various ways such as for display and for solar cells. There has been much research going on in this field. However, in order to use this wide area graphene, the graphene must be removed from the catalyst metal without damage.

Until now, the metal had been melted away through the use of chemical substances in order to separate the graphene. However, this method has been very problematic. The metal can not be reused, the costs are very high, much harmful wastes were created in the process of melting the metals, and the process was very complicated.

The research teams of Professors Taek Su Kim and Byung Jin Cho measured the interfacial adhesive energy of the synthesized graphene and learned that it could be easily removed.

Also, the mechanically removed graphene was successfully used in creating molecular electronic devices directly. This has thus innovatively shortened the graphene manufacturing process. Also, it has been confirmed that the metalic board can be reused multiple times after the graphene is removed. A new, ecofriendly and cost friendly method of graphene manufacturing has been paved.

Through this discovery, it is expected that graphene will become easier to manufacture and that the period til the commercialization date of graphene will therefore be greatly reduced

Prof. Cho stated " This reserach has much academical meaning significance in that it has successfully defined the surfacial adhesive energy between the graphene and its catalyst material and it should receive much attention in that it solved the largest technical problem involved in the production of graphene.

2012.04.04 View 16097 -

A Step Closer to Ultra Slim Mobile Phone

Professor Baek Kyung Wook (department of Material Science and Engineering) succeeded in developing an ultra-thin conjugation technique that can perfectly replace the modular contact in electronic devices.

The research team developed a compound material using ultra-fine solder-adhesive film and developed the vertical ultrasonic conjugation process thereby making a reliable utra-thin conjugation.

The developed technique allowed for very thin and reliable conjugation and will be able to replace the socket type connector and is expected to revolutionize the electronic device industry.

In mobile electronic devices like the smartphone, the trend is to incorporate various functional modules like camera, display, touchscreens, etc. in addition to striving for miniaturization of the device.

Recently the problem was the fact that the number of modules within the device was increasing due to the incorporation of various functions, and consequently the volume that these modules took up increased as well, which made miniaturization almost impossible.

Professor Baek‘s team succeeded in improving upon this problem by creating a compound material that has ultra-fine solder particles that can melt to form alloy fusion with the electrode and thermosetting adhesive film that can wrap around the electrode and provide mechanical protection.

The use of this material made it possible to reduce the thickness of the connector by hundredth fold which improved electrical, mechanical properties and highly reliable.

From a processing standpoint the conventional conjugation process involved heating the mechanical block and was therefore hard to manage its production and also consumed 1000W and took up to 15 seconds.

By contrast, Professor Baek’s team’s new process uses only ultrasound to locally heat and melt the conjugation point itself thereby reducing power consumption to 100W and conjugation time to 1~5 seconds.

The technique developed by Professor Baek and Lee Ki Won Doctorate student was awarded Excellent Dissertation Award by world famous journals like the Electronic Components and Technology Conference and is being recognized worldwide.

2012.01.31 View 11113

A Step Closer to Ultra Slim Mobile Phone

Professor Baek Kyung Wook (department of Material Science and Engineering) succeeded in developing an ultra-thin conjugation technique that can perfectly replace the modular contact in electronic devices.

The research team developed a compound material using ultra-fine solder-adhesive film and developed the vertical ultrasonic conjugation process thereby making a reliable utra-thin conjugation.

The developed technique allowed for very thin and reliable conjugation and will be able to replace the socket type connector and is expected to revolutionize the electronic device industry.

In mobile electronic devices like the smartphone, the trend is to incorporate various functional modules like camera, display, touchscreens, etc. in addition to striving for miniaturization of the device.

Recently the problem was the fact that the number of modules within the device was increasing due to the incorporation of various functions, and consequently the volume that these modules took up increased as well, which made miniaturization almost impossible.

Professor Baek‘s team succeeded in improving upon this problem by creating a compound material that has ultra-fine solder particles that can melt to form alloy fusion with the electrode and thermosetting adhesive film that can wrap around the electrode and provide mechanical protection.

The use of this material made it possible to reduce the thickness of the connector by hundredth fold which improved electrical, mechanical properties and highly reliable.

From a processing standpoint the conventional conjugation process involved heating the mechanical block and was therefore hard to manage its production and also consumed 1000W and took up to 15 seconds.

By contrast, Professor Baek’s team’s new process uses only ultrasound to locally heat and melt the conjugation point itself thereby reducing power consumption to 100W and conjugation time to 1~5 seconds.

The technique developed by Professor Baek and Lee Ki Won Doctorate student was awarded Excellent Dissertation Award by world famous journals like the Electronic Components and Technology Conference and is being recognized worldwide.

2012.01.31 View 11113 -

Ten Breakthroughs of the Year 2011 by Science

Porous Zeolite Crytals

Science, an internationally renowned scientific journal based in the US, has recently released a special issue of “Breakthrough of the Year, 2011,” dated December 23, 2011. In the issue, the journal introduces ten most important research breakthroughs made this year, and Professor Ryong Ryoo, Department of Chemistry at KAIST, was one of the scientists behind such notable advancements in 2011. Professor Ryoo has been highly regarded internationally for his research on the development of synthetic version of zeolites, a family of porous minerals that is widely used for products such as laundry detergents, cat litters, etc. Below is the article from Science, stating the zeolite research:

For Science’s “Breakthrough of the Year, 2011”, please go to:

http://www.sciencemag.org/site/special/btoy2011/

[Excerpt from the December 23, 2011 Issue of Science]

Industrial Molecules, Tailor-Made

If you ever doubt that chemistry is still a creative endeavor, just look at zeolites. This family of porous minerals was first discovered in 1756. They"re formed from different arrangements of aluminum, silicon, and oxygen atoms that crystallize into holey structures pocked with a perfect arrangement of pores. Over the past 250 years, 40 natural zeolites have been discovered, and chemists have chipped in roughly 150 more synthetic versions.

View larger version:

In this page

In a new window

Assembly required.

Porous zeolite crystals are widely used as filters and catalysts. This year, researchers found new ways to tailor the size of their pores and create thinner, cheaper membranes.

CREDIT: K. VAROON ET AL., SCIENCE334, 6052 (7 OCTOBER 2001)

This abundance isn"t just for show. Three million tons of zeolites are produced every year for use in laundry detergents, cat litter, and many other products. But zeolites really strut their stuff in two uses: as catalysts and molecular sieves. Oil refineries use zeolite catalysts to break down long hydrocarbon chains in oil into the shorter, volatile hydrocarbons in gasoline. And the minerals" small, regularly arranged pores make them ideal filters for purifying everything from the air on spaceships to the contaminated water around the nuclear reactors destroyed earlier this year in Fukushima, Japan.

Zeolites have their limitations, though. Their pores are almost universally tiny, making it tough to use them as catalysts for large molecules. And they"re difficult to form into ultrathin membranes, which researchers would like to do to enable cheaper separations. But progress by numerous teams on zeolite synthesis this year gave this “mature” area of chemistry new life.

Researchers in South Korea crafted a family of zeolites in which the usual network of small pores is surrounded by walls holed with larger voids. That combination of large and small pores should lead to catalysts for numerous large organic molecules.

Labs in Spain and China produced related large- and small-pore zeolites by using a combination of inorganic and organic materials to guide the structures as they formed.

Meanwhile, researchers in France and Germany discovered that, by carefully controlling growth conditions, they could form a large-pore zeolite without the need for the expensive organic compounds typically used to guide their architecture as they grow. The advance opens the way for cheaper catalysts. In yet another lab, researchers in Minnesota came up with a new route for making ultrathin zeolite membranes, which are likely to be useful as a wide variety of chemically selective filters.

This surge of molecular wizardry provides a vivid reminder that the creativity of chemists keeps their field ever young.

Related References and Web Sites

2011.12.23 View 13572

Ten Breakthroughs of the Year 2011 by Science

Porous Zeolite Crytals

Science, an internationally renowned scientific journal based in the US, has recently released a special issue of “Breakthrough of the Year, 2011,” dated December 23, 2011. In the issue, the journal introduces ten most important research breakthroughs made this year, and Professor Ryong Ryoo, Department of Chemistry at KAIST, was one of the scientists behind such notable advancements in 2011. Professor Ryoo has been highly regarded internationally for his research on the development of synthetic version of zeolites, a family of porous minerals that is widely used for products such as laundry detergents, cat litters, etc. Below is the article from Science, stating the zeolite research:

For Science’s “Breakthrough of the Year, 2011”, please go to:

http://www.sciencemag.org/site/special/btoy2011/

[Excerpt from the December 23, 2011 Issue of Science]

Industrial Molecules, Tailor-Made

If you ever doubt that chemistry is still a creative endeavor, just look at zeolites. This family of porous minerals was first discovered in 1756. They"re formed from different arrangements of aluminum, silicon, and oxygen atoms that crystallize into holey structures pocked with a perfect arrangement of pores. Over the past 250 years, 40 natural zeolites have been discovered, and chemists have chipped in roughly 150 more synthetic versions.

View larger version:

In this page

In a new window

Assembly required.

Porous zeolite crystals are widely used as filters and catalysts. This year, researchers found new ways to tailor the size of their pores and create thinner, cheaper membranes.

CREDIT: K. VAROON ET AL., SCIENCE334, 6052 (7 OCTOBER 2001)

This abundance isn"t just for show. Three million tons of zeolites are produced every year for use in laundry detergents, cat litter, and many other products. But zeolites really strut their stuff in two uses: as catalysts and molecular sieves. Oil refineries use zeolite catalysts to break down long hydrocarbon chains in oil into the shorter, volatile hydrocarbons in gasoline. And the minerals" small, regularly arranged pores make them ideal filters for purifying everything from the air on spaceships to the contaminated water around the nuclear reactors destroyed earlier this year in Fukushima, Japan.

Zeolites have their limitations, though. Their pores are almost universally tiny, making it tough to use them as catalysts for large molecules. And they"re difficult to form into ultrathin membranes, which researchers would like to do to enable cheaper separations. But progress by numerous teams on zeolite synthesis this year gave this “mature” area of chemistry new life.

Researchers in South Korea crafted a family of zeolites in which the usual network of small pores is surrounded by walls holed with larger voids. That combination of large and small pores should lead to catalysts for numerous large organic molecules.

Labs in Spain and China produced related large- and small-pore zeolites by using a combination of inorganic and organic materials to guide the structures as they formed.

Meanwhile, researchers in France and Germany discovered that, by carefully controlling growth conditions, they could form a large-pore zeolite without the need for the expensive organic compounds typically used to guide their architecture as they grow. The advance opens the way for cheaper catalysts. In yet another lab, researchers in Minnesota came up with a new route for making ultrathin zeolite membranes, which are likely to be useful as a wide variety of chemically selective filters.

This surge of molecular wizardry provides a vivid reminder that the creativity of chemists keeps their field ever young.

Related References and Web Sites

2011.12.23 View 13572 -

Spintronics: A high wire act by Nanowerk News

An article by Nanowerk News on the integration of ferromagnetic nanowire arrays on grapheme substrates was published. Professor Bong-Soo Kim from the Department of Chemistry, KAIST, led the research in conjunction with Hanyang University and Samsung in Korea.

http://www.nanowerk.com/news/newsid=22204.php

Posted: Jul 25th, 2011

Spintronics: A high wire act

(Nanowerk News) Graphene is a promising material for a wide range of applications due to its remarkable mechanical and electronic properties. An application of particular interest is spin-based electronics, or spintronics, in which the spin orientation of an electron is used to perform circuit functions in addition to its charge. Bongsoo Kim and colleagues from KAIST, Hanyang University and Samsung in Korea now report the integration of ferromagnetic nanowire arrays on graphene substrates, opening up a route for the construction of graphene-based spintronic devices using nanowires as spin-injecting contacts ("Epitaxially Integrating Ferromagnetic Fe1.3Ge Nanowire Arrays on Few-Layer Graphene").

The spin of an electron is a property that, like charge, can be used to encode, process and transport information. However, spin information is easily lost in most media, which has made spintronics difficult to realize in practice. In graphene, on the other hand, spin can be preserved for longer due to its peculiar electron transport properties. "Low intrinsic spin–orbit coupling, long spin diffusion lengths and vanishing hyperfine interaction are features of graphene that make it a promising medium for spin transport," explains Kim.

Scanning electron microscopy image of vertical iron germanide nanowires grown on graphene. (© ACS 2011)

A prerequisite for the realization of spintronic devices based on graphene is its integration with ferromagnetic contacts to allow spin injection. Kim and his co-workers found that nanowires of iron germanide (Fe1.3Ge) serve as efficient contacts for this purpose. "Iron germanide nanowires show low resistivity and room-temperature ferromagnetism, and they are compatible with existing complementary metal–oxide–semiconductor technologies," says Kim.

To produce the atomically well-defined interfacial contact between the nanowires and the graphene surface needed for optimum device performance, the researchers deposited the contacts by an epitaxial method based on chemical vapor transport. Through careful adjustment of deposition parameters such as carrier gas flow rate and reaction temperature, the researchers produced vertically aligned nanowires that are closely lattice-matched to the graphene sheets (see image).

Initially preparing the graphene sheets on a substrate of silicon oxide allowed the researchers to isolate the final nanowire–graphene structure by etching and then transfer it to another substrate, greatly expanding the versatility of the approach. It is a delicate process, however. "It is necessary to transfer the graphene films onto the substrate very carefully in order to avoid folding and wrinkling of the graphene," says Kim.

Source: Tokyo Institute of Technology

2011.07.26 View 11779

Spintronics: A high wire act by Nanowerk News

An article by Nanowerk News on the integration of ferromagnetic nanowire arrays on grapheme substrates was published. Professor Bong-Soo Kim from the Department of Chemistry, KAIST, led the research in conjunction with Hanyang University and Samsung in Korea.

http://www.nanowerk.com/news/newsid=22204.php

Posted: Jul 25th, 2011

Spintronics: A high wire act

(Nanowerk News) Graphene is a promising material for a wide range of applications due to its remarkable mechanical and electronic properties. An application of particular interest is spin-based electronics, or spintronics, in which the spin orientation of an electron is used to perform circuit functions in addition to its charge. Bongsoo Kim and colleagues from KAIST, Hanyang University and Samsung in Korea now report the integration of ferromagnetic nanowire arrays on graphene substrates, opening up a route for the construction of graphene-based spintronic devices using nanowires as spin-injecting contacts ("Epitaxially Integrating Ferromagnetic Fe1.3Ge Nanowire Arrays on Few-Layer Graphene").

The spin of an electron is a property that, like charge, can be used to encode, process and transport information. However, spin information is easily lost in most media, which has made spintronics difficult to realize in practice. In graphene, on the other hand, spin can be preserved for longer due to its peculiar electron transport properties. "Low intrinsic spin–orbit coupling, long spin diffusion lengths and vanishing hyperfine interaction are features of graphene that make it a promising medium for spin transport," explains Kim.

Scanning electron microscopy image of vertical iron germanide nanowires grown on graphene. (© ACS 2011)

A prerequisite for the realization of spintronic devices based on graphene is its integration with ferromagnetic contacts to allow spin injection. Kim and his co-workers found that nanowires of iron germanide (Fe1.3Ge) serve as efficient contacts for this purpose. "Iron germanide nanowires show low resistivity and room-temperature ferromagnetism, and they are compatible with existing complementary metal–oxide–semiconductor technologies," says Kim.

To produce the atomically well-defined interfacial contact between the nanowires and the graphene surface needed for optimum device performance, the researchers deposited the contacts by an epitaxial method based on chemical vapor transport. Through careful adjustment of deposition parameters such as carrier gas flow rate and reaction temperature, the researchers produced vertically aligned nanowires that are closely lattice-matched to the graphene sheets (see image).

Initially preparing the graphene sheets on a substrate of silicon oxide allowed the researchers to isolate the final nanowire–graphene structure by etching and then transfer it to another substrate, greatly expanding the versatility of the approach. It is a delicate process, however. "It is necessary to transfer the graphene films onto the substrate very carefully in order to avoid folding and wrinkling of the graphene," says Kim.

Source: Tokyo Institute of Technology

2011.07.26 View 11779 -

Biomimetic Carbon Nanotube Fiber Synthesis Technology Developed

The byssus of the mussel allows it to live in harsh conditions where it is constantly battered by crashing waves by allowing the mussel to latch onto the seaside rocks. This particular characteristic of the mussel is due to the unique structure and high adhesiveness of the mussel’s byssus.

KAIST’s Professor Hong Soon Hyung (Department of Material Science and Engineering) and Professor Lee Hae Shin (Department of Chemistry) and the late Professor Park Tae Kwan (Department of Bio Engineering) were able to reproduce the mussel’s byssus using carbon nanotubes.

The carbon nanotube, since its discovery in 1991, was regarded as the next generation material due to its electrical, thermal, and mechanical properties. However due to its short length of several nanometers, its industrial use was limited.

The KAIST research team referred to the structure of the byssus of the mussel to solve this problem.

The byssus is composed of collagen fibers and Mefp-1 protein which are in a cross-linking structure. The Mefp-1 protein has catecholamine that allows it to bind strongly with the collagen fiber.

In the artificial structure, the carbon nanotube took on the role of the collagen fibers and the macromolecular adhesive took on the role of the catecholamine. The result was a fiber that was ultra-light and ultra-strong.

The results of the experiment were published in the Advanced Materials magazine and is patent registered both domestically and internationally.

2011.06.20 View 14539

Biomimetic Carbon Nanotube Fiber Synthesis Technology Developed

The byssus of the mussel allows it to live in harsh conditions where it is constantly battered by crashing waves by allowing the mussel to latch onto the seaside rocks. This particular characteristic of the mussel is due to the unique structure and high adhesiveness of the mussel’s byssus.

KAIST’s Professor Hong Soon Hyung (Department of Material Science and Engineering) and Professor Lee Hae Shin (Department of Chemistry) and the late Professor Park Tae Kwan (Department of Bio Engineering) were able to reproduce the mussel’s byssus using carbon nanotubes.

The carbon nanotube, since its discovery in 1991, was regarded as the next generation material due to its electrical, thermal, and mechanical properties. However due to its short length of several nanometers, its industrial use was limited.

The KAIST research team referred to the structure of the byssus of the mussel to solve this problem.

The byssus is composed of collagen fibers and Mefp-1 protein which are in a cross-linking structure. The Mefp-1 protein has catecholamine that allows it to bind strongly with the collagen fiber.

In the artificial structure, the carbon nanotube took on the role of the collagen fibers and the macromolecular adhesive took on the role of the catecholamine. The result was a fiber that was ultra-light and ultra-strong.

The results of the experiment were published in the Advanced Materials magazine and is patent registered both domestically and internationally.

2011.06.20 View 14539 -

From Pencil Lead to Batteries: the Unlimited Transformation of Carbon

Those materials, like lead or diamond, made completely up of Carbon are being used in numerous ways as materials or parts. Especially with the discovery of carbon nanotubes, graphemes, and other carbon based materials in nanoscale, the carbon based materials are receiving a lot of interest in both fields of research and industry.

The carbon nanotubes and graphemes are considered as the ‘dream material’ and have a structure of a cross section of a bee hive. Such structure allows the material to have strength higher than that of a diamond and still be able to bend, be transparent and also conduct electricity. However the problem up till now was that these carbon structures appeared in layers and in bunches and were therefore hard to separate to individual layers or tubes.

Professor Kim Sang Wook’s research team developed the technology that can assemble the grapheme and carbon nanotubes in a three dimensional manner.

The team was able to assemble the grapheme ad carbon nanotubes in an entirely new three dimensional structure. In addition, the team was able to efficiently extract single layered grapheme from cheap pencil lead.

Professor Kim is scheduled to give a guest lecture in the “Materials Research Society” in San Francisco and the paper was published in ‘Advanced Functional Materials’ magazine as an ‘Invited Feature Article’.

2011.05.11 View 12873

From Pencil Lead to Batteries: the Unlimited Transformation of Carbon

Those materials, like lead or diamond, made completely up of Carbon are being used in numerous ways as materials or parts. Especially with the discovery of carbon nanotubes, graphemes, and other carbon based materials in nanoscale, the carbon based materials are receiving a lot of interest in both fields of research and industry.

The carbon nanotubes and graphemes are considered as the ‘dream material’ and have a structure of a cross section of a bee hive. Such structure allows the material to have strength higher than that of a diamond and still be able to bend, be transparent and also conduct electricity. However the problem up till now was that these carbon structures appeared in layers and in bunches and were therefore hard to separate to individual layers or tubes.

Professor Kim Sang Wook’s research team developed the technology that can assemble the grapheme and carbon nanotubes in a three dimensional manner.

The team was able to assemble the grapheme ad carbon nanotubes in an entirely new three dimensional structure. In addition, the team was able to efficiently extract single layered grapheme from cheap pencil lead.

Professor Kim is scheduled to give a guest lecture in the “Materials Research Society” in San Francisco and the paper was published in ‘Advanced Functional Materials’ magazine as an ‘Invited Feature Article’.

2011.05.11 View 12873 -

Dong Ah Newspaper Publish '100 Koreans who will Represent Korea in 10 years'

The 2011 list of ‘100 Koreans who will Represent Korea in 10 years’ published by Dong Ah Newspaper includes people of varying ages, vocation, and gender.

In terms of University Professors, five professors from each of KAIST and SNU (Seoul National University) were selected. Especially Professor Charles Ahn received the most votes due to his world class talent, potential, and dedication.

Professor Kim Sang Wook of the Department of Materials Science and Engineering is the world leading expert in the field of ‘Atom Construction Nanotechnology’ which deals with using macromolecules, carbon nanotubes, and grapheme to form various structures. His work on ‘low cost, large area nano patterning technology’ is expected to overcome the limits of nano treatment processes and its application in semi-conductors or displays carries great promise.

Professor Kim Eun Sung of the Department of Physics discovered a new quantum behavior, supersolidity, in a low temperature, solid Helium for the first time in the world and is the leading scientist that leads the mechanics behind such a phenomenon. Professor Kim is leading the field of supersolidity through his works on hidden phase in a low temperature solid Helium, the understanding the role of crystalline faults in the supersolidity phenomenon, and the destruction of the supersolid’s macromolecular phenomenon through spinning solids.

Professor Charles Ahn of the Graduate School of Innovation and Technology Management has been working as the developer of the V3 series (an anti-computer virus Vaccine Program) since 1988. He established the ‘Charles Ahn Research Center’ in 1995 and his solid and practical management style won him rave reviews. Professor Ahn was appointed as the Professor of the Graduate School of Innovation and Technology Management and has been teaching entrepreneurial perspective and Technology Management.

Professor Lee Sang Yeop of the Department of Biology and Chemical Engineering developed world’s most efficient production method of succinic acid, developed high efficiency, tailored, culture for the production of key amino acids, Valine and Threonine, developed the production culture off bio-buthanol which is superior to bio-ethanol, and is widely known as one of the leaders in the field of metabolic engineering.

Professor Jeong Ha Woong of the Department of Physics is being regarded as world leader in the field of Complex System Network Sciences. He implemented Statistical Physics to Complex Systems and also used the concept of ‘Networks’ and published 80 papers, including 5 which were published in Nature Magazine.

2011.04.30 View 15036

Dong Ah Newspaper Publish '100 Koreans who will Represent Korea in 10 years'

The 2011 list of ‘100 Koreans who will Represent Korea in 10 years’ published by Dong Ah Newspaper includes people of varying ages, vocation, and gender.

In terms of University Professors, five professors from each of KAIST and SNU (Seoul National University) were selected. Especially Professor Charles Ahn received the most votes due to his world class talent, potential, and dedication.

Professor Kim Sang Wook of the Department of Materials Science and Engineering is the world leading expert in the field of ‘Atom Construction Nanotechnology’ which deals with using macromolecules, carbon nanotubes, and grapheme to form various structures. His work on ‘low cost, large area nano patterning technology’ is expected to overcome the limits of nano treatment processes and its application in semi-conductors or displays carries great promise.

Professor Kim Eun Sung of the Department of Physics discovered a new quantum behavior, supersolidity, in a low temperature, solid Helium for the first time in the world and is the leading scientist that leads the mechanics behind such a phenomenon. Professor Kim is leading the field of supersolidity through his works on hidden phase in a low temperature solid Helium, the understanding the role of crystalline faults in the supersolidity phenomenon, and the destruction of the supersolid’s macromolecular phenomenon through spinning solids.

Professor Charles Ahn of the Graduate School of Innovation and Technology Management has been working as the developer of the V3 series (an anti-computer virus Vaccine Program) since 1988. He established the ‘Charles Ahn Research Center’ in 1995 and his solid and practical management style won him rave reviews. Professor Ahn was appointed as the Professor of the Graduate School of Innovation and Technology Management and has been teaching entrepreneurial perspective and Technology Management.

Professor Lee Sang Yeop of the Department of Biology and Chemical Engineering developed world’s most efficient production method of succinic acid, developed high efficiency, tailored, culture for the production of key amino acids, Valine and Threonine, developed the production culture off bio-buthanol which is superior to bio-ethanol, and is widely known as one of the leaders in the field of metabolic engineering.

Professor Jeong Ha Woong of the Department of Physics is being regarded as world leader in the field of Complex System Network Sciences. He implemented Statistical Physics to Complex Systems and also used the concept of ‘Networks’ and published 80 papers, including 5 which were published in Nature Magazine.

2011.04.30 View 15036 -

Professor Min Beom Ki develops metamaterial with high index of refraction

Korean research team was able to theoretically prove that a metamaterial with high index of refraction does exist and produced it experimentally.

Professor Min Beom Ki, Dr. Choi Moo Han, and Doctorate candidate Lee Seung Hoon was joined by Dr. Kang Kwang Yong’s team from ETRI, KAIST’s Professor Less Yong Hee’s team, and Seoul National University’s Professor Park Nam Kyu’s team. The research was funded by the Basic Research Support Program initiated by the Ministry of Education, Science, and Technology and Korea Research Federation.

The result of the research was published in ‘Nature’ magazine and is one of the few researches carried out by teams composed entirely of Koreans.

Metamaterials are materials that have physical properties beyond those materials’ properties that are found in nature. It is formed not with atoms, but with synthetic atoms which have smaller structures than wavelengths.

The optical and electromagnetic waves’ properties of metamaterials can be altered significantly which has caught the attention of scientists worldwide.

Professor Min Beom Ki’s team independently designed and created a dielectric metamaterial with high polarization and low diamagnetism with an index of refraction of 38.6, highest synthesized index value.

It is expected that the result of the experiment will help develop high resolution imaging system and ultra small, hyper sensitive optical devices.

2011.02.23 View 19901

Professor Min Beom Ki develops metamaterial with high index of refraction

Korean research team was able to theoretically prove that a metamaterial with high index of refraction does exist and produced it experimentally.

Professor Min Beom Ki, Dr. Choi Moo Han, and Doctorate candidate Lee Seung Hoon was joined by Dr. Kang Kwang Yong’s team from ETRI, KAIST’s Professor Less Yong Hee’s team, and Seoul National University’s Professor Park Nam Kyu’s team. The research was funded by the Basic Research Support Program initiated by the Ministry of Education, Science, and Technology and Korea Research Federation.

The result of the research was published in ‘Nature’ magazine and is one of the few researches carried out by teams composed entirely of Koreans.

Metamaterials are materials that have physical properties beyond those materials’ properties that are found in nature. It is formed not with atoms, but with synthetic atoms which have smaller structures than wavelengths.

The optical and electromagnetic waves’ properties of metamaterials can be altered significantly which has caught the attention of scientists worldwide.

Professor Min Beom Ki’s team independently designed and created a dielectric metamaterial with high polarization and low diamagnetism with an index of refraction of 38.6, highest synthesized index value.

It is expected that the result of the experiment will help develop high resolution imaging system and ultra small, hyper sensitive optical devices.

2011.02.23 View 19901