College+of+Engineering

-

A KAIST Research Team Develops a Smart Color-Changing Flexible Battery with Ultra-high Efficiency

With the rapid growth of the smart and wearable electronic devices market, smart next-generation energy storage systems that have energy storage functions as well as additional color-changing properties are receiving a great deal of attention. However, existing electrochromic devices have low electrical conductivity, leading to low efficiency in electron and ion mobility, and low storage capacities. Such batteries have therefore been limited to use in flexible and wearable devices.

On August 21, a joint research team led by Professor Il-Doo Kim from the KAIST Department of Materials Science and Engineering (DMSE) and Professor Tae Gwang Yun from the Myongji University Department of Materials Science and Engineering announced the development of a smart electrochromic Zn-ion battery that can visually represent its charging and discharging processes using an electrochromic polymer anode incorporated with a “π-bridge spacer”, which increases electron and ion mobility efficiency.

Batteries topped with electrochromic properties are groundbreaking inventions that can visually represent their charged and discharged states using colors, and can be used as display devices that cut down energy consumption for indoor cooling by controlling solar absorbance. The research team successfully built a flexible and electrochromic smart Zn-ion battery that can maintain its excellent electrochromic and electrochemical properties, even under long-term exposure to the atmosphere and mechanical deformations.

< Figure 1. Electrochromic zinc ion battery whose anode is made of a polymer that turns dark blue when charged and transparent when discharged. >

To maximize the efficiency of electron and ion mobility, the team modelled and synthesized the first π-bridge spacer-incorporated polymer anode in the world. π-bonds can improve the mobility of electrons within a structure to speed up ion movement and maximize ion adsorption efficiency, which improves its energy storage capacity.

In anode-based batteries with a π-bridge spacer, the spacer provides room for quicker ion movement. This allows fast charging, an improved zinc-ion discharging capacity of 110 mAh/g, which is 40% greater than previously reported, and a 30% increase in electrochromic function that switches from dark blue to transparent when the device is charged/discharged. In addition, should the transparent flexible battery technology be applied to smart windows, they would display darker colors during the day while they absorb solar energy, and function as a futuristic energy storage technique that can block out UV radiation and replace curtains.

< Figure 2. A schematic diagram of the structure of the electrochromic polymer with π-π spacer and the operation of a smart flexible battery using this cathode material. >

< Figure 3. (A) Density Functional Theory (DFT) theory-based atomic and electronic structure analysis. (B) Comparison of rate characteristics for polymers with and without π-bridge spacers. (C) Electrochemical performance comparison graph with previously reported zinc ion batteries. The anode material, which has an electron donor-acceptor structure with a built-in π-bridge spacer, shows better electrochemical performance and electrochromic properties than existing zinc ion batteries and electrochromic devices. >

Professor Il-Doo Kim said, “We have developed a polymer incorporated with a π-bridge spacer and successfully built a smart Zn-ion battery with excellent electrochromic efficiency and high energy storage capacity.” He added, “This technique goes beyond the existing concept of batteries that are used simply as energy storage devices, and we expect this technology to be used as a futuristic energy storage system that accelerates innovation in smart batteries and wearable technologies.”

This research, co-first authored by the alums of KAIST Departments of Material Sciences of Engineering, Professor Tae Gwang Yun of Myongji University, Dr. Jiyoung Lee, a post-doctoral associate at Northwestern University, and Professor Han Seul Kim at Chungbuk National University, was published as an inside cover article for Advanced Materials on August 3 under the title, “A π-Bridge Spacer Embedded Electron Donor-Acceptor Polymer for Flexible Electrochromic Zn-Ion Batteries”.

< Figure 4. Advanced Materials Inside Cover (August Issue) >

This research was supported by the Nanomaterial Technology Development Project under the Korean Ministry of Science and ICT, the Nano and Material Technology Development Project under the National Research Foundation of Korea, the Successive Academic Generation Development Project under the Korean Ministry of Education, and the Alchemist Project under the Korean Ministry of Trade, Industry & Energy.

2023.09.01 View 10429

A KAIST Research Team Develops a Smart Color-Changing Flexible Battery with Ultra-high Efficiency

With the rapid growth of the smart and wearable electronic devices market, smart next-generation energy storage systems that have energy storage functions as well as additional color-changing properties are receiving a great deal of attention. However, existing electrochromic devices have low electrical conductivity, leading to low efficiency in electron and ion mobility, and low storage capacities. Such batteries have therefore been limited to use in flexible and wearable devices.

On August 21, a joint research team led by Professor Il-Doo Kim from the KAIST Department of Materials Science and Engineering (DMSE) and Professor Tae Gwang Yun from the Myongji University Department of Materials Science and Engineering announced the development of a smart electrochromic Zn-ion battery that can visually represent its charging and discharging processes using an electrochromic polymer anode incorporated with a “π-bridge spacer”, which increases electron and ion mobility efficiency.

Batteries topped with electrochromic properties are groundbreaking inventions that can visually represent their charged and discharged states using colors, and can be used as display devices that cut down energy consumption for indoor cooling by controlling solar absorbance. The research team successfully built a flexible and electrochromic smart Zn-ion battery that can maintain its excellent electrochromic and electrochemical properties, even under long-term exposure to the atmosphere and mechanical deformations.

< Figure 1. Electrochromic zinc ion battery whose anode is made of a polymer that turns dark blue when charged and transparent when discharged. >

To maximize the efficiency of electron and ion mobility, the team modelled and synthesized the first π-bridge spacer-incorporated polymer anode in the world. π-bonds can improve the mobility of electrons within a structure to speed up ion movement and maximize ion adsorption efficiency, which improves its energy storage capacity.

In anode-based batteries with a π-bridge spacer, the spacer provides room for quicker ion movement. This allows fast charging, an improved zinc-ion discharging capacity of 110 mAh/g, which is 40% greater than previously reported, and a 30% increase in electrochromic function that switches from dark blue to transparent when the device is charged/discharged. In addition, should the transparent flexible battery technology be applied to smart windows, they would display darker colors during the day while they absorb solar energy, and function as a futuristic energy storage technique that can block out UV radiation and replace curtains.

< Figure 2. A schematic diagram of the structure of the electrochromic polymer with π-π spacer and the operation of a smart flexible battery using this cathode material. >

< Figure 3. (A) Density Functional Theory (DFT) theory-based atomic and electronic structure analysis. (B) Comparison of rate characteristics for polymers with and without π-bridge spacers. (C) Electrochemical performance comparison graph with previously reported zinc ion batteries. The anode material, which has an electron donor-acceptor structure with a built-in π-bridge spacer, shows better electrochemical performance and electrochromic properties than existing zinc ion batteries and electrochromic devices. >

Professor Il-Doo Kim said, “We have developed a polymer incorporated with a π-bridge spacer and successfully built a smart Zn-ion battery with excellent electrochromic efficiency and high energy storage capacity.” He added, “This technique goes beyond the existing concept of batteries that are used simply as energy storage devices, and we expect this technology to be used as a futuristic energy storage system that accelerates innovation in smart batteries and wearable technologies.”

This research, co-first authored by the alums of KAIST Departments of Material Sciences of Engineering, Professor Tae Gwang Yun of Myongji University, Dr. Jiyoung Lee, a post-doctoral associate at Northwestern University, and Professor Han Seul Kim at Chungbuk National University, was published as an inside cover article for Advanced Materials on August 3 under the title, “A π-Bridge Spacer Embedded Electron Donor-Acceptor Polymer for Flexible Electrochromic Zn-Ion Batteries”.

< Figure 4. Advanced Materials Inside Cover (August Issue) >

This research was supported by the Nanomaterial Technology Development Project under the Korean Ministry of Science and ICT, the Nano and Material Technology Development Project under the National Research Foundation of Korea, the Successive Academic Generation Development Project under the Korean Ministry of Education, and the Alchemist Project under the Korean Ministry of Trade, Industry & Energy.

2023.09.01 View 10429 -

A KAIST Research Team Produces Eco-Friendly Nylon with Engineered Bacterium

With worsening climate change and environmental issues, in recent years, there has been increased interest in the eco-friendly production of polymers like nylon.

On August 10, Dr. Taehee Han from a KAIST research team led by Distinguished Professor Sang Yup Lee in the Department of Chemical and Biomolecular Engineering revealed the successful development of a microbial strain that produces valerolactam, a monomer of nylon-5.

Valerolactam is an important monomer that constitutes nylon-5 and nylon-6,5. Nylon is the oldest synthetic polymer, and nylon-5 is one of its derivatives composed of monomers with five carbons, while nylon-5,6 is composed of two types of monomers with either five or six carbons. They not only have excellent processability, but are also light and tough, which allows them to be applied in a wide range of industrial sectors including clothing, badminton rackets, fishing nets, tents, and gear parts. Monomers are materials that can be built into polymers, and synthetic processes are what connects them into a polymer.

The chemical production of valerolactam, however, is based on petrochemistry, where extreme reaction conditions are required and toxic waste is produced. To solve these problems, efforts are being made to develop environmentally friendly and highly efficient microbial cell factories for lactam production. Systems metabolic engineering, a key strategy for effective microbial strain development, is a research field pioneered by Professor Sang Yup Lee.

Professor Lee’s team used metabolic engineering, a technique for manipulating microbial metabolic pathways, to construct a synthetic metabolic pathway for valerolactam production in Corynebacteriam glutamicum, a bacterium commonly used for amino acid production. With this, they successfully developed a microbial strain that utilizes biomass-derived glucose as a carbon source to produce high-value valerolactam.

In 2017, the team suggested a novel method that metabolically manipulates Escherichia coli to produce valerolactam. However, there were several limitations at the time including low producibility and the generation of harmful byproducts.

< Figure 1. Schematic graphical representation of the development of microorganisms that produce valerolactam, a nylon-5 monomer >

In this research, the team improved valerolactam producibility and incorporated an additional systems metabolic strategy to the developed microbial strain while eliminating the harmful byproducts. By removing the gene involved in the production of the main byproduct and through gene screening, the team successfully converted 5-aminovaleric acid, a byproduct and a precursor, into valerolactam.

Furthermore, by employing a strategy where the 5-aminovaleric acid-converting gene is inserted multiple times into the genome, the team strengthened the metabolic flux for valerolactam production. As a result, they reached a world-record concentration of 76.1 g/L, which is 6.17 times greater than what was previously reported.

This study was published in Metabolic Engineering on July 12, under the title, “Metabolic engineering of Corynebacterium glutamicum for the high-level production of valerolactam, a nylon-5 monomer”.

Dr. Taehee Han, the first author of the paper, said, “The significance of this research lies in our development of an environmentally friendly technology that efficiently produces monomer lactam for nylon production using microorganisms.” She added, “Through this technology, we will be able to take a step forward in replacing the petrochemical industry with a microorganism-based biopolymer industry.”

This work was supported by the “Development of Next-Generation Biofinery Platform Technologies for Leading Bio-based Chemicals Industry Project” funded by the Korean Ministry of Science and ICT.

2023.08.24 View 7797

A KAIST Research Team Produces Eco-Friendly Nylon with Engineered Bacterium

With worsening climate change and environmental issues, in recent years, there has been increased interest in the eco-friendly production of polymers like nylon.

On August 10, Dr. Taehee Han from a KAIST research team led by Distinguished Professor Sang Yup Lee in the Department of Chemical and Biomolecular Engineering revealed the successful development of a microbial strain that produces valerolactam, a monomer of nylon-5.

Valerolactam is an important monomer that constitutes nylon-5 and nylon-6,5. Nylon is the oldest synthetic polymer, and nylon-5 is one of its derivatives composed of monomers with five carbons, while nylon-5,6 is composed of two types of monomers with either five or six carbons. They not only have excellent processability, but are also light and tough, which allows them to be applied in a wide range of industrial sectors including clothing, badminton rackets, fishing nets, tents, and gear parts. Monomers are materials that can be built into polymers, and synthetic processes are what connects them into a polymer.

The chemical production of valerolactam, however, is based on petrochemistry, where extreme reaction conditions are required and toxic waste is produced. To solve these problems, efforts are being made to develop environmentally friendly and highly efficient microbial cell factories for lactam production. Systems metabolic engineering, a key strategy for effective microbial strain development, is a research field pioneered by Professor Sang Yup Lee.

Professor Lee’s team used metabolic engineering, a technique for manipulating microbial metabolic pathways, to construct a synthetic metabolic pathway for valerolactam production in Corynebacteriam glutamicum, a bacterium commonly used for amino acid production. With this, they successfully developed a microbial strain that utilizes biomass-derived glucose as a carbon source to produce high-value valerolactam.

In 2017, the team suggested a novel method that metabolically manipulates Escherichia coli to produce valerolactam. However, there were several limitations at the time including low producibility and the generation of harmful byproducts.

< Figure 1. Schematic graphical representation of the development of microorganisms that produce valerolactam, a nylon-5 monomer >

In this research, the team improved valerolactam producibility and incorporated an additional systems metabolic strategy to the developed microbial strain while eliminating the harmful byproducts. By removing the gene involved in the production of the main byproduct and through gene screening, the team successfully converted 5-aminovaleric acid, a byproduct and a precursor, into valerolactam.

Furthermore, by employing a strategy where the 5-aminovaleric acid-converting gene is inserted multiple times into the genome, the team strengthened the metabolic flux for valerolactam production. As a result, they reached a world-record concentration of 76.1 g/L, which is 6.17 times greater than what was previously reported.

This study was published in Metabolic Engineering on July 12, under the title, “Metabolic engineering of Corynebacterium glutamicum for the high-level production of valerolactam, a nylon-5 monomer”.

Dr. Taehee Han, the first author of the paper, said, “The significance of this research lies in our development of an environmentally friendly technology that efficiently produces monomer lactam for nylon production using microorganisms.” She added, “Through this technology, we will be able to take a step forward in replacing the petrochemical industry with a microorganism-based biopolymer industry.”

This work was supported by the “Development of Next-Generation Biofinery Platform Technologies for Leading Bio-based Chemicals Industry Project” funded by the Korean Ministry of Science and ICT.

2023.08.24 View 7797 -

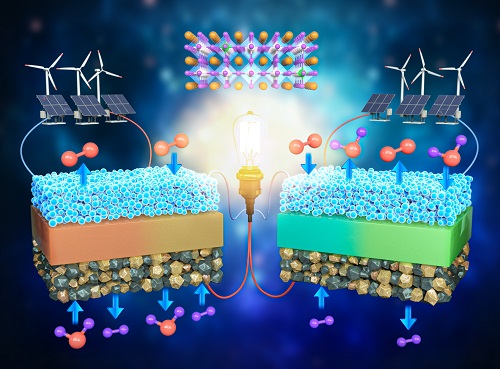

A KAIST Research Team Develops an Ultra-High Performing “Universal Electrode” for Next-Generation Fuel Cells

Fuel cells are devices that generate electricity with high efficiency using hydrogen, a clean energy source, and are expected to play an important part in the upcoming hydrogen society. The recent development of an excellent universal electrode material that is applicable to all next-generation fuel cells and can withstand 700 hours of operation has therefore garnered a great deal of attention.

On August 9, a joint research team led by Prof. WooChul Jung from the KAIST Department of Materials Science and Engineering, Prof. Kang Taek Lee from the KAIST Department of Mechanical Engineering, and Prof. Jun Hyuk Kim from the Department of Chemical Engineering at Hongik University announced the development of an electrode material that is applicable to both oxygen- and proton-conducting solid oxide cells.

Depending on the type of ion conducted by the electrolyte, ceramic fuel cells are categorized into either solid oxide fuel cells (SOFC) or protonic ceramic fuel cells (PCFC). As they can both convert between electricity and hydrogen production, fuel cells can be categorized into a total of four device types. These devices are applicable in hydrogen fuel cell vehicles, hydrogen charging stations, and power generation systems, and are henceforth emerging as core next-generation technologies for a carbon-neutral society.

However, these devices have a chronic problem where the speed of their slowest reaction would decrease with a drop of driving temperature, which greatly reduces device efficiency. Various studies have been conducted to solve this, but most reported that electrode materials have low catalytic activity and their applications are limited to specific devices, which limits them from being used as SOFCs that require reversible power conversion and hydrogen production.

< Figure 1. Schematic diagram of high-performance oxygen ion conductive solid oxide fuel cell (SOFC) and proton conductive ceramic fuel cell (PCFC) operates with the new universal electrodes >

To solve this issue, the research team doped a perovskite oxide material with Ta5+, a high valence ion that did not receive much attention in the field. Through this, the team successfully stabilized what is usually a highly unstable crystal structure, and confirmed that catalytic activity improved by 100 times.

The electrode material developed by the team was applied to all four of the mentioned device types. Furthermore, their efficiencies were greater than any of the devices reported thus far, and showed excellent performance by stably running for much longer (700 hours) compared to existing materials that deteriorated within the first 100 hours of operation.

< Figure 2. (a) Power conversion and hydrogen production performance chart for the protonic ceramic fuel cell (PCFC) with the new universal electrodes (b) and performance comparison with other reported devices >

This research, in which KAIST’s Ph.D. candidates Dongyeon Kim and Sejong Ahn, and Professor Jun Hyuk Kim from Hongik University contributed as co-first authors, was published in the internationally renowned Energy & Environmental Science under the title, "Oxygen-Electrode for Reversible Solid Oxide Electrochemical Cells at Reduced Temperatures".

Prof. WooChul Jung said, “We broke free from the idea that we must develop a completely new material to solve an existing problem, and instead suggested a way to control the crystal structure of a lesser-known material to develop a high-efficiency fuel cell, and that’s what makes these results more significant.”

Prof. Kang Taek Lee added, “Unlike previously reported materials that could only be applied to one device type at a time, our material has the flexibility of being applicable to all four. We therefore look forward to its contribution in the commercialization of eco-friendly energy technology including fuel cells and water-splitting equipment for hydrogen production.”

This research was supported by a National Research Foundation of Korea (NRF) grant funded by the Korean Ministry of Science and ICT.

2023.08.22 View 10336

A KAIST Research Team Develops an Ultra-High Performing “Universal Electrode” for Next-Generation Fuel Cells

Fuel cells are devices that generate electricity with high efficiency using hydrogen, a clean energy source, and are expected to play an important part in the upcoming hydrogen society. The recent development of an excellent universal electrode material that is applicable to all next-generation fuel cells and can withstand 700 hours of operation has therefore garnered a great deal of attention.

On August 9, a joint research team led by Prof. WooChul Jung from the KAIST Department of Materials Science and Engineering, Prof. Kang Taek Lee from the KAIST Department of Mechanical Engineering, and Prof. Jun Hyuk Kim from the Department of Chemical Engineering at Hongik University announced the development of an electrode material that is applicable to both oxygen- and proton-conducting solid oxide cells.

Depending on the type of ion conducted by the electrolyte, ceramic fuel cells are categorized into either solid oxide fuel cells (SOFC) or protonic ceramic fuel cells (PCFC). As they can both convert between electricity and hydrogen production, fuel cells can be categorized into a total of four device types. These devices are applicable in hydrogen fuel cell vehicles, hydrogen charging stations, and power generation systems, and are henceforth emerging as core next-generation technologies for a carbon-neutral society.

However, these devices have a chronic problem where the speed of their slowest reaction would decrease with a drop of driving temperature, which greatly reduces device efficiency. Various studies have been conducted to solve this, but most reported that electrode materials have low catalytic activity and their applications are limited to specific devices, which limits them from being used as SOFCs that require reversible power conversion and hydrogen production.

< Figure 1. Schematic diagram of high-performance oxygen ion conductive solid oxide fuel cell (SOFC) and proton conductive ceramic fuel cell (PCFC) operates with the new universal electrodes >

To solve this issue, the research team doped a perovskite oxide material with Ta5+, a high valence ion that did not receive much attention in the field. Through this, the team successfully stabilized what is usually a highly unstable crystal structure, and confirmed that catalytic activity improved by 100 times.

The electrode material developed by the team was applied to all four of the mentioned device types. Furthermore, their efficiencies were greater than any of the devices reported thus far, and showed excellent performance by stably running for much longer (700 hours) compared to existing materials that deteriorated within the first 100 hours of operation.

< Figure 2. (a) Power conversion and hydrogen production performance chart for the protonic ceramic fuel cell (PCFC) with the new universal electrodes (b) and performance comparison with other reported devices >

This research, in which KAIST’s Ph.D. candidates Dongyeon Kim and Sejong Ahn, and Professor Jun Hyuk Kim from Hongik University contributed as co-first authors, was published in the internationally renowned Energy & Environmental Science under the title, "Oxygen-Electrode for Reversible Solid Oxide Electrochemical Cells at Reduced Temperatures".

Prof. WooChul Jung said, “We broke free from the idea that we must develop a completely new material to solve an existing problem, and instead suggested a way to control the crystal structure of a lesser-known material to develop a high-efficiency fuel cell, and that’s what makes these results more significant.”

Prof. Kang Taek Lee added, “Unlike previously reported materials that could only be applied to one device type at a time, our material has the flexibility of being applicable to all four. We therefore look forward to its contribution in the commercialization of eco-friendly energy technology including fuel cells and water-splitting equipment for hydrogen production.”

This research was supported by a National Research Foundation of Korea (NRF) grant funded by the Korean Ministry of Science and ICT.

2023.08.22 View 10336 -

KAIST Research Team Develops World’s First Humanoid Pilot, PIBOT

In the Spring of last year, the legendary, fictional pilot “Maverick” flew his plane in the film “Top Gun: Maverick” that drew crowds to theatres around the world. This year, the appearance of a humanoid pilot, PIBOT, has stolen the spotlight at KAIST.

< Photo 1. Humanoid pilot robot, PIBOT >

A KAIST research team has developed a humanoid robot that can understand manuals written in natural language and fly a plane on its own. The team also announced their plans to commercialize the humanoid pilot.

< Photo 2. PIBOT on flight simulator (view from above) >

The project was led by KAIST Professor David Hyunchul Shim, and was conducted as a joint research project with Professors Jaegul Choo, Kuk-Jin Yoon, and Min Jun Kim. The study was supported by Future Challenge Funding under the project title, “Development of Human-like Pilot Robot based on Natural Language Processing”. The team utilized AI and robotics technologies, and demonstrated that the humanoid could sit itself in a real cockpit and operate the various pieces of equipment without modifying any part of the aircraft. This is a fundamental difference that distinguishes this technology from existing autopilot functions or unmanned aircrafts.

< Photo 3. PIBOT operating a flight simulator (side) >

The KAIST team’s humanoid pilot is still under development but it can already remember Jeppeson charts from all around the world, which is impossible for human pilots to do, and fly without error. In particular, it can make use of recent ChatGPT technology to remember the full Quick Reference Handbook (QRF) and respond immediately to various situations, as well as calculate safe routes in real time based on the flight status of the aircraft, with emergency response times quicker than human pilots.

Furthermore, while existing robots usually carry out repeated motions in a fixed position, PIBOT can analyze the state of the cockpit as well as the situation outside the aircraft using an embedded camera. PIBOT can accurately control the various switches in the cockpit and, using high-precision control technology, it can accurately control its robotic arms and hands even during harsh turbulence.

< Photo 4. PIBOT on-board KLA-100, Korea’s first light aircraft >

The humanoid pilot is currently capable of carrying out all operations from starting the aircraft to taxiing, takeoff and landing, cruising, and cycling using a flight control simulator. The research team plans to use the humanoid pilot to fly a real-life light aircraft to verify its abilities. Prof. Shim explained, “Humanoid pilot robots do not require the modification of existing aircrafts and can be applied immediately to automated flights. They are therefore highly applicable and practical. We expect them to be applied into various other vehicles like cars and military trucks since they can control a wide range of equipment. They will particularly be particularly helpful in situations where military resources are severely depleted.”

This research was supported by Future Challenge Funding (total: 5.7 bn KRW) from the Agency for Defense Development. The project started in 2022 as a joint research project by Prof. David Hyunchul Shim (chief of research) from the KAIST School of Electrical Engineering (EE), Prof. Jaegul Choo from the Kim Jaechul Graduate School of AI at KAIST, Prof. Kuk-Jin Yoon from the KAIST Department of Mechanical Engineering, and Prof. Min Jun Kim from the KAIST School of EE. The project is to be completed by 2026 and the involved researchers are also considering commercialization strategies for both military and civil use.

2023.08.03 View 17473

KAIST Research Team Develops World’s First Humanoid Pilot, PIBOT

In the Spring of last year, the legendary, fictional pilot “Maverick” flew his plane in the film “Top Gun: Maverick” that drew crowds to theatres around the world. This year, the appearance of a humanoid pilot, PIBOT, has stolen the spotlight at KAIST.

< Photo 1. Humanoid pilot robot, PIBOT >

A KAIST research team has developed a humanoid robot that can understand manuals written in natural language and fly a plane on its own. The team also announced their plans to commercialize the humanoid pilot.

< Photo 2. PIBOT on flight simulator (view from above) >

The project was led by KAIST Professor David Hyunchul Shim, and was conducted as a joint research project with Professors Jaegul Choo, Kuk-Jin Yoon, and Min Jun Kim. The study was supported by Future Challenge Funding under the project title, “Development of Human-like Pilot Robot based on Natural Language Processing”. The team utilized AI and robotics technologies, and demonstrated that the humanoid could sit itself in a real cockpit and operate the various pieces of equipment without modifying any part of the aircraft. This is a fundamental difference that distinguishes this technology from existing autopilot functions or unmanned aircrafts.

< Photo 3. PIBOT operating a flight simulator (side) >

The KAIST team’s humanoid pilot is still under development but it can already remember Jeppeson charts from all around the world, which is impossible for human pilots to do, and fly without error. In particular, it can make use of recent ChatGPT technology to remember the full Quick Reference Handbook (QRF) and respond immediately to various situations, as well as calculate safe routes in real time based on the flight status of the aircraft, with emergency response times quicker than human pilots.

Furthermore, while existing robots usually carry out repeated motions in a fixed position, PIBOT can analyze the state of the cockpit as well as the situation outside the aircraft using an embedded camera. PIBOT can accurately control the various switches in the cockpit and, using high-precision control technology, it can accurately control its robotic arms and hands even during harsh turbulence.

< Photo 4. PIBOT on-board KLA-100, Korea’s first light aircraft >

The humanoid pilot is currently capable of carrying out all operations from starting the aircraft to taxiing, takeoff and landing, cruising, and cycling using a flight control simulator. The research team plans to use the humanoid pilot to fly a real-life light aircraft to verify its abilities. Prof. Shim explained, “Humanoid pilot robots do not require the modification of existing aircrafts and can be applied immediately to automated flights. They are therefore highly applicable and practical. We expect them to be applied into various other vehicles like cars and military trucks since they can control a wide range of equipment. They will particularly be particularly helpful in situations where military resources are severely depleted.”

This research was supported by Future Challenge Funding (total: 5.7 bn KRW) from the Agency for Defense Development. The project started in 2022 as a joint research project by Prof. David Hyunchul Shim (chief of research) from the KAIST School of Electrical Engineering (EE), Prof. Jaegul Choo from the Kim Jaechul Graduate School of AI at KAIST, Prof. Kuk-Jin Yoon from the KAIST Department of Mechanical Engineering, and Prof. Min Jun Kim from the KAIST School of EE. The project is to be completed by 2026 and the involved researchers are also considering commercialization strategies for both military and civil use.

2023.08.03 View 17473 -

Professor Joseph J. Lim of KAIST receives the Best System Paper Award from RSS 2023, First in Korea

- Professor Joseph J. Lim from the Kim Jaechul Graduate School of AI at KAIST and his team receive an award for the most outstanding paper in the implementation of robot systems.

- Professor Lim works on AI-based perception, reasoning, and sequential decision-making to develop systems capable of intelligent decision-making, including robot learning

< Photo 1. RSS2023 Best System Paper Award Presentation >

The team of Professor Joseph J. Lim from the Kim Jaechul Graduate School of AI at KAIST has been honored with the 'Best System Paper Award' at "Robotics: Science and Systems (RSS) 2023".

The RSS conference is globally recognized as a leading event for showcasing the latest discoveries and advancements in the field of robotics. It is a venue where the greatest minds in robotics engineering and robot learning come together to share their research breakthroughs. The RSS Best System Paper Award is a prestigious honor granted to a paper that excels in presenting real-world robot system implementation and experimental results.

< Photo 2. Professor Joseph J. Lim of Kim Jaechul Graduate School of AI at KAIST >

The team led by Professor Lim, including two Master's students and an alumnus (soon to be appointed at Yonsei University), received the prestigious RSS Best System Paper Award, making it the first-ever achievement for a Korean and for a domestic institution.

< Photo 3. Certificate of the Best System Paper Award presented at RSS 2023 >

This award is especially meaningful considering the broader challenges in the field. Although recent progress in artificial intelligence and deep learning algorithms has resulted in numerous breakthroughs in robotics, most of these achievements have been confined to relatively simple and short tasks, like walking or pick-and-place. Moreover, tasks are typically performed in simulated environments rather than dealing with more complex, long-horizon real-world tasks such as factory operations or household chores. These limitations primarily stem from the considerable challenge of acquiring data required to develop and validate learning-based AI techniques, particularly in real-world complex tasks.

In light of these challenges, this paper introduced a benchmark that employs 3D printing to simplify the reproduction of furniture assembly tasks in real-world environments. Furthermore, it proposed a standard benchmark for the development and comparison of algorithms for complex and long-horizon tasks, supported by teleoperation data. Ultimately, the paper suggests a new research direction of addressing complex and long-horizon tasks and encourages diverse advancements in research by facilitating reproducible experiments in real-world environments.

Professor Lim underscored the growing potential for integrating robots into daily life, driven by an aging population and an increase in single-person households. As robots become part of everyday life, testing their performance in real-world scenarios becomes increasingly crucial. He hoped this research would serve as a cornerstone for future studies in this field.

The Master's students, Minho Heo and Doohyun Lee, from the Kim Jaechul Graduate School of AI at KAIST, also shared their aspirations to become global researchers in the domain of robot learning. Meanwhile, the alumnus of Professor Lim's research lab, Dr. Youngwoon Lee, is set to be appointed to the Graduate School of AI at Yonsei University and will continue pursuing research in robot learning.

Paper title: Furniture Bench: Reproducible Real-World Benchmark for Long-Horizon Complex Manipulation. Robotics: Science and Systems.

< Image. Conceptual Summary of the 3D Printing Technology >

2023.07.31 View 12556

Professor Joseph J. Lim of KAIST receives the Best System Paper Award from RSS 2023, First in Korea

- Professor Joseph J. Lim from the Kim Jaechul Graduate School of AI at KAIST and his team receive an award for the most outstanding paper in the implementation of robot systems.

- Professor Lim works on AI-based perception, reasoning, and sequential decision-making to develop systems capable of intelligent decision-making, including robot learning

< Photo 1. RSS2023 Best System Paper Award Presentation >

The team of Professor Joseph J. Lim from the Kim Jaechul Graduate School of AI at KAIST has been honored with the 'Best System Paper Award' at "Robotics: Science and Systems (RSS) 2023".

The RSS conference is globally recognized as a leading event for showcasing the latest discoveries and advancements in the field of robotics. It is a venue where the greatest minds in robotics engineering and robot learning come together to share their research breakthroughs. The RSS Best System Paper Award is a prestigious honor granted to a paper that excels in presenting real-world robot system implementation and experimental results.

< Photo 2. Professor Joseph J. Lim of Kim Jaechul Graduate School of AI at KAIST >

The team led by Professor Lim, including two Master's students and an alumnus (soon to be appointed at Yonsei University), received the prestigious RSS Best System Paper Award, making it the first-ever achievement for a Korean and for a domestic institution.

< Photo 3. Certificate of the Best System Paper Award presented at RSS 2023 >

This award is especially meaningful considering the broader challenges in the field. Although recent progress in artificial intelligence and deep learning algorithms has resulted in numerous breakthroughs in robotics, most of these achievements have been confined to relatively simple and short tasks, like walking or pick-and-place. Moreover, tasks are typically performed in simulated environments rather than dealing with more complex, long-horizon real-world tasks such as factory operations or household chores. These limitations primarily stem from the considerable challenge of acquiring data required to develop and validate learning-based AI techniques, particularly in real-world complex tasks.

In light of these challenges, this paper introduced a benchmark that employs 3D printing to simplify the reproduction of furniture assembly tasks in real-world environments. Furthermore, it proposed a standard benchmark for the development and comparison of algorithms for complex and long-horizon tasks, supported by teleoperation data. Ultimately, the paper suggests a new research direction of addressing complex and long-horizon tasks and encourages diverse advancements in research by facilitating reproducible experiments in real-world environments.

Professor Lim underscored the growing potential for integrating robots into daily life, driven by an aging population and an increase in single-person households. As robots become part of everyday life, testing their performance in real-world scenarios becomes increasingly crucial. He hoped this research would serve as a cornerstone for future studies in this field.

The Master's students, Minho Heo and Doohyun Lee, from the Kim Jaechul Graduate School of AI at KAIST, also shared their aspirations to become global researchers in the domain of robot learning. Meanwhile, the alumnus of Professor Lim's research lab, Dr. Youngwoon Lee, is set to be appointed to the Graduate School of AI at Yonsei University and will continue pursuing research in robot learning.

Paper title: Furniture Bench: Reproducible Real-World Benchmark for Long-Horizon Complex Manipulation. Robotics: Science and Systems.

< Image. Conceptual Summary of the 3D Printing Technology >

2023.07.31 View 12556 -

KAIST presents a microbial cell factory as a source of eco-friendly food and cosmetic coloring

Despite decades of global population growth, global food crisis seems to be at hand yet again because the food productivity is cut severely due to prolonged presence of abnormal weather from intensifying climate change and global food supply chain is deteriorated due to international conflicts such as wars exacerbating food shortages and nutritional inequality around the globe. At the same time, however, as awareness of the environment and sustainability rises, an increase in demand for more eco-friendly and high-quality food and beauty products is being observed not without a sense of irony. At a time like this, microorganisms are attracting attention as a key that can handle this couple of seemingly distant problems.

KAIST (President Kwang-Hyung Lee) announced on the 26th that Kyeong Rok Choi, a research professor of the Bioprocess Research Center and Sang Yup Lee, a Distinguished Professor of the Department of Chemical and Biomolecular Engineering, published a paper titled “Metabolic Engineering of Microorganisms for Food and Cosmetics Production” upon invitation by “Nature Reviews Bioengineering” to be published online published by Nature after peer review.

※ Paper title: Systems metabolic engineering of microorganisms for food and cosmetics production

※ Author information: Kyeong Rok Choi (first author) and Sang Yup Lee (corresponding author)

Systems metabolic engineering is a research field founded by Distinguished Professor Sang Yup Lee of KAIST to more effectively develop microbial cell factories, the core factor of the next-generation bio industry to replace the existing chemical industry that relies heavily on petroleum. By applying a systemic metabolic engineering strategy, the researchers have developed a number of high-performance microbial cell factories that produce a variety of food and cosmetic compounds including natural substances like heme and zinc protoporphyrin IX compounds which can improve the flavor and color of synthetic meat, lycopene and β-carotene which are functional natural pigments that can be widely used in food and cosmetics, and methyl anthranilate, a grape-derived compound widely used to impart grape flavor in food and beverage manufacturing.

In this paper written upon invitation by Nature, the research team covered remarkable cases of microbial cell factory that can produce amino acids, proteins, fats and fatty acids, vitamins, flavors, pigments, alcohols, functional compounds and other food additives used in various foods and cosmetics and the companies that have successfully commercialized these microbial-derived materials Furthermore, the paper organized and presents systems metabolic engineering strategies that can spur the development of industrial microbial cell factories that can produce more diverse food and cosmetic compounds in an eco-friendly way with economic feasibility.

< Figure 1. Examples of production of food and cosmetic compounds using microbial cell factories >

For example, by producing proteins or amino acids with high nutritional value through non-edible biomass used as animal feed or fertilizer through the microbial fermentation process, it will contribute to the increase in production and stable supply of food around the world. Furthermore, by contributing to developing more viable alternative meat, further reducing dependence on animal protein, it can also contribute to reducing greenhouse gases and environmental pollution generated through livestock breeding or fish farming.

In addition, vanillin or methyl anthranilate, which give off vanilla or grape flavor, are widely added to various foods, but natural products isolated and refined from plants are low in production and high in production cost, so in most cases, petrochemicals substances derived from vanillin and methylanthranilic acid are added to food. These materials can also be produced through an eco-friendly and human-friendly method by borrowing the power of microorganisms.

Ethical and resource problems that arise in producing compounds like Calmin (cochineal pigment), a coloring added to various cosmetics and foods such as red lipstick and strawberry-flavored milk, which must be extracted from cochineal insects that live only in certain cacti. and Hyaluronic acid, which is widely consumed as a health supplement, but is only present in omega-3 fatty acids extracted from shark or fish livers, can also be resolved when they can be produced in an eco-friendly way using microorganisms.

KAIST Research Professor Kyeong Rok Choi, the first author of this paper, said, “In addition to traditional fermented foods such as kimchi and yogurt, foods produced with the help of microorganisms like cocoa butter, a base ingredient for chocolate that can only be obtained from fermented cacao beans, and monosodium glutamate, a seasoning produced through microbial fermentation are already familiar to us”. “In the future, we will be able to acquire a wider variety of foods and cosmetics even more easily produced in an eco-friendly and sustainable way in our daily lives through microbial cell factories.” he added.

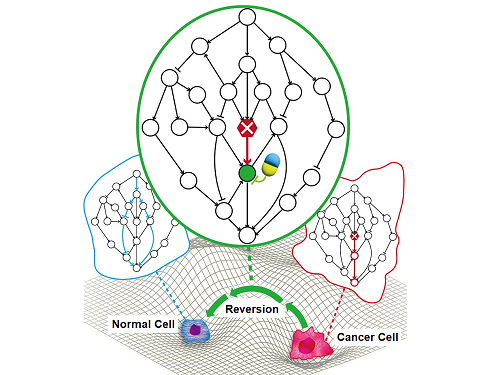

< Figure 2. Systems metabolic engineering strategy to improve metabolic flow in microbial cell factories >

Distinguished Professor Sang Yup Lee said, “It is engineers’ mission to make the world a better place utilizing science and technology.” and added, “Continuous advancement and active use of systems metabolic engineering will contribute greatly to easing and resolving the problems arising from both the food crisis and the climate change."

This research was carried out as a part of the “Development of Protein Production Technology from Inorganic Substances through Control of Microbial Metabolism System Project” (Project Leader: Kyeong Rok Choi, KAIST Research Professor) of the the Center for Agricultural Microorganism and Enzyme (Director Pahn-Shick Chang) supported by the Rural Development Administration and the “Development of Platform Technologies of Microbial Cell Factories for the Next-generation Biorefineries Project” (Project Leader: Sang Yup Lee, KAIST Distinguished Professor) of the Petroleum-Substitute Eco-friendly Chemical Technology Development Program supported by the Ministry of Science and ICT.

2023.07.28 View 11145

KAIST presents a microbial cell factory as a source of eco-friendly food and cosmetic coloring

Despite decades of global population growth, global food crisis seems to be at hand yet again because the food productivity is cut severely due to prolonged presence of abnormal weather from intensifying climate change and global food supply chain is deteriorated due to international conflicts such as wars exacerbating food shortages and nutritional inequality around the globe. At the same time, however, as awareness of the environment and sustainability rises, an increase in demand for more eco-friendly and high-quality food and beauty products is being observed not without a sense of irony. At a time like this, microorganisms are attracting attention as a key that can handle this couple of seemingly distant problems.

KAIST (President Kwang-Hyung Lee) announced on the 26th that Kyeong Rok Choi, a research professor of the Bioprocess Research Center and Sang Yup Lee, a Distinguished Professor of the Department of Chemical and Biomolecular Engineering, published a paper titled “Metabolic Engineering of Microorganisms for Food and Cosmetics Production” upon invitation by “Nature Reviews Bioengineering” to be published online published by Nature after peer review.

※ Paper title: Systems metabolic engineering of microorganisms for food and cosmetics production

※ Author information: Kyeong Rok Choi (first author) and Sang Yup Lee (corresponding author)

Systems metabolic engineering is a research field founded by Distinguished Professor Sang Yup Lee of KAIST to more effectively develop microbial cell factories, the core factor of the next-generation bio industry to replace the existing chemical industry that relies heavily on petroleum. By applying a systemic metabolic engineering strategy, the researchers have developed a number of high-performance microbial cell factories that produce a variety of food and cosmetic compounds including natural substances like heme and zinc protoporphyrin IX compounds which can improve the flavor and color of synthetic meat, lycopene and β-carotene which are functional natural pigments that can be widely used in food and cosmetics, and methyl anthranilate, a grape-derived compound widely used to impart grape flavor in food and beverage manufacturing.

In this paper written upon invitation by Nature, the research team covered remarkable cases of microbial cell factory that can produce amino acids, proteins, fats and fatty acids, vitamins, flavors, pigments, alcohols, functional compounds and other food additives used in various foods and cosmetics and the companies that have successfully commercialized these microbial-derived materials Furthermore, the paper organized and presents systems metabolic engineering strategies that can spur the development of industrial microbial cell factories that can produce more diverse food and cosmetic compounds in an eco-friendly way with economic feasibility.

< Figure 1. Examples of production of food and cosmetic compounds using microbial cell factories >

For example, by producing proteins or amino acids with high nutritional value through non-edible biomass used as animal feed or fertilizer through the microbial fermentation process, it will contribute to the increase in production and stable supply of food around the world. Furthermore, by contributing to developing more viable alternative meat, further reducing dependence on animal protein, it can also contribute to reducing greenhouse gases and environmental pollution generated through livestock breeding or fish farming.

In addition, vanillin or methyl anthranilate, which give off vanilla or grape flavor, are widely added to various foods, but natural products isolated and refined from plants are low in production and high in production cost, so in most cases, petrochemicals substances derived from vanillin and methylanthranilic acid are added to food. These materials can also be produced through an eco-friendly and human-friendly method by borrowing the power of microorganisms.

Ethical and resource problems that arise in producing compounds like Calmin (cochineal pigment), a coloring added to various cosmetics and foods such as red lipstick and strawberry-flavored milk, which must be extracted from cochineal insects that live only in certain cacti. and Hyaluronic acid, which is widely consumed as a health supplement, but is only present in omega-3 fatty acids extracted from shark or fish livers, can also be resolved when they can be produced in an eco-friendly way using microorganisms.

KAIST Research Professor Kyeong Rok Choi, the first author of this paper, said, “In addition to traditional fermented foods such as kimchi and yogurt, foods produced with the help of microorganisms like cocoa butter, a base ingredient for chocolate that can only be obtained from fermented cacao beans, and monosodium glutamate, a seasoning produced through microbial fermentation are already familiar to us”. “In the future, we will be able to acquire a wider variety of foods and cosmetics even more easily produced in an eco-friendly and sustainable way in our daily lives through microbial cell factories.” he added.

< Figure 2. Systems metabolic engineering strategy to improve metabolic flow in microbial cell factories >

Distinguished Professor Sang Yup Lee said, “It is engineers’ mission to make the world a better place utilizing science and technology.” and added, “Continuous advancement and active use of systems metabolic engineering will contribute greatly to easing and resolving the problems arising from both the food crisis and the climate change."

This research was carried out as a part of the “Development of Protein Production Technology from Inorganic Substances through Control of Microbial Metabolism System Project” (Project Leader: Kyeong Rok Choi, KAIST Research Professor) of the the Center for Agricultural Microorganism and Enzyme (Director Pahn-Shick Chang) supported by the Rural Development Administration and the “Development of Platform Technologies of Microbial Cell Factories for the Next-generation Biorefineries Project” (Project Leader: Sang Yup Lee, KAIST Distinguished Professor) of the Petroleum-Substitute Eco-friendly Chemical Technology Development Program supported by the Ministry of Science and ICT.

2023.07.28 View 11145 -

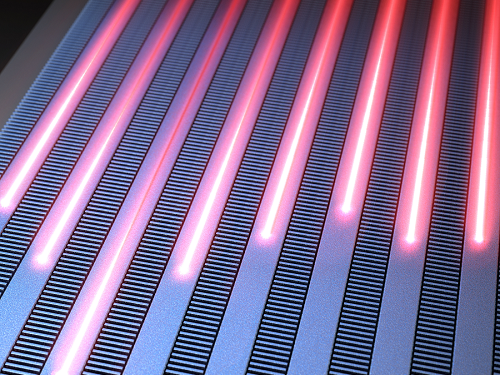

A KAIST research team develops a washable, transparent, and flexible OLED with MXene nanotechnology

Transparent and flexible displays, which have received a lot of attention in various fields including automobile displays, bio-healthcare, military, and fashion, are in fact known to break easily when experiencing small deformations. To solve this problem, active research is being conducted on many transparent and flexible conductive materials such as carbon nanotubes, graphene, silver nanowires, and conductive polymers.

On June 13, a joint research team led by Professor Kyung Cheol Choi from the KAIST School of Electrical Engineering and Dr. Yonghee Lee from the National Nano Fab Center (NNFC) announced the successful development of a water-resistant, transparent, and flexible OLED using MXene nanotechnology. The material can emit and transmit light even when exposed to water.

MXene is a 2D material with high electrical conductivity and optical transmittance, and it can be produced on a large scale through solution processes. However, despite these attractive properties, MXene’s applications were limited as a long-term electrical device due to its electrical properties being degraded easily by atmospheric moisture and water. The material was therefore unable to be systemized into the form of a matrix that can display information.

Professor Choi’s research team used an encapsulation tactic that can protect materials from oxidation caused by moisture and oxygen to develop a MXene-based OLED with a long lifespan and high stability against external environmental factors. The research team first focused on analyzing the degradation mechanism of MXene’s electrical conductivity, and then concentrated on designing an encapsulation membrane. The team blocked moisture and provided flexibility through residual stress offset, ultimately producing a double-layered encapsulation membrane. In addition, a thin plastic film with a thickness of a few micrometers was attached to the top layer to allow washing in water without degradation.

< Figure 1. (a) Transparent passive-matrix display made of MXene-based OLED, (b) Cross-sectional image of MXene-based OLED observed by transmission electron microscope (TEM), (c) Electro-optical characteristic graph of red, green, and blue MXene-based OLED >

Through this study, the research team developed a MXene-based red(R)/green(G)/blue(B) OLED that emits a brightness of over 1,000 cd/m2 that is detectable by the naked eye even under sunlight, thereby meeting the conditions for outdoor displays. As for the red MXene-based OLED, the researchers confirmed a standby storage life of 2,000 hours (under 70% luminescence), a standby operation life of 1,500 hours (under 60% luminescence), and a flexibility withstanding 1,000 cycles under a low curvature of under 1.5mm. In addition, they showed that its performance was maintained even after six hours of immersion under water (under 80% luminescence). Furthermore, a patterning technique was used to produce the MXene-based OLED in the form of a passive matrix, and the team demonstrated its use as a transparent display by displaying letters and shapes.

Ph.D. candidate So Yeong Jeong, who led this study, said, “To improve the reliability of MXene OLED, we focused on producing an adequate encapsulation structure and a suitable process design.” She added, “By producing a matrix-type MXene OLED and displaying simple letters and shapes, we have laid the foundations for MXene’s application in the field of transparent displays.”

< Image 1. Cover of ACS Nano Front Cover (Conceptual diagram of MXene-based OLED display) >

Professor Choi said, “This research will become the guideline for applying MXene in electrical devices, but we expect for it to also be applied in other fields that require flexible and transparent displays like automobiles, fashion, and functional clothing. And to widen the gap with China’s OLED technology, these new OLED convergence technologies must continue to be developed.”

This research was supported by the National Research Foundation of Korea and funded by the Ministry of Science and ICT, Korea. It was published as a front cover story of ACS Nano under the title, “Highly Air-Stable, Flexible, and Water-Resistive 2D Titanium Carbide MXene-Based RGB Organic Light-Emitting Diode Displays for Transparent Free-Form Electronics” on June 13.

2023.07.10 View 9036

A KAIST research team develops a washable, transparent, and flexible OLED with MXene nanotechnology

Transparent and flexible displays, which have received a lot of attention in various fields including automobile displays, bio-healthcare, military, and fashion, are in fact known to break easily when experiencing small deformations. To solve this problem, active research is being conducted on many transparent and flexible conductive materials such as carbon nanotubes, graphene, silver nanowires, and conductive polymers.

On June 13, a joint research team led by Professor Kyung Cheol Choi from the KAIST School of Electrical Engineering and Dr. Yonghee Lee from the National Nano Fab Center (NNFC) announced the successful development of a water-resistant, transparent, and flexible OLED using MXene nanotechnology. The material can emit and transmit light even when exposed to water.

MXene is a 2D material with high electrical conductivity and optical transmittance, and it can be produced on a large scale through solution processes. However, despite these attractive properties, MXene’s applications were limited as a long-term electrical device due to its electrical properties being degraded easily by atmospheric moisture and water. The material was therefore unable to be systemized into the form of a matrix that can display information.

Professor Choi’s research team used an encapsulation tactic that can protect materials from oxidation caused by moisture and oxygen to develop a MXene-based OLED with a long lifespan and high stability against external environmental factors. The research team first focused on analyzing the degradation mechanism of MXene’s electrical conductivity, and then concentrated on designing an encapsulation membrane. The team blocked moisture and provided flexibility through residual stress offset, ultimately producing a double-layered encapsulation membrane. In addition, a thin plastic film with a thickness of a few micrometers was attached to the top layer to allow washing in water without degradation.

< Figure 1. (a) Transparent passive-matrix display made of MXene-based OLED, (b) Cross-sectional image of MXene-based OLED observed by transmission electron microscope (TEM), (c) Electro-optical characteristic graph of red, green, and blue MXene-based OLED >

Through this study, the research team developed a MXene-based red(R)/green(G)/blue(B) OLED that emits a brightness of over 1,000 cd/m2 that is detectable by the naked eye even under sunlight, thereby meeting the conditions for outdoor displays. As for the red MXene-based OLED, the researchers confirmed a standby storage life of 2,000 hours (under 70% luminescence), a standby operation life of 1,500 hours (under 60% luminescence), and a flexibility withstanding 1,000 cycles under a low curvature of under 1.5mm. In addition, they showed that its performance was maintained even after six hours of immersion under water (under 80% luminescence). Furthermore, a patterning technique was used to produce the MXene-based OLED in the form of a passive matrix, and the team demonstrated its use as a transparent display by displaying letters and shapes.

Ph.D. candidate So Yeong Jeong, who led this study, said, “To improve the reliability of MXene OLED, we focused on producing an adequate encapsulation structure and a suitable process design.” She added, “By producing a matrix-type MXene OLED and displaying simple letters and shapes, we have laid the foundations for MXene’s application in the field of transparent displays.”

< Image 1. Cover of ACS Nano Front Cover (Conceptual diagram of MXene-based OLED display) >

Professor Choi said, “This research will become the guideline for applying MXene in electrical devices, but we expect for it to also be applied in other fields that require flexible and transparent displays like automobiles, fashion, and functional clothing. And to widen the gap with China’s OLED technology, these new OLED convergence technologies must continue to be developed.”

This research was supported by the National Research Foundation of Korea and funded by the Ministry of Science and ICT, Korea. It was published as a front cover story of ACS Nano under the title, “Highly Air-Stable, Flexible, and Water-Resistive 2D Titanium Carbide MXene-Based RGB Organic Light-Emitting Diode Displays for Transparent Free-Form Electronics” on June 13.

2023.07.10 View 9036 -

KAIST researchers find sleep delays more prevalent in countries of particular culture than others

Sleep has a huge impact on health, well-being and productivity, but how long and how well people sleep these days has not been accurately reported. Previous research on how much and how well we sleep has mostly relied on self-reports or was confined within the data from the unnatural environments of the sleep laboratories.

So, the questions remained: Is the amount and quality of sleep purely a personal choice? Could they be independent from social factors such as culture and geography?

< From left to right, Sungkyu Park of Kangwon National University, South Korea; Assem Zhunis of KAIST and IBS, South Korea; Marios Constantinides of Nokia Bell Labs, UK; Luca Maria Aiello of the IT University of Copenhagen, Denmark; Daniele Quercia of Nokia Bell Labs and King's College London, UK; and Meeyoung Cha of IBS and KAIST, South Korea >

A new study led by researchers at Korea Advanced Institute of Science and Technology (KAIST) and Nokia Bell Labs in the United Kingdom investigated the cultural and individual factors that influence sleep. In contrast to previous studies that relied on surveys or controlled experiments at labs, the team used commercially available smartwatches for extensive data collection, analyzing 52 million logs collected over a four-year period from 30,082 individuals in 11 countries. These people wore Nokia smartwatches, which allowed the team to investigate country-specific sleep patterns based on the digital logs from the devices.

< Figure comparing survey and smartwatch logs on average sleep-time, wake-time, and sleep durations. Digital logs consistently recorded delayed hours of wake- and sleep-time, resulting in shorter sleep durations. >

Digital logs collected from the smartwatches revealed discrepancies in wake-up times and sleep-times, sometimes by tens of minutes to an hour, from the data previously collected from self-report assessments. The average sleep-time overall was calculated to be around midnight, and the average wake-up time was 7:42 AM. The team discovered, however, that individuals' sleep is heavily linked to their geographical location and cultural factors. While wake-up times were similar, sleep-time varied by country. Individuals in higher GDP countries had more records of delayed bedtime. Those in collectivist culture, compared to individualist culture, also showed more records of delayed bedtime. Among the studied countries, Japan had the shortest total sleep duration, averaging a duration of under 7 hours, while Finland had the longest, averaging 8 hours.

Researchers calculated essential sleep metrics used in clinical studies, such as sleep efficiency, sleep duration, and overslept hours on weekends, to analyze the extensive sleep patterns. Using Principal Component Analysis (PCA), they further condensed these metrics into two major sleep dimensions representing sleep quality and quantity. A cross-country comparison revealed that societal factors account for 55% of the variation in sleep quality and 63% of the variation in sleep quantity.

Countries with a higher individualism index (IDV), which placed greater emphasis on individual achievements and relationships, had significantly longer sleep durations, which could be attributed to such societies having a norm of going to bed early. Spain and Japan, on the other hand, had the bedtime scheduled at the latest hours despite having the highest collectivism scores (low IDV). The study also discovered a moderate relationship between a higher uncertainty avoidance index (UAI), which measures implementation of general laws and regulation in daily lives of regular citizens, and better sleep quality.

Researchers also investigated how physical activity can affect sleep quantity and quality to see if individuals can counterbalance cultural influences through personal interventions. They discovered that increasing daily activity can improve sleep quality in terms of shortened time needed in falling asleep and waking up. Individuals who exercise more, however, did not sleep longer. The effect of exercise differed by country, with more pronounced effects observed in some countries, such as the United States and Finland. Interestingly, in Japan, no obvious effect of exercise could be observed. These findings suggest that the relationship between daily activity and sleep may differ by country and that different exercise regimens may be more effective in different cultures.

This research published on the Scientific Reports by the international journal, Nature, sheds light on the influence of social factors on sleep. (Paper Title "Social dimensions impact individual sleep quantity and quality" Article number: 9681)

One of the co-authors, Daniele Quercia, commented: “Excessive work schedules, long working hours, and late bedtime in high-income countries and social engagement due to high collectivism may cause bedtimes to be delayed.”

Commenting on the research, the first author Shaun Sungkyu Park said, "While it is intriguing to see that a society can play a role in determining the quantity and quality of an individual's sleep with large-scale data, the significance of this study is that it quantitatively shows that even within the same culture (country), individual efforts such as daily exercise can have a positive impact on sleep quantity and quality."

"Sleep not only has a great impact on one’s well-being but it is also known to be associated with health issues such as obesity and dementia," said the lead author, Meeyoung Cha. "In order to ensure adequate sleep and improve sleep quality in an aging society, not only individual efforts but also a social support must be provided to work together," she said. The research team will contribute to the development of the high-tech sleep industry by making a code that easily calculates the sleep indicators developed in this study available free of charge, as well as providing the benchmark data for various types of sleep research to follow.

2023.07.07 View 9957

KAIST researchers find sleep delays more prevalent in countries of particular culture than others

Sleep has a huge impact on health, well-being and productivity, but how long and how well people sleep these days has not been accurately reported. Previous research on how much and how well we sleep has mostly relied on self-reports or was confined within the data from the unnatural environments of the sleep laboratories.

So, the questions remained: Is the amount and quality of sleep purely a personal choice? Could they be independent from social factors such as culture and geography?

< From left to right, Sungkyu Park of Kangwon National University, South Korea; Assem Zhunis of KAIST and IBS, South Korea; Marios Constantinides of Nokia Bell Labs, UK; Luca Maria Aiello of the IT University of Copenhagen, Denmark; Daniele Quercia of Nokia Bell Labs and King's College London, UK; and Meeyoung Cha of IBS and KAIST, South Korea >

A new study led by researchers at Korea Advanced Institute of Science and Technology (KAIST) and Nokia Bell Labs in the United Kingdom investigated the cultural and individual factors that influence sleep. In contrast to previous studies that relied on surveys or controlled experiments at labs, the team used commercially available smartwatches for extensive data collection, analyzing 52 million logs collected over a four-year period from 30,082 individuals in 11 countries. These people wore Nokia smartwatches, which allowed the team to investigate country-specific sleep patterns based on the digital logs from the devices.

< Figure comparing survey and smartwatch logs on average sleep-time, wake-time, and sleep durations. Digital logs consistently recorded delayed hours of wake- and sleep-time, resulting in shorter sleep durations. >

Digital logs collected from the smartwatches revealed discrepancies in wake-up times and sleep-times, sometimes by tens of minutes to an hour, from the data previously collected from self-report assessments. The average sleep-time overall was calculated to be around midnight, and the average wake-up time was 7:42 AM. The team discovered, however, that individuals' sleep is heavily linked to their geographical location and cultural factors. While wake-up times were similar, sleep-time varied by country. Individuals in higher GDP countries had more records of delayed bedtime. Those in collectivist culture, compared to individualist culture, also showed more records of delayed bedtime. Among the studied countries, Japan had the shortest total sleep duration, averaging a duration of under 7 hours, while Finland had the longest, averaging 8 hours.

Researchers calculated essential sleep metrics used in clinical studies, such as sleep efficiency, sleep duration, and overslept hours on weekends, to analyze the extensive sleep patterns. Using Principal Component Analysis (PCA), they further condensed these metrics into two major sleep dimensions representing sleep quality and quantity. A cross-country comparison revealed that societal factors account for 55% of the variation in sleep quality and 63% of the variation in sleep quantity.

Countries with a higher individualism index (IDV), which placed greater emphasis on individual achievements and relationships, had significantly longer sleep durations, which could be attributed to such societies having a norm of going to bed early. Spain and Japan, on the other hand, had the bedtime scheduled at the latest hours despite having the highest collectivism scores (low IDV). The study also discovered a moderate relationship between a higher uncertainty avoidance index (UAI), which measures implementation of general laws and regulation in daily lives of regular citizens, and better sleep quality.

Researchers also investigated how physical activity can affect sleep quantity and quality to see if individuals can counterbalance cultural influences through personal interventions. They discovered that increasing daily activity can improve sleep quality in terms of shortened time needed in falling asleep and waking up. Individuals who exercise more, however, did not sleep longer. The effect of exercise differed by country, with more pronounced effects observed in some countries, such as the United States and Finland. Interestingly, in Japan, no obvious effect of exercise could be observed. These findings suggest that the relationship between daily activity and sleep may differ by country and that different exercise regimens may be more effective in different cultures.

This research published on the Scientific Reports by the international journal, Nature, sheds light on the influence of social factors on sleep. (Paper Title "Social dimensions impact individual sleep quantity and quality" Article number: 9681)

One of the co-authors, Daniele Quercia, commented: “Excessive work schedules, long working hours, and late bedtime in high-income countries and social engagement due to high collectivism may cause bedtimes to be delayed.”

Commenting on the research, the first author Shaun Sungkyu Park said, "While it is intriguing to see that a society can play a role in determining the quantity and quality of an individual's sleep with large-scale data, the significance of this study is that it quantitatively shows that even within the same culture (country), individual efforts such as daily exercise can have a positive impact on sleep quantity and quality."

"Sleep not only has a great impact on one’s well-being but it is also known to be associated with health issues such as obesity and dementia," said the lead author, Meeyoung Cha. "In order to ensure adequate sleep and improve sleep quality in an aging society, not only individual efforts but also a social support must be provided to work together," she said. The research team will contribute to the development of the high-tech sleep industry by making a code that easily calculates the sleep indicators developed in this study available free of charge, as well as providing the benchmark data for various types of sleep research to follow.

2023.07.07 View 9957 -

KAIST Civil Engineering Students named Runner-up at the 2023 ULI Hines Student Competition - Asia Pacific

A team of five students from the Korea Advanced Institute of Science and Technology (KAIST) were awarded second place in a premier urban design student competition hosted by the Urban Land Institute and Hines, 2023 ULI Hines Student Competition - Asia Pacific.

The competition, which was held for the first time in the Asia-Pacific region, is an internationally recognized event which typically attract hundreds of applicants.

Jonah Remigio, Sojung Noh, Estefania Rodriguez, Jihyun Kang, and Ayantu Teshome, who joined forces under the name of “Team Hashtag Development”, were supported by faculty advisors Dr. Albert Han and Dr. Youngchul Kim of the Department of Civil and Environmental Engineering to imagine a more sustainable and enriched way of living in the Jurong district of Singapore.

Their submission, titled “Proposal: The Nest”, analyzed the big data within Singapore, using the data to determine which real estate business strategies would best enhance the quality of living and economy of the region.

Their final design, "The Nest" utilized mixed-use zoning to integrate the site’s scenic waterfront with homes, medical innovation, and sustainable technology, altogether creating a place to innovate, inhabit, and immerse.

< The Nest by Team Hashtag Development (Jonah Remigio, Ayantu Teshome Mossisa, Estefania Ayelen Rodriguez del Puerto, Sojung Noh, Jihyun Kang) ©2023 Urban Land Institute >

Ultimately, the team was recognized for their hard work and determination, imprinting South Korea’s indelible footprint in the arena of international scholastic achievement as they were named to be one of the Finalists on April 13th.

< Members of Team Hashtag Development >

Team Hashtag Development gave a virtual presentation to a jury of six ULI members on April 20th along with the "Team The REAL" from the University of Economics Ho Chi Minh City of Vietnam and "Team Omusubi" from the Waseda University of Japan, the team that submitted the proposal "Jurong Urban Health Campus" which was announced to be the winner on the 31st of May, after the virtual briefing by the top three finalists.

2023.06.26 View 10780

KAIST Civil Engineering Students named Runner-up at the 2023 ULI Hines Student Competition - Asia Pacific

A team of five students from the Korea Advanced Institute of Science and Technology (KAIST) were awarded second place in a premier urban design student competition hosted by the Urban Land Institute and Hines, 2023 ULI Hines Student Competition - Asia Pacific.

The competition, which was held for the first time in the Asia-Pacific region, is an internationally recognized event which typically attract hundreds of applicants.

Jonah Remigio, Sojung Noh, Estefania Rodriguez, Jihyun Kang, and Ayantu Teshome, who joined forces under the name of “Team Hashtag Development”, were supported by faculty advisors Dr. Albert Han and Dr. Youngchul Kim of the Department of Civil and Environmental Engineering to imagine a more sustainable and enriched way of living in the Jurong district of Singapore.

Their submission, titled “Proposal: The Nest”, analyzed the big data within Singapore, using the data to determine which real estate business strategies would best enhance the quality of living and economy of the region.

Their final design, "The Nest" utilized mixed-use zoning to integrate the site’s scenic waterfront with homes, medical innovation, and sustainable technology, altogether creating a place to innovate, inhabit, and immerse.

< The Nest by Team Hashtag Development (Jonah Remigio, Ayantu Teshome Mossisa, Estefania Ayelen Rodriguez del Puerto, Sojung Noh, Jihyun Kang) ©2023 Urban Land Institute >

Ultimately, the team was recognized for their hard work and determination, imprinting South Korea’s indelible footprint in the arena of international scholastic achievement as they were named to be one of the Finalists on April 13th.