GS

-

KAIST Professor Whang Turns VLDB Journal Into One of the Best in Its Field

Kyu-Young Whang, a Distinguished Professor at KAIST’s Computer Science Department, has developed The VLDB Journal into one of the world’s best journals on database technology.

Professor Whang, Editor-in-Chief of The VLDB Journal, is credited for the journal’s remarkable success evidenced by the rise of the publication’s Science Citation Index (SCI) impact factor from 3.818 to 6.8 in the period of one year. This placed the VLDB in the first place amongst 99 information systems journals and 44 hardware and architecture-related journals registered with the SCI. With only the exception of the Survey Journal, this makes The VLDB Journal the best in computer science.

The VLDB Journal is a quarterly journal published on behalf of the VLDB Endowment. The journal, launched in 1992, is dedicated to the publication of scholarly contributions to the advancement of information system architectures, the impact of technological advancements on information systems, and the development of novel database applications.

The VLDB Journal’s closest competitors in database technology, IEEE Transactions on Knowledge and Data Engineering and ACM Transactions on Database Systems, received an impact factor of 2.236 and 1.613 respectively. Comparatively, Professor Whang’s journal retains an impact factor nearly 3 to 4 times greater.

During Professor Whang’s six-year term as Editor-in-Chief, he has actively pursued the use of innovative ideas, strengthened the board of editors, standardized the length of review time, and made the journal much more accessible through the Internet. Furthermore, he drastically reduced publication time and sought a policy that focused more on the journal’s readers, which led to The VLDB Journal’s SCI impact factor rising from 1.149 (2002) to 6.8 (2008).

As one of The VLDB Journal’s founding members, Professor Whang has worked for the advancement of his journal tirelessly for 19 years with many accomplishments in database technology, including physical database design, determining the quality of a database, and the creation of a database management system. As a result, Professor Whang became the first IEEE fellow concerning domestic computer science. He is also a trustee of The VLDB Endowment, a fellow of the Korean Academy of Science and Technology, and of course, a Distinguished Professor at KAIST.

2009.07.16 View 17158

KAIST Professor Whang Turns VLDB Journal Into One of the Best in Its Field

Kyu-Young Whang, a Distinguished Professor at KAIST’s Computer Science Department, has developed The VLDB Journal into one of the world’s best journals on database technology.

Professor Whang, Editor-in-Chief of The VLDB Journal, is credited for the journal’s remarkable success evidenced by the rise of the publication’s Science Citation Index (SCI) impact factor from 3.818 to 6.8 in the period of one year. This placed the VLDB in the first place amongst 99 information systems journals and 44 hardware and architecture-related journals registered with the SCI. With only the exception of the Survey Journal, this makes The VLDB Journal the best in computer science.

The VLDB Journal is a quarterly journal published on behalf of the VLDB Endowment. The journal, launched in 1992, is dedicated to the publication of scholarly contributions to the advancement of information system architectures, the impact of technological advancements on information systems, and the development of novel database applications.

The VLDB Journal’s closest competitors in database technology, IEEE Transactions on Knowledge and Data Engineering and ACM Transactions on Database Systems, received an impact factor of 2.236 and 1.613 respectively. Comparatively, Professor Whang’s journal retains an impact factor nearly 3 to 4 times greater.

During Professor Whang’s six-year term as Editor-in-Chief, he has actively pursued the use of innovative ideas, strengthened the board of editors, standardized the length of review time, and made the journal much more accessible through the Internet. Furthermore, he drastically reduced publication time and sought a policy that focused more on the journal’s readers, which led to The VLDB Journal’s SCI impact factor rising from 1.149 (2002) to 6.8 (2008).

As one of The VLDB Journal’s founding members, Professor Whang has worked for the advancement of his journal tirelessly for 19 years with many accomplishments in database technology, including physical database design, determining the quality of a database, and the creation of a database management system. As a result, Professor Whang became the first IEEE fellow concerning domestic computer science. He is also a trustee of The VLDB Endowment, a fellow of the Korean Academy of Science and Technology, and of course, a Distinguished Professor at KAIST.

2009.07.16 View 17158 -

KAIST Ranks 95th among World Universities

Oct. 13, 2008 --KAIST is ranked 95th among Top 200 Universities of the World this year, scoring a notable increase from last year"s ranking of 132nd. KAIST, Seoul National University which was placed 50th, and POSTECH ranked 188th became the only three institutions of higher education in Korea to make it to the list, called "The Times Higher Education -- QS World University Rankings."

KAIST"s advancement was more conspicuous in specific area evaluations. In the area of Engineering and Information Technology, it is ranked 34th (49th last year), in Natural Sciences 46th (86th last year), and in Biological Sciences and Biotechnology 134th (166th last year).

While North America dominates the ranking with 42 universities on the list, Europe and Asia Pacific are also well represented with 36 and 22 institutions, respectively.

The list, compiled by The Times (of London) newspaper annually, is topped by Harvard University (USA), followed by Yale University (USA) and University of Cambridge (United Kingdom).

Last year, only KAIST and SNU were included in the top 200 list. This year, Yonsei University raised its ranking to 203rd from last year"s 223rd while Korea University improved from 243rd to 236th, showing overall improvement of universities in Korea.

Again this year, Japan and China had most of the top ranked universities in Asia, each sharing three in the top 50. University of Tokyo, ranked 19th, led all Japanese universities; Kyoto University was placed 25th and Osaka University 44th. University of Hong Kong was listed 26th, followed by Hong Kong University of Science and Technology on 39th and the Chinese University of Hong Kong on 42nd.

The Times Higher Education--QS World University Rankings evaluates four main categories: quality of research, globalization, and quality of education and work of graduates in society. The evaluation also considers academic peer review, citations per faculty, recruiter review, international faculty, international students and faculty-student ratio.

QS Top 100 Universities 2008

Source: QS Quacquarelli Symonds (www.topuniversities.com)

Copyright?004-2008QSQuacquarelliSymondsLtd.

1

HARVARD University

United States

2

YALE University

United States

3

University of CAMBRIDGE

United Kingdom

4

University of OXFORD

United Kingdom

5

CALIFORNIA Institute of Technology (Calt...

United States

6

IMPERIAL College London

United Kingdom

7

UCL (University College London)

United Kingdom

8

University of CHICAGO

United States

9

MASSACHUSETTS Institute of Technology (M...

United States

10

COLUMBIA University

United States

11

University of PENNSYLVANIA

United States

12

PRINCETON University

United States

13=

DUKE University

United States

13=

JOHNS HOPKINS University

United States

15

CORNELL University

United States

16

AUSTRALIAN National University

Australia

17

STANFORD University

United States

18

University of MICHIGAN

United States

19

University of TOKYO

Japan

20

MCGILL University

Canada

21

CARNEGIE MELLON University

United States

22

KING"S College London

United Kingdom

23

University of EDINBURGH

United Kingdom

24

ETH Zurich (Swiss Federal Institute of T...

Switzerland

25

KYOTO University

Japan

26

University of HONG KONG

Hong Kong

27

BROWN University

United States

28

?ole Normale Sup?ieure, PARIS

France

29

University of MANCHESTER

United Kingdom

30=

National University of SINGAPORE(NUS)

Singapore

30=

University of CALIFORNIA, Los Angeles (U...

United States

32

University of BRISTOL

United Kingdom

33

NORTHWESTERN University

United States

34=

?OLE POLYTECHNIQUE

France

34=

University of BRITISH COLUMBIA

Canada

36

University of California, BERKELEY

United States

37

The University of SYDNEY

Australia

38

The University of MELBOURNE

Australia

39

HONG KONG University of Science & Techno...

Hong Kong

40

NEW YORK University (NYU)

United States

41

University of TORONTO

Canada

42

The CHINESE University of Hong Kong

Hong Kong

43

University of QUEENSLAND

Australia

44

OSAKA University

Japan

45

University of NEW SOUTH WALES

Australia

46

BOSTON University

United States

47

MONASH University

Australia

48

University of COPENHAGEN

Denmark

49

TRINITY College Dublin

Ireland

50=

Ecole Polytechnique F??ale de LAUSANNE...

Switzerland

50=

PEKING University

China

50=

SEOUL National University

Korea, South

53

University of AMSTERDAM

Netherlands

54

DARTMOUTH College

United States

55

University of WISCONSIN-Madison

United States

56

TSINGHUA University

China

57

HEIDELBERG Universit?

Germany

58

University of CALIFORNIA, San Diego

United States

59

University of WASHINGTON

United States

60

WASHINGTON University in St. Louis

United States

61

TOKYO Institute of Technology

Japan

62

EMORY University

United States

63

UPPSALA University

Sweden

64

LEIDEN University

Netherlands

65

The University of AUCKLAND

New Zealand

66

LONDON School of Economics and Political...

United Kingdom

67

UTRECHT University

Netherlands

68

University of GENEVA

Switzerland

69

University of WARWICK

United Kingdom

70

University of TEXAS at Austin

United States

71

University of ILLINOIS

United States

72

Katholieke Universiteit LEUVEN

Belgium

73

University of GLASGOW

United Kingdom

74

University of ALBERTA

Canada

75

University of BIRMINGHAM

United Kingdom

76

University of SHEFFIELD

United Kingdom

77

NANYANG Technological University

Singapore

78=

DELFT University of Technology

Netherlands

78=

RICE University

United States

78=

Technische Universit? M?CHEN

Germany

81=

University of AARHUS

Denmark

81=

University of YORK

United Kingdom

83=

GEORGIA Institute of Technology

United States

83=

The University of WESTERN AUSTRALIA

Australia

83=

University of ST ANDREWS

United Kingdom

86

University of NOTTINGHAM

United Kingdom

87

University of MINNESOTA

United States

88

LUND University

Sweden

89

University of CALIFORNIA, Davis

United States

90

CASE WESTERN RESERVE University

United States

91=

Universit?de Montr?l

Canada

91=

University of HELSINKI

Finland

93=

Hebrew University of JERUSALEM

Israel

93=

Ludwig-Maximilians-Universit? M?chen

Germany

95

KAIST - Korea Advanced Institute of Scie...

Korea, South

96

University of VIRGINIA

United States

97

University of PITTSBURGH

United States

98

University of CALIFORNIA, Santa Barbara

United States

99=

PURDUE University

United States

99=

University of SOUTHAMPTON

United Kingdom

2008.10.14 View 18537

KAIST Ranks 95th among World Universities

Oct. 13, 2008 --KAIST is ranked 95th among Top 200 Universities of the World this year, scoring a notable increase from last year"s ranking of 132nd. KAIST, Seoul National University which was placed 50th, and POSTECH ranked 188th became the only three institutions of higher education in Korea to make it to the list, called "The Times Higher Education -- QS World University Rankings."

KAIST"s advancement was more conspicuous in specific area evaluations. In the area of Engineering and Information Technology, it is ranked 34th (49th last year), in Natural Sciences 46th (86th last year), and in Biological Sciences and Biotechnology 134th (166th last year).

While North America dominates the ranking with 42 universities on the list, Europe and Asia Pacific are also well represented with 36 and 22 institutions, respectively.

The list, compiled by The Times (of London) newspaper annually, is topped by Harvard University (USA), followed by Yale University (USA) and University of Cambridge (United Kingdom).

Last year, only KAIST and SNU were included in the top 200 list. This year, Yonsei University raised its ranking to 203rd from last year"s 223rd while Korea University improved from 243rd to 236th, showing overall improvement of universities in Korea.

Again this year, Japan and China had most of the top ranked universities in Asia, each sharing three in the top 50. University of Tokyo, ranked 19th, led all Japanese universities; Kyoto University was placed 25th and Osaka University 44th. University of Hong Kong was listed 26th, followed by Hong Kong University of Science and Technology on 39th and the Chinese University of Hong Kong on 42nd.

The Times Higher Education--QS World University Rankings evaluates four main categories: quality of research, globalization, and quality of education and work of graduates in society. The evaluation also considers academic peer review, citations per faculty, recruiter review, international faculty, international students and faculty-student ratio.

QS Top 100 Universities 2008

Source: QS Quacquarelli Symonds (www.topuniversities.com)

Copyright?004-2008QSQuacquarelliSymondsLtd.

1

HARVARD University

United States

2

YALE University

United States

3

University of CAMBRIDGE

United Kingdom

4

University of OXFORD

United Kingdom

5

CALIFORNIA Institute of Technology (Calt...

United States

6

IMPERIAL College London

United Kingdom

7

UCL (University College London)

United Kingdom

8

University of CHICAGO

United States

9

MASSACHUSETTS Institute of Technology (M...

United States

10

COLUMBIA University

United States

11

University of PENNSYLVANIA

United States

12

PRINCETON University

United States

13=

DUKE University

United States

13=

JOHNS HOPKINS University

United States

15

CORNELL University

United States

16

AUSTRALIAN National University

Australia

17

STANFORD University

United States

18

University of MICHIGAN

United States

19

University of TOKYO

Japan

20

MCGILL University

Canada

21

CARNEGIE MELLON University

United States

22

KING"S College London

United Kingdom

23

University of EDINBURGH

United Kingdom

24

ETH Zurich (Swiss Federal Institute of T...

Switzerland

25

KYOTO University

Japan

26

University of HONG KONG

Hong Kong

27

BROWN University

United States

28

?ole Normale Sup?ieure, PARIS

France

29

University of MANCHESTER

United Kingdom

30=

National University of SINGAPORE(NUS)

Singapore

30=

University of CALIFORNIA, Los Angeles (U...

United States

32

University of BRISTOL

United Kingdom

33

NORTHWESTERN University

United States

34=

?OLE POLYTECHNIQUE

France

34=

University of BRITISH COLUMBIA

Canada

36

University of California, BERKELEY

United States

37

The University of SYDNEY

Australia

38

The University of MELBOURNE

Australia

39

HONG KONG University of Science & Techno...

Hong Kong

40

NEW YORK University (NYU)

United States

41

University of TORONTO

Canada

42

The CHINESE University of Hong Kong

Hong Kong

43

University of QUEENSLAND

Australia

44

OSAKA University

Japan

45

University of NEW SOUTH WALES

Australia

46

BOSTON University

United States

47

MONASH University

Australia

48

University of COPENHAGEN

Denmark

49

TRINITY College Dublin

Ireland

50=

Ecole Polytechnique F??ale de LAUSANNE...

Switzerland

50=

PEKING University

China

50=

SEOUL National University

Korea, South

53

University of AMSTERDAM

Netherlands

54

DARTMOUTH College

United States

55

University of WISCONSIN-Madison

United States

56

TSINGHUA University

China

57

HEIDELBERG Universit?

Germany

58

University of CALIFORNIA, San Diego

United States

59

University of WASHINGTON

United States

60

WASHINGTON University in St. Louis

United States

61

TOKYO Institute of Technology

Japan

62

EMORY University

United States

63

UPPSALA University

Sweden

64

LEIDEN University

Netherlands

65

The University of AUCKLAND

New Zealand

66

LONDON School of Economics and Political...

United Kingdom

67

UTRECHT University

Netherlands

68

University of GENEVA

Switzerland

69

University of WARWICK

United Kingdom

70

University of TEXAS at Austin

United States

71

University of ILLINOIS

United States

72

Katholieke Universiteit LEUVEN

Belgium

73

University of GLASGOW

United Kingdom

74

University of ALBERTA

Canada

75

University of BIRMINGHAM

United Kingdom

76

University of SHEFFIELD

United Kingdom

77

NANYANG Technological University

Singapore

78=

DELFT University of Technology

Netherlands

78=

RICE University

United States

78=

Technische Universit? M?CHEN

Germany

81=

University of AARHUS

Denmark

81=

University of YORK

United Kingdom

83=

GEORGIA Institute of Technology

United States

83=

The University of WESTERN AUSTRALIA

Australia

83=

University of ST ANDREWS

United Kingdom

86

University of NOTTINGHAM

United Kingdom

87

University of MINNESOTA

United States

88

LUND University

Sweden

89

University of CALIFORNIA, Davis

United States

90

CASE WESTERN RESERVE University

United States

91=

Universit?de Montr?l

Canada

91=

University of HELSINKI

Finland

93=

Hebrew University of JERUSALEM

Israel

93=

Ludwig-Maximilians-Universit? M?chen

Germany

95

KAIST - Korea Advanced Institute of Scie...

Korea, South

96

University of VIRGINIA

United States

97

University of PITTSBURGH

United States

98

University of CALIFORNIA, Santa Barbara

United States

99=

PURDUE University

United States

99=

University of SOUTHAMPTON

United Kingdom

2008.10.14 View 18537 -

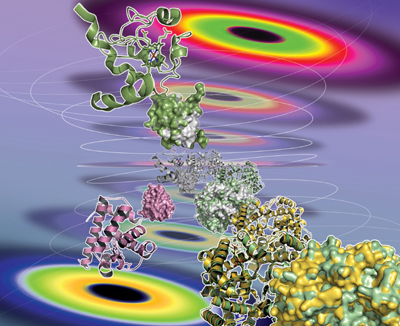

KAIST Professor Exposes Structural Dynamics of Protein in Solution

-- Dr. Hyot-Cherl Ihee"s 3-Year Research Is Valuable in Pharmaceutical Application

Prof. Hyot-Cherl Ihee and his team at the Department of Chemistry, KAIST, has successfully unveiled the structural dynamics of protein in solution as a result of more than three years" research work.

Nature Methods, a sister publication of the authoritative science magazine Nature, published the treatise, titled "Tracking the structural dynamics of proteins in solution using time-resolved wide-angle X-ray scattering" in its Sept. 22 online edition. The research paper will be carried in the magazine"s printed version in its October edition, according to Dr. Lee who is its correspondence author.

In May 2005, Prof. Ihee successfully photographed the structural dynamics of protein in solid state and his findings were published in the Proceedings of National Academy of Science of the United States. As protein normally exists in human body in solution, not in solid state, he directed his research to developing the technology to capture protein"s dynamics in resolved state.

In July that year, Prof. Ihee succeeded in measuring the structural changes of simple organic molecules in real time. He further developed the technology to uncover the structural dynamics of hemoglobin, myoglobin and cytochrome C.

Prof. Ihee"s research, helped with the Education-Science-Technology Ministry"s Creative Research Promotion Fund, can be applied to new pharmaceutical development projects as well as nanotechnology development, according to KAIST officials.

Prof. Ihee who earned his doctorate at California Institute of Technology in 1994 began teaching at KAIST in 2003. He won the Young Scientist Award given by the Korean government in 2006.

2008.09.22 View 15591

KAIST Professor Exposes Structural Dynamics of Protein in Solution

-- Dr. Hyot-Cherl Ihee"s 3-Year Research Is Valuable in Pharmaceutical Application

Prof. Hyot-Cherl Ihee and his team at the Department of Chemistry, KAIST, has successfully unveiled the structural dynamics of protein in solution as a result of more than three years" research work.

Nature Methods, a sister publication of the authoritative science magazine Nature, published the treatise, titled "Tracking the structural dynamics of proteins in solution using time-resolved wide-angle X-ray scattering" in its Sept. 22 online edition. The research paper will be carried in the magazine"s printed version in its October edition, according to Dr. Lee who is its correspondence author.

In May 2005, Prof. Ihee successfully photographed the structural dynamics of protein in solid state and his findings were published in the Proceedings of National Academy of Science of the United States. As protein normally exists in human body in solution, not in solid state, he directed his research to developing the technology to capture protein"s dynamics in resolved state.

In July that year, Prof. Ihee succeeded in measuring the structural changes of simple organic molecules in real time. He further developed the technology to uncover the structural dynamics of hemoglobin, myoglobin and cytochrome C.

Prof. Ihee"s research, helped with the Education-Science-Technology Ministry"s Creative Research Promotion Fund, can be applied to new pharmaceutical development projects as well as nanotechnology development, according to KAIST officials.

Prof. Ihee who earned his doctorate at California Institute of Technology in 1994 began teaching at KAIST in 2003. He won the Young Scientist Award given by the Korean government in 2006.

2008.09.22 View 15591 -

KAIST, GS Caltex Jointly Develop New Bacteria to Produce Biobutanol

KAIST and GS Caltex, Korea"s second-largest refiner, have jointly developed a new strain of bacteria to produce biobutanol, which is regarded as a promising next-generation biofuel, KAIST authorities said on Monday (June 2).

A research team led by Prof. Sang-Yup Lee of the Chemical and Biomolecular Engineering Department and researchers of GS Caltex succeeded in developing an improved strain of bacteria which enables to produce a large amount of biobutanol in the process of fermenting biomass. The research team has applied for international patent for the new technology.

Biomass refers to living and recently dead biological material that can be used as fuel or for industrial production. It usually refers to plant matter grown for use as biofuel, but it also includes plant or animal matter used for production of fibers, chemicals or heat.

In the 1970s and 1980s when scientists began researching the possibilities of alternative fuels, bacteria were used in the process of fermenting biomass. This ABE (acetone, butanol, ethanol) fermentation process yields butanol, acetone, and ethanol in a ratio of 6:3:1, respectively. Acetone produced in this process is not usable.

The newly developed technology to produce biobutanol has an advantage of lowering production cost by eliminating the process to separate acetone from butanol. This has been made possible by improving the bacteria used for the fermentation in metabolic engineering terms, and producing butanol and ethanol only in a ratio of 6:1, while curbing the generation of acetone.

In comparison with bioethanol, also a biofuel mixture which is currently under widespread use in some countries, butanol is more easily transported with gasoline and diesel through pipelines because of its lower tendency to separate from the fuel when contaminated with water. Butanol is also less corrosive than ethanol, another reason its transport through pipeline is preferable.

Global interest in full utilization of biomass and development of other alternative energy including biobutanol has deepened in recent years, as crude oil prices have skyrocketed to record levels and climate changes resulting from the excessive use of fossil fuel have been causing various problems around the world.

2008.06.04 View 14373

KAIST, GS Caltex Jointly Develop New Bacteria to Produce Biobutanol

KAIST and GS Caltex, Korea"s second-largest refiner, have jointly developed a new strain of bacteria to produce biobutanol, which is regarded as a promising next-generation biofuel, KAIST authorities said on Monday (June 2).

A research team led by Prof. Sang-Yup Lee of the Chemical and Biomolecular Engineering Department and researchers of GS Caltex succeeded in developing an improved strain of bacteria which enables to produce a large amount of biobutanol in the process of fermenting biomass. The research team has applied for international patent for the new technology.

Biomass refers to living and recently dead biological material that can be used as fuel or for industrial production. It usually refers to plant matter grown for use as biofuel, but it also includes plant or animal matter used for production of fibers, chemicals or heat.

In the 1970s and 1980s when scientists began researching the possibilities of alternative fuels, bacteria were used in the process of fermenting biomass. This ABE (acetone, butanol, ethanol) fermentation process yields butanol, acetone, and ethanol in a ratio of 6:3:1, respectively. Acetone produced in this process is not usable.

The newly developed technology to produce biobutanol has an advantage of lowering production cost by eliminating the process to separate acetone from butanol. This has been made possible by improving the bacteria used for the fermentation in metabolic engineering terms, and producing butanol and ethanol only in a ratio of 6:1, while curbing the generation of acetone.

In comparison with bioethanol, also a biofuel mixture which is currently under widespread use in some countries, butanol is more easily transported with gasoline and diesel through pipelines because of its lower tendency to separate from the fuel when contaminated with water. Butanol is also less corrosive than ethanol, another reason its transport through pipeline is preferable.

Global interest in full utilization of biomass and development of other alternative energy including biobutanol has deepened in recent years, as crude oil prices have skyrocketed to record levels and climate changes resulting from the excessive use of fossil fuel have been causing various problems around the world.

2008.06.04 View 14373 -

Cooperation Agreement with Ajou Motor College

Cooperation Agreement with Ajou Motor College

KAIST Graduate School of Automobile Technology to sign a cooperation agreement with Ajou Motor College

KAIST Graduate School of Automobile Technology (GSAT) signed a cooperation agreement with Ajou Motor College (AMC) on July 18th.

Under the agreement, the both schools will share education and research facilities and promote mutual cooperation for joint education and researches.

Lawmaker Geun-Chan Ryu, KAIST Vice President of Budget & Planning Ji-Won Yang, GSAT Dean Suck-Joo Na, AMC Dean Soo-Hoon Lee, etc. attended the ceremony.

2007.07.24 View 16896

Cooperation Agreement with Ajou Motor College

Cooperation Agreement with Ajou Motor College

KAIST Graduate School of Automobile Technology to sign a cooperation agreement with Ajou Motor College

KAIST Graduate School of Automobile Technology (GSAT) signed a cooperation agreement with Ajou Motor College (AMC) on July 18th.

Under the agreement, the both schools will share education and research facilities and promote mutual cooperation for joint education and researches.

Lawmaker Geun-Chan Ryu, KAIST Vice President of Budget & Planning Ji-Won Yang, GSAT Dean Suck-Joo Na, AMC Dean Soo-Hoon Lee, etc. attended the ceremony.

2007.07.24 View 16896 -

Maximum Yield Amino Acid-Producing Microorganism Developed with use of System Biotechnology

Maximum Yield Amino Acid-Producing Microorganism Developed with use of System Biotechnology

A team led by Sang-Yup Lee, a distinguished professor of Chemical and Biomolecular Engineering and chair professor of LG Chemical, has succeeded in developing maximum yield L-valine-producing microorganism by using System Biotechnology methods. The research results will be published at the April fourth week (April 23 - 27) edition of the Proceedings of the National Academy of Sciences (PNAS) of the USA.

Prof. Lee’s team has developed maximum yield amino acid-producing microorganism (target substance of L-valine, an essential amino-acid) by using microorganism E cell system and simulation methods.

His team produced initial producing microorganism by selectively operating necessary parts in colon bacillus genome and excavated preliminary target gene which is to newly be operated through transcriptome analysis using DNA chips. Then they performed a great amount of gene deletion experiment on computer by using MBEL979, E-cells of colon bacillus, and excavated secondary engineering targets. And they finally succeeded in developing maximum yield valine-producing microorganism that can extract 37.8 grams of valine from 100 grams of glucose by applying experiment results to the actual development of microorganism so as to achieve the optimization of metabolic flux in cells,

Prof. Lee said, “Since successfully used for the development of microorganism on a systematic system level, system biotechnology methods are expected to significantly contribute to the development of all biotechnology-relevant industries. At the beginning, we had huge obstacles in fusing IT and BT, but my team mates cleverly overcame such obstacles, hence I’m very proud of them.” The producing microorganism and its developing methods are pending international applications (PCT).

2007.04.26 View 16627

Maximum Yield Amino Acid-Producing Microorganism Developed with use of System Biotechnology

Maximum Yield Amino Acid-Producing Microorganism Developed with use of System Biotechnology

A team led by Sang-Yup Lee, a distinguished professor of Chemical and Biomolecular Engineering and chair professor of LG Chemical, has succeeded in developing maximum yield L-valine-producing microorganism by using System Biotechnology methods. The research results will be published at the April fourth week (April 23 - 27) edition of the Proceedings of the National Academy of Sciences (PNAS) of the USA.

Prof. Lee’s team has developed maximum yield amino acid-producing microorganism (target substance of L-valine, an essential amino-acid) by using microorganism E cell system and simulation methods.

His team produced initial producing microorganism by selectively operating necessary parts in colon bacillus genome and excavated preliminary target gene which is to newly be operated through transcriptome analysis using DNA chips. Then they performed a great amount of gene deletion experiment on computer by using MBEL979, E-cells of colon bacillus, and excavated secondary engineering targets. And they finally succeeded in developing maximum yield valine-producing microorganism that can extract 37.8 grams of valine from 100 grams of glucose by applying experiment results to the actual development of microorganism so as to achieve the optimization of metabolic flux in cells,

Prof. Lee said, “Since successfully used for the development of microorganism on a systematic system level, system biotechnology methods are expected to significantly contribute to the development of all biotechnology-relevant industries. At the beginning, we had huge obstacles in fusing IT and BT, but my team mates cleverly overcame such obstacles, hence I’m very proud of them.” The producing microorganism and its developing methods are pending international applications (PCT).

2007.04.26 View 16627 -

Austrian president and first lady visit KAIST

Austrian President Heinz Fischer and first lady Margit Fischer visited KAIST on April 4.

HUBO and Albert HUBO, humanoid robots of KAIST, welcomed Mr. and Mrs. President from Austria by giving bouquets to and shaking hands with them. HUBO also showed self-introduction, facial expression, and Tae-Geuk-Kwon demonstration.

KAIST President Nam-Pyo Suh said at his welcoming remarks, “KAIST has talented young people as its students, and over 32,000 KAIST graduates are playing very important roles at large conglomerates and schools. To become a world-class university, KAIST is promoting active global exchange programs and hopes to have joint programs with Austrian universities such as the Technical University of Vienna, etc.”

Austrian President Heinz Fischer said at his reply, “I am deeply impressed with KAIST, the final place visited during my trip to Korea. Albert HUBO evidently gave me a tip concerning the high technical power of KAIST. Austria is now on a strong education innovation program, and I hope to establish a long-term cooperation programs with distinguished Korean universities like KAIST.”

After the ceremony, Mr. and Mrs. President from Austria, Mr. and Mrs. President of KAIST, and distinguished guests had a 30-minute long luncheon at the grand seminar room.

2007.04.12 View 13944

Austrian president and first lady visit KAIST

Austrian President Heinz Fischer and first lady Margit Fischer visited KAIST on April 4.

HUBO and Albert HUBO, humanoid robots of KAIST, welcomed Mr. and Mrs. President from Austria by giving bouquets to and shaking hands with them. HUBO also showed self-introduction, facial expression, and Tae-Geuk-Kwon demonstration.

KAIST President Nam-Pyo Suh said at his welcoming remarks, “KAIST has talented young people as its students, and over 32,000 KAIST graduates are playing very important roles at large conglomerates and schools. To become a world-class university, KAIST is promoting active global exchange programs and hopes to have joint programs with Austrian universities such as the Technical University of Vienna, etc.”

Austrian President Heinz Fischer said at his reply, “I am deeply impressed with KAIST, the final place visited during my trip to Korea. Albert HUBO evidently gave me a tip concerning the high technical power of KAIST. Austria is now on a strong education innovation program, and I hope to establish a long-term cooperation programs with distinguished Korean universities like KAIST.”

After the ceremony, Mr. and Mrs. President from Austria, Mr. and Mrs. President of KAIST, and distinguished guests had a 30-minute long luncheon at the grand seminar room.

2007.04.12 View 13944 -

Professor Seong-Ihl Woo Develops New High-Speed Research Method

Professor Seong-Ihl Woo Develops New High-Speed Research Method

Reduce research periods and expenses for thin film materials several ten times

Posted on the online version of Proceedings of National Academy of Sciences of the United States of America (PNAS) on January 9

A team led by Seong-Ihl Woo, a professor of KAIST Department of Chemical & Biomolecular Engineering and the director of the Center for Ultramicrochemical Process Systems, has developed a high-speed research method that can maximize research performances and posted the relevant contents on the online version of Proceedings of National Academy of Sciences of the United States of America (PNAS), a distinguished scientific journal, on January 9, 2007.

Professor Woo’s team has developed a high-speed research method that can fabricate several tens or several thousands of thin films with different compositions (mixing ratio) at the same time and carry out structural analysis and performance evaluation more than ten times faster and accurately, which leads to the shortening of the research processes of thin film materials. This is an epoch-making method that can reduce research periods and expenses several ten times or more, compared to the previous methods.

The qualities of final products of electronic materials, displays, and semi-conductors depend on the features of thin film materials. Averagely, it takes about two weeks or longer to fabricate a functional thin film and analyze and evaluate its performances. In order to fabricate thin film materials in need successfully, more than several thousand times of tests are required.

The existing thin film-fabricating equipment is expensive one demanding high-degree vacuum, such as chemical vapor deposition, sputtering, physical vapor deposition, laser evaporation, and so on. In order to fabricate thin films of various compositions with this equipment, a several million won-worth target (solid-state raw material) and precursors (volatile organic metal compound) pricing several hundreds won per gram are required. Therefore, huge amount of experiment expense is demanded for fabrication of several ten thousands of thin films with various compositions.

Professor Woo’s team has developed ‘combinatorial droplet chemical deposition’ equipment, which does not demand high-degree vacuum and is automated by computers and robots, by using a new high-speed research measure. The equipment is priced at about 1/5 of the existing equipment and easy for maintenance.

This equipment uses cheap reagents, instead of expensive raw materials. Reagents necessary to form required compositions are dissolved in water or proper solvents, and then applied by high frequencies to make several micrometer-scaled droplets (fine liquid droplet). Theses droplets are moved by nitrogen and dropped onto a substrate, which is to be fabricated into a thin film, and then subsequent thermal treatment is applied to the substrate to fabricate a thin film of required composition. At this moment, several tens or several hundreds of thin films with various compositions can be fabricated at the same time by reducing the size of thin film specimens into millimeter scale with the use of shade mask and adjusting vaporization time with masks, the moving speed of which can be adjusted. The expenses for materials necessary for the fabrication of thin films with this equipment amount to several ten thousands won per 100 grams, which is in the range of 1/100 and 1/10 of the previous methods, and the research period can be shortened into one of several tenth.

“If this new method is applied to the development of elements in the fields of core energy, material and health, which have not been discovered by the existing research methods so far, as well as researches in thin film material field, substantial effects will be brought,” said Professor Woo.

‘Combinatorial droplet chemical vaporization’ equipment is pending a domestic patent application and international patent applications at Japan and Germany. This equipment will be produced by order and provided to general researchers.

2007.02.02 View 19277

Professor Seong-Ihl Woo Develops New High-Speed Research Method

Professor Seong-Ihl Woo Develops New High-Speed Research Method

Reduce research periods and expenses for thin film materials several ten times

Posted on the online version of Proceedings of National Academy of Sciences of the United States of America (PNAS) on January 9

A team led by Seong-Ihl Woo, a professor of KAIST Department of Chemical & Biomolecular Engineering and the director of the Center for Ultramicrochemical Process Systems, has developed a high-speed research method that can maximize research performances and posted the relevant contents on the online version of Proceedings of National Academy of Sciences of the United States of America (PNAS), a distinguished scientific journal, on January 9, 2007.

Professor Woo’s team has developed a high-speed research method that can fabricate several tens or several thousands of thin films with different compositions (mixing ratio) at the same time and carry out structural analysis and performance evaluation more than ten times faster and accurately, which leads to the shortening of the research processes of thin film materials. This is an epoch-making method that can reduce research periods and expenses several ten times or more, compared to the previous methods.

The qualities of final products of electronic materials, displays, and semi-conductors depend on the features of thin film materials. Averagely, it takes about two weeks or longer to fabricate a functional thin film and analyze and evaluate its performances. In order to fabricate thin film materials in need successfully, more than several thousand times of tests are required.

The existing thin film-fabricating equipment is expensive one demanding high-degree vacuum, such as chemical vapor deposition, sputtering, physical vapor deposition, laser evaporation, and so on. In order to fabricate thin films of various compositions with this equipment, a several million won-worth target (solid-state raw material) and precursors (volatile organic metal compound) pricing several hundreds won per gram are required. Therefore, huge amount of experiment expense is demanded for fabrication of several ten thousands of thin films with various compositions.

Professor Woo’s team has developed ‘combinatorial droplet chemical deposition’ equipment, which does not demand high-degree vacuum and is automated by computers and robots, by using a new high-speed research measure. The equipment is priced at about 1/5 of the existing equipment and easy for maintenance.

This equipment uses cheap reagents, instead of expensive raw materials. Reagents necessary to form required compositions are dissolved in water or proper solvents, and then applied by high frequencies to make several micrometer-scaled droplets (fine liquid droplet). Theses droplets are moved by nitrogen and dropped onto a substrate, which is to be fabricated into a thin film, and then subsequent thermal treatment is applied to the substrate to fabricate a thin film of required composition. At this moment, several tens or several hundreds of thin films with various compositions can be fabricated at the same time by reducing the size of thin film specimens into millimeter scale with the use of shade mask and adjusting vaporization time with masks, the moving speed of which can be adjusted. The expenses for materials necessary for the fabrication of thin films with this equipment amount to several ten thousands won per 100 grams, which is in the range of 1/100 and 1/10 of the previous methods, and the research period can be shortened into one of several tenth.

“If this new method is applied to the development of elements in the fields of core energy, material and health, which have not been discovered by the existing research methods so far, as well as researches in thin film material field, substantial effects will be brought,” said Professor Woo.

‘Combinatorial droplet chemical vaporization’ equipment is pending a domestic patent application and international patent applications at Japan and Germany. This equipment will be produced by order and provided to general researchers.

2007.02.02 View 19277