CT

-

KAIST presents a microbial cell factory as a source of eco-friendly food and cosmetic coloring

Despite decades of global population growth, global food crisis seems to be at hand yet again because the food productivity is cut severely due to prolonged presence of abnormal weather from intensifying climate change and global food supply chain is deteriorated due to international conflicts such as wars exacerbating food shortages and nutritional inequality around the globe. At the same time, however, as awareness of the environment and sustainability rises, an increase in demand for more eco-friendly and high-quality food and beauty products is being observed not without a sense of irony. At a time like this, microorganisms are attracting attention as a key that can handle this couple of seemingly distant problems.

KAIST (President Kwang-Hyung Lee) announced on the 26th that Kyeong Rok Choi, a research professor of the Bioprocess Research Center and Sang Yup Lee, a Distinguished Professor of the Department of Chemical and Biomolecular Engineering, published a paper titled “Metabolic Engineering of Microorganisms for Food and Cosmetics Production” upon invitation by “Nature Reviews Bioengineering” to be published online published by Nature after peer review.

※ Paper title: Systems metabolic engineering of microorganisms for food and cosmetics production

※ Author information: Kyeong Rok Choi (first author) and Sang Yup Lee (corresponding author)

Systems metabolic engineering is a research field founded by Distinguished Professor Sang Yup Lee of KAIST to more effectively develop microbial cell factories, the core factor of the next-generation bio industry to replace the existing chemical industry that relies heavily on petroleum. By applying a systemic metabolic engineering strategy, the researchers have developed a number of high-performance microbial cell factories that produce a variety of food and cosmetic compounds including natural substances like heme and zinc protoporphyrin IX compounds which can improve the flavor and color of synthetic meat, lycopene and β-carotene which are functional natural pigments that can be widely used in food and cosmetics, and methyl anthranilate, a grape-derived compound widely used to impart grape flavor in food and beverage manufacturing.

In this paper written upon invitation by Nature, the research team covered remarkable cases of microbial cell factory that can produce amino acids, proteins, fats and fatty acids, vitamins, flavors, pigments, alcohols, functional compounds and other food additives used in various foods and cosmetics and the companies that have successfully commercialized these microbial-derived materials Furthermore, the paper organized and presents systems metabolic engineering strategies that can spur the development of industrial microbial cell factories that can produce more diverse food and cosmetic compounds in an eco-friendly way with economic feasibility.

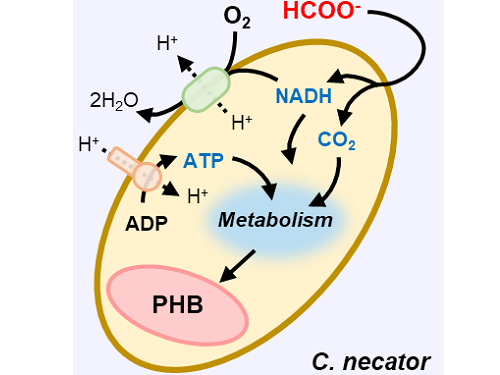

< Figure 1. Examples of production of food and cosmetic compounds using microbial cell factories >

For example, by producing proteins or amino acids with high nutritional value through non-edible biomass used as animal feed or fertilizer through the microbial fermentation process, it will contribute to the increase in production and stable supply of food around the world. Furthermore, by contributing to developing more viable alternative meat, further reducing dependence on animal protein, it can also contribute to reducing greenhouse gases and environmental pollution generated through livestock breeding or fish farming.

In addition, vanillin or methyl anthranilate, which give off vanilla or grape flavor, are widely added to various foods, but natural products isolated and refined from plants are low in production and high in production cost, so in most cases, petrochemicals substances derived from vanillin and methylanthranilic acid are added to food. These materials can also be produced through an eco-friendly and human-friendly method by borrowing the power of microorganisms.

Ethical and resource problems that arise in producing compounds like Calmin (cochineal pigment), a coloring added to various cosmetics and foods such as red lipstick and strawberry-flavored milk, which must be extracted from cochineal insects that live only in certain cacti. and Hyaluronic acid, which is widely consumed as a health supplement, but is only present in omega-3 fatty acids extracted from shark or fish livers, can also be resolved when they can be produced in an eco-friendly way using microorganisms.

KAIST Research Professor Kyeong Rok Choi, the first author of this paper, said, “In addition to traditional fermented foods such as kimchi and yogurt, foods produced with the help of microorganisms like cocoa butter, a base ingredient for chocolate that can only be obtained from fermented cacao beans, and monosodium glutamate, a seasoning produced through microbial fermentation are already familiar to us”. “In the future, we will be able to acquire a wider variety of foods and cosmetics even more easily produced in an eco-friendly and sustainable way in our daily lives through microbial cell factories.” he added.

< Figure 2. Systems metabolic engineering strategy to improve metabolic flow in microbial cell factories >

Distinguished Professor Sang Yup Lee said, “It is engineers’ mission to make the world a better place utilizing science and technology.” and added, “Continuous advancement and active use of systems metabolic engineering will contribute greatly to easing and resolving the problems arising from both the food crisis and the climate change."

This research was carried out as a part of the “Development of Protein Production Technology from Inorganic Substances through Control of Microbial Metabolism System Project” (Project Leader: Kyeong Rok Choi, KAIST Research Professor) of the the Center for Agricultural Microorganism and Enzyme (Director Pahn-Shick Chang) supported by the Rural Development Administration and the “Development of Platform Technologies of Microbial Cell Factories for the Next-generation Biorefineries Project” (Project Leader: Sang Yup Lee, KAIST Distinguished Professor) of the Petroleum-Substitute Eco-friendly Chemical Technology Development Program supported by the Ministry of Science and ICT.

2023.07.28 View 10609

KAIST presents a microbial cell factory as a source of eco-friendly food and cosmetic coloring

Despite decades of global population growth, global food crisis seems to be at hand yet again because the food productivity is cut severely due to prolonged presence of abnormal weather from intensifying climate change and global food supply chain is deteriorated due to international conflicts such as wars exacerbating food shortages and nutritional inequality around the globe. At the same time, however, as awareness of the environment and sustainability rises, an increase in demand for more eco-friendly and high-quality food and beauty products is being observed not without a sense of irony. At a time like this, microorganisms are attracting attention as a key that can handle this couple of seemingly distant problems.

KAIST (President Kwang-Hyung Lee) announced on the 26th that Kyeong Rok Choi, a research professor of the Bioprocess Research Center and Sang Yup Lee, a Distinguished Professor of the Department of Chemical and Biomolecular Engineering, published a paper titled “Metabolic Engineering of Microorganisms for Food and Cosmetics Production” upon invitation by “Nature Reviews Bioengineering” to be published online published by Nature after peer review.

※ Paper title: Systems metabolic engineering of microorganisms for food and cosmetics production

※ Author information: Kyeong Rok Choi (first author) and Sang Yup Lee (corresponding author)

Systems metabolic engineering is a research field founded by Distinguished Professor Sang Yup Lee of KAIST to more effectively develop microbial cell factories, the core factor of the next-generation bio industry to replace the existing chemical industry that relies heavily on petroleum. By applying a systemic metabolic engineering strategy, the researchers have developed a number of high-performance microbial cell factories that produce a variety of food and cosmetic compounds including natural substances like heme and zinc protoporphyrin IX compounds which can improve the flavor and color of synthetic meat, lycopene and β-carotene which are functional natural pigments that can be widely used in food and cosmetics, and methyl anthranilate, a grape-derived compound widely used to impart grape flavor in food and beverage manufacturing.

In this paper written upon invitation by Nature, the research team covered remarkable cases of microbial cell factory that can produce amino acids, proteins, fats and fatty acids, vitamins, flavors, pigments, alcohols, functional compounds and other food additives used in various foods and cosmetics and the companies that have successfully commercialized these microbial-derived materials Furthermore, the paper organized and presents systems metabolic engineering strategies that can spur the development of industrial microbial cell factories that can produce more diverse food and cosmetic compounds in an eco-friendly way with economic feasibility.

< Figure 1. Examples of production of food and cosmetic compounds using microbial cell factories >

For example, by producing proteins or amino acids with high nutritional value through non-edible biomass used as animal feed or fertilizer through the microbial fermentation process, it will contribute to the increase in production and stable supply of food around the world. Furthermore, by contributing to developing more viable alternative meat, further reducing dependence on animal protein, it can also contribute to reducing greenhouse gases and environmental pollution generated through livestock breeding or fish farming.

In addition, vanillin or methyl anthranilate, which give off vanilla or grape flavor, are widely added to various foods, but natural products isolated and refined from plants are low in production and high in production cost, so in most cases, petrochemicals substances derived from vanillin and methylanthranilic acid are added to food. These materials can also be produced through an eco-friendly and human-friendly method by borrowing the power of microorganisms.

Ethical and resource problems that arise in producing compounds like Calmin (cochineal pigment), a coloring added to various cosmetics and foods such as red lipstick and strawberry-flavored milk, which must be extracted from cochineal insects that live only in certain cacti. and Hyaluronic acid, which is widely consumed as a health supplement, but is only present in omega-3 fatty acids extracted from shark or fish livers, can also be resolved when they can be produced in an eco-friendly way using microorganisms.

KAIST Research Professor Kyeong Rok Choi, the first author of this paper, said, “In addition to traditional fermented foods such as kimchi and yogurt, foods produced with the help of microorganisms like cocoa butter, a base ingredient for chocolate that can only be obtained from fermented cacao beans, and monosodium glutamate, a seasoning produced through microbial fermentation are already familiar to us”. “In the future, we will be able to acquire a wider variety of foods and cosmetics even more easily produced in an eco-friendly and sustainable way in our daily lives through microbial cell factories.” he added.

< Figure 2. Systems metabolic engineering strategy to improve metabolic flow in microbial cell factories >

Distinguished Professor Sang Yup Lee said, “It is engineers’ mission to make the world a better place utilizing science and technology.” and added, “Continuous advancement and active use of systems metabolic engineering will contribute greatly to easing and resolving the problems arising from both the food crisis and the climate change."

This research was carried out as a part of the “Development of Protein Production Technology from Inorganic Substances through Control of Microbial Metabolism System Project” (Project Leader: Kyeong Rok Choi, KAIST Research Professor) of the the Center for Agricultural Microorganism and Enzyme (Director Pahn-Shick Chang) supported by the Rural Development Administration and the “Development of Platform Technologies of Microbial Cell Factories for the Next-generation Biorefineries Project” (Project Leader: Sang Yup Lee, KAIST Distinguished Professor) of the Petroleum-Substitute Eco-friendly Chemical Technology Development Program supported by the Ministry of Science and ICT.

2023.07.28 View 10609 -

2023 Global Entrepreneurship Summer School in Silicon Valley Successfully Concluded

< 2023 Silicon Valley Global Entrepreneurship Summer School Participants >

The 2023 KAIST Global Entrepreneurship Summer School (GESS) was successfully held. Co-hosted by the Center for Global Strategies and Planning (GSP) (Director Man-Sung Yim) and the Startup KAIST (Director Hyeonmin Bae), the 2023 KAIST GESS was the second one of the summer programs, repeating the Silicon Valley global entrepreneurship bootcamp of 2022 (2022 GESC), based on industry-academia collaboration. This program was designed to provide students with the opportunity to visit Silicon Valley, the global hub of entrepreneurship, and personally experience the Silicon Valley culture while developing human networks that would serve as a foundation for their overseas startup development.

A total of 20 participants were selected earlier this year, including potential KAISTian entrepreneurs and early-stage entrepreneurs from KAIST within one year of incorporation. In particular, a number of foreign students of various nationalities such as Vietnam, Azerbaijan, Honduras, Indonesia, Philippines, and Kazakhstan, increased significantly, demonstrating the enthusiasm for entrepreneurship across national boundaries along with the program's growing international status. This year's event was also open to 20 Impact MBA and Social Entrepreneur (SE) students from KAIST's College of Business for the Silicon Valley program.

For the past two months, the participants have trained on business model development and pitching at KAIST's main campus in Daejeon. From June 21st to the 30th, they visited the campuses of leading universities, such as, Stanford University, UC Santa Cruz, and UC Berkeley, as well as KOTRA Silicon Valley Trade Center (Manager Hyoung il Kim), and local alumni companies and Apple company to experience the global technology startups. The start-ups by KAIST alums including B Garage (CEO Aiden Kim), ImpriMed (CEO Sungwon Lim), Medic Life Sciences (CEO Kyuho Han), and VESSL AI (CEO Jaeman Ahn) participated in the program and gave lectures and company tours to inspire the participants to have passion to take on the entrepreneurial endeavors and challenges.

On the last day, the participants gave presentations on their team’s business items in front of local venture capitalists in Silicon Valley. After receiving continuous coaching from Silicon Valley's professional accelerators through remote video conferencing and face-to-face mentoring for the last two months, the participants developed their business models and presented their creative and innovative ideas, revealing their potential as future global entrepreneurs. At the final competition, Team Sparky that developed “Snoove” won the first prize. Snoove is a scientifically-proven mattress accessory that applies mild vibration to the mattress to aid users in achieving better sleep, a method previously used to soothe infants.

< GESS Pitching Day Presentation >

Kevin Choi from the Team Sparky said, "Seeing and experiencing the realities of entrepreneurship in Silicon Valley, a global startup scene, made me think about the importance of unlearning, challenging, and failing to be a global entrepreneur who contributes to our society." Man-Sung Yim, the Associate Vice President of the International Office, who organized the event added, "Through this experience, we expect KAIST students to grow to become global leaders who would create global values and enhance the international reputation of our university."

Meanwhile, the GSP and Startup KAIST commented that they will to continue to develop the KAIST GESS program to foster prospective entrepreneurs who can compete in the global market based on the success of this program.

2023.07.05 View 12618

2023 Global Entrepreneurship Summer School in Silicon Valley Successfully Concluded

< 2023 Silicon Valley Global Entrepreneurship Summer School Participants >

The 2023 KAIST Global Entrepreneurship Summer School (GESS) was successfully held. Co-hosted by the Center for Global Strategies and Planning (GSP) (Director Man-Sung Yim) and the Startup KAIST (Director Hyeonmin Bae), the 2023 KAIST GESS was the second one of the summer programs, repeating the Silicon Valley global entrepreneurship bootcamp of 2022 (2022 GESC), based on industry-academia collaboration. This program was designed to provide students with the opportunity to visit Silicon Valley, the global hub of entrepreneurship, and personally experience the Silicon Valley culture while developing human networks that would serve as a foundation for their overseas startup development.

A total of 20 participants were selected earlier this year, including potential KAISTian entrepreneurs and early-stage entrepreneurs from KAIST within one year of incorporation. In particular, a number of foreign students of various nationalities such as Vietnam, Azerbaijan, Honduras, Indonesia, Philippines, and Kazakhstan, increased significantly, demonstrating the enthusiasm for entrepreneurship across national boundaries along with the program's growing international status. This year's event was also open to 20 Impact MBA and Social Entrepreneur (SE) students from KAIST's College of Business for the Silicon Valley program.

For the past two months, the participants have trained on business model development and pitching at KAIST's main campus in Daejeon. From June 21st to the 30th, they visited the campuses of leading universities, such as, Stanford University, UC Santa Cruz, and UC Berkeley, as well as KOTRA Silicon Valley Trade Center (Manager Hyoung il Kim), and local alumni companies and Apple company to experience the global technology startups. The start-ups by KAIST alums including B Garage (CEO Aiden Kim), ImpriMed (CEO Sungwon Lim), Medic Life Sciences (CEO Kyuho Han), and VESSL AI (CEO Jaeman Ahn) participated in the program and gave lectures and company tours to inspire the participants to have passion to take on the entrepreneurial endeavors and challenges.

On the last day, the participants gave presentations on their team’s business items in front of local venture capitalists in Silicon Valley. After receiving continuous coaching from Silicon Valley's professional accelerators through remote video conferencing and face-to-face mentoring for the last two months, the participants developed their business models and presented their creative and innovative ideas, revealing their potential as future global entrepreneurs. At the final competition, Team Sparky that developed “Snoove” won the first prize. Snoove is a scientifically-proven mattress accessory that applies mild vibration to the mattress to aid users in achieving better sleep, a method previously used to soothe infants.

< GESS Pitching Day Presentation >

Kevin Choi from the Team Sparky said, "Seeing and experiencing the realities of entrepreneurship in Silicon Valley, a global startup scene, made me think about the importance of unlearning, challenging, and failing to be a global entrepreneur who contributes to our society." Man-Sung Yim, the Associate Vice President of the International Office, who organized the event added, "Through this experience, we expect KAIST students to grow to become global leaders who would create global values and enhance the international reputation of our university."

Meanwhile, the GSP and Startup KAIST commented that they will to continue to develop the KAIST GESS program to foster prospective entrepreneurs who can compete in the global market based on the success of this program.

2023.07.05 View 12618 -

KAIST Civil Engineering Students named Runner-up at the 2023 ULI Hines Student Competition - Asia Pacific

A team of five students from the Korea Advanced Institute of Science and Technology (KAIST) were awarded second place in a premier urban design student competition hosted by the Urban Land Institute and Hines, 2023 ULI Hines Student Competition - Asia Pacific.

The competition, which was held for the first time in the Asia-Pacific region, is an internationally recognized event which typically attract hundreds of applicants.

Jonah Remigio, Sojung Noh, Estefania Rodriguez, Jihyun Kang, and Ayantu Teshome, who joined forces under the name of “Team Hashtag Development”, were supported by faculty advisors Dr. Albert Han and Dr. Youngchul Kim of the Department of Civil and Environmental Engineering to imagine a more sustainable and enriched way of living in the Jurong district of Singapore.

Their submission, titled “Proposal: The Nest”, analyzed the big data within Singapore, using the data to determine which real estate business strategies would best enhance the quality of living and economy of the region.

Their final design, "The Nest" utilized mixed-use zoning to integrate the site’s scenic waterfront with homes, medical innovation, and sustainable technology, altogether creating a place to innovate, inhabit, and immerse.

< The Nest by Team Hashtag Development (Jonah Remigio, Ayantu Teshome Mossisa, Estefania Ayelen Rodriguez del Puerto, Sojung Noh, Jihyun Kang) ©2023 Urban Land Institute >

Ultimately, the team was recognized for their hard work and determination, imprinting South Korea’s indelible footprint in the arena of international scholastic achievement as they were named to be one of the Finalists on April 13th.

< Members of Team Hashtag Development >

Team Hashtag Development gave a virtual presentation to a jury of six ULI members on April 20th along with the "Team The REAL" from the University of Economics Ho Chi Minh City of Vietnam and "Team Omusubi" from the Waseda University of Japan, the team that submitted the proposal "Jurong Urban Health Campus" which was announced to be the winner on the 31st of May, after the virtual briefing by the top three finalists.

2023.06.26 View 10279

KAIST Civil Engineering Students named Runner-up at the 2023 ULI Hines Student Competition - Asia Pacific

A team of five students from the Korea Advanced Institute of Science and Technology (KAIST) were awarded second place in a premier urban design student competition hosted by the Urban Land Institute and Hines, 2023 ULI Hines Student Competition - Asia Pacific.

The competition, which was held for the first time in the Asia-Pacific region, is an internationally recognized event which typically attract hundreds of applicants.

Jonah Remigio, Sojung Noh, Estefania Rodriguez, Jihyun Kang, and Ayantu Teshome, who joined forces under the name of “Team Hashtag Development”, were supported by faculty advisors Dr. Albert Han and Dr. Youngchul Kim of the Department of Civil and Environmental Engineering to imagine a more sustainable and enriched way of living in the Jurong district of Singapore.

Their submission, titled “Proposal: The Nest”, analyzed the big data within Singapore, using the data to determine which real estate business strategies would best enhance the quality of living and economy of the region.

Their final design, "The Nest" utilized mixed-use zoning to integrate the site’s scenic waterfront with homes, medical innovation, and sustainable technology, altogether creating a place to innovate, inhabit, and immerse.

< The Nest by Team Hashtag Development (Jonah Remigio, Ayantu Teshome Mossisa, Estefania Ayelen Rodriguez del Puerto, Sojung Noh, Jihyun Kang) ©2023 Urban Land Institute >

Ultimately, the team was recognized for their hard work and determination, imprinting South Korea’s indelible footprint in the arena of international scholastic achievement as they were named to be one of the Finalists on April 13th.

< Members of Team Hashtag Development >

Team Hashtag Development gave a virtual presentation to a jury of six ULI members on April 20th along with the "Team The REAL" from the University of Economics Ho Chi Minh City of Vietnam and "Team Omusubi" from the Waseda University of Japan, the team that submitted the proposal "Jurong Urban Health Campus" which was announced to be the winner on the 31st of May, after the virtual briefing by the top three finalists.

2023.06.26 View 10279 -

A KAIST research team develops a high-performance modular SSD system semiconductor

In recent years, there has been a rise in demand for large amounts of data to train AI models and, thus, data size has become increasingly important over time. Accordingly, solid state drives (SSDs, storage devices that use a semiconductor memory unit), which are core storage devices for data centers and cloud services, have also seen an increase in demand. However, the internal components of higher performing SSDs have become more tightly coupled, and this tightly-coupled structure limits SSD from maximized performance.

On June 15, a KAIST research team led by Professor Dongjun Kim (John Kim) from the School of Electrical Engineering (EE) announced the development of the first SSD system semiconductor structure that can increase the reading/writing performance of next generation SSDs and extend their lifespan through high-performance modular SSD systems.

Professor Kim’s team identified the limitations of the tightly-coupled structures in existing SSD designs and proposed a de-coupled structure that can maximize SSD performance by configuring an internal on-chip network specialized for flash memory. This technique utilizes on-chip network technology, which can freely send packet-based data within the chip and is often used to design non-memory system semiconductors like CPUs and GPUs. Through this, the team developed a ‘modular SSD’, which shows reduced interdependence between front-end and back-end designs, and allows their independent design and assembly.

*on-chip network: a packet-based connection structure for the internal components of system semiconductors like CPUs/GPUs. On-chip networks are one of the most critical design components for high-performing system semiconductors, and their importance grows with the size of the semiconductor chip.

Professor Kim’s team refers to the components nearer to the CPU as the front-end and the parts closer to the flash memory as back-end. They newly constructed an on-chip network specific to flash memory in order to allow data transmission between the back-end’s flash controller, proposing a de-coupled structure that can minimize performance drop.

The SSD can accelerate some functions of the flash translation layer, a critical element to drive the SSD, in order to allow flash memory to actively overcome its limitations. Another advantage of the de-coupled, modular structure is that the flash translation layer is not limited to the characteristics of specific flash memories. Instead, their front-end and back-end designs can be carried out independently. Through this, the team could produce 21-times faster response times compared to existing systems and extend SSD lifespan by 23% by also applying the DDS defect detection technique.

< Figure 1. Schematic diagram of the structure of a high-performance modular SSD system developed by Professor Dong-Jun Kim's team >

This research, conducted by first author and Ph.D. candidate Jiho Kim from the KAIST School of EE and co-author Professor Myoungsoo Jung, was presented on the 19th of June at the 50th IEEE/ACM International Symposium on Computer Architecture, the most prestigious academic conference in the field of computer architecture, held in Orlando, Florida. (Paper Title: Decoupled SSD: Rethinking SSD Architecture through Network-based Flash Controllers)

< Figure 2. Conceptual diagram of hardware acceleration through high-performance modular SSD system >

Professor Dongjun Kim, who led the research, said, “This research is significant in that it identified the structural limitations of existing SSDs, and showed that on-chip network technology based on system memory semiconductors like CPUs can drive the hardware to actively carry out the necessary actions. We expect this to contribute greatly to the next-generation high-performance SSD market.” He added, “The de-coupled architecture is a structure that can actively operate to extend devices’ lifespan. In other words, its significance is not limited to the level of performance and can, therefore, be used for various applications.”

KAIST commented that this research is also meaningful in that the results were reaped through a collaborative study between two world-renowned researchers: Professor Myeongsoo Jung, recognized in the field of computer system storage devices, and Professor Dongjun Kim, a leading researcher in computer architecture and interconnection networks.

This research was funded by the National Research Foundation of Korea, Samsung Electronics, the IC Design Education Center, and Next Generation Semiconductor Technology and Development granted by the Institute of Information & Communications Technology, Planning & Evaluation.

2023.06.23 View 8984

A KAIST research team develops a high-performance modular SSD system semiconductor

In recent years, there has been a rise in demand for large amounts of data to train AI models and, thus, data size has become increasingly important over time. Accordingly, solid state drives (SSDs, storage devices that use a semiconductor memory unit), which are core storage devices for data centers and cloud services, have also seen an increase in demand. However, the internal components of higher performing SSDs have become more tightly coupled, and this tightly-coupled structure limits SSD from maximized performance.

On June 15, a KAIST research team led by Professor Dongjun Kim (John Kim) from the School of Electrical Engineering (EE) announced the development of the first SSD system semiconductor structure that can increase the reading/writing performance of next generation SSDs and extend their lifespan through high-performance modular SSD systems.

Professor Kim’s team identified the limitations of the tightly-coupled structures in existing SSD designs and proposed a de-coupled structure that can maximize SSD performance by configuring an internal on-chip network specialized for flash memory. This technique utilizes on-chip network technology, which can freely send packet-based data within the chip and is often used to design non-memory system semiconductors like CPUs and GPUs. Through this, the team developed a ‘modular SSD’, which shows reduced interdependence between front-end and back-end designs, and allows their independent design and assembly.

*on-chip network: a packet-based connection structure for the internal components of system semiconductors like CPUs/GPUs. On-chip networks are one of the most critical design components for high-performing system semiconductors, and their importance grows with the size of the semiconductor chip.

Professor Kim’s team refers to the components nearer to the CPU as the front-end and the parts closer to the flash memory as back-end. They newly constructed an on-chip network specific to flash memory in order to allow data transmission between the back-end’s flash controller, proposing a de-coupled structure that can minimize performance drop.

The SSD can accelerate some functions of the flash translation layer, a critical element to drive the SSD, in order to allow flash memory to actively overcome its limitations. Another advantage of the de-coupled, modular structure is that the flash translation layer is not limited to the characteristics of specific flash memories. Instead, their front-end and back-end designs can be carried out independently. Through this, the team could produce 21-times faster response times compared to existing systems and extend SSD lifespan by 23% by also applying the DDS defect detection technique.

< Figure 1. Schematic diagram of the structure of a high-performance modular SSD system developed by Professor Dong-Jun Kim's team >

This research, conducted by first author and Ph.D. candidate Jiho Kim from the KAIST School of EE and co-author Professor Myoungsoo Jung, was presented on the 19th of June at the 50th IEEE/ACM International Symposium on Computer Architecture, the most prestigious academic conference in the field of computer architecture, held in Orlando, Florida. (Paper Title: Decoupled SSD: Rethinking SSD Architecture through Network-based Flash Controllers)

< Figure 2. Conceptual diagram of hardware acceleration through high-performance modular SSD system >

Professor Dongjun Kim, who led the research, said, “This research is significant in that it identified the structural limitations of existing SSDs, and showed that on-chip network technology based on system memory semiconductors like CPUs can drive the hardware to actively carry out the necessary actions. We expect this to contribute greatly to the next-generation high-performance SSD market.” He added, “The de-coupled architecture is a structure that can actively operate to extend devices’ lifespan. In other words, its significance is not limited to the level of performance and can, therefore, be used for various applications.”

KAIST commented that this research is also meaningful in that the results were reaped through a collaborative study between two world-renowned researchers: Professor Myeongsoo Jung, recognized in the field of computer system storage devices, and Professor Dongjun Kim, a leading researcher in computer architecture and interconnection networks.

This research was funded by the National Research Foundation of Korea, Samsung Electronics, the IC Design Education Center, and Next Generation Semiconductor Technology and Development granted by the Institute of Information & Communications Technology, Planning & Evaluation.

2023.06.23 View 8984 -

KAIST research team develops a forgery prevention technique using salmon DNA

The authenticity scandal that plagued the artwork “Beautiful Woman” by Kyung-ja Chun for 30 years shows how concerns about replicas can become a burden to artists, as most of them are not experts in the field of anti-counterfeiting. To solve this problem, artist-friendly physical unclonable functions (PUFs) based on optical techniques instead of electronic ones, which can be applied immediately onto artwork through brushstrokes are needed.

On May 23, a KAIST research team led by Professor Dong Ki Yoon in the Department of Chemistry revealed the development of a proprietary technology for security and certification using random patterns that occur during the self-assembly of soft materials.

With the development of the Internet of Things in recent years, various electronic devices and services can now be connected to the internet and carry out new innovative functions. However, counterfeiting technologies that infringe on individuals’ privacy have also entered the marketplace.

The technique developed by the research team involves random and spontaneous patterns that naturally occur during the self-assembly of two different types of soft materials, which can be used in the same way as human fingerprints for non-replicable security. This is very significant in that even non-experts in the field of security can construct anti-counterfeiting systems through simple actions like drawing a picture.

The team developed two unique methods. The first method uses liquid crystals. When liquid crystals become trapped in patterned substrates, they induce the symmetrical destruction of the structure and create a maze-like topology (Figure 1). The research team defined the pathways open to the right as 0 (blue), and those open to the left as 1 (red), and confirmed that the structure could be converted into a digital code composed of 0’s and 1’s that can serve as a type of fingerprint through object recognition using machine learning. This groundbreaking technique can be utilized by non-experts, as it does not require complex semiconductor patterns that are required by existing technology, and can be observed through the level of resolution of a smartphone camera. In particular, this technique can reconstruct information more easily than conventional methods that use semiconductor chips.

< Figure 1. Security technology using the maze made up of magnetically-assembled structures formed on a substrate patterned with liquid crystal materials. >

The second method uses DNA extracted from salmon. The DNA can be dissolved in water and applied with a brush to induce bulking instability, which forms random patterns similar to a zebra’s stripes. Here, the patterns create ridge endings and bifurcation, which are characteristics in fingerprints, and these can also be digitalized into 0’s and 1’s through machine learning. The research team applied conventional fingerprint recognition technology to this patterning technique and demonstrated its use as an artificial fingerprint. This method can be easily carried out using a brush, and the solution can be mixed into various colors and used as a new security ink.

< Figure 2. Technology to produce security ink using DNA polymers extracted from salmon >

This new security technology developed by the research team uses only simple organic materials and requires basic manufacturing processes, making it possible to enhance security at a low cost. In addition, users can produce patterns in the shapes and sizes they want, and even if the patterns are made in the same way, their randomness makes each individual pattern different. This provides high levels of security and gives the technique enhanced marketability.

Professor Dong Ki Yoon said, “These studies have taken the randomness that naturally occurs during self-assembly to create non-replicable patterns that can act like human fingerprints.” He added, “These ideas will be the cornerstone of technology that applies the many randomities that exist in nature to security systems.”

The two studies were published in the journal Advanced Materials under the titles “1Planar Spin Glass with Topologically-Protected Mazes in the Liquid Crystal Targeting for Reconfigurable Micro Security Media” and “2Paintable Physical Unclonable Function Using DNA” on May 6 and 5, respectively.

Author Information: 1Geonhyeong Park, Yun-Seok Choi, S. Joon Kwon*, and Dong Ki Yoon*/ 2Soon Mo Park†, Geonhyeong Park†, Dong Ki Yoon*: †co-first authors, *corresponding author

This research was funded by the Center for Multiscale Chiral Architectures and supported by the Ministry of Science and ICT-Korea Research Foundation, BRIDGE Convergent Research and Development Program, the Running Together Project, and the Samsung Future Technology Development Program.

< Figure 1-1. A scene from the schematic animation of the process of Blues (0) and Reds (1) forming the PUF by exploring the maze. From "Planar Spin Glass with Topologically-Protected Mazes in the Liquid Crystal Targeting for Reconfigurable Micro Security Media" by Geonhyeong Park, Yun-Seok Choi, S. Joon Kwon, Dong Ki Yoon. https://doi.org/10.1002/adma.202303077 >

< Figure 2-1. A schematic diagram of the formation of digital fingerprints formed using the DNA ink. From "Paintable Physical Unclonable Function Using DNA" by Soon Mo Park, Geonhyeong Park, Dong Ki Yoon. https://doi.org/10.1002/adma.202302135 >

2023.06.08 View 9555

KAIST research team develops a forgery prevention technique using salmon DNA

The authenticity scandal that plagued the artwork “Beautiful Woman” by Kyung-ja Chun for 30 years shows how concerns about replicas can become a burden to artists, as most of them are not experts in the field of anti-counterfeiting. To solve this problem, artist-friendly physical unclonable functions (PUFs) based on optical techniques instead of electronic ones, which can be applied immediately onto artwork through brushstrokes are needed.

On May 23, a KAIST research team led by Professor Dong Ki Yoon in the Department of Chemistry revealed the development of a proprietary technology for security and certification using random patterns that occur during the self-assembly of soft materials.

With the development of the Internet of Things in recent years, various electronic devices and services can now be connected to the internet and carry out new innovative functions. However, counterfeiting technologies that infringe on individuals’ privacy have also entered the marketplace.

The technique developed by the research team involves random and spontaneous patterns that naturally occur during the self-assembly of two different types of soft materials, which can be used in the same way as human fingerprints for non-replicable security. This is very significant in that even non-experts in the field of security can construct anti-counterfeiting systems through simple actions like drawing a picture.

The team developed two unique methods. The first method uses liquid crystals. When liquid crystals become trapped in patterned substrates, they induce the symmetrical destruction of the structure and create a maze-like topology (Figure 1). The research team defined the pathways open to the right as 0 (blue), and those open to the left as 1 (red), and confirmed that the structure could be converted into a digital code composed of 0’s and 1’s that can serve as a type of fingerprint through object recognition using machine learning. This groundbreaking technique can be utilized by non-experts, as it does not require complex semiconductor patterns that are required by existing technology, and can be observed through the level of resolution of a smartphone camera. In particular, this technique can reconstruct information more easily than conventional methods that use semiconductor chips.

< Figure 1. Security technology using the maze made up of magnetically-assembled structures formed on a substrate patterned with liquid crystal materials. >

The second method uses DNA extracted from salmon. The DNA can be dissolved in water and applied with a brush to induce bulking instability, which forms random patterns similar to a zebra’s stripes. Here, the patterns create ridge endings and bifurcation, which are characteristics in fingerprints, and these can also be digitalized into 0’s and 1’s through machine learning. The research team applied conventional fingerprint recognition technology to this patterning technique and demonstrated its use as an artificial fingerprint. This method can be easily carried out using a brush, and the solution can be mixed into various colors and used as a new security ink.

< Figure 2. Technology to produce security ink using DNA polymers extracted from salmon >

This new security technology developed by the research team uses only simple organic materials and requires basic manufacturing processes, making it possible to enhance security at a low cost. In addition, users can produce patterns in the shapes and sizes they want, and even if the patterns are made in the same way, their randomness makes each individual pattern different. This provides high levels of security and gives the technique enhanced marketability.

Professor Dong Ki Yoon said, “These studies have taken the randomness that naturally occurs during self-assembly to create non-replicable patterns that can act like human fingerprints.” He added, “These ideas will be the cornerstone of technology that applies the many randomities that exist in nature to security systems.”

The two studies were published in the journal Advanced Materials under the titles “1Planar Spin Glass with Topologically-Protected Mazes in the Liquid Crystal Targeting for Reconfigurable Micro Security Media” and “2Paintable Physical Unclonable Function Using DNA” on May 6 and 5, respectively.

Author Information: 1Geonhyeong Park, Yun-Seok Choi, S. Joon Kwon*, and Dong Ki Yoon*/ 2Soon Mo Park†, Geonhyeong Park†, Dong Ki Yoon*: †co-first authors, *corresponding author

This research was funded by the Center for Multiscale Chiral Architectures and supported by the Ministry of Science and ICT-Korea Research Foundation, BRIDGE Convergent Research and Development Program, the Running Together Project, and the Samsung Future Technology Development Program.

< Figure 1-1. A scene from the schematic animation of the process of Blues (0) and Reds (1) forming the PUF by exploring the maze. From "Planar Spin Glass with Topologically-Protected Mazes in the Liquid Crystal Targeting for Reconfigurable Micro Security Media" by Geonhyeong Park, Yun-Seok Choi, S. Joon Kwon, Dong Ki Yoon. https://doi.org/10.1002/adma.202303077 >

< Figure 2-1. A schematic diagram of the formation of digital fingerprints formed using the DNA ink. From "Paintable Physical Unclonable Function Using DNA" by Soon Mo Park, Geonhyeong Park, Dong Ki Yoon. https://doi.org/10.1002/adma.202302135 >

2023.06.08 View 9555 -

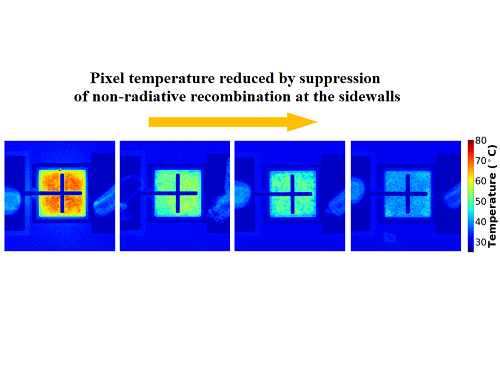

Researchers finds a way to reduce the overheating of semiconductor devices

The demand to shrink the size of semiconductors coupled with the problem of the heat generated at the hot spots of the devices not being effectively dispersed has negatively affected the reliability and durability of modern devices. Existing thermal management technologies have not been up to the task. Thus, the discovery of a new way of dispersing heat by using surface waves generated on the thin metal films over the substrate is an important breakthrough.

KAIST (President Kwang Hyung Lee) announced that Professor Bong Jae Lee's research team in the Department of Mechanical Engineering succeeded in measuring a newly observed transference of heat induced by 'surface plasmon polariton' (SPP) in a thin metal film deposited on a substrate for the first time in the world.

☞ Surface plasmon polariton (SPP) refers to a surface wave formed on the surface of a metal as a result of strong interaction between the electromagnetic field at the interface between the dielectric and the metal and the free electrons on the metal surface and similar collectively vibrating particles.

The research team utilized surface plasmon polaritons (SPP), which are surface waves generated at the metal-dielectric interface, to improve thermal diffusion in nanoscale thin metal films. Since this new heat transfer mode occurs when a thin film of metal is deposited on a substrate, it is highly usable in the device manufacturing process and has the advantage of being able to be manufactured over a large area. The research team showed that the thermal conductivity increased by about 25% due to surface waves generated over a 100-nm-thick titanium (Ti) film with a radius of about 3 cm.

KAIST Professor Bong Jae Lee, who led the research, said, "The significance of this research is that a new heat transfer mode using surface waves over a thin metal film deposited on a substrate with low processing difficulty was identified for the first time in the world. It can be applied as a nanoscale heat spreader to efficiently dissipate heat near the hot spots for easily overheatable semiconductor devices.”

The result has great implications for the development of high-performance semiconductor devices in the future in that it can be applied to rapidly dissipate heat on a nanoscale thin film. In particular, this new heat transfer mode identified by the research team is expected to solve the fundamental problem of thermal management in semiconductor devices as it enables even more effective heat transfer at nanoscale thickness while the thermal conductivity of the thin film usually decreases due to the boundary scattering effect.

This study was published online on April 26 in 'Physical Review Letters' and was selected as an Editors' Suggestion. The research was carried out with support from the Basic Research Laboratory Support Program of the National Research Foundation of Korea.

< Figure. Schematic diagram of the principle of measuring the thermal conductivity of thin Titanium (TI) films and the thermal conductivity of surface plasmon polariton measured on the Ti film >

2023.06.01 View 9609

Researchers finds a way to reduce the overheating of semiconductor devices

The demand to shrink the size of semiconductors coupled with the problem of the heat generated at the hot spots of the devices not being effectively dispersed has negatively affected the reliability and durability of modern devices. Existing thermal management technologies have not been up to the task. Thus, the discovery of a new way of dispersing heat by using surface waves generated on the thin metal films over the substrate is an important breakthrough.

KAIST (President Kwang Hyung Lee) announced that Professor Bong Jae Lee's research team in the Department of Mechanical Engineering succeeded in measuring a newly observed transference of heat induced by 'surface plasmon polariton' (SPP) in a thin metal film deposited on a substrate for the first time in the world.

☞ Surface plasmon polariton (SPP) refers to a surface wave formed on the surface of a metal as a result of strong interaction between the electromagnetic field at the interface between the dielectric and the metal and the free electrons on the metal surface and similar collectively vibrating particles.

The research team utilized surface plasmon polaritons (SPP), which are surface waves generated at the metal-dielectric interface, to improve thermal diffusion in nanoscale thin metal films. Since this new heat transfer mode occurs when a thin film of metal is deposited on a substrate, it is highly usable in the device manufacturing process and has the advantage of being able to be manufactured over a large area. The research team showed that the thermal conductivity increased by about 25% due to surface waves generated over a 100-nm-thick titanium (Ti) film with a radius of about 3 cm.

KAIST Professor Bong Jae Lee, who led the research, said, "The significance of this research is that a new heat transfer mode using surface waves over a thin metal film deposited on a substrate with low processing difficulty was identified for the first time in the world. It can be applied as a nanoscale heat spreader to efficiently dissipate heat near the hot spots for easily overheatable semiconductor devices.”

The result has great implications for the development of high-performance semiconductor devices in the future in that it can be applied to rapidly dissipate heat on a nanoscale thin film. In particular, this new heat transfer mode identified by the research team is expected to solve the fundamental problem of thermal management in semiconductor devices as it enables even more effective heat transfer at nanoscale thickness while the thermal conductivity of the thin film usually decreases due to the boundary scattering effect.

This study was published online on April 26 in 'Physical Review Letters' and was selected as an Editors' Suggestion. The research was carried out with support from the Basic Research Laboratory Support Program of the National Research Foundation of Korea.

< Figure. Schematic diagram of the principle of measuring the thermal conductivity of thin Titanium (TI) films and the thermal conductivity of surface plasmon polariton measured on the Ti film >

2023.06.01 View 9609 -

'Jumping Genes' Found to Alter Human Colon Genomes, Offering Insights into Aging and Tumorigenesis

The Korea Advanced Institute of Science and Technology (KAIST) and their collaborators have conducted a groundbreaking study targeting 'jumping genes' in the entire genomes of the human large intestine. Published in Nature on May 18 2023, the research unveils the surprising activity of 'Long interspersed nuclear element-1 (L1),' a type of jumping gene previously thought to be mostly dormant in human genomes. The study shows that L1 genes can become activated and disrupt genomic functions throughout an individual's lifetime, particularly in the colorectal epithelium.

(Paper Title: Widespread somatic L1 retrotransposition in normal colorectal epithelium, https://www.nature.com/articles/s41586-023-06046-z)

With approximately 500,000 L1 jumping genes, accounting for 17% of the human genome, they have long been recognized for their contribution to the evolution of the human species by introducing 'disruptive innovation' to genome sequences. Until now, it was believed that most L1 elements had lost their ability to jump in normal tissues of modern humans. However, this study reveals that some L1 jumping genes can be widely activated in normal cells, leading to the accumulation of genomic mutations over an individual's lifetime. The rate of L1 jumping and resulting genomic changes vary among different cell types, with a notable concentration observed in aged colon epithelial cells. The study illustrates that every colonic epithelial cell experiences an L1 jumping event by the age of 40 on average.

The research, led by co-first authors Chang Hyun Nam (a graduate student at KAIST) and Dr. Jeonghwan Youk (former graduate student at KAIST and assistant clinical professor at Seoul National University Hospital), involved the analysis of whole-genome sequences from 899 single cells obtained from skin (fibroblasts), blood, and colon epithelial tissues collected from 28 individuals. The study uncovers the activation of L1 jumping genes in normal cells, resulting in the gradual accumulation of genomic mutations over time. Additionally, the team explored epigenomic (DNA methylation) sequences to understand the mechanism behind L1 jumping gene activation. They found that cells with activated L1 jumping genes exhibit epigenetic instability, suggesting the critical role of epigenetic changes in regulating L1 jumping gene activity. Most of these epigenomic instabilities were found to arise during the early stages of embryogenesis. The study provides valuable insights into the aging process and the development of diseases in human colorectal tissues.

"This study illustrates that genomic damage in normal cells is acquired not only through exposure to carcinogens but also through the activity of endogenous components whose impact was previously unclear. Genomes of apparently healthy aged cells, particularly in the colorectal epithelium, become mosaic due to the activity of L1 jumping genes," said Prof. Young Seok Ju at KAIST.

"We emphasize the essential and ongoing collaboration among researchers in clinical medicine and basic medical sciences," said Prof. Min Jung Kim of the Department of Surgery at Seoul National University Hospital. "This case highlights the critical role of systematically collected human tissues from clinical settings in unraveling the complex process of disease development in humans."

"I am delighted that the research team's advancements in single-cell genome technology have come to fruition. We will persistently strive to lead in single-cell genome technology," said Prof. Hyun Woo Kwon of the Department of Nuclear Medicine at Korea University School of Medicine.

The research team received support from the Research Leader Program and the Young Researcher Program of the National Research Foundation of Korea, a grant from the MD-PhD/Medical Scientist Training Program through the Korea Health Industry Development Institute, and the Suh Kyungbae Foundation.

< Figure 1. Experimental design of the study >

< Figure 2. Schematic diagram illustrating factors influencing the soL1R landscape. >

Genetic composition of rc-L1s is inherited from the parents. The methylation landscape of rc-L1 promoters is predominantly determined by global DNA demethylation, followed by remethylation processes in the developmental stages. Then, when an rc-L1 is promoter demethylated in a specific cell lineage, the source expresses L1 transcripts thus making possible the induction of soL1Rs.

2023.05.22 View 10354

'Jumping Genes' Found to Alter Human Colon Genomes, Offering Insights into Aging and Tumorigenesis

The Korea Advanced Institute of Science and Technology (KAIST) and their collaborators have conducted a groundbreaking study targeting 'jumping genes' in the entire genomes of the human large intestine. Published in Nature on May 18 2023, the research unveils the surprising activity of 'Long interspersed nuclear element-1 (L1),' a type of jumping gene previously thought to be mostly dormant in human genomes. The study shows that L1 genes can become activated and disrupt genomic functions throughout an individual's lifetime, particularly in the colorectal epithelium.

(Paper Title: Widespread somatic L1 retrotransposition in normal colorectal epithelium, https://www.nature.com/articles/s41586-023-06046-z)

With approximately 500,000 L1 jumping genes, accounting for 17% of the human genome, they have long been recognized for their contribution to the evolution of the human species by introducing 'disruptive innovation' to genome sequences. Until now, it was believed that most L1 elements had lost their ability to jump in normal tissues of modern humans. However, this study reveals that some L1 jumping genes can be widely activated in normal cells, leading to the accumulation of genomic mutations over an individual's lifetime. The rate of L1 jumping and resulting genomic changes vary among different cell types, with a notable concentration observed in aged colon epithelial cells. The study illustrates that every colonic epithelial cell experiences an L1 jumping event by the age of 40 on average.

The research, led by co-first authors Chang Hyun Nam (a graduate student at KAIST) and Dr. Jeonghwan Youk (former graduate student at KAIST and assistant clinical professor at Seoul National University Hospital), involved the analysis of whole-genome sequences from 899 single cells obtained from skin (fibroblasts), blood, and colon epithelial tissues collected from 28 individuals. The study uncovers the activation of L1 jumping genes in normal cells, resulting in the gradual accumulation of genomic mutations over time. Additionally, the team explored epigenomic (DNA methylation) sequences to understand the mechanism behind L1 jumping gene activation. They found that cells with activated L1 jumping genes exhibit epigenetic instability, suggesting the critical role of epigenetic changes in regulating L1 jumping gene activity. Most of these epigenomic instabilities were found to arise during the early stages of embryogenesis. The study provides valuable insights into the aging process and the development of diseases in human colorectal tissues.

"This study illustrates that genomic damage in normal cells is acquired not only through exposure to carcinogens but also through the activity of endogenous components whose impact was previously unclear. Genomes of apparently healthy aged cells, particularly in the colorectal epithelium, become mosaic due to the activity of L1 jumping genes," said Prof. Young Seok Ju at KAIST.

"We emphasize the essential and ongoing collaboration among researchers in clinical medicine and basic medical sciences," said Prof. Min Jung Kim of the Department of Surgery at Seoul National University Hospital. "This case highlights the critical role of systematically collected human tissues from clinical settings in unraveling the complex process of disease development in humans."

"I am delighted that the research team's advancements in single-cell genome technology have come to fruition. We will persistently strive to lead in single-cell genome technology," said Prof. Hyun Woo Kwon of the Department of Nuclear Medicine at Korea University School of Medicine.

The research team received support from the Research Leader Program and the Young Researcher Program of the National Research Foundation of Korea, a grant from the MD-PhD/Medical Scientist Training Program through the Korea Health Industry Development Institute, and the Suh Kyungbae Foundation.

< Figure 1. Experimental design of the study >

< Figure 2. Schematic diagram illustrating factors influencing the soL1R landscape. >

Genetic composition of rc-L1s is inherited from the parents. The methylation landscape of rc-L1 promoters is predominantly determined by global DNA demethylation, followed by remethylation processes in the developmental stages. Then, when an rc-L1 is promoter demethylated in a specific cell lineage, the source expresses L1 transcripts thus making possible the induction of soL1Rs.

2023.05.22 View 10354 -

Synthetic sRNAs to knockdown genes in medical and industrial bacteria

Bacteria are intimately involved in our daily lives. These microorganisms have been used in human history for food such as cheese, yogurt, and wine, In more recent years, through metabolic engineering, microorganisms been used extensively as microbial cell factories to manufacture plastics, feed for livestock, dietary supplements, and drugs. However, in addition to these bacteria that are beneficial to human lives, pathogens such as Pneumonia, Salmonella, and Staphylococcus that cause various infectious diseases are also ubiquitously present. It is important to be able to metabolically control these beneficial industrial bacteria for high value-added chemicals production and to manipulate harmful pathogens to suppress its pathogenic traits.

KAIST (President Kwang Hyung Lee) announced on the 10th that a research team led by Distinguished Professor Sang Yup Lee of the Department of Biochemical Engineering has developed a new sRNA tool that can effectively inhibit target genes in various bacteria, including both Gram-negative and Gram-positive bacteria. The research results were published online on April 24 in Nature Communications.

※ Thesis title: Targeted and high-throughput gene knockdown in diverse bacteria using synthetic sRNAs

※ Author information : Jae Sung Cho (co-1st), Dongsoo Yang (co-1st), Cindy Pricilia Surya Prabowo (co-author), Mohammad Rifqi Ghiffary (co-author), Taehee Han (co-author), Kyeong Rok Choi (co-author), Cheon Woo Moon (co-author), Hengrui Zhou (co-author), Jae Yong Ryu (co-author), Hyun Uk Kim (co-author) and Sang Yup Lee (corresponding author).

sRNA is an effective tool for synthesizing and regulating target genes in E. coli, but it has been difficult to apply to industrially useful Gram-positive bacteria such as Bacillus subtilis and Corynebacterium in addition to Gram-negative bacteria such as E. coli.

To address this issue, a research team led by Distinguished Professor Lee Sang Yup Lee of the Department of Chemical and Biomolecular Engineering at KAIST developed a new sRNA platform that can effectively suppress target genes in various bacteria, including both Gram-negative and positive bacteria. The research team surveyed thousands of microbial-derived sRNA systems in the microbial database, and eventually designated the sRNA system derived from 'Bacillus subtilis' that showed the highest gene knockdown efficiency, and designated it as “Broad-Host-Range sRNA”, or BHR-sRNA.

A similar well-known system is the CRISPR interference (CRISPRi) system, which is a modified CRISPR system that knocks down gene expression by suppressing the gene transcription process. However, the Cas9 protein in the CRISPRi system has a very high molecular weight, and there have been reports growth inhibition in bacteria. The BHR-sRNA system developed in this study did not affect bacterial growth while showing similar gene knockdown efficiencies to CRISPRi.

< Figure 1. a) Schematic illustration demonstrating the mechanism of syntetic sRNA b) Phylogenetic tree of the 16 Gram-negative and Gram-positive bacterial species tested for gene knockdown by the BHR-sRNA system. >

To validate the versatility of the BHR-sRNA system, 16 different gram-negative and gram-positive bacteria were selected and tested, where the BHR-sRNA system worked successfully in 15 of them. In addition, it was demonstrated that the gene knockdown capability was more effective than that of the existing E. coli-based sRNA system in 10 bacteria. The BHR-sRNA system proved to be a universal tool capable of effectively inhibiting gene expression in various bacteria.

In order to address the problem of antibiotic-resistant pathogens that have recently become more serious, the BHR-sRNA was demonstrated to suppress the pathogenicity by suppressing the gene producing the virulence factor. By using BHR-sRNA, biofilm formation, one of the factors resulting in antibiotic resistance, was inhibited by 73% in Staphylococcus epidermidis a pathogen that can cause hospital-acquired infections. Antibiotic resistance was also weakened by 58% in the pneumonia causing bacteria Klebsiella pneumoniae. In addition, BHR-sRNA was applied to industrial bacteria to develop microbial cell factories to produce high value-added chemicals with better production performance. Notably, superior industrial strains were constructed with the aid of BHR-sRNA to produce the following chemicals: valerolactam, a raw material for polyamide polymers, methyl-anthranilate, a grape-flavor food additive, and indigoidine, a blue-toned natural dye.

The BHR-sRNA developed through this study will help expedite the commercialization of bioprocesses to produce high value-added compounds and materials such as artificial meat, jet fuel, health supplements, pharmaceuticals, and plastics. It is also anticipated that to help eradicating antibiotic-resistant pathogens in preparation for another upcoming pandemic. “In the past, we could only develop new tools for gene knockdown for each bacterium, but now we have developed a tool that works for a variety of bacteria” said Distinguished Professor Sang Yup Lee.

This work was supported by the Development of Next-generation Biorefinery Platform Technologies for Leading Bio-based Chemicals Industry Project and the Development of Platform Technologies of Microbial Cell Factories for the Next-generation Biorefineries Project from NRF supported by the Korean MSIT.

2023.05.10 View 9415

Synthetic sRNAs to knockdown genes in medical and industrial bacteria

Bacteria are intimately involved in our daily lives. These microorganisms have been used in human history for food such as cheese, yogurt, and wine, In more recent years, through metabolic engineering, microorganisms been used extensively as microbial cell factories to manufacture plastics, feed for livestock, dietary supplements, and drugs. However, in addition to these bacteria that are beneficial to human lives, pathogens such as Pneumonia, Salmonella, and Staphylococcus that cause various infectious diseases are also ubiquitously present. It is important to be able to metabolically control these beneficial industrial bacteria for high value-added chemicals production and to manipulate harmful pathogens to suppress its pathogenic traits.

KAIST (President Kwang Hyung Lee) announced on the 10th that a research team led by Distinguished Professor Sang Yup Lee of the Department of Biochemical Engineering has developed a new sRNA tool that can effectively inhibit target genes in various bacteria, including both Gram-negative and Gram-positive bacteria. The research results were published online on April 24 in Nature Communications.

※ Thesis title: Targeted and high-throughput gene knockdown in diverse bacteria using synthetic sRNAs

※ Author information : Jae Sung Cho (co-1st), Dongsoo Yang (co-1st), Cindy Pricilia Surya Prabowo (co-author), Mohammad Rifqi Ghiffary (co-author), Taehee Han (co-author), Kyeong Rok Choi (co-author), Cheon Woo Moon (co-author), Hengrui Zhou (co-author), Jae Yong Ryu (co-author), Hyun Uk Kim (co-author) and Sang Yup Lee (corresponding author).

sRNA is an effective tool for synthesizing and regulating target genes in E. coli, but it has been difficult to apply to industrially useful Gram-positive bacteria such as Bacillus subtilis and Corynebacterium in addition to Gram-negative bacteria such as E. coli.

To address this issue, a research team led by Distinguished Professor Lee Sang Yup Lee of the Department of Chemical and Biomolecular Engineering at KAIST developed a new sRNA platform that can effectively suppress target genes in various bacteria, including both Gram-negative and positive bacteria. The research team surveyed thousands of microbial-derived sRNA systems in the microbial database, and eventually designated the sRNA system derived from 'Bacillus subtilis' that showed the highest gene knockdown efficiency, and designated it as “Broad-Host-Range sRNA”, or BHR-sRNA.

A similar well-known system is the CRISPR interference (CRISPRi) system, which is a modified CRISPR system that knocks down gene expression by suppressing the gene transcription process. However, the Cas9 protein in the CRISPRi system has a very high molecular weight, and there have been reports growth inhibition in bacteria. The BHR-sRNA system developed in this study did not affect bacterial growth while showing similar gene knockdown efficiencies to CRISPRi.

< Figure 1. a) Schematic illustration demonstrating the mechanism of syntetic sRNA b) Phylogenetic tree of the 16 Gram-negative and Gram-positive bacterial species tested for gene knockdown by the BHR-sRNA system. >

To validate the versatility of the BHR-sRNA system, 16 different gram-negative and gram-positive bacteria were selected and tested, where the BHR-sRNA system worked successfully in 15 of them. In addition, it was demonstrated that the gene knockdown capability was more effective than that of the existing E. coli-based sRNA system in 10 bacteria. The BHR-sRNA system proved to be a universal tool capable of effectively inhibiting gene expression in various bacteria.

In order to address the problem of antibiotic-resistant pathogens that have recently become more serious, the BHR-sRNA was demonstrated to suppress the pathogenicity by suppressing the gene producing the virulence factor. By using BHR-sRNA, biofilm formation, one of the factors resulting in antibiotic resistance, was inhibited by 73% in Staphylococcus epidermidis a pathogen that can cause hospital-acquired infections. Antibiotic resistance was also weakened by 58% in the pneumonia causing bacteria Klebsiella pneumoniae. In addition, BHR-sRNA was applied to industrial bacteria to develop microbial cell factories to produce high value-added chemicals with better production performance. Notably, superior industrial strains were constructed with the aid of BHR-sRNA to produce the following chemicals: valerolactam, a raw material for polyamide polymers, methyl-anthranilate, a grape-flavor food additive, and indigoidine, a blue-toned natural dye.

The BHR-sRNA developed through this study will help expedite the commercialization of bioprocesses to produce high value-added compounds and materials such as artificial meat, jet fuel, health supplements, pharmaceuticals, and plastics. It is also anticipated that to help eradicating antibiotic-resistant pathogens in preparation for another upcoming pandemic. “In the past, we could only develop new tools for gene knockdown for each bacterium, but now we have developed a tool that works for a variety of bacteria” said Distinguished Professor Sang Yup Lee.

This work was supported by the Development of Next-generation Biorefinery Platform Technologies for Leading Bio-based Chemicals Industry Project and the Development of Platform Technologies of Microbial Cell Factories for the Next-generation Biorefineries Project from NRF supported by the Korean MSIT.

2023.05.10 View 9415 -

KAIST gearing up to train physician-scientists and BT Professionals joining hands with Boston-based organizations

KAIST (President Kwang Hyung Lee) announced on the 29th that it has signed MOUs with Massachusetts General Hospital, a founding member of the Mass General Brigham health care system and a world-class research-oriented hospital, and Moderna, a biotechnology company that developed a COVID-19 vaccine at the Langham Hotel in Boston, MA, USA on the morning of April 28th (local time). The signing ceremony was attended by officials from each institution joined by others headed by Minister LEE Young of the Korean Ministry of SMEs and Startups (MSS), and Commissioner LEE Insil of the Korean Intellectual Property Office.

< Photo 1. Photo from the Signing of MOU between KAIST-Harvard University Massachusetts General Hospital and KAIST-Moderna >

Mass General is the first and largest teaching hospital of Harvard Medical School in Boston, USA, and it is one of the most innovative hospitals in the world being the alma mater of more than 13 Nobel Prize winners and the home of the Mass General Research Institute, the world’s largest hospital-based research program that utilizes an annual research budget of more than $1.3 billion.

KAIST signed a general agreement to explore research and academic exchange with Mass General in September of last year and this MOU is a part of its follow-ups.

Mass General works with Harvard and the Massachusetts Institute of Technology (MIT), as well as local hospitals, to support students learn the theories of medicine and engineering, and gain rich clinical research experience.

Through this MOU, KAIST will explore cooperation with an innovative ecosystem created through the convergence of medicine and engineering. In particular, KAIST’s goal is to develop a Korean-style training program and implement a differentiated educational program when establishing the science and technology-oriented medical school in the future by further strengthening the science and engineering part of the training including a curriculum on artificial intelligence (AI) and the likes there of.

Also, in order to foster innovative physician-scientists, KAIST plans to pursue cooperation to develop programs for exchange of academic and human resources including programs for student and research exchanges and a program for students of the science and technology-oriented medical school at KAIST to have a chance to take part in practical training at Mass General.

David F.M. Brown, MD, Mass General President, said, “The collaboration with KAIST has a wide range of potentials, including advice on training of physician-scientists, academic and human resource exchanges, and vitalization of joint research by faculty from both institutions. Through this agreement, we will be able to actively contribute to global cooperation and achieve mutual goals.”

Meanwhile, an MOU between KAIST and Moderna was also held on the same day. Its main focus is to foster medical experts in cooperation with KAIST Graduate School of Medical Science and Engineering (GSMSE), and plans to cooperate in various ways in the future, including collaborating for development of vaccine and new drugs, virus research, joint mRNA research, and facilitation of technology commercialization.

In over 10 years since its inception, Moderna has transformed from a research-stage company advancing programs in the field of messenger RNA (mRNA) to an enterprise with a diverse clinical portfolio of vaccines and therapeutics across seven modalities. The Company has 48 programs in development across 45 development candidates, of which 38 are currently in active clinical trials.

“We are grateful to have laid a foundation for collaboration to foster industry experts with the Korea Advanced Institute of Science and Technology, a leader of science and technology innovation in Korea,” said Arpa Garay, Chief Commercial Officer, Moderna. “Based on our leadership and expertise in developing innovative mRNA vaccines and therapeutics, we hope to contribute to educating and collaborating with professionals in the bio-health field of Korea.“

President Kwang Hyung Lee of KAIST, said, “We deem this occasion to be of grave significance to be able to work closely with Massachusetts General Hospital, one of the world's best research-oriented hospitals, and Moderna, one of the most influential biomedical companies.”

President Lee continued, "On the basis of the collaboration with the two institutions, we will be able to bring up qualified physician-scientists and global leaders of the biomedical business who will solve problems of human health and their progress will in turn, accelerate the national R&D efforts in general and diversify the industry."

2023.04.29 View 16818

KAIST gearing up to train physician-scientists and BT Professionals joining hands with Boston-based organizations

KAIST (President Kwang Hyung Lee) announced on the 29th that it has signed MOUs with Massachusetts General Hospital, a founding member of the Mass General Brigham health care system and a world-class research-oriented hospital, and Moderna, a biotechnology company that developed a COVID-19 vaccine at the Langham Hotel in Boston, MA, USA on the morning of April 28th (local time). The signing ceremony was attended by officials from each institution joined by others headed by Minister LEE Young of the Korean Ministry of SMEs and Startups (MSS), and Commissioner LEE Insil of the Korean Intellectual Property Office.

< Photo 1. Photo from the Signing of MOU between KAIST-Harvard University Massachusetts General Hospital and KAIST-Moderna >

Mass General is the first and largest teaching hospital of Harvard Medical School in Boston, USA, and it is one of the most innovative hospitals in the world being the alma mater of more than 13 Nobel Prize winners and the home of the Mass General Research Institute, the world’s largest hospital-based research program that utilizes an annual research budget of more than $1.3 billion.

KAIST signed a general agreement to explore research and academic exchange with Mass General in September of last year and this MOU is a part of its follow-ups.

Mass General works with Harvard and the Massachusetts Institute of Technology (MIT), as well as local hospitals, to support students learn the theories of medicine and engineering, and gain rich clinical research experience.

Through this MOU, KAIST will explore cooperation with an innovative ecosystem created through the convergence of medicine and engineering. In particular, KAIST’s goal is to develop a Korean-style training program and implement a differentiated educational program when establishing the science and technology-oriented medical school in the future by further strengthening the science and engineering part of the training including a curriculum on artificial intelligence (AI) and the likes there of.