TE

-

Professor Jin-Hyung Kim appointed as the founding director of the Software Policy Research Center

Professor Jin-Hyung Kim from the Department of Computer Science at KAIST was appointed as the founding director of the newly established research institute, the Software Policy Research Center. He will serve as director for three years. The research center will undertake studies and analysis on software policy, statistics, and new software technology.

2014.01.05 View 9561

Professor Jin-Hyung Kim appointed as the founding director of the Software Policy Research Center

Professor Jin-Hyung Kim from the Department of Computer Science at KAIST was appointed as the founding director of the newly established research institute, the Software Policy Research Center. He will serve as director for three years. The research center will undertake studies and analysis on software policy, statistics, and new software technology.

2014.01.05 View 9561 -

Professor Dong-Yol Yang received an award for scholar of the year 2013 from the Korean mechanical engineering community

Professor Dong-Yol Yang from the Department of Mechanical Engineering at KAIST was selected as “the scholar of the year 2013” at an annual event held by the Korean Federation of Mechanical Engineering Societies, the Korea Association of Machinery Industry, and other mechanical engineering research institutes in Korea. The event, the Day of the Machines, is the nation’s biggest gathering for engineers, scholars, and researchers in mechanical engineering, at which winners of the awards for the person of the year in academia, business, and engineering are announced.

Professor Yang was chosen for his lifetime achievement as a scholar in the field of three-dimensional shape precision processing by developing an innovative processing technology that contributes to the advancement of mechanical engineering and industry. He also introduced the three-dimensional fast processing to Korea from 1990 and developed world-class subminiature fast processing, the first of its kind in Korea.In 2013, Professor Yang identified geometric deformation elements in mechanical engineering for the first time in the world, an essential component for nano mobile system and received the best conference paper award at the 3M-Nano International Conference.

2014.01.05 View 10775

Professor Dong-Yol Yang received an award for scholar of the year 2013 from the Korean mechanical engineering community

Professor Dong-Yol Yang from the Department of Mechanical Engineering at KAIST was selected as “the scholar of the year 2013” at an annual event held by the Korean Federation of Mechanical Engineering Societies, the Korea Association of Machinery Industry, and other mechanical engineering research institutes in Korea. The event, the Day of the Machines, is the nation’s biggest gathering for engineers, scholars, and researchers in mechanical engineering, at which winners of the awards for the person of the year in academia, business, and engineering are announced.

Professor Yang was chosen for his lifetime achievement as a scholar in the field of three-dimensional shape precision processing by developing an innovative processing technology that contributes to the advancement of mechanical engineering and industry. He also introduced the three-dimensional fast processing to Korea from 1990 and developed world-class subminiature fast processing, the first of its kind in Korea.In 2013, Professor Yang identified geometric deformation elements in mechanical engineering for the first time in the world, an essential component for nano mobile system and received the best conference paper award at the 3M-Nano International Conference.

2014.01.05 View 10775 -

Professor Dong-Soo Han received the Prime Minister's award for creative economy in 2013

The 2013 Korea Creative Economy Awards, presented to companies or individuals that contributed to the implementation of the Korean government’s economic growth initiative called “creative economy” with the development of new technology, was held on December 12th at the InterContinental Seoul Coex. Professor Dong-Soo Han from the Department of Computer Science at KAIST received the Prime Minister’s award.

Professor Han was recognized for his research accomplishments on the development of an indoor GPS system and an integrated indoor/outdoor navigation system, as well as for his publication of a book for beginners who are interested in patents. He has applied 50 patents and registered 30 patents in Korea and abroad for the indoor positioning technology and smartphone application services.

His research work was also introduced to the public at the exhibition held after the award ceremony during December 12th-15th at the Coex convention center in Seoul.

2014.01.05 View 9181

Professor Dong-Soo Han received the Prime Minister's award for creative economy in 2013

The 2013 Korea Creative Economy Awards, presented to companies or individuals that contributed to the implementation of the Korean government’s economic growth initiative called “creative economy” with the development of new technology, was held on December 12th at the InterContinental Seoul Coex. Professor Dong-Soo Han from the Department of Computer Science at KAIST received the Prime Minister’s award.

Professor Han was recognized for his research accomplishments on the development of an indoor GPS system and an integrated indoor/outdoor navigation system, as well as for his publication of a book for beginners who are interested in patents. He has applied 50 patents and registered 30 patents in Korea and abroad for the indoor positioning technology and smartphone application services.

His research work was also introduced to the public at the exhibition held after the award ceremony during December 12th-15th at the Coex convention center in Seoul.

2014.01.05 View 9181 -

Professor Kwy-Ro Lee Appointed Distinguished Member of IEEE

Professor Kwy-Ro Lee from the Department of Electrical Engineering at KAIST was selected as a distinguished member of the Institute of Electrical and Electronics Engineers (IEEE) where his contribution to research development of the technological management of semiconductors was recognized.

Professor Lee earned his BS from Seoul National University and MS & Ph.D. from the University of Minnesota. He has been working as a professor in the Department of Electrical Engineering since 1986. He has also served as the president of the LG Electronics Research Center in 2005 and the president of the Nanoscience and Technology Center at KAIST in 2010.

IEEE is the largest professional association for the advancement of technology in electrical, electronics, computing and communication with 400,000 members in 160 countries. Only 0.1 percent of members with over ten years of service can be selected as distinguished members based on their research devotion for society.

2014.01.02 View 9239

Professor Kwy-Ro Lee Appointed Distinguished Member of IEEE

Professor Kwy-Ro Lee from the Department of Electrical Engineering at KAIST was selected as a distinguished member of the Institute of Electrical and Electronics Engineers (IEEE) where his contribution to research development of the technological management of semiconductors was recognized.

Professor Lee earned his BS from Seoul National University and MS & Ph.D. from the University of Minnesota. He has been working as a professor in the Department of Electrical Engineering since 1986. He has also served as the president of the LG Electronics Research Center in 2005 and the president of the Nanoscience and Technology Center at KAIST in 2010.

IEEE is the largest professional association for the advancement of technology in electrical, electronics, computing and communication with 400,000 members in 160 countries. Only 0.1 percent of members with over ten years of service can be selected as distinguished members based on their research devotion for society.

2014.01.02 View 9239 -

Freshmen join a volunteer program to assist people in need

“Learning how to share love is the first step to start a good, meaningful college life,” said President Steve Kang.

KAIST offers an opportunity to all freshmen entering KAIST in 2014 to participate in a volunteer program to help people in need. Under the program, about 800 students will visit a shelter for the homeless, senior citizens, and orphans, which is called “The Flower Town” located two hours away from KAIST campus.

The town was founded by a Catholic organization, “The Flower Town Preservation Foundation,” to provide housing, education, and health services to the most vulnerable and neglected populations in our society.

President Steve Kang and Woong-Jin Oh, the president of the foundation, made a partnership agreement to promote volunteerism and spread the spirit of sharing and caring among young people, including KAIST students. The participating students will stay at the shelter for a few days and engage in various volunteering activities such as serving meals, cleaning, playing with children, and teaching.

President Kang said, “I am very happy that we are able to give our students a chance to develop into warm-hearted people. Scientists without a heart may bring about modern conveniences but not necessarily the betterment of humanity. Learning how to share love is the first step to start a good, meaningful college life.”

2013.12.30 View 6452

Freshmen join a volunteer program to assist people in need

“Learning how to share love is the first step to start a good, meaningful college life,” said President Steve Kang.

KAIST offers an opportunity to all freshmen entering KAIST in 2014 to participate in a volunteer program to help people in need. Under the program, about 800 students will visit a shelter for the homeless, senior citizens, and orphans, which is called “The Flower Town” located two hours away from KAIST campus.

The town was founded by a Catholic organization, “The Flower Town Preservation Foundation,” to provide housing, education, and health services to the most vulnerable and neglected populations in our society.

President Steve Kang and Woong-Jin Oh, the president of the foundation, made a partnership agreement to promote volunteerism and spread the spirit of sharing and caring among young people, including KAIST students. The participating students will stay at the shelter for a few days and engage in various volunteering activities such as serving meals, cleaning, playing with children, and teaching.

President Kang said, “I am very happy that we are able to give our students a chance to develop into warm-hearted people. Scientists without a heart may bring about modern conveniences but not necessarily the betterment of humanity. Learning how to share love is the first step to start a good, meaningful college life.”

2013.12.30 View 6452 -

KAIST Student Awarded Prize from Energy Saving Contest

Jun-Min Kwon, an undergraduate student in the Department of Chemistry at KAIST, was awarded a prize from the Ministry of Trade, Industry and Energy, Republic of Korea, at the 35th Energy Saving Contest which was held on November 20.

The student club he has been leading was also selected as one of the best groups by the Save Energy Save Earth (SESE), a volunteer organization supported by the Korea Energy Management Corporation and the Ministry of Knowledge Economy, Republic of Korea.

Kwon began promoting energy conservation through a blog and participated in related meetings and workshops as a high school student to improve the understanding on the importance of energy saving and recycling.He also received awards from the Second National Assembly Forum on Climate Change, the Korean National Science Fair, as well as the Samsung Human Tech Paper Award.

2013.12.24 View 14648

KAIST Student Awarded Prize from Energy Saving Contest

Jun-Min Kwon, an undergraduate student in the Department of Chemistry at KAIST, was awarded a prize from the Ministry of Trade, Industry and Energy, Republic of Korea, at the 35th Energy Saving Contest which was held on November 20.

The student club he has been leading was also selected as one of the best groups by the Save Energy Save Earth (SESE), a volunteer organization supported by the Korea Energy Management Corporation and the Ministry of Knowledge Economy, Republic of Korea.

Kwon began promoting energy conservation through a blog and participated in related meetings and workshops as a high school student to improve the understanding on the importance of energy saving and recycling.He also received awards from the Second National Assembly Forum on Climate Change, the Korean National Science Fair, as well as the Samsung Human Tech Paper Award.

2013.12.24 View 14648 -

Professor Suk-Joo Na Invited to Finland as Distinguished Professor

Professor Suk-Joo Na, from the Department of Mechanical Engineering at KAIST, has been invited as a distinguished professor for an international research project in Finland.

As a leading scientist in the field of arc welding and numerical analysis of the laser welding process, Na will assemble a research group for the interpretation of the welding processes for three years at the VVT Technical Research Centre of Finland beginning in January of 2014.

The project was established to improve the research level and national competitiveness of Finland by inviting leading international scientists to the National Technology Agency of Finland and Academy of Finland since 2006 and over one hundred projects have been carried out thus far. A total of 17 billion won will be invested for the eleven new projects selected this year. Professor Na said, “The fusion welding field contains important technology for improving the competitiveness of mechanical products of Finland. Improvements in productivity, the life cycles of products, and energy saving through interpretation technology for the numerical analysis of the welding process will make a huge impact on the national economy of Finland.”

2013.12.24 View 10946

Professor Suk-Joo Na Invited to Finland as Distinguished Professor

Professor Suk-Joo Na, from the Department of Mechanical Engineering at KAIST, has been invited as a distinguished professor for an international research project in Finland.

As a leading scientist in the field of arc welding and numerical analysis of the laser welding process, Na will assemble a research group for the interpretation of the welding processes for three years at the VVT Technical Research Centre of Finland beginning in January of 2014.

The project was established to improve the research level and national competitiveness of Finland by inviting leading international scientists to the National Technology Agency of Finland and Academy of Finland since 2006 and over one hundred projects have been carried out thus far. A total of 17 billion won will be invested for the eleven new projects selected this year. Professor Na said, “The fusion welding field contains important technology for improving the competitiveness of mechanical products of Finland. Improvements in productivity, the life cycles of products, and energy saving through interpretation technology for the numerical analysis of the welding process will make a huge impact on the national economy of Finland.”

2013.12.24 View 10946 -

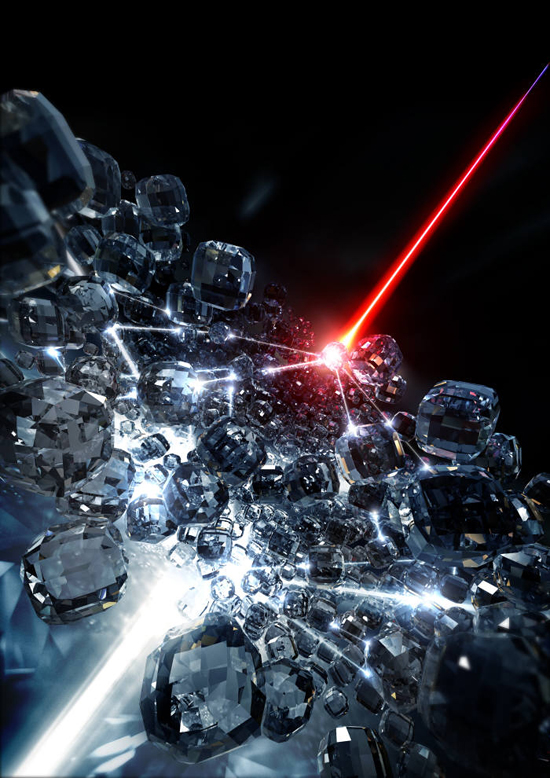

Nanoparticle based Super Lens selected as 2013 Science and Technology News

Professor Yong-keun Park

"Nanoparticle-based Super Lens", an article by KAIST Physics Department’s Professor Yong-keun Park and Professor Yong-hoon Cho’s joint research team, has been selected as one of the ten representative 2013 Science and Technology News, by the Korea Federation of Science and Technology Societies.

This new concept super lens uses the scattering of light, which can yield over three times more superior resolution of previous optical lenses.

Unlike the conventional optical lens that utilizes refraction of the light, the super lens can give the image of viruses and structure within the cell at 100㎚. This lens is also applicable to state-of-the-art optical and semiconductor processes.

In addition, this year's research achievements also include the successful launch of Naro, a new technology to remove the brain cell membrane which gives a more transparent view of the brain, a new drug to inhibit cancer metastasis, as well as the development of ultra-wide-angle insect eye camera technology.

Articles for 2013 Science and Technology News are chosen in three trial reviews by committee and online voting by 5,437 people over the course of [two weeks]14 days, from November 21st to December 4th.

2013.12.14 View 11856

Nanoparticle based Super Lens selected as 2013 Science and Technology News

Professor Yong-keun Park

"Nanoparticle-based Super Lens", an article by KAIST Physics Department’s Professor Yong-keun Park and Professor Yong-hoon Cho’s joint research team, has been selected as one of the ten representative 2013 Science and Technology News, by the Korea Federation of Science and Technology Societies.

This new concept super lens uses the scattering of light, which can yield over three times more superior resolution of previous optical lenses.

Unlike the conventional optical lens that utilizes refraction of the light, the super lens can give the image of viruses and structure within the cell at 100㎚. This lens is also applicable to state-of-the-art optical and semiconductor processes.

In addition, this year's research achievements also include the successful launch of Naro, a new technology to remove the brain cell membrane which gives a more transparent view of the brain, a new drug to inhibit cancer metastasis, as well as the development of ultra-wide-angle insect eye camera technology.

Articles for 2013 Science and Technology News are chosen in three trial reviews by committee and online voting by 5,437 people over the course of [two weeks]14 days, from November 21st to December 4th.

2013.12.14 View 11856 -

Prime Minister's Prize for KAIST TBIC at 2013 Korean Venture & Business Expo

The KAIST Technology Business Incubation Center (TBIC) received the Prime Minister’s Prize at the 2013 Korean Venture & Business Expo. TBIC started its service in 1994 and was selected as the best center by the Asia Association of Business Incubation (AABI) in 2007.

The center has contributed to business incubation for competitive enterprises through consulting, venture capital, educational curriculums, and infrastructure service. It has also encouraged and activated business startups by KAIST students through educational programs and supporting services such as hidden champion buildup, mentoring & networking, startup auditions, and special lecture sessions for entrepreneurship.

TBIC has supported 488 businesses since 1994, and 278 companies (57%) are still in business. Eleven companies have been listed on the Korea Stock Exchange through the support of TBIC and eight of them are still on the list as of today. Those companies have been contributing to the national economy with total sales of 1.9 trillion won and in job creation by hiring 5,908 employees.

2013.12.11 View 8763

Prime Minister's Prize for KAIST TBIC at 2013 Korean Venture & Business Expo

The KAIST Technology Business Incubation Center (TBIC) received the Prime Minister’s Prize at the 2013 Korean Venture & Business Expo. TBIC started its service in 1994 and was selected as the best center by the Asia Association of Business Incubation (AABI) in 2007.

The center has contributed to business incubation for competitive enterprises through consulting, venture capital, educational curriculums, and infrastructure service. It has also encouraged and activated business startups by KAIST students through educational programs and supporting services such as hidden champion buildup, mentoring & networking, startup auditions, and special lecture sessions for entrepreneurship.

TBIC has supported 488 businesses since 1994, and 278 companies (57%) are still in business. Eleven companies have been listed on the Korea Stock Exchange through the support of TBIC and eight of them are still on the list as of today. Those companies have been contributing to the national economy with total sales of 1.9 trillion won and in job creation by hiring 5,908 employees.

2013.12.11 View 8763 -

KAIST Takes Steps towards a Self-Sustainable Campus

KAIST has been selected for a $45-million national smart grid initiative organized under the Ministry of Trade, Industry and Energy. Ninteen institutions will participate in the 2-year-long initiative. The consortium’s work is expected to take place from 2015 to 2017 after a review by the Ministry of Strategy and Finance.

The Smart Grid Explansion Initiative which has been considered the future of electric power industry implements information and communications technology to conventional grid system to maximize energy efficiency. The ROK government has selected the Smart Grid Expansion Initiative as one of South Korea’s primary national projects and plans to implement it nationwide based on multiple demonstration projects in major cities including Jeju.

KAIST plans to invest $45 million in developing systems for renewable energy power plants, efficient energy management, smart grid data, and electric vehicles to build the energy self-sustainable campus. It also hopes to contribute to fostering specialized talents and companies in energy management.

Byoung-Yoon Kim, the vice-president for research at KAIST, expects that by 2017, KAIST will be able to dramatically improve its energy capacity especially during peak periods and gain energy efficiency around the campus. He hopes that the micro grid project at KAIST will set a new standard for the self-sustainable campus.

2013.12.11 View 10106

KAIST Takes Steps towards a Self-Sustainable Campus

KAIST has been selected for a $45-million national smart grid initiative organized under the Ministry of Trade, Industry and Energy. Ninteen institutions will participate in the 2-year-long initiative. The consortium’s work is expected to take place from 2015 to 2017 after a review by the Ministry of Strategy and Finance.

The Smart Grid Explansion Initiative which has been considered the future of electric power industry implements information and communications technology to conventional grid system to maximize energy efficiency. The ROK government has selected the Smart Grid Expansion Initiative as one of South Korea’s primary national projects and plans to implement it nationwide based on multiple demonstration projects in major cities including Jeju.

KAIST plans to invest $45 million in developing systems for renewable energy power plants, efficient energy management, smart grid data, and electric vehicles to build the energy self-sustainable campus. It also hopes to contribute to fostering specialized talents and companies in energy management.

Byoung-Yoon Kim, the vice-president for research at KAIST, expects that by 2017, KAIST will be able to dramatically improve its energy capacity especially during peak periods and gain energy efficiency around the campus. He hopes that the micro grid project at KAIST will set a new standard for the self-sustainable campus.

2013.12.11 View 10106 -

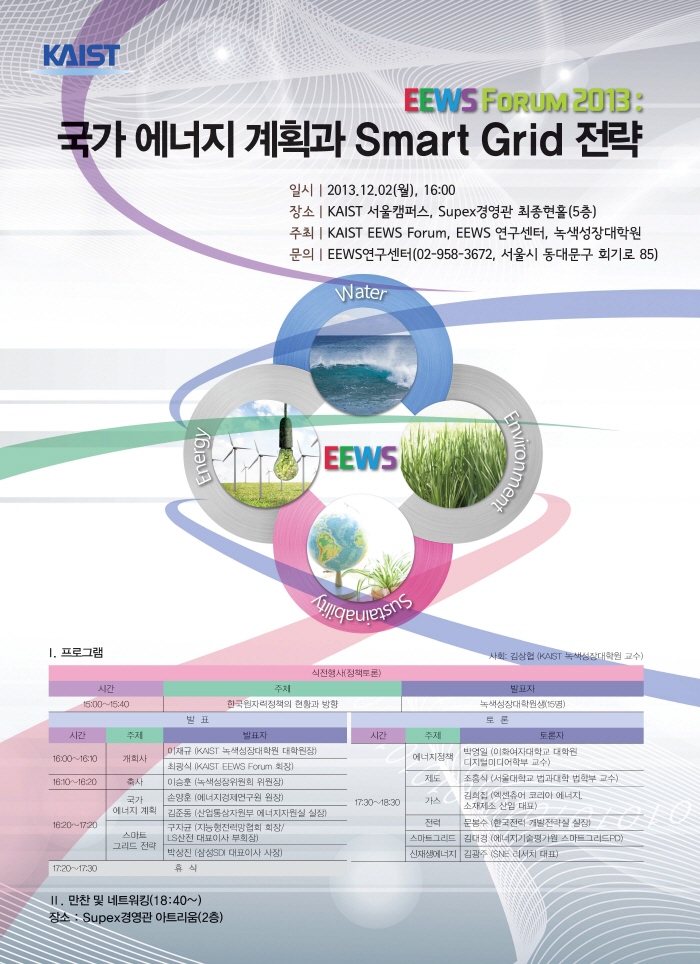

2013 EEWS Forum on National Energy Plan and Smart Grid Strategy

The Graduate School of Energy, Environment, Water, and Sustainability (EEWS) at KAIST hosted a forum on national energy planning and smart grid strategies on December 2 in the Jong-Hyun Choi Hall on KAIST’s Seoul campus. EEWS is a research and education program operated by KAIST to deal with the issues of energy, global warming, water, and sustainable growth.About 20 specialists including Jae-Kyu Lee, President of the Graduate School of Green Growth at KAIST; Kwang-Sik Choi, President of the EEWS Forum; Seong-Hoon Lee, Chairman of the Presidential Committee on Green Growth; Yang-Hoon Sohn, President of the Energy Economics Institute; and Jun-Dong Kim, Deputy Minister in the Ministry of Trade, Industry, and Energy, participated in the forum. Presentations and discussions were made in the fields of national energy plans, smart grid strategies, energy policy, as well as gas, electricity and sustainable energy.

2013.12.11 View 8912

2013 EEWS Forum on National Energy Plan and Smart Grid Strategy

The Graduate School of Energy, Environment, Water, and Sustainability (EEWS) at KAIST hosted a forum on national energy planning and smart grid strategies on December 2 in the Jong-Hyun Choi Hall on KAIST’s Seoul campus. EEWS is a research and education program operated by KAIST to deal with the issues of energy, global warming, water, and sustainable growth.About 20 specialists including Jae-Kyu Lee, President of the Graduate School of Green Growth at KAIST; Kwang-Sik Choi, President of the EEWS Forum; Seong-Hoon Lee, Chairman of the Presidential Committee on Green Growth; Yang-Hoon Sohn, President of the Energy Economics Institute; and Jun-Dong Kim, Deputy Minister in the Ministry of Trade, Industry, and Energy, participated in the forum. Presentations and discussions were made in the fields of national energy plans, smart grid strategies, energy policy, as well as gas, electricity and sustainable energy.

2013.12.11 View 8912 -

Graduate Student at KAIST Awarded Best Prize at the 9th Inside Edge

Sun-Jin Choi, a Ph. D. candidate in the Department of Materials Science and Engineering at KAIST, under the guidance of Professor Il-Doo Kim, won the best prize at the 9th Inside Edge Contest hosted by Samsung Electro-Mechanics.

Choi was awarded prize money totaling fifteen million won at the award ceremony held on November 22 at the Mirae Hall at the headquarters of Samsung Electro-Mechanics in Suwon.

Choi’s research, titled “Exhaled Breath Sensor Arrays for the Non-invasive and Real-time Diagnosis of Diabetes by Detection of Acetone,” was recognized for its creativity and uniqueness.The Inside Edge is an international thesis competition which was started in 2005 to encourage and support creative research and potential technological development among young scientists and engineers.

Sun-Jin Choi (left) and Professor Il-Doo Kim (right).

2013.12.11 View 10941

Graduate Student at KAIST Awarded Best Prize at the 9th Inside Edge

Sun-Jin Choi, a Ph. D. candidate in the Department of Materials Science and Engineering at KAIST, under the guidance of Professor Il-Doo Kim, won the best prize at the 9th Inside Edge Contest hosted by Samsung Electro-Mechanics.

Choi was awarded prize money totaling fifteen million won at the award ceremony held on November 22 at the Mirae Hall at the headquarters of Samsung Electro-Mechanics in Suwon.

Choi’s research, titled “Exhaled Breath Sensor Arrays for the Non-invasive and Real-time Diagnosis of Diabetes by Detection of Acetone,” was recognized for its creativity and uniqueness.The Inside Edge is an international thesis competition which was started in 2005 to encourage and support creative research and potential technological development among young scientists and engineers.

Sun-Jin Choi (left) and Professor Il-Doo Kim (right).

2013.12.11 View 10941