Engineering

-

Green Technology for Data Centers: Ultra-low Power 100 Gbps Ethernet Integrated Circuit Developed

A new integrated circuit (IC), consuming only 0.75W of electricity, will reduce the power usage of data chips installed at data centers by one-third.

Each day, billions of people surf the Internet for information, entertainment, and educational content. The Internet contains an immeasurable amount of information and knowledge generated every minute all around the world that is readily available to everyone with a click of a computer mouse. The real magic of the Internet, however, lies in data centers, where hundreds of billions of data are stored and distributed to designated users around the clock.

Today, almost every business or organization either has its own data centers or outsources data center services to a third party. These centers house highly specialized equipment responsible for the support of computers, networks, data storage, and business security. Accordingly, the operational cost of data centers is tremendous because they consume a large amount of electricity.

Data centers can consume up to 100 times more energy than a standard office building. Data center energy consumption doubled from 2000 to 2006, reaching more than 60 billion kilowatt hours per year. If the current usage and technology trends continue, the energy consumption of data centers in the US will reach 8% of the country’s total electric power consumption by 2020.

A research team at the Korea Advanced Institute of Science and Technology (KAIST) and Terasquare, Inc. (

http://www.terasquare.co.kr

), a spin-off company of the university,

developed an extremely low-powered integrated circuit for Ethernet that consumes less than 0.75W of electricity but is able to send and receive data at the high speed of 100 gigabits per second (Gbps). The research team, headed by Hyeon-Min Bae, assistant professor of electrical engineering at KAIST, claims that the new microchip uses only one-third of the electricity consumed by the currently installed chips at data centers, thereby helping the centers to save energy.

Integrated circuits are embedded on communication modules that are inserted into a line card. Data centers have numerous line cards to build a network including routers and switches. Currently, 8W ICs are the most common in the market, and they consume a lot of energy and require the largest modules (112 cm

2

of CFP), decreasing the port density of line cards and, thus, limiting the amount of data transmission.

The ultra-low-power-circuit, 100-gigabit, full-transceiver CDR, is the world’s first solution that can be loaded to the smallest communication modules (20 cm

2

of CFP4 or 16 cm

2

of

QSFP28), the next-generation chips for data centers. Compared with other chip producers, the 100 Gbps CDR is a greener version of the technology that improves the energy efficiency of data centers while maintaining the high speed of data transmission.

Professor Hyeon-Min Bae said, “When we demonstrate our chip in September of this year at one of the leading companies that manufacture optical communication components and systems, they said that our product is two years ahead of those of our competitors. We plan to produce the chip from 2014 and expect that it will lead the 100 Gbps Ethernet IC market, which is expected to grow to USD 1 billion by 2017.”

The commercial model of the IC was first introduced at the 39

th

European Conference and Exhibition on Optical Communication (ECOC), the largest optical communication forum for new results and developments in Europe, held from September 22-26 at ExCeL London, an international exhibition and convention center.

Professor Bae added, “We received positive responses to our ultra-low-power 100-Gbps Ethernet IC at the ECOC. The chip will be used not only for a particular industry but also for many of next-generation, super-high-speed information communications technologies, such as high-speed USB, high-definition multimedia interface (HDMI), and TV interface.”

Before joining KAIST, Hyeon-Min Bae worked for many years at Finisar as a researcher who designed and developed the world’s first super-high-speed circuit, the 100 Gbps Ethernet IC.

2013.11.25 View 10522

Green Technology for Data Centers: Ultra-low Power 100 Gbps Ethernet Integrated Circuit Developed

A new integrated circuit (IC), consuming only 0.75W of electricity, will reduce the power usage of data chips installed at data centers by one-third.

Each day, billions of people surf the Internet for information, entertainment, and educational content. The Internet contains an immeasurable amount of information and knowledge generated every minute all around the world that is readily available to everyone with a click of a computer mouse. The real magic of the Internet, however, lies in data centers, where hundreds of billions of data are stored and distributed to designated users around the clock.

Today, almost every business or organization either has its own data centers or outsources data center services to a third party. These centers house highly specialized equipment responsible for the support of computers, networks, data storage, and business security. Accordingly, the operational cost of data centers is tremendous because they consume a large amount of electricity.

Data centers can consume up to 100 times more energy than a standard office building. Data center energy consumption doubled from 2000 to 2006, reaching more than 60 billion kilowatt hours per year. If the current usage and technology trends continue, the energy consumption of data centers in the US will reach 8% of the country’s total electric power consumption by 2020.

A research team at the Korea Advanced Institute of Science and Technology (KAIST) and Terasquare, Inc. (

http://www.terasquare.co.kr

), a spin-off company of the university,

developed an extremely low-powered integrated circuit for Ethernet that consumes less than 0.75W of electricity but is able to send and receive data at the high speed of 100 gigabits per second (Gbps). The research team, headed by Hyeon-Min Bae, assistant professor of electrical engineering at KAIST, claims that the new microchip uses only one-third of the electricity consumed by the currently installed chips at data centers, thereby helping the centers to save energy.

Integrated circuits are embedded on communication modules that are inserted into a line card. Data centers have numerous line cards to build a network including routers and switches. Currently, 8W ICs are the most common in the market, and they consume a lot of energy and require the largest modules (112 cm

2

of CFP), decreasing the port density of line cards and, thus, limiting the amount of data transmission.

The ultra-low-power-circuit, 100-gigabit, full-transceiver CDR, is the world’s first solution that can be loaded to the smallest communication modules (20 cm

2

of CFP4 or 16 cm

2

of

QSFP28), the next-generation chips for data centers. Compared with other chip producers, the 100 Gbps CDR is a greener version of the technology that improves the energy efficiency of data centers while maintaining the high speed of data transmission.

Professor Hyeon-Min Bae said, “When we demonstrate our chip in September of this year at one of the leading companies that manufacture optical communication components and systems, they said that our product is two years ahead of those of our competitors. We plan to produce the chip from 2014 and expect that it will lead the 100 Gbps Ethernet IC market, which is expected to grow to USD 1 billion by 2017.”

The commercial model of the IC was first introduced at the 39

th

European Conference and Exhibition on Optical Communication (ECOC), the largest optical communication forum for new results and developments in Europe, held from September 22-26 at ExCeL London, an international exhibition and convention center.

Professor Bae added, “We received positive responses to our ultra-low-power 100-Gbps Ethernet IC at the ECOC. The chip will be used not only for a particular industry but also for many of next-generation, super-high-speed information communications technologies, such as high-speed USB, high-definition multimedia interface (HDMI), and TV interface.”

Before joining KAIST, Hyeon-Min Bae worked for many years at Finisar as a researcher who designed and developed the world’s first super-high-speed circuit, the 100 Gbps Ethernet IC.

2013.11.25 View 10522 -

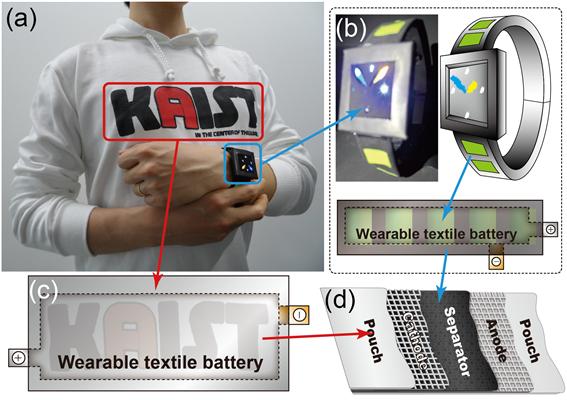

Technology Developed for Flexible, Foldable & Rechargeable Battery

Flexible, Foldable & Rechargeable Battery

The research group of professors Jang-Wook Choi & Jung-Yong Lee from the Graduate School of EEWS and Taek-Soo Kim from the Department of Mechanical Engineering at KAIST has developed technology for flexible and foldable batteries which are rechargeable using solar energy. The research result was published in the online issue of Nano Letters on November 5.

Trial versions of flexible and wearable electronics are being developed and introduced in the market such as Galaxy Gear, Apple’s i-Watch, and Google Glass. Research is being conducted to make the batteries softer and more wearable and to compete in the fast-growing market for flexible electronics.

This new technology is expected to be applied to the development of wearable computers as well as winter outdoor clothing since it is flexible and light. The research group expects that the new technology can be applied to current battery production lines without additional investment.

Professor Choi said, “It can be used as a core-source technology in the rechargeable battery industry in the future. Various wearable mobile electronic products can be developed through cooperation and collaboration within the industry.”

2013.11.21 View 13280

Technology Developed for Flexible, Foldable & Rechargeable Battery

Flexible, Foldable & Rechargeable Battery

The research group of professors Jang-Wook Choi & Jung-Yong Lee from the Graduate School of EEWS and Taek-Soo Kim from the Department of Mechanical Engineering at KAIST has developed technology for flexible and foldable batteries which are rechargeable using solar energy. The research result was published in the online issue of Nano Letters on November 5.

Trial versions of flexible and wearable electronics are being developed and introduced in the market such as Galaxy Gear, Apple’s i-Watch, and Google Glass. Research is being conducted to make the batteries softer and more wearable and to compete in the fast-growing market for flexible electronics.

This new technology is expected to be applied to the development of wearable computers as well as winter outdoor clothing since it is flexible and light. The research group expects that the new technology can be applied to current battery production lines without additional investment.

Professor Choi said, “It can be used as a core-source technology in the rechargeable battery industry in the future. Various wearable mobile electronic products can be developed through cooperation and collaboration within the industry.”

2013.11.21 View 13280 -

Final Results of the 2013 Intelligent SoC Robot War

KAIST hosted the 2013 Intelligent System on Chip (SoC) Robot War, the largest intelligent robot contest in Korea, from Oct. 24 to 27 at KINTEX in Ilsan, Korea.

Professor Hoi-Jun Yoo, from the Department of Electrical Engineering at KAIST, started the contest in 2003 to promote Taekwondo, a Korean martial art, and Korean semiconductor technology to the world.

The winning team was awarded an honorary certificate from Kookiwon, the world headquarters of Taekwondo.

Competitions were held in two different categories: Taekwon Robot and Huro Competition.

In the Taekwon Robot contest, intelligent robots loaded with cameras and semiconductor chips competed in Taekwondo skills.

In the Huro Competition, intelligent humanoid robots competed in detecting and passing huddles.

Approximately 550 participants from 107 groups applied for the 12th Intelligent SoC Robot War and 22 groups were selected for the final tournament. The best teams in each category received an award from the president and prime minister of the Republic of Korea, respectively.

Professor Yoo, the operating chair of the contest, said, “The contest was organized to introduce both technology and tradition by presenting robots with Taekwondo skills. The experiences from this contest could be the foundation for future robot technology and the growth engine for the next generation.”

Professor Yoo is a leading researcher in the field of object recognition chip, and his papers were often presented at the International Solid State Circuits Conference.Details of the contest can be found at http://www.socrobotwar.org.

2013.11.15 View 9509

Final Results of the 2013 Intelligent SoC Robot War

KAIST hosted the 2013 Intelligent System on Chip (SoC) Robot War, the largest intelligent robot contest in Korea, from Oct. 24 to 27 at KINTEX in Ilsan, Korea.

Professor Hoi-Jun Yoo, from the Department of Electrical Engineering at KAIST, started the contest in 2003 to promote Taekwondo, a Korean martial art, and Korean semiconductor technology to the world.

The winning team was awarded an honorary certificate from Kookiwon, the world headquarters of Taekwondo.

Competitions were held in two different categories: Taekwon Robot and Huro Competition.

In the Taekwon Robot contest, intelligent robots loaded with cameras and semiconductor chips competed in Taekwondo skills.

In the Huro Competition, intelligent humanoid robots competed in detecting and passing huddles.

Approximately 550 participants from 107 groups applied for the 12th Intelligent SoC Robot War and 22 groups were selected for the final tournament. The best teams in each category received an award from the president and prime minister of the Republic of Korea, respectively.

Professor Yoo, the operating chair of the contest, said, “The contest was organized to introduce both technology and tradition by presenting robots with Taekwondo skills. The experiences from this contest could be the foundation for future robot technology and the growth engine for the next generation.”

Professor Yoo is a leading researcher in the field of object recognition chip, and his papers were often presented at the International Solid State Circuits Conference.Details of the contest can be found at http://www.socrobotwar.org.

2013.11.15 View 9509 -

Professor Chun-Taek Rim Appointed as Associate Editor for IEEE TPEL

Professor Chun-Taek Rim of the nuclear and quantum engineering at KAIST was appointed as an associate editor of the Institute of Electrical and Electronics Engineers (IEEE) Transactions on Power Electronics (TPEL), an eminent academic journal bio-monthly published in the field of power electronics.The journal has a high impact factor (4.08), a measure reflecting the average number of citations to recent articles published in an academic journal, which ranks as the 6th the most influential journal among the 100 journals published by IEEE.Professor Rim was also appointed to an associate editor for IEEE Journal of Emerging and Selected Topics in Power Electronics in September in recognition of his expertise in wireless power and electric vehicles.

2013.11.15 View 12063

Professor Chun-Taek Rim Appointed as Associate Editor for IEEE TPEL

Professor Chun-Taek Rim of the nuclear and quantum engineering at KAIST was appointed as an associate editor of the Institute of Electrical and Electronics Engineers (IEEE) Transactions on Power Electronics (TPEL), an eminent academic journal bio-monthly published in the field of power electronics.The journal has a high impact factor (4.08), a measure reflecting the average number of citations to recent articles published in an academic journal, which ranks as the 6th the most influential journal among the 100 journals published by IEEE.Professor Rim was also appointed to an associate editor for IEEE Journal of Emerging and Selected Topics in Power Electronics in September in recognition of his expertise in wireless power and electric vehicles.

2013.11.15 View 12063 -

Professor Ji-Yun Lee, Received FAA Recognition Award

Professor Ji-Yun Lee, from the Department of Aerospace Engineering at KAIST, received the US Federal Aviation Administration (FAA) Recognition Award for her Ground-Based Augmentation System (GBAS) and her contribution to the development of satellite navigation technology.

GBAS contributes to the safety of aircraft navigation by providing flawless information with real-time location accuracy within one meter.

Professor Lee developed the monitoring software to improve the safety of GBAS users in her paper published in the International Journal of Radio Science in July of 2012.

The software will be distributed and used by many organizations including Eurocontrol following verification from the FAA technical center. It is expected to be standardized after discussions among international organizations.Professor Lee said, “As satellite navigation is applied to the infrastructure of air, marine, and ground transportation, as well as information & communications and finance, ensuring the performance and safety of the system is the most important factor. GBAS will be further developed and applied as a part of a global service system through international collaboration.”

2013.11.15 View 12650

Professor Ji-Yun Lee, Received FAA Recognition Award

Professor Ji-Yun Lee, from the Department of Aerospace Engineering at KAIST, received the US Federal Aviation Administration (FAA) Recognition Award for her Ground-Based Augmentation System (GBAS) and her contribution to the development of satellite navigation technology.

GBAS contributes to the safety of aircraft navigation by providing flawless information with real-time location accuracy within one meter.

Professor Lee developed the monitoring software to improve the safety of GBAS users in her paper published in the International Journal of Radio Science in July of 2012.

The software will be distributed and used by many organizations including Eurocontrol following verification from the FAA technical center. It is expected to be standardized after discussions among international organizations.Professor Lee said, “As satellite navigation is applied to the infrastructure of air, marine, and ground transportation, as well as information & communications and finance, ensuring the performance and safety of the system is the most important factor. GBAS will be further developed and applied as a part of a global service system through international collaboration.”

2013.11.15 View 12650 -

KAIST student wins Aerospace Student Papers Grand Prize

Dong-Il Yoo, a doctoral candidate under Professor Hyun-Chul Shim, at the Department of Aerospace Engineering, KAIST, has been awarded the Second Prize Award at the 11th Korea Aerospace Industries (KAI) Paper Contest. The award ceremony was held on October 30th at the media conference room at the KINTEX ADEX 2013 Exhibition in Seoul.

Yoo"s paper, titled "A Study on Virtual Pursuit Point-based Autonomous Air Combat Guidance Law for UCAV," is highly regarded for originality and creativity. The Field Robotics Center at the KAIST Institute, where Yoo conducted his research, also received the first prize at the 7th KAI Paper Contest.

The KAI Paper Contest was first organized in 2003 to promote academic interest and advance research and development in aerospace engineering among university students.

The KAI Paper Contest is one of the most prestigious contests in Korea. It is sponsored by the Ministry of Trade, Industry and Energy, the Ministry of Land, Infrastructure and Transport, the Korean Society for Aeronautical and Space Sciences, the Korea Aerospace Industries Association, and the Korea Civil Aviation Development Association.

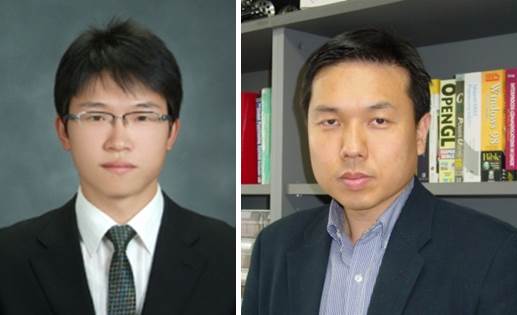

Dong-Il Yoo (left) and Professor Hyun-Chul Shim (right)

2013.11.11 View 14374

KAIST student wins Aerospace Student Papers Grand Prize

Dong-Il Yoo, a doctoral candidate under Professor Hyun-Chul Shim, at the Department of Aerospace Engineering, KAIST, has been awarded the Second Prize Award at the 11th Korea Aerospace Industries (KAI) Paper Contest. The award ceremony was held on October 30th at the media conference room at the KINTEX ADEX 2013 Exhibition in Seoul.

Yoo"s paper, titled "A Study on Virtual Pursuit Point-based Autonomous Air Combat Guidance Law for UCAV," is highly regarded for originality and creativity. The Field Robotics Center at the KAIST Institute, where Yoo conducted his research, also received the first prize at the 7th KAI Paper Contest.

The KAI Paper Contest was first organized in 2003 to promote academic interest and advance research and development in aerospace engineering among university students.

The KAI Paper Contest is one of the most prestigious contests in Korea. It is sponsored by the Ministry of Trade, Industry and Energy, the Ministry of Land, Infrastructure and Transport, the Korean Society for Aeronautical and Space Sciences, the Korea Aerospace Industries Association, and the Korea Civil Aviation Development Association.

Dong-Il Yoo (left) and Professor Hyun-Chul Shim (right)

2013.11.11 View 14374 -

Kinetic Lighting, Dlight, Dominates World Renowned Design Awards

Professor Sang-Min Bae

“D’light,” a lamp that transforms its lampshade shape, developed by a team led by KAIST Department of Industrial Design’s Professor Sang-Min Bae, won Japan’s Good Design Awards on October the 2nd, soon after winning the internationally renowned 2013 International Design Excellence Awards (IDEA) in August.

IDEA, sponsored by the Industrial Design Society of America (IDSA) and BusinessWeek, awards the best work from over 6,000 exhibits from 50 countries. Japan’s Good Design Awards, founded by the Japan Institute of Design Promotion (JDP) in 1957, is the most prestigious and one of the World’s four major design awards.

“D’light” combines “donative” and “light.” Its meaning originates from the meaning of “delight” which means “giving great joy.” The shape and the brightness of the lamp can be transformed by turning the end of the heart-shaped lampshade. The team states that the lamp carries a figurative meaning of generous hearts lighting the neglected of the world by designing the lamp to be the brightest when it takes the shape of a heart. D’light developed as the 5th product of “the Nanum” project that started in 2006. Professor Bae first participated in the project in developing the 2nd product, “Cross Cube” in 2007. The he designed and launched the environmentally friendly humidifier “Lovepot” in 2008 and interactive tumbler “Hearty” in 2009.

The “Nanum” project aims to develop innovative products for charity to create a humane social circulatory system. The project, led by the international relief and development organisation, World Vision and KAIST’s ID+IM laboratory run by Professor Bae, donates all profits to educate the children of low-income families. The project raised a total of 1.7 billion Korean won from 2007 this year to provide scholarships to 240 children in need.

Professor Bae’s team has undertaken seed and “Nanum” projects with the theme of philanthropy design helping people in need by creating innovative designs. The project has produced four excellent and authentic products which received 44 world renowned design awards.

Professor Bae said, “’The Nanum’ project consists of planning, designing, producing and selling for charity and donates all profit to children in need through education and scholarship.” He continued, “The consumers can purchase products that are aesthetically pleasing and convenient as well as gaining an opportunity to donate to children in need.”

Figure1 Kinetic lighting D’light

Figure 2. Characteristics of “Nanum” D’light

The shape of the lampshade can be transformed. The lamp sheds the brightest light when it takes the shape of a heart, hence showing the figurative meaning of brightening the neglected parts of the world with generous hearts.

Figure 3. Detailed Images of D’light

2013.11.11 View 11410

Kinetic Lighting, Dlight, Dominates World Renowned Design Awards

Professor Sang-Min Bae

“D’light,” a lamp that transforms its lampshade shape, developed by a team led by KAIST Department of Industrial Design’s Professor Sang-Min Bae, won Japan’s Good Design Awards on October the 2nd, soon after winning the internationally renowned 2013 International Design Excellence Awards (IDEA) in August.

IDEA, sponsored by the Industrial Design Society of America (IDSA) and BusinessWeek, awards the best work from over 6,000 exhibits from 50 countries. Japan’s Good Design Awards, founded by the Japan Institute of Design Promotion (JDP) in 1957, is the most prestigious and one of the World’s four major design awards.

“D’light” combines “donative” and “light.” Its meaning originates from the meaning of “delight” which means “giving great joy.” The shape and the brightness of the lamp can be transformed by turning the end of the heart-shaped lampshade. The team states that the lamp carries a figurative meaning of generous hearts lighting the neglected of the world by designing the lamp to be the brightest when it takes the shape of a heart. D’light developed as the 5th product of “the Nanum” project that started in 2006. Professor Bae first participated in the project in developing the 2nd product, “Cross Cube” in 2007. The he designed and launched the environmentally friendly humidifier “Lovepot” in 2008 and interactive tumbler “Hearty” in 2009.

The “Nanum” project aims to develop innovative products for charity to create a humane social circulatory system. The project, led by the international relief and development organisation, World Vision and KAIST’s ID+IM laboratory run by Professor Bae, donates all profits to educate the children of low-income families. The project raised a total of 1.7 billion Korean won from 2007 this year to provide scholarships to 240 children in need.

Professor Bae’s team has undertaken seed and “Nanum” projects with the theme of philanthropy design helping people in need by creating innovative designs. The project has produced four excellent and authentic products which received 44 world renowned design awards.

Professor Bae said, “’The Nanum’ project consists of planning, designing, producing and selling for charity and donates all profit to children in need through education and scholarship.” He continued, “The consumers can purchase products that are aesthetically pleasing and convenient as well as gaining an opportunity to donate to children in need.”

Figure1 Kinetic lighting D’light

Figure 2. Characteristics of “Nanum” D’light

The shape of the lampshade can be transformed. The lamp sheds the brightest light when it takes the shape of a heart, hence showing the figurative meaning of brightening the neglected parts of the world with generous hearts.

Figure 3. Detailed Images of D’light

2013.11.11 View 11410 -

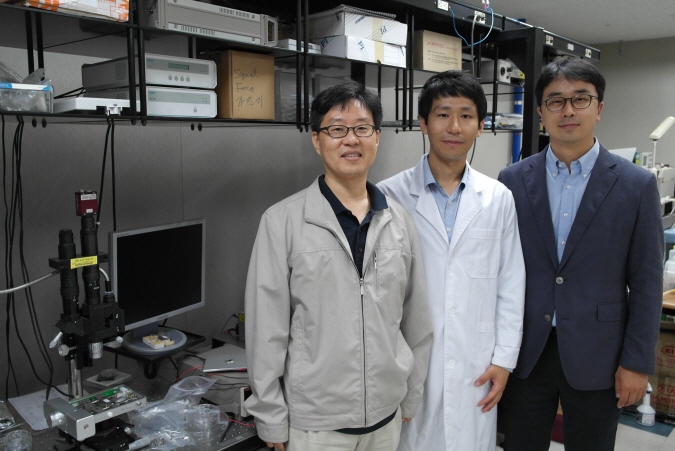

Observation of a water strider led to a new method of measuring properties of Nano films

Even the mechanical properties of Nano films of a few nanometers thick can be measured

Posted online Nature Communications on the 3rd of October

The joint research team of KAIST’s Department of Mechanical Engineering’s Professor Taek-Soo Kim and Doctor Seung-Min Hyun of the Nano mechanics laboratory of Korea Institute of Machinery and Materials has developed a new method to evaluate mechanical properties of Nano films using the characteristics of water surfaces.

The research findings have been posted on the online edition of Nature Communications on the 3rd of October. The technology can obtain accurate results by directly measuring the mechanical properties such as the strength and elasticity of Nano films. Academia and the industry expect the simplicity of the technology to present a new paradigm in the evaluation of mechanical properties of Nano films.

Evaluation of the mechanical properties of Nano films is essential not only in predicting the reliability of semiconductors and displays, but also in finding new phenomena in the Nano world. However, mechanical strength was difficult to test since the test demands the falling of objects to the ground to measure their strength, and nano films can easily break in the process.

The research team observed insects such as water striders freely floating on the surface of the water. The team used the properties of water, large surface tension and low viscosity, to float a 55 nanometers (nm) gold Nano film to successfully measure its mechanical properties without damaging it. The technology could be used to measure the mechanical properties of not only various types of Nano films but also films only a few nm thick.

Professor Taek-Soo Kim said, “We effectively performed an evaluation of the mechanical characteristics of Nano films, which was difficult in the past, by developing a new strength test using the properties of water.” He continued to say, “The team plans to discover the mechanical properties of 2D Nano films such as graphene that could not have been measured with the existing strength test methods.”

The research by KAIST’s Department of Mechanical Engineering’s graduate student Jae-Han Kim (lead author) under the supervision of Professor Taek-Soo Kim and Doctor Seung-Min Hyun of Korea Institute of Machinery and Materials was sponsored by the National Research Foundation of Korea.

Evaluation process of mechanical properties of Nano films by using the characteristics of water surfaces

Dr Seung-Min Hyun, Jae-Han Kim, and Professor Taek-Soo Kim from left to right

2013.11.11 View 9841

Observation of a water strider led to a new method of measuring properties of Nano films

Even the mechanical properties of Nano films of a few nanometers thick can be measured

Posted online Nature Communications on the 3rd of October

The joint research team of KAIST’s Department of Mechanical Engineering’s Professor Taek-Soo Kim and Doctor Seung-Min Hyun of the Nano mechanics laboratory of Korea Institute of Machinery and Materials has developed a new method to evaluate mechanical properties of Nano films using the characteristics of water surfaces.

The research findings have been posted on the online edition of Nature Communications on the 3rd of October. The technology can obtain accurate results by directly measuring the mechanical properties such as the strength and elasticity of Nano films. Academia and the industry expect the simplicity of the technology to present a new paradigm in the evaluation of mechanical properties of Nano films.

Evaluation of the mechanical properties of Nano films is essential not only in predicting the reliability of semiconductors and displays, but also in finding new phenomena in the Nano world. However, mechanical strength was difficult to test since the test demands the falling of objects to the ground to measure their strength, and nano films can easily break in the process.

The research team observed insects such as water striders freely floating on the surface of the water. The team used the properties of water, large surface tension and low viscosity, to float a 55 nanometers (nm) gold Nano film to successfully measure its mechanical properties without damaging it. The technology could be used to measure the mechanical properties of not only various types of Nano films but also films only a few nm thick.

Professor Taek-Soo Kim said, “We effectively performed an evaluation of the mechanical characteristics of Nano films, which was difficult in the past, by developing a new strength test using the properties of water.” He continued to say, “The team plans to discover the mechanical properties of 2D Nano films such as graphene that could not have been measured with the existing strength test methods.”

The research by KAIST’s Department of Mechanical Engineering’s graduate student Jae-Han Kim (lead author) under the supervision of Professor Taek-Soo Kim and Doctor Seung-Min Hyun of Korea Institute of Machinery and Materials was sponsored by the National Research Foundation of Korea.

Evaluation process of mechanical properties of Nano films by using the characteristics of water surfaces

Dr Seung-Min Hyun, Jae-Han Kim, and Professor Taek-Soo Kim from left to right

2013.11.11 View 9841 -

KAIST graduate appointed as professor at Southeast University in China

Dr. Yoon-Kyu Ahn has been appointed as a professor in the civil engineering department at Southeast University in Nanjing, China.

Dr. Ahn earned his Master’s and Ph.D. in civil & environmental engineering at KAIST, under the guidance of Professor Hoon Sohn, following his undergraduate studies at Korea University.His appointment is considered quite exceptional since most of top Chinese universities are likely hiring professors from the US and EU as a general trend.Ranked third in the field of civil engineering in China, Southeast University has been among the top ten universities in the nation. The university has 27,000 students with 1,300 faculty members in 34 schools.

2013.11.06 View 7892

KAIST graduate appointed as professor at Southeast University in China

Dr. Yoon-Kyu Ahn has been appointed as a professor in the civil engineering department at Southeast University in Nanjing, China.

Dr. Ahn earned his Master’s and Ph.D. in civil & environmental engineering at KAIST, under the guidance of Professor Hoon Sohn, following his undergraduate studies at Korea University.His appointment is considered quite exceptional since most of top Chinese universities are likely hiring professors from the US and EU as a general trend.Ranked third in the field of civil engineering in China, Southeast University has been among the top ten universities in the nation. The university has 27,000 students with 1,300 faculty members in 34 schools.

2013.11.06 View 7892 -

Professor Jae-Hyung Lee appointed as AIChE fellow

Professor Jae-Hyung Lee from the Department of Chemical and Bimolecular Engineering at KAIST was appointed as a fellow in the American Institute of Chemical Engineers (AIChE).

Established in 1908, AIChE is the largest association of chemical engineers worldwide, which now boasts more than 40,000 members from 90 countries.

Following Distinguished Professor Sang Yup Lee from the same department at KAIST, Professor Jae-Hyung Lee is the second Korean appointed as a fellow by the organization.

He has been acknowledged for his innovative research on the improvement of model predictive control of industrial processes.

Professor Lee is the director of the Saudi Armaco-KAIST CO2 Management Center at KAIST, a fellow of the Institute of Electrical and Electronics Engineers (IEEE) and the International Federation of Automatic Control (IFAC), and a member of the Korean Academy of Science and Technology.

He received the Young Investigator Award from the National Science Foundation (NSF) in 1994 and the Computing in Chemical Engineering Award from AIChE in 2013.

2013.11.05 View 10859

Professor Jae-Hyung Lee appointed as AIChE fellow

Professor Jae-Hyung Lee from the Department of Chemical and Bimolecular Engineering at KAIST was appointed as a fellow in the American Institute of Chemical Engineers (AIChE).

Established in 1908, AIChE is the largest association of chemical engineers worldwide, which now boasts more than 40,000 members from 90 countries.

Following Distinguished Professor Sang Yup Lee from the same department at KAIST, Professor Jae-Hyung Lee is the second Korean appointed as a fellow by the organization.

He has been acknowledged for his innovative research on the improvement of model predictive control of industrial processes.

Professor Lee is the director of the Saudi Armaco-KAIST CO2 Management Center at KAIST, a fellow of the Institute of Electrical and Electronics Engineers (IEEE) and the International Federation of Automatic Control (IFAC), and a member of the Korean Academy of Science and Technology.

He received the Young Investigator Award from the National Science Foundation (NSF) in 1994 and the Computing in Chemical Engineering Award from AIChE in 2013.

2013.11.05 View 10859 -

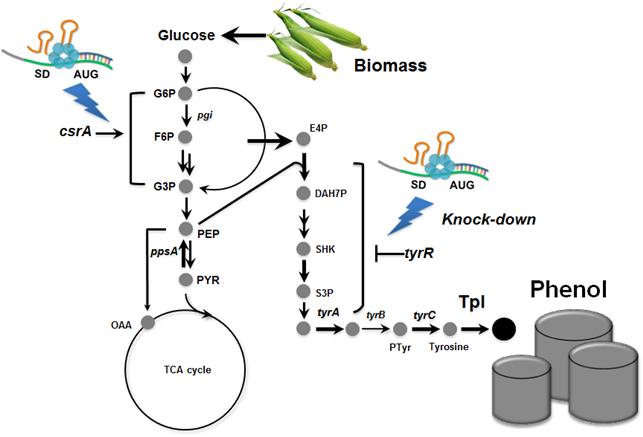

Metabolically engineered E. coli producing phenol

Many chemicals we use in everyday life are derived from fossil resources. Due to the increasing concerns on the use of fossil resources, there has been much interest in producing chemicals from renewable resources through biotechnology.

Phenol is an important commodity chemical, and is a starting material for the production of numerous industrial chemicals and polymers, including bisphenol A and phenolic resins, and others. At present, the production of phenol entirely depends on the chemical synthesis from benzene, and its annual production exceeds 8 million tons worldwide. Microbial production of phenol seems to be a non-viable process considering the high toxicity of phenol to the cell.

In the paper published online in Biotechnology Journal, a Korean research team led by Distinguished Professor Sang Yup Lee at the Department of Chemical and Biomolecular Engineering from the Korea Advanced Institute of Science and Technology (KAIST) reported the successful development of an engineered Escherichia coli (E. coli) strain which can produce phenol from glucose. E. coli has been a workhorse for biological production of various value-added compounds such as succinic acid and 1,4-butanediol in industrial scale. However, due to its low tolerance to phenol, E. coli was not considered a viable host strain for the biological production of phenol.

Professor Lee"s team, a leading research group in metabolic engineering, noted the genetic and physiological differences of various E. coli strains and investigated 18 different E. coli strains with respect to phenol tolerance and engineered all of the 18 strains simultaneously. If the traditional genetic engineering methods were used, this work would have taken years to do. To overcome this challenge, the research team used synthetic small RNA (sRNA) technology they recently developed (Nature Biotechnology, vol 31, pp 170-174, 2013). The sRNA technology allowed the team to screen 18 E. coli strains with respect to the phenol tolerance, and the activities of the metabolic pathway and enzyme involved in the production of phenol. The research team also metabolically engineered the E. coli strains to increase carbon flux toward phenol and finally generated an engineered E. coli strain which can produce phenol from glucose.

Furthermore, the team developed a biphasic extractive fermentation process to minimize the toxicity of phenol to E. coli cells. Glycerol tributyrate was found to have low toxicity to E. coli and allowed efficient extraction of phenol from the culture broth. Through the biphasic fed-batch fermentation using glycerol tributyrate as an in situ extractant, the final engineered E. coli strain produced phenol to the highest titer and productivity reported (3.8 g/L and 0.18 g/L/h, respectively). The strategy used for the strain development and the fermentation process will serve as a framework for metabolic engineering of microorganisms for the production of toxic chemicals from renewable resources.

This work was supported by the Intelligent Synthetic Biology Center through the Global Frontier Project (2011-0031963) of the Ministry of Science, ICT & Future Planning through the National Research Foundation of Korea.

Process of Phenol Production

2013.11.05 View 11494

Metabolically engineered E. coli producing phenol

Many chemicals we use in everyday life are derived from fossil resources. Due to the increasing concerns on the use of fossil resources, there has been much interest in producing chemicals from renewable resources through biotechnology.

Phenol is an important commodity chemical, and is a starting material for the production of numerous industrial chemicals and polymers, including bisphenol A and phenolic resins, and others. At present, the production of phenol entirely depends on the chemical synthesis from benzene, and its annual production exceeds 8 million tons worldwide. Microbial production of phenol seems to be a non-viable process considering the high toxicity of phenol to the cell.

In the paper published online in Biotechnology Journal, a Korean research team led by Distinguished Professor Sang Yup Lee at the Department of Chemical and Biomolecular Engineering from the Korea Advanced Institute of Science and Technology (KAIST) reported the successful development of an engineered Escherichia coli (E. coli) strain which can produce phenol from glucose. E. coli has been a workhorse for biological production of various value-added compounds such as succinic acid and 1,4-butanediol in industrial scale. However, due to its low tolerance to phenol, E. coli was not considered a viable host strain for the biological production of phenol.

Professor Lee"s team, a leading research group in metabolic engineering, noted the genetic and physiological differences of various E. coli strains and investigated 18 different E. coli strains with respect to phenol tolerance and engineered all of the 18 strains simultaneously. If the traditional genetic engineering methods were used, this work would have taken years to do. To overcome this challenge, the research team used synthetic small RNA (sRNA) technology they recently developed (Nature Biotechnology, vol 31, pp 170-174, 2013). The sRNA technology allowed the team to screen 18 E. coli strains with respect to the phenol tolerance, and the activities of the metabolic pathway and enzyme involved in the production of phenol. The research team also metabolically engineered the E. coli strains to increase carbon flux toward phenol and finally generated an engineered E. coli strain which can produce phenol from glucose.

Furthermore, the team developed a biphasic extractive fermentation process to minimize the toxicity of phenol to E. coli cells. Glycerol tributyrate was found to have low toxicity to E. coli and allowed efficient extraction of phenol from the culture broth. Through the biphasic fed-batch fermentation using glycerol tributyrate as an in situ extractant, the final engineered E. coli strain produced phenol to the highest titer and productivity reported (3.8 g/L and 0.18 g/L/h, respectively). The strategy used for the strain development and the fermentation process will serve as a framework for metabolic engineering of microorganisms for the production of toxic chemicals from renewable resources.

This work was supported by the Intelligent Synthetic Biology Center through the Global Frontier Project (2011-0031963) of the Ministry of Science, ICT & Future Planning through the National Research Foundation of Korea.

Process of Phenol Production

2013.11.05 View 11494 -

KAIST announced a novel technology to produce gasoline by a metabolically engineered microorganism

A major scientific breakthrough in the development of renewable energy sources and other important chemicals; The research team succeeded in producing 580 mg of gasoline per liter of cultured broth by converting in vivo generated fatty acids

For many decades, we have been relying on fossil resources to produce liquid fuels such as gasoline, diesel, and many industrial and consumer chemicals for daily use. However, increasing strains on natural resources as well as environmental issues including global warming have triggered a strong interest in developing sustainable ways to obtain fuels and chemicals.

Gasoline, the petroleum-derived product that is most widely used as a fuel for transportation, is a mixture of hydrocarbons, additives, and blending agents. The hydrocarbons, called alkanes, consist only of carbon and hydrogen atoms. Gasoline has a combination of straight-chain and branched-chain alkanes (hydrocarbons) consisted of 4-12 carbon atoms linked by direct carbon-carbon bonds.

Previously, through metabolic engineering of Escherichia coli (E. coli), there have been a few research results on the production of long-chain alkanes, which consist of 13-17 carbon atoms, suitable for replacing diesel. However, there has been no report on the microbial production of short-chain alkanes, a possible substitute for gasoline.

In the paper (entitled "Microbial Production of Short-chain Alkanes") published online in Nature on September 29, a Korean research team led by Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering at the Korea Advanced Institute of Science and Technology (KAIST) reported, for the first time, the development of a novel strategy for microbial gasoline production through metabolic engineering of E. coli.

The research team engineered the fatty acid metabolism to provide the fatty acid derivatives that are shorter than normal intracellular fatty acid metabolites, and introduced a novel synthetic pathway for the biosynthesis of short-chain alkanes. This allowed the development of platform E. coli strain capable of producing gasoline for the first time. Furthermore, this platform strain, if desired, can be modified to produce other products such as short-chain fatty esters and short-chain fatty alcohols.

In this paper, the Korean researchers described detailed strategies for 1) screening of enzymes associated with the production of fatty acids, 2) engineering of enzymes and fatty acid biosynthetic pathways to concentrate carbon flux towards the short-chain fatty acid production, and 3) converting short-chain fatty acids to their corresponding alkanes (gasoline) by introducing a novel synthetic pathway and optimization of culture conditions. Furthermore, the research team showed the possibility of producing fatty esters and alcohols by introducing responsible enzymes into the same platform strain.

Professor Sang Yup Lee said, "It is only the beginning of the work towards sustainable production of gasoline. The titer is rather low due to the low metabolic flux towards the formation of short-chain fatty acids and their derivatives. We are currently working on increasing the titer, yield and productivity of bio-gasoline. Nonetheless, we are pleased to report, for the first time, the production of gasoline through the metabolic engineering of E. coli, which we hope will serve as a basis for the metabolic engineering of microorganisms to produce fuels and chemicals from renewable resources."

This research was supported by the Advanced Biomass Research and Development Center of Korea (ABC-2010-0029799) through the Global Frontier Research Program of the Ministry of Science, ICT and Future Planning (MSIP) through the National Research Foundation (NRF), Republic of Korea. Systems metabolic engineering work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries (NRF-2012-C1AAA001-2012M1A2A2026556) by MSIP through NRF.

Short-Chain Alkanes Generated from Renewable Biomass

This diagram shows the metabolic engineering of Escherichia coli for the production of short-chain alkanes (gasoline) from renewable biomass.

Nature Cover Page (September 29th, 2013)

2013.11.04 View 13503

KAIST announced a novel technology to produce gasoline by a metabolically engineered microorganism

A major scientific breakthrough in the development of renewable energy sources and other important chemicals; The research team succeeded in producing 580 mg of gasoline per liter of cultured broth by converting in vivo generated fatty acids

For many decades, we have been relying on fossil resources to produce liquid fuels such as gasoline, diesel, and many industrial and consumer chemicals for daily use. However, increasing strains on natural resources as well as environmental issues including global warming have triggered a strong interest in developing sustainable ways to obtain fuels and chemicals.

Gasoline, the petroleum-derived product that is most widely used as a fuel for transportation, is a mixture of hydrocarbons, additives, and blending agents. The hydrocarbons, called alkanes, consist only of carbon and hydrogen atoms. Gasoline has a combination of straight-chain and branched-chain alkanes (hydrocarbons) consisted of 4-12 carbon atoms linked by direct carbon-carbon bonds.

Previously, through metabolic engineering of Escherichia coli (E. coli), there have been a few research results on the production of long-chain alkanes, which consist of 13-17 carbon atoms, suitable for replacing diesel. However, there has been no report on the microbial production of short-chain alkanes, a possible substitute for gasoline.

In the paper (entitled "Microbial Production of Short-chain Alkanes") published online in Nature on September 29, a Korean research team led by Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering at the Korea Advanced Institute of Science and Technology (KAIST) reported, for the first time, the development of a novel strategy for microbial gasoline production through metabolic engineering of E. coli.

The research team engineered the fatty acid metabolism to provide the fatty acid derivatives that are shorter than normal intracellular fatty acid metabolites, and introduced a novel synthetic pathway for the biosynthesis of short-chain alkanes. This allowed the development of platform E. coli strain capable of producing gasoline for the first time. Furthermore, this platform strain, if desired, can be modified to produce other products such as short-chain fatty esters and short-chain fatty alcohols.

In this paper, the Korean researchers described detailed strategies for 1) screening of enzymes associated with the production of fatty acids, 2) engineering of enzymes and fatty acid biosynthetic pathways to concentrate carbon flux towards the short-chain fatty acid production, and 3) converting short-chain fatty acids to their corresponding alkanes (gasoline) by introducing a novel synthetic pathway and optimization of culture conditions. Furthermore, the research team showed the possibility of producing fatty esters and alcohols by introducing responsible enzymes into the same platform strain.

Professor Sang Yup Lee said, "It is only the beginning of the work towards sustainable production of gasoline. The titer is rather low due to the low metabolic flux towards the formation of short-chain fatty acids and their derivatives. We are currently working on increasing the titer, yield and productivity of bio-gasoline. Nonetheless, we are pleased to report, for the first time, the production of gasoline through the metabolic engineering of E. coli, which we hope will serve as a basis for the metabolic engineering of microorganisms to produce fuels and chemicals from renewable resources."

This research was supported by the Advanced Biomass Research and Development Center of Korea (ABC-2010-0029799) through the Global Frontier Research Program of the Ministry of Science, ICT and Future Planning (MSIP) through the National Research Foundation (NRF), Republic of Korea. Systems metabolic engineering work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries (NRF-2012-C1AAA001-2012M1A2A2026556) by MSIP through NRF.

Short-Chain Alkanes Generated from Renewable Biomass

This diagram shows the metabolic engineering of Escherichia coli for the production of short-chain alkanes (gasoline) from renewable biomass.

Nature Cover Page (September 29th, 2013)

2013.11.04 View 13503