Technology

-

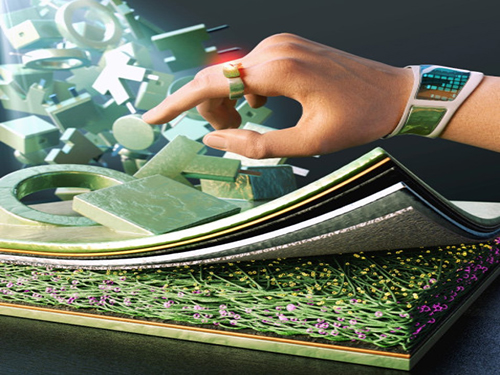

Flexible User Interface Distribution for Ubiquitous Multi-Device Interaction

< Research Group of Professor Insik Shin (center) >

KAIST researchers have developed mobile software platform technology that allows a mobile application (app) to be executed simultaneously and more dynamically on multiple smart devices. Its high flexibility and broad applicability can help accelerate a shift from the current single-device paradigm to a multiple one, which enables users to utilize mobile apps in ways previously unthinkable.

Recent trends in mobile and IoT technologies in this era of 5G high-speed wireless communication have been hallmarked by the emergence of new display hardware and smart devices such as dual screens, foldable screens, smart watches, smart TVs, and smart cars. However, the current mobile app ecosystem is still confined to the conventional single-device paradigm in which users can employ only one screen on one device at a time. Due to this limitation, the real potential of multi-device environments has not been fully explored.

A KAIST research team led by Professor Insik Shin from the School of Computing, in collaboration with Professor Steve Ko’s group from the State University of New York at Buffalo, has developed mobile software platform technology named FLUID that can flexibly distribute the user interfaces (UIs) of an app to a number of other devices in real time without needing any modifications. The proposed technology provides single-device virtualization, and ensures that the interactions between the distributed UI elements across multiple devices remain intact.

This flexible multimodal interaction can be realized in diverse ubiquitous user experiences (UX), such as using live video steaming and chatting apps including YouTube, LiveMe, and AfreecaTV. FLUID can ensure that the video is not obscured by the chat window by distributing and displaying them separately on different devices respectively, which lets users enjoy the chat function while watching the video at the same time.

In addition, the UI for the destination input on a navigation app can be migrated into the passenger’s device with the help of FLUID, so that the destination can be easily and safely entered by the passenger while the driver is at the wheel.

FLUID can also support 5G multi-view apps – the latest service that allows sports or games to be viewed from various angles on a single device. With FLUID, the user can watch the event simultaneously from different viewpoints on multiple devices without switching between viewpoints on a single screen.

PhD candidate Sangeun Oh, who is the first author, and his team implemented the prototype of FLUID on the leading open-source mobile operating system, Android, and confirmed that it can successfully deliver the new UX to 20 existing legacy apps.

“This new technology can be applied to next-generation products from South Korean companies such as LG’s dual screen phone and Samsung’s foldable phone and is expected to embolden their competitiveness by giving them a head-start in the global market.” said Professor Shin.

This study will be presented at the 25th Annual International Conference on Mobile Computing and Networking (ACM MobiCom 2019) October 21 through 25 in Los Cabos, Mexico. The research was supported by the National Science Foundation (NSF) (CNS-1350883 (CAREER) and CNS-1618531).

Figure 1. Live video streaming and chatting app scenario

Figure 2. Navigation app scenario

Figure 3. 5G multi-view app scenario

Publication: Sangeun Oh, Ahyeon Kim, Sunjae Lee, Kilho Lee, Dae R. Jeong, Steven Y. Ko, and Insik Shin. 2019. FLUID: Flexible User Interface Distribution for Ubiquitous Multi-device Interaction. To be published in Proceedings of the 25th Annual International Conference on Mobile Computing and Networking (ACM MobiCom 2019). ACM, New York, NY, USA. Article Number and DOI Name TBD.

Video Material:

https://youtu.be/lGO4GwH4enA

Profile: Prof. Insik Shin, MS, PhD

ishin@kaist.ac.kr

https://cps.kaist.ac.kr/~ishin

Professor

Cyber-Physical Systems (CPS) Lab

School of Computing

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Sangeun Oh, PhD Candidate

ohsang1213@kaist.ac.kr

https://cps.kaist.ac.kr/

PhD Candidate

Cyber-Physical Systems (CPS) Lab

School of Computing

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Prof. Steve Ko, PhD

stevko@buffalo.edu

https://nsr.cse.buffalo.edu/?page_id=272

Associate Professor

Networked Systems Research Group

Department of Computer Science and Engineering

State University of New York at Buffalo

http://www.buffalo.edu/ Buffalo 14260, USA

(END)

2019.07.20 View 40118

Flexible User Interface Distribution for Ubiquitous Multi-Device Interaction

< Research Group of Professor Insik Shin (center) >

KAIST researchers have developed mobile software platform technology that allows a mobile application (app) to be executed simultaneously and more dynamically on multiple smart devices. Its high flexibility and broad applicability can help accelerate a shift from the current single-device paradigm to a multiple one, which enables users to utilize mobile apps in ways previously unthinkable.

Recent trends in mobile and IoT technologies in this era of 5G high-speed wireless communication have been hallmarked by the emergence of new display hardware and smart devices such as dual screens, foldable screens, smart watches, smart TVs, and smart cars. However, the current mobile app ecosystem is still confined to the conventional single-device paradigm in which users can employ only one screen on one device at a time. Due to this limitation, the real potential of multi-device environments has not been fully explored.

A KAIST research team led by Professor Insik Shin from the School of Computing, in collaboration with Professor Steve Ko’s group from the State University of New York at Buffalo, has developed mobile software platform technology named FLUID that can flexibly distribute the user interfaces (UIs) of an app to a number of other devices in real time without needing any modifications. The proposed technology provides single-device virtualization, and ensures that the interactions between the distributed UI elements across multiple devices remain intact.

This flexible multimodal interaction can be realized in diverse ubiquitous user experiences (UX), such as using live video steaming and chatting apps including YouTube, LiveMe, and AfreecaTV. FLUID can ensure that the video is not obscured by the chat window by distributing and displaying them separately on different devices respectively, which lets users enjoy the chat function while watching the video at the same time.

In addition, the UI for the destination input on a navigation app can be migrated into the passenger’s device with the help of FLUID, so that the destination can be easily and safely entered by the passenger while the driver is at the wheel.

FLUID can also support 5G multi-view apps – the latest service that allows sports or games to be viewed from various angles on a single device. With FLUID, the user can watch the event simultaneously from different viewpoints on multiple devices without switching between viewpoints on a single screen.

PhD candidate Sangeun Oh, who is the first author, and his team implemented the prototype of FLUID on the leading open-source mobile operating system, Android, and confirmed that it can successfully deliver the new UX to 20 existing legacy apps.

“This new technology can be applied to next-generation products from South Korean companies such as LG’s dual screen phone and Samsung’s foldable phone and is expected to embolden their competitiveness by giving them a head-start in the global market.” said Professor Shin.

This study will be presented at the 25th Annual International Conference on Mobile Computing and Networking (ACM MobiCom 2019) October 21 through 25 in Los Cabos, Mexico. The research was supported by the National Science Foundation (NSF) (CNS-1350883 (CAREER) and CNS-1618531).

Figure 1. Live video streaming and chatting app scenario

Figure 2. Navigation app scenario

Figure 3. 5G multi-view app scenario

Publication: Sangeun Oh, Ahyeon Kim, Sunjae Lee, Kilho Lee, Dae R. Jeong, Steven Y. Ko, and Insik Shin. 2019. FLUID: Flexible User Interface Distribution for Ubiquitous Multi-device Interaction. To be published in Proceedings of the 25th Annual International Conference on Mobile Computing and Networking (ACM MobiCom 2019). ACM, New York, NY, USA. Article Number and DOI Name TBD.

Video Material:

https://youtu.be/lGO4GwH4enA

Profile: Prof. Insik Shin, MS, PhD

ishin@kaist.ac.kr

https://cps.kaist.ac.kr/~ishin

Professor

Cyber-Physical Systems (CPS) Lab

School of Computing

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Sangeun Oh, PhD Candidate

ohsang1213@kaist.ac.kr

https://cps.kaist.ac.kr/

PhD Candidate

Cyber-Physical Systems (CPS) Lab

School of Computing

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Prof. Steve Ko, PhD

stevko@buffalo.edu

https://nsr.cse.buffalo.edu/?page_id=272

Associate Professor

Networked Systems Research Group

Department of Computer Science and Engineering

State University of New York at Buffalo

http://www.buffalo.edu/ Buffalo 14260, USA

(END)

2019.07.20 View 40118 -

Deep Learning-Powered 'DeepEC' Helps Accurately Understand Enzyme Functions

(Figure: Overall scheme of DeepEC)

A deep learning-powered computational framework, ‘DeepEC,’ will allow the high-quality and high-throughput prediction of enzyme commission numbers, which is essential for the accurate understanding of enzyme functions.

A team of Dr. Jae Yong Ryu, Professor Hyun Uk Kim, and Distinguished Professor Sang Yup Lee at KAIST reported the computational framework powered by deep learning that predicts enzyme commission (EC) numbers with high precision in a high-throughput manner.

DeepEC takes a protein sequence as an input and accurately predicts EC numbers as an output. Enzymes are proteins that catalyze biochemical reactions and EC numbers consisting of four level numbers (i.e., a.b.c.d) indicate biochemical reactions. Thus, the identification of EC numbers is critical for accurately understanding enzyme functions and metabolism.

EC numbers are usually given to a protein sequence encoding an enzyme during a genome annotation procedure. Because of the importance of EC numbers, several EC number prediction tools have been developed, but they have room for further improvement with respect to computation time, precision, coverage, and the total size of the files needed for the EC number prediction.

DeepEC uses three convolutional neural networks (CNNs) as a major engine for the prediction of EC numbers, and also implements homology analysis for EC numbers if the three CNNs do not produce reliable EC numbers for a given protein sequence. DeepEC was developed by using a gold standard dataset covering 1,388,606 protein sequences and 4,669 EC numbers.

In particular, benchmarking studies of DeepEC and five other representative EC number prediction tools showed that DeepEC made the most precise and fastest predictions for EC numbers. DeepEC also required the smallest disk space for implementation, which makes it an ideal third-party software component.

Furthermore, DeepEC was the most sensitive in detecting enzymatic function loss as a result of mutations in domains/binding site residue of protein sequences; in this comparative analysis, all the domains or binding site residue were substituted with L-alanine residue in order to remove the protein function, which is known as the L-alanine scanning method.

This study was published online in the Proceedings of the National Academy of Sciences of the United States of America (PNAS) on June 20, 2019, entitled “Deep learning enables high-quality and high-throughput prediction of enzyme commission numbers.”

“DeepEC can be used as an independent tool and also as a third-party software component in combination with other computational platforms that examine metabolic reactions. DeepEC is freely available online,” said Professor Kim.

Distinguished Professor Lee said, “With DeepEC, it has become possible to process ever-increasing volumes of protein sequence data more efficiently and more accurately.”

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT through the National Research Foundation of Korea. This work was also funded by the Bio & Medical Technology Development Program of the National Research Foundation of Korea funded by the Korean government, the Ministry of Science and ICT.

Profile:

-Professor Hyun Uk Kim (ehukim@kaist.ac.kr)

https://sites.google.com/view/ehukim

Department of Chemical and Biomolecular Engineering

-Distinguished Professor Sang Yup Lee (leesy@kaist.ac.kr)

Department of Chemical and Biomolecular Engineering

http://mbel.kaist.ac.kr

2019.07.09 View 37756

Deep Learning-Powered 'DeepEC' Helps Accurately Understand Enzyme Functions

(Figure: Overall scheme of DeepEC)

A deep learning-powered computational framework, ‘DeepEC,’ will allow the high-quality and high-throughput prediction of enzyme commission numbers, which is essential for the accurate understanding of enzyme functions.

A team of Dr. Jae Yong Ryu, Professor Hyun Uk Kim, and Distinguished Professor Sang Yup Lee at KAIST reported the computational framework powered by deep learning that predicts enzyme commission (EC) numbers with high precision in a high-throughput manner.

DeepEC takes a protein sequence as an input and accurately predicts EC numbers as an output. Enzymes are proteins that catalyze biochemical reactions and EC numbers consisting of four level numbers (i.e., a.b.c.d) indicate biochemical reactions. Thus, the identification of EC numbers is critical for accurately understanding enzyme functions and metabolism.

EC numbers are usually given to a protein sequence encoding an enzyme during a genome annotation procedure. Because of the importance of EC numbers, several EC number prediction tools have been developed, but they have room for further improvement with respect to computation time, precision, coverage, and the total size of the files needed for the EC number prediction.

DeepEC uses three convolutional neural networks (CNNs) as a major engine for the prediction of EC numbers, and also implements homology analysis for EC numbers if the three CNNs do not produce reliable EC numbers for a given protein sequence. DeepEC was developed by using a gold standard dataset covering 1,388,606 protein sequences and 4,669 EC numbers.

In particular, benchmarking studies of DeepEC and five other representative EC number prediction tools showed that DeepEC made the most precise and fastest predictions for EC numbers. DeepEC also required the smallest disk space for implementation, which makes it an ideal third-party software component.

Furthermore, DeepEC was the most sensitive in detecting enzymatic function loss as a result of mutations in domains/binding site residue of protein sequences; in this comparative analysis, all the domains or binding site residue were substituted with L-alanine residue in order to remove the protein function, which is known as the L-alanine scanning method.

This study was published online in the Proceedings of the National Academy of Sciences of the United States of America (PNAS) on June 20, 2019, entitled “Deep learning enables high-quality and high-throughput prediction of enzyme commission numbers.”

“DeepEC can be used as an independent tool and also as a third-party software component in combination with other computational platforms that examine metabolic reactions. DeepEC is freely available online,” said Professor Kim.

Distinguished Professor Lee said, “With DeepEC, it has become possible to process ever-increasing volumes of protein sequence data more efficiently and more accurately.”

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT through the National Research Foundation of Korea. This work was also funded by the Bio & Medical Technology Development Program of the National Research Foundation of Korea funded by the Korean government, the Ministry of Science and ICT.

Profile:

-Professor Hyun Uk Kim (ehukim@kaist.ac.kr)

https://sites.google.com/view/ehukim

Department of Chemical and Biomolecular Engineering

-Distinguished Professor Sang Yup Lee (leesy@kaist.ac.kr)

Department of Chemical and Biomolecular Engineering

http://mbel.kaist.ac.kr

2019.07.09 View 37756 -

Two Alumni Win the Korea Best Scientist and Technologist Awards

Vice Chairman Ki-Nam Kim (Left) and Distinguished Professor Sukbok Chang (Right)

<ⓒ Photo by MSIT and KOFST>

Distinguished KAIST Professor Sukbok Chang from the Department of Chemistry and Vice Chairman Ki-Nam Kim of Samsung Electronics were selected as the winners of the “2019 Korea Best Scientist and Technologist Awards” by the Ministry of Science and ICT (MSIT) and the Korean Federation of Science and Technology Societies (KOFST). The awards, which were first handed out in 2003, are the highest honor bestowed to the two most outstanding scientists in Korea every year, and this year’s awardees are of greater significance as they are both KAIST alumni.

Professor Chang was recognized for his pioneering achievements and lifetime contributions to the development of carbon-hydrogen activation strategies, especially for carbon-carbon, carbon-nitrogen, and carbon-oxygen formations. His research group has also been actively involved in the development of highly selective catalytic systems allowing the controlled defunctionalization of bio-derived platform substrates under mild conditions, and opening a new avenue for the utilization of biomass-derived platform chemicals. The results of his study have been introduced worldwide through many prestigious journals including Science, Nature Chemistry, and Nature Catalysis, making him one of the world's top 1% researchers by the number of references made to his papers by his peers over four consecutive years from 2015 to 2018.

Vice Chairman Kim, who received his M.E. degree from KAIST’s School of Electrical Engineering in 1983, has been credited with playing a leading role in the development of system semiconductors.

The awards were conferred on July 4 at the opening ceremony of the 2019 Korea Science and Technology Annual Meeting.

(END)

2019.07.09 View 12503

Two Alumni Win the Korea Best Scientist and Technologist Awards

Vice Chairman Ki-Nam Kim (Left) and Distinguished Professor Sukbok Chang (Right)

<ⓒ Photo by MSIT and KOFST>

Distinguished KAIST Professor Sukbok Chang from the Department of Chemistry and Vice Chairman Ki-Nam Kim of Samsung Electronics were selected as the winners of the “2019 Korea Best Scientist and Technologist Awards” by the Ministry of Science and ICT (MSIT) and the Korean Federation of Science and Technology Societies (KOFST). The awards, which were first handed out in 2003, are the highest honor bestowed to the two most outstanding scientists in Korea every year, and this year’s awardees are of greater significance as they are both KAIST alumni.

Professor Chang was recognized for his pioneering achievements and lifetime contributions to the development of carbon-hydrogen activation strategies, especially for carbon-carbon, carbon-nitrogen, and carbon-oxygen formations. His research group has also been actively involved in the development of highly selective catalytic systems allowing the controlled defunctionalization of bio-derived platform substrates under mild conditions, and opening a new avenue for the utilization of biomass-derived platform chemicals. The results of his study have been introduced worldwide through many prestigious journals including Science, Nature Chemistry, and Nature Catalysis, making him one of the world's top 1% researchers by the number of references made to his papers by his peers over four consecutive years from 2015 to 2018.

Vice Chairman Kim, who received his M.E. degree from KAIST’s School of Electrical Engineering in 1983, has been credited with playing a leading role in the development of system semiconductors.

The awards were conferred on July 4 at the opening ceremony of the 2019 Korea Science and Technology Annual Meeting.

(END)

2019.07.09 View 12503 -

Wearable Robot 'WalkON Suit' Off to Cybathlon 2020

Standing upright and walking alone are very simple but noble motions that separate humans from many other creatures. Wearable and prosthetic technologies have emerged to augment human function in locomotion and manipulation. However, advances in wearable robot technology have been especially momentous to Byoung-Wook Kim, a triplegic for 22 years following a devastating car accident.

Kim rejoiced after standing upright and walking again by putting on the ‘WalkON Suit,’ the wearable robot developed by Professor Kyoungchul Kong’s team. Even more, Kim won third prize in the powered exoskeleton race at Cybathlon 2016, an international cyborg Olympics hosted by ETH Zurich.

Now Kim and Professor Kong’s team are all geared up for the Cybathlon Championship 2020. Professor Kong and his startup, Angel Robotics, held a kickoff ceremony for Cybathlon 2020 at KAIST on June 24. The 2020 championship will take place in Switzerland.

Only pilots with complete paralysis of the legs resulting from spinal cord injuries are eligible to participate in the Cybathlon, which takes place every four years. Pilots compete against each other while completing everyday tasks using technical assistance systems in six different disciplines: a brain-computer interface race, a functional electrical stimulation bike race, a powered arm prosthesis race, a powered leg prosthesis race, a powered exoskeleton race, and a powered wheelchair race. The 2016 championship drew 66 pilots from 56 teams representing 25 countries.

In the powered exoskeleton race, pilots complete everyday activities such as getting up from a sofa and overcoming obstacles such as stairs, ramps, or slopes and up to four pilots compete simultaneously on tracks to solve six tasks; and the pilot that solves the most tasks in the least amount of time wins the race.

(Kim, a triplegic for 22 years demonstrates walking and climbing the stairs (below photo) wearing the WalkOn Suit during the media day on June 21 at KAIST.)

Kim, who demonstrated walking and climbing the stairs wearing the WalkON Suit during the media day for the Cybathlon 2020 kickoff ceremony on June 21 at KAIST, said, “I have been confined to a wheelchair for more than 20 years. I am used to it so I feel like the wheelchair is one of my body parts. Actually, I don’t feel any big difficulties in doing everyday tasks in wheelchair. But whenever I face the fact that I will never be able to stand up with my own two legs again, I am so devastated.” He continued, “I still remember the day when I stood up with my own two legs by myself after 22 years. It was beyond description.”

The market for wearable robots, especially for exoskeleton robots, is continuing to grow as the aging population has been a major challenge in almost every advanced country. The global market for these robots expects to see annual growth of 41.2% to 8.3 billion US dollars by 2025. Healthcare wearable robots for the elderly and rehabilitation take up the half of the market share followed by wearable robots for industrial and defense purposes.

Professor Kong from the Department of Mechanical Engineering and his colleagues have developed two wearable robot systems in 2014: The "WalkON Suit" for complete paraplegics and “Angel Suit” for those with partial impairment in walking ability such as the elderly and rehabilitation patients.

Professor Kong said after 15 years of basic research, the team is now able to develop its own distinct technologies. He said their robots are powered by non-resistant precision drives with algorithms recognizing the user’s moving intention. Incorporated with prosthetic devices technology from the Severance Rehabilitation Hospital, their control technology has led to the production of a customizable robot suit optimized for each user’s physical condition.

The WalkON Suit, which boasts a maximum force of 250 Nm and maximum rotation speed of 45 RPM, gives the user high-energy efficiency modeled after the physiology of the human leg. It allows users to walk on flat ground and down stairs, climb up and down inclines, and sit and lie down. Currently the battery lasts five to six hours for locomotion and the approximate 25 kg of robot weight still remains a technical challenge to upgrade.

Professor Kong’s team has grafted AR glass technology into the WalkOn Suit that one of his pilots put on for the torch relay of the PyongChang Paralympics in 2018. His team is now upgrading the WalkON Suit 4.0 for next year’s competition. Severance Rehabilitation Hospital will help the seven pilots with their training.

Professor Kong said his goal is to make robots that can make people with disabilities much more independent. He stressed, “Wearable robots should be designed for each single user. We provide a very good graphical user interface so that we can design, check, and also verify our optimized design for users’ best performance.”

(Seven pilots and Professor Kong (fifth from left in second row) pose with guests who joined the Cybathlon 2020 kickoff ceremony. President Shin (fifth from right) made a congratulatory remarks during the ceremony.)

2019.06.25 View 41083

Wearable Robot 'WalkON Suit' Off to Cybathlon 2020

Standing upright and walking alone are very simple but noble motions that separate humans from many other creatures. Wearable and prosthetic technologies have emerged to augment human function in locomotion and manipulation. However, advances in wearable robot technology have been especially momentous to Byoung-Wook Kim, a triplegic for 22 years following a devastating car accident.

Kim rejoiced after standing upright and walking again by putting on the ‘WalkON Suit,’ the wearable robot developed by Professor Kyoungchul Kong’s team. Even more, Kim won third prize in the powered exoskeleton race at Cybathlon 2016, an international cyborg Olympics hosted by ETH Zurich.

Now Kim and Professor Kong’s team are all geared up for the Cybathlon Championship 2020. Professor Kong and his startup, Angel Robotics, held a kickoff ceremony for Cybathlon 2020 at KAIST on June 24. The 2020 championship will take place in Switzerland.

Only pilots with complete paralysis of the legs resulting from spinal cord injuries are eligible to participate in the Cybathlon, which takes place every four years. Pilots compete against each other while completing everyday tasks using technical assistance systems in six different disciplines: a brain-computer interface race, a functional electrical stimulation bike race, a powered arm prosthesis race, a powered leg prosthesis race, a powered exoskeleton race, and a powered wheelchair race. The 2016 championship drew 66 pilots from 56 teams representing 25 countries.

In the powered exoskeleton race, pilots complete everyday activities such as getting up from a sofa and overcoming obstacles such as stairs, ramps, or slopes and up to four pilots compete simultaneously on tracks to solve six tasks; and the pilot that solves the most tasks in the least amount of time wins the race.

(Kim, a triplegic for 22 years demonstrates walking and climbing the stairs (below photo) wearing the WalkOn Suit during the media day on June 21 at KAIST.)

Kim, who demonstrated walking and climbing the stairs wearing the WalkON Suit during the media day for the Cybathlon 2020 kickoff ceremony on June 21 at KAIST, said, “I have been confined to a wheelchair for more than 20 years. I am used to it so I feel like the wheelchair is one of my body parts. Actually, I don’t feel any big difficulties in doing everyday tasks in wheelchair. But whenever I face the fact that I will never be able to stand up with my own two legs again, I am so devastated.” He continued, “I still remember the day when I stood up with my own two legs by myself after 22 years. It was beyond description.”

The market for wearable robots, especially for exoskeleton robots, is continuing to grow as the aging population has been a major challenge in almost every advanced country. The global market for these robots expects to see annual growth of 41.2% to 8.3 billion US dollars by 2025. Healthcare wearable robots for the elderly and rehabilitation take up the half of the market share followed by wearable robots for industrial and defense purposes.

Professor Kong from the Department of Mechanical Engineering and his colleagues have developed two wearable robot systems in 2014: The "WalkON Suit" for complete paraplegics and “Angel Suit” for those with partial impairment in walking ability such as the elderly and rehabilitation patients.

Professor Kong said after 15 years of basic research, the team is now able to develop its own distinct technologies. He said their robots are powered by non-resistant precision drives with algorithms recognizing the user’s moving intention. Incorporated with prosthetic devices technology from the Severance Rehabilitation Hospital, their control technology has led to the production of a customizable robot suit optimized for each user’s physical condition.

The WalkON Suit, which boasts a maximum force of 250 Nm and maximum rotation speed of 45 RPM, gives the user high-energy efficiency modeled after the physiology of the human leg. It allows users to walk on flat ground and down stairs, climb up and down inclines, and sit and lie down. Currently the battery lasts five to six hours for locomotion and the approximate 25 kg of robot weight still remains a technical challenge to upgrade.

Professor Kong’s team has grafted AR glass technology into the WalkOn Suit that one of his pilots put on for the torch relay of the PyongChang Paralympics in 2018. His team is now upgrading the WalkON Suit 4.0 for next year’s competition. Severance Rehabilitation Hospital will help the seven pilots with their training.

Professor Kong said his goal is to make robots that can make people with disabilities much more independent. He stressed, “Wearable robots should be designed for each single user. We provide a very good graphical user interface so that we can design, check, and also verify our optimized design for users’ best performance.”

(Seven pilots and Professor Kong (fifth from left in second row) pose with guests who joined the Cybathlon 2020 kickoff ceremony. President Shin (fifth from right) made a congratulatory remarks during the ceremony.)

2019.06.25 View 41083 -

Efficiently Producing Fatty Acids and Biofuels from Glucose

Researchers have presented a new strategy for efficiently producing fatty acids and biofuels that can transform glucose and oleaginous microorganisms into microbial diesel fuel, with one-step direct fermentative production.

The newly developed strain, created by Distinguished Professor Sang Yup Lee and his team, showed the highest efficiency in producing fatty acids and biodiesels ever reported. It will be expected to serve as a new platform to sustainably produce a wide array of fatty acid-based products from glucose and other carbon substrates.

Fossil fuels, which have long been energy resources for our daily lives, are now facing serious challenges: depletion of their reserves and their role in global warming. The production of sustainable bio-based renewable energy has emerged as an essential alternative and many studies to replace fossil fuels are underway. One of the representative examples is biodiesel. Currently, it is mainly being produced through the transesterification of vegetable oils or animal fats.

The research team engineered oleaginous microorganisms, Rhodococcus opacus, to produce fatty acids and their derivatives that can be used as biodiesel from glucose, one of the most abundant and cheap sugars derived from non-edible biomass.

Professor Lee’s team has already engineered Escherichia coli to produce short-chain hydrocarbons, which can be used as gasoline (published in Nature as the cover paper in 2013). However, the production efficiency of the short-chain hydrocarbons using E. coli (0.58 g/L) fell short of the levels required for commercialization.

To overcome these issues, the team employed oil-accumulating Rhodococcus opacus as a host strain in this study. First, the team optimized the cultivation conditions of Rhodococcus opacus to maximize the accumulation of oil (triacylglycerol), which serves as a precursor for the biosynthesis of fatty acids and their derivatives. Then, they systematically analyzed the metabolism of the strain and redesigned it to enable higher levels of fatty acids and two kinds of fatty acid-derived biodiesels (fatty acid ethyl esters and long-chain hydrocarbons) to be produced.

They found that the resulting strains produced 50.2, 21.3, and 5.2 g/L of fatty acids, fatty acid ethyl esters, and long-chain hydrocarbons, respectively. These are all the highest concentrations ever reported by microbial fermentations. It is expected that these strains can contribute to the future industrialization of microbial-based biodiesel production.

“This technology creates fatty acids and biodiesel with high efficiency by utilizing lignocellulose, one of the most abundant resources on the Earth, without depending on fossil fuels and vegetable or animal oils. This will provide new opportunities for oil and petroleum industries, which have long relied on fossil fuels, to turn to sustainable and eco-friendly biotechnologies,” said Professor Lee.

This paper titled “Engineering of an oleaginous bacterium for the production of fatty acids and fuels” was published in Nature Chemical Biology on June 17.

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT through the National Research Foundation (NRF) of Korea (NRF-2012M1A2A2026556 and NRF-2012M1A2A2026557).

(Figure: Metabolic engineering for the production of free fatty acids (FFAs), fatty acid ethyl esters (FAEEs), and long-chain hydrocarbons (LCHCs) in Rhodococcus opacus PD630. Researchers have presented a new strategy for efficiently producing fatty acids and biofuels that can transform glucose and oleaginous microorganisms into microbial diesel fuel, with one-step direct fermentative production.)

# # #

Source:

Hye Mi Kim, Tong Un Chae, So Young Choi, Won Jun Kim and Sang Yup Lee. Engineering of an oleaginous bacterium for the production of fatty acids and fuels. Nature Chemical Biology ( https://www.nature.com/nchembio/ ) DOI: 10.1038/s41589-019-0295-5

Profile

Dr. Sang Yup Lee

leesy@kaist.ac.kr

Distinguished Professor at the Department of Chemical and Biomolecular Engineering

KAIST

2019.06.19 View 49623

Efficiently Producing Fatty Acids and Biofuels from Glucose

Researchers have presented a new strategy for efficiently producing fatty acids and biofuels that can transform glucose and oleaginous microorganisms into microbial diesel fuel, with one-step direct fermentative production.

The newly developed strain, created by Distinguished Professor Sang Yup Lee and his team, showed the highest efficiency in producing fatty acids and biodiesels ever reported. It will be expected to serve as a new platform to sustainably produce a wide array of fatty acid-based products from glucose and other carbon substrates.

Fossil fuels, which have long been energy resources for our daily lives, are now facing serious challenges: depletion of their reserves and their role in global warming. The production of sustainable bio-based renewable energy has emerged as an essential alternative and many studies to replace fossil fuels are underway. One of the representative examples is biodiesel. Currently, it is mainly being produced through the transesterification of vegetable oils or animal fats.

The research team engineered oleaginous microorganisms, Rhodococcus opacus, to produce fatty acids and their derivatives that can be used as biodiesel from glucose, one of the most abundant and cheap sugars derived from non-edible biomass.

Professor Lee’s team has already engineered Escherichia coli to produce short-chain hydrocarbons, which can be used as gasoline (published in Nature as the cover paper in 2013). However, the production efficiency of the short-chain hydrocarbons using E. coli (0.58 g/L) fell short of the levels required for commercialization.

To overcome these issues, the team employed oil-accumulating Rhodococcus opacus as a host strain in this study. First, the team optimized the cultivation conditions of Rhodococcus opacus to maximize the accumulation of oil (triacylglycerol), which serves as a precursor for the biosynthesis of fatty acids and their derivatives. Then, they systematically analyzed the metabolism of the strain and redesigned it to enable higher levels of fatty acids and two kinds of fatty acid-derived biodiesels (fatty acid ethyl esters and long-chain hydrocarbons) to be produced.

They found that the resulting strains produced 50.2, 21.3, and 5.2 g/L of fatty acids, fatty acid ethyl esters, and long-chain hydrocarbons, respectively. These are all the highest concentrations ever reported by microbial fermentations. It is expected that these strains can contribute to the future industrialization of microbial-based biodiesel production.

“This technology creates fatty acids and biodiesel with high efficiency by utilizing lignocellulose, one of the most abundant resources on the Earth, without depending on fossil fuels and vegetable or animal oils. This will provide new opportunities for oil and petroleum industries, which have long relied on fossil fuels, to turn to sustainable and eco-friendly biotechnologies,” said Professor Lee.

This paper titled “Engineering of an oleaginous bacterium for the production of fatty acids and fuels” was published in Nature Chemical Biology on June 17.

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT through the National Research Foundation (NRF) of Korea (NRF-2012M1A2A2026556 and NRF-2012M1A2A2026557).

(Figure: Metabolic engineering for the production of free fatty acids (FFAs), fatty acid ethyl esters (FAEEs), and long-chain hydrocarbons (LCHCs) in Rhodococcus opacus PD630. Researchers have presented a new strategy for efficiently producing fatty acids and biofuels that can transform glucose and oleaginous microorganisms into microbial diesel fuel, with one-step direct fermentative production.)

# # #

Source:

Hye Mi Kim, Tong Un Chae, So Young Choi, Won Jun Kim and Sang Yup Lee. Engineering of an oleaginous bacterium for the production of fatty acids and fuels. Nature Chemical Biology ( https://www.nature.com/nchembio/ ) DOI: 10.1038/s41589-019-0295-5

Profile

Dr. Sang Yup Lee

leesy@kaist.ac.kr

Distinguished Professor at the Department of Chemical and Biomolecular Engineering

KAIST

2019.06.19 View 49623 -

Play Games With No Latency

One of the most challenging issues for game players looks to be resolved soon with the introduction of a zero-latency gaming environment. A KAIST team developed a technology that helps game players maintain zero-latency performance. The new technology transforms the shapes of game design according to the amount of latency.

Latency in human-computer interactions is often caused by various factors related to the environment and performance of the devices, networks, and data processing. The term ‘lag’ is used to refer to any latency during gaming which impacts the user’s performance.

Professor Byungjoo Lee at the Graduate School of Culture Technology in collaboration with Aalto University in Finland presented a mathematical model for predicting players' behavior by understanding the effects of latency on players. This cognitive model is capable of predicting the success rate of a user when there is latency in a 'moving target selection' task which requires button input in a time constrained situation.

The model predicts the players’ task success rate when latency is added to the gaming environment. Using these predicted success rates, the design elements of the game are geometrically modified to help players maintain similar success rates as they would achieve in a zero-latency environment. In fact, this research succeeded in modifying the pillar heights of the Flappy Bird game, allowing the players to maintain their gaming performance regardless of the added latency.

Professor Lee said, "This technique is unique in the sense that it does not interfere with a player's gaming flow, unlike traditional methods which manipulate the game clock by the amount of latency. This study can be extended to various games such as reducing the size of obstacles in the latent computing environment.”

This research, in collaboration with Dr. Sunjun Kim from Aalto University and led by PhD candidate Injung Lee, was presented during the 2019 CHI Conference on Human Factors in Computing Systems last month in Glasgow in the UK.

This research was supported by the National Research Foundation of Korea (NRF) (2017R1C1B2002101, 2018R1A5A7025409), and the Aalto University Seed Funding Granted to the GamerLab respectively.

Figure 1. Overview of Geometric Compensation

Publication:

Injung Lee, Sunjun Kim, and Byungjoo Lee. 2019. Geometrically Compensating Effect of End-to-End Latency in Moving-Target Selection Games. In Proceedings of the 2019 CHI Conference on Human Factors in Computing Systems (CHI’19) . ACM, New York, NY, USA, Article 560, 12 pages. https://doi.org/10.1145/3290605.3300790

Video Material:

https://youtu.be/TTi7dipAKJs

Profile: Prof. Byungjoo Lee, MD, PhD

byungjoo.lee@kaist.ac.kr

http://kiml.org/

Assistant Professor

Graduate School of Culture Technology (CT)

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Injung Lee, PhD Candidate

edndn@kaist.ac.kr

PhD Candidate

Interactive Media Lab

Graduate School of Culture Technology (CT)

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Postdoc. Sunjun Kim, MD, PhD

kuaa.net@gmail.com

Postdoctoral Researcher

User Interfaces Group

Aalto University

https://www.aalto.fi Espoo 02150, Finland

(END)

2019.06.11 View 47002

Play Games With No Latency

One of the most challenging issues for game players looks to be resolved soon with the introduction of a zero-latency gaming environment. A KAIST team developed a technology that helps game players maintain zero-latency performance. The new technology transforms the shapes of game design according to the amount of latency.

Latency in human-computer interactions is often caused by various factors related to the environment and performance of the devices, networks, and data processing. The term ‘lag’ is used to refer to any latency during gaming which impacts the user’s performance.

Professor Byungjoo Lee at the Graduate School of Culture Technology in collaboration with Aalto University in Finland presented a mathematical model for predicting players' behavior by understanding the effects of latency on players. This cognitive model is capable of predicting the success rate of a user when there is latency in a 'moving target selection' task which requires button input in a time constrained situation.

The model predicts the players’ task success rate when latency is added to the gaming environment. Using these predicted success rates, the design elements of the game are geometrically modified to help players maintain similar success rates as they would achieve in a zero-latency environment. In fact, this research succeeded in modifying the pillar heights of the Flappy Bird game, allowing the players to maintain their gaming performance regardless of the added latency.

Professor Lee said, "This technique is unique in the sense that it does not interfere with a player's gaming flow, unlike traditional methods which manipulate the game clock by the amount of latency. This study can be extended to various games such as reducing the size of obstacles in the latent computing environment.”

This research, in collaboration with Dr. Sunjun Kim from Aalto University and led by PhD candidate Injung Lee, was presented during the 2019 CHI Conference on Human Factors in Computing Systems last month in Glasgow in the UK.

This research was supported by the National Research Foundation of Korea (NRF) (2017R1C1B2002101, 2018R1A5A7025409), and the Aalto University Seed Funding Granted to the GamerLab respectively.

Figure 1. Overview of Geometric Compensation

Publication:

Injung Lee, Sunjun Kim, and Byungjoo Lee. 2019. Geometrically Compensating Effect of End-to-End Latency in Moving-Target Selection Games. In Proceedings of the 2019 CHI Conference on Human Factors in Computing Systems (CHI’19) . ACM, New York, NY, USA, Article 560, 12 pages. https://doi.org/10.1145/3290605.3300790

Video Material:

https://youtu.be/TTi7dipAKJs

Profile: Prof. Byungjoo Lee, MD, PhD

byungjoo.lee@kaist.ac.kr

http://kiml.org/

Assistant Professor

Graduate School of Culture Technology (CT)

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Injung Lee, PhD Candidate

edndn@kaist.ac.kr

PhD Candidate

Interactive Media Lab

Graduate School of Culture Technology (CT)

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Postdoc. Sunjun Kim, MD, PhD

kuaa.net@gmail.com

Postdoctoral Researcher

User Interfaces Group

Aalto University

https://www.aalto.fi Espoo 02150, Finland

(END)

2019.06.11 View 47002 -

Professor Yim Appointed As Associate Editor of Nuclear Technology

Professor Man-Sung Yim from the Department of Nuclear and Quantum Engineering was appointed as the associate editor (for the Asian region) of Nuclear Technology ― a leading international research journal of the American Nuclear Society. Professor Yim will serve his term for three years from May 2019.

The American Nuclear Society, established in 1954, is comprised of more than 11,000 global members and aims to advance nuclear science, engineering, and technology while supporting the peaceful and beneficial applications of nuclear energy. Since its first publication in 1971, Nuclear Technology has been a representative journal of the society, reporting state-of-the-art information on all phases of the practical applications of nuclear technology.

Professor Yim is being recognized worldwide for his pioneering nuclear education, research, and policy studies in the fields of non-proliferation, safeguards for severe accident management, and waste management. He served as the head professor of the Department of Nuclear and Quantum Engineering and established the Nonproliferation Education and Research Center (NEREC) at KAIST.

Professor Yim remarked, “Asia has an important role to play at the forefront of the world’s nuclear research considering that nuclear development is most actively being carried out in the Asian region these days.”

2019.05.17 View 8098

Professor Yim Appointed As Associate Editor of Nuclear Technology

Professor Man-Sung Yim from the Department of Nuclear and Quantum Engineering was appointed as the associate editor (for the Asian region) of Nuclear Technology ― a leading international research journal of the American Nuclear Society. Professor Yim will serve his term for three years from May 2019.

The American Nuclear Society, established in 1954, is comprised of more than 11,000 global members and aims to advance nuclear science, engineering, and technology while supporting the peaceful and beneficial applications of nuclear energy. Since its first publication in 1971, Nuclear Technology has been a representative journal of the society, reporting state-of-the-art information on all phases of the practical applications of nuclear technology.

Professor Yim is being recognized worldwide for his pioneering nuclear education, research, and policy studies in the fields of non-proliferation, safeguards for severe accident management, and waste management. He served as the head professor of the Department of Nuclear and Quantum Engineering and established the Nonproliferation Education and Research Center (NEREC) at KAIST.

Professor Yim remarked, “Asia has an important role to play at the forefront of the world’s nuclear research considering that nuclear development is most actively being carried out in the Asian region these days.”

2019.05.17 View 8098 -

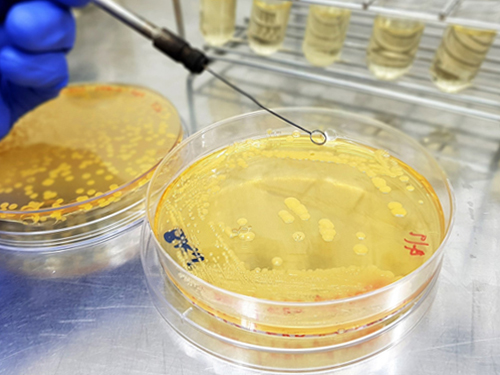

Engineered Microbial Production of Grape Flavoring

(Image 1: Engineered bacteria that produce grape flavoring.)

Researchers report a microbial method for producing an artificial grape flavor. Methyl anthranilate (MANT) is a common grape flavoring and odorant compound currently produced through a petroleum-based process that uses large volumes of toxic acid catalysts.

Professor Sang-Yup Lee’s team at the Department of Chemical and Biomolecular Engineering demonstrated production of MANT, a naturally occurring compound, via engineered bacteria. The authors engineered strains of Escherichia coli and Corynebacetrium glutamicum to produce MANT through a plant-based engineered metabolic pathway.

The authors tuned the bacterial metabolic pathway by optimizing the levels of AAMT1, the key enzyme in the process. To maximize production of MANT, the authors tested six strategies, including increasing the supply of a precursor compound and enhancing the availability of a co-substrate. The most productive strategy proved to be a two-phase extractive culture, in which MANT was extracted into a solvent. This strategy produced MANT on the scale of 4.47 to 5.74 grams per liter, a significant amount, considering that engineered microbes produce most natural products at a scale of milligrams or micrograms per liter.

According to the authors, the results suggest that MANT and other related molecules produced through industrial processes can be produced at scale by engineered microbes in a manner that would allow them to be marketed as natural one, instead of artificial one.

This study, featured at the Proceeding of the National Academy of Sciences of the USA on May 13, was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT.

(Image 2. Overview of the strategies applied for the microbial production of grape flavoring.)

2019.05.15 View 55656

Engineered Microbial Production of Grape Flavoring

(Image 1: Engineered bacteria that produce grape flavoring.)

Researchers report a microbial method for producing an artificial grape flavor. Methyl anthranilate (MANT) is a common grape flavoring and odorant compound currently produced through a petroleum-based process that uses large volumes of toxic acid catalysts.

Professor Sang-Yup Lee’s team at the Department of Chemical and Biomolecular Engineering demonstrated production of MANT, a naturally occurring compound, via engineered bacteria. The authors engineered strains of Escherichia coli and Corynebacetrium glutamicum to produce MANT through a plant-based engineered metabolic pathway.

The authors tuned the bacterial metabolic pathway by optimizing the levels of AAMT1, the key enzyme in the process. To maximize production of MANT, the authors tested six strategies, including increasing the supply of a precursor compound and enhancing the availability of a co-substrate. The most productive strategy proved to be a two-phase extractive culture, in which MANT was extracted into a solvent. This strategy produced MANT on the scale of 4.47 to 5.74 grams per liter, a significant amount, considering that engineered microbes produce most natural products at a scale of milligrams or micrograms per liter.

According to the authors, the results suggest that MANT and other related molecules produced through industrial processes can be produced at scale by engineered microbes in a manner that would allow them to be marketed as natural one, instead of artificial one.

This study, featured at the Proceeding of the National Academy of Sciences of the USA on May 13, was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT.

(Image 2. Overview of the strategies applied for the microbial production of grape flavoring.)

2019.05.15 View 55656 -

Distinguished Professor Sang Yup Lee Honored with the 23rd NAEK Award

(Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering)

Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering was honored to be the laureate of the 23rd NAEK Award.

The NAEK (National Academy of Engineering of Korea) Award was instituted in 1997 to honor and recognize engineers who have made significant contributions to the development of the engineering and technology field at universities, industries, and institutions. Every year, it is conferred to only one person who has achieved original and world-leading research that has led to national development.

Distinguished Professor Lee is a pioneering scholar of the field of systems metabolic engineering and he was recognized for his significant achievements in the biochemical industry by developing novel microbial bioprocesses. In particular, he is globally renowned for biological plastic synthesis, making or decomposing polymers with microorganisms instead of using fossil resources.

He has produced numerous high-quality research breakthroughs in metabolic and systems engineering. In 2016, he produced an easily degradable plastic with Escherichia coli (E. coli). In 2018, he successfully produced aromatic polyesters, the main material for PET (poly ethylene terephthalate) from E. coli strains. He also identified microorganism structures for PET degradation and improved its degradability with a novel variant.

His research was ranked number one in the research and development division of Top Ten Science and Technology News 2018 announced by Korean Federation of Science & Technology Societies. He is one of highly cited researchers (HCR) ranked in the top 1% by citations for their field by the Clarivate Analytics.

2019.03.21 View 8766

Distinguished Professor Sang Yup Lee Honored with the 23rd NAEK Award

(Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering)

Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering was honored to be the laureate of the 23rd NAEK Award.

The NAEK (National Academy of Engineering of Korea) Award was instituted in 1997 to honor and recognize engineers who have made significant contributions to the development of the engineering and technology field at universities, industries, and institutions. Every year, it is conferred to only one person who has achieved original and world-leading research that has led to national development.

Distinguished Professor Lee is a pioneering scholar of the field of systems metabolic engineering and he was recognized for his significant achievements in the biochemical industry by developing novel microbial bioprocesses. In particular, he is globally renowned for biological plastic synthesis, making or decomposing polymers with microorganisms instead of using fossil resources.

He has produced numerous high-quality research breakthroughs in metabolic and systems engineering. In 2016, he produced an easily degradable plastic with Escherichia coli (E. coli). In 2018, he successfully produced aromatic polyesters, the main material for PET (poly ethylene terephthalate) from E. coli strains. He also identified microorganism structures for PET degradation and improved its degradability with a novel variant.

His research was ranked number one in the research and development division of Top Ten Science and Technology News 2018 announced by Korean Federation of Science & Technology Societies. He is one of highly cited researchers (HCR) ranked in the top 1% by citations for their field by the Clarivate Analytics.

2019.03.21 View 8766 -

The Future Mobility of the Year 2019

KAIST announced the Future Mobility of the Year (FMOTY) 2019. The winners are Volvo 360C, Toyota e-Palette, and Toyota Concept-i WALK.

FMOTY are the first awards that recognizes concept cars that exhibit innovative services and practical transportation technology in three categories: private mobility, public and commercial mobility, and personal mobility.

Figure 1. The winner in the private mobility division, the Volvo 360C

In the private mobility division, the award went to the Volvo 360C. With targeted routes of roughly 186 miles, this vehicle has an ambitious service goal to replace airplanes by traveling these routes with great comfort. Goro Okazaki, a journalist with Car and Driver Japan, said, “The Volvo 360C clearly shows how highly personalized autonomous driving can change the future.”

Figure 2. The winner in the public mobility division, the Toyota e-Palette

The Toyota e-Palette was the winning car in commercial mobility division. This vehicle provides the best solution as a mobile service platform by transforming itself into mobile hospitals, hotels, stores and food trucks. Carlo Calderón, a journalist for Autopista Spain, said, “It has a great strength in remodeling its indoor and outdoor spaces according to various commercial uses.”

Figure 3. The winner in the personal mobility division, the Toyota Concept-i WALK

In the personal mobility division, the award went to the Toyota Concept-i WALK. It was recognized for having an exquisite user environment and artificial intelligent agent, along with an excellent completion. Jun Miao, a journalist with MJ CarShow China, said, “It is aesthetically pleasing. Beyond the upright control of conventional personal mobility, it allows agile control with a joystick.”

FMOTY conducted a screening process for 45 concept cars over three months and 16 renowned automotive experts from 11 countries participated as judges for this award, including Editor in Chief of BBC Top Gear Magazine Charlie Turner and European Bureau Chief of Automobile Magazine Georg Kacher. The judges said that FMOTY was born to propose a new aspect of future mobility, and in terms of evaluating technical and social values of concept cars, FMOTY carries great significance.

Kyung-soo Kim, Dean of the Cho Chun Shik Graduate School of Green Transportation said, “Globally renowned experts in the automotive field participated as judges to elevate the prestige and fairness of the awards. KAIST members were excluded from the entire judging process. I believe that the FMOTY Awards will expand public attention from the present to the future.”

Details can be found on the official website of FMOTY ( www.fmoty.org ).

2019.03.11 View 7281

The Future Mobility of the Year 2019

KAIST announced the Future Mobility of the Year (FMOTY) 2019. The winners are Volvo 360C, Toyota e-Palette, and Toyota Concept-i WALK.

FMOTY are the first awards that recognizes concept cars that exhibit innovative services and practical transportation technology in three categories: private mobility, public and commercial mobility, and personal mobility.

Figure 1. The winner in the private mobility division, the Volvo 360C

In the private mobility division, the award went to the Volvo 360C. With targeted routes of roughly 186 miles, this vehicle has an ambitious service goal to replace airplanes by traveling these routes with great comfort. Goro Okazaki, a journalist with Car and Driver Japan, said, “The Volvo 360C clearly shows how highly personalized autonomous driving can change the future.”

Figure 2. The winner in the public mobility division, the Toyota e-Palette

The Toyota e-Palette was the winning car in commercial mobility division. This vehicle provides the best solution as a mobile service platform by transforming itself into mobile hospitals, hotels, stores and food trucks. Carlo Calderón, a journalist for Autopista Spain, said, “It has a great strength in remodeling its indoor and outdoor spaces according to various commercial uses.”

Figure 3. The winner in the personal mobility division, the Toyota Concept-i WALK

In the personal mobility division, the award went to the Toyota Concept-i WALK. It was recognized for having an exquisite user environment and artificial intelligent agent, along with an excellent completion. Jun Miao, a journalist with MJ CarShow China, said, “It is aesthetically pleasing. Beyond the upright control of conventional personal mobility, it allows agile control with a joystick.”

FMOTY conducted a screening process for 45 concept cars over three months and 16 renowned automotive experts from 11 countries participated as judges for this award, including Editor in Chief of BBC Top Gear Magazine Charlie Turner and European Bureau Chief of Automobile Magazine Georg Kacher. The judges said that FMOTY was born to propose a new aspect of future mobility, and in terms of evaluating technical and social values of concept cars, FMOTY carries great significance.

Kyung-soo Kim, Dean of the Cho Chun Shik Graduate School of Green Transportation said, “Globally renowned experts in the automotive field participated as judges to elevate the prestige and fairness of the awards. KAIST members were excluded from the entire judging process. I believe that the FMOTY Awards will expand public attention from the present to the future.”

Details can be found on the official website of FMOTY ( www.fmoty.org ).

2019.03.11 View 7281 -

New Members of KAST and Y-KAST 2019

(Professor Eui-Cheol Shin from the Graduate School of Medical Science and Engineering)

Professor Eui-Cheol Shin from the Graduate School of Medical Science and Engineering became a new fellow of the Korean Academy of Science and Technology (KAST) along with 25 other scientists in Korea. He is one of the top virus immunologists in Korea and has published a review article in Nature Reviews Immunology.

Meanwhile KAST selected and announced 26 young scientists under the age 43 who have shown great potential and the creativity to carry out next-generation research. The list of Y-KAST (Young Korean Academy of Science and Technology) includes six KAIST professors: Professor Ji Oon Lee from the Department of Mathematical Sciences, Professor Mi Hee Lim from the Department of Chemistry, Professor Shin-Hyun Kim from the Department of Chemical and Biomolecular Engineering, Professor Jung-Ryul Lee from the Department of Aerospace Engineering, Professor Hyunjoo Jenny Lee from the School of Electrical Engineering, and Professor Yeon Sik Jung from the Department of Materials Science and Engineering.

KAST conferred their fellowships and Y-KAST membership during the New Year Reception.

2019.01.22 View 9511

New Members of KAST and Y-KAST 2019

(Professor Eui-Cheol Shin from the Graduate School of Medical Science and Engineering)

Professor Eui-Cheol Shin from the Graduate School of Medical Science and Engineering became a new fellow of the Korean Academy of Science and Technology (KAST) along with 25 other scientists in Korea. He is one of the top virus immunologists in Korea and has published a review article in Nature Reviews Immunology.

Meanwhile KAST selected and announced 26 young scientists under the age 43 who have shown great potential and the creativity to carry out next-generation research. The list of Y-KAST (Young Korean Academy of Science and Technology) includes six KAIST professors: Professor Ji Oon Lee from the Department of Mathematical Sciences, Professor Mi Hee Lim from the Department of Chemistry, Professor Shin-Hyun Kim from the Department of Chemical and Biomolecular Engineering, Professor Jung-Ryul Lee from the Department of Aerospace Engineering, Professor Hyunjoo Jenny Lee from the School of Electrical Engineering, and Professor Yeon Sik Jung from the Department of Materials Science and Engineering.

KAST conferred their fellowships and Y-KAST membership during the New Year Reception.

2019.01.22 View 9511 -

Fabrication of Shape-conformable Batteries with 3D-Printing

(from left: Dr. Bok Yeop Ahn, Dr. Chanhoon Kim, Professor Il-Doo Kim and Professor Jennifer A. Lewis)

Flexible, wireless electronic devices are rapidly emerging and have reached the level of commercialization; nevertheless, most of battery shapes are limited to either spherical and/or rectangular structures, which results in inefficient space use. Professor Il-Doo Kim’s team from the Department of Materials Science at KAIST has successfully developed technology to significantly enhance the variability of battery design through collaboration research with Professor Jennifer A. Lewis and her team from the School of Engineering and Applied Sciences at Harvard University.

Most of the battery shapes today are optimized for coin cell and/or pouch cells. Since the battery as an energy storage device occupies most of the space in microelectronic devices with different designs, new technology to freely change the shape of the battery is required.

The KAIST-Harvard research collaboration team has successfully manufactured various kinds of battery shapes, such as ring-type, H, and U shape, using 3D printing technology. And through the research collaboration with Dr. Youngmin Choi at the Korea Research Institute of Chemical Technology (KRICT), 3D-printed batteries were applied to small-scale wearable electronic devices (wearable light sensor rings).

The research group has adopted environmentally friendly aqueous Zn-ion batteries to make customized battery packs. This system, which uses Zn2+ instead of Li+ as charge carriers, is much safer compared with the conventional lithium rechargeable batteries that use highly inflammable organic electrolytes. Moreover, the processing conditions of lithium-ion batteries are very complicated because organic solvents can ignite upon exposure to moisture and oxygen.

As the aqueous Zn-ion batteries adopted by the research team are stable upon contact with atmospheric moisture and oxygen, they can be fabricated in the ambient air condition, and have advantages in packaging since packaged plastic does not dissolve in water even when plastic packaging is applied using a 3D printer.

To fabricate a stable cathode that can be modulated in various forms and allows high charge-discharge, the research team fabricated a carbon fiber current collector using electrospinning process and uniformly coated electrochemically active polyaniline conductive polymer on the surface of carbon fiber for a current collector-active layer integrated cathode. The cathode, based on conductive polyaniline consisting of a 3D structure, exhibits very fast charging speeds (50% of the charge in two minutes) and can be fabricated without the detachment of active cathode materials, so various battery forms with high mechanical stability can be manufactured.

Prof. Kim said, “Zn-ion batteries employing aqueous electrolytes have the advantage of fabrication under ambient conditions, so it is easy to fabricate the customized battery packs using 3D printing.”

“3D-printed batteries can be easily applied for niche applications such as wearable, personalized, miniaturized micro-robots, and implantable medical devices or microelectronic storage devices with unique designs,” added Professor Lewis.

With Dr. Chanhoon Kim in the Department of Materials Science and Engineering at KAIST and Dr. Bok Yeop Ahn School of Engineering and Applied Sciences at Harvard University participating as equally contributing first authors, this work was published in the December issue of ACS Nano.

This work was financially supported by the Global Research Laboratory (NRF-2015K1A1A2029679) and Wearable Platform Materials Technology Center (2016R1A5A1009926).

Figure 1.Fabrication of shape-conformable batteries based on 3D-printing technology and the application of polyaniline carbon nanofiber cathodes and wearable electronic devices

Figure 2.Fabricated shape-conformable batteries based on a 3D-printing method

Meanwhile, Professor Il-Doo Kim was recently appointed as an Associate Editor of ACS Nano, a highly renowned journal in the field of nanoscience.

Professor Kim said, “It is my great honor to be an Associate Editor of the highly renowned journal ACS Nano, which has an impact factor reaching 13.709 with 134,596 citations as of 2017. Through the editorial activities in the fields of energy, I will dedicate myself to improving the prominence of KAIST and expanding the scope of Korea’s science and technology. I will also contribute to carrying out more international collaborations with world-leading research groups.”

(Associate Editor of ACS Nano Professor Il-Doo Kim)

2018.12.20 View 10886

Fabrication of Shape-conformable Batteries with 3D-Printing

(from left: Dr. Bok Yeop Ahn, Dr. Chanhoon Kim, Professor Il-Doo Kim and Professor Jennifer A. Lewis)

Flexible, wireless electronic devices are rapidly emerging and have reached the level of commercialization; nevertheless, most of battery shapes are limited to either spherical and/or rectangular structures, which results in inefficient space use. Professor Il-Doo Kim’s team from the Department of Materials Science at KAIST has successfully developed technology to significantly enhance the variability of battery design through collaboration research with Professor Jennifer A. Lewis and her team from the School of Engineering and Applied Sciences at Harvard University.

Most of the battery shapes today are optimized for coin cell and/or pouch cells. Since the battery as an energy storage device occupies most of the space in microelectronic devices with different designs, new technology to freely change the shape of the battery is required.

The KAIST-Harvard research collaboration team has successfully manufactured various kinds of battery shapes, such as ring-type, H, and U shape, using 3D printing technology. And through the research collaboration with Dr. Youngmin Choi at the Korea Research Institute of Chemical Technology (KRICT), 3D-printed batteries were applied to small-scale wearable electronic devices (wearable light sensor rings).

The research group has adopted environmentally friendly aqueous Zn-ion batteries to make customized battery packs. This system, which uses Zn2+ instead of Li+ as charge carriers, is much safer compared with the conventional lithium rechargeable batteries that use highly inflammable organic electrolytes. Moreover, the processing conditions of lithium-ion batteries are very complicated because organic solvents can ignite upon exposure to moisture and oxygen.

As the aqueous Zn-ion batteries adopted by the research team are stable upon contact with atmospheric moisture and oxygen, they can be fabricated in the ambient air condition, and have advantages in packaging since packaged plastic does not dissolve in water even when plastic packaging is applied using a 3D printer.

To fabricate a stable cathode that can be modulated in various forms and allows high charge-discharge, the research team fabricated a carbon fiber current collector using electrospinning process and uniformly coated electrochemically active polyaniline conductive polymer on the surface of carbon fiber for a current collector-active layer integrated cathode. The cathode, based on conductive polyaniline consisting of a 3D structure, exhibits very fast charging speeds (50% of the charge in two minutes) and can be fabricated without the detachment of active cathode materials, so various battery forms with high mechanical stability can be manufactured.

Prof. Kim said, “Zn-ion batteries employing aqueous electrolytes have the advantage of fabrication under ambient conditions, so it is easy to fabricate the customized battery packs using 3D printing.”

“3D-printed batteries can be easily applied for niche applications such as wearable, personalized, miniaturized micro-robots, and implantable medical devices or microelectronic storage devices with unique designs,” added Professor Lewis.

With Dr. Chanhoon Kim in the Department of Materials Science and Engineering at KAIST and Dr. Bok Yeop Ahn School of Engineering and Applied Sciences at Harvard University participating as equally contributing first authors, this work was published in the December issue of ACS Nano.

This work was financially supported by the Global Research Laboratory (NRF-2015K1A1A2029679) and Wearable Platform Materials Technology Center (2016R1A5A1009926).

Figure 1.Fabrication of shape-conformable batteries based on 3D-printing technology and the application of polyaniline carbon nanofiber cathodes and wearable electronic devices

Figure 2.Fabricated shape-conformable batteries based on a 3D-printing method

Meanwhile, Professor Il-Doo Kim was recently appointed as an Associate Editor of ACS Nano, a highly renowned journal in the field of nanoscience.

Professor Kim said, “It is my great honor to be an Associate Editor of the highly renowned journal ACS Nano, which has an impact factor reaching 13.709 with 134,596 citations as of 2017. Through the editorial activities in the fields of energy, I will dedicate myself to improving the prominence of KAIST and expanding the scope of Korea’s science and technology. I will also contribute to carrying out more international collaborations with world-leading research groups.”

(Associate Editor of ACS Nano Professor Il-Doo Kim)

2018.12.20 View 10886